Fronius prints on elemental chlorine free paper (ECF) sourced from certified sustainable forests (FSC).

/ Perfect Charging / Perfect Welding / Solar Energy

MagicCleaner 150

Operating instructions

EN-US

42,0426,0395,EA 002-17012022

Table of contents

Safety Instructions 5

Explanation of Safety Instructions 5

General 5

Intended use 5

Environmental conditions 6

Obligations of the Operating Company 6

Obligations of Personnel 6

Personal protection and protection of others 6

Notes on the correct handling of the cleaning and Print electrolytes 7

Risks from grid current and cleaning current 8

EMC measures 9

Particular hazard areas 10

Safety measures at the setup location and during transport 10

Safety measures in normal operation 10

Commissioning, maintenance and repair 11

Safety inspection 11

Safety Symbols 11

Copyright 11

General information 12

Device concept 12

Intended use 12

Scope of supply 13

Options 14

Transport information 16

Setup regulations 17

Warning notices on the device 17

Operating controls, connections and mechanical components 18

Safety 18

Operating controls and connections 18

Safety Instructions for commissioning, operation, and maintenance 20

Read and follow the Safety Instructions! 20

Safety Instructions for commissioning, operation, and maintenance 20

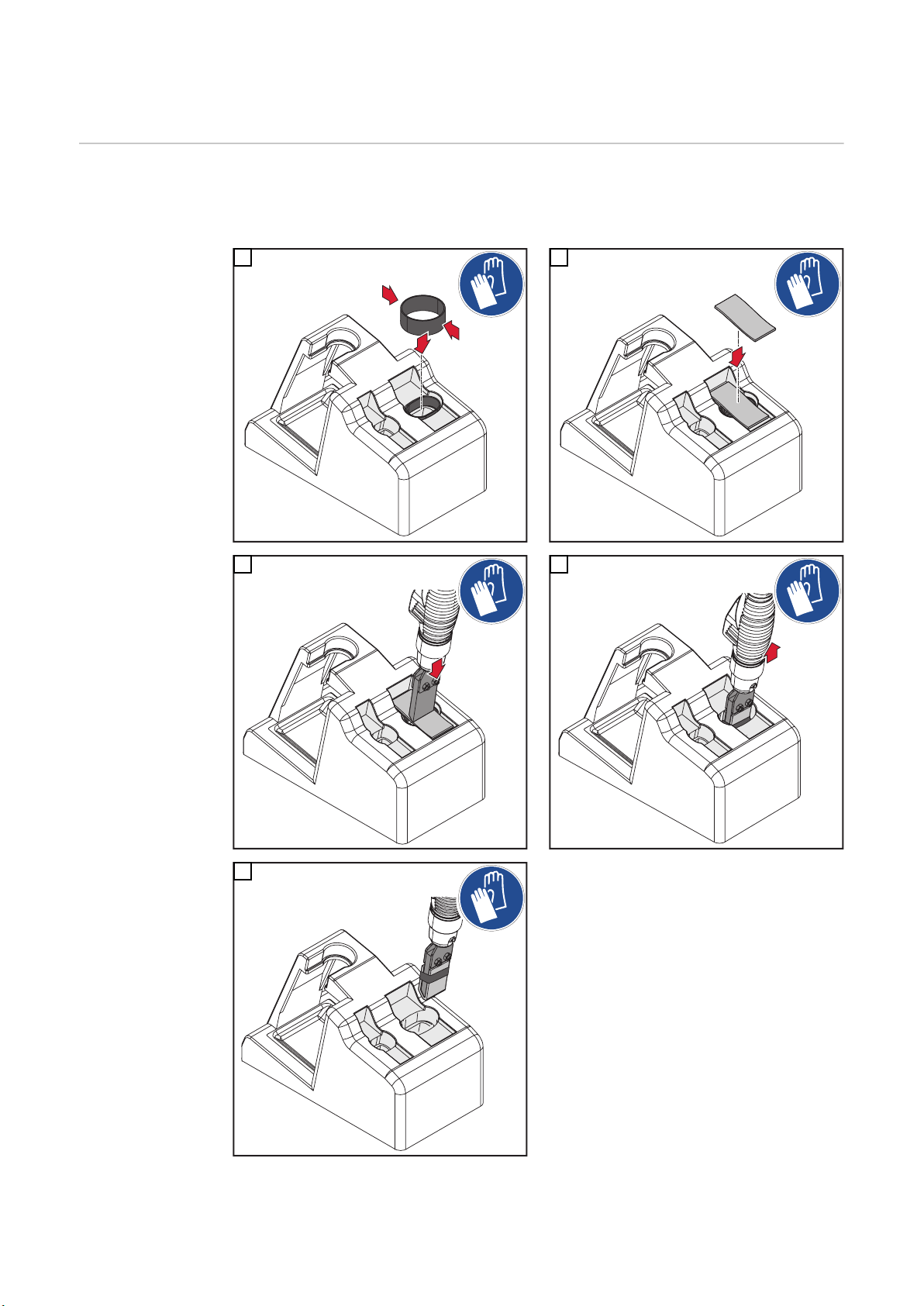

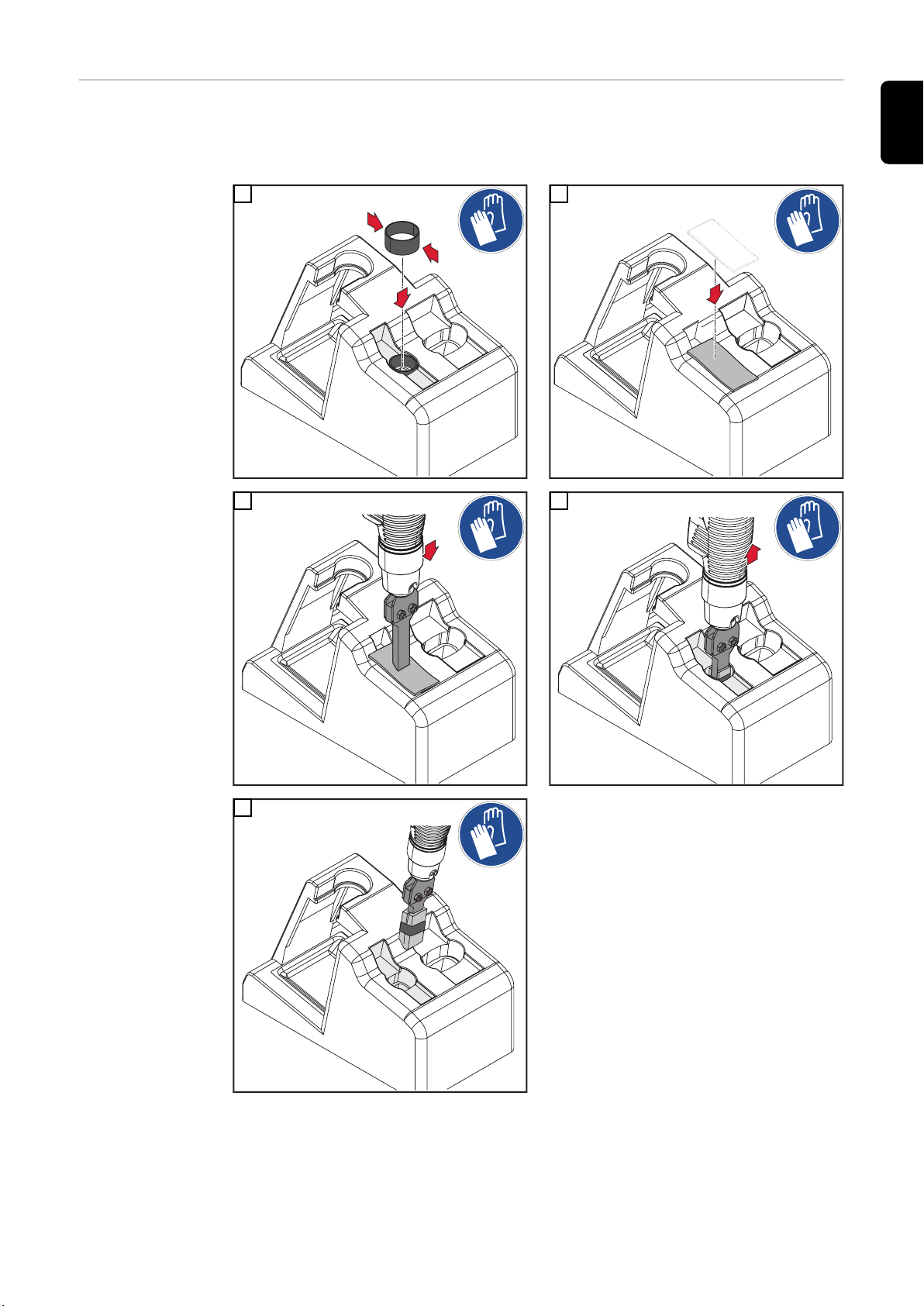

Mounting the cleaning electrode 23

Overview 23

Mounting the cleaning electrode 24

Attaching the supplied cleaning felt to the cleaning electrode 25

Mounting the optionally available cleaning felt 26

Mounting cleaning felt by means of torch holder - 22 mm / 0.87 inch cleaning electrode 26

