Operating

manuals.fronius.com/

html/4204260459

e-Manual

Instructions

MTG Exento

MTW Exento

EN-US

Operating instructions

42,0426,0459,EA 005-21092022

Table of contents

Safety, information on correct use 5

Safety 7

Safety 7

Intended use, requirements for the extraction system 8

Intended use 8

Requirements for the extraction system 8

Extraction information on the rating plate 10

Available interfaces, functions of the torch trigger 11

Available interfaces 13

Up/Down-function 13

JobMaster-function 13

Functions of the torch trigger 14

Functions of the two-staged torch trigger 14

Commissioning 15

Commissioning procedure 17

Procedure for commissioning welding torches with Fronius System Connector 17

Procedure for commissioning welding torches with Euro connection 17

Fitting inner liner in welding torch with Fronius System Connector 18

Note on inner liner in gascooled welding torches 18

Fitting the inner liner 19

Fitting steel inner liner in welding torch with Euro connection 23

Fitting the steel inner liner 23

Fitting plastic inner liner in welding torch with Euro connection 27

Note on inner liner in gascooled welding torches 27

Fitting the plastic inner liner 28

Connecting welding torches to devices with Fronius System Connector 31

Connecting the welding torch to the power source 31

Connecting the welding torch to the wirefeeder 32

Connecting welding torches to devices with Euro connection 33

Connecting the welding torch 33

Connecting welding torch to extraction system and measuring extraction capacity 34

Connecting the welding torch to the extraction system 34

Measuring the extraction capacity (extraction volumetric flow) with the Exentometer 34

Adjusting the extraction capacity 37

Setting the extraction capacity on the welding torch 37

Setting extraction capacity with external air flow regulator 39

EN-US

Fault diagnosis, troubleshooting, maintenance 41

Troubleshooting 43

Troubleshooting 43

Maintenance 49

Detecting defective wear parts 49

Maintenance at the beginning of each working day 50

Maintenance every 48 hours 51

Maintenance at every wirespool/basket-type spool replacement 52

Technical data 55

Technical data of water-cooled welding torches 57

General 57

MTW Exento welding torch technical data 57

Technical data of gascooled welding torches 61

General 61

MTG Exento welding torch technical data 61

3

4

Safety, information on correct use

5

6

Safety

EN-US

Safety

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in serious personal injury and damage to property.

All the work and functions described in this document must only be carried

▶

out by technically trained and qualified personnel.

Read and understand this document in full.

▶

Read and understand all safety rules and user documentation for this equip-

▶

ment and all system components.

WARNING!

Danger from electrical current.

This can result in serious personal injury and damage to property.

Before starting work, switch off all the devices and components involved and

▶

disconnect them from the grid.

Secure all devices and components involved so they cannot be switched back

▶

on.

WARNING!

Danger due to emerging wire electrode.

Serious personal injuries may result.

Hold the welding torch so that the tip of the welding torch points away from

▶

the face and body.

Wear suitable protective goggles.

▶

Do not point the welding torch at people.

▶

Ensure that the wire electrode can only intentionally make contact with elec-

▶

trically conductive objects.

WARNING!

Danger due to hot system components and/or equipment.

This can result in serious burns or scalding.

Before starting work, allow all hot system components and/or equipment to

▶

cool to +25°C/+77°F (e.g., coolant, water-cooled system components,

wirefeeder drive motor, etc.).

Wear suitable protective equipment (e.g., heat-resistant gloves, safety

▶

goggles, etc.) if cooling down is not possible.

WARNING!

Danger from contact with toxic welding fumes.

Serious personal injuries may result.

Welding is not permitted without an extraction unit being switched on.

▶

It may not be sufficient to only use a fume extraction torch to reduce the

▶

concentration of noxious substances at the work station. In this case, install

an additional extraction system to properly reduce the concentration of noxious substances at the work station.

In case of doubt, the concentration of noxious substances at the work sta-

▶

tion should be assessed by a safety engineer.

7

Intended use, requirements for the extraction

system

Intended use The MIG/MAG manual welding torch is intended exclusively for MIG/MAG weld-

ing in conjunction with a sufficiently powerful extraction system (see section Re-

quirements for the extraction system from page 8). Any other use is deemed

to be "not in accordance with the intended purpose." The manufacturer accepts

no liability for any damage resulting from improper use.

Intended use also means:

Reading these Operating Instructions in their entirety

-

Following all instructions and safety rules in this document

-

Carrying out all the specified inspection and maintenance work

-

Requirements

for the extraction system

Only operate Schweißbrenner with extraction systems that meet the following

requirements:

-

Extraction capacity (extraction volumetric flow) of at least 70 - 110 m3/h

(2472 - 3885 cfh); depending on the welding torch used

if the value is lower, there is a risk that the welding fumes will not be ad-

-

equately extracted

a higher value means there is a risk that shielding gas will be unintention-

-

ally sucked off the weld seam

Depending on the length of the extraction hose and the welding torch used, a

-

negative pressure of at least 10 - 18 kPa (100 - 180 mbar) must be generated

the shorter and thicker the extraction hose, the smaller the extraction

-

unit can be dimensioned / the less extraction capacity must be provided

to ensure that the welding fumes are optimally extracted

When the altitude increases, the extraction capacity must be reduced ac-

-

cording to the altitude due to the changing environmental conditions (lower

air pressure, etc.), for example by opening the air flow regulator of the welding torch or reducing the extraction capacity

in any case, the requirements for extraction must be met

-

use the Exentometer to determine the current extraction volumetric flow

-

of the welding torch - for this, see section Measuring the extraction ca-

pacity (extraction volumetric flow) with the Exentometer from page 34

The exact requirements for extraction can be found on the rating plate of the respective welding torch (see section Extraction information on the rating plate on

page 10) and in the technical data.

8

Rating plate on the welding torch

EN-US

9

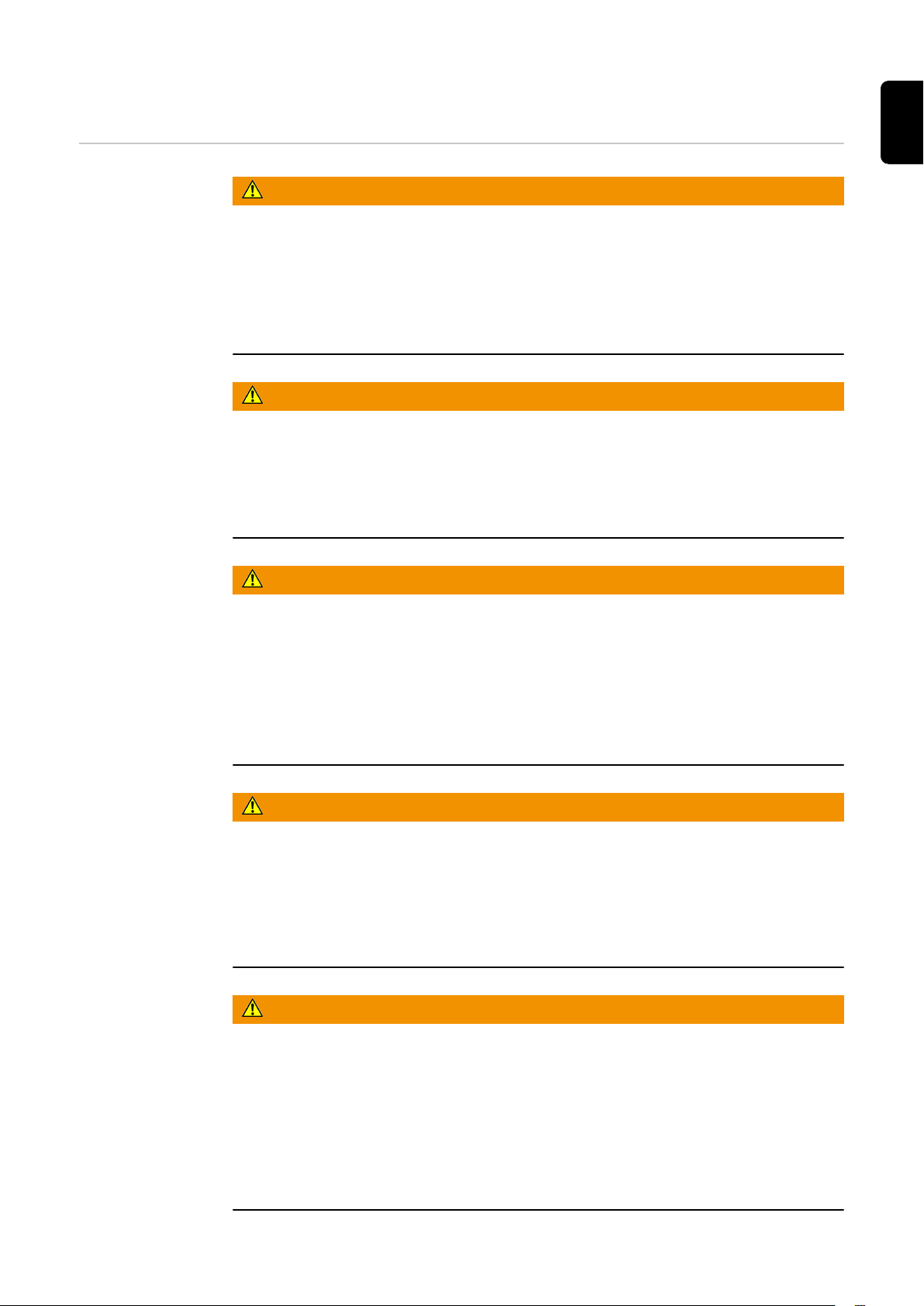

Extraction in-

∆

p

c

[kPa]

Check

Qv,c [m³/h] Qv,n [m³/h]

11,0 94 57

MIXED

CO2

I2

X (40°C)

EN IEC 60974-7/-10 Cl.A

EN ISO 21904-1

Charge No.

