Installation

Instructions

OPT/i CWF TMC Brenner

OPT/i CWF TMC Torch

DE

EN-US

Installationsanleitung

Installation instructions

42,0410,2864 001-09112022

Inhaltsverzeichnis

Allgemeines 4

Sicherheit 4

Lieferumfang 5

Erforderliche Werkzeuge 5

OPT/i CWF TMC Brenner einbauen 6

Vorbereitung 6

OPT/i CWF TMC Brenner einbauen 8

Abschließende Tätigkeiten 15

OPT/i CWF TMC Brenner anschließen 15

Abschließende Tätigkeiten 19

DE

3

Allgemeines

Sicherheit

WARNUNG!

Gefahr durch Fehlbedienung und fehlerhaft durchgeführte Arbeiten.

Schwere Personen- und Sachschäden können die Folge sein.

Alle in diesem Dokument beschriebenen Arbeiten und Funktionen dürfen

▶

nur von technisch geschultem Fachpersonal ausgeführt werden.

Dieses Dokument vollständig lesen und verstehen.

▶

Sämtliche Sicherheitsvorschriften und Benutzerdokumentationen dieses

▶

Gerätes und aller Systemkomponenten lesen und verstehen.

WARNUNG!

Gefahr durch elektrischen Strom.

Schwere Personen- und Sachschäden können die Folge sein.

Vor Beginn der Arbeiten alle beteiligten Geräte und Komponenten ausschal-

▶

ten und von Stromnetz trennen.

Alle beteiligten Geräte und Komponenten gegen Wiedereinschalten sichern.

▶

Nach dem Öffnen des Gerätes mit Hilfe eines geeigneten Messgerätes si-

▶

cherstellen, dass elektrisch geladene Bauteile (beispielsweise Kondensatoren) entladen sind.

4

Lieferumfang

(1) (2) (3) (4) (5) (6) (7)

(14)

(13)

(12)

(11)

(10)

(8) (9)

(21)

(20)

(18)(19) (17)

(16)

(15)

DE

(1) Stromkabel

(2) Kabel 10p

(3) TMC-Kabel

(4) Strombuchse mit Abdeckung

(5) Print

(6) Zugentlastung

(7) TMC-Montagering

(8) Gas-Strom-Anschluss

(9) 2x Scheibe ISO 7089 M12 A2

(10) 2x Tellerfeder

Da 23 x Di 12,2 x 1,5 mm

(11) 2x Sechskant-Mutter M12

(12) 2x Federring DIN 127 B d6

Erforderliche

Werkzeuge

TORX®-Schraubendreher TX 25

-

TORX®-Schraubendreher TX 20

-

Gabelschlüssel SW 19 mm

-

Gabelschlüssel SW 22 mm

-

Gabelschlüssel SW 32 mm

-

Innensechskant-Schlüssel SW 5 mm

-

Messer

-

Bohrer Ø 8 mm / 0,31 inch

-

(13) 2x Scheibe DIN 134 A M6

(14) 4x Schraube 4 x 12 mm

(15) 2x Innensechskant-Schraube

SW 5 mm

(16) Gasschlauch 0,14 m schwarz

(17) 2x Kühlmittel-Schlauch 0,5 m

(18) Kühlmittel-Anschlüsse An-

schlussbereich (Stecknippel -

rot, blau)

(19) 4x Schraube TX 20, 20 mm

(20) Kühlmittel-Anschlüsse Vorder-

seite (Kupplung - rot, blau)

(21) 2x Steckanschluss

5

OPT/i CWF TMC Brenner einbauen

3

3

4

Vorbereitung

Stromquelle ausschalten und vom Netz trennen

1

Drahtvorschub CWF 25i von allen Systemkomponenten abschließen

2

2 Schrauben TX25 entfernen

3

Seitendeckel abnehmen

4

6

6

5

5

5

7

3 Blindabdeckungen an der Vorderseite entfernen

8

8

8

5

Folie an Position „Option“ ausschneiden

6

Öffnung freibrechen

7

DE

3 Blindabdeckungen im Anschlussbereich entfernen

8

7

OPT/i CWF TMC

1

1

1

1

1

3

3

3

2

2

2

4

5

4

(3)

(4)

(1)

(2)

(5)

(6)

(7)

(8)