Mounting cleaning felt by means of torch holder - 10 mm / 0.39 inch cleaning electrode 27

Mounting cleaning felt by means of O-ring - 35 mm / 1.38 inch cleaning electrode 28

Mounting the cleaning brush 29

Mounting the cleaning brush 29

Readjusting the cleaning brush 30

Preparing the workstation 31

Connecting the grounding cable and cleaning torch cable 31

Preparing the workstation 31

Before using the cleaning torch for the first time 32

Cleaning 33

Screwing the cleaning electrolyte onto the cleaning torch 33

Placing the cleaning torch in the cleaning torch holder 34

Cleaning 34

After cleaning 36

Polishing 38

General 38

Placing the cleaning torch in the cleaning torch holder 38

Polishing 39

After polishing 40

Printing 42

General 42

Mounting the Print electrode and Print felt 43

EN-US

3

Preparing the workstation for Printing 44

Printing 45

After the Print process 46

Service, maintenance and disposal 49

General 49

At every start-up 49

At the end of each shift 49

Disposal 49

Technical data 51

MagicCleaner 150 /EF 150 /CN 150 /np 51

MagicCleaner 150 MV/B 150 MV/np 52

4

Safety Instructions

EN-US

Explanation of

Safety Instructions

DANGER!

Indicates an immediate danger.

Death or serious injury may result if appropriate precautions are not taken.

▶

WARNING!

Indicates a possibly dangerous situation.

Death or serious injury may result if appropriate precautions are not taken.

▶

CAUTION!

Indicates a situation where damage or injury could occur.

Minor injury or damage to property may result if appropriate precautions are not

▶

taken.

NOTE!

Indicates the possibility of flawed results and damage to the equipment.

General The device has been manufactured in line with the state of the art and according to re-

cognized safety standards. If used incorrectly or misused, however, it can cause:

- Serious or fatal injury to the operator or third parties

- Damage to the device and other material assets belonging to the operating company

- Inefficient operation of the device

All persons involved in the commissioning, operation, maintenance, and servicing of the

device must

- Be suitably qualified

- Have fully read and precisely followed these Operating Instructions

The Operating Instructions must always be kept to hand wherever the device is being

used. In addition to the Operating Instructions, all applicable local rules and regulations

regarding accident prevention and environmental protection must also be followed.

All safety and danger notices on the device:

- Must be kept in a legible state

- Must not be damaged/marked

- Must not be removed

- Must not be covered, pasted, or painted over

Before starting up the device, remedy any faults that could compromise safety.

Your personal safety is at stake!

Intended use The device is to be used exclusively for its intended purpose.

The manufacturer shall not be liable for any damage resulting from any other use or use

beyond the scope of this manual.

5

Intended use also means

- Carefully reading and adhering to these Operating Instructions

- Following all instructions, safety and hazard warnings

- Carrying out all the specified inspection and maintenance work.

The device is designed for operation in industry and business. The manufacturer shall

not be liable for any damage resulting from use in a living area.

The manufacturer shall also not be liable for faulty or incorrect work results.

Environmental

conditions

Obligations of the

Operating Company

Operation or storage of the device outside the stipulated area will be deemed as not in

accordance with the intended purpose. The manufacturer accepts no liability for any

damage resulting from improper use.

Temperature range of ambient air:

- During operation: 0 °C to +40 °C (32 °F to 104 °F)

- During transport and storage: -20 °C to +55 °C (-4 °F to 131 °F)

NOTE!

The minus temperature range for transport and storage refers only to the device

and accessories, not to the cleaning and Print electrolytes.

Relative humidity:

- up to 50% at 40 °C (104 °F)

- up to 90% at 20 °C (68 °F)

Ambient air: free of dust, acids, corrosive gases or substances.

Altitude above sea level: up to 2000 m (6561 ft. 8.16 in.)

