/ Battery Charging Systems / Welding Technology / Solar Electronics

EN

Robacta TX options

Operating Instructions

System extension

42,0426,0109,EN 010-12082013

0

Dear reader,

Introduction Thank you for the trust you have placed in our company and congratulations on buying this

high-quality Fronius product. These instructions will help you familiarise yourself with the

product. Reading the instructions carefully will enable you to learn about the many different

features it has to offer. This will allow you to make full use of its advantages.

Please also note the safety rules to ensure greater safety when using the product. Careful

handling of the product will repay you with years of safe and reliable operation. These are

essential prerequisites for excellent results.

EN

1

2

Contents

Robacta TX cover 7

Safety......................................................................................................................................................... 9

Safety.................................................................................................................................................... 9

General ...................................................................................................................................................... 10

Device concept ..................................................................................................................................... 10

Scope of supply .................................................................................................................................... 10

Tools required ....................................................................................................................................... 10

Fitting the Robacta TX cover ..................................................................................................................... 11

Preparation ........................................................................................................................................... 11

Fitting the Robacta TX cover ................................................................................................................ 13

And finally... .......................................................................................................................................... 14

Locking the Robacta TX cover................................................................................................................... 15

Locking the cover.................................................................................................................................. 15

Robacta TX W with Robacta TX cover program sequence ....................................................................... 16

Safety.................................................................................................................................................... 16

General ................................................................................................................................................. 16

Speed data for the program sequence ................................................................................................. 16

Subprograms in the program sequence................................................................................................ 16

Program sequence................................................................................................................................ 17

Servicing the Robacta TX cover ................................................................................................................ 25

Weekly .................................................................................................................................................. 25

Yearly or after 30,000 torch neck changeover cycles ........................................................................... 25

EN

Pneumatic Robacta TX cover 29

Safety......................................................................................................................................................... 31

Safety.................................................................................................................................................... 31

General ...................................................................................................................................................... 32

Device concept ..................................................................................................................................... 32

Scope of supply .................................................................................................................................... 32

Tools required ....................................................................................................................................... 32

Commissioning the pneumatic Robacta TX cover ..................................................................................... 33

Preparation ........................................................................................................................................... 33

Fitting one pneumatic Robacta TX cover.............................................................................................. 34

Installing one pneumatic Robacta TX cover ......................................................................................... 35

Fitting two pneumatic Robacta TX covers ............................................................................................ 37

Installing two pneumatic Robacta TX covers ........................................................................................ 38

Checking the function of the pneumatic Robacta TX cover .................................................................. 39

Locking the pneumatic Robacta TX cover ................................................................................................. 41

Locking the cover.................................................................................................................................. 41

Robacta TX slide, Robacta TX slide XL 43

Safety......................................................................................................................................................... 45

Safety.................................................................................................................................................... 45

Fitting the Robacta TX slide....................................................................................................................... 46

Preparation ........................................................................................................................................... 46

Safety.................................................................................................................................................... 46

Fit the slide............................................................................................................................................ 46

And finally... .......................................................................................................................................... 47

Fitting the Robacta TX slide XL ................................................................................................................. 48

Preparation ........................................................................................................................................... 48

Safety.................................................................................................................................................... 48

Screw base to the underlying surface................................................................................................... 48

Fit the XL slide ...................................................................................................................................... 49

Fit the standard slide to the XL base .................................................................................................... 49

And finally... .......................................................................................................................................... 49

Commissioning the Robacta TX slide / Robacta TX slide XL .................................................................... 50

3

Placing a torch neck in the Robacta TX slide / Robacta TX slide XL.................................................... 50

Changing the program sequence to account for the Robacta TX slide / Robacta TX slide XL............. 50

Robacta TX W torch neck rack 53

Safety......................................................................................................................................................... 55

Safety.................................................................................................................................................... 55

Fitting a torch neck rack piece ................................................................................................................... 56

Scope of supply .................................................................................................................................... 56

Preparation ........................................................................................................................................... 56

Safety.................................................................................................................................................... 56

Fitting a torch neck rack piece .............................................................................................................. 56

And finally... .......................................................................................................................................... 57

Robacta TX G torch neck rack 59

Safety......................................................................................................................................................... 61

Safety.................................................................................................................................................... 61

Fitting a torch neck rack piece ................................................................................................................... 62

Scope of supply .................................................................................................................................... 62

Preparation ........................................................................................................................................... 62

Safety.................................................................................................................................................... 62

Fitting a torch neck rack piece .............................................................................................................. 62

And finally... .......................................................................................................................................... 63

Torch neck coding 65

Safety......................................................................................................................................................... 67

Safety.................................................................................................................................................... 67

Coding the torch neck ................................................................................................................................ 68

General ................................................................................................................................................. 68

Preparation ........................................................................................................................................... 68

Safety.................................................................................................................................................... 68

Coding the torch neck ........................................................................................................................... 69

And finally... .......................................................................................................................................... 70

Compressed air maintenance unit 71

Safety......................................................................................................................................................... 73

Safety.................................................................................................................................................... 73

General ...................................................................................................................................................... 74

General ................................................................................................................................................. 74

Scope of supply .................................................................................................................................... 74

Tools required ....................................................................................................................................... 74

Fitting the compressed air maintenance unit ............................................................................................. 75

Preparation ........................................................................................................................................... 75

Safety.................................................................................................................................................... 75

Fitting the compressed air maintenance unit ........................................................................................ 75

And finally... .......................................................................................................................................... 77

Wire cutter 79

Safety......................................................................................................................................................... 81

Safety.................................................................................................................................................... 81

Installing the wire cutter ............................................................................................................................. 82

Preparation ........................................................................................................................................... 82

Safety.................................................................................................................................................... 82

Installing the wire cutter ........................................................................................................................ 82

And finally... .......................................................................................................................................... 83

Welding torch cleaning devices 85

Safety......................................................................................................................................................... 87

Safety.................................................................................................................................................... 87

4

Installing the Robacta TC 1000.................................................................................................................. 88

General ................................................................................................................................................. 88

Preparation ........................................................................................................................................... 88

Safety.................................................................................................................................................... 88

Fitting the wire cutter............................................................................................................................. 88

Installing the welding torch cleaning device.......................................................................................... 89

And finally... .......................................................................................................................................... 89

Installing the Robacta Reamer V Easy, Robacta Reamer aluminium brush head..................................... 90

General ................................................................................................................................................. 90

Preparation ........................................................................................................................................... 90

Safety.................................................................................................................................................... 90

Installing the welding torch cleaning device.......................................................................................... 90

And finally... .......................................................................................................................................... 91

Installing the Robacta Reamer V ............................................................................................................... 92

Preparation ........................................................................................................................................... 92

Safety.................................................................................................................................................... 92

Installing the welding torch cleaning device.......................................................................................... 92

And finally... .......................................................................................................................................... 93

Mounting bracket for a TCP measurement unit 95

Safety......................................................................................................................................................... 97

Safety.................................................................................................................................................... 97

Mounting bracket for advintec standard ..................................................................................................... 98

Preparation ........................................................................................................................................... 98

Safety.................................................................................................................................................... 98

Fitting the mounting bracket.................................................................................................................. 98

And finally... .......................................................................................................................................... 99

Mounting bracket for advintec adjustable .................................................................................................. 100

Preparation ........................................................................................................................................... 100

Safety.................................................................................................................................................... 100

Fitting the mounting bracket.................................................................................................................. 100

And finally... .......................................................................................................................................... 101

EN

5

6

Robacta TX cover

Safety

Safety Observe the following safety rules for all work described in the "Robacta TX cover" section.

WARNING! Incorrect operation or shoddy workmanship can cause serious injury

or damage. All activities described in these operating instructions may only be

carried out by trained and qualified personnel. All functions described in these operating instructions may only be used by trained and qualified personnel. Do not

carry out any of the work or use any of the functions described until you have fully

read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

WARNING! Machines that start up automatically can cause serious injury and

damage. In addition to these operating instructions, the safety rules issued by the

manufacturers of the robot and welding systems must also be observed. For your

personal safety, ensure that all protective measures have been taken and will remain in place while you are in the working area of the robot.

WARNING! Risk of severe injury from the robot arm. Ensure there is no one else

within the working area of the robot whenever work is carried out.

EN

WARNING! Work that is carried out incorrectly can cause serious injury or dam-

age. Before starting work:

- turn the power source mains switch to the "O" position

- disconnect the power source from the mains

- put up an easy-to-understand warning sign to stop anybody inadvertently

switching it back on again

CAUTION! Risk of injury from sharp flying parts. During the work described below, always wear the following protective equipment:

- protective goggles with side protection

- ear protection

- gloves - electrically insulated and providing protection against heat

CAUTION! Risk of burns from hot torch neck, hot torch neck coupling and other

hot welding torch components. Before carrying out work, allow the torch neck,

torch neck coupling and all other welding torch components to cool down to room

temperature (+25 °C, +77 °F).

9

General

Device concept The Robacta TX cover shields all the torch neck rack pieces on the torch neck changeover

station. To facilitate work on the torch neck rack pieces, the cover can be fixed in place by

a locking bolt. An integral sensor monitors the position of the cover.

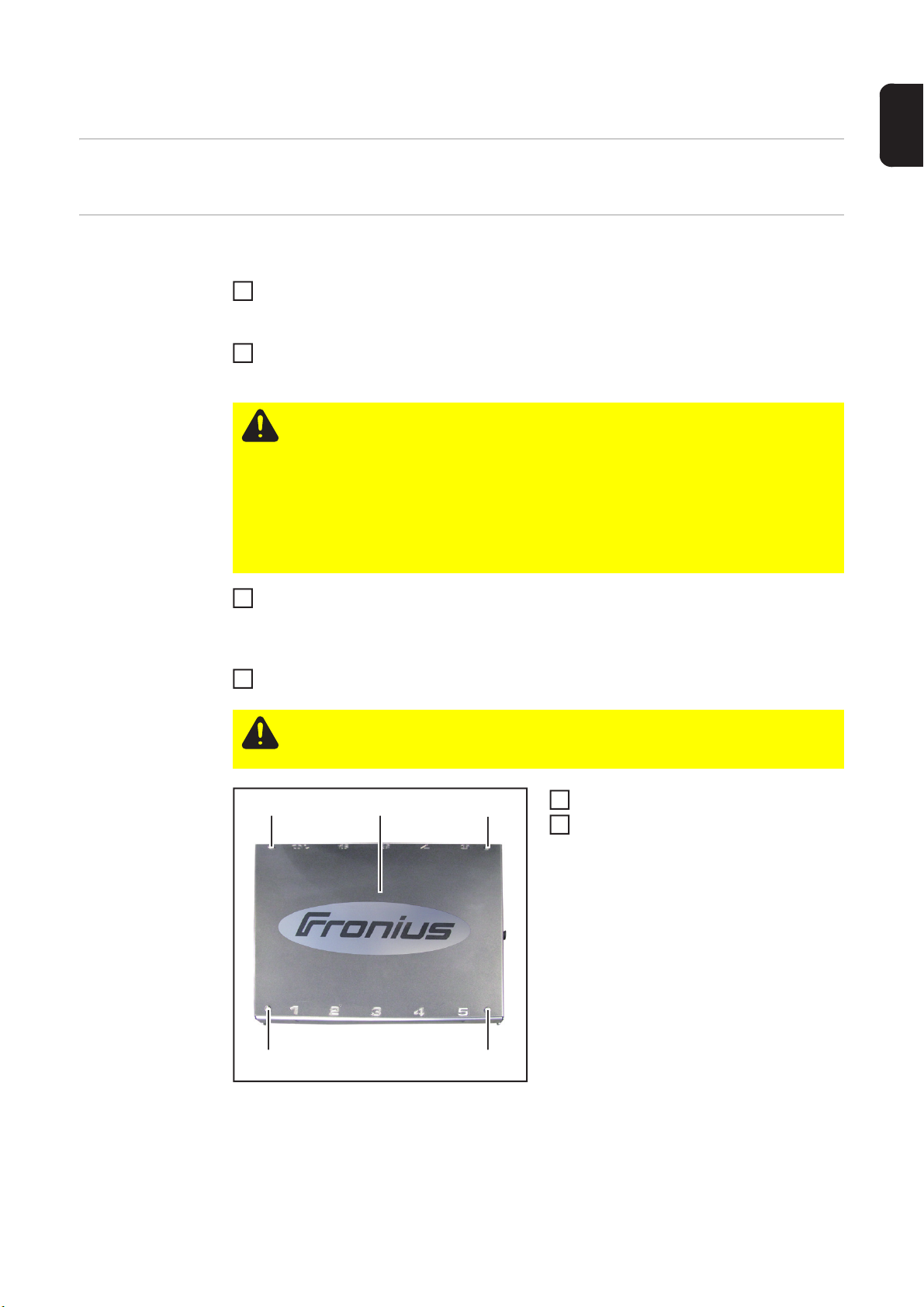

Scope of supply

(1)

