Page 1

Operating

Instructions

RI FB PRO/i TWIN Controller

EN-US

Operating instructions

42,0426,0299,EA 006-09022023

Page 2

Page 3

Table of contents

General 4

Safety 4

Scope of Supply 4

Environmental Conditions 5

Technical Data 5

Connection Sockets and Indicators on the Robot Interface 6

General 6

Connection Sockets for the Power Source and System Components 6

Connection sockets for the robot control 7

Indicators on the Robot Interface 8

System Overview 9

System Overview 9

Inserting the Bus Module in the Interface and Connecting it to the Robot Control 10

Inserting the Bus Module into the Robot Interface and Connecting it to the Robot Control 10

Fitting the Robot Interface and Connecting it to the System Components 11

Safety 11

Fitting the Robot Interface 11

Connecting Process Line 1 to the Interface 12

Connecting Process Line 2 to the Interface 12

Dip Switch 14

General 14

Example: Setting the node address/IP address 14

Notes on the Robot Interface Power Supply 15

Notes on the Interface Power Supply 15

Troubleshooting 16

Safety 16

LEDs on the Robot Interface PC board 16

EN-US

3

Page 4

General

Safety

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in serious personal injury and damage to property.

All the work and functions described in this document must only be carried

▶

out by technically trained and qualified personnel.

Read and understand this document in full.

▶

Read and understand all safety rules and user documentation for this equip-

▶

ment and all system components.

WARNING!

Danger from electrical current.

This can result in serious personal injury and damage to property.

Before starting work, switch off all the devices and components involved and

▶

disconnect them from the grid.

Secure all devices and components involved so they cannot be switched back

▶

on.

WARNING!

Danger from unplanned signal transmission.

This can result in serious personal injury and damage to property.

Do not transfer safety signals via the interface.

▶

Scope of Supply

4

Page 5

Environmental

Conditions

CAUTION!

A risk is posed by prohibited environmental conditions.

This can result in severe damage to equipment.

Only store and operate the device under the following environmental condi-

▶

tions.

Temperature range of ambient air:

During operation: -10 °C to +40 °C (14 °F to 104 °F)

-

During transport and storage: -20 °C to +55 °C (-4 °F to 131 °F)

-

Relative humidity:

Up to 50% at 40 °C (104 °F)

-

Up to 90% at 20 °C (68 °F)

-

Ambient air: free of dust, acids, corrosive gases or substances, etc.

Altitude above sea level: up to 2000 m (6500 ft).

EN-US

Technical Data

Power supply internally (24 V)

Protection class IP 20

5

Page 6

Connection Sockets and Indicators on the Robot

Interface

General As a result of customer-specific requirements, you may find that your device has

certain connection sockets that are not described in these Operating Instructions, or vice versa.

However, this does not affect the basic functions of the device.

Connection

Sockets for the

Power Source

and System

Components

(1) SpeedNet connection socket

To connect to the first power

source.

Connection using SpeedNet

connection cable.

(2) SpeedNet connection socket

To connect to other system

components, such as the first

wirefeeder.

Connection using SpeedNet

cable from interconnecting

hosepack.

(3) SpeedNet connection socket

To connect to the second power source.

Connection using SpeedNet connection cable.

(4) SpeedNet connection socket

To connect to other system components, such as the second wirefeeder.

Connection using SpeedNet cable from interconnecting hosepack.

6

Page 7

Connection

(1)

(2)

sockets for the

robot control

The robot interface is supplied with one of the following connection configurations depending on the requirement.

Basic configuration example:

(1) Strain-relief device

The robot control cable harness

must be guided through the

strain-relief device inside the

robot interface and connected

directly to the bus module.

ProfiNet IO, Ethernet/IP 2P, etc. configuration example:

EN-US

(2) Connection sockets for the rel-

evant bus module

The connection sockets for the

bus module are routed to the

outside of the robot interface at

the factory. The robot control

cable harness can be connected

directly to the outside of the robot interface.

