Page 1

APPLICATION GUIDE

SETTING UP FULL BATTERY BACKUP

WITH FRONIUS PRIMO GEN24 PLUS

THIS DOCUMENT AIMS TO PROVIDE EASY-TO-FOLLOW INSTRUCTIONS ON HOW TO BEST DEPLOY

THE BATTERY BACKUP FUNCTION OF FRONIUS PRIMO GEN24 PLUS INVERTER SYSTEM

Application Guide

© Fronius Australia Pty Ltd.

Version 3.0/2021

Fronius reserves all rights, in particular rights of reproduction, distribution and translation.

No part of this work may be reproduced in any way without the written consent of Fronius. It must not be saved, edited,

reproduced or distributed using any electrical or electronic system.

You are hereby reminded that the information published in this document, despite exercising the greatest of care in its

preparation, is subject to change and that neither the author nor Fronius can accept any legal liability

Gender-specific wording refers equally to female and male form.

(c) Fronius Australia Pty. Ltd, 2021 1/16

Page 2

Date

Version

Comments

Author

08/09/21

3.0

Multiple major changes

Fronius Australia

16/11/20

2.0

Minor wording changes

Fronius Australia

11/11/20

1.0

Initial release

Fronius Australia

1. CHANGE LOG

2. GENERAL

Fronius Primo GEN24 Plus offer the opportunity to supply select electrical loads or possibly entire household

during grid outages. This functionality is referred to as Full Backup function.

This solution works in combination with an energy storage system and supplies electrical loads whenever

sufficient energy is available.

Key features are:

Supply electrical loads in grid outage (1-phase loads),

Automatic switch to backup power in the event of grid failure,

Efficient energy flows due to the Multi-Flow Technology, even in backup power situation.

o This means even in backup mode PV is operational and could charge the battery.

3. REQUIREMENTS

Basic requirements for using the full backup functionality are correctly installed and configured:

Fronius Smart Meter,

Compatible BYD battery,

External backup control and switchover components.

Having PV installed is optional, but recommended because it could charge the battery in backup mode during

sun hours (if sufficient power is available) which makes this solution self-sustainable.

Additionally, for successful integration please make sure following items are ticked:

Inverter is Fronius Primo GEN24 3.0/3.6/4.0/4.6/5.0/6.0 Plus,

Suitable battery installed,

Inverter+Battery capacity suitable for the backup loads connected,

Fronius Smart Meter correctly installed (feed-in point),

Correct Hardware applied,

Correct Software Settings applied,

Warning notice - Backup Power Supply installed, see appendix A,

Backup power checklist completed, see appendix B.

(c) Fronius Australia Pty. Ltd, 2021 2/16

Page 3

4. TECHNICAL INFORMATION

4.1 Battery compatibility

Compatible batteries are listed below.

Table 4.1.a: Primo GEN24 Plus compatible BYD batteries

4.2 BYD Battery-Box Premium information

Key relevant specifications of the BYD Battery-Box Premium batteries are shown below. For more information

visit BYD’s online documentation available here.

Table 4.2.a: BYD Battery-Box HVS/HVM Premium specifications

Table 4.2.b: Charging/discharging power capability of Fronius Primo GEN24 Plus inverters and BYD HVM/HVS

It is possible to combine multiple BYD batteries to increase energy storage capacity, with key information show

below. Compatibility confirmation is available here.

Table 4.2.c: Energy capacity of paralleled BYD HVM/HVS batteries.

* Follow BYD's installation manual on correct installation/configuration instructions when paralleling multiple batteries.

(c) Fronius Australia Pty. Ltd, 2021 3/16

Page 4

4.3 Primo GEN24 Plus information

Fronius Primo GEN24 Plus inverter is available in few power classes 3-6 kVA with full backup functionality

available to all. Inverter’s technical details are shown below.