(2)

(3)

(1) Robacta TX cover

(2) Wire sensor fitting panel

(3) 2x M5 x 16 mm Allen screws

(4) 4x A5 washers

(5) 2x M5 self-locking hexagonal nuts

(6) 4x M10 hexagon bolts with 1.25

fine-pitch thread

Tools required - TX 25 Torx screwdriver

- Box spanner, size 17

- Box spanner, size 8

- 8 mm Allen key

- 4 mm Allen key

- 2.5 mm Allen key

(4)

(5)

(6)

10

Fitting the Robacta TX cover

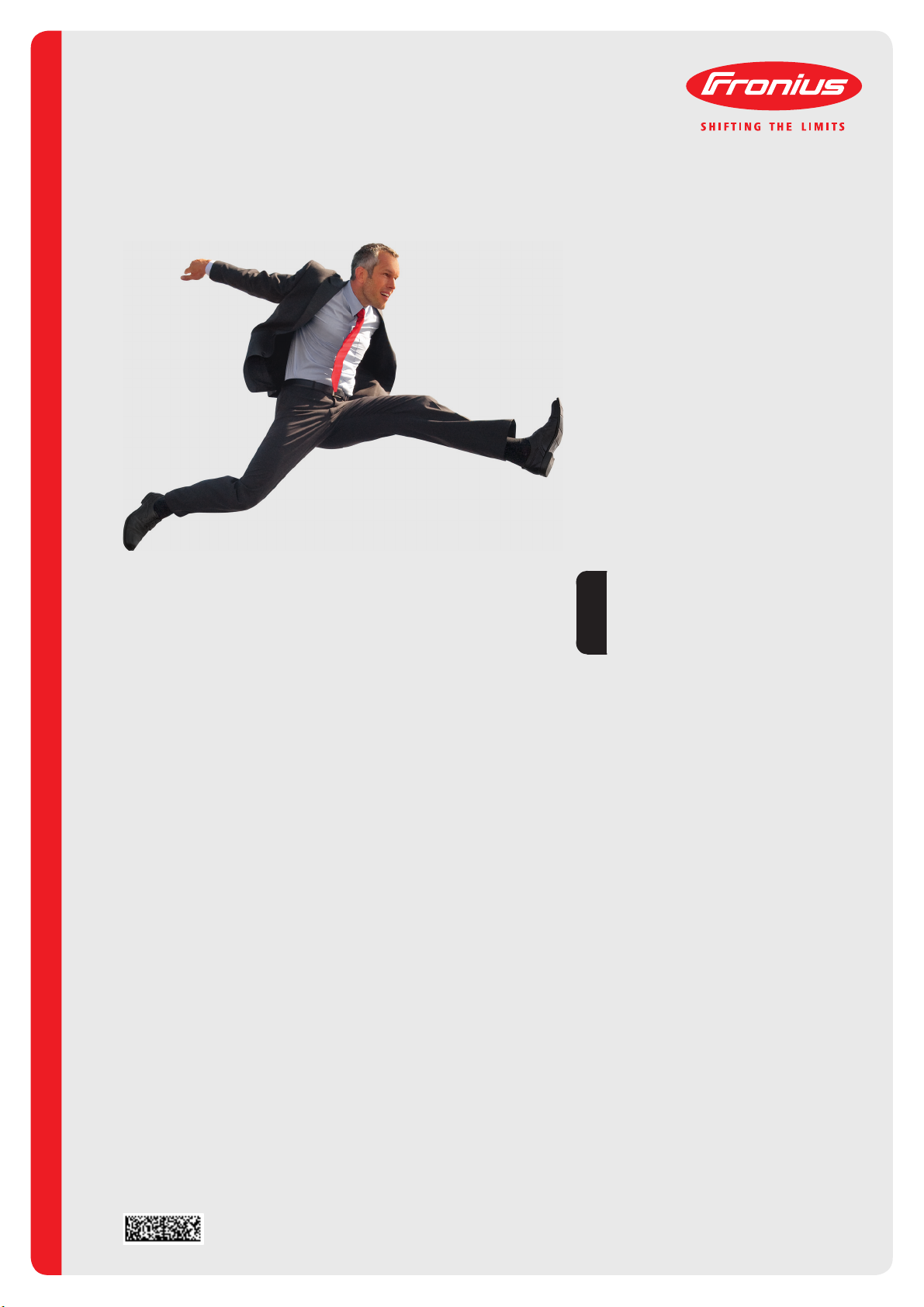

1

(1)

Preparation Depressurise the compressed air line of the torch neck changeover station and ensure

that this compressed air line remains depressurised for the duration of the work on the

device

Disconnect the compressed air line from compressed air connection "A" on the torch

2

neck changeover station

CAUTION! Risk of injury from escaping compressed air from compressed air

connection "A". Compressed air emerges at up to 16 bar (232.06 psi) from compressed air connection "A" when the Unlock/Lock button is pressed. While compressed air is emerging from compressed air connection "A":

- wear ear protection

- keep the face and all other body parts away from compressed air connection

"A"

- ensure that no other persons are in the vicinity of the torch neck changeover

station

Press and hold the Unlock/Lock button on the torch neck changeover station until

3

compressed air no longer emerges from compressed air connection "A" on the torch

neck changeover station

- compressed-air booster unit in the torch neck changeover station discharges

De-energise the torch neck changeover station

4

EN

CAUTION! Risk of injury from compressed air escaping unintentionally. The torch

neck changeover station must remain depressurised and de-energised until all

work is completed.

Undo screws (1)

5

Keep screws, nuts and washers for la-

6

ter use

11

Fit the wire sensor mounting plate (2)

(3)

(2)

7

as shown, using

- 2x M5 x 16 mm screws (3)

- 4x A5 washers

- 2x M5 self-locking hexagonal nuts

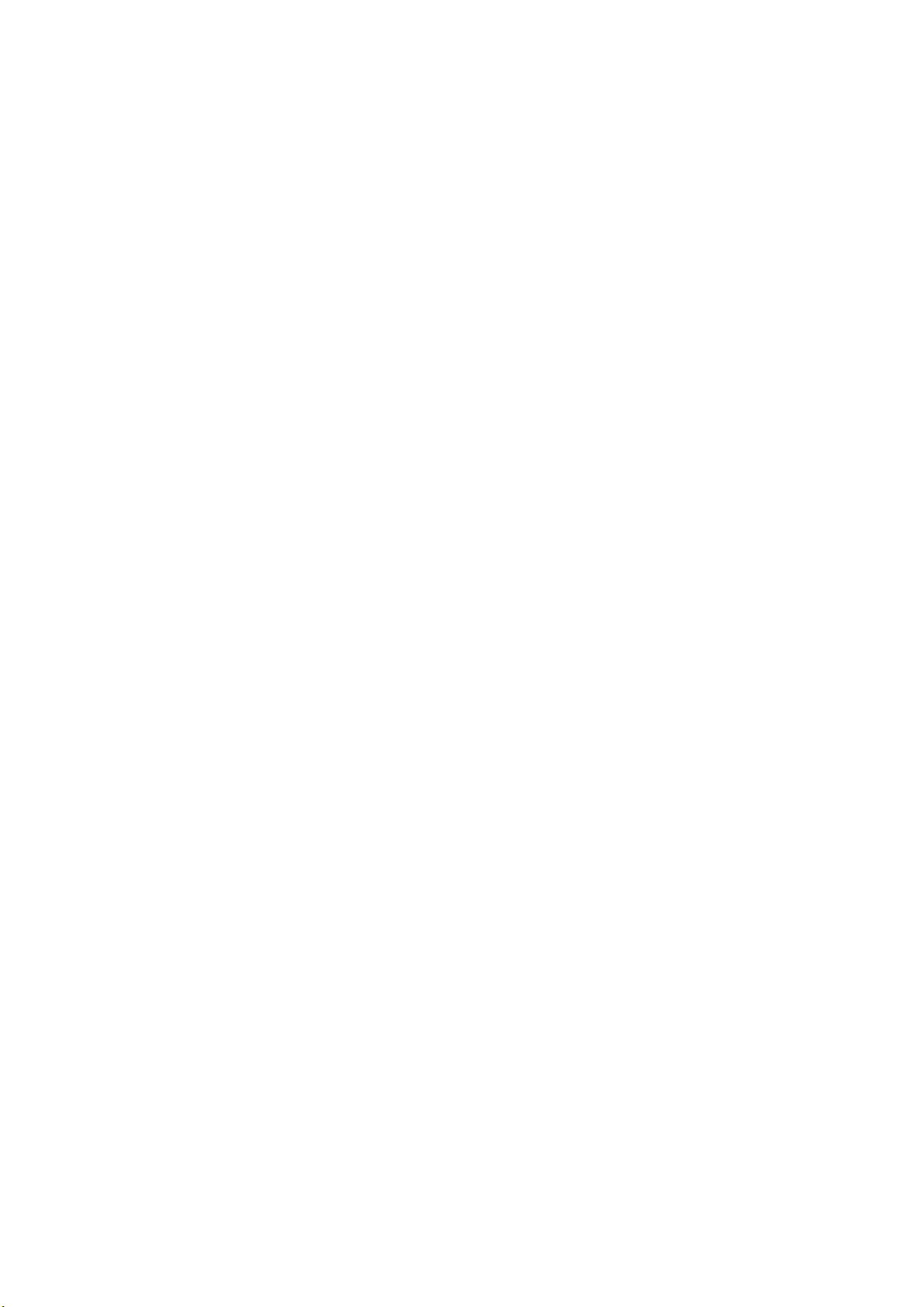

Secure the wire sensor (4) to the wire

8

sensor mounting plate as shown

(5) (6)

(5)

(5)(5)

(4)

Undo screws (5)

9

Remove the cover lid (6)

10

12

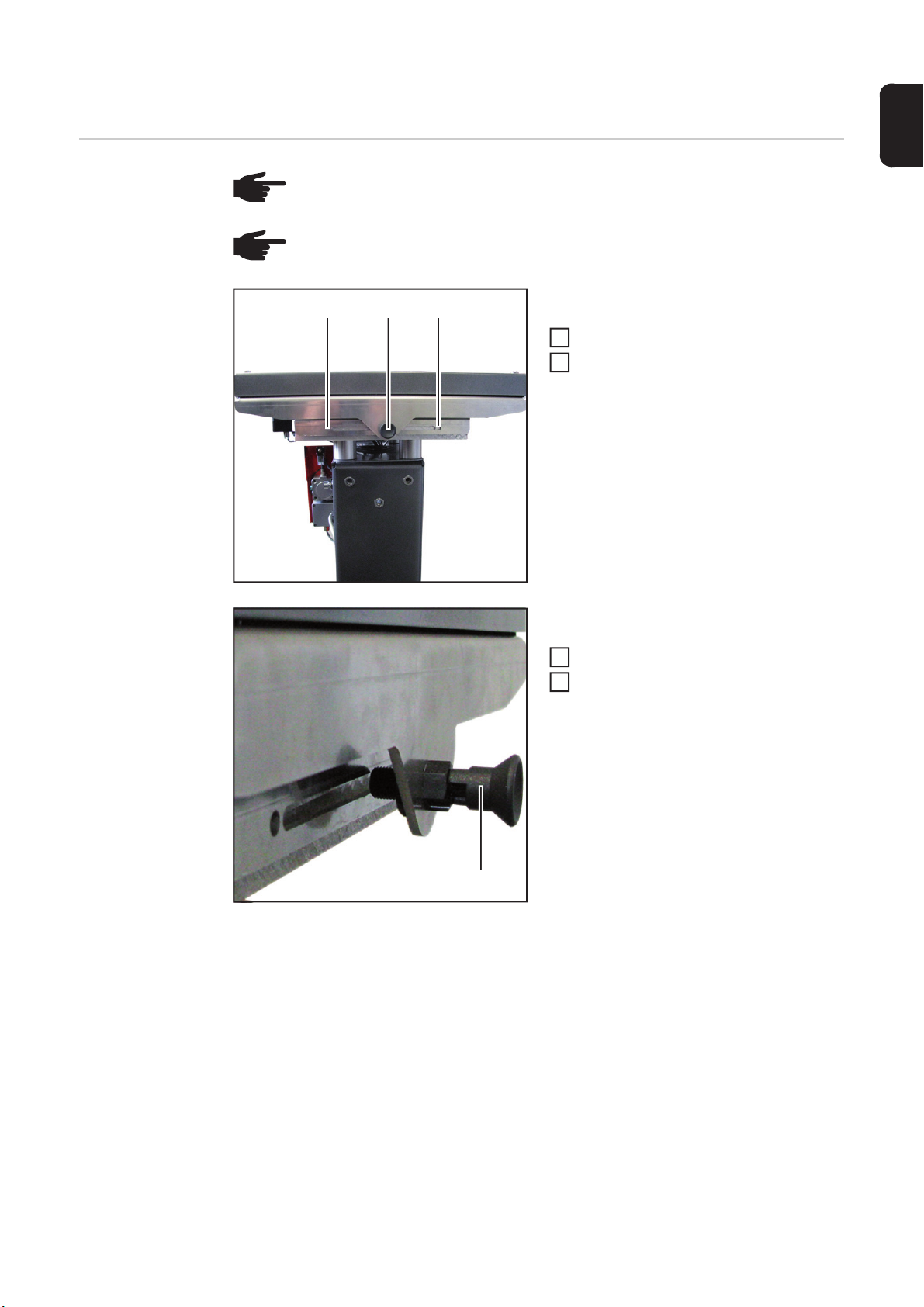

Fitting the Robac-

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(3)

