Operating

Instructions

RI FB/i FANUC 1.0

RI MOD/i CC-M40 Ethernet/IP - 2P

EN-US

Operating instructions

42,0426,0223,EA 023-01092022

Table of contents

General 4

Safety 4

Device Concept 4

Block Diagram 5

Scope of Supply 5

Required Tools and Materials 5

Installation Requirements 5

Connections and Indicators 6

Connections on the Robot Interface 6

LEDs on Robot Interface PCB 6

LEDs for Power Supply Diagnosis 7

LEDs for Network Connection Diagnosis 8

Connections and Indicators on RJ 45 module 9

Technical data 11

Environmental Conditions 11

Robot Interface Technical Data 11

Data Transfer Properties 11

Configuration Parameters 11

Configuration of robot interface 13

General 13

Configuring the Process Image 13

Setting the IP Address 13

Configuring the Robot Interface 14

Installing the Robot Interface 15

Safety 15

Preparation 15

Routing the Data Cable 16

Installing the Robot Interface 17

Final Tasks 17

Installing the Bus Module 18

Safety 18

Installing the Bus Module 18

Input and Output Signals Standard Image FANUC 1.0 19

Data types 19

Availability of input signals 19

Input signals (from robot to power source) 19

Value range for Working mode 28

Value range Process line selection 28

Value Range for TWIN Mode 29

Value Range for Documentation mode 29

Value range Process controlled correction 29

Value Range for Command value selection 29

Value range Process controlled correction 2 29

Availability of the output signals 30

Output signals (from power source to robot) 30

Assignment of Sensor Statuses 1–4 36

Value range Safety status 36

Value Range for Function status 36

Value Range for Process Bit 37

TAG Table for Input Signals 37

Value Range for Cooling unit mode 38

Value Table 38

TAG Table for Output Signals 40

EN-US

3

General

(3)(1) (2) (5)(4)

Robot

Control

(6) (7) (8)

Safety

Danger from incorrect operation and work that is not carried out properly.

Serious injury and damage to property may result.

▶

▶

▶

Danger from unplanned signal transmission.

Serious injury and damage to property may result.

▶

Device Concept The robot interface serves as an interface between the power source and stand-

ardized bus modules supporting a wide range of communication protocols.

Fronius may factory-fit the robot interface in the power source but it can also be

retrofitted by appropriately trained and qualified personnel.

WARNING!

All the work and functions described in this document must only be carried

out by trained and qualified personnel.

Read and understand this document.

Read and understand all the Operating Instructions for the system components, especially the safety rules.

WARNING!

Do not transfer safety signals via the interface.