Table 4.3.a: Primo GEN24 Plus technical details

(c) Fronius Australia Pty. Ltd, 2021 4/16

Page 5

Power Class

3.0

3.6

4.0

4.6

5.0

6.0

Continuous [VA]

3000

3600

4000

4600

5000

6000

Continuous [A] @ 230Vac

13

15.6

17.3

20

21.7

26

Overload (5sec) [VA]

6200 (27.9A @ 230Vac)

Load

Comment

Example 1

3 kW / 3 kVA

Ok

Example 2

4 kW / 6 kVA

Ok

Example 3

5 kW / 5 kVA

Battery capacity surpassed

1

4.4 Backup Capability - Nominal and Overload

Continuous and overload capability1 of the inverters are listed below.

Table 4.4.a: AC output capability for Primo GEN24 Plus

Any active power demand imposed to the inverter from the loads will be met with energy coming from the

battery and PV, if available.

Any reactive power demand imposed to the inverter from the loads will be met without discharging the battery or

without using energy from PV, if available.

4.4.1 System Capacity Limitations - Examples

To better explain the continuous capacity constraints of the whole system comprised of batteries and inverter,

an example with different load configurations is shown below.

Example 1: Primo GEN24 6.0 Plus + BYD HVM 11

Max battery discharge: 4.5 kW,

Max inverter capacity (total): 6 kVA.

Table 4.4.1.a: Example 1 System and loads capacity considerations

The key takeaway is to understand the capacity limitations of the whole system comprised of a battery and an

inverter.

As PV might be present during the backup operation, it will top up the battery capacity if available and if

needed. However, as PV by nature is not a reliable energy source this can’t be guaranteed.

Note 1: Battery size/capacity may limit this further, refer to table 4.2.2.b

(c) Fronius Australia Pty. Ltd, 2021 5/16

Page 6

5. OPERATIONAL MODES

There are two main operational modes, Grid and Backup as well as one informational Energy Saving mode,

discussed in detail below.

5.1 GRID MODE

This mode denotes that the inverter is AC coupled with the local grid, backup control logic is turned off and

backup loads supplied from the grid.

5.1.1 GRID-TO-BACKUP TRANSITION

Successful transition to backup mode requires the following conditions to be met:

1) Grid (via the AC port of the inverter) is monitored by the inverter’s internal protection unit and

Fronius Smart Meter.

2) Grid fails (blackout).

3) The inverter carries out measurement according to country standard and then shuts down.

4) The inverter starts Backup mode after a short time window.

5) Backup control logic is switched on and loads connected to the backup power circuit are supplied

by the inverter.

5.2 BACKUP MODE

Operation in Backup mode usually means the grid is not available and the inverter is supplying backup loads.

The interlocking mechanism from the backup control components is on/activated.

In backup mode inverter's AC output acts as a voltage source with AC voltage set at 230 Vac (L-N) and AC

frequency set at 53 Hz. AC frequency is purposely increased with the intention of disconnecting other inverters

connected to the backup circuit if any.

5.2.1 BACKUP-TO-GRID TRANSITION

Successful transition to grid mode requires the following conditions to be met:

1) Inverter operating in backup power mode.

2) The grid is back and stable.

3) Fronius Smart Meter monitors grid voltage values and passes this information to the inverter.

4) Inverter checks if the grid voltage is within the correct range.

5) Inverter ends backup power mode.

6) Backup control logic is turned off and AC loads are reconnected to the grid.

7) The inverter checks if the grid is within specified parameters (relevant standard) and if successful starts

producing energy.

5.3 ENERGY SAVING MODE

Energy Saving mode usually means that the battery is running at or below the minimum state of charge and

there is no sufficient power to charge (PV or grid).

The inverter enters this mode if either of the following is true:

1) The battery is discharged to the minimum state of charge and no energy is coming from the PV

modules.

2) The inverter/battery is set to Energy Saving mode (standby mode).

If battery and inverter are in Energy Saving mode, the system could be reactivated by one of the following:

1) Enough energy is available from the solar PV modules.

2) Grid is functioning again.

3) The battery is switched off and on.