2

ta TX cover

(1)

Undo the 8 screws (2)

1

Remove lid (3)

Place the cover onto the torch neck

3

changeover station in such a way that

the Robacta TX cover sensor (1) is on

the same side of the torch neck changeover station as the wire sensor

EN

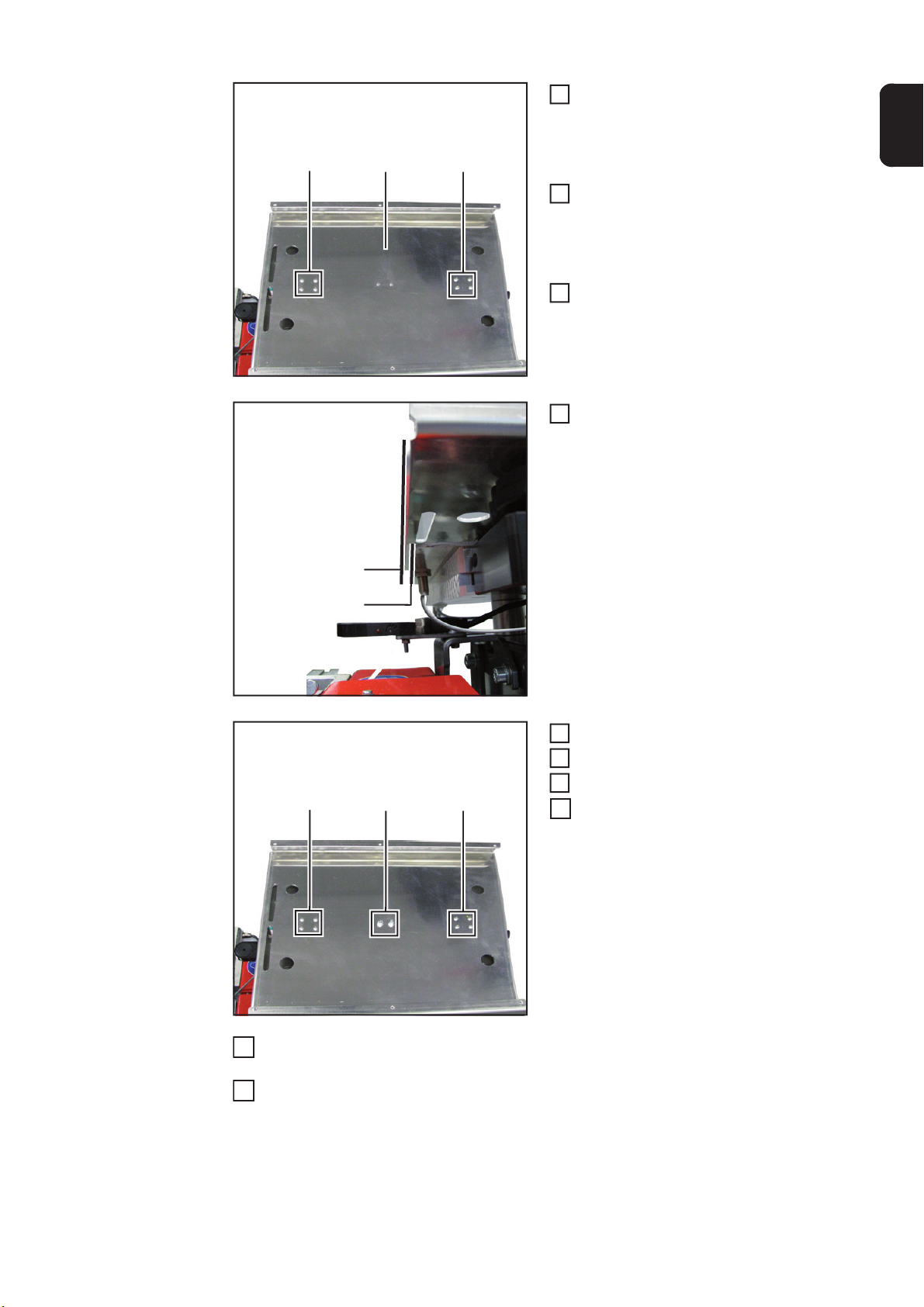

Underside of cover

(3) (3)(2)

Insert four M10 screws into the holes

4

(3) and secure the cover in place

(3)(3)

13

(4) (5)

5

Guide the sensor cable (4) through the

5

housing opening (5)

Connect the sensor plug to connection

6

X14 on the PC board in the torch neck

changeover station

Fit the lid for the Robacta TX cover

7

onto the subframe of the Robacta TX

cover

Fit the torch neck changeover station

8

cover onto the torch neck changeover

station

And finally...

Attempt to move the cover back and

1

forth

- the cover must be easy to move

Establish the power supply to the torch

2

neck changeover station

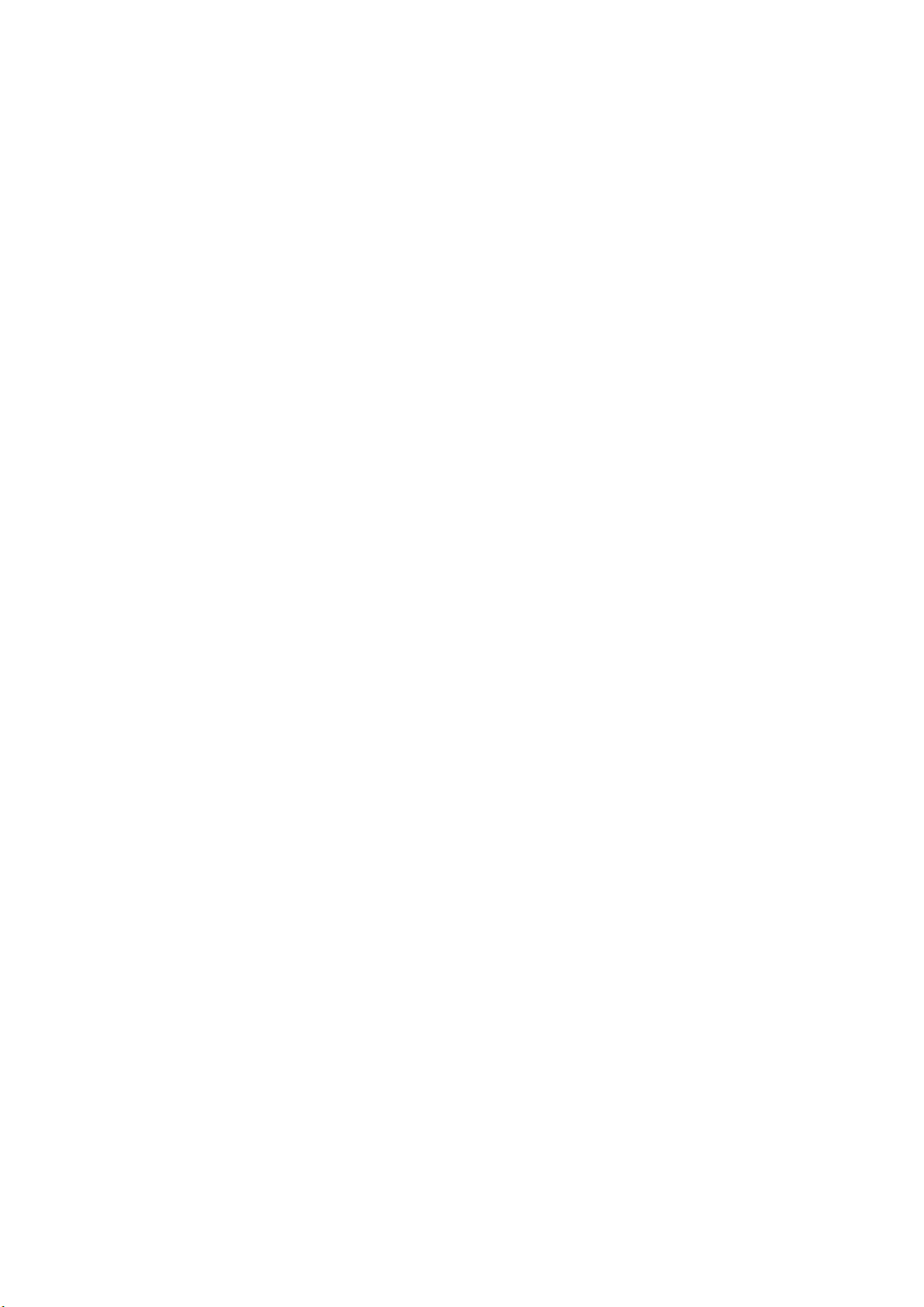

When the cover is in a central position:

- the LED (1) on the base of the sensor

lights up

- a signal is sent to the robot control

When the cover is not in a central position:

- the LED (1) on the base of the sensor

does not light up

(1)

Connect the compressed air line to compressed air connection "A" on the torch neck

3

changeover station

Establish the compressed air supply to the torch neck changeover station

4

Change the position of the wire sensor in the robot program

NOTE! After fitting the cover, program the robot with the Robacta TX W with Robacta TX cover program sequence

