Fronius prints on elemental chlorine free paper (ECF) sourced from certified sustainable forests (FSC).

/ Perfect Charging / Perfect Welding / Solar Energy

RI FB/i Yaskawa WeldCom 2.0

RI MOD/i CC Modbus TCP-2P

Operating instructions

EN-US

42,0426,0218,EA 029-11012022

Table of contents

General 5

Safety 5

Device Concept 5

Block Diagram 6

Scope of Supply 6

Required Tools and Materials 6

Installation Requirements 6

Connections and Indicators 7

Connections on the Robot Interface 7

Pin Assignment of M12 Connection 7

LEDs on Robot Interface PCB 8

LEDs for Power Supply Diagnosis 9

LEDs for Network Connection Diagnosis 9

Connections and indicators on RJ 45 module 10

Examples of How the M12 Connection Is Used 12

Examples of How the M12 Connection Is Used 12

Technical data 13

Environmental Conditions 13

Robot Interface Technical Data 13

Data Transfer Properties 13

Configuration Parameters 14

Configuration of robot interface 15

General 15

Configuring the Process Image 15

Setting the IP Address 15

Configuring the Robot Interface 16

Installing the Robot Interface 17

Safety 17

Preparation 17

Fitting the M12 Connection 18

Routing the Data Cable 19

Installing the Robot Interface 20

Final Tasks 20

Installing the Bus Module 21

Safety 21

Installing the Bus Module 21

Input and output signals 22

Data types 22

Input Signals 22

Value range Process line selection 25

Value Range for TWIN Mode 25

Value Range for Documentation mode 26

Value range Working mode 26

Value Range for Command value selection 26

Output signals 27

Value Range for Welding Process and Process Image 30

Assignment of Sensor Statuses 1–3 30

Value range Safety status 30

TAG Table 31

Retrofit Image Input and Output Signals 34

Input signals 34

Value Range for Operating Mode 35

Output Signals 37

TAG Table 38

Modbus – General Information 40

Protocol Description 40

Data Coding 40

Application Data Unit (ADU) 41

Modbus Functions 42

03 (03) Read Holding Register 42

EN-US

3

06 (06) Write Single Register 43

16 (10) Write Multiple Register 44

23 (17) Read/Write Multiple Register 46

103 (67) Read Holding Register Float 47

104 (68) Write Single Register Float 48

4

General

(3)(1) (2) (5)(4)

Robot

Control

(6) (7) (8)

EN-US

Safety

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in serious personal injury and damage to property.

All the work and functions described in this document must only be carried out by

▶

technically trained and qualified personnel.

Read and understand this document in full.

▶

Read and understand all safety rules and user documentation for this equipment

▶

and all system components.

WARNING!

Danger from electrical current.

This can result in serious personal injury and damage to property.

Before starting work, switch off all devices and components involved, and discon-

▶

nect them from the grid.

Secure all devices and components involved so they cannot be switched back on.

▶

WARNING!

Danger from unplanned signal transmission.

This can result in serious personal injury and damage to property.

Do not transfer safety signals via the interface.

▶

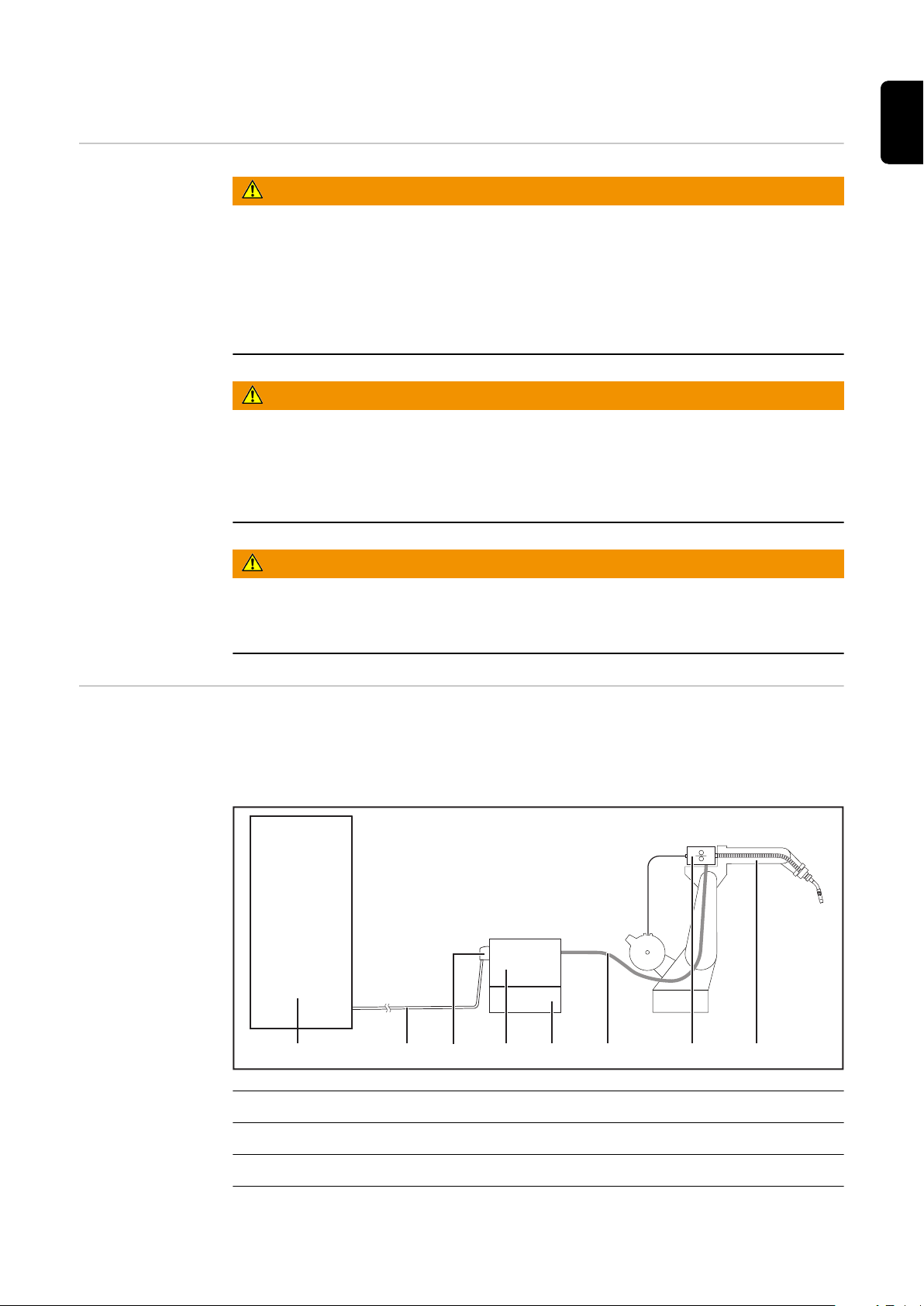

Device Concept The robot interface serves as an interface between the power source and standardized

bus modules supporting a wide range of communication protocols.

Fronius may factory-fit the robot interface in the power source but it can also be retrofitted by appropriately trained and qualified personnel.

(1) Robot control system

(2) SpeedNet data cable

(3) Robot interface

(4) Power source

5

Block Diagram

Spider NT241

RI FB/i Yaskawa

WeldCom 2.0

Data

24 V

Module

(1)

(2)

(4)

(5)

(3)

(5) Cooling unit

(6) Interconnecting hosepack

(7) Wirefeeder

(8) Robot

Scope of Supply

Required Tools

and Materials

(1) RI FB/i Yaskawa WeldCom 2.0

(2) Data cable

4-pin

(3) M12 connection (5-pin)

with connection cable

(4) Cable ties

(5) 2 screws for M12 connection

(6) These Operating Instructions

(not pictured)

- Screwdriver TX8

- Screwdriver TX20

- Screwdriver TX25

- Diagonal cutting pliers

Installation Requirements

The robot interface may only be installed in the designated opening on the rear of the

power source.