(c) Fronius Australia Pty. Ltd, 2021 6/16

Page 7

Option 1 2 3 4

Manufacturer

Noark

Schneider

IMO

IMO

Type

Ex9CH63 11

A9C20862

A9C15914

HC63-11230

HC63-11230

HCA11

Component

description

Main

Main

Auxiliary

Main

Main

Auxiliary

Control Coil

Rated Voltage

230 Vac @ 50

Hz

230 Vac @ 50

Hz

230 Vac @ 50

Hz

230 Vac @ 50

Hz

230 Vac @ 50

Hz

Mechanical

interlock

Control Coil

Power Consumption

5.10 VA

4.6 VA

n/a

5-7 VA

5-7 VA

n/a

Pole Configuration

1 NO + 1 NC

2 NO

1 NO + 1 NC

1 NO + 1 NC

2 NO

1 NO + 1 NC

Rated Voltage

230 Vac @ 50

Hz

230 Vac @ 50

Hz

as main module

230 Vac @ 50

Hz

230 Vac @ 50

Hz

as main module

Rated Current

63 A

63 A

2 A

63 A

63 A

3 A

Image

n/a

Option

1

Manufacturer

Finder

Type

22.23.9.012.4000

Control Coil Rated

Voltage

12 Vdc

Control Coil

Power Consumption

1.25 VA

Pole configuration

1 NO + 1 NC

Rated Voltage

230 Vac @ 50 Hz

Rated Output

20 A

Image

6. HARDWARE SETUP

6.1 Required Components – Backup Control

For successful battery backup interfacing, external components K1 (main) and K3 (interface) are required, and

not supplied with the unit. They will need to be purchased separately from your electrical wholesaler or electrical

supplier.

Compatible options for K1 are shown below. Options two and four require two devices main and auxiliary

component, while options one and three require main component only.

Table 6.1.a: Options for K1 – Main

Compatible devices for K3 are shown in the table below. Unfortunately, only one option is available at the

moment. If you have an alternative that matches the requirements feel free to contact us directly at the email

supplied at the end of the document.

Table 6.1.b: Options for K3 – Interface

(c) Fronius Australia Pty. Ltd, 2021 7/16

Page 8

6.2 Control Wiring

The figure below shows a typical wiring diagram of the backup control interface with necessary backup control

components. Also shown in Appendix D for better clarity.

Figure 6.2.a: Backup control wiring diagram (K1 matching option 2)

Important notes to consider:

1) Components K1 and K3 need to be purchased separately from relevant electrical suppliers.

2) When selecting/installing K1 ensure connected load capacity is lower than the capacity of the contactor.

Special considerations must be in place for sites that have only backup loads and/or other inverter in

backup circuit.

(c) Fronius Australia Pty. Ltd, 2021 8/16

Page 9

6.2.1 Control Wiring – Correct Device Positioning

When following the Control Wiring it’s important to understand correct device positioning is crucial to ensure

correct operation of the full backup functionality.

Important points relevant to correct device positioning are as follows:

1) Fronius Smart Meter installed at the feed-in point.

2) K1 main contacts:

a. 3xNO installed at:

i. Load side of Fronius Smart Meter and,

ii. Supply side of Backup loads/GEN24 Inverter.

b. 1xNC installed at:

i. Supply side of K3 NC coil and,

ii. Load site of V+ terminals.

3) K1 control coil installed at load side Fronius Smart Meter (L1/Red phase) and supply side of K1 main

contacts.

4) Backup loads & GEN24 inverter installed at load side of K1 main contacts (3xNO).

5) Non-backup loads (if present) installed at load side of Fronius Smart Meter and supply side of K1.

Additional PV inverters – Grid only (AS/NZS 4777 compliant) can be installed in the backup power circuit. As

operational frequency in backup mode is 53 Hz they will not produce power.