- no signal is sent to the robot control

14

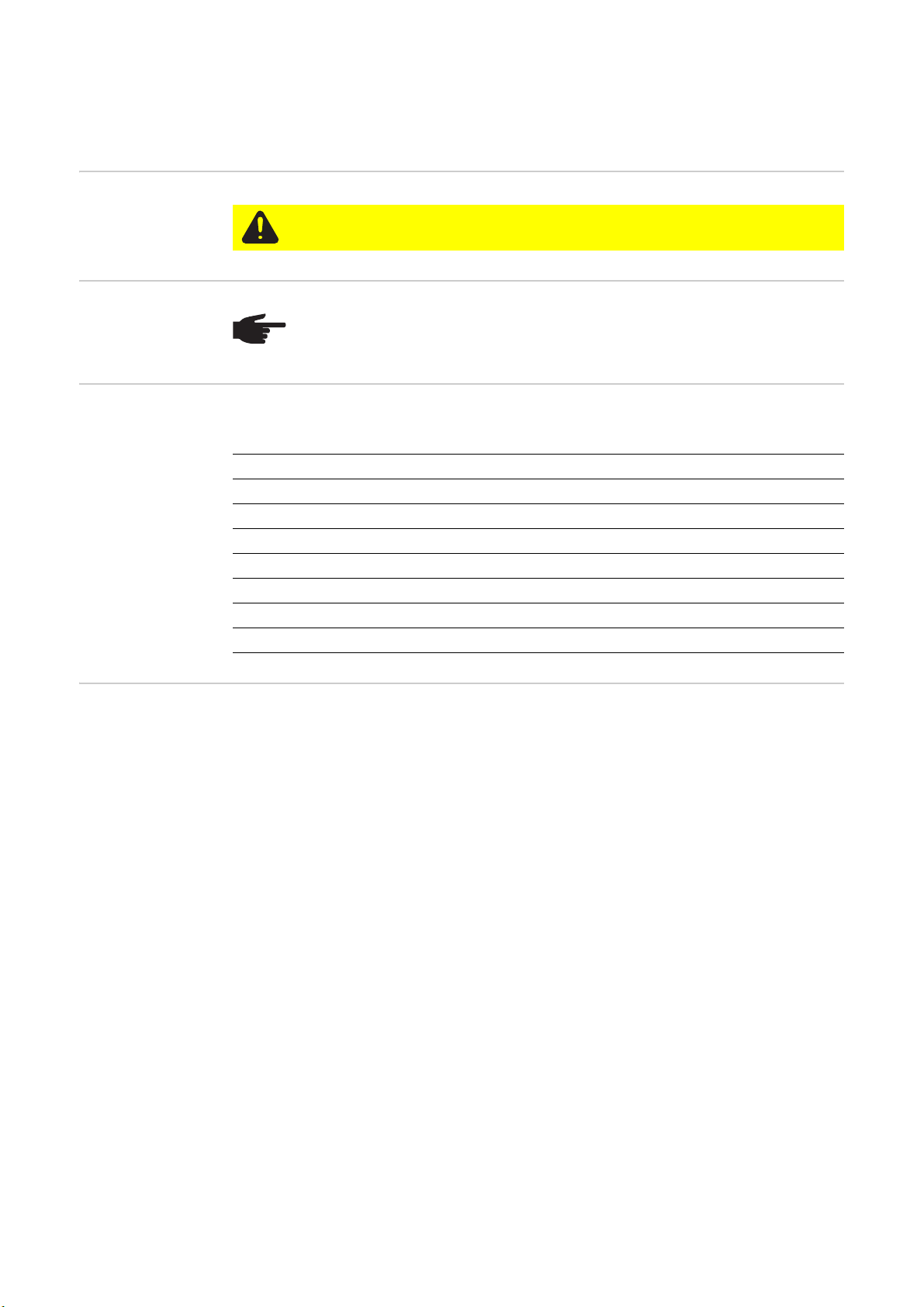

Locking the Robacta TX cover

1

2

EN

Locking the cover

NOTE! Do not lock the cover while the torch neck changeover station is in use.

NOTE! Ensure that the cover locking bolt remains in the operating position while

the torch neck changeover station is in use.

(2) (2)(1)

Lock the cover as follows

Push the cover to the desired side

Allow the locking bolt (1) to latch in the

2

respective locking hole (2)

(1)

To unlock, proceed as follows

Hold the cover

1

Remove the locking bolt (1) from the

locking hole and move to the position

shown

- the locking bolt is in the operating

position

15

Robacta TX W with Robacta TX cover program sequence

Safety

General

Speed data for

the program sequence

CAUTION! Risk of damage. Do not start in automatic mode until the torch neck

changeover station has been properly installed and started up.

NOTE! After fitting the cover, program the robot with the following program sequence.

A list of all speeds and corresponding units in the program sequence:

cm/min m/s ipm

1000 = 0.17 = 393.70

600 = 0.1 = 236.22

100 = 0.017 = 39.37

70 = 0.012 = 27.56

50 = 0.008 = 19.69

35 = 0.006 = 13.78

30 = 0.005 = 11.81

Subprograms in

the program sequence

To facilitate programming, the program sequence is split into the following subprograms:

- Cut wire electrode

- Wind back wire electrode

- Set down torch neck

- Pick up torch neck

- Advance wire electrode

- Cut wire electrode

16

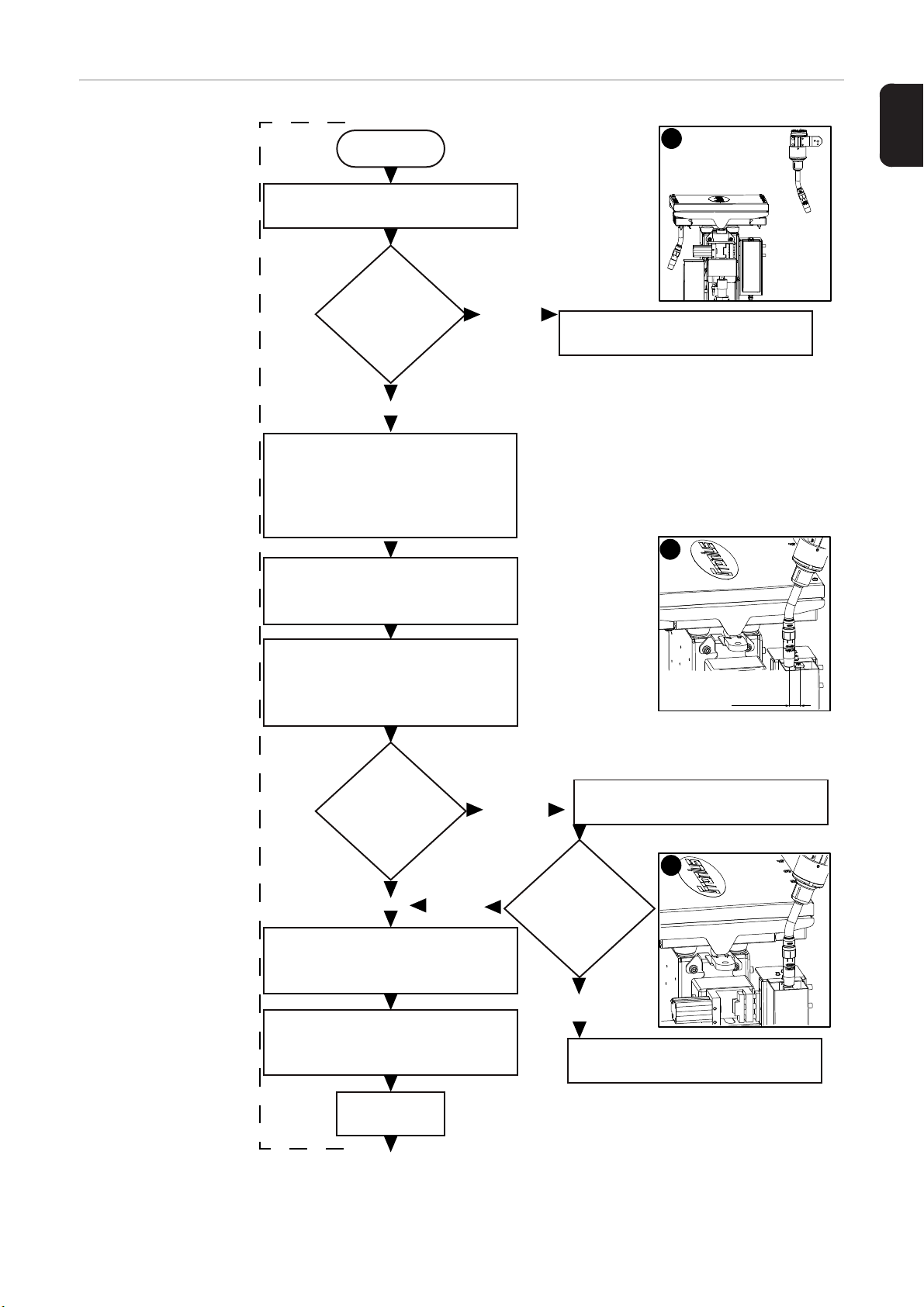

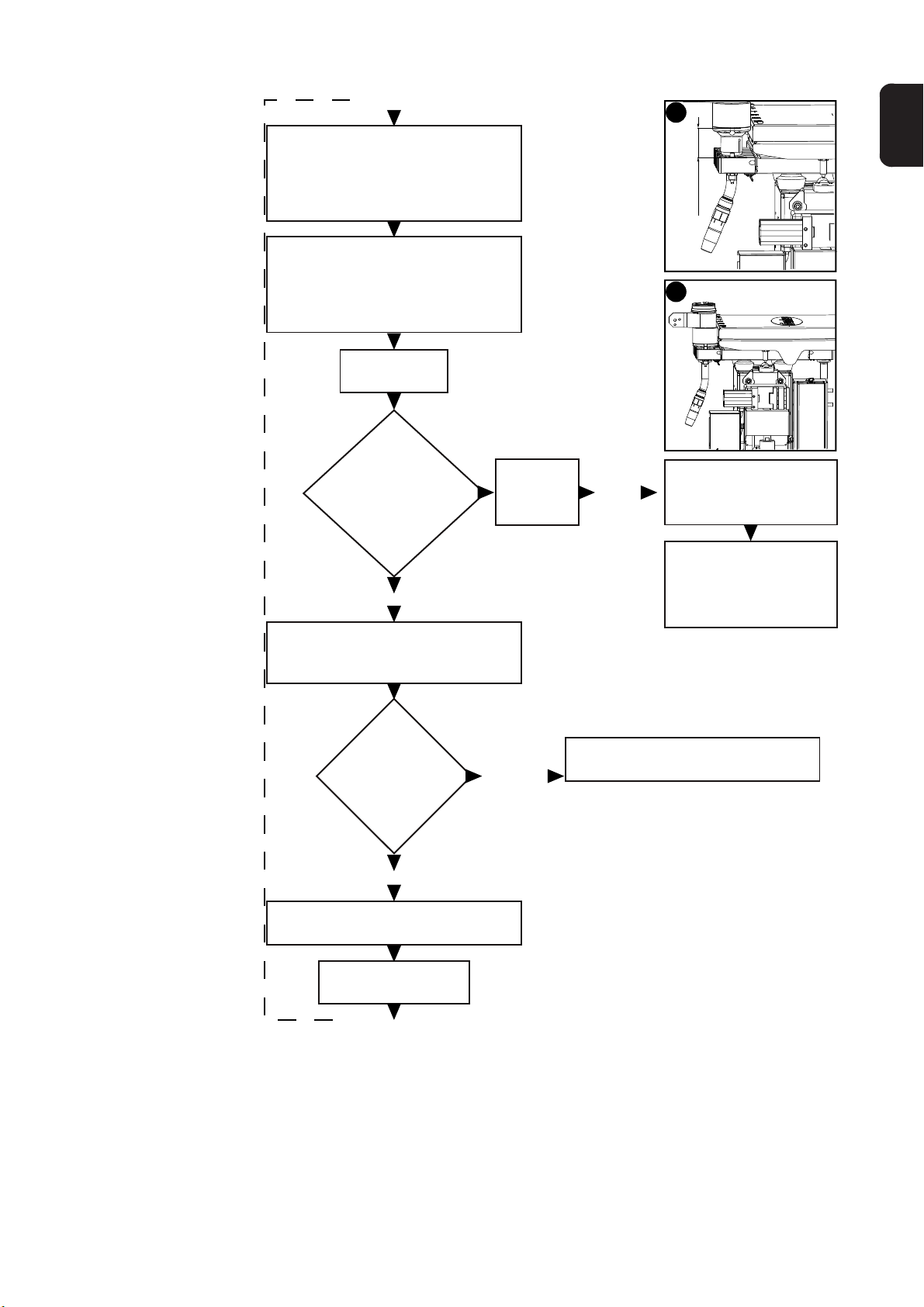

Program se-

Wait 0.5

seconds

Move to pos. A

- above torch neck rack

Program stop

- power source error

Reset

- wire cutter signal

Program stop

- wire cutter error

Move to pos. B

- approx. 25 mm (0.98 in.) next

to wire cutter

Set

- select job to advance

wire electrode

- wire threading speed:

600 cm/min (236.22 ipm)

Move to pos. C

- enter wire cutter

Set

- cut wire electrode signal

Set

- advance wire electrode signal

- duration of signal: 2 seconds

Start

Query

- power

source ready

Query

- wire

cutter open

Query

- wire

cutter open

'False'

'True'

'True'

'False'

'True'

'False'

Cut wire electrode

A

B

25 mm

0.98 in.