6

Connections and Indicators

(2) (3)

(1)

(1) (2)

(3)(4)

(5)

EN-US

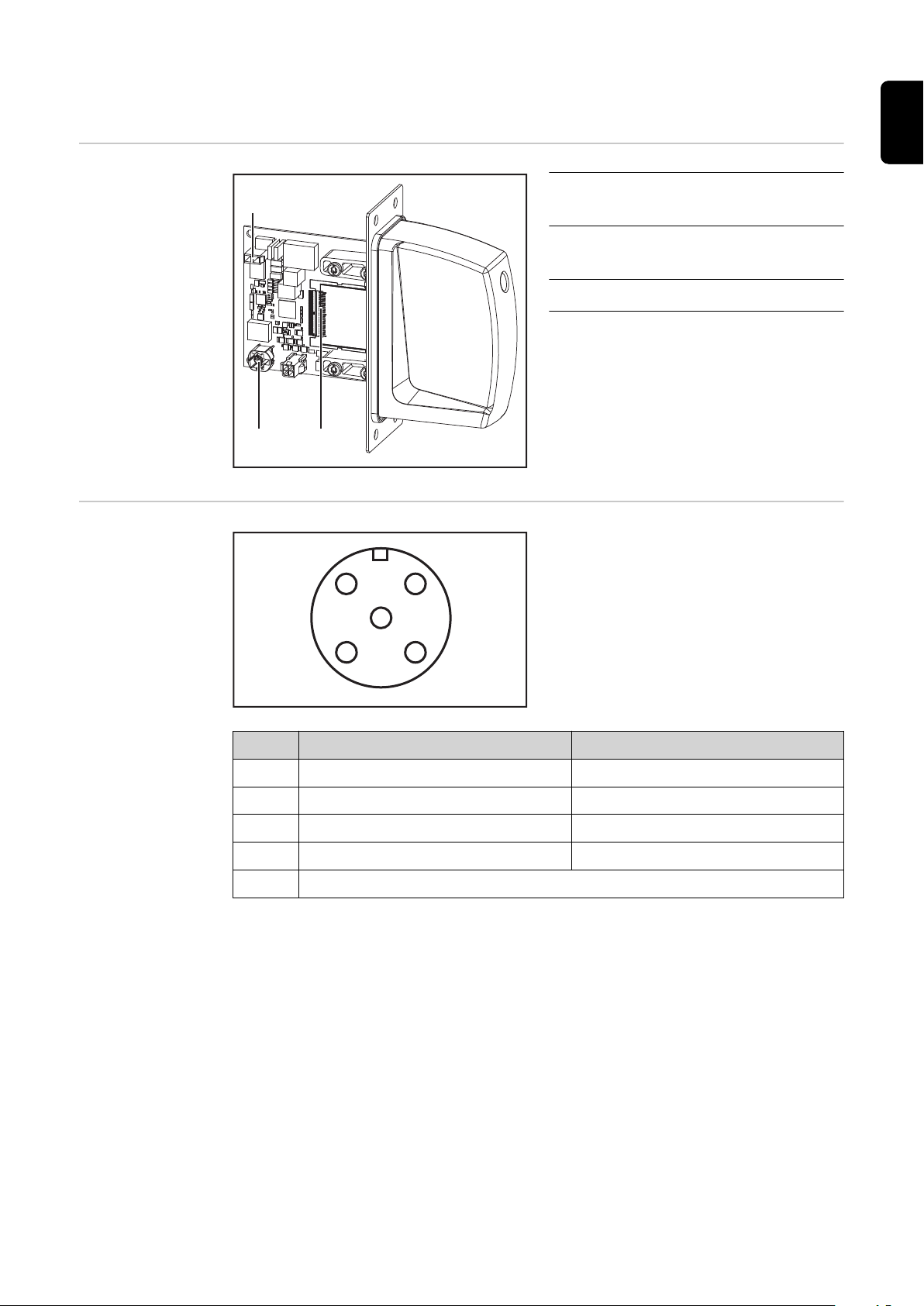

Connections on

the Robot Interface

Pin Assignment

of M12 Connection

(1) Power supply connection

2-pin

(2) SpeedNet data cableconnection

4-pin

(3) Bus module connection

WeldCom 2.0 Retrofit

(1) CAT signal CAT signal

(2) Touched Arc stable

(3) CAT signal GND CAT signal GND

(4) Touched GND Arc stable GND

(5) n.c (not connected)

7

LEDs on Robot

(14)

(13)

(12)

(11)

(2)

(1)

(9)

(10)

(8)

(7)

(3) (4)

(5) (6)

Interface PCB

(1) ETH1 LED Green For diagnosing the network connection.

For details, see section below titled "LEDs

(2) ETH2 LED Orange

for Network Connection Diagnosis"

(3) LED 3 Green

No function

(4) LED 4 Green

- Flashes at 4 Hz = No SpeedNet connection

(5) LED 5 Green

- Flashes at 20 Hz = Establishing

SpeedNet connection

- Flashes at 1 Hz = SpeedNet connection established

Lights up when an internal error occurs.

(6) LED 6 Red

Remedy: Restart the robot interface. If this

does not resolve the issue, inform the service team.

(7) +3V3 LED Green For diagnosing the power supply.

For details, see section below titled "LEDs

(8) +24V LED Green

for Power Supply Diagnosis"

(9) DIG OUT 2 LED Green Digital output 2. LED lights up when active

(10) DIG OUT 1 LED Green Digital output 1. LED lights up when active

8

(11) LED 11 Green

LEDs for Power

Supply Diagnosis

(12) LED 12 Green

(13) LED 13 Green

(14) LED 14 Green

LED Indicator Meaning Cause

Off

+24V

Lights up

Off

+3V3

Lights up

No supply voltage available for

interface

24 VDC supply voltage

present on robot interface

No operating voltage present

on robot interface

3 VDC operating voltage

present on robot interface

No function

- Robot interface power

supply not established

- Power supply cable faulty

- 24 VDC supply voltage

not present

- Robot interface power

supply unit is faulty

EN-US

LEDs for Network

Connection Diagnosis

LED Indicator Meaning Cause

- No network connection

ETH1

ETH2

Off No network connection

Lights up

Flashes Data transfer in progress

Off Transmission speed 10 Mbit/s

Lights up

Network connection established

Transmission speed

100 Mbit/s

established for interface

- Network cable faulty

9

Connections and

(12)(11)(10)

(14)(13)

(9)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

indicators on RJ

45 module

(11) RJ-45 Ethernet connection 2

(12) RJ-45 Ethernet connection 1

(13) Link/Activity LED 1

(14) Network status LED

(1) TX+

(2) TX-

(3) RX+

(6) RX-

(4) Not normally used; to ensure

(5)

(7)

(8)

signal completeness, these pins

must be interconnected and,

after passing through a filter circuit, must terminate at the

ground conductor (PE).

(9) Link/Activity LED 2

(10) Module status LED

Network Status LED:

Status Meaning

Off No IP address or exception state

Lights up green At least one Modbus message received

Flashes green Waiting for first Modbus message

Lights up red IP address conflict, serious error

Flashes red Connection timeout. No Modbus message was received

within the period defined for the "Process active timeout"

Module Status LED:

Status Meaning

Off No supply voltage

Lights up green Normal operation

Lights up red Major error (exception state, serious fault, etc.)

