Page 1

/ Perfect Charging / Perfect Welding / Solar Energy

Fronius Primo:

Explanation of symbols and choice

of location

Notes regarding installation and

connection

Operating Instructions

EN

Grid-connected inverter

42,0426,0204,EN 001-01042015

Page 2

0

Page 3

Contents

Explanation of symbols .............................................................................................................................. 3

Explanation of safety symbols .............................................................................................................. 3

Explanation of symbols and choice of location ..................................................................................... 3

Explanation of symbols - installation position ....................................................................................... 5

Choice of location ...................................................................................................................................... 7

Proper use ............................................................................................................................................ 7

General comments regarding choice of location...................................................................................7

Installation notes ........................................................................................................................................ 9

Selecting wall plugs and screws ........................................................................................................... 9

Recommended screws ......................................................................................................................... 9

Mounting the wall bracket ..................................................................................................................... 9

Installing the inverter on a mast ............................................................................................................ 9

Notes regarding grid connection ................................................................................................................ 10

Monitoring the Grid ............................................................................................................................... 10

AC terminals ......................................................................................................................................... 10

Type of AC cable .................................................................................................................................. 10

Connecting aluminum cables................................................................................................................ 11

Grid connection of inverter or dummy device ....................................................................................... 11

Maximum fuse rating on alternating current side .................................................................................. 13

Notes regarding DC connection................................................................................................................. 14

General comments regarding solar modules ........................................................................................14

DC terminals ......................................................................................................................................... 14

Connecting aluminum cables................................................................................................................ 15

Notes regarding dummy devices .......................................................................................................... 15

Inverter DC connection ......................................................................................................................... 16

Inverter with multiple MPP trackers ...................................................................................................... 17

Notes regarding the laying of data communication cables ........................................................................ 19

Laying data communication cables....................................................................................................... 19

Notes regarding attaching the inverter to the wall bracket......................................................................... 20

Attaching the inverter to the wall bracket .............................................................................................. 20

Notes regarding software updates ............................................................................................................. 21

Notes regarding software updates ........................................................................................................ 21

USB Stick as a Data Logger and for Updating Inverter Software .............................................................. 22

USB stick as a data logger.................................................................................................................... 22

Data on the USB stick........................................................................................................................... 22

Data volume and storage capacity........................................................................................................ 23

Buffer memory ...................................................................................................................................... 23

Suitable USB flash drives ..................................................................................................................... 24

USB stick for updating the inverter software......................................................................................... 24

Remove USB stick ................................................................................................................................ 25

Notes regarding maintenance.................................................................................................................... 26

Maintenance ......................................................................................................................................... 26

Cleaning................................................................................................................................................ 26

EN

1

Page 4

2

Page 5

Explanation of symbols

EN

Explanation of

safety symbols

Explanation of

symbols and

choice of location

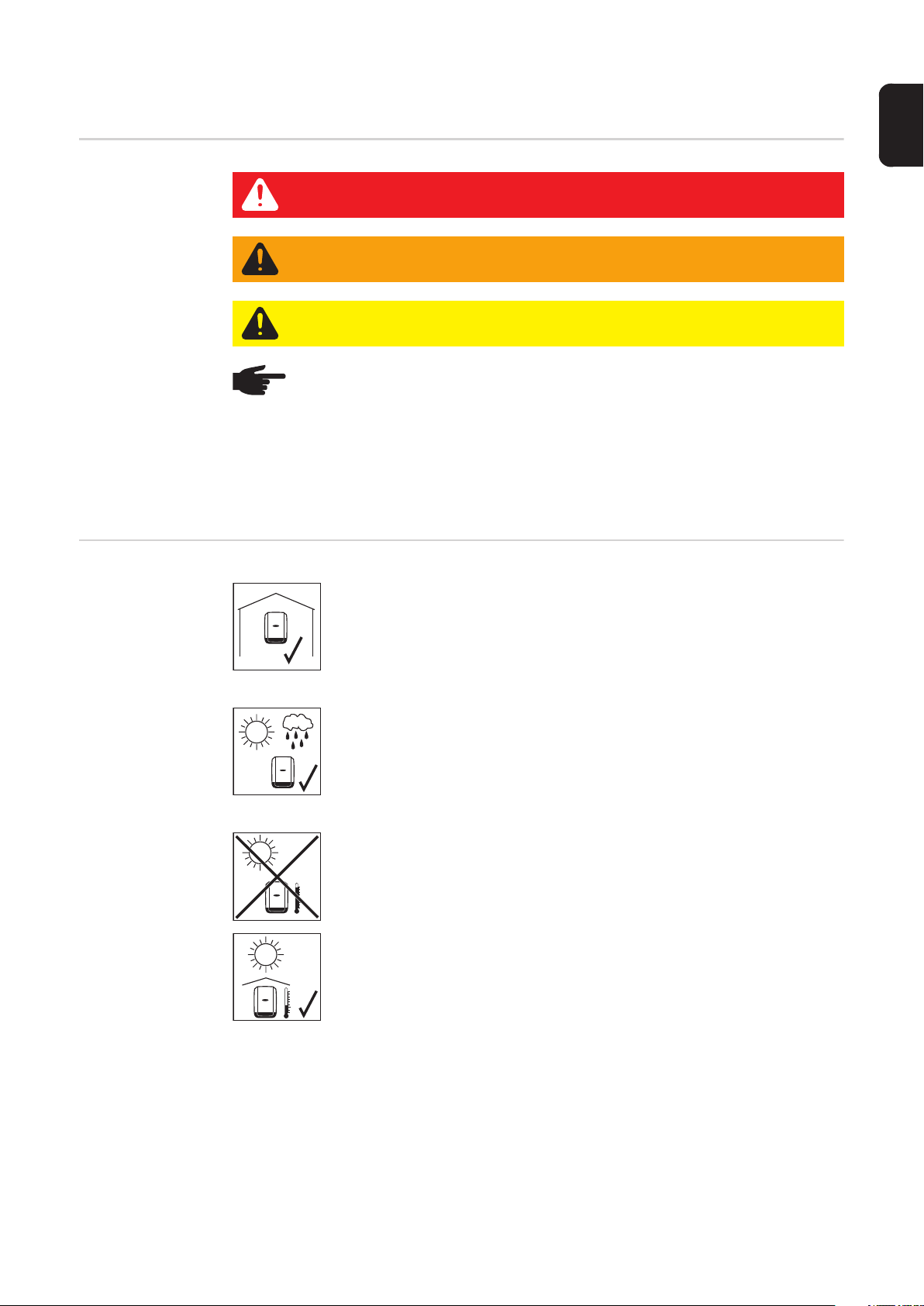

DANGER! Indicates immediate and real danger. If it is not avoided, death or se-

rious injury will result.