7

Page 8

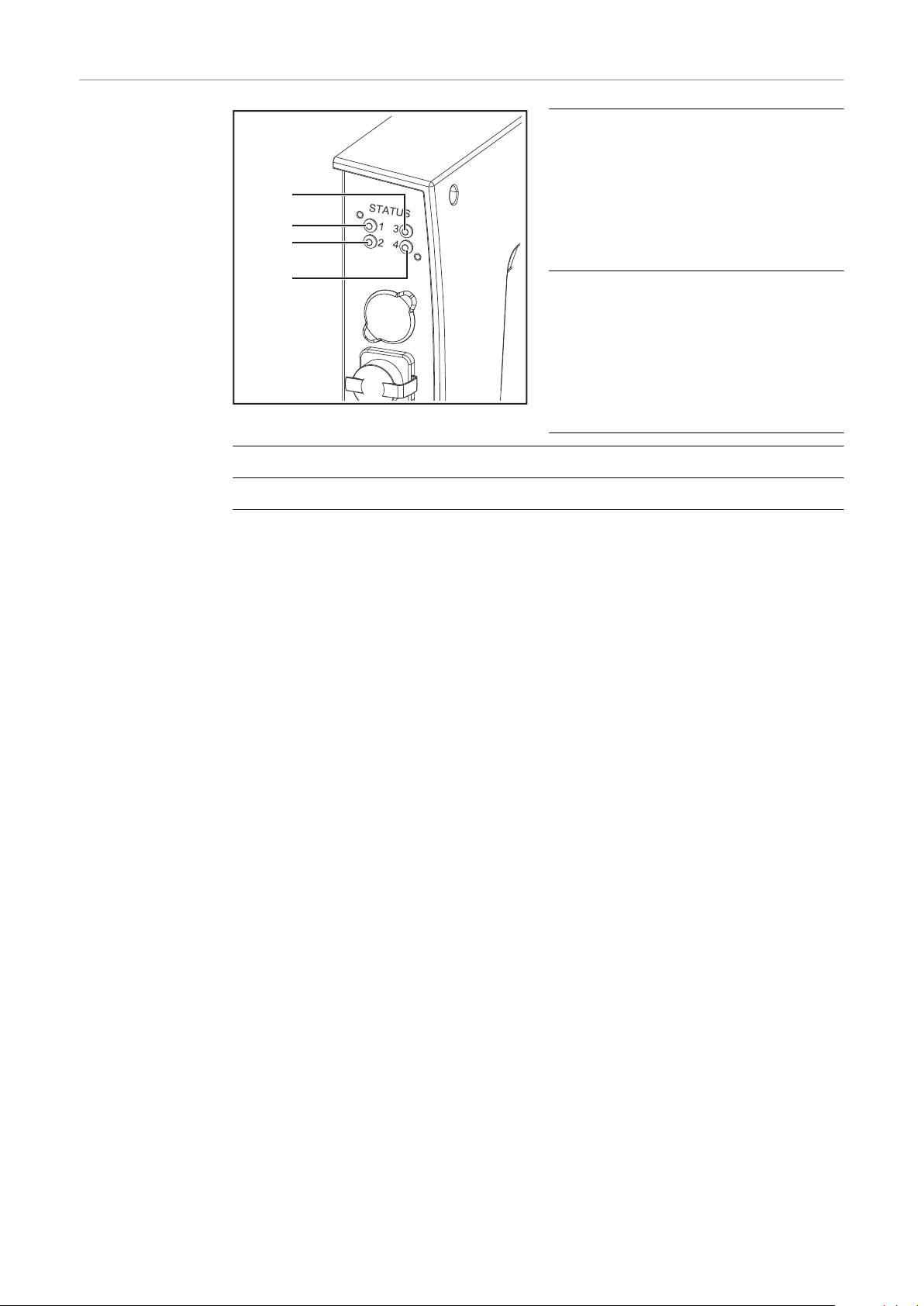

Indicators on the

(1)

(2)

(3)

(4)

Robot Interface

(1) Heartbeat LED

Off:

Offline; no supply voltage

Flashes green:

The PC board operating system

is working properly

(2) Synchronisation LED

Lights up green:

Power sources are synchronized

Lights up red:

Power sources are not synchronized

(3) see description of the respective bus module

(4) see description of the respective bus module

8

Page 9

System Overview

(1)

(2)

(3)

(4)

(1)

(2)

(3)

(4)