Brenner einbauen

5 Schrauben TX25 entfernen

1

3 Stecker (1), (2) und (3) vom Print abstecken

2

3 Stecker (4), (5) und (6) vom Print abstecken

3

2 Datenkabel (7) und (8) vom Print abstecken

4

Print mit Print-Halterung herausnehmen

5

8

6

8

4x TX20

7

7

7

7

10p

Print aus dem Lieferumfang gemäß Abbildung an der Unterseite der zuvor

9

9

6

entnommenen Print-Halterung ansetzen

Print mit 4 Schrauben TX20 fixieren

7

Anzugsmoment = 1,2 Nm

Kabel 10p am Print anstecken

8

DE

TMC-Montagering mit den Bohrungen nach vorne in die Öffnung einsetzen

9

9

1

2

11

10

10

11

TMC-Montagering mit 2 Schrauben TX20 von vorne fixieren

14

13

15

13

14

15

10

Anzugsmoment = 3 Nm

Bohrungen durchstechen

11

TMC-Kabel von vorne einführen

12

10

TMC-Buchse mit 2 Schrauben TX20 fixieren

13

Anzugsmoment = 3 Nm

Kühlmittelanschlüsse Vorderseite von innen nach außen gemäß Abbildung in

14

die Öffnungen einsetzen

Kühlmittelanschlüsse Vorderseite mit 2 Sechskant-Muttern SW 22 mm fixie-

15

ren:

rot rechts, blau links - handfest festziehen

16

17

17

Sechskant-Mutter SW 32 mm und Isolierscheibe von der Strombuchse mit

18

19

18

19

16

Abdeckung entfernen;

Strombuchse mit Abdeckung von vorne in die Öffnung einsetzen

Isolierscheibe auf die Strombuchse aufsetzen und mit Sechskant-Mutter

17

SW 32 mm an der Innenseite fixieren

Anzugsmoment = 35 Nm

DE

Kühlmittel-Anschlüsse Anschlussbereich von innen nach außen gemäß Abbil-

18

dung in die Öffnungen einsetzen

Kühlmittel-Anschlüsse Anschlussbereich mit 2 Sechskant-Muttern SW 22

19

mm fixieren:

rot oben, blau unten - handfest festziehen

11

20

2

1

2

1

Sechskant-Mutter SW 32 mm und Isolierscheibe vom Gas-Strom-Anschluss

22

2

3

20

entfernen;

Gas-Strom-Anschluss von vorne in die Öffnung einsetzen

Isolierscheibe auf Gas-Strom-Anschluss aufsetzen und mit Sechskant-Mut-

21

ter SW 32 mm an der Innenseite fixieren

Anzugsmoment = 35 Nm

12

Stromkabel am Gas-Strom-Anschluss ansetzen

22

Stromkabel + Scheibe + Tellerfeder mittels Sechskant-Mutter SW 19 mm fi-

23

xieren

Anzugsmoment = 25 Nm

24

25

Stromkabel an der vorderen Strombuchse ansetzen

26

26

24

Stromkabel + Scheibe + Tellerfeder mittels Sechskant-Mutter SW 19 mm fi-

25

xieren

Anzugsmoment = 25 Nm

DE

Kühlmittel-Schläuche an den Kühlmittel-Anschlüssen Vorderseite bis auf An-

26

schlag anstecken

13

27

27

WICHTIG! Beim Anstecken der Kühlmittel-Schläuche an die Kühlmittel-

28

2

8

2

9

29

Anschlüsse Anschlussbereich die Farbmarkierungen beachten!

Kühlmittel-Schläuche an den Kühlmittel-Anschlüssen Anschlussbereich bis

27

auf Anschlag anstecken

14

Gasschlauch und Steckanschlüsse zusammenstecken

28

Gasschlauch an den Stromanschlüssen anstecken

29

Abschließende Tätigkeiten

1

1

2

3

8p

10p

OPT/i CWF TMC

Brenner anschließen

DE

2 Schrauben TX25 entfernen

1

Bedienpanel herausnehmen

2

TMC-Kabel 8p (vom TMC-Anschluss) am Print anstecken

3

15

10p

4

WICHTIG!