Art.No.

Type

www.fronius.com

Q

v,n

Q

v,c

pc

pc

formation on the

rating plate

Example of a rating plate

Extraction information on the rating plate

Extraction volumetric flow at the front end of the welding torch ( =

the extraction volumetric flow provided by the welding torch)

Extraction volumetric flow at the extraction connection of the welding torch ( = the extraction volumetric flow that the extraction system must provide)

Required negative pressure at the extraction connection of the welding torch (= the negative pressure that the extraction system must

generate)

10

Available interfaces, functions of

the torch trigger

11

12

Available interfaces

EN-US

Up/Down-function

JobMaster-function

The Up/Down torch has the following

functions:

Changing the welding power in

-

synergic operation by means of up/

down buttons

Error display:

-

in the event of a system error,

-

all the LEDs turn red

in the event of a data commu-

-

nication error, all the LEDs

flash red.

Self-testing in the start-up se-

-

quence:

all the LEDs briefly light up in

-

succession.

The JobMaster welding torch has the

following functions:

The desired parameters are chosen

-

via arrow keys at the power source

Use the +/- keys to change the se-

-

lected parameters

The display shows the current

-

parameters and value

13

Functions of the torch trigger

Functions of the

two-staged

torch trigger

Function of the torch trigger at switch position 1 (torch trigger pushed halfway down) = LED lights up

NOTE!

An LED on the welding torch does not work for welding torches with optional

top torch trigger.

14

Function of the torch trigger in switch position 2 (torch trigger pressed all the way down) = LED goes

out, welding process starts

Commissioning

15

16

Commissioning procedure

EN-US

Procedure for

commissioning

welding torches

with Fronius

System Connector

Procedure for

commissioning

welding torches

with Euro connection

Perform the following activities for the correct commissioning of the welding

torch:

Fit the inner liner - Description from page 18

1

Connect the welding torch

2

Description of power source from page 31

-

Description of wirefeeder from page 32

-

Connect the welding torch to the extraction system - Description from page

3

34

Measure extraction capacity - Description from page 34

4

If necessary, adjust the extraction capacity:

Set the extraction capacity directly on the welding torch - Description from

5

page 37

Set the extraction capacity with external air flow regulator - Description

6

from page 39

Perform the following activities for the correct commissioning of the welding

torch:

Fit the inner liner

1

Description of steel inner liner from page 23

-

Description of plastic inner liner from page 27

-

Connect the welding torch to the power source - Description from page 33

2

Connect the welding torch to the extraction system - Description from page

3

34

Measure extraction capacity - Description from page 34

4

If necessary, adjust the extraction capacity:

Set the extraction capacity directly on the welding torch - Description from

5

page 37

Set the extraction capacity with external air flow regulator - Description

6

from page 39

17

Fitting inner liner in welding torch with Fronius

System Connector

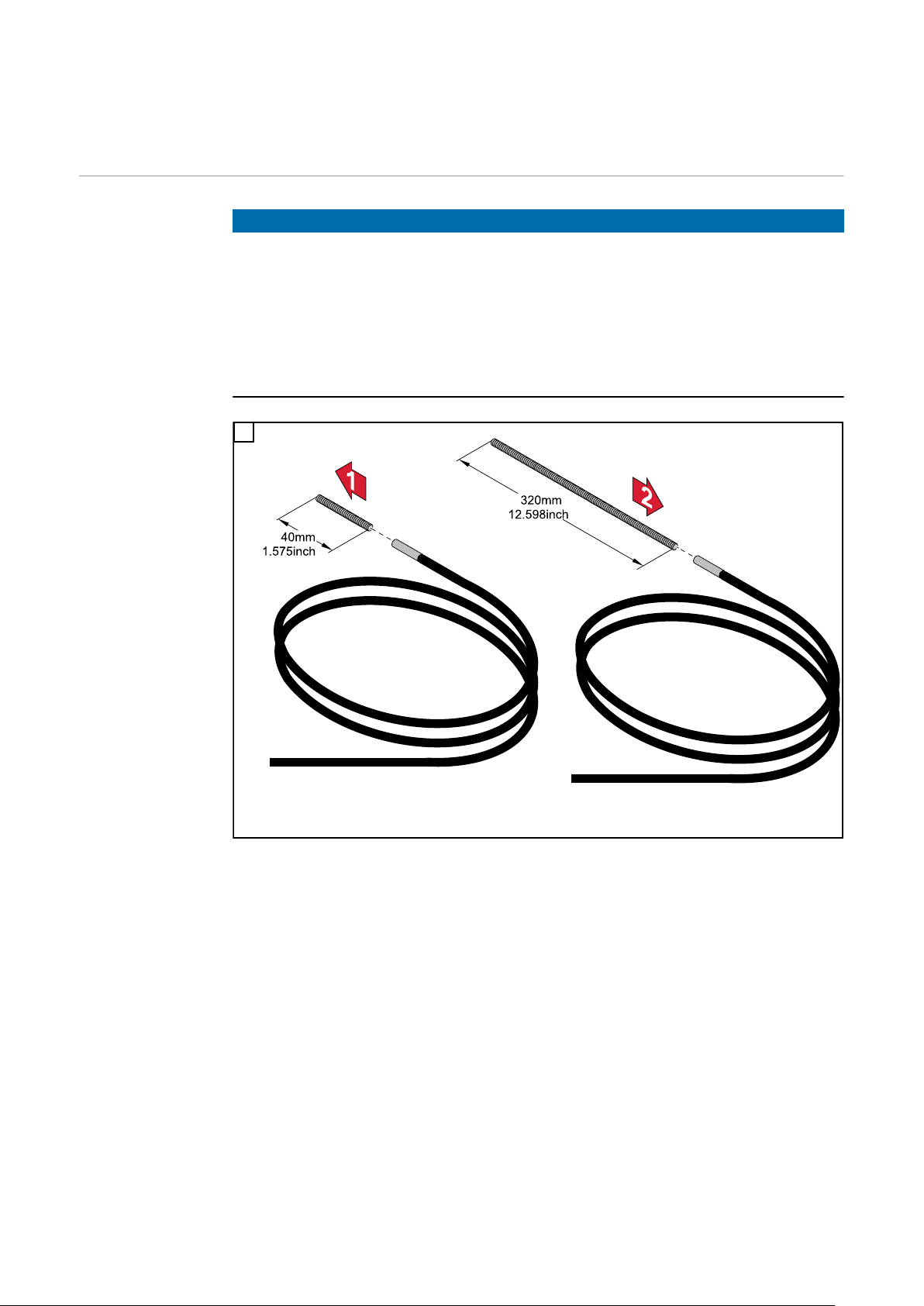

Note on inner

liner in gascooled welding

torches

NOTE!

Risk due to incorrect wire-guide insert.

This can result in poor-quality weld properties.

If a plastic inner liner with a bronze wire-guide insert is used in gascooled

▶

welding torches instead of a steel inner liner, the power data stated in the

technical data of the welding torch must be reduced by 30%.

In order to operate gascooled welding torches at maximum power, replace

▶

the 40 mm (1.575 in.) wire-guide insert with a 320 mm (12.598 in.) wire-guide

insert.