4

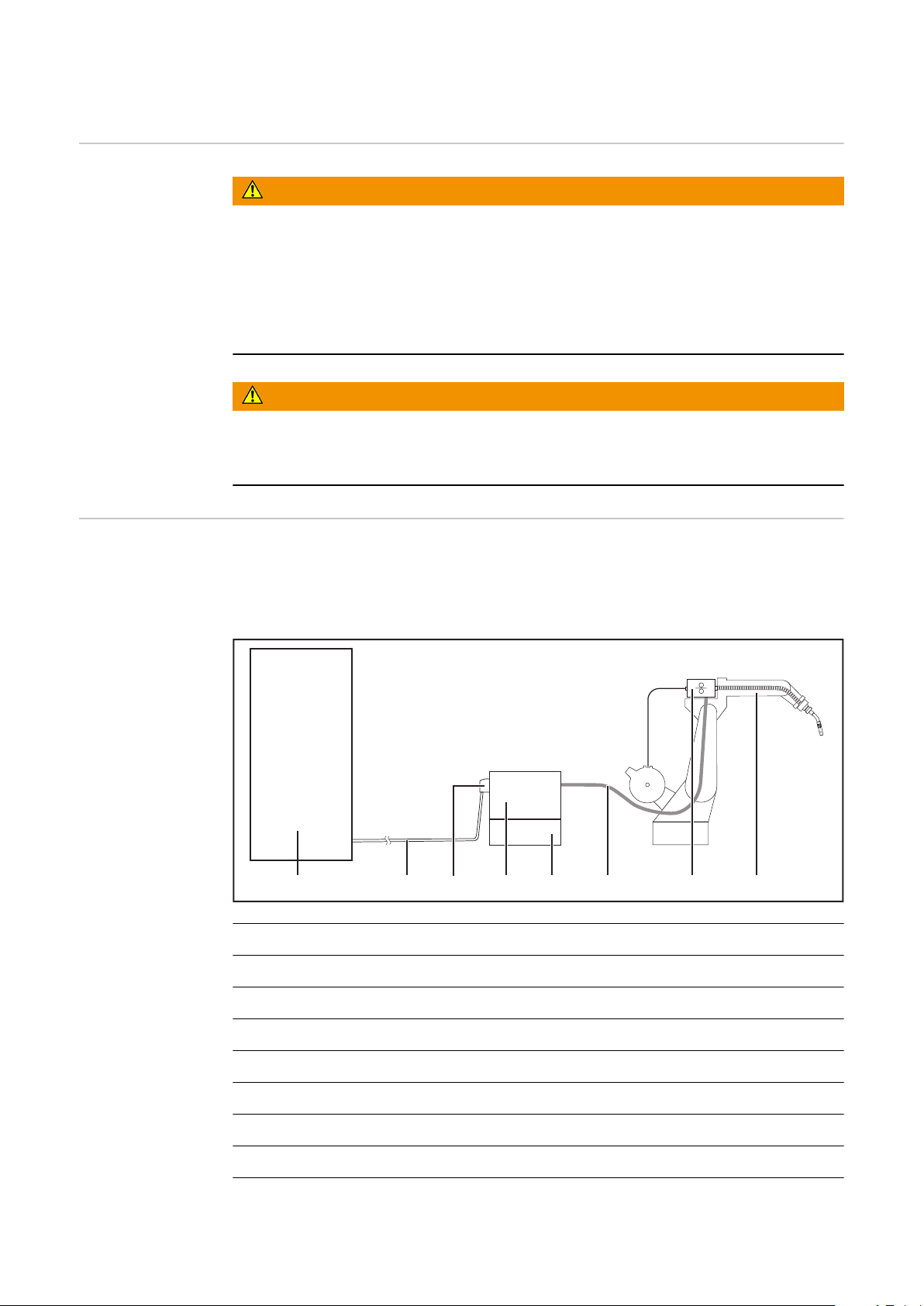

(1) Robot control system

(2) SpeedNet data cable

(3) Robot interface

(4) Power source

(5) Cooling unit

(6) Interconnecting hosepack

(7) Wirefeeder

(8) Robot

Block Diagram

Spider NT241

RI FB/i FANUC 1.0

Data

24 V

Module

(1)

(2)

(3)

EN-US

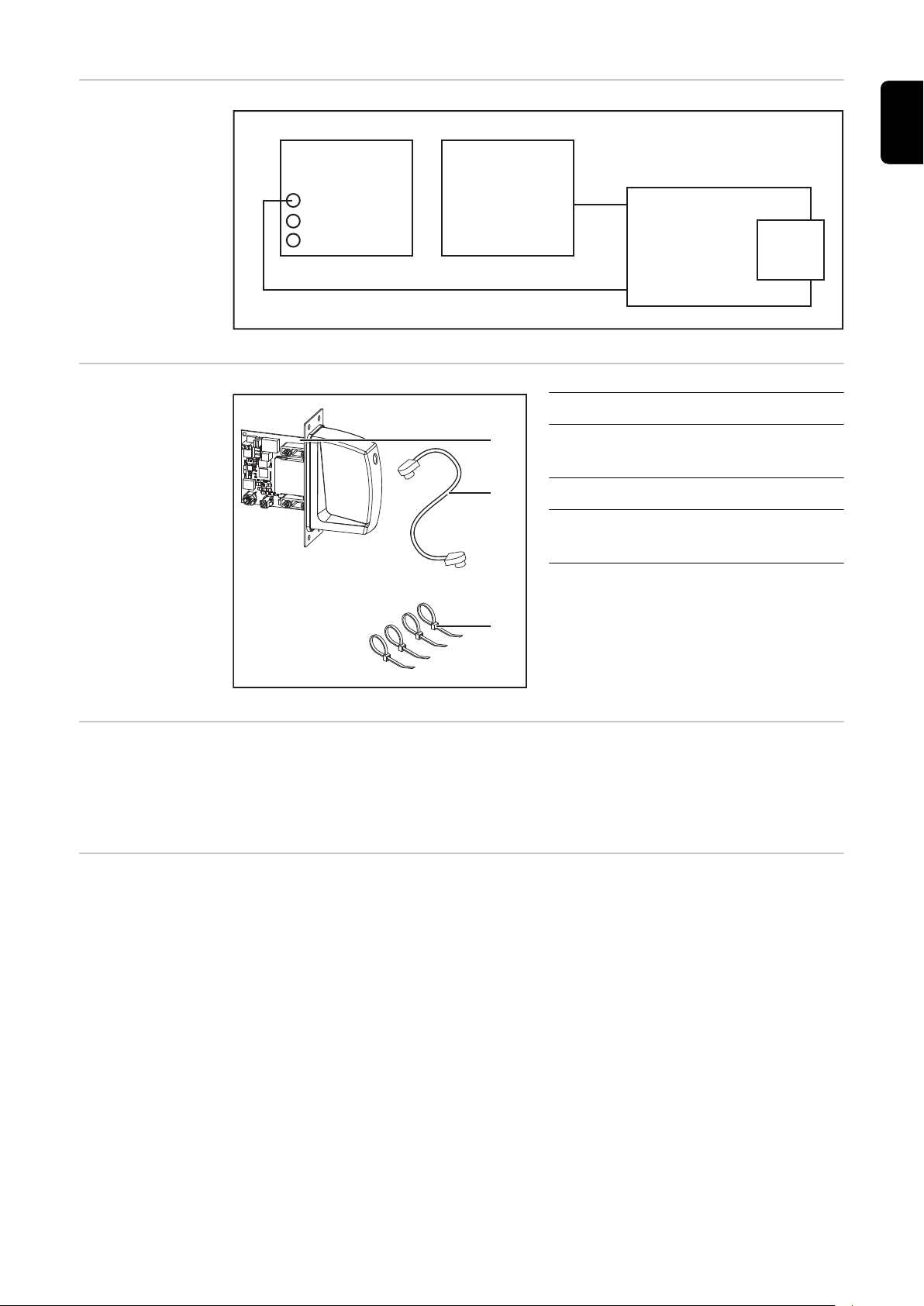

Scope of Supply

Required Tools

and Materials

Screwdriver TX8

-

Screwdriver TX20

-

Screwdriver TX25

-

Diagonal cutting pliers

-

(1) RI FB/i FANUC 1.0

(2) Data cable

4-pin

(3) Cable ties

(4) These Operating Instructions

(not pictured)

Installation Requirements

The robot interface may only be installed in the designated opening on the rear

of the power source.

5

Connections and Indicators

(2) (3)

(1)

(14)

(13)

(12)

(11)

(2)

(1)

(9)

(10)

(8)

(7)

(3) (4)

(5) (6)

Connections on

the Robot Interface

LEDs on Robot

Interface PCB

(1) Power supply connection

2-pin

(2) SpeedNet data cableconnec-

tion

4-pin

(3) Bus module connection

6

(1) ETH1 LED Green For diagnosing the network connec-

tion.