6.2.2 GEN24 Pilot – Connection Area

Figure 6.2.2.a: Backup control wiring connection area (GEN24 Pilot)

Figure 6.2.2.b: GEN24 Pilot connection area

(c) Fronius Australia Pty. Ltd, 2021 9/16

Page 10

7. SOFTWARE SETUP

The following assumes standard commissioning process for the battery and inverter (including Fronius Smart

Meter) have been completed.

Primo GEN24 installation instructions GEN24 Operation manual,

GEN24 commissioning Fronius Solar.Start from your phone/tablet/pc.

When ready to set the full backup mode, follow the steps below:

1) From the WebUI, log in as Technician

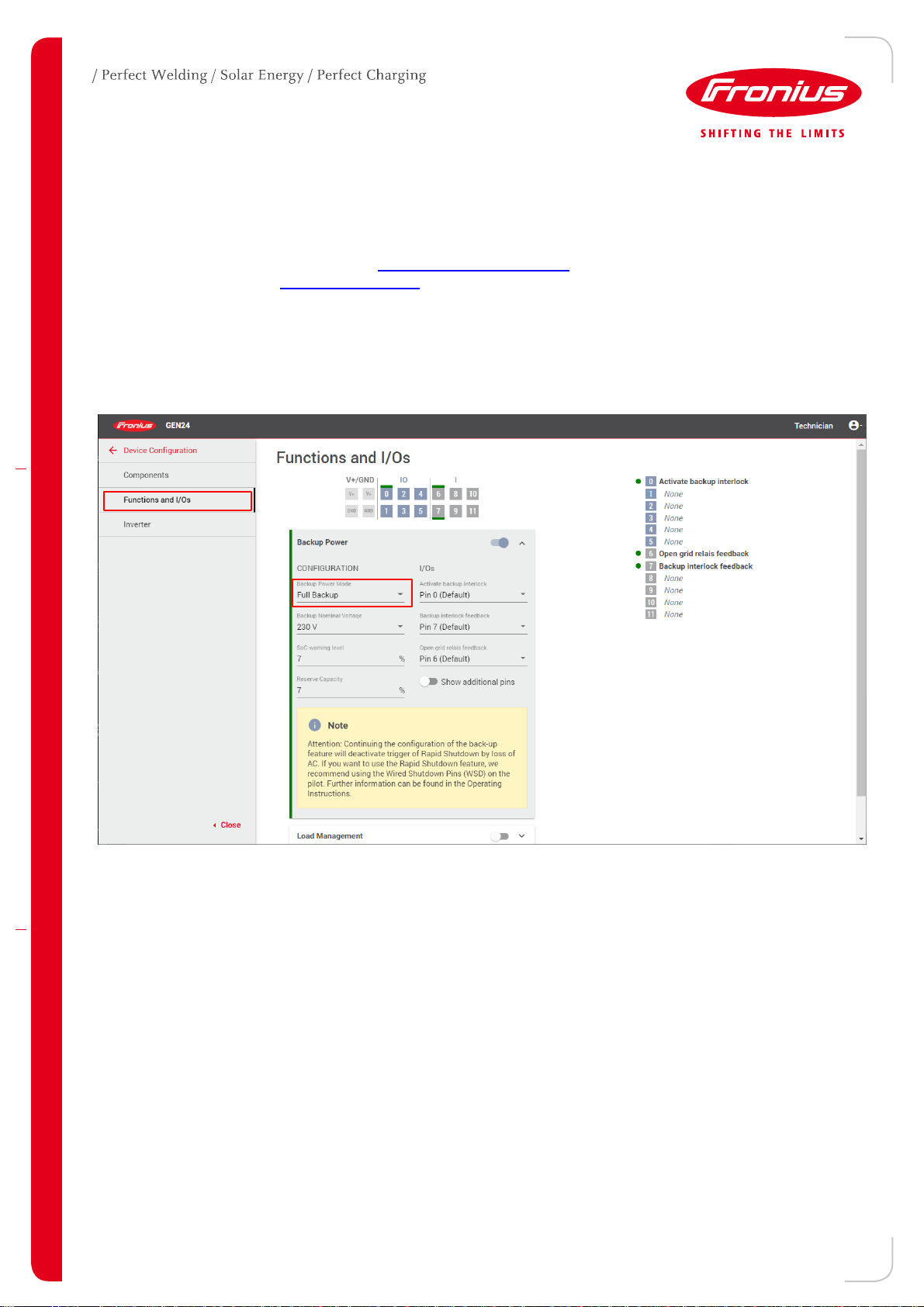

2) Go to Device Configuration Functions and I/Os

3) Select Backup Power and set Backup Power Mode to Full Backup, refer to below.