1

18

Fitting the inner

liner

1

EN-US

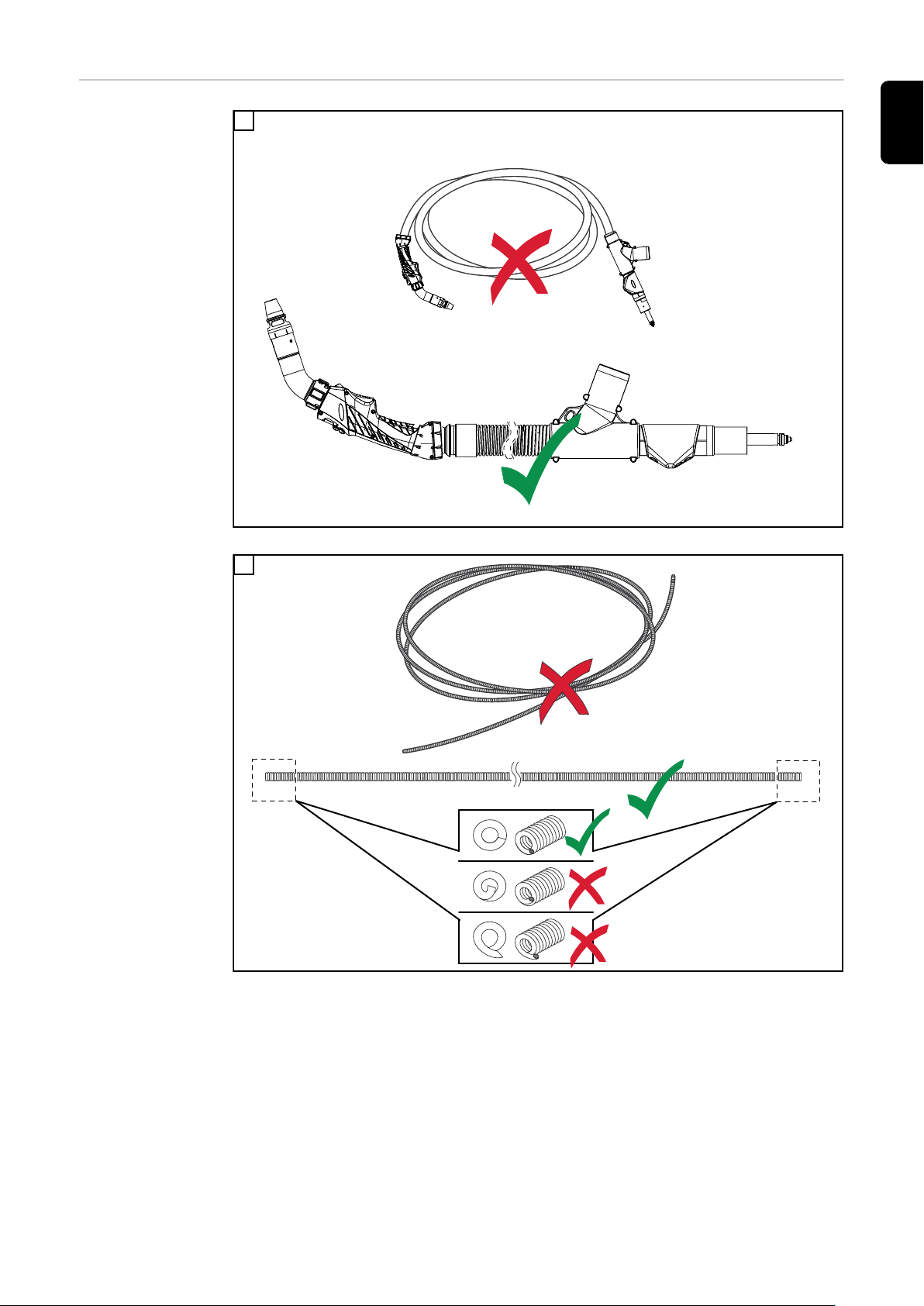

Lay out the welding torch straight

2

Lay out the inner liner straight; make sure that no burr protrudes into or out of the inner liner

19

3

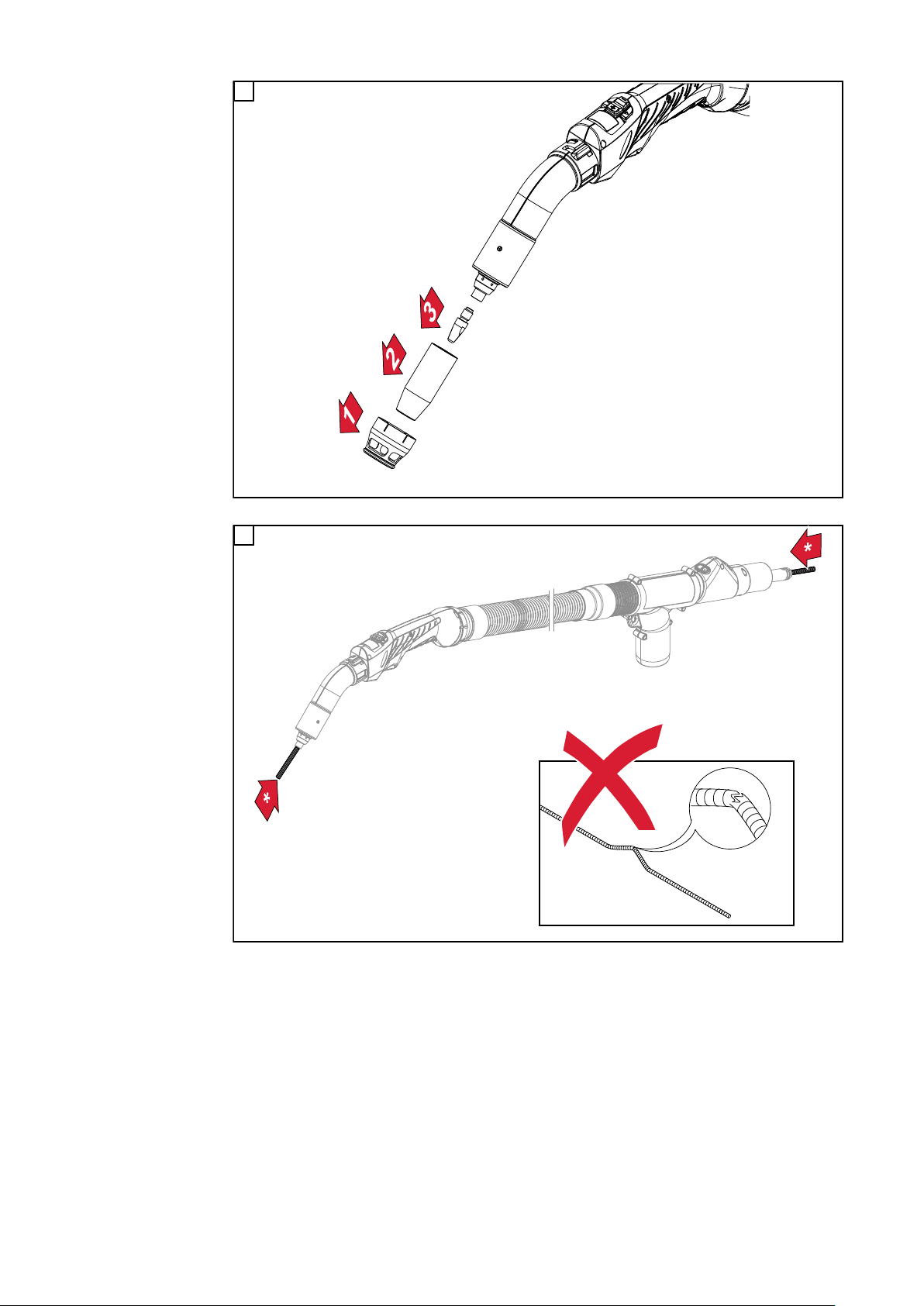

If the extraction nozzle, gas nozzle, and contact tip are already mounted, remove them