(2) ETH2 LED Orange

For details, see section below titled

"LEDs for Network Connection Diagnosis"

(3) LED 3 Green

(4) LED 4 Green

(5) LED 5 Green

(6) LED 6 Red

(7) +3V3 LED Green For diagnosing the power supply.

(8) +24V LED Green

No function

Flashes at 4 Hz = No SpeedNet

-

connection

Flashes at 20 Hz = Establishing

-

SpeedNet connection

Flashes at 1 Hz = SpeedNet con-

-

nection established

Lights up when an internal error occurs.

Remedy: Restart the robot interface.

If this does not resolve the issue, inform the service team.

For details, see section below titled

"LEDs for Power Supply Diagnosis"

EN-US

LEDs for Power

Supply Diagnosis

(9) DIG OUT 2 LED Green

(10) DIG OUT 1 LED Green

(11) LED 11 Green

(12) LED 12 Green

(13) LED 13 Green

(14) LED 14 Green

LED Indicat-orMeaning Cause

Off

+24V

Lights up

No supply voltage available

for interface

24 VDC supply voltage

present on robot interface

Digital output 2. LED lights up when

active

Digital output 1. LED lights up when

active

No function

Robot interface power

-

supply not established

Power supply cable

-

faulty

+3V3

Off

Lights up

No operating voltage

present on robot interface

3 VDC operating voltage

present on robot interface

24 VDC supply voltage

-

not present

Robot interface power

-

supply unit is faulty

7

LEDs for Network Connection

Diagnosis

LED Indicat-orMeaning Cause

No network connection

-

established for interface

Network cable faulty

-

ETH1

Off No network connection

Lights up

Flashes Data transfer in progress

Network connection established

ETH2

Off

Lights up

Transmission speed

10 Mbit/s

Transmission speed

100 Mbit/s

8

Connections and

(12)(11)(10)

(14)(13)

(9)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Indicators on RJ

45 module

(1) TX+

(2) TX-

(3) RX+

EN-US

(4),

(5)

(6) RX-

(7),

(8)

(9) Connection/activity at connection 2 LED

(10) MS LED (module status)

(11) RJ-45 Ethernet connection 2

(12) RJ-45 Ethernet connection 1

Not normally used; to ensure

signal completeness, these

pins must be interconnected

and, after passing through a

filter circuit, must terminate

at the ground conductor

(PE).

Not normally used; to ensure

signal completeness, these

pins must be interconnected

and, after passing through a

filter circuit, must terminate

at the ground conductor

(PE).

(13) Connection/activity at connection 1 LED

(14) NS LED (network status)

NS LED (Network Status)

Status Meaning

Off No supply voltage or no IP address

Lights up green Online, one or more connections established

(CIP category 1 or 3)

Flashes green Online, no connections established

Lights up red Double IP address, serious error

Flashes red Overrun of time for one or more connections

(CIP category 1 or 3)

MS LED (Module Status)

Status Meaning

Off No supply voltage

Lights up green Controlled by a Scanner in Run state and, if CIP Sync is

enabled, time is synchronized to a Grandmaster clock

Flashes green Not configured, Scanner in Idle state, or, if CIP Sync is

enabled, time is synchronized Grandmaster clock

Lights up red Major error - exception state, serious fault, etc.

9

MS LED (Module Status)

Flashes red Correctable error - the module is configured, but there

is a difference between the parameters stored and the

parameters used (configuration process image, IP address)

Connection/Activity LED

Status Meaning

Off No connection, no activity

Lights up green Connection established (100 Mbit/s)

Flickers green Activity (100 Mbit/s)

Lights up yellow Connection established (10 Mbit/s)

Flickers yellow Activity (10 Mbit/s)

10

Technical data

EN-US

Environmental

Conditions

Robot Interface

Technical Data

CAUTION!

A risk is posed by prohibited environmental conditions.

This can result in severe damage to equipment.

Only store and operate the device under the following environmental condi-

▶

tions.

Temperature range of ambient air:

During operation: -10 °C to +40 °C (14 °F to 104 °F)

-

During transport and storage: -20 °C to +55 °C (-4 °F to 131 °F)

-

Relative humidity:

Up to 50% at 40 °C (104 °F)

-

Up to 90% at 20 °C (68 °F)

-

Ambient air: free of dust, acids, corrosive gases or substances, etc.

Altitude above sea level: up to 2000 m (6500 ft).

Power supply Internal (24 V)

Degree of protection IP 23

Data Transfer

Properties

Configuration

Parameters

RJ-45 Connection

Transmission technology:

Ethernet

Medium (4 x 2 twisted-pair copper cable):

Category 3 (10 Mbit/s)

Category 5 (100 Mbit/s)

When selecting the cables, plugs, and termination resistances, the ODVA recommendation for the planning and installation of EtherNet/IP systems must

be observed.

The EMC tests were carried out by the manufacturer with the cable IEC5ES8VG0030M40M40-F.

Transmission speed:

10 Mbit/s or 100 Mbit/s

Bus connection:

RJ-45 Ethernet

In some robot control systems, it may be necessary to state the configuration

parameters described here so that the bus module can communicate with the robot.

11

Parameter Value

Vendor ID 534

Device Type C

hex

Product Code 340

hex

(12

hex

(1332

)

dec

(832

dec

dec

)

)

12

Configuration of robot interface

(1)

(2)

EN-US

General

Configuring the

Process Image

The DIP switch on the robot interface

is used to configure:

The process image (standard im-

-

age)

The IP address

-

Default setting for process image:

Positions 7 and 8 of DIP switch set to

OFF (1) = standard image = RI FB/i

FANUC 1.0

Default setting for IP address =

192.168.0.2:

Positions 6, 5, 4, 3, 1 of DIP switch

-

set to OFF (1)

Position 2 of DIP switch set to ON

-

(2)

DIP Switch

8 7 6 5 4 3 2 1 Configuration

OFF OFF

OFF ON

- - - - - -

- - - - - -

Standard-Image

(FANUC 1.0)

Not used

Setting the IP

Address

ON OFF

ON ON

- - - - - -

- - - - - -

Not used

Not used

The process image defines the volume of data transferred and the system compatibility.