WARNING! Indicates a potentially dangerous situation. Death or serious injury

may result if appropriate precautions are not taken.

CAUTION! Indicates a situation where damage or injury could occur. If it is not

avoided, minor injury and/or damage to property may result.

NOTE! Indicates a risk of flawed results and possible damage to the equipment.

IMPORTANT! Indicates tips for correct operation and other particularly useful information.

It does not indicate a potentially damaging or dangerous situation.

If you see any of the symbols depicted in the "Safety rules" chapter, special care is required.

The inverter is suitable for installation indoors.

IP 65

The inverter is suitable for installation outdoors.

Its IP 65 degree of protection means that the inverter is resistant to water

jets from any direction and can also be used in damp environments.

In order to minimise the heating up of the inverter, do not expose it to direct insolation. The inverter should ideally be mounted in a protected position, e.g. in the vicinity of the solar modules or beneath the eaves.

3

Page 6

max.

4000 m

> 4000 m

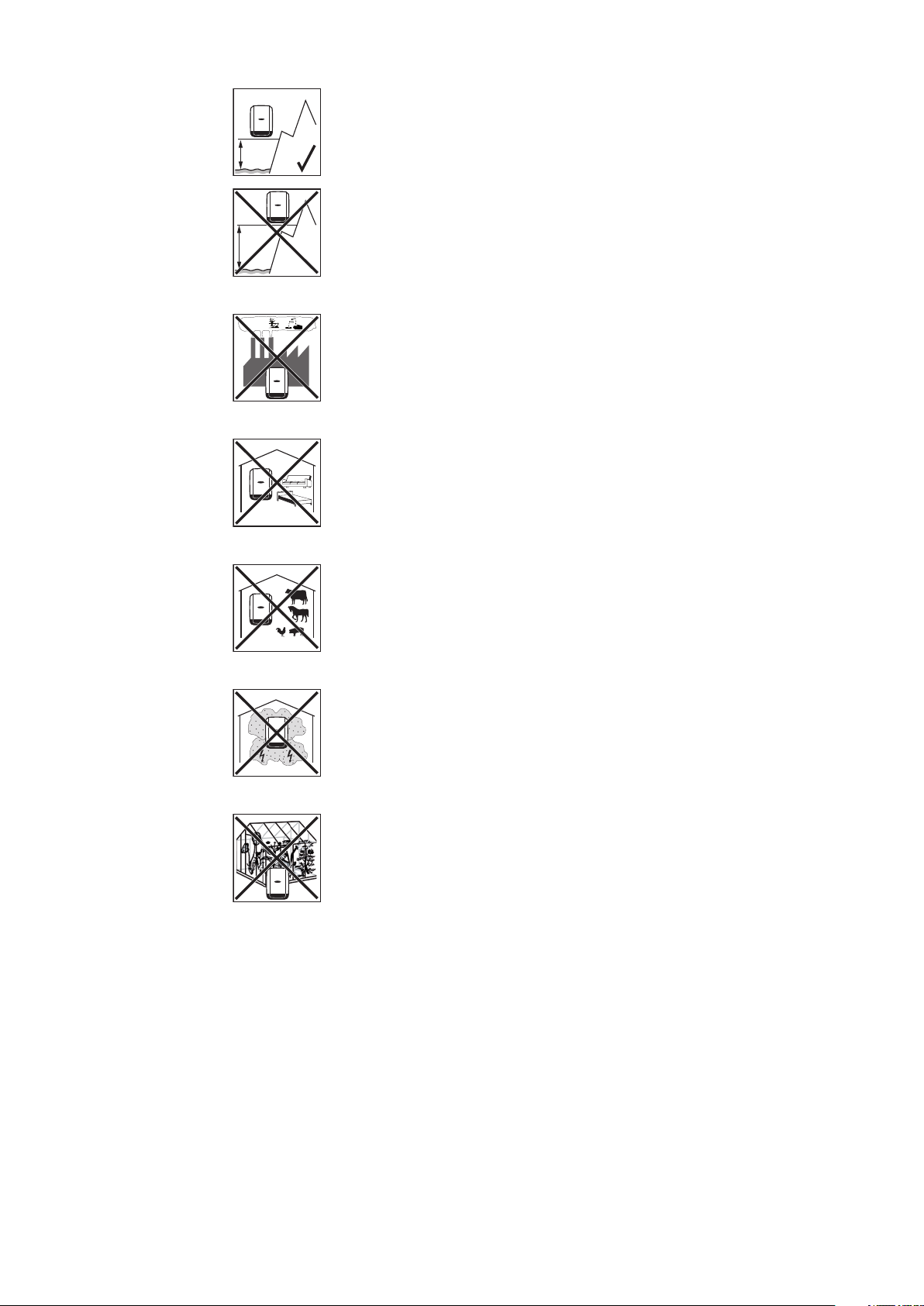

Can be used at altitudes of up to 4000 m

IMPORTANT! The inverter must not be installed or used at altitudes

above 4000 m.

NH

3

Do not install the inverter:

- in areas where ammonia, corrosive vapours, acids or salts are present

(e.g. fertiliser stores, ventilation openings from cattle sheds, chemical plants, tanneries, etc.)

As the inverter generates low levels of noise at certain times, it should

not be installed close to living areas.

Do not install the inverter:

- in places where there is an increased risk of damage from farm animals (horses, cattle, sheep, pigs, etc.)

- in stables or adjoining areas

- in storage areas for hay, straw, chaff, animal feed, fertilisers, etc.

Do not install the inverter:

- in places and environments subject to heavy build-up of dust

- in places and environments in which a heavy build-up of dust containing conductive particles (e.g. iron chips) is likely

Do not install the inverter:

- in greenhouses

- in storage or processing areas for fruit, vegetables or winegrowing

products

- in places used to prepare grain, green fodder or animal feeds

4

Page 7

Explanation of

symbols - installation position

EN

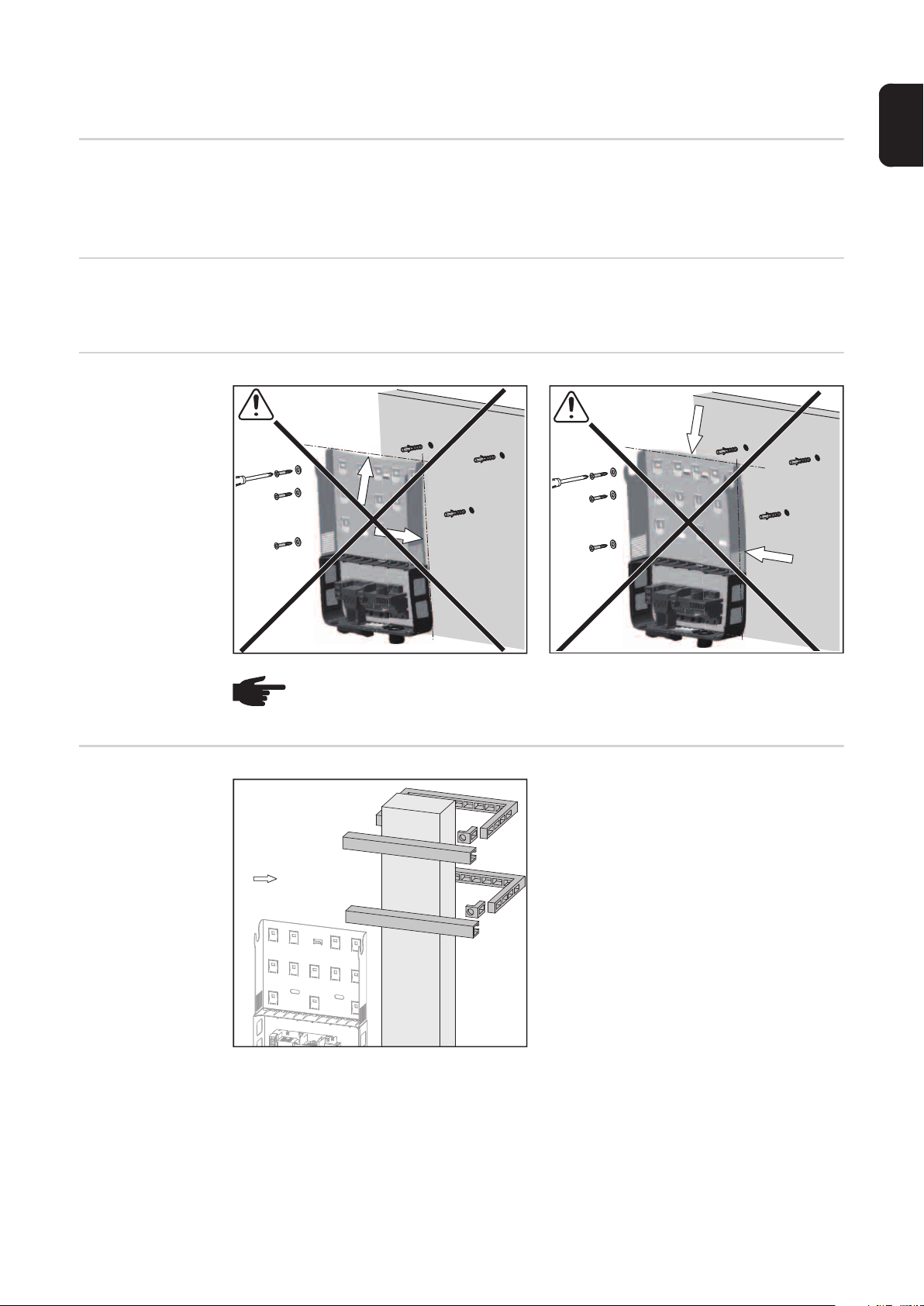

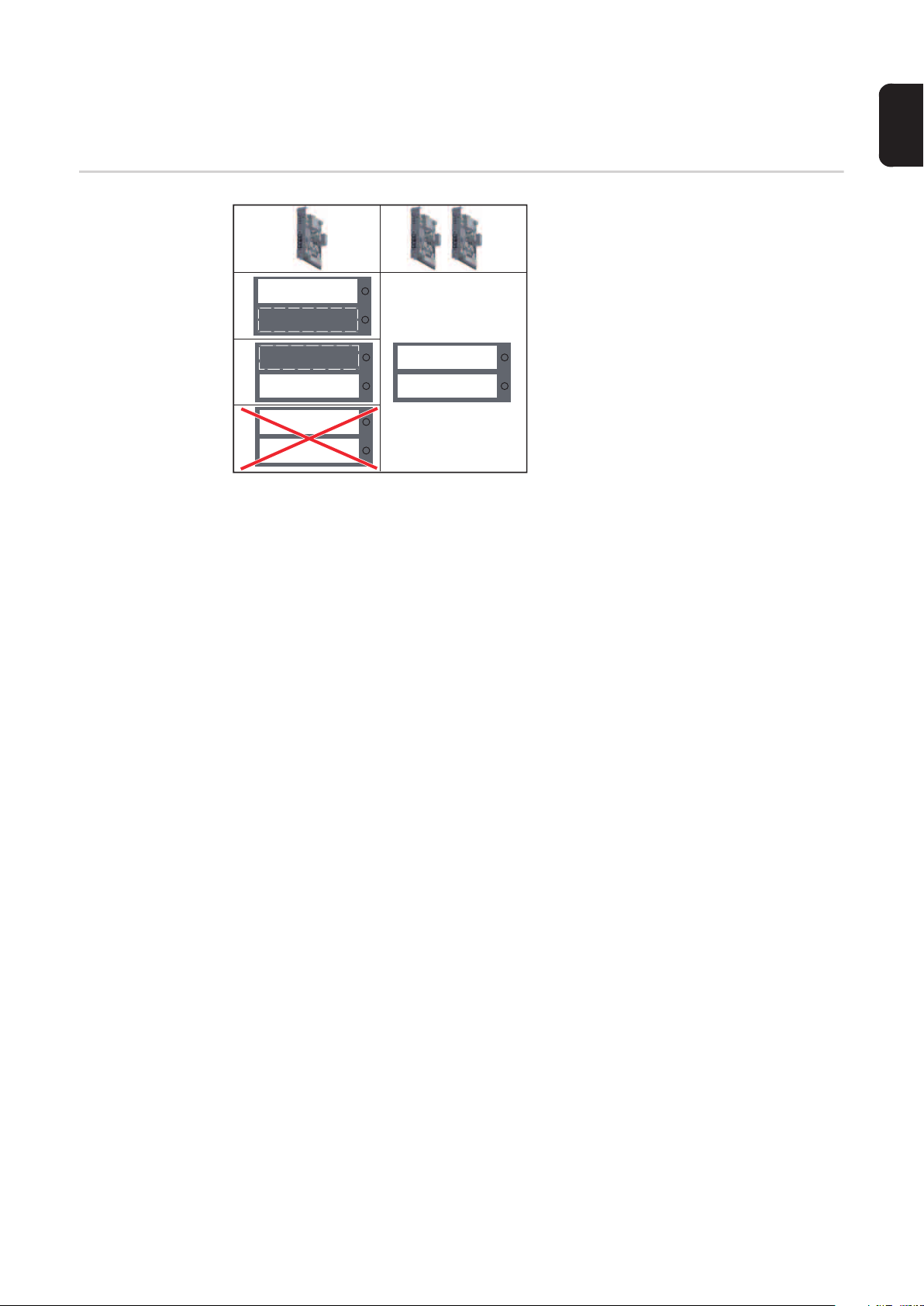

The inverter is designed to be installed vertically on a vertical wall or pillar.