Flashes red Minor error

Alternates between red

Firmware update in progress

and green

10

Link/Activity LED:

Status Meaning

Off No connection, no activity

Lights up green Connection established (100 Mbit/s)

Flickers green Activity (100 Mbit/s)

Lights up yellow Connection established (10 Mbit/s)

Link/Activity LED:

Status Meaning

Flickers yellow Activity (10 Mbit/s)

EN-US

11

Examples of How the M12 Connection Is Used

1 2

34

5

Pin 1 / M12

Pin 3 / M12

Pin 3 / M12

Pin 1 / M12

High-active =

Low-active =

+ 24 V from

+ 24 V from

+ 24 V

DC

/ 20 mA

+ 24 V

DC

/ 20 mA

uP

uP

max. 100 V

LED (10)

V

CC

V

CC

LED (10)

max. 100 V

Pin 2 / M12

Pin 4 / M12

Pin 4 / M12

Pin 2 / M12

High-active =

Low-active =

+ 24 V from

+ 24 V from

+ 24 V

DC

/ 20 mA

+ 24 V

DC

/ 20 mA

uP

uP

max. 100 V

max. 100 V

LED (9)

LED (9)

V

CC

V

CC

Examples of How

the M12 Connection Is Used

M12 Connection on Power Source

12

CAT signal (DIG OUT 1)

WeldCom 2.0 = Touched, Retrofit = Arc Stable (DIG OUT 2)

Technical data

EN-US

Environmental

Conditions

Robot Interface

Technical Data

CAUTION!

A risk is posed by prohibited environmental conditions.

This can result in severe damage to equipment.

Only store and operate the device under the following environmental conditions.

▶

Temperature range of ambient air:

- During operation: -10 °C to +40 °C (14 °F to 104 °F)

- During transport and storage: -20 °C to +55 °C (-4 °F to 131 °F)

Relative humidity:

- Up to 50% at 40 °C (104 °F)

- Up to 90% at 20 °C (68 °F)

Ambient air: free of dust, acids, corrosive gases or substances, etc.

Altitude above sea level: up to 2000 m (6500 ft).

Power supply Internal (24 V)

Degree of protection IP 23

Data Transfer

Properties

RJ-45 Connection

Transmission technology:

Ethernet

Medium (4 x 2 twisted-pair copper cable):

Category 5 (100 Mbit/s) or higher

Transmission speed:

10 Mbit/s or 100 Mbit/s

Bus connection:

Ethernet RJ-45

M12 Connection

Voltage:

24 V

Current load per output:

Max. 20 mA

13

Configuration

Parameters

In some robot control systems, it may be necessary to state the configuration

parameters described here so that the bus module can communicate with the

robot.

Parameter Value

Vendor Name Fronius International GmbH

Product Code 0340

hex

(832

dec

)

Major / Minor Revision V1.00

Vendor URL www.fronius.com

Product Name yaskawa-weldcom2-0-modbus-tcp

Model Name yaskawa-weldcom2-0

User Application Name Fronius welding controller for the series TPS/i WeldCom2.0

(ModbusTCP)

14

Configuration of robot interface

(1)

(2)

EN-US

General

Configuring the

Process Image

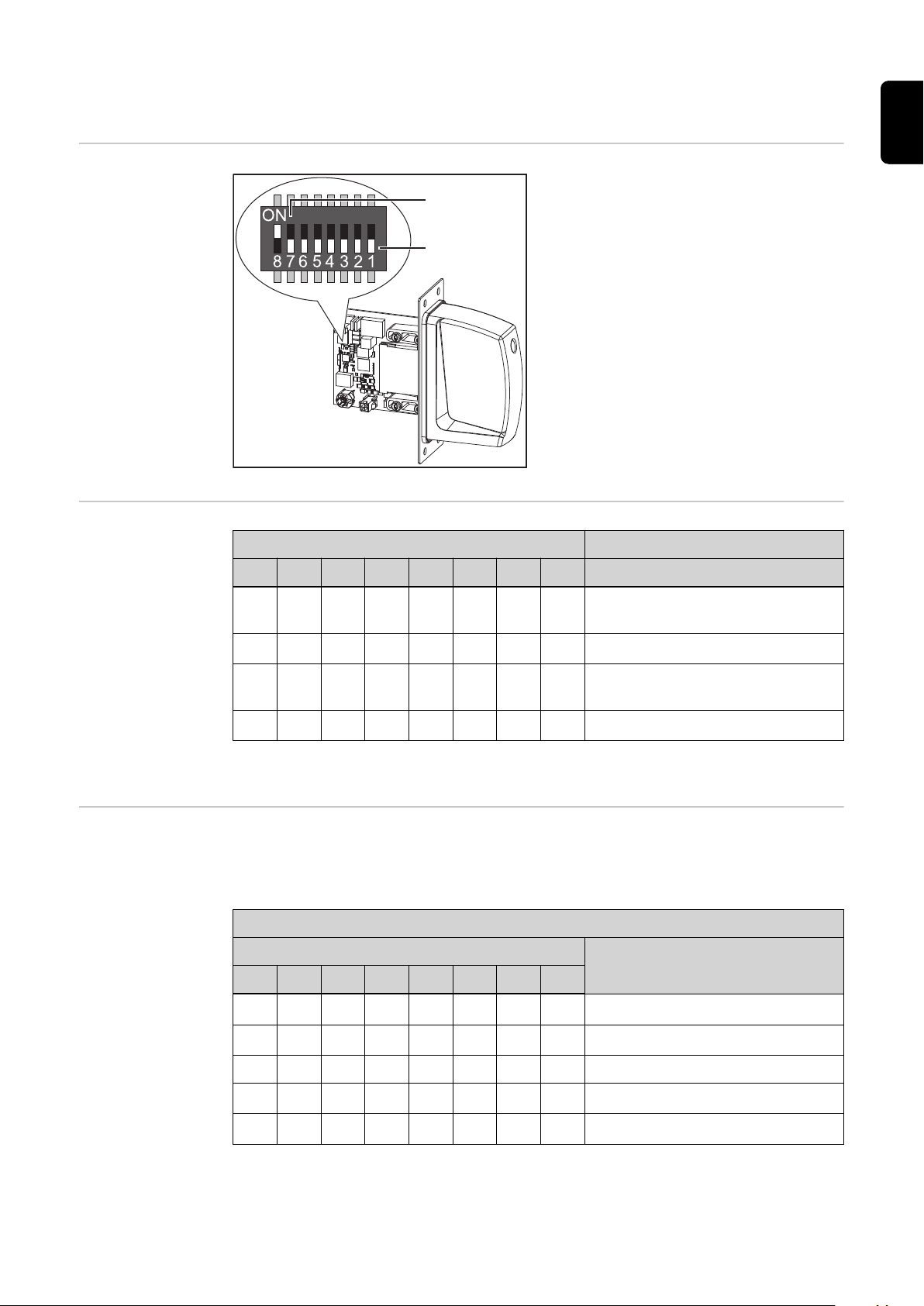

The DIP switch on the robot interface is

used to configure:

- The process image (standard image,

retrofit image)

- The IP address

Default setting for process image:

Positions 7 and 8 of DIP switch set to OFF

(1) = standard image = Weldcom V2.0

Default setting for IP address =

192.168.255.210:

- Positions 6, 5, 3, and 1 of DIP switch

set to OFF (1)

- Positions 2 and 4 of DIP switch set to

ON (2)

DIP Switch

8 7 6 5 4 3 2 1 Configuration

OFF OFF

OFF ON

- - - - - -

- - - - - -

Standard image

(Weldcom V2.0)

Not used

Setting the IP Address

ON OFF

ON ON

- - - - - -

- - - - - -

Retrofit image

(Weldcom TPS series)

Not used

The process image defines the volume of data transferred and the system compatibility.