You can set the IP address as follows:

Via the DIP switches within the range defined by 192.168.0.xxx

-

(xx = DIP switch setting = 0 to 63)

Setting the Address via the DIP Switches:

DIP switch

IP address

8 7 6 5 4 3 2 1

- -

- -

- -

OFF OFF OFF OFF OFF ON

OFF OFF OFF OFF ON OFF

ON ON OFF ON ON OFF

192.168.0.1

192.168.0.2

:

192.168.0.54

- -

ON ON OFF ON ON ON

192.168.0.55

13

The IP address can be set via positions 1 to 6 of the DIP switch.

The configuration is carried out in binary format. In decimal format, the setting

range is 0 through 63.

The following IP address is set via the DIP switches on delivery:

IP address: 192.168.0.2

-

Subnet mask: 255.255.255.0

-

Default gateway: 0.0.0.0

-

Configuring the

Robot Interface

Set the DIP switch in accordance with the desired configuration

1

NOTE!

Risk due to invalid DIP switch settings.

This may result in malfunctions.

Whenever changes are made to the DIP switch settings, the interface must

▶

be restarted. This is the only way for the changes to take effect.

Restart the interface = interrupting and restoring the power supply or ex-

▶

ecuting the relevant function on the website of the power source (SmartManager).

14

Installing the Robot Interface

EN-US

Safety

Preparation

WARNING!

Electrical current hazard.

This can result in serious injuries or death.

Before starting work, switch off all the devices and components involved and

▶

disconnect them from the grid.

Secure all the devices and components involved to prevent unintentional re-

▶

starting.

After opening the device, use a suitable measuring instrument to check that

▶

electrically charged components (such as capacitors) have been discharged.

WARNING!

Electrical current hazard caused by an inadequate ground conductor connection.

This can result in severe personal injury and damage to property.

Always use the original housing screws in the original quantity.

▶

1 2

3 4

15

5

Routing the Data

Cable

1 2

3

16

Installing the

Robot Interface

1 2

EN-US

Final Tasks

1 2

17

Installing the Bus Module

Safety

Installing the

Bus Module

WARNING!

Danger from electrical current.

Serious injuries or death may result.

Before starting work, switch off all devices and components involved, and

▶

disconnect them from the grid.

Secure all devices and components involved so that they cannot be switched

▶

back on.

WARNING!

Danger from electrical current due to inadequate ground conductor connection.

Serious personal injury and property damage may result.

Always use the original housing screws in the quantity initially supplied.

▶

1 2

18

3

Input and Output Signals Standard Image FANUC 1.0

Data types The following data types are used:

UINT16 (Unsigned Integer)

-

Whole number in the range from 0 to 65535

SINT16 (Signed Integer)

-

Whole number in the range from -32768 to 32767

Conversion examples:

for a positive value (SINT16)

-

e.g. desired wire speed x factor

Availability of input signals

12.3 m/min x 100 = 1230

for a negative value (SINT16)

-

e.g. arc correction x factor

-6.4 x 10 = -64

The input signals listed below are available from firmware V3.2.30 of the TPS/i

power source.

= FFC0

dec

= 04CE

dec

hex

EN-US

hex

Input signals

(from robot to

power source)

19

Address

Relative Absolute

WORD

0

BYTE

0

1

BIT

0 1 Welding Start

1 2 Robot ready High

2 3 Working mode Bit 0 High

3 4 Working mode Bit 1 High

4 5 Working mode Bit 2 High

5 6 Working mode Bit 3 High

6 7 Working mode Bit 4 High

7 8 —

0 9 Gas on

1 10 Wire forward

2 11 Wire backward

3 12 Error quit

4 13 Touch sensing

BIT

Signal

Description

Activity /

data type

Increas-

ing

Increas-

ing

Increas-

ing

Increas-

ing

Increas-

ing

Increas-

ing

Range

See table

Value range

for Working

mode on page

28

Factor

5 14 Torch blow out

6 15 Processline selection Bit 0 High See table

7 16 Processline selection Bit 1 High

Increas-

ing

Value range

Process line

selection on

page 28

20

Address

Relative Absolute

EN-US

WORD

1

BYTE

2

3

BIT

0 17 Welding Simulation High

1 18 Synchro pulse on High

2 19 SFI on High

3 20 —

4 21 —

5 22 —

6 23 Wire brake on High

7 24 Torchbody Xchange High

0 25 —

1 26 Teach mode High

2 27 —

3 28 —

4 29 —

5 30 Wire sense start

6 31 Wire sense break

BIT

Signal

Description

Activity /

data type

Increas-

ing

Increas-

ing

Range

Factor

7 32 —

21

Address

Relative Absolute

WORD

2

BYTE

4

BIT

0 33 TWIN mode Bit 0 High See table

1 34 TWIN mode Bit 1 High

2 35 —

3 36 —

4 37 —

5 38 Documentation mode High

6 39 —

7 40 —

0 41 —

1 42 —

2 43 —

BIT

Signal

Description

Activity /

data type

Value Range

for TWIN

Mode on page

See table

Value Range

for Document-

ation mode on

page 29

Range

29

Factor

3 44 —

5

4 45 —

5 46 —

6 47 —

7 48

Disable process controlled correction

High

22

Address

Relative Absolute

EN-US

WORD

3

BYTE

6

7

BIT

0 49 —

1 50 —

2 51 —

3 52 —

4 53 —

5 54 —

6 55 —

7 56 —

0 57 ExtInput1 => OPT_Output 1 High

1 58 ExtInput2 => OPT_Output 2 High

2 59 ExtInput3 => OPT_Output 3 High

3 60 ExtInput4 => OPT_Output 4 High

4 61 ExtInput5 => OPT_Output 5 High

5 62 ExtInput6 => OPT_Output 6 High

6 63 ExtInput7 => OPT_Output 7 High

7 64 ExtInput8 => OPT_Output 8 High

BIT

Signal

Description

Activity /

data type

Range

Factor

4

5

8 0–7

9 0–7

10,

0–7 81–96

11

65–80

Welding characteristic- / Job

number

For the welding processes

MIG/MAG pulse synergic,

MIG/MAG standard synergic,

MIG/MAG standard manual,

MIG/MAG PMC,

MIG/MAG LSC,

CMT,

ConstantWire:

Wire feed speed command

value

For job operation:

Power correction

Group

3

Group

3

UINT16

SINT16

SINT16

0 to

1000

-327.68

to 327.67

[m/min]

-20.00 to

20.00

[%]

1

10

0

23

Address

Relative Absolute

WORD

6

7

BYTE

12,

0–7 97–112

13

14,

0–7 113–128

15

BIT

BIT

Signal

Welding processes

MIG/MAG pulse synergic,

MIG/MAG standard synergic,

MIG/MAG PMC,

MIG/MAG LSC,

CMT:

Arclength correction

For the welding process

MIG/MAG standard manual:

Welding voltage

For job operation:

Arclength correction

In the welding process ConstantWire:

Hotwire current

For the welding processes

MIG/MAG pulse synergic,

MIG/MAG standard synergic,

MIG/MAG PMC,

MIG/MAG LSC,

CMT:

Pulse-/dynamic correction

Description

Group

3

Group

3

Activity /

data type

SINT16

UINT16

SINT16

UINT16

SINT16

Range

-10.0 to

100.0

[m/min]

0.0 to

6553.5

[V]

-10.0 to

10.0

[steps]

0.0 to

6553.5

[A]

-10.0 to

10.0

[steps]

Factor

10

10

10

10

10

8

9

10

11

12

13

16 0–7

17 0–7

18 0–7

19 0–7

20 0–7

21 0–7

22 0–7

23 0–7

24 0–7

25 0–7

26 0–7

27 0–7

For the welding process

MIG/MAG standard manual:

Dynamic

129–144 Wire retract correction

145–160 Welding speed

161–176 Process controlled correction

177–192 —

193–208 —

209–224 —

Group

2

Group

3

Group

2

UINT16

UINT16 0 to 10 10

UINT16

See table Value range

Process controlled cor-

rection on page 29

0.0 to

10.0

[steps]

0 to

1000

[cm/min]

10

10

24

Address

Relative Absolute

EN-US

WORD

14

15

16

17

18

19

BYTE

28 0–7

29 0–7

30 0–7

31 0–7

32 0–7

33 0–7

34 0–7

35 0–7

36 0–7

37 0–7

38 0–7

39 0–7

0 321

1 322 Disable SFI-Parameter (Image) High

BIT

BIT

225–240 —

241–256 Wire forward / backward length UINT16

257–272 Wire sense edge detection

273–288 —

289–304 —

305–320 Seam number

Signal

Disable Start-End-Parameter

(Image)

Description

Group

2

Activity /

data type

OFF / 1

to 65535

[mm]

OFF /

UINT16

UINT

16

High

0.5 to 20

[mm]

0 to

65,535

Range

Factor

1

10

1

20

40

41

2 323 Disable SP-Parameter (Image) High

3 324

4 325 Disable gas-settings (Image) High

5 326

6 327

7 328

0 329

1 330 —

2 331 —

3 332 —

4 333 —

5 334 —

6 335 —

Disable Process-Mix-Parameter

(Image)

Disable components setup

(TAG)

Disable language/units/standards (TAG)

Disable process controlled correction 2 (Image)

Enable arc break monitoring /

arc loss

High

High

High

High

High

7 336 —

25

Address

Relative Absolute

21

WORD

42

43

BYTE

BIT

0 337 Enable resistance overwrite High

1 338 Set resistance value High

2 339 Enable inductance overwrite High

3 340 Set inductance value High

4 341 —

5 342 —

6 343 —

7 344 —

0 345 —

1 346 —

2 347 —

3 348 —

4 349 —

5 350 —

6 351 Command value selection Bit 0 High See table

7 352

BIT

Signal

Reserve (Command value selection Bit 1)

Description

Activity /

data type

Value Range

for Command

value selection

Range

on page 29

Factor

44 0–7

22

45 0–7

46 0–7

23

47 0–7

48 0–7

24

49 0–7

50 0–7

25

51 0–7

52 0–7

26

53 0–7

54 0–7

27

55 0–7

56 0–7 449–456 TAG Quantity UINT 8 0 to 8 1

28

57 0–7 457–464 TAG Command

353–368 TAG Start address

369–384 TAG value 1

385–400 TAG value 2

401–416 TAG value 3

417–432 TAG value 4

433–448 TAG value 5

Group

1

Group

1

Group

1

Group

1

Group

1

0x0001

= TAG

Read |

0x0002

=TAG

Write

UINT

16

UINT

16

UINT

16

UINT

16

UINT

16

UINT

16

UINT 8 0 to 2 1

0 to

65,535

1

1

1

1

1

1

26

Address

Relative Absolute

EN-US

WORD

29

30

31

32

33

34

35

36

BYTE

58 0–7

59 0–7

60 0–7

61 0–7

62 0–7

63 0–7

64 0–7

65 0–7

66 0–7

67 0–7

68 0–7

69 0–7

70 0–7

71 0–7

72 0–7

73 0–7

BIT

BIT

465–480 Gas preflow

481–496 Gas postflow

497–512 Inching Value

513–528 S2T Starting current

529–544 S2T Starting current time

545–560 S2T Slope 1

561–576 S2T Slope 2

577–592 S2T End current

Signal

Description

Group

2

Group

2

Group

2

Group

2

Group

2

Group

2

Group

2

Group

2

Activity /

data type

UINT

16

UINT

16

SINT 16

UINT

16

UINT

16

UINT

16

UINT

16

UINT

16

Range

0 to 9.9

[s]