System Overview

EN-US

(1) Power source 1 connection / socket

(2) Wirefeeder 1 connection / socket

(3) Power source 2 connection / socket

(4) Wirefeeder 2 connection / socket

9

Page 10

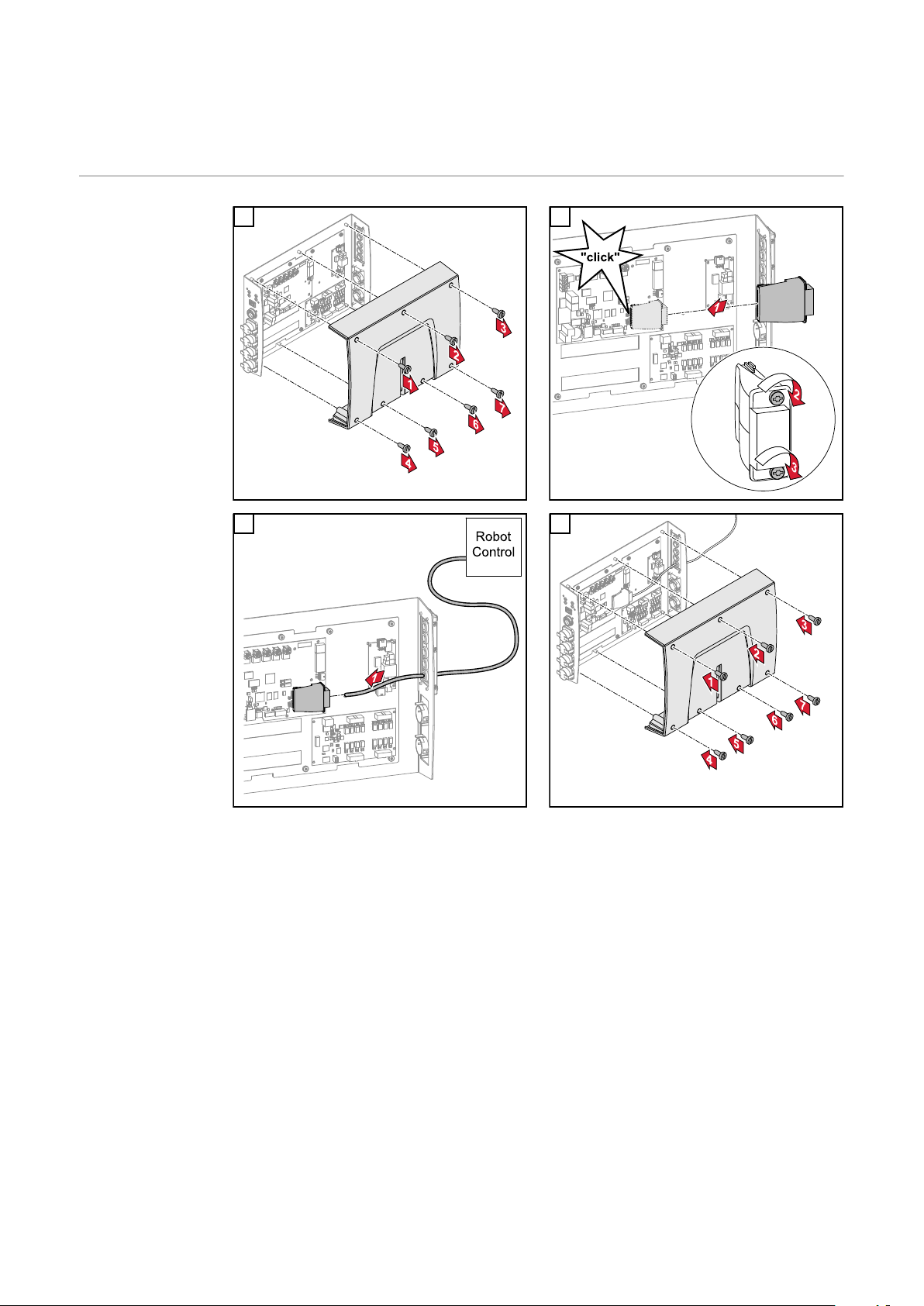

Inserting the Bus Module in the Interface and

Connecting it to the Robot Control

Inserting the

Bus Module into

the Robot Interface and Connecting it to the

Robot Control

1 2

3 4

10

Page 11

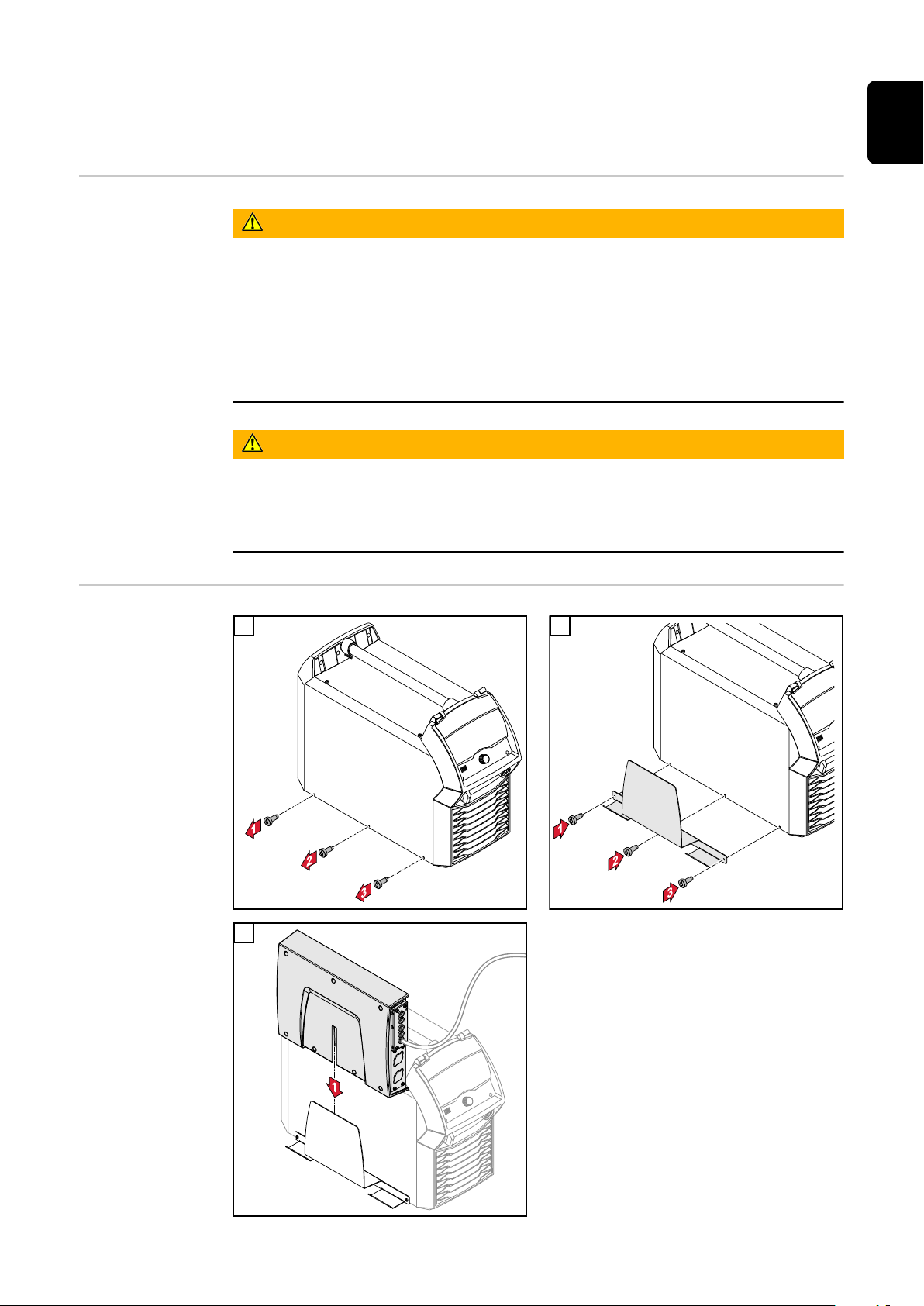

Fitting the Robot Interface and Connecting it to

the System Components

Safety

Electrical current hazard.

This can result in serious injuries or death.

▶

▶

▶

Electrical current hazard caused by an inadequate ground conductor connection.

This can result in severe personal injury and damage to property.

▶

WARNING!

Before starting work, switch off all the devices and components involved and

disconnect them from the grid.

Secure all the devices and components involved to prevent unintentional restarting.