C

quence

EN

17

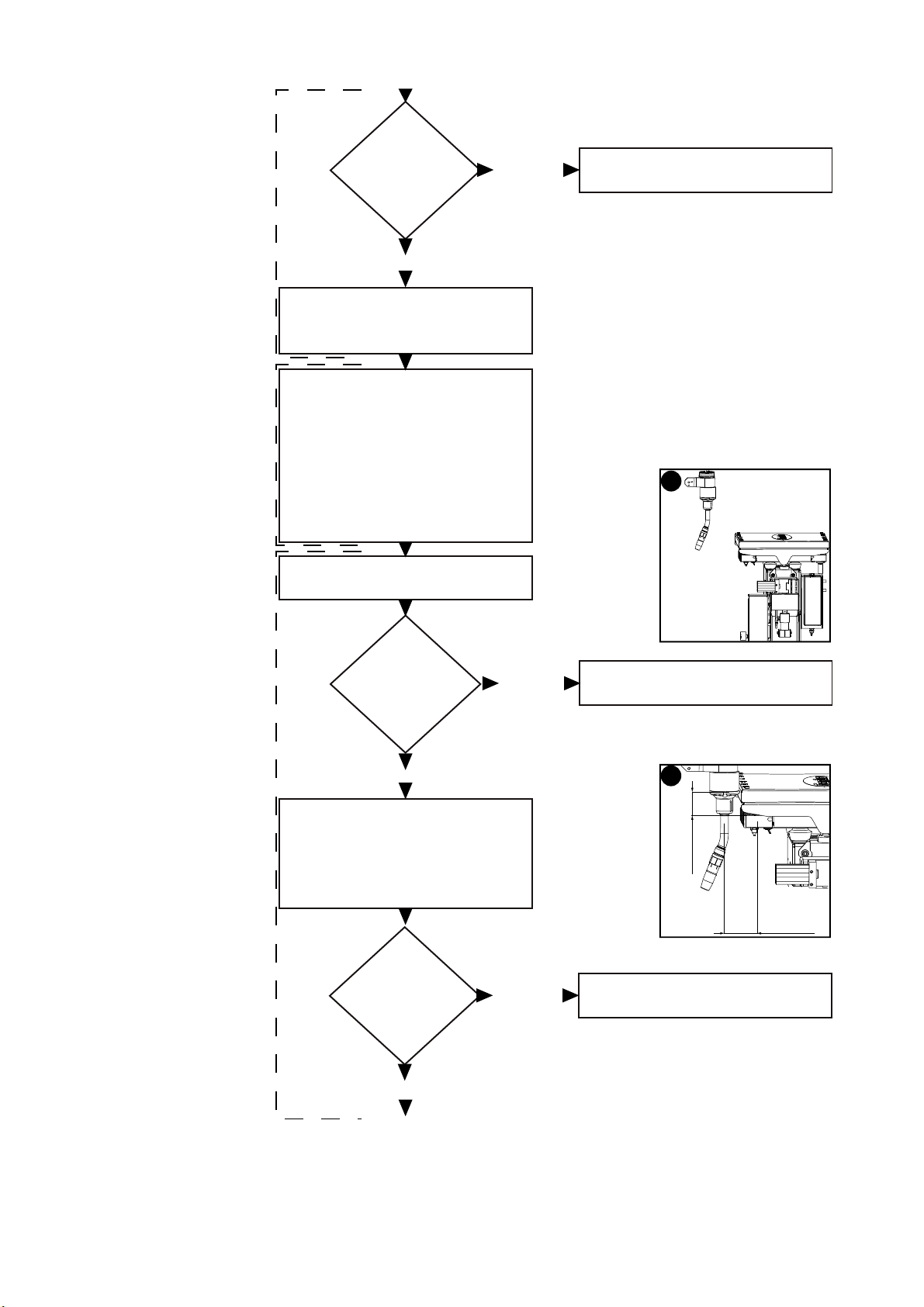

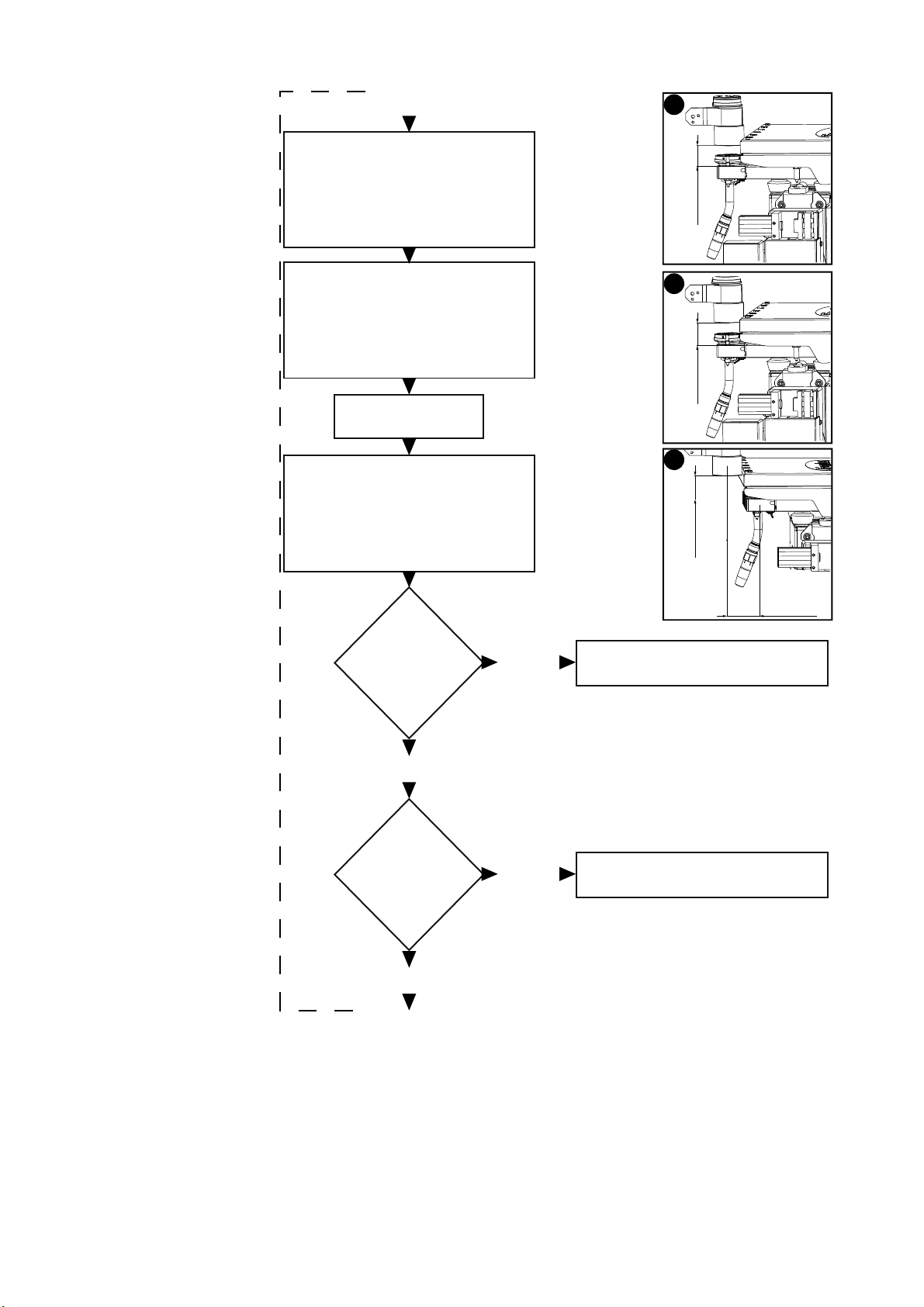

Query

- wire cutter

closed

'False'

Program stop

- wire cutter error

(continued)

Cut wire electrode

- cut wire electrode signal

- rewind wire electrode signal

- rewind wire electrode until

behind coupling point

Rewind wire electrode

- wire threading speed:

600 cm/min (236.22 ipm)

- duration of signal: calculated

using torch neck length

above rack positions

'True'

Reset

Move to pos. D

Query

- torch neck

sensor

Set

'True'

D

Program stop

- torch neck change error

'False'

Move to pos. E

- 70 mm (2.76 in.) next to middle

of torch neck rack

- 40 mm (1.57 in.) above top of

torch neck rack

Set down torch neck

Query

- Robacta TX

cover

'True'

'False'

E

40 mm

1.57 in.

70 mm

2.76 in.

Program stop

- torch neck change error

18

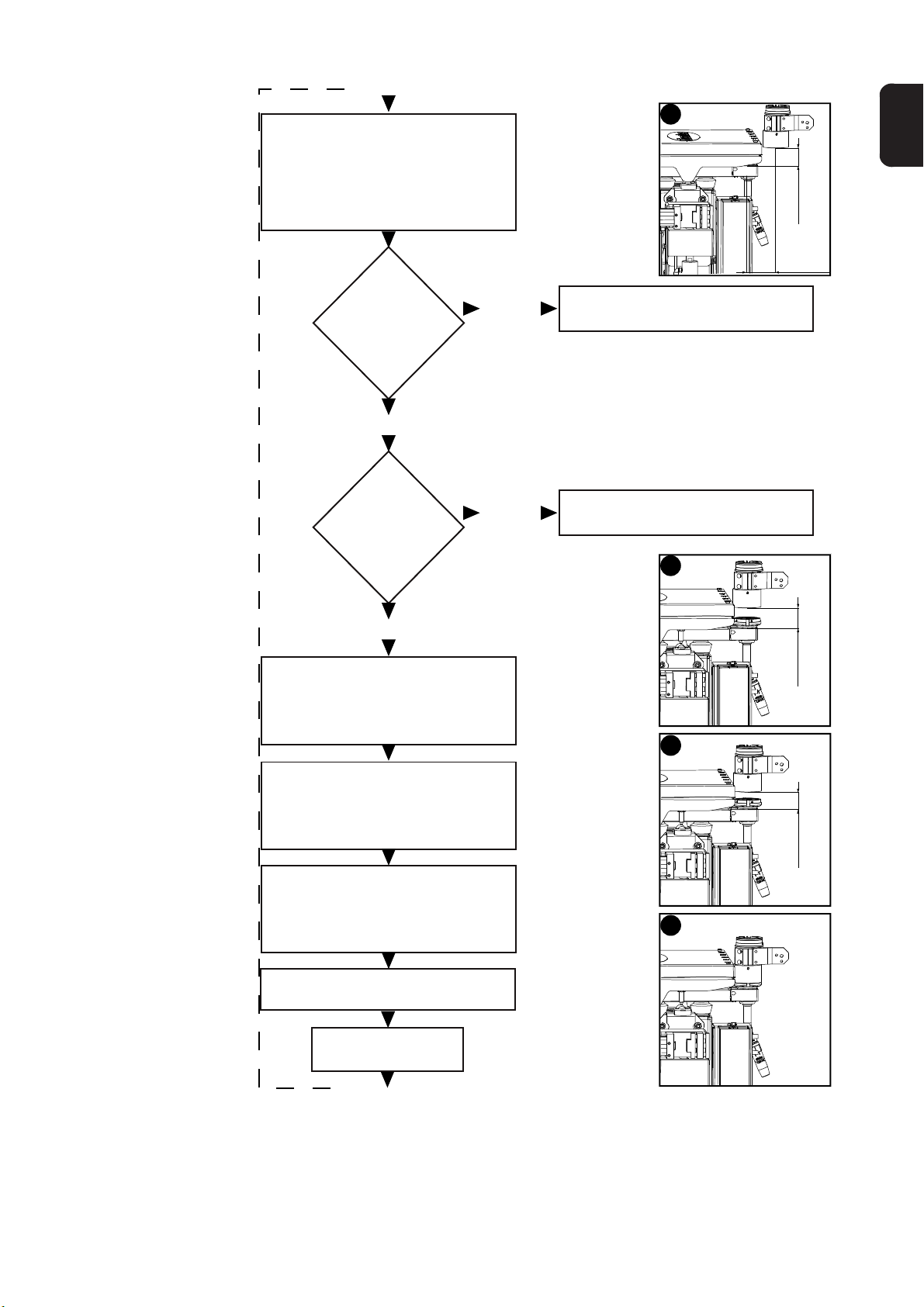

Move to pos. F

- move 40 mm (1.57 in.) above

middle of torch neck rack

- speed:

max. 100 cm/min (39.37 ipm)

Move to pos. G

- move down into torch neck

rack

- speed:

max. 50 cm/min (19.69 ipm)

Wait 0.5

seconds

Query

- torch neck

sensor (torch neck

picked up

flush)

Wait 5

seconds

'False'

F

40 mm

1.57 in.