The inverter is suitable for horizontal installation.

The inverter is suitable for installation on a sloping surface.

Do not install the inverter on a sloping surface with its connection sockets

facing upwards.

Do not install the inverter at an angle on a vertical wall or pillar.

Do not install the inverter horizontally on a vertical wall or pillar.

Do not install the inverter on a vertical wall or pillar with its connection

sockets facing upwards.

Do not install the inverter such that it overhangs with its connection sockets facing upwards.

5

Page 8

Do not install the inverter such that it overhangs with its connection sockets facing downwards.

Do not install the inverter on the ceiling.

6

Page 9

Choice of location

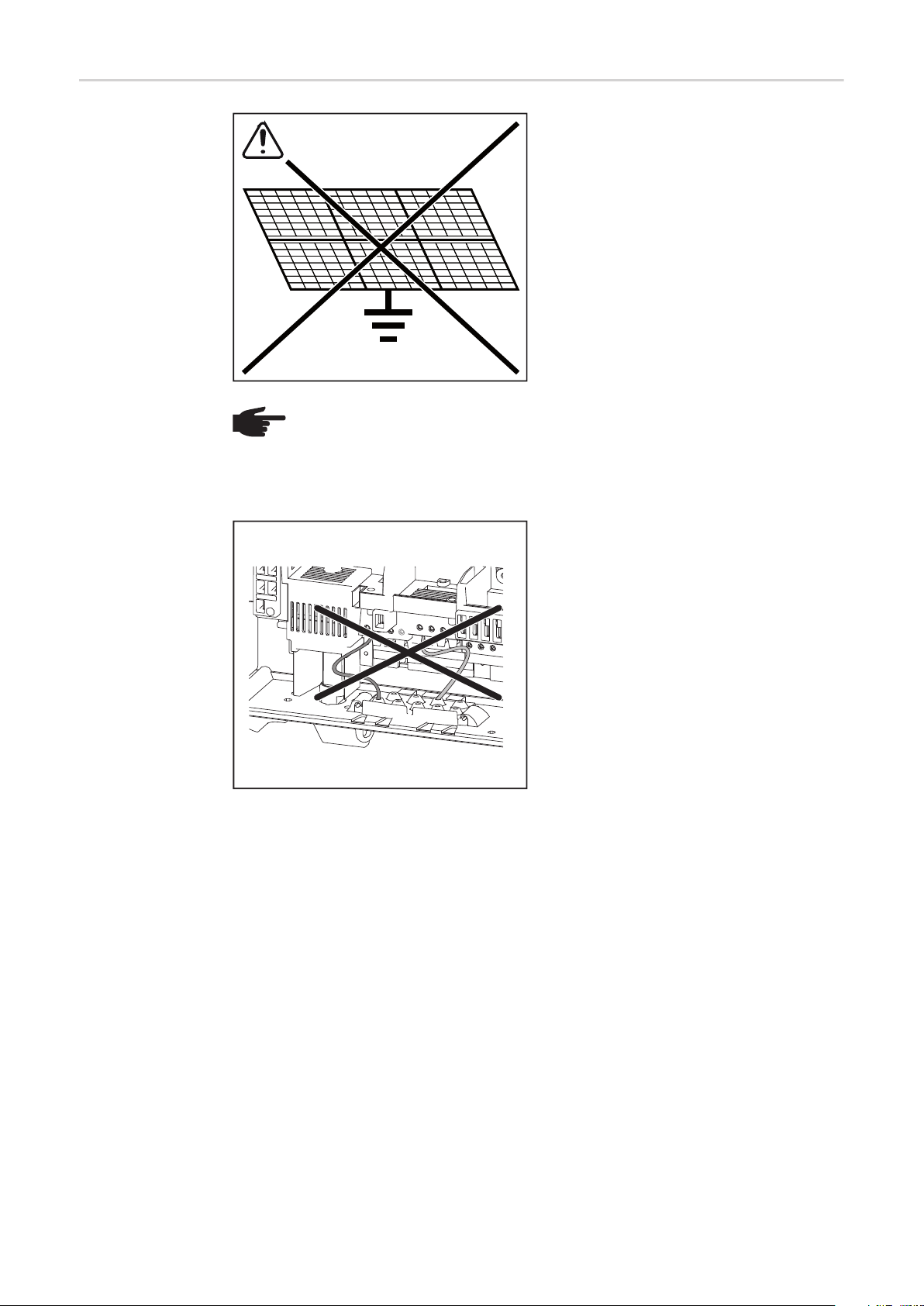

Proper use The inverter is designed to be connected and used exclusively in conjunction with un-

grounded solar modules. The solar modules may either be grounded on the positive or

negative pole.

The solar inverter is intended exclusively to convert direct current from solar modules into

alternating current and to feed this into the public grid.

Utilisation not in accordance with the intended purpose comprises:

- any use above and beyond this purpose

- making any modifications to the inverter that have not been expressly approved by

Fronius

- the installation of components that are not distributed or expressly approved by Fronius.

Fronius shall not be liable for any damage resulting from such action.

No warranty claims will be entertained.

Proper use also includes

- carefully reading and obeying all the instructions and all the safety and danger notices

in the operating instructions

- performing all stipulated inspection and maintenance work

- installation as specified in the operating instructions

EN

General comments regarding

choice of location

When designing the photovoltaic system, ensure that all of its components are operated

within their permitted operating ranges at all times.

Observe all the measures recommended by the solar module manufacturer to ensure the

lasting maintenance of the properties of the solar module.

Obey the regulations of the power supply company regarding energy fed into the grid.

The following criteria should be taken into account when choosing a location for the inverter:

Install only on a solid surface

Max. ambient temperatures:

150 mm

200 mm

100 mm

-40 °C / +55 °C

Relative humidity:

0 - 100 %

The airflow within the inverter is

from the left and right to the top

(cold air taken in from the left and

right, hot air dissipated out of the

top).

-40 °C - +55 °C

0 - 100 %

7

Page 10

If the inverter is installed in a switch cabinet or a similar sealed area, then forced-air ventilation must be provided to ensure adequate heat dissipation.

If the inverter is to be installed on the outer wall of a cattle shed, maintain a minimum allround clearance of 2 m between the inverter and all ventilation and other openings in the

building.

The installation location must not be exposed to ammonia, corrosive vapours, salts or acids.