Beim Einsetzen der Print-Halterung

das Kabel 10p vom Print durch die Öffnung führen,

-

darauf achten, dass das Kabel 10p nicht eingeklemmt, geknickt, abgeschert

-

oder auf andere Weise beschädigt wird.

Kabel 10p durch die Öffnung führen und Print-Halterung von der gegenüber-

4

liegenden Seite einsetzen

16

5

6

Kabel 10p am Bedienpanel an X3 anstecken

7

7

2x TX25

5

WICHTIG! Beim Einsetzen des Bedienpanels darauf achten, dass Kabel nicht

eingeklemmt, geknickt, abgeschert oder sonst irgendwie beschädigt werden.

DE

Bedienpanel einsetzen

6

Bedienpanel mit 2 Schrauben TX25 fixieren

7

Anzugsmoment = 2,2 Nm

17

8

8

8

8

8

10

9

9

9

10

10

1

1

1

1

(3)

(4)

(1)

(2)

(5)

(6)

(7)

(8)

Print mit Print-Halterung mit 5 Schrauben TX 25 fixieren

8

Anzugsmoment = 3 Nm

18

3 Stecker (1), (2) und (3) am Print anstecken

9

3 Stecker (4), (5) und (6) am Print anstecken

10

2 Datenkabel (7) und (8) am Print anstecken

11

Abschließende

2x TX25

2

2

1

2x ø 8 mm / 0.31 inch

3

3

Tätigkeiten

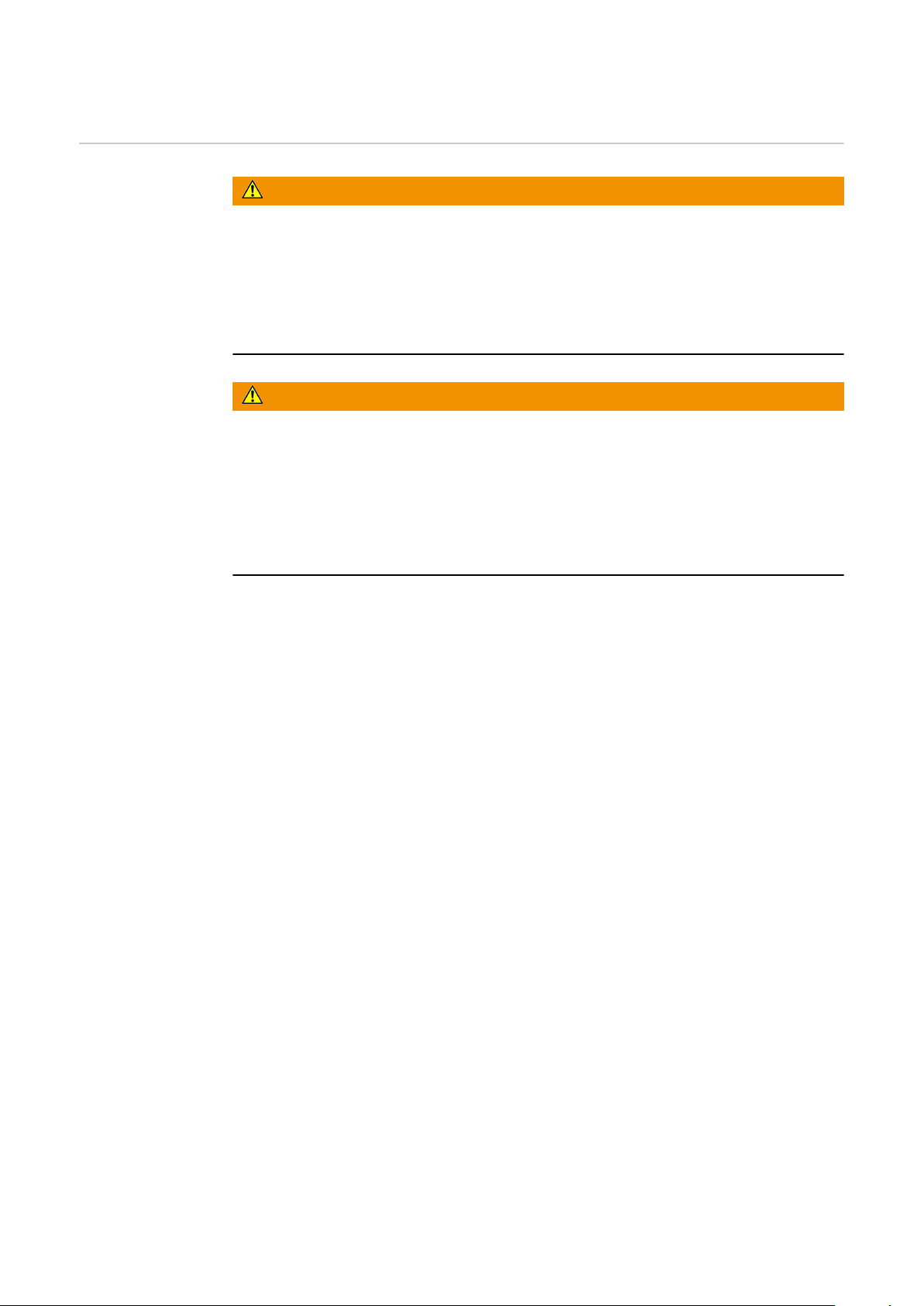