The operating company must only allow persons to work with the device if they

- Are familiar with the basic occupational safety and accident prevention regulations

and are trained in handling the device

- Have read and understood these Operating Instructions, especially the section

"Safety Rules," and have confirmed this with their signature

- Are trained according to the requirements for the work results

Obligations of

Personnel

Personal protection and protection of others

6

The safety-conscious work of the personnel must be checked regularly.

All persons who are assigned to work with the device must do the following before beginning the work:

- Follow the basic regulations for occupational safety and accident prevention

- Read these Operating Instructions, especially the section "Safety Rules," and confirm that they have understood and will follow them by signing

Before leaving the workplace, ensure that no personal injury or property damage can occur in one's absence.

You are exposed to numerous hazards while working with the device, for example:

- Irritation or burning of the skin due to contact with cleaning electrolyte or Print electrolyte

- Danger of serious eye damage due to contact with cleaning electrolyte or Print electrolyte

- General hazards when handling chemicals

Observe the safety data sheets of the cleaning and Print electrolytes!

- Electrical risks from grid current and cleaning current

- Harmful vapors

Individuals working on the workpiece during the cleaning process must wear suitable

work clothing with the following properties:

- Resistant against acids and chemicals

- Insulating and dry

- Covering the entire body and in good condition with no damage

Work clothing includes the following:

- Tightly fitting safety goggles (eye protection)

- Rigid, wet-insulating footwear

- Protective gloves (hand protection): impermeable, resistant to acids and chemicals

- Breathing protection

EN-US

The required condition of work clothing and protective measures are indicated on the

safety data sheet of the cleaning and Print electrolytes.

Immediately remove work clothing contaminated with cleaning agent!

- Do not eat or drink when working with the device

- Keep cleaning and Print electrolytes away from food, beverages, and feedstuffs

- Wash hands before breaks and at the end of work

Keep persons, especially children, and those who are pregnant or unwell, away during

the operation of the devices and during the working process. However, if persons are in

the vicinity:

- Inform them of all risks

- Provide suitable protective equipment

or

- Construct suitable protective walls or curtains.

Notes on the correct handling of

the cleaning and

Print electrolytes

The following points must be observed when handling the cleaning and Print electrolytes.

For exact data, please refer to the respective safety data sheets. For current safety data

sheets, use the following link:

7

www.fronius.com/magiccleaner

First aid measures

- After inhalation provide fresh air. Consult a physician if complaints persist.

- After skin contact, wash immediately with soap and water, and rinse thoroughly.

Consult a physician if skin irritation persists.

- If swallowed, do not induce vomiting, rinse mouth and drink plenty of water, seek

medical advice immediately.

- After eye contact, rinse opened eye for several minutes under running water (eye

wash) and seek medical advice.

If present, remove contact lenses and continue rinsing.

Storage

- Only use containers specifically approved for the cleaning agents

- Keep container tightly closed

- Do not store together with alkalis (lyes) and metals

- Store in a cool and dry place

- Provide acid resistant floor

Risks from grid

current and

cleaning current

- Keep under lock and key and out of reach of children

Other notes

- To avoid thermal decomposition, do not heat (danger of toxic gases being produced)

- Provide emergency cooling in the event of a fire in the environment

- Avoid contact with skin, eyes, and mucous membranes

- Use only in well ventilated areas, use respiratory protection or adequate exhaust

ventilation.

- When diluting, always add acid to water - not vice versa!

- Dispose of cleaning agents or uncleaned packaging in accordance with national regulations. Do not dispose of with household waste!

- Do not allow to enter drains, watercourses or groundwater (e.g., via the soil)

An electric shock can be fatal. Every electric shock poses a risk of death.

Do not touch voltage-carrying parts inside or outside the device.

8

Ensure suitable personal protection with dry temporary backing or cover with sufficient

insulation against the ground potential. The temporary backing or cover must completely

cover the entire area between the body and the ground potential.

All cables and leads must be secured, undamaged, insulated, and adequately dimensioned. Replace loose connections and scorched, damaged, or inadequately dimensioned cables and leads immediately.

Do not wrap cables or leads around your body or parts of the body.

Have the mains and device supply lead regularly inspected by an electrician to ensure

that the ground conductor is functioning properly.

Only operate the device on a grid with a ground conductor and a socket with a ground

conductor contact.

Operating the device on a grid without a ground conductor and on a socket without a

ground conductor contact is considered gross negligence. The manufacturer accepts no

liability for any damage resulting from improper use.