You can set the IP address as follows:

- Via the DIP switch within the range defined by 192.168.255.2xx

(xx = DIP switch setting = 01 to 55)

Setting the Address via the DIP Switch:

DIP Switch

IP Address

8 7 6 5 4 3 2 1

- -

- -

OFF OFF OFF OFF OFF ON

OFF OFF OFF OFF ON OFF

192.168.255.201

192.168.255.202

:

- -

- -

ON ON OFF ON ON OFF

ON ON OFF ON ON ON

192.168.255.254

192.168.255.255

The IP address can be set via positions 1 to 6 of the DIP switch.

The configuration is carried out in binary format. In decimal format, the setting range is

01 through 55.

15

The following IP address is set via the DIP switch on delivery:

- IP address: 192.168.255.210

- Subnet mask: 255.255.255.0

- Default gateway: 0.0.0.0

Configuring the

Robot Interface

Set the DIP switch in accordance with the desired configuration

1

NOTE!

Risk due to invalid DIP switch settings.

This may result in malfunctions.

Whenever changes are made to the DIP switch settings, the interface must be re-

▶

started. This is the only way for the changes to take effect.

Restart the interface = interrupting and restoring the power supply or executing the

▶

relevant function on the website of the power source (SmartManager).

16

Installing the Robot Interface

EN-US

Safety

Preparation

WARNING!

Electrical current hazard.

This can result in serious injuries or death.

Before starting work, switch off all the devices and components involved and discon-

▶

nect them from the grid.

Secure all the devices and components involved to prevent unintentional restarting.

▶

After opening the device, use a suitable measuring instrument to check that electric-

▶

ally charged components (such as capacitors) have been discharged.

WARNING!

Electrical current hazard caused by an inadequate ground conductor connection.

This can result in severe personal injury and damage to property.

Always use the original housing screws in the original quantity.

▶

1 2

3 4

17

5

Fitting the M12

Connection

1 2

3 4

18

5 6

EN-US

Routing the Data

Cable

1 2

3

19

Installing the Robot Interface

1 2

Final Tasks

1 2

20

Installing the Bus Module

EN-US

Safety

Installing the Bus

Module

WARNING!

Danger from electrical current.

Serious injuries or death may result.

Before starting work, switch off all devices and components involved, and discon-

▶

nect them from the grid.

Secure all devices and components involved so that they cannot be switched back

▶

on.

WARNING!

Danger from electrical current due to inadequate ground conductor connection.

Serious personal injury and property damage may result.

Always use the original housing screws in the quantity initially supplied.

▶

1 2

3

21

Input and output signals

Data types The following data types are used:

- UINT16 (Unsigned Integer)

Whole number in the range from 0 to 65535

- SINT16 (Signed Integer)

Whole number in the range from -32768 to 32767

Conversion examples:

- for a positive value (SINT16)

e.g. desired wire speed x factor

12.3 m/min x 100 = 1230

- for a negative value (SINT16)

e.g. arc correction x factor

-6.4 x 10 = -64

Input Signals From robot to power source

Applicable to firmware V2.3.0 and higher

= FFC0

dec

= 04CE

dec

hex

hex

HEX

Ad-

ress Signal Type

F000 Control Flag Group 1

Bits 0 to 7 Process active timeout Byte ms 10

F001

Bits 8 to

15

Control Flag Group 2

Bit 0 Welding start Boolean

Bit 1 Robot ready Boolean

Bit 2 Source error reset Boolean

Bit 3 Gas on Boolean

Bit 4 Wire inching Boolean

Bit 5 Wire retract Boolean

Bit 6 Torch blow out Boolean

Bit 7 Welding simulation Boolean

Bit 8 Touch sensing Boolean

Bit 9 Reserved

Bit 10 SFI ON Boolean

Reserved

Range /

Unit

Factor

22

Bit 11 Synchro pulse on Boolean

Bit 12 WireBrake Boolean

Bit 13 Torch XChange Boolean

Bit 14 TeachMode Boolean

Bit 15 Reserved

HEX

Ad-

ress Signal Type

F002 Control Flag Group 3

Range /

Unit

Factor

EN-US

Bit 0 Process line selection Bit

0

Bit 1 Process line selection Bit

1

Bit 2 TWIN mode Bit 0 Boolean

Bit 3 TWIN mode Bit 1

Bits 4 to 9 Reserved

Bit 10 Active heat control Boolean

Bit 11 Wire sense start Boolean

Bit 12 Wire sense break Boolean

Bits 13 to15Reserved Boolean

Boolean

See section

Value

range Pro-

Boolean

Boolean

cess line

selection on

page 25

See section

Value

Range for

TWIN Mode

on page 25

F003 Control Flag Group 4

Bit 0 Documentation mode Boolean See section

Value

Range for

Documenta-

tion mode

on page 26

Bits 1 to

15

F004 Control Flag Group 5

Bits 0 to

15

F005 Control Flag Group 6

Bits 0 to

15

F006 Control Flag Group 7

Bits 0 to

15

Reserved

Reserved

Reserved

Reserved

23

HEX

Ad-

ress Signal Type

F007 Control Flag Group 8

Range /

Unit

Factor

F008

Bit 0 ExtInput1 => OPT_Out-

put 1

Bit 1 ExtInput2 => OPT_Out-

put 2

Bit 2 ExtInput3 => OPT_Out-

put 3

Bit 3 ExtInput4 => OPT_Out-

put 4

Bit 4 ExtInput5 => OPT_Out-

put 5

Bit 5 ExtInput6 => OPT_Out-

put 6

Bit 6 ExtInput7 => OPT_Out-

put 7

Bit 7 ExtInput8 => OPT_Out-

put 8

Bits 8 to

15

Working mode

Bit 0 Working Mode Bit 0

Bit 1 Working Mode Bit 1

Bit 2 Working Mode Bit 2

Bit 3 Working Mode Bit 3

Bit 4 Working Mode Bit 4

Bits 5 to

13

Reserved

Reserved

Boolean

Boolean

Boolean

Boolean

Boolean

Boolean

Boolean

Boolean

See section

Value

range

Working

mode on

page 26

Bit 14 Command value selec-

tion

Bit 15 Reserved

F009 Job number UINT16 0 to 1000

F00A Program number (xml-file) UINT16 0 to 65,535

F00B Feeder command Value SINT16 -327.68 to

F00C Arc length correction SINT16 -10 to +10 10

F00D Puls/Dynamik correction SINT16 -10 to +10 10

F00E Wire retract SINT16 0 to +10 10

Boolean See section

Value

Range for

Command

value selection on page

26

100

327.67

[m/min]

24

HEX

Ad-

ress Signal Type

Range /

Unit

F00F Welding speed UINT16 0 to 65,535

(0 to 6553.5

10

m/min)

F010 Penetration stabilizer SINT16 0 to +10 10

F011 Arc length stabilizer UINT16 0 to +10 10

F012 Reserved

F013 Reserved

F014 Reserved

F015 Reserved

F016 Reserved

F017 Reserved

F018 Reserved

F019 Reserved

Factor

EN-US

Value range Process line selection

F01A Wire forward / backward length UINT16 OFF / 1 to

65,535 mm

F01B Wire sense edge detection UINT16 OFF / 0.5 to

20.0 mm

F01C Reserved

F01D Seam number UINT16 0 to 65,535 1

Bit 1 Bit 0 Description

0 0 Process line 1 (default)