0 to 60

[s]

0.5 to 25

[m/min]

0 to 200

[%]

Off (0) /

0.1 to 10

[s]

0 to 9.9

[s]

0 to 9.9

[s]

0 to 200

[%]

Factor

10

10

10

0

1

10

10

10

1

37

38

39

40

41

42

43

44

74 0–7

75 0–7

76 0–7

77 0–7

78 0–7

79 0–7

80 0–7

81 0–7

82 0–7

83 0–7

84 0–7

85 0–7

86 0–7

87 0–7

88 0–7

89 0–7

593–608 S2T End current time

609–624 S2T Start Arclength correction

625–640 S2T End Arclength correction

641–656

657–672

673–688

689–704 SFI Hotstart

705–720 Process controlled correction 2

Process-Mix High power time

correction

Process-Mix Low power time

correction

Process-Mix Low power correction

Group

2

Group

2

Group

2

Group

3

Group

3

Group

3

Group

2

Group

2

UINT

16

SINT 16

SINT 16

SINT 16

SINT 16

SINT 16

UINT

16

See table Value range

Process controlled cor-

rection 2 on page 29

Off (0) /

0.1 to 10

[s]

-10 to

+10

-10 to

+10

-10 to

+10

-10 to

+10

-10 to

+10

Off

(0.0) /

0.01 to

2.00

[s]

10

10

10

10

10

10

10

0

27

Address

Relative Absolute

WORD

45

46

47

48

49

50

51

BYTE

90 0–7

91 0–7

92 0–7

93 0–7

94 0–7

95 0–7

96 0–7

97 0–7

98 0–7

99 0–7

100 0–7

101 0–7

102 0–7

103 0–7

BIT

BIT

Signal

721–736 SP Delta wire feed

737–752 SP Frequency

753–768 SP Duty Cycle

769–784 SP Arclength correction high

785–800 SP Arclength correction low

801–816 Resistance

817–832 Inductance

Description

Group

2

Group

2

Group

2

Group

2

Group

2

Group

2

Group

2

Activity /

data type

SINT 16

SINT 16

SINT 16

SINT 16

SINT 16

UINT

16

UINT

16

Range

-10 to

+10

-10 to

+10

-100 to

+100

-10 to

+10

-10 to

+10

0 to

+400

[mOhm]

0 to

+250

[micro-

henries]

Factor

10

10

1

10

10

10

10

Value range for

Working mode

Value range Process line selection

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Description

0 0 0 0 0 Internal parameter selection

0 0 0 0 1 Special 2-step mode characteristics

0 0 0 1 0 Job mode

0 1 0 0 0 2-step mode characteristics

0 1 0 0 1 MIG/MAG Standard Manual, 2-step

1 1 0 0 0 R/L measurement

1 1 0 0 1 R/L alignment

Value range for operating mode

Bit 1 Bit 0 Description

0 0 Process line 1 (default)

0 1 Process line 2

1 0 Process line 3

1 1 Reserved

Value range for process line selection

28

Value Range for

TWIN Mode

Bit 1 Bit 0 Description

0 0 TWIN Single mode

0 1 TWIN Lead mode

1 0 TWIN Trail mode

1 1 Reserved

Value range for TWIN mode

EN-US

Value Range for

Documentation

mode

Value range Process controlled

correction

Value Range for

Command value

selection

Bit 0 Description

0 Seam number of power source (internal)

1 Seam number of robot

Value range for documentation mode

Activity

Data

Process Signal

type

Arc length stabil-

PMC

Value range for process-dependent correction

Bit

Description

izer SINT16

351

0 Wirefeeder set value

Value range

Configuration

range Unit

-3276.8 to

+3276.7

0.0 to +5.0 Volts 10

Facto

r

Value range Process controlled

correction 2

1 Welding current set value

Value range for set value

Activity

Process Signal

PMC,

LSC

Value range for process-dependent correction 2

Penetration stabil-

izer SINT16

Data

type

Value range

Configuration

Facto

range Unit

-3276.8 to

+3276.7

0.0 to +10.0 m/min 10

r

29

Availability of

the output signals

Output signals

(from power

source to robot)

Address

Relative Absolute

The output signals listed below are available from firmware V3.2.30 of the TPS/i

power source.