G

Stop

- enter torch neck rack

EN

'True'

Stop

- enter torch neck rack

Set down torch neck (continued)

Query

- pressure switch

'True'

Set

- change torch neck signal

Wait 1.5

seconds

'False'

Program stop

- torch neck change

error

Program stop

- torch neck change error

19

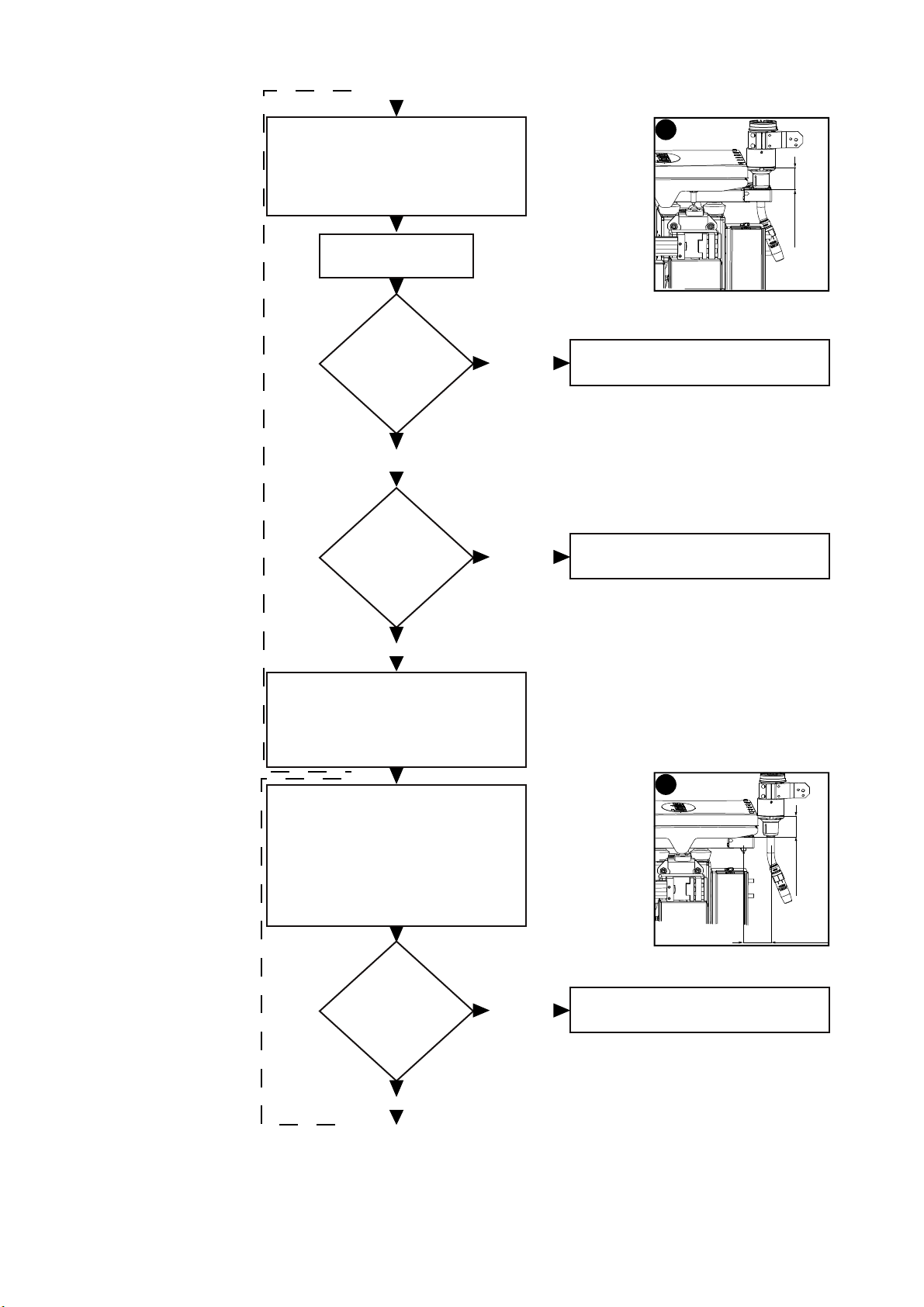

Move to pos. H

- raise 15 mm (0.59 in.) above

middle of torch neck rack

- speed:

max. 30 cm/min (11.81 ipm)

H

15 mm

0.59 in.

Move to pos. I

- raise 40 mm (1.57 in.) above

middle of torch neck rack

- speed: high

Wait 0.5

seconds

Move to pos. J

- 70 mm (2.76 in.) next to middle

of torch neck rack

- 40 mm (1.57 in.) above top of

torch neck rack

(continued)

Set down torch neck

Query

Robacta TX

cover

'False'

I

40 mm

1.57 in.

J

40 mm

1.57 in.

Program stop

- torch neck change error

70 mm

2.76 in.

'True'

Query

- torch neck

sensor

'False'

'True'

Program stop

- torch neck change error

20

Move to pos. K

- 70 mm (2.76 in.) next to middle

of torch neck rack

- 40 mm (1.57 in.) above top of

torch neck rack

K

EN

40 mm

1.57 in.

70 mm

2.76 in.

Query

- Robacta TX

cover

'True'

Query

- torch neck

sensor

'True'

Pick up torch neck

Move to pos. L

- 40 mm (1.57 in.) above middle

of torch neck to be picked up

'False'

'False'

Program stop

- torch neck change error

Program stop

- torch neck change error

L

40 mm

1.57 in.

Move to pos. M

- 15 mm (0.59 in.) above middle

of torch neck to be picked up

Move to pos. N

- pick up torch neck flush

max. 70 cm/min (27.56 ipm)

- change torch neck signal

- speed:

Reset

Wait 3 - 4

seconds

M

N

15 mm

0.59 in.

21

Move to pos. R

- raise 40 mm (1.57 in.) above

middle of torch neck rack

- speed: high

Wait 0.5

seconds

R

40 mm

1.57 in.

Query

- torch neck

sensor

'False'

Query

pressure switch

Pick up torch neck (continued)

- power source reset error (only if

using a flow sensor)

- 40 mm (1.57 in.) above top of

- 70 mm (2.76 in.) next to middle

1000 cm/min (393.70 ipm)

'True'

Set

Move to pos. S

torch neck rack

of torch neck rack

- speed: max.

Advance wire electrode

'True'

'False'

Program stop

- torch neck change error

Program stop

- torch neck change error

S

40 mm

70 mm

2.76 in.

1.57 in.

22

Query

- Robacta TX

cover

'True'

'False'

Program stop

- torch neck change error

Advance wire electrode (continued)

'True'

Cut wire electrode

Wait 15

seconds

Reset

- advance wire

electrode signal

Program stop

- torch neck change

error

Reset

- wire cutter signal

Program stop

- wire cutter error

Move to pos. Q

- align gas nozzle approx. 10 mm

(0.39 in.) centrally above wire

sensor

Set

- advance wire electrode signal

- wire threading speed:

600 cm/min (236.22 ipm)

Reset

- advance wire electrode signal

Move to pos. B

- approx. 25 mm (0.98 in.) next

to wire cutter

Set

- advance wire electrode signal

- duration of signal: 1 second

'False'

'True'

Query

- wire cutter

open

Query

- wire cutter

open

'False'

Query

wire sensor

'False'

'True'

Q

10 mm

0.39 in.

B

25 mm

0.98 in.

EN

23

Move to pos. C

- enter wire cutter

Set

- cut wire electrode signal

Reset

- cut wire electrode signal

Wait 0.5

seconds

Program stop

- wire cutter error

Query

- wire cutter

closed

'False'

'True'

Program stop

- torch neck change error

Query

- power source

ready

'False'

'True'

Cut wire electrode (continued)

End

C

24

Servicing the Robacta TX cover

2

(1) (2)

(1)

(1)(1)

Weekly Check the cover for damage

EN

Yearly or after

30,000 torch neck

changeover cycles

Clean and lubricate the profiled rail guides:

Depressurise the compressed air line of the torch neck changeover station and ensure

1

that this compressed air line remains depressurised for the duration of the work on the

device

Disconnect the compressed air line from compressed air connection "A" on the torch

neck changeover station

CAUTION! Risk of injury from escaping compressed air from compressed air

connection "A". Compressed air emerges at up to 16 bar (232.06 psi) from compressed air connection "A" when the Unlock/Lock button is pressed. While compressed air is emerging from compressed air connection "A":

- wear ear protection

- keep the face and all other body parts away from compressed air connection

"A"

- ensure that no other persons are in the vicinity of the torch neck changeover

station

Press and hold the Unlock/Lock button on the torch neck changeover station until

3

compressed air no longer emerges from compressed air connection "A" on the torch

neck changeover station

- compressed-air booster unit in the torch neck changeover station discharges

De-energise the torch neck changeover station

4

CAUTION! Risk of injury from compressed air escaping unintentionally. The torch

neck changeover station must remain depressurised and de-energised until all

work is completed.

Undo screws (1)

5

Remove the lid (2)

6

25

Undo screws (3) and (4)

8

(9)(9)

7

Remove cover plate (5)

(6)

(3) (4)

(7)

(5)

(8)

(3)

(6)

Clean the profiled rails (6)

9

Clean the centring spindle (7)

10

Clean the centring carriage (8)

11

11

Lubricate the profiled rails (6)

12

Move the trolleys (9) up and down the

13

profiled rails to distribute the lubricant

26

(10) (11)

(12)

(13)

17

(10) (14)

(10)

20

21

22

23

(10)

Screw in the eight screws with

14

washers (10), tighten slightly

- the cover plate (11) must still be

able to move on the profiled rail

trolleys

Move the cover plate as far as it will go

15

in one direction

- this aligns the cover plate and the

profiled rail trolleys with each

other

Once the trolleys and cover plate are

16

aligned, tighten the screws (10) to fix

the cover plate in this position

Check whether the edges (12) and (13)

are parallel to each other

- if not, undo the screws (10) and

align the cover plate again

EN

Tighten screws and washers (10)

18

Tighten screws and washers (14)

19

Fit the lid

Check the cover is functioning correctly

Connect the compressed air line to compressed air connection "A" on the torch neck

changeover station

Establish the compressed air and power supply to the torch neck changeover station

27

28

Pneumatic Robacta TX cover

Safety

Safety Observe the following safety rules for all work described in the "Pneumatic Robacta TX

cover" section.

WARNING! Incorrect operation or shoddy workmanship can cause serious injury

or damage. All activities described in these operating instructions may only be

carried out by trained and qualified personnel. All functions described in these operating instructions may only be used by trained and qualified personnel. Do not

carry out any of the work or use any of the functions described until you have fully

read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

WARNING! Machines that start up automatically can cause serious injury and

damage. In addition to these operating instructions, the safety rules issued by the

manufacturers of the robot and welding systems must also be observed. For your

personal safety, ensure that all protective measures have been taken and will remain in place while you are in the working area of the robot.

WARNING! Risk of severe injury from the robot arm. Ensure there is no one else

within the working area of the robot whenever work is carried out.

EN

WARNING! Work that is carried out incorrectly can cause serious injury or dam-

age. Before starting work:

- turn the power source mains switch to the "O" position

- disconnect the power source from the mains

- put up an easy-to-understand warning sign to stop anybody inadvertently

switching it back on again

CAUTION! Risk of injury from sharp flying parts. During the work described below, always wear the following protective equipment:

- protective goggles with side protection

- ear protection

- gloves - electrically insulated and providing protection against heat

CAUTION! Risk of burns from hot torch neck, hot torch neck coupling and other

hot welding torch components. Before carrying out work, allow the torch neck,

torch neck coupling and all other welding torch components to cool down to room

temperature (+25 °C, +77 °F).

31

General

(1)

Device concept The pneumatic Robacta TX cover shields up to five torch neck rack pieces on one side of

the torch neck changeover station rack holder. A signal from the robot control opens and

closes the cover. An integral sensor monitors the position of the cover. Two covers are

needed to shield both sides of the rack holder.

Scope of supply

(2)

(3)

(1) Pneumatic Robacta TX cover

(2) Compressed air line

(3) Compressed air distributor

Tools required - TX 25 Torx screwdriver

- 8 mm Allen key

32

Commissioning the pneumatic Robacta TX cover

1

Preparation Depressurise the compressed air line of the torch neck changeover station and ensure

that this compressed air line remains depressurised for the duration of the work on the

device

Disconnect the compressed air line from compressed air connection "A" on the torch

2

neck changeover station

CAUTION! Risk of injury from escaping compressed air from compressed air

connection "A". Compressed air emerges at up to 16 bar (232.06 psi) from compressed air connection "A" when the Unlock/Lock button is pressed. While compressed air is emerging from compressed air connection "A":

- wear ear protection

- keep the face and all other body parts away from compressed air connection

"A"

- ensure that no other persons are in the vicinity of the torch neck changeover

station

Press and hold the Unlock/Lock button on the torch neck changeover station until

3

compressed air no longer emerges from compressed air connection "A" on the torch

neck changeover station

- compressed-air booster unit in the torch neck changeover station discharges

De-energise the torch neck changeover station

4

EN

(3)

CAUTION! Risk of injury from compressed air escaping unintentionally. The torch

neck changeover station must remain depressurised and de-energised until all

work is completed.