0 1 Process line 2

1 0 Process line 3

1 1 Reserved

Value range for process line selection

1

10

Value Range for

TWIN Mode

Bit 1 Bit 0 Description

0 0 TWIN Single mode

0 1 TWIN Lead mode

1 0 TWIN Trail mode

1 1 Reserved

Value range for TWIN mode

25

Value Range for

Documentation

mode

Bit 0 Description

0 Seam number of power source (internal)

1 Seam number of robot

Value range for documentation mode

Value range

Working mode

Value Range for

Command value

selection

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Description

0 0 0 0 0 Internal parameter selection

0 0 0 0 1 Special 2-step mode characteristics

0 0 0 1 0 Job mode

0 1 0 0 0 2-step mode characteristics

Value range for operating mode

Bit 14 Description

0 Wirefeeder set value

1 Welding current set value

Value range for set value

26

Output signals From Power Source to Robot

Applicable to firmware V2.3.0 and higher

HEX

Ad-

ress Signal Type

F100 Status Flag Group 1

Bit 0 = 15 Reserved

Range /

Unit

EN-US

Factor

F101

Status Flag Group 2

Bit 0 Heartbeat Powersource Boolean 1

Hz

Bit 1 Power source ready Boolean

Bit 2 Arc stable Boolean

Bit 3 Current flow Boolean

Bit 4 Main current signal Boolean

Bit 5 Torch collision protection Boolean

Bit 6 Reserved

Bit 7 Reserved

Bit 8 Touched Boolean

Bit 9 Torchbody connected Boolean

Bit 10 Command value out of

range

Bit 11 Correction out of range Boolean

Bit 12 Process active Boolean

Bit 13 RobotMotionRelease Boolean

Boolean

F102

Bit 14 Wire stick workpiece Boolean

Bit 15 Reserved

Status Flag Group 3

Bit 0 Welding Mode Bit 0 Boolean See section

Bit 1 Welding Mode Bit 1 Boolean

Bit 2 Welding Mode Bit 2 Boolean

Bit 3 Welding Mode Bit 3 Boolean

Bit 4 Welding Mode Bit 4 Boolean

Bit 5 = 7 Reserved

Bit 8 Parameter selection in-

ternally

Bit 9 Characteristic number

valid

Bit 10 =

13

Bit 14 Process image Bit 0 Boolean

Bit 15 Process image Bit 1 Boolean

Reserved

Boolean

Boolean

Value

Range for

Welding

Process

and Pro-

cess Image

on page 30

27

HEX

Ad-

ress Signal Type

F103 Status Flag Group 4

Bit 0 Penetration stabilizier Boolean

Bit 1 Arclength stabilizier Boolean

Bit 2 = 15 Reserved

F104 Status Flag Group 5

Range /

Unit

Factor

Bit 0 Sensor status 1 High Boolean See section

Bit 1 Sensor status 2 High Boolean

Bit 2 Sensor status 3 High Boolean

Bit 3 = 10 Reserved

Bit 11 Safety status Bit 0 Boolean See section

Bit 12 Safety status Bit 1 Boolean

Bit 13 Reserved

Bit 14 Notification Boolean

Bit 15 System not ready Boolean

F105 Status Flag Group 6

Bit 0 Limit Signal Boolean

Bit 1 = 7 Reserved

Assign-

ment of

Sensor

Statuses 1–

3 on page

30

Value

range

Safety

status on

page 30

Bit 8 Reserved

Bit 9 TWIN synchronization

active

Bit 10 Line supply status Boolean

Bit 11 =

13

Bit 14 Warning Boolean

Bit 15 Reserved

F106 Status Flag Group 7

Bit 0 = 15 Reserved Boolean

Reserved

Boolean

28

HEX

Ad-

ress Signal Type

F107 Status Flag Group 8

Range /

Unit

Factor

EN-US

Bit 0 ExtOutput1 <= OPT_In-

put1

Bit 1 ExtOutput2 <= OPT_In-

put2

Bit 2 ExtOutput3 <= OPT_In-

put3

Bit 3 ExtOutput4 <= OPT_In-

put4

Bit 4 ExtOutput5 <= OPT_In-

put5

Bit 5 ExtOutput6 <= OPT_In-

put6

Bit 6 ExtOutput7 <= OPT_In-

put7

Bit 7 ExtOutput8 <= OPT_In-

put8

Bit 8 = 15 Reserved Boolean

F108 Main error number UINT16 0 to 65,535

F109 Warning number UINT16 0 to 65,535 1

Boolean

Boolean

Boolean

Boolean

Boolean

Boolean

Boolean

Boolean

F10A Welding voltage actual value UINT16 0.0 to

327.67 volts

F10B Welding current actual value UINT16 0.0 to

3276.7

amperes

F10C Motor current actual value M1 SINT16 -327.68 to

327.67

amperes

F10D Motor current actual value M2 SINT16 -327.68 to

327.67

amperes

F10E Motor current actual value M3 SINT16 -327.68 to

327.67

amperes

F10F Reserved

F110 Wire speed actual value SINT16 -327.68 to

327.67

m/min

F111 Seam tracking actual value UINT16 0 to 6.5535 10000

F112 Real energy actual value UINT16 0 to 6553.5

kilojoules

100

10

100

100

100

100

10

F113 Wire position SINT16 -327.68 to

327.67 mm

F114 Reserved

F115 Reserved

100

29

HEX

Ad-

ress Signal Type

Range /

Unit

F116 Reserved

F117 Reserved

F118 Reserved

F119 Reserved

F11A Reserved

F11B Reserved

F11C Reserved

F11D Reserved

Factor

Value Range for

Welding Process

and Process Image

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Description

0 0 0 0 0 Internal mode selection

0 0 0 0 1 MIG/MAG pulsed synergic

0 0 0 1 0 MIG/MAG standard synergic

0 0 0 1 1 MIG/MAG PMC

0 0 1 0 0 MIG/MAG LSC

0 0 1 0 1 MIG/MAG standard manual

0 0 1 1 0 Electrode

0 0 1 1 1 TIG

0 1 0 0 0 CMT

Value range for welding process

Bit 15 Bit 14 Bit 0-13 Description

0 0 - Standard image (Weldcom V2.0)

1 0 - Retrofit image (Weldcom TPS series)

Value range for process image

Assignment of

Sensor Statuses

1–3

Value range

Safety status

30

Bit 2 Bit 1 Bit 0 Description

0 0 1 OPT/i WF R wire end

0 1 0 OPT/i WF R DE wire drum

1 0 0 OPT/i WF R DE ring sensor

Bit 1 Bit 0 Description

0 0 Reserve

0 1 Hold

TAG Table

Bit 1 Bit 0 Description

1 0 Stop

1 1 Not installed / active

EN-US

- To read the following TAGs, use the mode function 03dec (03hex) - see section 03

dec

(03

hex

) Read

Holding Register from page 42

- To edit the following TAGs, use the mode function 06dec (06hex) - see section 06

dec

(06

hex

) Write

Single Register from page 43

HEX

address Description Reading / writing Unit Type Step size

E064 Gas preflow [Gpr] Reading & writing s Word 0.1

E065 Gas postflow [Gpo] Reading & writing s Word 0.1

E098 Error number Read only 1

E062 Min. feeder value Read only m/min Word 0.1

E063 Max. feeder value Read only m/min Word 0.1

E0A3 Inching speed [Fdi] Reading & writing m/min Word 0.1

E032 SynchroPulse DeltaWireFeed Reading & writing m/min Word

E031 SynchroPulse Frequency Reading & writing Hz Word 0.1

E033 SynchroPulse DutyCycle Reading & writing % Word 1

E034 SynchroPulse

Reading & writing 0.1

ArcLength Correction High

E035 SynchroPulse

Reading & writing 0.1

ArcLength Correction Low

E06A Starting current [I-S] Reading & writing % Word 1

E06B Slope 1 Reading & writing s Word 0.1

E06C Slope 2 Reading & writing s Word 0.1

E06D End current [I-E] Reading & writing % Word 1

E056 Starting Current Time [t-S] Reading & writing s Word 0.1

OFF=12e34

E057 End Current Time [t-e] Reading & writing s Word 0.1

OFF=12e34

E02E SFI HotStart Reading & writing s Word 0.01

31

HEX

address Description Reading / writing Unit Type Step size

E06F Language Reading & writing Con-

Name: Language

Constant: English (8e34)