8

Page 11

Installation notes

EN

Selecting wall

plugs and screws

Recommended

screws

Mounting the wall

bracket

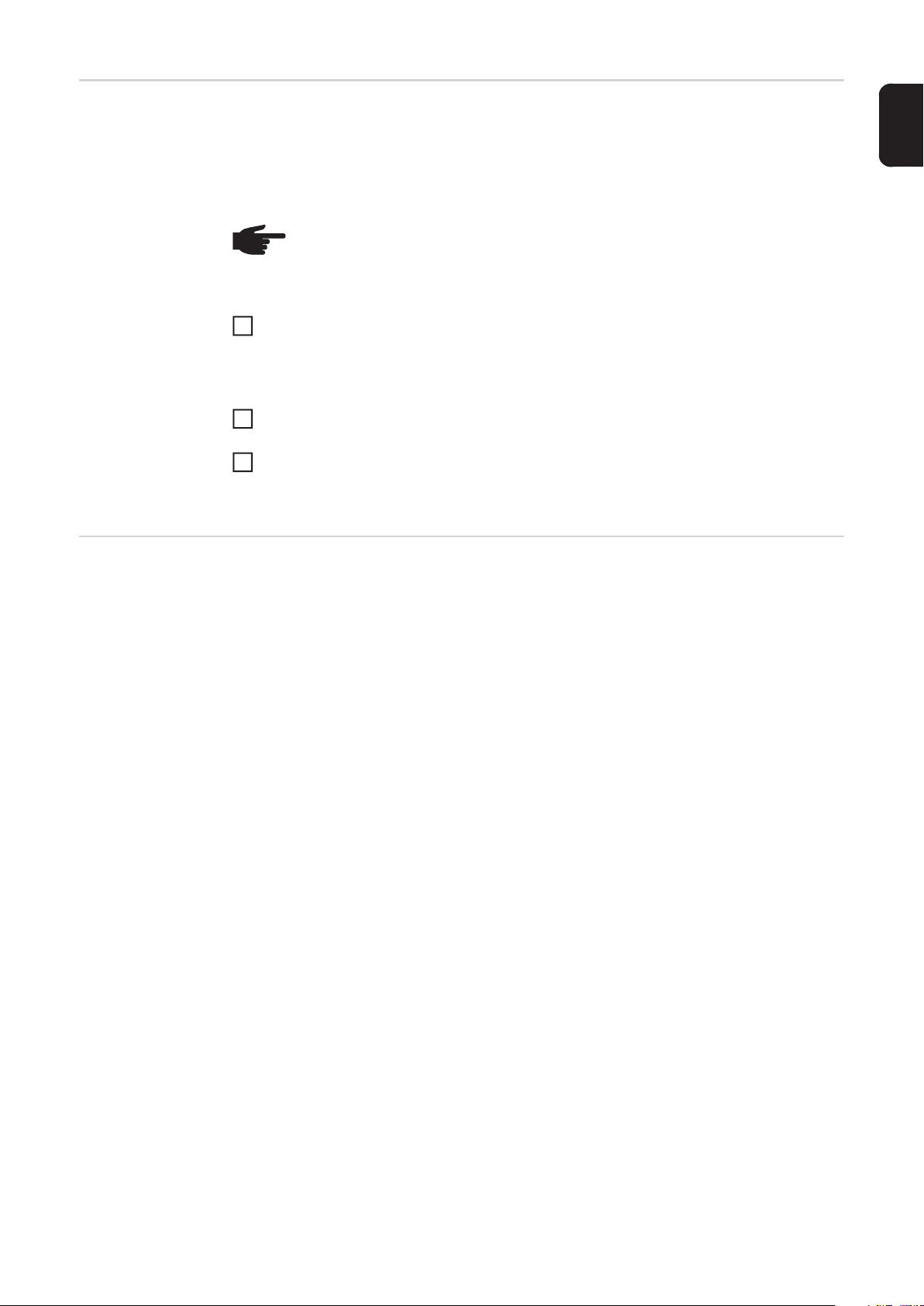

IMPORTANT! Different fixings may be required to fit the wall bracket depending on the

type of underlying surface. Fixings are therefore not included in the scope of supply of the

inverter. The installer is responsible for selecting the right type of fixing.

To install the inverter, the manufacturer recommends the use of steel or aluminium screws

with a diameter of 6 - 8 mm.

Installing the inverter on a mast

NOTE! When mounting the wall bracket, ensure that the wall bracket is not

warped or deformed.

Fronius Primo

?

Installation Help

Example of a mast fixing kit

When mounting the inverter on a mast or a

vertical carrier, Fronius recommends the

use of a standard mast fixing kit.

This kit enables the inverter to be mounted

on round or rectangular masts with various

cross-sections.

9

Page 12

Notes regarding grid connection

Monitoring the

Grid

AC terminals

IMPORTANT! The resistance in the leads to the AC-side connection terminals must be as

low as possible for optimal functioning of grid monitoring.

min. 2,5 mm² - max. 16 mm²

min. 1,5 Nm - max. 1,8 Nm

In the case of an AC cable with a cross-section of 16 mm², ferrules can be either not used

or only used to a limited extent depending on the type of ferrule and crimping.

PE Ground conductor / grounding

L1 Phase conductor

N Neutral conductor

Max. cross-section of each conductor cable:

16 mm²

Min. cross-section of each conductor cable:

in accordance with the fuse rating on the

AC side, but at least 2.5 mm²

The AC cables can be connected to the AC

terminals without ferrules.

Type of AC cable The following types of AC cable can be connected to the AC terminals of the inverter:

Cu / Al Cu

max. Class 4

- copper or aluminium: round, single wire

- Copper: round, finely stranded up to conductor category 4

10

Page 13

Connecting aluminum cables

The AC-side terminals are designed for connecting single-wire, round, aluminum cables.

The following points must be taken into account when connecting aluminum cables due to

the non-conducting oxide layer of aluminum:

- Reduced rated currents for aluminum cables

- The connection requirements listed below

NOTE! Take into account local specifications when configuring cable cross sections.

Connection Requirements:

Carefully clean off the oxide layer of the stripped end of the cable, e.g., using a knife.

1

IMPORTANTDo not use brushes, files or sandpaper. Aluminum particles may get stuck

and can transfer to other cables.

After removing the oxide layer of the cable end, rub in a neutral grease, e.g., acid- and

2

alkali-free Vaseline.

Then immediately connect it to the terminal.

3

Repeat the steps above whenever the cable is disconnected and then reconnected.

EN

Grid connection

of inverter or

dummy device

NOTE! To ensure a proper ground connection, all three PE grounding terminals

must be tightened to the specified torque when the inverter is installed.

NOTE! Form loops with the AC cables when connecting them to the AC terminals!

When securing the AC cables using a metric screw joint, ensure that the loops do

not protrude beyond the connection area. Under certain circumstances it may otherwise no longer be possible to close the inverter.

NOTE!

- Ensure that the grid neutral conductor is grounded. In the case of IT networks

(insulated networks with no grounding) this may not be the case; it will then

not be possible to use the inverter.