After opening the device, use a suitable measuring instrument to check that

electrically charged components (such as capacitors) have been discharged.

WARNING!

Always use the original housing screws in the original quantity.

EN-US

Fitting the Robot

Interface

1 2

3

11

Page 12

Connecting Process Line 1 to the

Interface

1 2

3

Connecting Process Line 2 to the

Interface

Mark the process line 1 system components with the stickers supplied

4

1 2

12

Page 13

3

Mark the process line 2 system components with the stickers supplied

4

EN-US

13

Page 14

Dip Switch

General Depending on the bus module being

used, the DIP switch inside the robot

interface can be used to set the node

address/IP address.

Example: Setting

the node address/IP address

Dip switch

8 7 6 5 4 3 2 1 Node address

- - OFF OFF OFF OFF OFF ON 1

- - OFF OFF OFF OFF ON OFF 2

- - OFF OFF OFF OFF ON ON 3

- - ON ON ON ON ON OFF 62

- - ON ON ON ON ON ON 63

The node address/IP address is set using dip switch positions 1 to 6.

The setting is in binary format. This results in a configuration range of 1 to 63 in

decimal format.

14

Page 15

Notes on the Robot Interface Power Supply

(1)

(2)

(3)

Notes on the Interface Power

Supply

By default the interface is supplied with +24 V DC via connector X19 (1)

-

If the interface has connection sockets for an external power supply, these

-

sockets must be connected to connector X20 (2) or X27 (3), through which

the interface is supplied with +24 V DC

The interface can be supplied with power though connectors X19, X20, and

-

X27 in parallel. If this is the case, the interface will continue to function even

if one of the power supply lines is disconnected

If the interface is to be switched on and off via an external power supply, the

-

connection between the interface and connector X19 must be broken

EN-US

15

Page 16

Troubleshooting

(1)

(2) (3)

(4)

(5)

(6)

(7)

(10)

(8)

(9)

X3 X5X6 X7 X8

(16)

(15)

(14)

(13)

(12)

(11)

Safety

LEDs on the Robot Interface PC

board

WARNING!

Electrical current hazard.

This can result in serious injuries or death.

Before starting work, switch off all the devices and components involved and

▶

disconnect them from the grid.

Secure all the devices and components involved to prevent unintentional re-

▶

starting.

After opening the device, use a suitable measuring instrument to check that

▶

electrically charged components (such as capacitors) have been discharged.

WARNING!

Electrical current hazard caused by an inadequate ground conductor connection.

This can result in severe personal injury and damage to property.

Always use the original housing screws in the original quantity.

▶

16

Page 17

LEDs for network connection diagnosis:

(1) LED LINK

Lights up orange:

Transmission speed 100 Mbps

Off:

Transmission speed 10 Mbps

(2) LED LINK

Lights up orange:

Transmission speed 100 Mbps

Off:

Transmission speed 10 Mbps

(3) LED LINK

Lights up orange:

Transmission speed 100 Mbps

Off:

Transmission speed 10 Mbps

EN-US

(4) LED LINK

Lights up orange:

Transmission speed 100 Mbps

Off:

Transmission speed 10 Mbps

(5) LED ACTIVITY

Lights up orange:

A cable is connected to the X7 connector

Lights up/flashes green:

Data transfer active

(6) LED ACTIVITY

Lights up orange:

A cable is connected to the X8 connector

Lights up/flashes green:

Data transfer active

(7) LED ACTIVITY

Lights up orange:

A cable is connected to the X3 connector

Lights up/flashes green:

Data transfer active

(8) LED ACTIVITY

Lights up orange:

A cable is connected to the X5 connector

17

Page 18

Lights up/flashes green:

Data transfer active

(9) LED ACTIVITY

Lights up/flashes green:

Data transfer active

(10) LED SPEED

Lights up green:

A cable is connected to the X6 connector

(11) LED LINK

Not assigned

(12) LED LINK

Not assigned

(13) LED LINK

Not assigned

(14) LED USER3

Lights up/flashes green:

For fault analysis

(15) LED USER4

Flashes green:

The PC board operating system is working properly

LEDs for power supply diagnosis:

(16) LED +5V

Lights up green:

5 V operating voltage present

Off:

No operating voltage present

18

Page 19

EN-US

19

Page 20

Loading...

Loading...