4

20

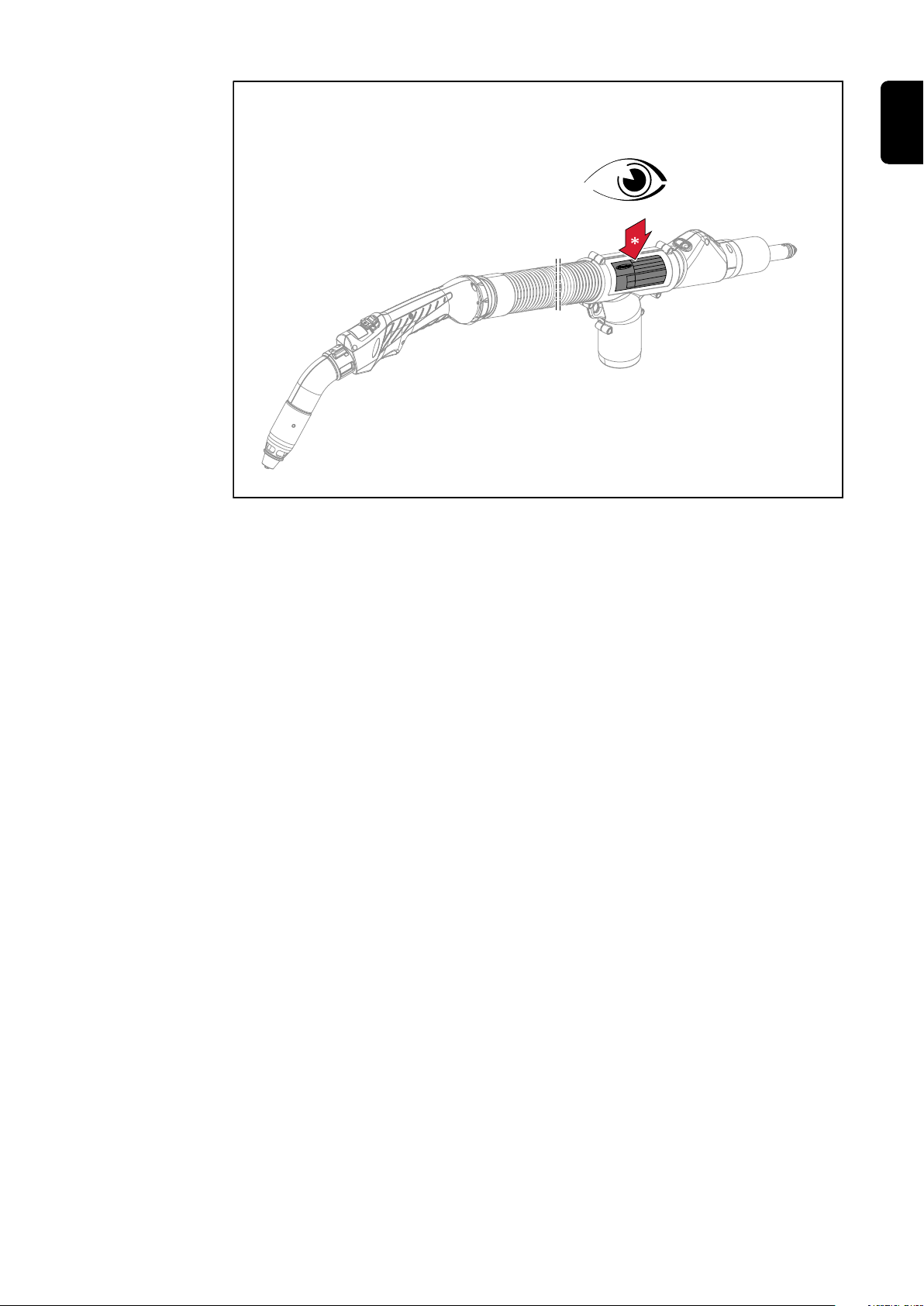

Push the inner liner into the welding torch (*this can be done from both sides) until it protrudes from

the front and rear of the welding torch; make sure that the inner liner is not kinked or snapped

5

Push the inner liner with the contact tip back into the torch body; mount the contact tip, gas nozzle,

and extraction nozzle; mark the inner liner at the end of the Schweißbrenners

6

EN-US

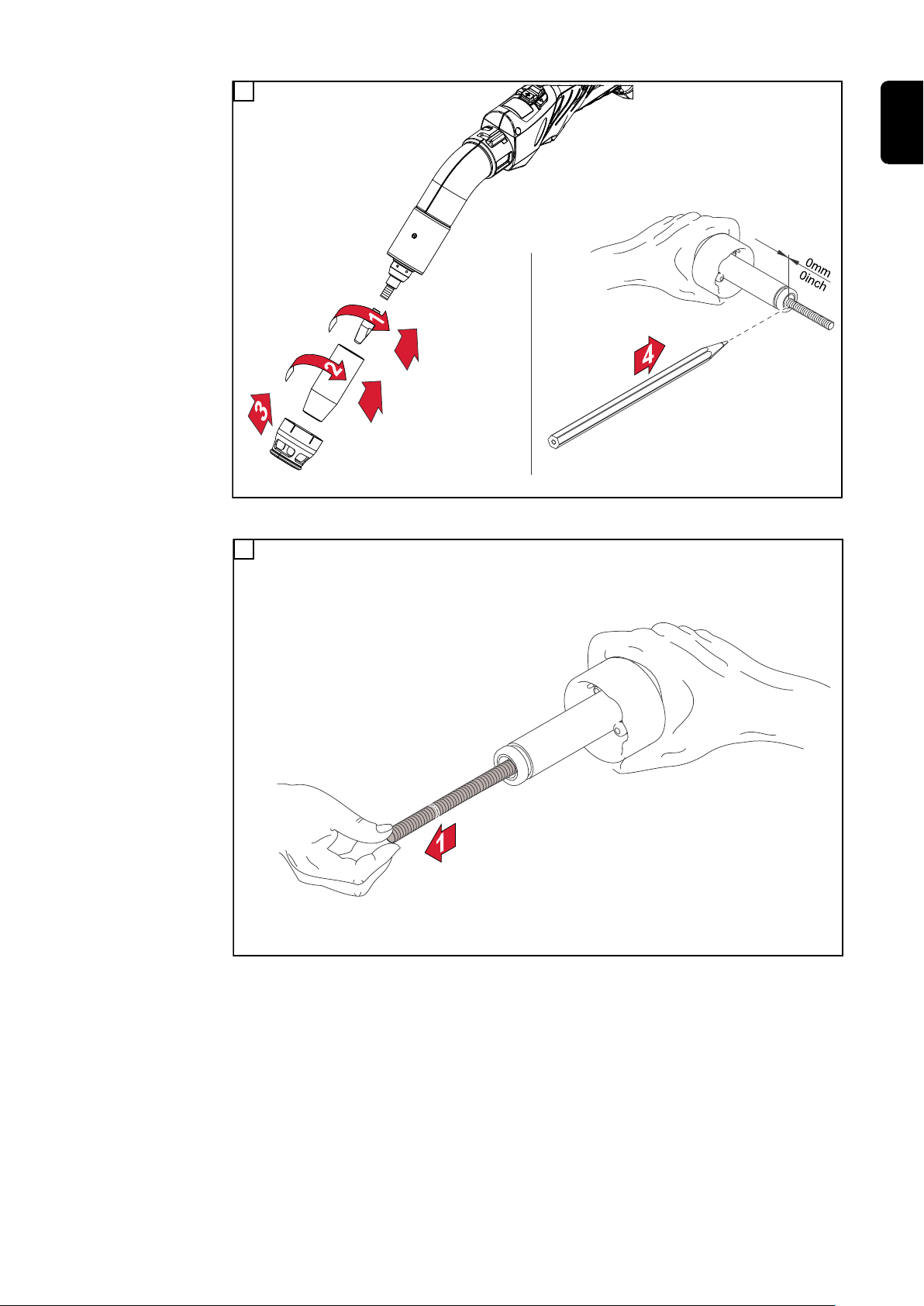

Pull inner liner 10 cm (3.94 in.) out of the welding torch

21

7

Left inner liner made of steel, right plastic: Cut and deburr the inner liner at the previously marked

position; make sure that no burr protrudes into or out of the inner liner

8

22

Screw the cap onto the inner liner up to the stop (the inner liner needs to be visible through the hole

in the cap); push the cap into the welding torch and secure

Fitting steel inner liner in welding torch with Euro

connection

Fitting the steel

inner liner

EN-US

1

Lay out the welding torch straight

2

Lay out the inner liner straight; make sure that no burr protrudes into or out of the inner liner

23

3

If already mounted, remove the extraction nozzle, gas nozzle, contact tip, and cap from the Euro

connection

4

24

Push the inner liner into the welding torch (*this can be done from both sides) until it protrudes from

the front and rear of the welding torch; make sure that the inner liner is not kinked or snapped

5

Push the inner liner with the contact tip back into the torch body; mount the contact tip, gas nozzle,

and extraction nozzle; mark the inner liner at the end of the welding torch

6

EN-US

Pull inner liner 10 cm (3.94 in.) out of the welding torch, cut, and deburr; make sure that no burr protrudes into or out of the inner liner

25

7

Screw the cap onto the inner liner up to the stop; screw the cap into the welding torch

26

Fitting plastic inner liner in welding torch with

Euro connection

Note on inner

liner in gascooled welding

torches

NOTE!

Risk due to incorrect wire-guide insert.

This can result in poor-quality weld properties.

If a plastic inner liner with a bronze wire-guide insert is used in gascooled

▶

welding torches instead of a steel inner liner, the power data stated in the

technical data of the welding torch must be reduced by 30%.

In order to operate gascooled welding torches at maximum power, replace

▶

the 40 mm (1.575 in.) wire-guide insert with a 320 mm (12.598 in.) wire-guide

insert.