Constant: German (9e34)

Constant: Chinese (10e34)

Constant: Spanish (23e34)

Constant: French (24e34)

Constant: Czech (25e34)

Constant: Hungarian (26e34)

Constant: Italian (27e34)

Constant: Norwegian (28e34)

Constant: Polish (29e34)

Constant: Portuguese (30e34)

Constant: Slovak (31e34)

Constant: Turkish (32e34)

Constant: Russian (33e34)

Constant: Swedish (34e34)

stant

Float

Constant: Estonian (35e34)

Constant: Finnish (36e34)

Constant: Lithuanian (39e34)

Constant: Latvian (40e34)

Constant: Dutch (41e34)

Constant: Slovenian (42e34)

Constant: Romanian (43e34)

Constant: Croatian (44e34)

Constant: Japanese (58e34)

Constant: Ukrainian (59e34)

Constant: Korean (61e34)

Constant: Icelandic (66e34)

Constant: Vietnamese (67e34)

Constant: Thai (70e34)

Constant: Indonesian (71e34)

Constant: Serbian (75e34)

Constant: Hindi (76e34)

Constant: Tamil (130e34)

Constant: Danish (151e34)

Constant: Bulgarian (156e34)

E0A6 Hourmeter Current flow Read only h Float 0.1

E0A7 Hourmeter Power on Read only h Float 0.1

32

HEX

address Description Reading / writing Unit Type Step size

E0AA Power value Read only kW Float 0.1

E0AB Real energy value Read only kJ Float 0.1

E0BB Coolertemperature Read only C Float 0.1

E0BC Coolerflow Read only l/min Float 0.01

EN-US

33

Retrofit Image Input and Output Signals

Input signals From robot to power source

Applicable to firmware V1.9.0 and higher

HEX

address Signal Type Range / Unit

F000

F001

Control Flag Group 1

Bits 0 to 7 Process active timeout Byte [ms] 10

Bits 8 to 15 Reserved

Control Flag Group 2

Bit 0 Welding start Boolean

Bit 1 Robot ready Boolean

Bit 2 Source error reset Boolean

Bit 3 Gas test Boolean

Bit 4 Wire inching Boolean

Bit 5 Wire retract Boolean

Bit 6 Torch blow out Boolean

Bit 7 Welding simulation Boolean

Bit 8 Touch sensing Boolean

Bit 9 Reserved

Bit 10 SFI on Boolean

Factor

Bit 11 Synchro pulse on Boolean

Bits 12 to

13

Bit 14 Power full range Boolean

Bit 15 Reserved

F002 Control Flag Group 3

Bits 0 to 15 Reserved

F003 Control Flag Group 4

Bits 0 to 15 Reserved

F004 Control Flag Group 5

Bits 0 to 15 Reserved

F005 Control Flag Group 6

Bits 0 to 15 Reserved

F006 Control Flag Group 7

Bits 0 to 15 Reserved

F007 Control Flag Group 8

Bits 0 to 15 Reserved

Reserved

34

HEX

address Signal Type Range / Unit

Factor

F008

F009 Job number Byte 0 to 255

F00A Program number Byte 0 to 127

F00B Power Word 0 to 65,535

F00C Arc length correction Word 0 to 65,535

F00D Pulse-/dynamic correction Byte 0 to 255

F00E Reserved

F00F Reserved

F010 Reserved

F011 Reserved

Operating mode

Bit 0 Operating mode 0 Boolean

Bit 1 Operating mode 1 Boolean

Bit 2 Operating mode 2 Boolean

Bit 3 Operating mode 3 Boolean

Bits 4 to 15 Reserved Boolean

See table Value

Range for Oper-

ating Mode on

page 35

(0 to 100%)

(-10 to +10%)

(-5 to +5%)

EN-US

F012 Reserved

F013 Reserved

F014 Reserved

F015 Reserved

F016 Reserved

F017 Reserved

F018 Reserved

F019 Reserved

F01A Reserved

F01B Reserved

F01C Reserved

F01D Reserved

F01E Reserved

Value Range for

Operating Mode

Bit

4-15

Bit 3 Bit 2 Bit 1 Bit 0 Description

- 0 0 0 0 MIG standard

- 0 0 0 1 MIG pulse

- 0 0 1 0 Job mode

- 0 0 1 1

Internal parameter selection/special 2step mode

35

Bit

4-15

- 0 1 0 0 Synergic operation/special 2-step mode

- 0 1 0 1 Synergic operation/special 2-step mode

- 0 1 1 0 MIG standard manual

- 0 1 1 1 Synergic operation/special 2-step mode

- 1 0 0 0 MIG LSC

- 1 0 0 1 MIG PMC

Bit 3 Bit 2 Bit 1 Bit 0 Description

36

Output Signals From Power Source to Robot

Applicable to firmware V1.9.0 and higher

HEX

Ad-

ress Signal Type

F100 Status Flag Group 1

Range /

Unit

EN-US

Factor

F101

Bits 0 to

15

Status Flag Group 2

Bit 0 Communication ready Boolean

Bit 1 Power source ready Boolean

Bit 2 Arc stable Boolean

Bit 3 Process active Boolean

Bit 4 Main current signal Boolean

Bit 5 Torch collision protection Boolean

Bit 6 Wire stick control Boolean

Bit 7 Wire available Boolean

Bit 8 Short circuit timeout Boolean

Bit 9 Power out of Range Boolean

Bits 10 to11- Boolean

Bit 12 Limit signal High Boolean

Bits 13 to15- Boolean

Reserved Boolean

F102 Status Flag Group 3

Bits 0 to

13

Bit 14 Process image Bit 0 Boolean

Bit 15 Process image Bit 1 Boolean

F103 Status Flag Group 4

Bits 0 to

15

F104 Status Flag Group 5

Bits 0 to

15

F105 Status Flag Group 6

Bits 0 to

15

F106 Status Flag Group 7

Bits 0 to

15

Reserved

Reserved

Reserved

Reserved

Reserved

37

HEX

Ad-

ress Signal Type

Range /

Unit

F107 Status Flag Group 8

Factor

Bits 0 to

Reserved

15

F108 Main error number Word

F109 Reserved

F10A Welding voltage actual value Word 0 to 65535

(0 to 100 V)

F10B Welding current actual value Word 0 to 65535

(0 to

1000 A)

F10C Motor current actual value Byte 0 to 255

(0 to 5 A)

F10D Reserved

F10E Reserved

F10F Reserved

F110 Wire speed actual value Word 0 to vDmax 100

F111 Reserved

F112 Reserved

TAG Table

- To read the following TAGs, use the mode function 03dec (03hex) - see section 03

dec

(03

hex

) Read

Holding Register from page 42

- To edit the following TAGs, use the mode function 06dec (06hex) or 16

(06

) Write Single Register from page 43 / section 16

hex

dec

(10

) Write Multiple Register from page

hex

dec

(10

) - see section 06

hex

43

HEX

address Description Reading / writing Unit Type Step size

E011 Gas preflow [Gpr] Reading / writing s Word 0.001

E012 Gas postflow [Gpo] Reading / writing s Word 0.001

E000 Error number Read only 1

E072 Min. feeder value Read only m/min Word 0.01

E073 Max. feeder value Read only m/min Word 0.01

E013 Inching speed [Fdi] Reading / writing m/min Word 0.01

E015 Power offset [dFd] Reading / writing m/min Word 0.01

dec

E016 SynchroPulse Frequency Reading / writing Hz Word 0.1

E01D Starting current [I-S] Reading / writing % Word 0.1

38

HEX

address Description Reading / writing Unit Type Step size

E01F Slope 1 + Slope 2 Reading / writing s Word 0.001

E020 End current [I-E] Reading / writing % Word 0.1

E01E Starting Current Time [t-S] Reading / writing s Word OFF = 0.0 and

E021 End Current Time [t-e] Reading / writing s Word

E007 Arc length correction 2 (Al2) Reading / writing % Word 0.1

0.1

EN-US

39

Modbus – General Information

Protocol Description

The MODBUS ADU is constructed by the client that initiates the MODBUS transaction.