- In order to use the inverter, the neutral conductor must be connected.

A neutral conductor that is too small may adversely affect the grid power

feed operation of the inverter. The neutral conductor must therefore be the

same size as the other live conductors.

IMPORTANT! The PE ground conductor of the AC cable must be laid in such a way that it

is the last to be disconnected in the event that the strain-relief device should fail.

This can be ensured, for example, by making it somewhat longer and by laying it in a loop.

11

Page 14

P

E

P

E

P

E

If AC cables are laid over the shaft of the DC main switch or across the connection block

of the DC main switch, they may be damaged when the inverter is swung in, or they may

even prevent the inverter from being swung in.

IMPORTANT! Do not lay AC cables over the shaft of the DC main switch or across the connection block of the DC main switch!

If overlength AC or DC cables are to be laid

in loops in the connection area, attach the

cables with cable ties to the eyelets provided on the top and bottom of the connection blocks.

e.g.: AC cable

12

Page 15

Maximum fuse

rating on alternating current side

AC ~

max. 63 A

Inverter Phases Max. output Max. fuse rating

Fronius Primo 3.0-1 1 3000 W 1 x C 63 A

Fronius Primo 3.5-1 1 3500 W 1 x C 63 A

Fronius Primo 3.6-1 1 3600 W 1 x C 63 A

Fronius Primo 4.0-1 1 4000 W 1 x C 63 A

Fronius Primo 4.6-1 1 4600 W 1 x C 63 A

Fronius Primo 5.0-1 AUS 1 5000 W 1 x C 63 A

Fronius Primo 5.0-1 1 5000 W 1 x C 63 A

Fronius Primo 6.0-1 1 6000 W 1 x C 63 A

Fronius Primo 8.2-1 1 8200 W 1 x C 63 A

EN

NOTE! Local regulations, the energy supply company or other factors may re-

quire a residual current protective device (RCD) in the grid line. For this situation,

a type A residual current protective device is generally adequate. In particular

cases, and depending on local factors, however, the type A residual current protection device may trip at the wrong time.

For this reason, Fronius recommends that a residual current protection device

suitable for frequency converters be used.

13

Page 16

Notes regarding DC connection

General comments regarding

solar modules

DC terminals

To enable suitable solar modules to be chosen and to use the inverter as efficiently as possible, it is important to bear the following points in mind:

- If insolation is constant and the temperature is falling, the open circuit voltage of the

solar modules will increase.

- The temperature coefficients on the solar modules data sheet must be observed

- More exact values for dimensioning the solar modules can be provided by suitable calculation programs, like the Fronius Solar.configurator (which can be downloaded from

www.fronius.com).

NOTE! Before connecting up the solar modules, check that the voltage for the solar modules specified by the manufacturer corresponds to the actual measured

voltage.

The solar module manufacturer's safety instructions and regulations regarding

solar module grounding must be observed.

Max. cross-section of each DC cable:

min. 2,5 mm² - max. 26 mm²

min. 1,5 Nm - max. 1,8 Nm

16 mm²

Min. cross-section of each DC cable:

2.5 mm²

The DC cables can be connected to the DC

terminals without ferrules.

MPPT1

MPPT2

DC= (+)

DC= (-)

D1

D1

NOTE! To ensure effective strain

relief of the solar module strings,

only use cables with identical

cross-sections.

D2

D3

D1

D1

In the case of a DC cable with a cross-section of 16 mm², ferrules can be either not used

or only used to a limited extent depending on the type of ferrule and crimping.

14

Page 17

Connecting aluminum cables

The DC-side terminals are designed for connecting single-wire, round aluminum cables.

The following points must be taken into account when connecting aluminum cables due to

the non-conducting oxide layer of aluminum:

- Reduced rated currents for aluminum cables

- The connection requirements listed below

NOTE! Take into account local specifications when configuring cable cross sections.

Connection Requirements:

Carefully clean off the oxide layer of the stripped end of the cable, e.g., using a knife.

1

IMPORTANT Do not use brushes, files or sandpaper. Aluminum particles may get stuck

and can transfer to other cables.

After removing the oxide layer of the cable end, rub in a neutral grease, e.g., acid- and

2

alkali-free Vaseline.

Then immediately connect it to the terminal.

3

Repeat the steps above whenever the cable is disconnected and then reconnected.

EN

Notes regarding

dummy devices

A dummy device is not suitable for connecting operationally to a photovoltaic system, and

must only ever be used for demonstration purposes. Dummy devices are indicated as such

on their rating plate.

IMPORTANT! Never connect DC cables to the DC connection sockets on a dummy device.

The connection of de-energised cables or sections of cable for demonstration purposes is

permissible.

15

Page 18

Inverter DC connection

The inverter is designed to be connected

and used exclusively in conjunction with

ungrounded solar modules.

The solar modules may either be grounded

on the positive or negative pole.

NOTE! Only break out as many target break points as the number of cables that

are provided (e.g. if there are two DC cables, then break out two recesses).

IMPORTANT! Check the polarity and voltage of the solar module strings.

The difference between the individual solar module strings must not exceed 10 V.

If DC cables are laid over the shaft of the

DC main switch or across the connection

block of the DC main switch, they may be

damaged when the inverter is swung in, or

they may even prevent the inverter from

being swung in.

IMPORTANT! Do not lay DC cables over

the shaft of the DC main switch or across

the connection block of the DC main switch!

16

Page 19

Inverter with multiple MPP trackers

In the case of inverters with multiple MPP trackers, there are two independent DC inputs

(MPP trackers) available. These can be connected to an unequal number of solar modules.

There are two terminals for DC+ available per MPP tracker. In total there are four terminals

for DC-.

Connecting two to four strings in multiple MPP tracker mode:

EN

PV 1

PV 2

Divide the strings between the two MPP tracker inputs (DC+1/DC+2). The DC- terminals can be used however you wish, as

they are internally connected.

When starting for the first time, set MPP

TRACKER 2 to "ON" (this will also later be

DC+2

DC-2

DC-1

DC+1

Connecting two solar module fields to an inverter with

multiple MPP trackers

max. 18 A

per MPPT

DC+1 DC+2

12

12

DC-

12

34

possible from the Basic menu).

Single MPP tracker mode on an inverter with multiple MPP trackers:

PV 1

PV 2

max. 36 A to

a single

DC terminal

DC+1

DC+2

1

1

22

DC-

1234

If the strings are connected using a string

collection box and only one bus is used for

connection to the inverter, the connection

DC+1 (pin 2) and DC+2 (pin 1) must be

jumpered.

The cable cross-section of the DC connection lead and the jumpering must be the same. Jumpering of the DC terminal is not

necessary, as these terminals are jumpe-

DC-1

DC+1

red internally.