1

EN-US

27

Fitting the

plastic inner

liner

1

Lay out the welding torch straight

2

28

Lay out the inner liner straight; ensure that no burr protrudes into or out of the wire-guide insert

3

If already mounted, remove the extraction nozzle, gas nozzle, contact tip, and cap from the Euro

connection

4

EN-US

Push the inner liner into the welding torch (*this can be done from both sides) until it protrudes from

the front and rear of the welding torch; make sure that the inner liner is not kinked or snapped

29

5

Push the inner liner with the contact tip back into the torch body; mount the contact tip, gas nozzle,

and extraction nozzle; secure the inner liner in the welding torch

Refer to the user documentation of the wirefeeder / power source used for

6

instructions on how to correctly cut the inner liner to length

30

Connecting welding torches to devices with Fronius System Connector

Connecting the

welding torch to

the power source

1

EN-US

2

* only with water-cooled welding torches

31

3

Connecting the

welding torch to

the wirefeeder

1

* only with water-cooled welding torches

32

Connecting welding torches to devices with Euro

connection

Connecting the

welding torch

EN-US

1

* only with water-cooled welding torches; connect welding torch to the cooling

unit

** the control line must be provided with the required control plug by the customer. The installer is responsible for the correct execution of the work.

33

Connecting welding torch to extraction system

and measuring extraction capacity

Connecting the

welding torch to

the extraction

system

The welding torch can be connected to an external extraction unit as well as to a

central extraction system. The welding torch is always connected in the same way.

1

Measuring the

extraction capacity (extraction

volumetric flow)

with the Exentometer

Connecting welding torch to external extraction unit

* Recommendations for the extraction hose:

Use Fronius extraction hoses. The design and material composition of Froni-

-

us extraction hoses ensure maximum compatibility and leak-tightness

Keep the extraction hose as short as possible; the shorter the extraction

-

hose, the less energy the extraction unit has to apply to achieve the required

extraction values (for more information on the required extraction values, see

section Requirements for the extraction system from page 8 and technical

data)

The extraction volumetric flow is used as a measured value for the extraction capacity of the welding torch. The extraction volumetric flow is measured with the

Exentometer .

Measure the extraction capacity (extraction volumetric flow):

Switch on the extraction system

1

Read off the required extraction volumetric flow (Q

2

the welding torch - see also Extraction information on the rating plate on

page 10) or in the technical data

Ensure that the welding torch (including hosepack) and the extraction hose

3

do not have any holes, cracks, or other damage

Ensure that external adjustment devices do not falsify the check of the ex-

4

traction capacity (for example, external air flow regulators - see section Set-

ting extraction capacity with external air flow regulator from page 39, ....)

) - on the rating plate of

v,n

34

Remove the extraction nozzle and close the air flow regulator - see the figure

5

below

EN-US

Removing extraction nozzle and closing air flow regulator

Place the Exentometer upright on a solid surface (for example, on a work-

6

bench)

Insert the welding torch into the Exentometer as far as it will go

7

Since the extraction system is already running, the Exentometer immedi-

-

ately displays the current extraction capacity

* Ensure that the welding torch is fully inserted into the Exentometer and

8

that no air can escape between the welding torch and the Exentometer

This ensures that the displayed value for the extraction capacity is not

-

distorted

Putting welding torch in the Exentometer

35

Compare the measured extraction volumetric flow with the required extrac-

9

tion volumetric flow

if the two values match, no further measures are necessary

-

if the two values do not match, increase or reduce the power of the ex-

-

traction system until the extraction volumetric flow is in the correct

range

if the extraction volumetric flow is too low, there is a risk that the

-

welding fumes will not be optimally extracted

an excessively high extraction volumetric flow means there is a risk

-

that shielding gas will be unintentionally sucked off the weld seam

36

Adjusting the extraction capacity

EN-US

Setting the extraction capacity

on the welding

torch

The air flow regulator can be opened to reduce the extraction capacity. If the air

flow regulator is fully open, this reduces the extraction capacity of the welding

torch by 40%.

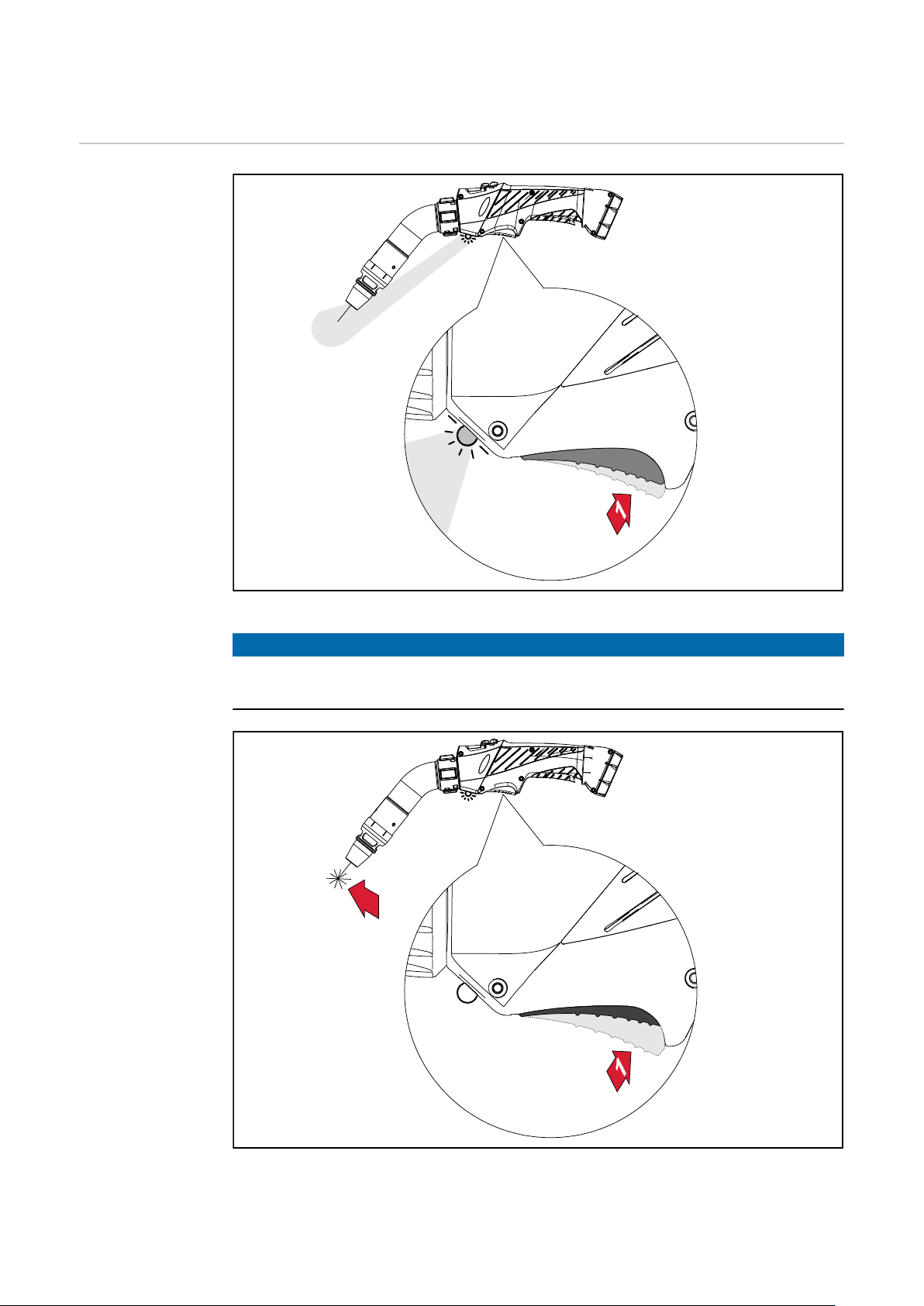

1

Left: air flow regulator closed = extraction capacity 100%; right: air flow regulator open = extraction

capacity 60%

Applications of the air flow regulator:

When welding in corners or fillet welds, it is possible for the welding fumes to

-

be optimally extracted even with reduced extraction capacity

In this case, too high an extraction capacity could lead to unintentional ex-

-

traction of the shielding gas

In this case, it is recommended to open the air flow regulator and thereby re-

-

duce the extraction capacity

37

Welding of a fillet weld; air flow regulator open = extraction capacity reduced

When welding on open surfaces (such as square butt welds), it may be necessary

to close the air flow regulator and thus use the maximum extraction capacity.

This provides the best possible extraction of welding fumes.

38

Welding of a square butt weld; air flow regulator closed = maximum extraction capacity

WARNING!

Danger from contact with toxic welding fumes.

Serious personal injuries may result.

Always ensure that all welding fumes are extracted, regardless of the welding

▶

task.