Seitendeckel aufsetzen

1

Seitendeckel mit 2 Schrauben TX25 montieren

2

Anzugsmoment = 1,9 Nm

DE

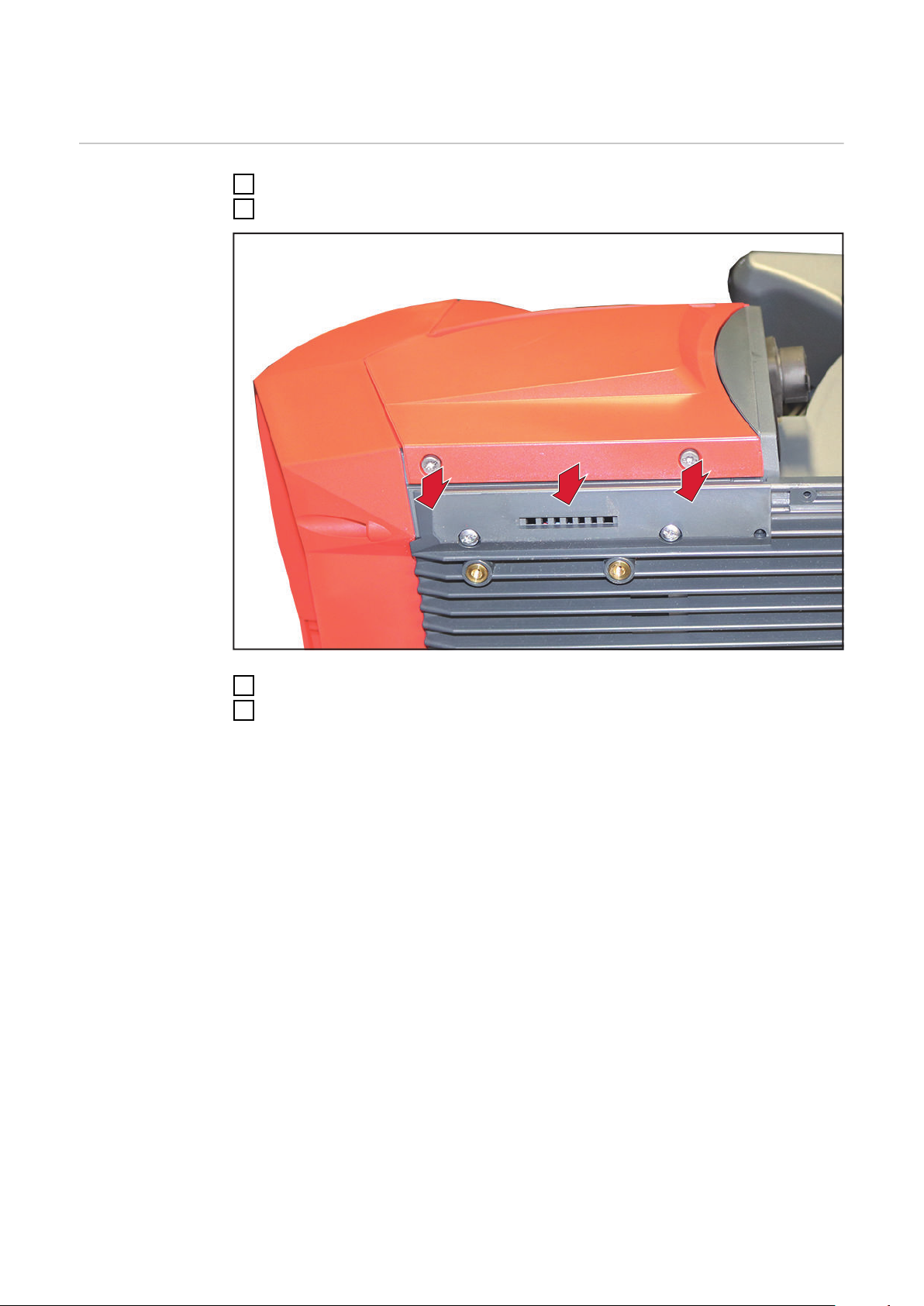

An den vorgekörnten Positionen an der rechten Geräteseite 2 Bohrungen

3

Durchmesser 8 mm / 0,31 inch im Kunststoff anbringen

19

4

5

5

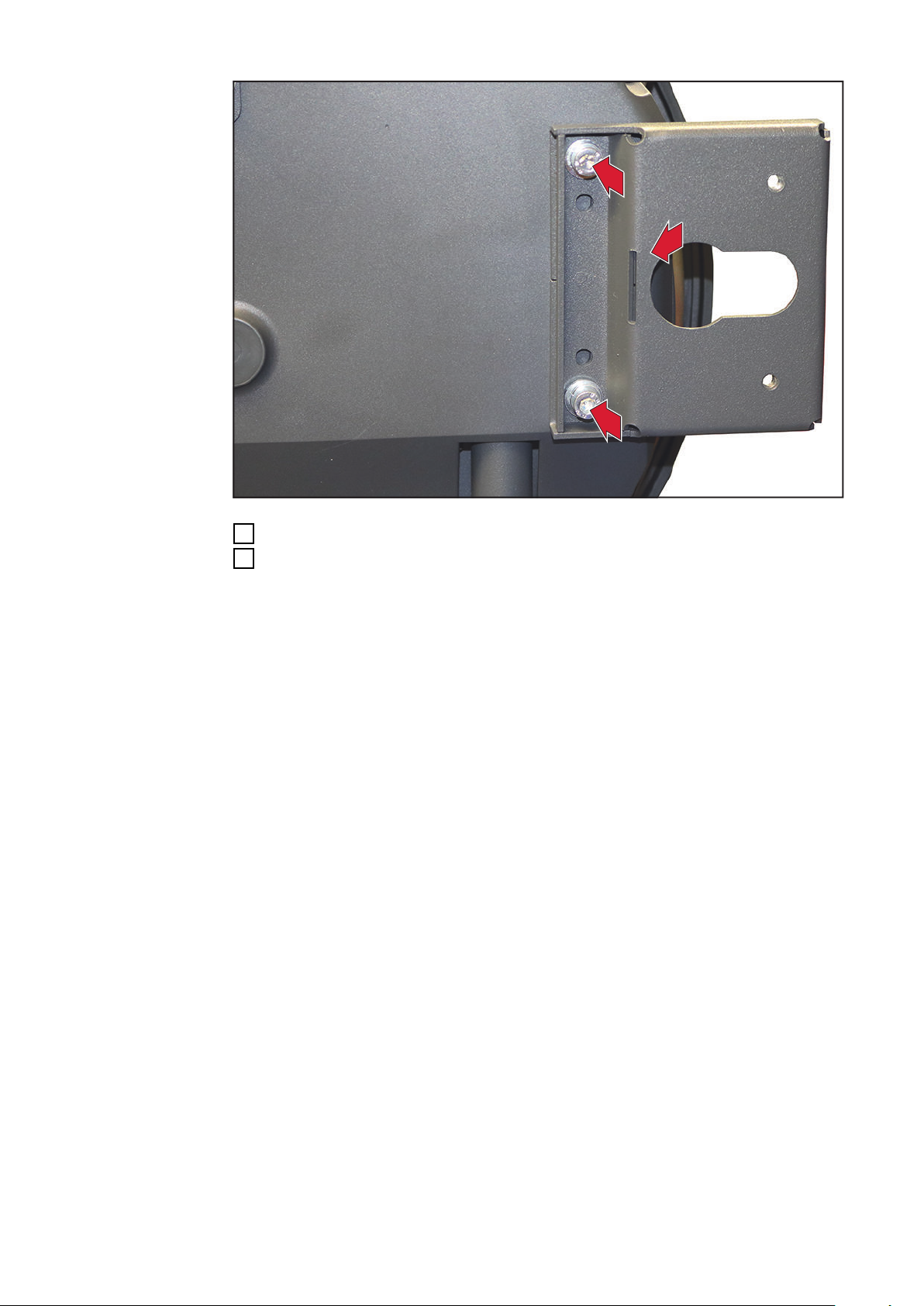

Zugentlastung gemäß Abbildung ansetzen

4

Zugentlastung mit 2 Innensechskant-Schrauben SW 5 mm, Scheiben und

5

Federringen fixieren

Anzugsmoment = 3,5 Nm

20

Table of contents

General 22

Safety 22

Scope of supply 23

Tools required 23

Installing the OPT/i CWF TMC welding torch 24

Preparation 24

Installing the OPT/i CWF TMC welding torch 26

Finally... 33

Connecting the OPT/i CWF TMC welding torch 33

Final tasks 37

EN-US

21

General

Safety

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in serious personal injury and damage to property.

All the work and functions described in this document must only be carried

▶

out by technically trained and qualified personnel.

Read and understand this document in full.