Figure 7.a: Battery backup setup – functions and I/Os

(c) Fronius Australia Pty. Ltd, 2021 10/16

Page 11

Mode

Grid

IO0

DI6

DI7

K3

K1

Backup

loads

Non-

backup

loads

Grid

ON

OFF

OFF

OFF

DISENGAGED

ENGAGED

ON

ON

Backup

OFF

ON

ON

ON

ENGAGED

DISENGAGED

ON

OFF

Function

Contact

Purpose & clarification

Activate feedback

K3 COIL/IO0

When the inverter wants to turn on Backup Mode IO0 is energized

(12Vdc), which in turn engages K3 -> disengages K1

Grid Isolation

K3 NC

Supplies 230Vac to K1 coil which in turn connect or disconnect backup

loads and inverter to the grid

Backup interlock

feedback

K3 NO

Signals the state of the backup mechanism

Open grid relay

feedback

K1 NC

Signals the state of the grid to the inverter

8. TESTING & TROUBLESHOOTING

8.1 Testing

Test backup mode functionality when the system is installed and commissioned for the first time. The battery

should have a state of charge of at least 30% when performing the test.

Furthermore, we have developed a checklist that clearly shows steps to be followed for successful integration,

shown in Appendix B (click on the image for the actual document).

Upon successful commissioning, Fronius Battery Warning Notice, shown in Appendix A, could be used to

denote Backup presence at premises.

8.2 Troubleshooting

The table below summarises states of important control parameters which could be used for troubleshooting or

assessing faulty components. For example, when Grid mode is active K1 is Engaged, IO0 is OFF, etc.

Table 8.2.a: Input/output states as a function of main operational modes

Additional clarification of the control logic and used contacts with their accompanying actions is shown below.

Table 8.2.b: Backup control functions and relevant contacts

(c) Fronius Australia Pty. Ltd, 2021 11/16

Page 12

9. APPENDIX A – WARNING NOTICE BACKUP POWER

(c) Fronius Australia Pty. Ltd, 2021 12/16

Page 13

10. APPENDIX B – BACKUP INSTALLATION CHECKLIST

(c) Fronius Australia Pty. Ltd, 2021 13/16

Page 14

K1 – main

K3 – interface

Main Contacts

Main pole configuration

1 NO + 1 NC

1 NO + 1 NC

Rated Operational Voltage

230 Vac

230 Vac / 12 Vdc

Rated Operational Current

at least 63 A

at least 10 A

Rated Operational Frequency

50 Hz

50 Hz / DC

Control Coil

Rated Operational Voltage

230 Vac

12 Vdc

Rated Operational Frequency

50 Hz

n/a (DC)

Rated Inrush Power

below 100 VA

below 3 W

11. APPENDIX C – BACKUP CONTROL K1 AND K3 REQUIREMENTS

Table C.1: Backup control components – operational requirements

(c) Fronius Australia Pty. Ltd, 2021 14/16

Page 15

12. APPENDIX D – CONTROL WIRING

(c) Fronius Australia Pty. Ltd, 2021 15/16

Page 16

END OF DOCUMENT

Fronius Australia Technical Support

Email: PV-Support-Australia@fronius.com

Phone: 03 8340 2910

For more detailed information see the operation manual available on the product specific page on http://www.fronius.com/en-au/australia

(c) Fronius Australia Pty. Ltd, 2021 16/16

Loading...

Loading...