Setting extraction capacity

with external air

flow regulator

Particularly in the case of central extraction systems, it may be necessary to adjust the extraction capacity manually using the optionally available external air

flow regulator:

by completely opening the external air flow regulator, the air flow remains al-

-

most unchanged

by completely closing the external air flow regulator, the air flow is reduced

-

to a minimum level

1

EN-US

(1) central extraction system, (2) extraction hose, (3) external air flow regulator, (4) welding torch

After adjusting the air flow, always measure the extraction capacity of the

2

welding torch - for this, see section Measuring the extraction capacity (ex-

traction volumetric flow) with the Exentometer from page 34

39

40

Fault diagnosis, troubleshooting,

maintenance

41

42

Troubleshooting

EN-US

Troubleshooting

Porosity of weld seam

Cause:

Remedy:

Extraction too low

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

No welding current

Power source switched on, power source indication illuminates, shielding gas

present

Cause:

Remedy:

Extraction too strong

Reduce extraction

Holes in the extraction hose

Replace extraction hose

Displaced extraction unit filter

Replace extraction unit filter

Air passages otherwise blocked

Remove blockages

Extraction capacity of extraction unit too low

Use extraction unit with higher extraction capacity

Incorrect ground connection

Establish proper ground connection

Cause:

Remedy:

No shielding gas

All other functions present

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Power cable in welding torch damaged or broken.

Replace welding torch

Gas cylinder empty

Change gas cylinder

Gas pressure regulator faulty

Replace gas pressure regulator

Gas hose kinked, damaged, or not attached

Attach and straighten gas hose. Replace faulty gas hose

Welding torch faulty

Replace welding torch

Gas solenoid valve faulty

Contact service team (have gas solenoid valve replaced)

43

No function after pressing torch trigger

Power source switched on, power source indication illuminates

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

FSC (‘Fronius System Connector’—central connector) not inserted

up to the stop

Insert FSC up to the stop

Welding torch or welding torch control line faulty

Replace welding torch

Interconnecting hosepack not properly connected or faulty

Connect interconnecting hosepack properly

Replace faulty interconnecting hosepack

Faulty power source

Notify service provider

44

Poor-quality weld properties

Cause:

Remedy:

Incorrect welding parameters

Correct settings

EN-US

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Poor ground earth connection

Establish good contact with workpiece

Too little or no shielding gas

Check pressure regulator, gas hose, gas solenoid valve and welding

torch gas connection. For gas-cooled welding torches, check gas seal,

use suitable inner liner

Welding torch leaks

Replace welding torch

Excessively large or heavily worn contact tip

Change contact tip

Incorrect wire alloy or incorrect wire diameter

Check the inserted wire spool/basket-type spool

Incorrect wire alloy or incorrect wire diameter

Check the weldability of the parent materials

Shielding gas not suitable for wire alloy

Use correct shielding gas

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Unfavorable welding conditions: Shielding gas contaminated (moisture, air), inadequate gas shield (weld pool “boiling”, draft), impurities

in the workpiece (rust, paint, grease)

Optimize welding conditions

Welding spatter in the gas nozzle

Remove welding spatter

Turbulence due to excessively high quantity of shielding gas

Reduce quantity of shielding gas; recommended:

shielding gas quantity (l/min) = wirespool diameter (mm) x 10

(for example 16 l/min for 1.6 mm wire electrode)

Excessively large distance between welding torch and workpiece

Reduce distance between welding torch and workpiece (approx. 10–

15 mm/0.39–0.59 in.)

Excessively large work angle of the welding torch

Reduce work angle of the welding torch

Wirefeed components do not correspond to the diameter of the wire

electrode/the material of the wire electrode

Use correct wirefeed components

45

Poor wirefeeding

Cause:

Remedy:

Depending on the system, brakes in the wirefeeder or power source

set too tightly

Set the brakes to be looser

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Hole in the contact tip displaced

Replace contact tip

Faulty inner liner or wire-guide insert

Check inner liner or wire-guide insert for kinks, soiling, etc.

Replace faulty inner liner or wire-guide insert

Feed rollers not suitable for wire electrode used

Use suitable feed rollers

Incorrect contact pressure of the feed rollers

Optimize contact pressure

Feed rollers soiled or damaged

Clean or replace feed rollers

Inner liner displaced or kinked

Replace inner liner

Inner liner too short after cutting to length

Replace inner liner and cut new inner liner to correct length

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Gas nozzle gets very hot

Cause:

Remedy:

Wear of the wire electrode due to excessive contact pressure from

the feed rollers

Reduce contact pressure from the feed rollers

Wire electrode soiled or rusted

Use high-quality wire electrode without soiling

For steel inner liners: use of uncoated inner liner

Use a coated inner liner

No heat dissipation due to gas nozzle being fitted too loosely

Screw the gas nozzle tightly up to the stop

46

Welding torch gets very hot

Cause:

Remedy:

Only in multi-lock welding torches: Union nut of the torch body loose

Tighten union nut

EN-US

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Short service life of the contact tip

Cause:

Remedy:

Cause:

Remedy:

Welding torch has been operated above the maximum welding current

Reduce welding power or use more powerful welding torch

Welding torch is inadequately sized

Observe duty cycle and load limits

For water-cooled systems only: Coolant flow too low

Check coolant level, coolant flow, coolant contamination, displace-

ment of the hosepack, etc.

Tip of the welding torch too close to the arc

Increase stick out

Incorrect feed rollers

Use correct feed rollers

Wear of the wire electrode due to excessive contact pressure at the

feed rollers

Reduce contact pressure at the feed rollers

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

NOTE!

In CrNi applications, greater contact tip wear may occur due to the surface finish of the CrNi wire electrode.

Wire electrode soiled/rusted

Use high-quality wire electrode without soiling

Uncoated wire electrode

Use wire electrode with suitable coating

Incorrect dimensions of the contact tip

Use contact tip of the correct size

Duty cycle of the welding torch too long

Reduce duty cycle or use more powerful welding torch

Contact tip overheats. No heat dissipation due to contact tip being

fitted too loosely

Tighten contact tip

47

Malfunction of the torch trigger

Cause:

Remedy:

Faulty plug connections between the welding torch and the power

source

Establish correct plug connections/send power source or welding

torch to service team

Cause:

Remedy:

Cause:

Remedy:

Porosity of weld seam

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Soiling between torch trigger and torch trigger housing

Remove soiling

Faulty control line

Notify service provider

Spattering in the gas nozzle, causing inadequate gas shield for weld

seam

Remove welding spatter

Holes in gas hose or imprecise gas hose connection

Replace gas hose

O-ring at central connector is cut or faulty

Replace O-ring

Moisture/condensate in the gas line

Dry gas line

Gas flow too strong or weak

Correct gas flow

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Inadequate quantity of gas at the start or end of welding

Increase gas pre-flow and gas post-flow

Rusted or poor quality wire electrode

Use high-quality wire electrode without soiling

Applies to gas-cooled welding torches: Gas leakage with non-isolated

inner liners

For gas-cooled welding torches, only use isolated inner liners

Too much parting agent applied

Remove excess parting agent/apply less parting agent

48

Maintenance

Detecting defective wear

parts

1.

2.

3.

4.

5.

6.

Nozzle fitting

Burnt outer edges, notches

-

Heavily coated with welding spatter

-

Spatter guard (only for water-cooled welding torches)

Burnt outer edges, notches

-

Extraction nozzle

Burnt outer edges, notches

-

Contact tip

Ground (oval) wire entry and wire exit bores

-

Heavily coated with welding spatter

-

Penetration at the tip of the contact tip

-

Gas nozzle

Heavily coated with welding spatter

-

Burnt outer edges

-

Notches

-

Insulating parts

Burnt outer edges, notches

-

EN-US

49

Maintenance at

the beginning of

each working day

Check extraction nozzle and replace if damaged:

1

Clean gas nozzle, contact tip, spatter guard (only for water-cooled welding

torches), nozzle fitting, and insulating parts from welding splatter, check for

damage, and replace damaged parts:

2

50

In addition to the steps listed above, prior to starting up water-cooled weld-

3

ing torches always:

Ensure that all coolant connections are leak-tight

-

Ensure that there is a proper coolant return flow - refer to the user docu-

-

mentation of the cooling unit for more information

Maintenance

every 48 hours

Open and close the air flow regulator every 48 hours:

Switch on the extraction system

1

2

EN-US

Opening and closing the air flow regulator

If the air inlets are dirty and / or the air flow regulator can no longer be opened

smoothly, clean the air inlets with compressed air:

3

Ensure that any particles released during cleaning are picked up by the extraction system

51

Maintenance at

every wirespool/

basket-type

spool replacement

Clean the wirefeeding hose with reduced compressed air:

1

Dismantling the wearing parts

Switch on the extraction system

2

3

52

Cleaning the hosepack; ensure that any particles released during cleaning are picked up by the extraction system

Recommended - When replacing the inner liner, clean the wearing parts before

re-installing the inner liner:

4

Cleaning the contact tip, spatter guard, and nozzle fitting with compressed air; ensure that any

particles released during cleaning are picked up by the extraction system

5

EN-US

Cleaning extraction nozzle and gas nozzle with brush

53

54

Technical data

55

56

Technical data of water-cooled welding torches

General Voltage rating (V-peak):

For hand-held welding torches: 113 V

-

For machine-guided welding torches: 141 V

-

Torch trigger technical data:

U

-

-

The torch trigger can only be operated within the limits of the technical data.