WORD

0

BYTE

0

1

BIT

0 1 Heartbeat Powersource 1 Hz

1 2 Power source ready High

2 3 Warning High

3 4 Process active High

4 5 Current flow High

5 6 Arc stable- / touch signal High

6 7 Main current signal High

7 8 Touch signal High

0 9 Collisionbox active Low

1 10 Robot Motion Release High

2 11 Wire stick workpiece High

3 12 —

4 13 Short circuit contact tip High

5 14 Parameter selection internally High

BIT

Signal

Description

Activity /

data type

Range

0 = colli-

sion or

cable

break

Factor

30

6 15 Characteristic number valid High

7 16 Torch body gripped High

Address

Relative Absolute

EN-US

WORD

1

BYTE

2

3

BIT

0 17 Command value out of range High

1 18 Correction out of range High

2 19 —

3 20 Limitsignal High

4 21 —

5 22 —

6 23 Main supply status Low

7 24 —

0 25 Sensor status 1 High

1 26 Sensor status 2 High

2 27 Sensor status 3 High

3 28 Sensor status 4 High

4 29 —

5 30 —

6 31 —

7 32 —

BIT

Signal

Description

Activity /

data type

See table As-

signment of

Statuses 1–4

Range

Sensor

on page 36

Factor

0 33 Function status Bit 0 High See table

Value Range

1 34 Function status Bit 1 High

2 35 —

4

2

5

3 36 Safety status Bit 0 High See table

4 37 Safety status Bit 1 High

5 38 —

6 39 Notification High

7 40 System not ready High

0 41 —

1 42 —

2 43 —

3 44 —

4 45 —

5 46 —

for Function

status on page

36

Value range

Safety status

on page 36

6 47 —

7 48 —

31

Address

Relative Absolute

WORD

3

BYTE

6

7

BIT

0 49 Process Bit 0 High

1 50 Process Bit 1 High

2 51 Process Bit 2 High

3 52 Process Bit 3 High

4 53 Process Bit 4 High

5 54 —

6 55 Gas nozzle touched High

7 56 TWIN synchronisation active High

0 57 ExtOutput1 <= OPT_Input1 High

1 58 ExtOutput2 <= OPT_Input2 High

2 59 ExtOutput3 <= OPT_Input3 High

3 60 ExtOutput4 <= OPT_Input4 High

4 61 ExtOutput5 <= OPT_Input5 High

5 62 ExtOutput6 <= OPT_Input6 High

6 63 ExtOutput7 <= OPT_Input7 High

7 64 ExtOutput8 <= OPT_Input8 High

BIT

Signal

Description

Activity /

data type

See table

Value Range

for Process Bit

on page 37

Range

Factor

4

5

6

7

8

9

10

8 0–7

9 0–7

10 0–7

11 0–7

12 0–7

13 0–7

14 0–7

15 0–7

16 0–7

17 0–7

18 0–7

19 0–7

20 0–7

21 0–7

Group

65–80 Real value welding voltage

81–96 Real value welding current

97–112 Real value wire feed speed

113–128

129–144 Error number UINT16

145–160 Warning number UINT16

161–176 Motor current M1 SINT16

Actual real value for seam

tracking

3 ana-

log

meter

Group

3 ana-

log

meter

Analog

meter

UINT16

UINT16

UINT16

SINT16

0.0 to

327.67

[V]

0.0 to

327.67

[A]

-327.68

to 327.67

[m/min]

0 to

65,535

0 to

65,535

0 to

65,535

-327.68

to 327.67

[A]

10

0

10

10

0

10

00

0

1

1

10

0

32

11

22 0–7

23 0–7

177–192 Motor current M2 SINT16

-327.68

to 327.67

[A]

10

0

Address

Relative Absolute

EN-US

WORD

12

13

14

15

16

17

18

19

BYTE

24 0–7

25 0–7

26 0–7

27 0–7

28 0–7

29 0–7

30 0–7

31 0–7

32 0–7

33 0–7

34 0–7

35 0–7

36 0–7

37 0–7

38 0–7

39 0–7

BIT

BIT

193–208 Motor current M3 SINT16

209–224 —

225–240 —

241–256 —

257–272 Wire position SINT16

273–288 —

289–304 —

305–320 —

Signal

Description

Activity /

data type

-327.68

to 327.67

[A]

-327.68

to 327.67

[mm]

Range

Factor

10

0

10

0

20

0 321 WebJobEditor enable High

1 322 —

2 323 —

3 324 —

40

4 325 —

5 326 —

6 327 —

7 328 —

0 329 —

1 330 —

2 331 —

3 332 —

41

4 333 —

5 334 —

6 335 —

7 336 —

33

Address

Relative Absolute

21

WORD

42

43

BYTE

BIT

0 337 — High

1 338 —

2 339 —

3 340 —

4 341 —

5 342 —

6 343 —

7 344 —

0 345 —

1 346 —

2 347 —

3 348 —

4 349 —

5 350 —

6 351 —

7 352 —

BIT

Signal

Description

Activity /

data type

Range

Factor

44 0–7

22

45 0–7

46 0–7

23

47 0–7

48 0–7

24

49 0–7

50 0–7

25

51 0–7

52 0–7

26

53 0–7

54 0–7

27

55 0–7

56 0–7 449–456 TAG Quantity UINT8 0 to 5 1

28

57 0–7 457–464 TAG Command

353–368 TAG Start adress UINT16

369–384 TAG value 1 UINT16

385–400 TAG value 2 UINT16 1

401–416 TAG value 3 UINT16 1

417–432 TAG value 4 UINT16 1

433–448 TAG value 5 UINT16 1

0x0001

= TAG

Read |

0x0002

=TAG

Write

UINT8 0 to 2 1

0 to

65,535

1

34

29

58 0–7

59 0–7

465–480 Cooler temperature SINT16

-100 to

+200

[°C]

10

Address

Relative Absolute

EN-US

WORD

30

31

32

33

34

35

36

37

BYTE

60 0–7

61 0–7

62 0–7

63 0–7

64 0–7

65 0–7

66 0–7

67 0–7

68 0–7

69 0–7

70 0–7

71 0–7

72 0–7

73 0–7

74 0–7

75 0–7

BIT

BIT

481–496 Cooler flow rate SINT16

497–512 Real energy actual value UINT16

513–528 Power value UINT16

529–560 Hour meter power on UINT32

561–576

577–592

593–608 Gaspreflow UINT16

Signal

Arc on time UINT32

Description

Activity /

data type

Range

-100 to

+100 [l/

min]

0 to

6553.5

[kJ]

0 to

6553.5

[kW]

0 to

100000

[h]

0 to

100000

[h]

0.0 to

9.9 [s]

Factor

10

0

10

10

10

10

10

38

39

40

41

42

43

44

45

76 0–7

77 0–7

78 0–7

79 0–7

80 0–7

81 0–7

82 0–7

83 0–7

84 0–7

85 0–7

86 0–7

87 0–7

88 0–7

89 0–7

90 0–7

91 0–7

609–624 Gaspostflow UINT16

625–640 S2T Starting current time UINT16

641–656 S2T Slope 1 UINT16

657–672 S2T Slope 2 UINT16

673–688 S2T End current time UINT16

689–704 —

705–720 —

721–736 —

0.0 to

60.0 [s]