The function tells the server which action is to be performed. The MODBUS application

protocol defines the format of a client-initiated request.

The function code field of a MODBUS data unit is coded in one byte. Valid codes are in

the range of 1 ... 255 decimal (the range 128-255 is reserved for exception responses).

When the server receives a message from a client, the function code field tells the server

which action to perform.

If several actions are to be performed, subfunction codes are added to some function

codes. When messages are sent to servers by a client, the data field in the message

contains additional information that the server uses to perform the action defined by the

function code. This can include elements such as discrete addresses, register addresses, the quantity to be handled, or the number of actual data bytes contained within

the field.

With certain types of request, there might not be a data field (length: zero). In this case,

the server does not require any additional information because the action is specified by

the function code alone.

If a MODBUS ADU is correctly received without any errors occurring in connection with

the requested MODBUS function, the requested data will be included in the data field

when a server responds to a client. If an error does occur in connection with the requested MODBUS function, the field will contain an exception code that the server application

can use to determine what action to perform next.

For instance, a client can read the ON/OFF statuses of a group of discrete inputs or outputs, or it can read/write the data contents of a group of registers.

When sending a response to the client, the server uses the function code field either to

indicate that the response is normal (free of errors) or that an error has occurred (this

kind of response is called an "exception response"). In the case of a normal response,

the server simply echoes the original function code.

Data Coding For addresses and data elements, MODBUS uses a big-endian format. When a number

larger than a single byte is transmitted, this means that the most significant byte is sent

first.

Register Size Value

16 bits, 1234

hex

12

is sent as the first byte and then 34

hex

hex

40

Application Data

Unit (ADU)

This section describes the encapsulation method used for a MODBUS request or response when it is transmitted over a MODBUS TCP network.

MPAP header Function code Data

Description of MPAP header:

Transaction Identifier

Used to allocate the transaction. The MODBUS server copies the Transaction Identifier of the request into the response.

Transaction Identifier

This is used for transaction pairing. The MODBUS server copies the transaction identifier from the request into the response.

Length: 2 bytes

Description: For identifying a MODBUS request/response transaction

Client: Initialized by the client

Server: Copied back by the server from the request received

Protocol Identifier

This is used for multiplexing within the system. The MODBUS protocol is identified by

the value 0.

Length: 2 bytes

EN-US

Description: 0 = Modbus protocol

Client: Initialized by the client

Server: Copied back by the server from the request received

Length

This field is used to specify the number of bytes in the field to follow, including the unit

identifier, function code, and data field.

Length: 2 bytes

Description: Number of bytes to follow

Client: Initialized by the client

Server: -

Unit Identifier

This field is used for routing within the system. It is usually used for communication

with a serially connected MODBUS- or MODBUS+ slave where communication takes

place via a gateway between an Ethernet network and a serial MODBUS line. The

field value is set in the request by the MODBUS client and must be replicated exactly

in the response from the server.

Length: 1 byte

Description: For identifying a remote slave that is connected via a serial

line or other type of bus.

Client: Initialized by the client

All MODBUS/TCP ADUs are sent via TCP on registered port 502.

41

Modbus Functions

03

(03

dec

Holding Register

hex

) Read

This code is used to read the contents of a contiguous block of holding registers in a remote device. The request PDU determines the starting register address and the number

of registers.

The registers are addressed in the PDU starting at zero. This means registers numbered

1-16 will be addressed using 0-15.

The register data in the response message is packed as two bytes per register, with the

binary contents precisely aligned/justified within each byte. Within the individual registers, the first byte contains the high-order bits and the second byte the low-order bits.

Request

Function code 1 byte 03

Start address 2 bytes 0000

Number of registers 2 bytes 1 to 125 (7D

hex

to FFFF

hex

hex

hex

)

Response

Function code 1 byte 03

hex

Number of bytes 2 bytes 2 x N*

Register value N* x 2 bytes -

N* = Number of registers

Errors

Error code 1 byte 83

hex

Exception code 1 byte 01 or 02 or 03 or 04

Example

Example of a read request for register F009 (job number).

Request Response

Field name Hex Field name Hex

42

Transaction Identifier Hi 00 Transaction Identifier Hi 00

Transaction Identifier Lo 01 Transaction Identifier Lo 01

Protocol Identifier Hi 00 Protocol Identifier Hi 00

Protocol Identifier Lo 00 Protocol Identifier Lo 00

Length Hi 00 Length Hi 00

Length Lo 06 Length Lo 05

Unit Identifier 00 Unit Identifier 00

Function code 03 Function code 03

Starting Address Hi F0 Byte Count 02

Starting Address Lo F9 Register value Hi (108) 02

No. of Registers Hi 00 Register value Lo (108) 37

No. of Registers Lo 01

06

dec

(06

hex

)

Write Single Register

The contents of register F009 (job number) are displayed in the form of the two-byte values 237

hex

or 567

dec

.

This function code is used to write a single holding register in a remote device. The request PDU specifies the address of the register to be written. Registers are addressed

starting at zero. This means that the register that has been numbered as 1 will be addressed using 0.

The normal response is an echo of the request, which is returned after the register contents are written.

Request

EN-US

Function code 1 byte 06

Register address 2 bytes 0000

Register value 2 bytes 0000

hex

to FFFF

hex

or FFFF

hex

hex

hex

Response

Function code 1 byte 06

Register address 2 bytes 0000

Register value 2 bytes 0000

hex

to FFFF

hex

or FFFF

hex

hex

hex

Errors

Error code 1 byte 86

hex

Exception code 1 byte 01 or 02 or 03 or 04

Example

Example request for writing the value 237

hex

(567

) to register F009 (job num-

dec

ber).

Request Response

Field name Hex Field name Hex

Transaction Identifier Hi 00 Transaction Identifier Hi 00

Transaction Identifier Lo 01 Transaction Identifier Lo 01

Protocol Identifier Hi 00 Protocol Identifier Hi 00

Protocol Identifier Lo 00 Protocol Identifier Lo 00

Length Hi 00 Length Hi 00

Length Lo 06 Length Lo 06

Unit Identifier 00 Unit Identifier 00

Function code 06 Function code 06

Register Address Hi F0 Register Address Hi F0

Register Address Lo 09 Register Address Lo 09

Register Value Hi 02 Register Value Hi 02

Register Value Lo 37 Register Value Lo 37

43

16

dec

(10

hex

)

Write Multiple Register

This function code is used to write a block of contiguous registers in a remote device.

The requested written values are specified in the request data field. Data is packed as

two bytes per register. The normal response returns the function code, the starting address, and the number of registers written.

Request

Function code 1 byte 10

Starting address 2 bytes 0000

Number of registers 2 bytes 0001

hex

to FFFF

hex

or 0078

hex

hex

hex

Number of bytes 1 byte 2 x N*

Register values N* x 2 bytes Value

N* = number of registers to be written

Response

Function code 1 byte 10

Starting address 2 bytes 0000

Number of registers 2 bytes 1 to 123 (7B

hex

to FFFF

hex

hex

hex

)

Errors

Error code 1 byte 90

hex

Exception code 1 byte 01 or 02 or 03 or 04

Example

Example request for writing two registers (F00B

– F00C

hex

hex

).