*

*

D1

D1

=

When starting for the first time, set MPP

TRACKER 2 to "OFF" (this will also later be

possible from the Basic menu).

Connecting multiple interconnected solar module

fields to an inverter with multiple MPP trackers using

one lead

If the inverter with multiple MPP trackers is

operated in single MPP tracker mode, the

currents from the DC leads connected are

divided evenly across both inputs.

17

Page 20

Single MPP tracker mode with only one string on an inverter with multiple MPP

trackers:

If only one string is used for connection to

WHEN ONLY ONE STRING IS USED

the inverter, the connection DC+1 (pin 2)

and DC+2 (pin 1) must be jumpered.

PV 1

DC-1

DC+1

max. 36 A to

a single

DC terminal

DC+1

DC+2

1

1

22

DC-

1234

The cable cross-section of the DC connection lead and the jumpering must be the same. Jumpering of the DC terminal is not

necessary, as these terminals are jumpered internally.

When starting for the first time, set MPP

*

TRACKER 2 to "OFF" (this will also later be

possible from the Basic menu).

*

D1

D1

=

If the inverter with multiple MPP trackers is

operated in single MPP tracker mode, the

Connecting only one string to an inverter with multiple

MPP trackers

currents from the DC leads connected are

divided evenly across both inputs.

18

Page 21

Notes regarding the laying of data communication

cables

Laying data communication cables

EN

IMPORTANT! Operating the inverter with

an option card and two broken-out option

card divisions is not permitted.

To cater for this eventuality, a relevant

blanking cover (42,0405,2020) is available

from Fronius as an option.

IMPORTANT! Note the following if data communication cables are being introduced into

the inverter:

- depending on the number and cross-section of the data communication cables that

are being introduced, take the relevant blanking plugs out of the sealing insert and insert the data communication cable.

- insert without fail the relevant blanking plugs into the free openings on the sealing insert.

19

Page 22

Notes regarding attaching the inverter to the wall

bracket

Attaching the inverter to the wall

bracket

The side sections of the housing lid are designed to function as holding and carrying handles.

NOTE! For safety reasons, the inverter is fitted with a latch that prevents the inverter from being swung into the wall bracket unless the DC main switch is

switched off.

- Never attach the inverter to the wall bracket or swing it in unless the DC main

switch is switched off,

- Never use force to attach the inverter or swing it in.

The fastening screws in the data communication area of the inverter are used for securing

the inverter to the wall bracket. Correctly tightened fastening screws are a prerequisite if

proper contact is to be established between inverter and wall bracket.

CAUTION! If the fastening screws are not tightened correctly, then the inverter is

at risk of being damaged.

Fastening screws that are not correctly tightened can result in arcs occurring

when the inverter is in operation, which in turn can cause fires. Always use the

specified torque when tightening the fastening screws.

20

Page 23

Notes regarding software updates

EN

Notes regarding

software updates

If the inverter is supplied with a USB stick,

the inverter software must be updated as

soon as the inverter has been commissioned:

+

1

2

2

USB

Plug the USB stick into the data com-

1

munication area of the inverter

Open the Setup menu

2

Select the "USB" menu item

3

3

4

4

5

Select "Software Update"

4

Update the software

5

21

Page 24

USB Stick as a Data Logger and for Updating Inverter Software

USB stick as a

data logger

Data on the USB

stick

A USB stick connected to the USB A socket can act as a data logger for an inverter.

Logging data saved to the USB stick can at any time

- be imported into the Fronius Solar.access software via the included FLD file,

- be viewed directly in third-party applications (e.g., Microsoft® Excel) via the included

CSV file.

Older Excel versions (up to Excel 2007) have a row limit of 65536.

If the USB stick is being used as a data logger, three files will be created automatically:

- FRONIUS.sys system file:

This file stores information from the inverter that is irrelevant to the customer. The file

must not be deleted separately. Only delete all of the files (sys, fld, csv) at one time.

- DALO.fld log file:

A log file for reading the data in the Fronius Solar.access software.

Further details on the Fronius Solar.access software can be found in the "DATCOM

Details" operating instructions at http://www.fronius.com

- DATA.csv log file:

A log file for reading the data in a spreadsheet program (e.g.: Microsoft® Excel)

(1) USB root directory

USB_Drive (1)

GALVO / SYMO / PRIMO / ECO

(2)

01 (3)

FRONIUS.sys

DALO.fld

DATA.csv

02

FRONIUS.sys

DALO.fld

DATA.csv

Data structure on the USB stick

Structure of the CSV file:

(1) (2) (3) (4) (5) (6) (7)

(2) Fronius inverters (Fronius Galvo,

Fronius Symo, Fronius Primo or

Fronius Eco)

(3) Inverter number - can be set in the

Setup menu under DATCOM

If there are several inverters with the same

inverter number, the three files will be saved in the same folder. A digit is added to

the file name as a suffix (e.g.: DALO_02.fld)

22

Page 25

(8) (9)

(1) ID

(2) Inverter no.

(3) Inverter type (DATCOM code)

(4) Logging interval in seconds

(5) Energy in watts per second, relative to the logging interval

(6) Inductive reactive power

(7) Capacitive reactive power

(8) Average values during the logging interval (AC voltage, AC current, DC voltage,

DC current)

(9) Additional information

EN

Data volume and

storage capacity

A USB stick with a storage capacity of 1 GB can record logging data for roughly seven

years at a logging interval of five minutes.

CSV file

CSV files can only store 65,535 lines (data records) (up to Microsoft® Excel 2007; there is

no restriction from this version onwards).

At a five-minute logging interval, the 65,535 lines will be written within approximately seven

months (CSV data size of approx. 8 MB).

In order to avoid data loss, the CSV file should be backed up to a PC and deleted from the

USB stick within this seven-month period. If the logging interval is set to a longer period,

this time frame will be increased accordingly.

FLD file

The FLD file should not be larger than 16 MB. This will provide enough storage capacity

for approximately six years at a logging interval of five minutes.

If the file exceeds the 16 MB limit, it should be backed up to a PC and all of the data on the

USB stick should be deleted.

After backing up and removing the data, the USB stick can be reconnected immediately to

resume recording the logging data without any further steps being required.

NOTE! Using a full USB stick can lead to data loss or data being overwritten.

When using USB sticks, always ensure that there is sufficient storage capacity on

the stick.

Buffer memory If the USB stick is unplugged (e.g. for data backup purposes), the logging data is written to

a buffer memory in the inverter.

As soon as the USB stick is plugged in again, the data is copied automatically from the buffer memory to the stick.

The buffer memory can store a maximum of six logging points. Data is only logged while

the inverter is running (output greater than 0 W). The logging interval is permanently set at

30 minutes. Data can be recorded on the buffer memory for a three-hour time period as a

result.