Off (0) /

0.1 to

10.0 [s]

0.0 to

9.9 [s]

0.0 to

9.9 [s]

Off (0) /

0.1 to 10

[s]

10

10

10

10

10

46

92 0–7

737–752 —

93 0–7

35

Address

Relative Absolute

WORD

BYTE

94 0–7

47

95 0–7

96 0–7

48

97 0–7

98 0–7

49

99 0–7

100 0–7

50

101 0–7

102 0–7

51

103 0–7

Assignment of

Sensor Statuses

1–4

BIT

BIT

Signal

Description

Activity /

data type

753–768 —

769–784 —

785–800 —

0 to

+400

[mOhm]

801–816 Resistance

Group

2

UINT16

0 to

817–832 Inductance

Group

2

UINT16

+250

[micro-

henries]

Signal Description

Sensor status 1 OPT/i WF R wire end (4,100,869)

Sensor status 2 OPT/i WF R wire drum (4,100,879)

Range

Factor

10

10

Value range

Safety status

Value Range for

Function status

Sensor status 3 OPT/i WF R ring sensor (4,100,878)

Sensor status 4 Wire buffer set CMT TPS/i (4,001,763)

Bit 1 Bit 0 Description

0 0 Reserve

0 1 Hold

1 0 Stop

1 1 Not installed / active

Bit 1 Bit 0 Description

0 0 inactive

0 1 idle

1 0 finished

36

1 1 Error

Value range for function status

Value Range for

Process Bit

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Description

0 0 0 0 0 No internal parameter selection or

process

0 0 0 0 1 MIG/MAG pulse synergic

0 0 0 1 0 MIG/MAG standard synergic

0 0 0 1 1 MIG/MAG PMC

0 0 1 0 0 MIG/MAG LSC

0 0 1 0 1 MIG/MAG standard manual

0 0 1 1 0 Electrode

0 0 1 1 1 TIG

0 1 0 0 0 CMT

0 1 0 0 1 ConstantWire

EN-US

TAG Table for

Input Signals

Address TAG Value

BIT 325 Disable Gas settings:

TAG 30 MIG Gasvalue

TAG 31 MIG Gasfactor

TAG 32 —

TAG 33 —

TAG 34 —

TAG 35 —

TAG 36 —

TAG 37 —

TAG 38 —

TAG 39 —

Address TAG Value

BIT 326 Disable components setup:

TAG 40 Cooling unit mode See table Value Range for

Cooling unit mode on page

38

TAG 41 Delay time flow sensor

TAG 42 Touch sensing sensitivity

TAG 43 Ignition time out

TAG 44 —

TAG 45 —

TAG 46 —

TAG 47 —

TAG 48 —

37

Address TAG Value

BIT 326 Disable components setup:

TAG 49 —

Address TAG Value

BIT 327 Disable language/units/

standards:

TAG 50 Language See Value Table on page 38

TAG 51 Unit (metric/imperial)

TAG 52 Welding standard (AWS/EU)

TAG 53 —

TAG 54 —

TAG 55 —

TAG 56 —

TAG 57 —

TAG 58 —

TAG 59 —

TAG 60 Arc break filter time / arc

loss error time

TAG 61 Arc break monitoring reac-

tion

Value Range for

Cooling unit

mode

Value Table

TAG 40 Description

1 eco

2 auto

3 on

4 off

Value Range for Cooling unit mode

Address Description Value

Language:

0 —

1 English

2 German

3 Japanese

4 Chinese

5 Spanish

38

6 French

7 Czech

Address Description Value

Language:

8 Hungarian

9 Italian

10 Norwegian

11 Polish

12 Portuguese

13 Slovakian

14 Turkish

15 Russian

16 Swedish

17 Estonian

18 Finnish

19 Lithuanian

20 Latvian

21 Dutch

22 Slovenian

EN-US

23 Romanian

24 Croatian

25 Ukrainian

26 Korean

27 Icelandic

28 Vietnamese

29 Thai

30 Indonesian

31 Serbian

32 Hindi

33 Tamil

34 Danish

35 Bulgarian

Address Description Value

Unit (imperial/metric):

0 —

1 Imperial

2 Metric

Address Description Value

Welding standard (AWS/EU):

0 —

1 AWS

39

Address Description Value

Welding standard (AWS/EU):

2 CEN

TAG Table for

Output Signals

Address Description Value

Welding-relevant values:

TAG 10001 Welding voltage

TAG 10002 Welding current

TAG 10003 Wire feed speed

TAG 10004 Real value power

TAG 10005 Ignitiondistance

TAG 10006 —

TAG 10007 —

TAG 10008 —

TAG 10009 —

TAG 10010 —

TAG 10011 —

TAG 10012 —

TAG 10013 —

TAG 10014 —

TAG 10015 —

Address Description Value

Welding system-relevant values:

TAG 10100 Vd max. processline

TAG 10101 Max. current weldingsystem

TAG 10102 —

TAG 10103 Safety status

TAG 10104 —

TAG 10105 —

TAG 10106 —

TAG 10107 —

TAG 10108 —

TAG 10109 —

TAG 10110 —

TAG 10111 —

40

Address Description Value

Documentation-relevant values:

TAG 10200 Welding time

TAG 10201 Section time

TAG 10202 —

EN-US

41

42

EN-US

43

Fronius International GmbH

Froniusstraße 1

4643 Pettenbach

Austria

contact@fronius.com

www.fronius.com

Under www.fronius.com/contact you will find the adresses

of all Fronius Sales & Service Partners and locations.

spareparts.fronius.com

SPAREPARTS

ONLINE

Loading...

Loading...