This product meets the requirements set out in standard

-

-

The welding fume detection efficiency of torch-integrated extraction systems

(according to EN ISO 21904-3) depends on several influencing factors, such as:

-

-

-

-

-

-

-

-

-

= 5 V

max

I

= 10 mA

max

EN IEC 60974-7 / - 10 CI. A and

EN ISO 21904-1.

Workpiece quality and the associated fume formation during welding

Welding process

Welding direction (trailing or leading)

Welding positions (PA, PC, PF, etc.)

Workpiece geometry (open or closed design, etc.)

Volumetric flow of the shielding gas

Work angle of the welding torch

Environmental conditions

...

EN-US

MTW Exento

welding torch

technical data

MTW 300i Exento | Welding torch length = 3.5 m (11 ft. 5.8 in.)

Welding current at 10 min / 40 °C (104 °F);

100% D.C.1) / 300 A

Values apply with CO2 and mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction con-

52 m3/h (1837 cfh)

95 m3/h (1837 cfh)

13.5 kPa (135 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Required minimum cooling power according to standard

IEC 60974-2

Required minimum coolant flow Q

min

(0.26 gal. [US]/min)

Required minimum coolant pressure p

Maximum permissible coolant pressure p

min

max

Permissible wire electrodes (diameter)

700 W

1 l/min

3 bar (43 psi)

5.5 bar (79 psi)

0.8 - 1.2 mm

(0.032 - 0.047 in.)

57

MTW 300i Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Welding current at 10 min / 40 °C (104 °F);

100% D.C.1) / 300 A

Values apply with CO2 and mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction con-

52 m3/h (1837 cfh)

100 m3/h (3532 cfh)

15 kPa (150 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Required minimum cooling power according to standard

IEC 60974-2

Required minimum coolant flow Q

min

(0.26 gal. [US]/min)

Required minimum coolant pressure p

Maximum permissible coolant pressure p

Permissible wire electrodes (diameter)

min

max

(0.032 - 0.047 in.)

MTW 300d Exento | Welding torch length = 3.5 m (11 ft. 5.8 in.)

900 W

1 l/min

3 bar (43 psi)

5.5 bar (79 psi)

0.8 - 1.2 mm

Welding current at 10 min / 40 °C (104 °F);

100% D.C.1) / 300 A

Values apply with CO2 and mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction con-

52 m3/h (1837 cfh)

95 m3/h (1837 cfh)

13.5 kPa (135 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Required minimum cooling power according to standard

IEC 60974-2

Required minimum coolant flow Q

min

(0.26 gal. [US]/min)

Required minimum coolant pressure p

Maximum permissible coolant pressure p

Permissible wire electrodes (diameter)

min

max

(0.032 - 0.047 in.)

MTW 300d Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

700 W

1 l/min

3 bar (43 psi)

5.5 bar (79 psi)

0.8 - 1.2 mm

58

Welding current at 10 min / 40 °C (104 °F);

Values apply with CO2 and mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

100% D.C.1) / 300 A

52 m3/h (1837 cfh)

100 m3/h (3532 cfh)

MTW 300d Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Required negative pressure Δpc at the extraction con-

15 kPa (150 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Required minimum cooling power according to standard

IEC 60974-2

Required minimum coolant flow Q

min

(0.26 gal. [US]/min)

Required minimum coolant pressure p

Maximum permissible coolant pressure p

min

max

Permissible wire electrodes (diameter)

MTW 500i Exento | Welding torch length = 3.5 m (11 ft. 5.8 in.)

Welding current at 10 min / 40 °C (104 °F);

Values apply with CO2 and mixed gas as shielding gas

100% D.C.1) / 400 A

40% D.C.1) / 500 A

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

57 m3/h (2013 cfh)

100 m3/h (3532 cfh)

EN-US

900 W

1 l/min

3 bar (43 psi)

5.5 bar (79 psi)

0.8 - 1.2 mm

(0.032 - 0.047 in.)

Required negative pressure Δpc at the extraction con-

11.9 kPa (119 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Required minimum cooling power according to standard

IEC 60974-2

Required minimum coolant flow Q

min

(0.26 gal. [US]/min)

Required minimum coolant pressure p

Maximum permissible coolant pressure p

Permissible wire electrodes (diameter)

min

max

(0.039 - 0.063 in.)

MTW 500i Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Welding current at 10 min / 40 °C (104 °F);

Values apply with CO2 and mixed gas as shielding gas

100% D.C.1) / 400 A

40% D.C.1) / 500 A

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

57 m3/h (2013 cfh)

105 m3/h (3709 cfh)

1000 W

1 l/min

3 bar (43 psi)

5.5 bar (79 psi)

1 - 1.6 mm

Required negative pressure Δpc at the extraction connection of the welding torch (EN IEC ISO 21904-1)

Required minimum cooling power according to standard

IEC 60974-2

Required minimum coolant flow Q

Required minimum coolant pressure p

min

min

14 kPa (140 mbar)

1200 W

1 l/min

(0.26 gal. [US]/min)

3 bar (43 psi)

59

MTW 500i Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Maximum permissible coolant pressure p

Permissible wire electrodes (diameter)

max

(0.039 - 0.063 in.)

MTW 500d Exento | Welding torch length = 3.5 m (11 ft. 5.8 in.)

Welding current at 10 min / 40 °C (104 °F);

Values apply with CO2 and mixed gas as shielding gas

100% D.C.1) / 400 A

40% D.C.1) / 500 A

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction con-

57 m3/h (2013 cfh)

100 m3/h (3532 cfh)

11.9 kPa (119 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Required minimum cooling power according to standard

IEC 60974-2

Required minimum coolant flow Q

min

(0.26 gal. [US]/min)

Required minimum coolant pressure p

min

5.5 bar (79 psi)

1 - 1.6 mm

1000 W

1 l/min

3 bar (43 psi)

Maximum permissible coolant pressure p

Permissible wire electrodes (diameter)

max

(0.039 - 0.063 in.)

MTW 500d Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Welding current at 10 min / 40 °C (104 °F);

Values apply with CO2 and mixed gas as shielding gas

100% D.C.1) / 400 A

40% D.C.1) / 500 A

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc of the extraction sys-

57 m3/h (2013 cfh)

105 m3/h (3709 cfh)

14 kPa (140 mbar)

tem (EN IEC ISO 21904-1)

Minimum cooling power according to standard

IEC 60974-2

Minimum coolant flow Q

min

(0.26 gal. [US]/min)

Minimum coolant pressure p

min

5.5 bar (79 psi)

1 - 1.6 mm

1200 W

1 l/min

3 bar (43 psi)

60

Maximum coolant pressure p

max

Permissible wire electrodes (diameter)

1)

ED = Duty cycle; after-run time of extraction system after end of welding

= 30 seconds

5.5 bar (79 psi)

1 - 1.6 mm

(0.039 - 0.063 in.)

Technical data of gascooled welding torches

General Voltage rating (V-peak):

For hand-held welding torches: 113 V

-

For machine-guided welding torches: 141 V

-

Torch trigger technical data:

U

-

-

The torch trigger can only be operated within the limits of the technical data.

This product meets the requirements set out in standard

-

-

The welding fume detection efficiency of torch-integrated extraction systems

(according to EN ISO 21904-3) depends on several influencing factors, such as:

-

-

-

-

-

-

-

-

-

= 5 V

max

I

= 10 mA

max

EN IEC 60974-7 / - 10 CI. A and

EN ISO 21904-1.

Workpiece quality and the associated fume formation during welding

Welding process

Welding direction (trailing or leading)

Welding positions (PA, PC, PF, etc.)

Workpiece geometry (open or closed design, etc.)

Volumetric flow of the shielding gas

Work angle of the welding torch

Environmental conditions

...

EN-US

MTG Exento

welding torch

technical data

MTG 250i Exento | Welding torch length = 3.5 m (11 ft. 5.8 in.)

Welding current at 10 min / 40 °C (104 °F);

Values apply with CO2 as shielding gas

(EN ISO 14175)

Welding current at 10 min / 40 °C (104 °F);

Values apply with mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

Extraction volumetric flow at the extraction connection

of the welding torch Q

Required negative pressure Δpc at the extraction connection of the welding torch (EN IEC ISO 21904-1)

Permissible wire electrodes (diameter)

MTG 250i Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Welding current at 10 min / 40 °C (104 °F);

Values apply with CO2 as shielding gas

(EN ISO 14175)

(EN IEC ISO 21904-1)

v,n

(EN IEC ISO 21904-1)

v,c

40% D.C.1) / 250 A

60% D.C.1) / 210 A

100% D.C.1) / 170 A

40% D.C.1) / 250 A

60% D.C.1) / 210 A

100% D.C.1) / 170 A

52 m3/h (1837 cfh)

70 m3/h (2472 cfh)

10 kPa (100 mbar)

(0.032 - 0.047 in.)