23

Page 26

When the buffer memory is full, the oldest data in the memory will be overwritten by the

next batch of data.

IMPORTANT! The buffer memory requires a permanent power supply.

If there is a power failure while the inverter is in operation, all the data in the buffer memory

will be lost. To avoid losing data during the night, the automatic night switch-off facility must

be deactivated (switch the 'Night Mode' setup parameter to ON - see the section 'Setting

and displaying the menu items', 'Viewing and adjusting parameters in the DATCOM menu

item').

Suitable USB

flash drives

Due to the variety of USB flash drives available on the market, it cannot be guaranteed that

every USB flash drive will be detected by the inverter.

Fronius recommends that only certified USB flash drives suitable for building sites are used

(look out for the USB-IF logo).

The inverter supports USB flash drives with the following file systems:

- FAT12

- FAT16

- FAT32

Fronius recommends that the USB flash drives employed should only be used for recording logging data or updating the inverter software. The USB flash drives should not contain

any other data.

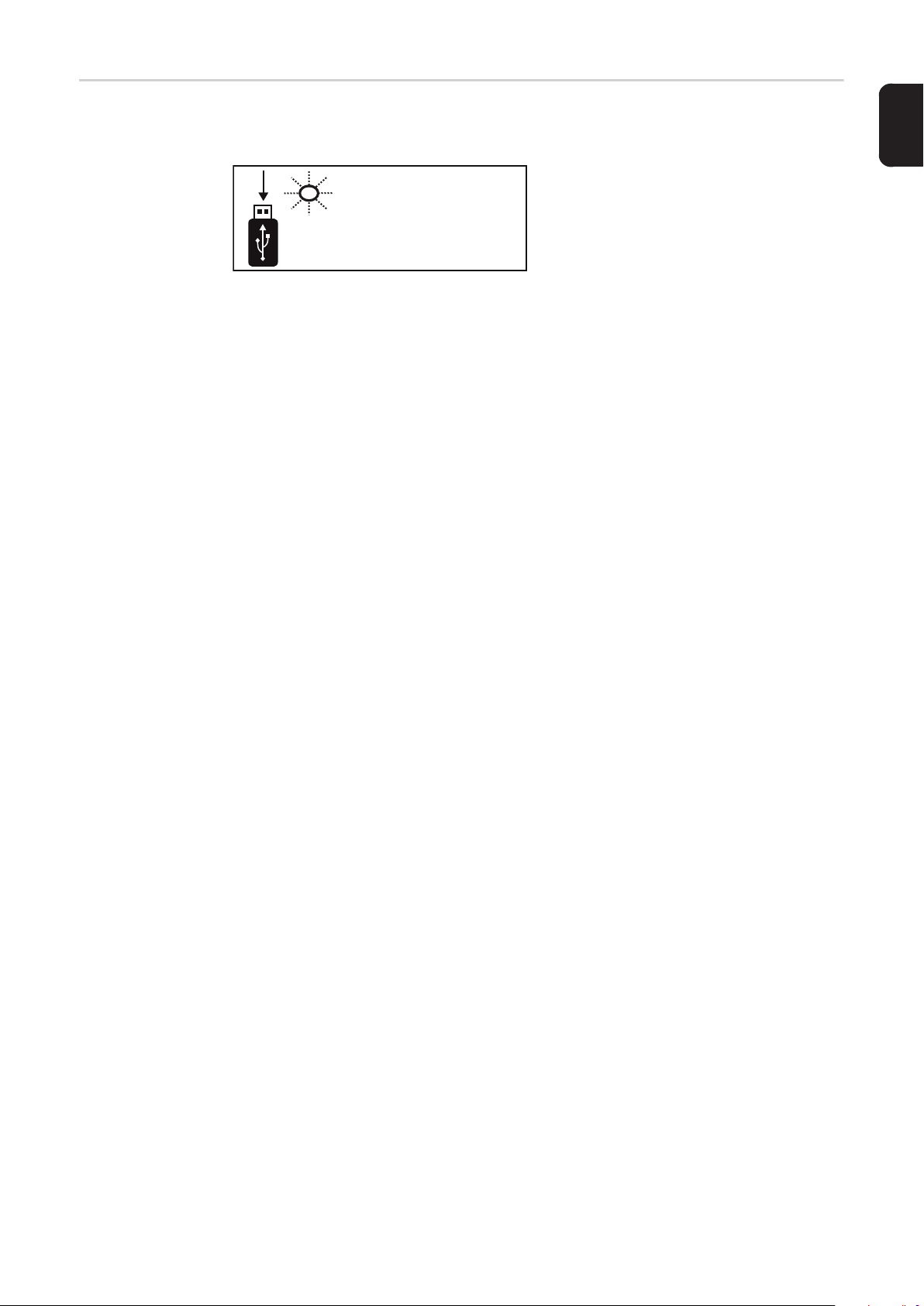

USB symbol on the inverter display, e.g. in display mode 'NOW':

If the inverter detects a USB flash drive,

the USB symbol will appear in the top right

corner of the display.

When inserting a USB flash drive, check

whether the USB symbol is displayed (it

may also flash).

USB stick for updating the inverter software

NOW

AC Output Power

NOTE! Please note for outdoor applications that conventional USB flash drives

are often only guaranteed to work within a restricted temperature range. For outdoor applications ensure that the USB flash drive also functions, for example, at

low temperatures.

With the help of the USB stick, end customers can also update the inverter software via the

USB item on the SETUP menu: the update file is first saved to the USB stick, from where

it is then transferred to the inverter. The update file must be saved in the root directory on

the USB stick.

24

Page 27

Remove USB

stick

Security note concerning the removal of a USB stick:

IMPORTANT! To avoid any loss of data, a

X

Do not disconnect

USB-Stick

while LED is flashing!

USB stick may only be removed if the following conditions are met:

- only remove a USB stick via the

'Safely remove USB / HW' item on the

SETUP menu

- the 'Data transmission' LED has

stopped flashing or comes on steady.

EN

25

Page 28

Notes regarding maintenance

Maintenance

Cleaning Clean the inverter and the display as required with a damp cloth.

Do not use cleaning agents, abrasives or solvents to clean the inverter.

NOTE! When installed outdoors in a horizontal position:

once a year, check that all screw joints are tight!

26

Page 29

EN

27

Page 30

Fronius Worldwide - www.fronius.com/addresses

Fronius International GmbH

4600 Wels, Froniusplatz 1, Austria

E-Mail: pv-sales@fronius.com

http://www.fronius.com

Under http://www.fronius.com/addresses you will find all addresses of our sales branches and partner firms!

Fronius USA LLC Solar Electronics Division

6797 Fronius Drive, Portage, IN 46368

E-Mail: pv-us@fronius.com

http://www.fronius-usa.com

Loading...

Loading...