Undo screws (3)

(3) (4)

(3)

(3)

5

Remove the cover lid (4)

6

33

(5)

8

2

(5)

Undo screws (5)

7

Remove lid (6)

Fitting one pneumatic Robacta TX

cover

(5)

(5)

(5)

(1)

(2)

(2)

(5)

(6)

(5)

(5)

(1)

Undo screws and washers (1) to fit the

1

cover, if required, for torch neck rack

pieces 1-5

Undo screws and washers (2) to fit the

cover, if required, for torch neck rack

pieces 6-10

- Keep the screws for later use

- The washers may be disposed of

(3)

(4)

Remove blanking plug (3) to fit the cover, if required, for torch neck rack pieces 1-5

Remove blanking plug (4) to fit the cover, if required, for torch neck rack pieces 6-10

- The blanking plugs may be disposed of

34

(7)

7

(5)

(7)

(6)

Open the cover

3

Place the cover on the holder retainer

4

as shown

Ensure that the edges of the cover (5)

5

and the holder retainer (6) are parallel

to each other

Close the cover

6

NOTE! Screw cover in place without washers.

Screw cover in place using the screws

(7) previously removed from the holder

retainer

EN

Installing one

pneumatic Robacta TX cover

(4)

(5)

(3)

Connect the compressed air line sup-

1

(2)(1)

plied (1) to connection (2) and guide

through the hole (3) in the torch neck

changeover station

Guide the valve (4) and sensor (5)

2

cables through the hole (3) into the

torch neck changeover station

Connect the sensor cable (5) to con-

3

nection X14 on the PC board in the

torch neck changeover station

Connect the valve cable (4) to connec-

4

tion X16 on the PC board in the torch

neck changeover station

35

(6)

(8)

(7)

(6)

Disconnect the compressed air line for

5

the accessory equipment (6)

Fit the compressed air distributor (7) as

6

shown

Connect the compressed air line for

7

the accessory equipment (6) to the

compressed air distributor (7) as

shown

Connect the compressed air line for

8

the cover (8) to the compressed air distributor (7) as shown

(10)

(10)

(10)

(10)

(10)

(10)

(9)

(10)

(10)

Fit the cover lid

9

Place the lid (9) on the torch neck

10

changeover station

Tighten screws and washers (10)

11

11

36

Fitting two pneu-

(1)

(1)

(2)

(2)

4

matic Robacta TX

covers

(4)

Undo screws and washers (1) and (2)

1

- Keep the screws for later use

- The washers may be disposed of

Remove blanking plugs (3) and (4)

2

- The blanking plugs may be disposed of

EN

(3)

(5)

(6)

Open the cover

3

Place the cover on the holder retainer

as shown

Ensure that the edges of the cover (5)

5

and the holder retainer (6) are parallel

to each other

Close the cover

6

37

(7)

(1)

(3)

(2)

(4)

(6)

(5)

(7)

NOTE! Screw cover in place without washers.

Screw cover in place using the screws

7

(7) previously removed from the holder

retainer

Repeat steps 3 - 7 with the second co-

8

ver

Installing two

pneumatic Robacta TX covers

Connect the compressed air line sup-

1

plied (1) to connection (2) and guide

through the hole (3) in the torch neck

changeover station

Connect the compressed air line sup-

2

plied (4) to connection (5) and guide

through the hole (6) in the torch neck

changeover station

Disconnect the compressed air line for

3

the accessory equipment (7)

38

(7)

6

(12)

(11)

(9)

(8)

(10)

(7)

(12)

Fit the compressed air distributor for

4

the first cover (8) as shown

Connect the compressed air line for

5

the first cover (9) to the compressed air

distributor (8) as shown

Fit the compressed air distributor for

the second cover (10) as shown

Connect the compressed air line for

7

the cover (11) to the compressed air

distributor (10) as shown

Connect the compressed air line for

8

the accessory equipment (7) to the

compressed air distributor (10) as

shown

Fit the lid to both covers

9

Place the lid (11) on the torch neck

10

changeover station

Tighten screws and washers (12)

11

11

EN

Checking the

function of the

pneumatic Robacta TX cover

(12)

(12)

(11)

(12)

(12)

Connect the compressed air line to compressed air connection "A" on the torch neck

1

changeover station

Establish the compressed air and power supply to the torch neck changeover station

2

Open and close the cover by sending a signal from the relevant control system

3

- The cover must open and close silently

(1)

(12)

(2)

If necessary, regulate the cover ope-

4

ning speed using a throttle (1)

39

(2)

If necessary, regulate the cover closing

5

speed using a throttle (2)

NOTE! After fitting the pneumatic cover(s), apply the necessary program sequence additions to the robot program for the respective torch neck changeover

station.

40

Locking the pneumatic Robacta TX cover

(1)

(1)

EN

Locking the cover

NOTE! Ensure that the cover locking bolt remains in the operating position while

the torch neck changeover station is in use.

Lock the cover as follows

Allow the locking bolt (1) to lock in po-

1

sition as shown

(1)

NOTE! Do not lock the cover while the torch neck changeover station is in use.

Unlock as follows

Remove the locking bolt (1) from the

1

locking hole and move to the position

shown

- the locking bolt is in the operating

position

41

42

Robacta TX slide, Robacta TX slide

XL

Safety

Safety Observe the following safety rules for all work described in the "Robacta TX slide, Robacta

TX slide XL" section.

WARNING! Incorrect operation or shoddy workmanship can cause serious injury

or damage. All activities described in these operating instructions may only be

carried out by trained and qualified personnel. All functions described in these operating instructions may only be used by trained and qualified personnel. Do not

carry out any of the work or use any of the functions described until you have fully

read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

WARNING! Machines that start up automatically can cause serious injury and

damage. In addition to these operating instructions, the safety rules issued by the

manufacturers of the robot and welding systems must also be observed. For your

personal safety, ensure that all protective measures have been taken and will remain in place while you are in the working area of the robot.

WARNING! Risk of severe injury from the robot arm. Ensure there is no one else

within the working area of the robot whenever work is carried out.

EN

WARNING! Work that is carried out incorrectly can cause serious injury or dam-

age. Before starting work:

- turn the power source mains switch to the "O" position

- disconnect the power source from the mains

- put up an easy-to-understand warning sign to stop anybody inadvertently

switching it back on again

CAUTION! Risk of injury from sharp flying parts. During the work described below, always wear the following protective equipment:

- protective goggles with side protection

- ear protection

- gloves - electrically insulated and providing protection against heat

CAUTION! Risk of burns from hot torch neck, hot torch neck coupling and other

hot welding torch components. Before carrying out work, allow the torch neck,

torch neck coupling and all other welding torch components to cool down to room

temperature (+25 °C, +77 °F).

45

Fitting the Robacta TX slide

1

Preparation Depressurise the compressed air line of the torch neck changeover station and make

sure that this compressed air line remains depressurised for the duration of the work

on the device

Disconnect the compressed air line from compressed air connection "A" on the torch

2

neck changeover station

CAUTION! Risk of injury from escaping compressed air from compressed air

connection "A". Compressed air emerges at up to 16 bar (232.06 psi) from compressed air connection "A" when the Unlock/Lock button is pressed. While compressed air is emerging from compressed air connection "A":

- wear ear protection

- keep the face and all other body parts away from compressed air connection

"A"

- ensure that no other persons are in the vicinity of the torch neck changeover

station

Press and hold the Unlock/Lock button on the torch neck changeover station until

3

compressed air no longer emerges from compressed air connection "A" on the torch

neck changeover station

- compressed-air booster unit in the torch neck changeover station discharges

De-energise the torch neck changeover station

4

Safety

Fit the slide

CAUTION! Risk of injury from compressed air escaping unintentionally. The torch

neck changeover station must remain depressurised and de-energised until all

work is completed.

Undo the screws (1)

1

- Keep the screws and washers for

(1)

(1)

(1)

fitting the slide

46

Place the slide on the torch neck chan-

1

2

(1)

(1)

2

geover station as shown

Secure the slide in position using the

3

screws and washers (1) as shown

Connect the sensor cable to the exter-

4

nal power supply connection "A" on the

torch neck changeover station

(1)

And finally... Connect the compressed air line to compressed air connection "A" on the torch neck

changeover station

Establish the compressed air and power supply to the torch neck changeover station

EN

47

Fitting the Robacta TX slide XL

1

Preparation Depressurise the compressed air line of the torch neck changeover station and make

sure that this compressed air line remains depressurised for the duration of the work

on the device

Disconnect the compressed air line from compressed air connection "A" on the torch

2

neck changeover station

CAUTION! Risk of injury from escaping compressed air from compressed air

connection "A". Compressed air emerges at up to 16 bar (232.06 psi) from compressed air connection "A" when the Unlock/Lock button is pressed. While compressed air is emerging from compressed air connection "A":

- wear ear protection

- keep the face and all other body parts away from compressed air connection

"A"

- ensure that no other persons are in the vicinity of the torch neck changeover

station

Press and hold the Unlock/Lock button on the torch neck changeover station until

3

compressed air no longer emerges from compressed air connection "A" on the torch

neck changeover station

- compressed-air booster unit in the torch neck changeover station discharges

De-energise the torch neck changeover station

4

Safety

Screw base to the

underlying surface

CAUTION! Risk of injury from compressed air escaping unintentionally. The torch

neck changeover station must remain depressurised and de-energised until all

work is completed.

NOTE! Different fixings may be required to fit the base depending on the type of

surface. Fixings are therefore not included in the scope of supply of the base. The

installer is responsible for selecting the right type of fixing.

Place the base in a suitable location

1

If necessary, align the base horizontal-

2

ly and vertically using adjustment

plates

Bolt the base (1) to the underlying sur-

3

face

Once bolted down, check that the base

4

is horizontally and vertically aligned

with the underlying surface

(1)

(1)

48

Fit the XL slide The XL slide is an enhanced version of the standard slide. It provides an additional dis-

(2)

(3)

(3)

(4)

(1)

charge area for the torch necks.

Attach the XL slide (1) to the specified positions (3) on the base using the 4 screw con-

1

nections supplied.

- The XL slide can be adjusted as required using the additional holes (4)

Connect the sensor cable (2) to the external power supply connection "A" on the torch

2

neck changeover station

EN

Fit the standard

slide to the XL

base

And finally... Connect the compressed air line to compressed air connection "A" on the torch neck

The standard slide can also be fitted to the base for the XL slide.

It is also possible to fit slides to each side of the base.

Attach the slide (1) to position (2) or (3)

(1) (2) (3)

1

on the base using the 4 screw connections supplied.

Connect the slide sensor cable to the

2

external power supply connection "A"

on the torch neck changeover station

1

changeover station

Establish the compressed air and power supply to the torch neck changeover station

2

49

Commissioning the Robacta TX slide / Robacta TX

1

slide XL

Placing a torch

neck in the Robacta TX slide /

Robacta TX slide

XL

WARNING! Risk of severe injury from the robot arm. During the course of the

whole process:

- carry out all work outside of the robot working area

- make sure that there is no-one else within the robot working area

Position the robot arm above the slide

as shown

Undo the torch neck coupling

2

- the torch neck will fall from the

torch neck coupling

50 mm

1.97 in.

Changing the program sequence to

account for the

Robacta TX slide /

Robacta TX slide

XL

50 mm

1.97 in.

NOTE! The slide can accommodate a maximum of five torch necks.

Change the relevant program sequence for the torch neck changeover as follows:

Set the 'Set down welding torch' signal on the robot

1

Wait until the slide sensor signal is output

2

- the signal confirms that the torch neck has been placed in the slide

Only continue to move the robot once the signal has been output

3

50

NOTE! Use one of the following methods to check the number of torch necks in

the slide.

For 1 - 4 torch necks:

- create a counter in the robot program that monitors the signals from the slide

sensor.

For 5 torch necks:

- wait until the slide sensor outputs a continuous signal. A continuous signal

indicates that the slide is occupied by 5 torch necks and is therefore full.

EN

51

52

Robacta TX W torch neck rack

Safety

Safety Observe the following safety rules for all work described in the "Robacta TX W torch neck

rack" section.