▶

Read and understand all safety rules and user documentation for this equip-

▶

ment and all system components.

WARNING!

Danger from electrical current.

This can result in serious personal injury and damage to property.

Before starting work, switch off all devices and components involved, and

▶

disconnect them from the grid.

Secure all devices and components involved so they cannot be switched back

▶

on.

After opening the device, use a suitable measuring instrument to check that

▶

electrically charged components (such as capacitors) have been discharged.

22

Scope of supply

(1) (2) (3) (4) (5) (6) (7)

(14)

(13)

(12)

(11)

(10)

(8) (9)

(21)

(20)

(18)(19) (17)

(16)

(15)

EN-US

(1) Power cable

(2) Cable 10p

(3) TIG Multi Connector cable

(4) Current socket with cover

(5) PC board

(6) Strain-relief device

(7) TIG Multi Connector mounting

ring

(8) Gas/power connection

(9) 2x washer ISO 7089 M12 A2

(10) 2x disc spring

Do 23 x Di 12.2 x 1.5 mm

(11) 2x hexagonal nut M12

(12) 2x spring lock washer DIN 127

B d6

Tools required

TORX® screwdriver TX 25

-

TORX® screwdriver TX 20

-

19 mm wrench

-

22 mm wrench

-

32 mm wrench

-

5 mm Allen key

-

Knife

-

Drill Ø 8 mm / 0.31 in.

-

(13) 2x washer DIN 134 A M6

(14) 4x screw 4 x 12 mm

(15) 2x Allen screws size 5 mm

(16) Gas hose 0.14 m black

(17) 2x coolant hose 0.5 m

(18) Connection area coolant con-

nections (plug nipple - red,

blue)

(19) 4x screw TX 20, 20 mm

(20) Front coolant connections

(coupling - red, blue)

(21) 2x connection sockets

23

Installing the OPT/i CWF TMC welding torch

3

3

4

Preparation

Switch off the power source and disconnect from the grid

1

Disconnect the CWF 25i wirefeeder from all system components

2

Remove the two TX25 screws

3

Remove the side cover

4

24

6

5

5

5

7

Remove the three dummy covers on the front

8

8

8

5

Cut the film at position "Option"

6

Break the opening

7

EN-US

Remove the three dummy covers in the connection area

8

25

Installing the

1

1

1

1

1

3

3

3

2

2

2

4

5

4

(3)

(4)

(1)

(2)

(5)

(6)

(7)

(8)