40% D.C.1) / 250 A

60% D.C.1) / 210 A

100% D.C.1) / 170 A

0.8 - 1.2 mm

61

MTG 250i Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Welding current at 10 min / 40 °C (104 °F);

Values apply with mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction con-

40% D.C.1) / 250 A

60% D.C.1) / 210 A

100% D.C.1) / 170 A

52 m3/h (1837 cfh)

80 m3/h (2526 cfh)

10.8 kPa (108 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Permissible wire electrodes (diameter)

MTG 250d Exento | Welding torch length = 3.5 m (11 ft. 5.8 in.)

Welding current at 10 min / 40 °C (104 °F):

Values apply with CO2 as shielding gas

(EN ISO 14175)

Welding current at 10 min / 40 °C (104 °F);

Values apply with mixed gas as shielding gas

(EN ISO 14175)

40% D.C.1) / 250 A

60% D.C.1) / 210 A

100% D.C.1) / 170 A

40% D.C.1) / 200 A

60% D.C.1) / 160 A

100% D.C.1) / 120 A

0.8 - 1.2 mm

(0.032 - 0.047 in.)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction con-

52 m3/h (1837 cfh)

70 m3/h (2472 cfh)

10 kPa (100 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Permissible wire electrodes (diameter)

(0.032 - 0.047 in.)

MTG 250d Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Welding current at 10 min / 40 °C (104 °F):

Values apply with CO2 as shielding gas

(EN ISO 14175)

Welding current at 10 min / 40 °C (104 °F);

Values apply with mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

40% D.C.1) / 250 A

60% D.C.1) / 210 A

100% D.C.1) / 170 A

40% D.C.1) / 200 A

60% D.C.1) / 160 A

100% D.C.1) / 120 A

52 m3/h (1837 cfh)

80 m3/h (2526 cfh)

0.8 - 1.2 mm

62

Required negative pressure Δpc at the extraction connection of the welding torch (EN IEC ISO 21904-1)

Permissible wire electrodes (diameter)

10.8 kPa (108 mbar)

0.8 - 1.2 mm

(0.032 - 0.047 in.)

MTG 320i Exento | Welding torch length = 3.5 m (11 ft. 5.8 in.)

Welding current at 10 min / 40 °C (104 °F):

Values apply with CO2 as shielding gas

(EN ISO 14175)

Welding current at 10 min / 40 °C (104 °F);

Values apply with mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction con-

40% D.C.1) / 320 A

60% D.C.1) / 260 A

100% D.C.1) / 210 A

40% D.C.1) / 320 A

60% D.C.1) / 260 A

100% D.C.1) / 210 A

57 m3/h (2013 cfh)

90 m3/h (3179 cfh)

10.2 kPa (102 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Permissible wire electrodes (diameter)

(0.032 - 0.063 in.)

MTG 320i Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Welding current at 10 min / 40 °C (104 °F):

Values apply with CO2 as shielding gas

(EN ISO 14175)

40% D.C.1) / 320 A

60% D.C.1) / 260 A

100% D.C.1) / 210 A

EN-US

0.8 - 1.6 mm

Welding current at 10 min / 40 °C (104 °F);

Values apply with mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction con-

40% D.C.1) / 320 A

60% D.C.1) / 260 A

100% D.C.1) / 210 A

57 m3/h (2013 cfh)

94 m3/h (3320 cfh)

11 kPa (110 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Permissible wire electrodes (diameter)

MTG 320d Exento | Welding torch length = 3.5 m (11 ft. 5.8 in.)

Welding current at 10 min / 40 °C (104 °F):

Values apply with CO2 as shielding gas

(EN ISO 14175)

Welding current at 10 min / 40 °C (104 °F);

Values apply with mixed gas as shielding gas

(EN ISO 14175)

40% D.C.1) / 320 A

60% D.C.1) / 260 A

100% D.C.1) / 210 A

40% D.C.1) / 260 A

60% D.C.1) / 210 A

100% D.C.1) / 160 A

0.8 - 1.6 mm

(0.032 - 0.063 in.)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction connection of the welding torch (EN IEC ISO 21904-1)

57 m3/h (2013 cfh)

90 m3/h (3179 cfh)

10.2 kPa (102 mbar)

63

MTG 320d Exento | Welding torch length = 3.5 m (11 ft. 5.8 in.)

Permissible wire electrodes (diameter)

(0.032 - 0.063 in.)

MTG 320d Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Welding current at 10 min / 40 °C (104 °F):

Values apply with CO2 as shielding gas

(EN ISO 14175)

Welding current at 10 min / 40 °C (104 °F);

Values apply with mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction con-

40% D.C.1) / 320 A

60% D.C.1) / 260 A

100% D.C.1) / 210 A

40% D.C.1) / 260 A

60% D.C.1) / 210 A

100% D.C.1) / 160 A

57 m3/h (2013 cfh)

94 m3/h (3320 cfh)

11 kPa (110 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Permissible wire electrodes (diameter)

(0.032 - 0.063 in.)

0.8 - 1.6 mm

0.8 - 1.6 mm

MTG 400i Exento | Welding torch length = 3.5 m (11 ft. 5.8 in.)

Welding current at 10 min / 40 °C (104 °F):

Values apply with CO2 as shielding gas

(EN ISO 14175)

Welding current at 10 min / 40 °C (104 °F);

Values apply with mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction con-

30% D.C.1) / 400 A

60% D.C.1) / 320 A

100% D.C.1) / 260 A

30% D.C.1) / 400 A

60% D.C.1) / 320 A

100% D.C.1) / 260 A

57 m3/h (2013 cfh)

90 m3/h (3179 cfh)

10.2 kPa (102 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Permissible wire electrodes (diameter)

(0.032 - 0.063 in.)

MTG 400i Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Welding current at 10 min / 40 °C (104 °F):

Values apply with CO2 as shielding gas

(EN ISO 14175)

30% D.C.1) / 400 A

60% D.C.1) / 320 A

100% D.C.1) / 260 A

0.8 - 1.6 mm

64

Welding current at 10 min / 40 °C (104 °F);

Values apply with mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

30% D.C.1) / 400 A

60% D.C.1) / 320 A

100% D.C.1) / 260 A

57 m3/h (2013 cfh)

MTG 400i Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction con-

94 m3/h (3320 cfh)

11 kPa (110 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

Permissible wire electrodes (diameter)

MTG 400d Exento | Welding torch length = 3.5 m (11 ft. 5.8 in.)

Welding current at 10 min / 40 °C (104 °F):

Values apply with CO2 as shielding gas

(EN ISO 14175)

Welding current at 10 min / 40 °C (104 °F);

Values apply with mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

Required negative pressure Δpc at the extraction con-

30% D.C.1) / 400 A

60% D.C.1) / 320 A

100% D.C.1) / 260 A

30% D.C.1) / 320 A

60% D.C.1) / 260 A

100% D.C.1) / 210 A

57 m3/h (2013 cfh)

90 m3/h (3179 cfh)

10.2 kPa (102 mbar)

nection of the welding torch (EN IEC ISO 21904-1)

EN-US

0.8 - 1.6 mm

(0.032 - 0.063 in.)

Permissible wire electrodes (diameter)

MTG 400d Exento | Welding torch length = 4.5 m (14 ft. 9.17 in.)

Welding current at 10 min / 40 °C (104 °F):

30% D.C.1) / 400 A

Values apply with CO2 as shielding gas

(EN ISO 14175)

100% D.C.1) / 260 A

Welding current at 10 min / 40 °C (104 °F);

Values apply with mixed gas as shielding gas

(EN ISO 14175)

Extraction volumetric flow at the front end of the welding torch Q

(EN IEC ISO 21904-1)

v,n

Extraction volumetric flow at the extraction connection

of the welding torch Q

(EN IEC ISO 21904-1)

v,c

60% D.C.1) / 260 A

100% D.C.1) / 210 A

57 m3/h (2013 cfh)

94 m3/h (3320 cfh)

Required negative pressure Δpc at the extraction connection of the welding torch (EN IEC ISO 21904-1)

Permissible wire electrodes (diameter)

1)

ED = Duty cycle; after-run time of extraction system after end of welding

= 30 seconds

0.8 - 1.6 mm

(0.032 - 0.063 in.)

60% D.C.1) / 320 A

30% D.C.1) / 320 A

11 kPa (110 mbar)

0.8 - 1.6 mm

(0.032 - 0.063 in.)

65

66

EN-US

67

Loading...

Loading...