WARNING! Incorrect operation or shoddy workmanship can cause serious injury

or damage. All activities described in these operating instructions may only be

carried out by trained and qualified personnel. All functions described in these operating instructions may only be used by trained and qualified personnel. Do not

carry out any of the work or use any of the functions described until you have fully

read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

WARNING! Machines that start up automatically can cause serious injury and

damage. In addition to these operating instructions, the safety rules issued by the

manufacturers of the robot and welding systems must also be observed. For your

personal safety, ensure that all protective measures have been taken and will remain in place while you are in the working area of the robot.

WARNING! Risk of severe injury from the robot arm. Ensure there is no one else

within the working area of the robot whenever work is carried out.

EN

WARNING! Work that is carried out incorrectly can cause serious injury or dam-

age. Before starting work:

- turn the power source mains switch to the "O" position

- disconnect the power source from the mains

- put up an easy-to-understand warning sign to stop anybody inadvertently

switching it back on again

CAUTION! Risk of injury from sharp flying parts. During the work described below, always wear the following protective equipment:

- protective goggles with side protection

- ear protection

- gloves - electrically insulated and providing protection against heat

CAUTION! Risk of burns from hot torch neck, hot torch neck coupling and other

hot welding torch components. Before carrying out work, allow the torch neck,

torch neck coupling and all other welding torch components to cool down to room

temperature (+25 °C, +77 °F).

55

Fitting a torch neck rack piece

2

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(2)

1

2

Scope of supply - Torch neck rack piece

- M6 x 20 mm screw

Preparation Depressurise the compressed air line of the torch neck changeover station and make

1

sure that this compressed air line remains depressurised for the duration of the work

on the device

Disconnect the compressed air line from compressed air connection "A" on the torch

neck changeover station

CAUTION! Risk of injury from escaping compressed air from compressed air

connection "A". Compressed air emerges at up to 16 bar (232.06 psi) from compressed air connection "A" when the Unlock/Lock button is pressed. While compressed air is emerging from compressed air connection "A":

- wear ear protection

- keep the face and all other body parts away from compressed air connection

"A"

- ensure that no other persons are in the vicinity of the torch neck changeover

station

Press and hold the Unlock/Lock button on the torch neck changeover station until

3

compressed air no longer emerges from compressed air connection "A" on the torch

neck changeover station

- compressed-air booster unit in the torch neck changeover station discharges

De-energise the torch neck changeover station

4

Safety

Fitting a torch

neck rack piece

CAUTION! Risk of injury from compressed air escaping unintentionally. The torch

neck changeover station must remain depressurised and de-energised until all

work is completed.

Undo the 8 screws (1)

Remove lid (2)

56

(3)

7

(5)

(8) (7)

(4)

(6)

Place the torch neck rack piece (3)

3

onto the rack holder (4) as shown

Secure torch neck rack piece in place

4

using the M6 x 20 mm screw supplied

(5)

Guide the cable for the torch neck sen-

5

sor through the housing opening (6)

Remove the cable tie (7)

6

Connect the plug to the PC board according to the position on the rack holder. In this case (8)

Example:

- Torch neck rack piece mounted at

position 2 on the rack holder - connect the plug of the torch neck

sensor at connection 'X3 sensor 2'

on the PC board in the torch neck

changeover station

Fix the torch neck sensor cable using a

8

cable tie as shown

EN

Place the lid (9) on the torch neck

9

changeover station

Tighten 8 screws and washers (10)

(10)

(10)

(10)

(10)

And finally... Connect the compressed air line to compressed air connection "A" on the torch neck

1

changeover station

Establish the compressed air and power supply to the torch neck changeover station

2

(10)

(10)

(9)

(10)

(10)

10

57

58

Robacta TX G torch neck rack

Safety

Safety Observe the following safety rules for all work described in the "Robacta TX G torch neck

rack" section.

WARNING! Incorrect operation or shoddy workmanship can cause serious injury

or damage. All activities described in these operating instructions may only be

carried out by trained and qualified personnel. All functions described in these operating instructions may only be used by trained and qualified personnel. Do not

carry out any of the work or use any of the functions described until you have fully

read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

WARNING! Machines that start up automatically can cause serious injury and

damage. In addition to these operating instructions, the safety rules issued by the

manufacturers of the robot and welding systems must also be observed. For your

personal safety, ensure that all protective measures have been taken and will remain in place while you are in the working area of the robot.

WARNING! Risk of severe injury from the robot arm. Ensure there is no one else

within the working area of the robot whenever work is carried out.

EN

WARNING! Work that is carried out incorrectly can cause serious injury or dam-

age. Before starting work:

- turn the power source mains switch to the "O" position

- disconnect the power source from the mains

- put up an easy-to-understand warning sign to stop anybody inadvertently

switching it back on again

CAUTION! Risk of injury from sharp flying parts. During the work described below, always wear the following protective equipment:

- protective goggles with side protection

- ear protection

- gloves - electrically insulated and providing protection against heat

CAUTION! Risk of burns from hot torch neck, hot torch neck coupling and other

hot welding torch components. Before carrying out work, allow the torch neck,

torch neck coupling and all other welding torch components to cool down to room

temperature (+25 °C, +77 °F).

61

Fitting a torch neck rack piece

2

(1)

(1)

(2)

(1)

(1)

(1)

(1)

(1)

(1)

1

2

Scope of supply - Torch neck rack piece

- M6 x 20 mm screw

Preparation Depressurise the compressed air line of the torch neck changeover station and make

1

sure that this compressed air line remains depressurised for the duration of the work

on the device

Disconnect the compressed air line from compressed air connection "A" on the torch

neck changeover station

CAUTION! Risk of injury from escaping compressed air from compressed air

connection "A". Compressed air emerges at up to 16 bar (232.06 psi) from compressed air connection "A" when the Unlock/Lock button is pressed. While compressed air is emerging from compressed air connection "A":

- wear ear protection

- keep the face and all other body parts away from compressed air connection

"A"

- ensure that no other persons are in the vicinity of the torch neck changeover

station

Press and hold the Unlock/Lock button on the torch neck changeover station until

3

compressed air no longer emerges from compressed air connection "A" on the torch

neck changeover station

- compressed-air booster unit in the torch neck changeover station discharges

De-energise the torch neck changeover station

4

Safety

Fitting a torch

neck rack piece

CAUTION! Risk of injury from compressed air escaping unintentionally. The torch

neck changeover station must remain depressurised and de-energised until all

work is completed.

Undo the 8 screws (1)

Remove lid (2)

62

(6)

7

(4) (3)

(8) (7)

(5)

Place the torch neck rack piece (3)

3

onto the rack holder (4) as shown

Secure torch neck rack piece in place

4

using the M6 x 20 mm screw supplied

(5)

Guide the cable for the torch neck sen-

5

sor through the housing opening (6)

Remove the cable tie (7)

6

Connect the plug to the PC board according to the position on the rack holder. In this case (8)

Example:

- Torch neck rack piece mounted at

position 4 on the rack holder - connect the plug of the torch neck

sensor at connection 'X5 sensor 4'

on the PC board in the torch neck

changeover station

Fix the torch neck sensor cable using a

8

cable tie as shown

EN

Place the lid (9) on the torch neck

9

changeover station

Tighten 8 screws and washers (10)

(10)

10

(10)

(10)

(10)

(9)

(10)

(10)

And finally... Connect the compressed air line to compressed air connection "A" on the torch neck

1

changeover station

Establish the compressed air and power supply to the torch neck changeover station

2

(10)

(10)

63

64

Torch neck coding

Safety

Safety Observe the following safety rules for all work described in the "Torch neck coding" section.

WARNING! Incorrect operation or shoddy workmanship can cause serious injury

or damage. All activities described in these operating instructions may only be

carried out by trained and qualified personnel. All functions described in these operating instructions may only be used by trained and qualified personnel. Do not

carry out any of the work or use any of the functions described until you have fully

read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

WARNING! Machines that start up automatically can cause serious injury and

damage. In addition to these operating instructions, the safety rules issued by the

manufacturers of the robot and welding systems must also be observed. For your

personal safety, ensure that all protective measures have been taken and will remain in place while you are in the working area of the robot.

WARNING! Risk of severe injury from the robot arm. Ensure there is no one else

within the working area of the robot whenever work is carried out.

EN

WARNING! Work that is carried out incorrectly can cause serious injury or dam-

age. Before starting work:

- turn the power source mains switch to the "O" position

- disconnect the power source from the mains

- put up an easy-to-understand warning sign to stop anybody inadvertently

switching it back on again

CAUTION! Risk of injury from sharp flying parts. During the work described below, always wear the following protective equipment:

- protective goggles with side protection

- ear protection

- gloves - electrically insulated and providing protection against heat

CAUTION! Risk of burns from hot torch neck, hot torch neck coupling and other

hot welding torch components. Before carrying out work, allow the torch neck,

torch neck coupling and all other welding torch components to cool down to room

temperature (+25 °C, +77 °F).

67

Coding the torch neck

General Coding the torch necks ensures that each torch neck is always stored in the correct torch

neck rack piece. Once the torch necks have been coded it is impossible for them to be

placed in the wrong rack piece.

How it works:

- Each torch neck rack piece has holes drilled into it

- Notched pins are then placed in the rack piece holes; the number and position of the

notched pin(s) can be chosen by the user

- Holes on the torch neck are exposed to align exactly with the holes containing notched

pins on the rack piece

- The torch neck can only be stored in a rack piece if an open hole on the torch neck is

aligned exactly with a notched pin in the torch neck rack piece

Preparation Depressurise the compressed air line of the torch neck changeover station and make

1

sure that this compressed air line remains depressurised for the duration of the work

on the device

Disconnect the compressed air line from compressed air connection "A" on the torch

2

neck changeover station

CAUTION! Risk of injury from escaping compressed air from compressed air

connection "A". Compressed air emerges at up to 16 bar (232.06 psi) from compressed air connection "A" when the Unlock/Lock button is pressed. While compressed air is emerging from compressed air connection "A":

- wear ear protection

- keep the face and all other body parts away from compressed air connection

"A"

- ensure that no other persons are in the vicinity of the torch neck changeover

station

Press and hold the Unlock/Lock button on the torch neck changeover station until

3

compressed air no longer emerges from compressed air connection "A" on the torch

neck changeover station

- compressed-air booster unit in the torch neck changeover station discharges

De-energise the torch neck changeover station

4

Safety

68

CAUTION! Risk of injury from compressed air escaping unintentionally. The torch

neck changeover station must remain depressurised and de-energised until all

work is completed.

Coding the torch

(1)

neck

Place a 3 x 20 mm (0.12 in. x 0.79 in.)

1

notched pin (1) the desired hole on the

torch neck rack piece

Screw threaded studs into the holes to

2

be closed on the torch neck

Example

- Screw five threaded studs into the

holes (2)

- Leave hole (3) open for the notched pin

EN

(2)

(2)

(3)

(2)

(2)

(2)

Place the torch neck into the torch

3

neck rack piece and check that the notched pin is aligned with the open hole

Torch neck coded correctly

69

Torch neck coded incorrectly

Code the remaining torch necks

4

And finally... Connect the compressed air line to compressed air connection "A" on the torch neck

1

changeover station

Establish the compressed air and power supply to the torch neck changeover station

2

70

Compressed air maintenance unit

Safety

Safety Observe the following safety rules for all work described in the "Compressed air mainte-

nance unit" section.

WARNING! Incorrect operation or shoddy workmanship can cause serious injury

or damage. All activities described in these operating instructions may only be

carried out by trained and qualified personnel. All functions described in these operating instructions may only be used by trained and qualified personnel. Do not

carry out any of the work or use any of the functions described until you have fully

read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

WARNING! Machines that start up automatically can cause serious injury and

damage. In addition to these operating instructions, the safety rules issued by the

manufacturers of the robot and welding systems must also be observed. For your

personal safety, ensure that all protective measures have been taken and will remain in place while you are in the working area of the robot.

WARNING! Risk of severe injury from the robot arm. Ensure there is no one else

within the working area of the robot whenever work is carried out.

EN

WARNING! Work that is carried out incorrectly can cause serious injury or dam-

age. Before starting work:

- turn the power source mains switch to the "O" position

- disconnect the power source from the mains

- put up an easy-to-understand warning sign to stop anybody inadvertently

switching it back on again

CAUTION! Risk of injury from sharp flying parts. During the work described below, always wear the following protective equipment:

- protective goggles with side protection

- ear protection

- gloves - electrically insulated and providing protection against heat

CAUTION! Risk of burns from hot torch neck, hot torch neck coupling and other

hot welding torch components. Before carrying out work, allow the torch neck,

torch neck coupling and all other welding torch components to cool down to room

temperature (+25 °C, +77 °F).

73

General