Request Response

Field name Hex Field name Hex

Transaction Identifier Hi 00 Transaction Identifier Hi 00

Transaction Identifier Lo 01 Transaction Identifier Lo 01

Protocol Identifier Hi 00 Protocol Identifier Hi 00

Protocol Identifier Lo 00 Protocol Identifier Lo 00

Length Hi 00 Length Hi 00

Length Lo 11 Length Lo 11

Unit Identifier 00 Unit Identifier 00

Function code 10 Function code 10

Starting Address Hi F0 Starting Address Hi F0

Starting Address Lo 0B Starting Address Lo 0B

Quantity of Registers Hi 00 Quantity of Registers Hi 00

Quantity of Registers Lo 02 Quantity of Registers Lo 02

Byte Count 04

Register Value Hi 04

Register Value Lo CE

44

Example

Example request for writing two registers (F00B

– F00C

hex

hex

).

Request Response

Field name Hex Field name Hex

Register Value Hi FF

Register Value Lo C0

EN-US

45

23

dec

(17

hex

)

Read/Write Multiple Register

This function code performs a combination of one read operation and one write operation

in a single MODBUS transaction. The write operation is performed before the read operation.

Holding registers are addressed starting at zero. This means that holding registers 1-16

will be addressed in the PDU using 0-15.

The request PDU specifies:

- The starting address and number of holding registers to be read

- The starting address, number of holding registers, and data for the write operation.

The byte count field specifies the number of bytes to follow in the write data field.

The normal response contains the data from the group of registers read. The byte count

field specifies the number of bytes to follow in the read data field.

Request

Function code 1 byte 17

hex

Read starting address 2 bytes 0000

Number of registers to

2 bytes 0001

read

Write starting address 2 bytes 0000

Number of registers to

2 bytes 0001

write

Write number of bytes 1 byte 2 x N*

Write register values N* x 2 bytes

N* = number of registers to be written

Response

Function code 1 byte 17

hex

Number of bytes 1 byte 2 x N*

Write register values N* x 2 bytes

N* = number of registers to be read

Errors

to FFFF

hex

to approx. 0076

hex

to FFFF

hex

to approx. 0076

hex

hex

hex

hex

hex

46

Error code 1 byte 97

hex

Exception code 1 byte 01 or 02 or 03 or 04

Example

Example request for reading 2 registers and writing 2 registers.

Request Response

Field name Hex Field name Hex

Transaction Identifier Hi 00 Transaction Identifier Hi 00

Transaction Identifier Lo 01 Transaction Identifier Lo 01

Protocol Identifier Hi 00 Protocol Identifier Hi 00

Protocol Identifier Lo 00 Protocol Identifier Lo 00

Length Hi 00 Length Hi 00

Example

Example request for reading 2 registers and writing 2 registers.

Request Response

Field name Hex Field name Hex

Length Lo 11 Length Lo 7

Unit Identifier 00 Unit Identifier 00

Function code 17 Function code 17

Read Starting Address Hi F1 Byte Count 2

Read Starting Address Lo 0A Read Registers Value Hi 04

Quantity to Read Hi 00 Read Registers Value Lo 08

Quantity to Read Lo 2 Read Registers Value Hi 0A

Write Starting Address Hi F0 Read Registers Value Lo C8

Write Starting Address Lo 0B

Quantity to Write Hi 00

Quantity to Write Lo 04

Write Byte Count 2

Write Registers Value Hi 04

Write Registers Value Lo CE

Write Registers Value Hi FF

EN-US

103

dec

(67

hex

)

Read Holding Register Float

Write Registers Value Lo C0

Transaction Identifier Hi 00

This function is used to read the contents of a contiguous block of registers in the TAG

tables contained in this document. The register uses floating-point format (32 bits). The

request PDU determines the starting register address and the number of registers.

The registers are addressed in the PDU starting at zero. This means registers numbered

1-16 will be addressed using 0-15.

The register data in the response message is packed as two bytes per register, with the

binary contents precisely aligned/justified within each byte. Within the individual registers, the first byte contains the high-order bits and the second byte the low-order bits.

Requirement

Function code 1 byte xx

Starting address 2 bytes xxxx

Number of registers 2 bytes 1 to 125 (7D

hex

hex

to xxxx

hex

hex

)

Response

Function code 1 byte 03

hex

Number of bytes 2 bytes 2 x N*

Register value N* x 2 bytes -

N* = number of registers

47

Error

Error code 1 bytes 83

hex

Exception code 1 byte 01 or 02 or 03 or 04

Example

Example read request for register E064

(gas pre-flow):

hex

Requirement Response

Field Name Hex Field Name Hex

Transaction Identifier Hi 00 Transaction Identifier Hi 00

Transaction Identifier Lo 01 Transaction Identifier Lo 01

Protocol Identifier Hi 00 Protocol Identifier Hi 00

Protocol Identifier Lo 00 Protocol Identifier Lo 00

Length Hi 00 Length Hi 00

Length Lo 06 Length Lo 05

Unit Identifier 00 Unit Identifier 00

Function code 67 Function code 67

Starting Address Hi E0 Byte Count 02

Starting Address Lo 64 Register Value High Hi 3F

104

dec

(68

hex

)

Write Single Register Float

No. of Registers Hi 00 Register Value High Lo C0

No. of Registers Lo 01 Register Value Low Hi 00

Register Value Low Lo 00

The contents of register E064

values 3FC00000 or 1.5

dec

(gas pre-flow) are displayed in the form of the two-byte

hex

.

This function is used to edit registers in the TAG tables contained in this document. The

register uses floating-point format (32 bits). The request PDU specifies the address of

the register to be written. Registers are addressed starting at zero. This means that the

register that has been numbered as 1 will be addressed using 0.

The normal response is an echo of the request, which is returned after the register contents are written.

Requirement

Function code 1 byte 68

Register address 2 bytes E000

Register value 2 bytes 0000

hex

to Exxx

hex

or FFFFFFFF

hex

hex

hex

48

Response

Function code 1 byte 68

hex

Register address 2 bytes E000

Register value 2 bytes 0000

to Exxx

hex

or FFFFFFFF

hex

hex

hex

Error

Error code 1 bytes E8

hex

Exception code 1 byte 01 or 02 or 03

Example

Example request for writing the value 3FC00000

hex

(1.5

) to register E064

dec

hex

(gas pre-flow):

Requirement Response

Field Name Hex Field Name Hex

Transaction Identifier Hi 00 Transaction Identifier Hi 00

Transaction Identifier Lo 01 Transaction Identifier Lo 01

Protocol Identifier Hi 00 Protocol Identifier Hi 00

Protocol Identifier Lo 00 Protocol Identifier Lo 00

Length Hi 00 Length Hi 00

Length Lo 08 Length Lo 08

Unit Identifier 00 Unit Identifier 00

Function code 68 Function code 68

Register Address Hi E0 Register Address Hi E0

EN-US

Register Address Lo 64 Register Address Lo 64

Register Value High Hi 3F Register Value Hi 45

Register Value High Lo C0 Register Value Lo 09

Register Value Low Hi 00 Register Value Hi 80

Register Value Low Lo 00 Register Value Lo 00

49

50

EN-US

51

Fronius International GmbH

Froniusstraße 1

4643 Pettenbach

Austria

contact@fronius.com

www.fronius.com

Under www.fronius.com/contact you will find the adresses

of all Fronius Sales & Service Partners and locations.

spareparts.fronius.com

SPAREPARTS

ONLINE

Loading...

Loading...