OPT/i CWF TMC

welding torch

Remove the five TX25 screws

1

26

Disconnect the three connectors (1), (2), and (3) from the PC board

2

Disconnect the three connectors (4), (5), and (6) from the PC board

3

Disconnect the two data cables (7) and (8) from the PC board

4

Remove the PC board with PC board holder

5

6

8

4x TX20

7

7

7

7

10p

Attach the PC board from the scope of supply to the underside of the pre-

9

9

6

viously removed PC board holder as shown

Secure the PC board using four TX20 screws

7

Tightening torque = 1.2 Nm

Connect cable 10p to the PC board

8

EN-US

Insert the TIG Multi Connector mounting ring into the opening with the holes

9

facing forwards

27

1

2

11

10

10

11

Secure the TIG Multi Connector mounting ring with two TX20 screws from

14

13

15

13

14

15

10

the front

Tightening torque = 3 Nm

Pierce holes

11

Insert the TIG Multi Connector cable from the front

12

28

Secure the TIG Multi Connector socket using two TX20 screws

13

Tightening torque = 3 Nm

Insert the front coolant connections into the openings from inside out as

14

shown

Secure the front coolant connections using two 22 mm hexagonal nuts:

15

red right, blue left – tighten hand-tight

16

17

17

Remove the 32 mm hexagonal nut and insulating washer from the current so-

18

19

18

19

16

cket with cover;

Insert current socket with cover into the opening from the front

Place the insulating washer on the current socket and secure with the 32 mm

17

hexagonal nut on the inside

Tightening torque = 35 Nm

EN-US

Insert the connection area coolant connections into the openings from inside

18

out as shown

Secure the connection area coolant connections using two 22 mm hexagonal

19

nuts:

red top, blue bottom – tighten hand-tight

29

20

2

1

2

1

Remove the 32 mm hexagonal nut and insulating washer from the gas/power

22

2

3

20

connection;

Insert gas/power connection into the opening from the front

Place the insulating washer on the gas/power connection and secure with the

21

32 mm hexagonal nut on the inside

Tightening torque = 35 Nm

30

Attach the power cable to the gas/power connection

22

Secure power cable + washer + disc spring using the 19 mm hexagonal nut

23

Tightening torque = 25 Nm

24

25

Attach the power cable to the front current socket

26

26

24

Secure power cable + washer + disc spring using the 19 mm hexagonal nut

25

Tightening torque = 25 Nm

EN-US

Push the coolant hoses onto the front coolant connections as far as they will

26

go

31

27

27

IMPORTANT! When connecting the coolant hoses to the connection area coo-

28

2

8

2

9

29

lant connections, observe the color markings!

Push the coolant hoses onto the connection area coolant connections as far

27

as they will go

32

Connect the gas hose and connection sockets

28

Connect the gas hose to the power connections

29

Finally...

1

1

2

3

8p

10p

Connecting the

OPT/i CWF TMC

welding torch

EN-US

Remove the two TX25 screws

1

Remove the control panel

2

Connect the TIG Multi Connector cable 8p (from the TMC) to the PC board

3

33

10p

4

IMPORTANT!

When inserting the PC board holder

guide cable 10p from the PC board through the opening

-

make sure that cable 10p is not pinched, kinked, sheared, or damaged in any

-

other way

Feed cable 10p through the opening and insert the PC board holder from the

4

opposite side

34

5

6

Connect cable 10p to X3 on the control panel

7

7

2x TX25

5

IMPORTANT! When inserting the control panel, ensure that the cables are

not pinched, kinked, sheared, or otherwise damaged.

Insert the control panel

6

EN-US

Secure the control panel using two TX25 screws

7

Tightening torque = 2.2 Nm

35

8

8

8

8

8

10

9

9

9

10

10

1

1

1

1

(3)

(4)

(1)

(2)

(5)

(6)

(7)

(8)

Secure the PC board with PC board holder with five TX 25 screws

8

Tightening torque = 3 Nm

36

Connect the three connectors (1), (2), and (3) to the PC board

9

Connect the three connectors (4), (5), and (6) to the PC board

10

Connect the two data cables (7) and (8) to the PC board

11

Final tasks

2x TX25

2

2

1

2x ø 8 mm / 0.31 inch

3

3

Fit the side cover

1

Secure the side cover using two TX25 screws

2

Tightening torque = 1.9 Nm

EN-US

Drill two holes of diameter 8 mm / 0.31 in. in the plastic at the pre-punched

3

positions on the right-hand side of the device

37

4

5

5

Attach the strain-relief device as shown

4

Secure the strain-relief device with two 5 mm Allen screws, washers, and

5

spring lock washers

Tightening torque = 3.5 Nm

38

EN-US

39

Loading...

Loading...