Use suitable equipment to ensure that the workpiece is sufficiently grounded if necessary.

Switch off unused devices.

Before working on the device, switch off the device and unplug the mains plug.

EN-US

Secure the device to prevent the mains plug from being connected and switched on

again by applying a clearly legible and understandable warning sign.

The device may only be opened by professionally trained service technicians.

EMC measures It is the responsibility of the operator to take care to ensure that there is no electromag-

netic interference with electrical and electronic equipment.

If electromagnetic interference is identified, then the operator is obliged to take action to

rectify the situation

Check and evaluate possible problems and the interference immunity of equipment in

the vicinity according to national and international regulations:

- Safety devices

- Mains power lines, signal lines, and data transfer lines

- IT and telecommunications equipment

- Devices for measuring and calibrating

- The health of persons close by, e.g., those with pacemakers and hearing aids

- Persons with pacemakers must seek advice from their doctor before staying in the

immediate vicinity of the device and the cleaning process

Electromagnetic fields may cause health problems that are not yet known.

Supporting measures to avoid EMC problems:

1. Mains power supply

- If electromagnetic interference occurs despite a mains connection that complies

with regulations, take additional measures (e.g., use a suitable mains filter).

2. Equipotential bonding

3. Workpiece grounding

- If necessary, establish grounding using suitable capacitors.

4. Shield, if necessary

- Shield other devices in the vicinity

- Shield entire system

9

Particular hazard

areas

Special regulations apply in areas at risk of fire or explosion

- Follow the appropriate national and international regulations.

Devices for work in areas with increased electrical hazard (such as boilers) must be

labeled with the symbol [S] (Safety).

Measurements of toxic emissions when working with the device showed values below

permissible "average workplace concentrations" (MAK).

Nevertheless:

- Ensure there is a sufficient supply of fresh air.

- Keep your face away from any vapors that arise.

- Do not inhale vapors, or extract vapors from the work area by suitable means.

During operation

- Ensure that all covers are closed, and all side parts have been mounted properly.

- Keep all covers and side parts closed.

If the device is equipped with a carrier belt or handle, then this is used exclusively for

transport by hand. The carrier belt is not suitable for transport by crane, counterbalanced

lift truck or other mechanical lifting tools.

Safety measures

at the setup location and during

transport

A toppling device can be deadly! Set up the device securely on an even, solid surface

- The maximum permitted tilt angle is 10°.

Special regulations apply in areas at risk of fire or explosion

- Follow the appropriate national and international regulations.

Use instructions and checks within the company to ensure that the vicinity of the workplace is always clean and organized.

Only set up and operate the device in accordance with the protection class shown on the

rating plate.

When setting up the device, ensure that there is an all-round clearance of 0.5 m (1 ft.

7.69 in.) to allow cooling air to circulate unhindered.

Take care to ensure that the applicable national and regional guidelines and accident

prevention regulations are observed when transporting the device, especially guidelines

concerning hazards during transport and shipment.

Before transporting the device, always completely drain the cleaning agent.

It is essential to conduct a visual inspection of the device to check for damage after it has

been transported but before commissioning. Have any damage repaired by trained service technicians before commissioning the device.

Safety measures

in normal operation

10

Only operate the device when all safety devices are fully functional. If the protection

devices are not fully functional, there is a danger of:

- Serious or fatal injury to the operator or third parties

- Damage to the device and other material assets belonging to the operating company

- Inefficient operation of the device

Safety devices that are not fully functional must be repaired before the device is switched

on.

Never bypass or disable protection devices.

Before switching on the device, ensure that no one can be put in danger.

The device must be examined at least once a week for externally detectable damage

and functionality of the safety devices.

Commissioning,

maintenance and

repair

Only Fronius cleaning and Print electrolytes are suitable for use in our devices.

Do not mix Fronius cleaning and Print electrolytes with other cleaning agents.

If damage occurs due to the use of other cleaning agents, the manufacture is not liable

for this and all warranty claims are forfeited.

Transport the cleaning and Print electrolytes in closed original containers exclusively.

It is impossible to guarantee that externally procured parts are designed and manufactured to meet the demands made on them, or that they satisfy safety requirements.

- Use only original spare and wearing parts (also applies to standard parts).

- Do not carry out any alterations, installations, or modifications to the device without

first obtaining the manufacturer's permission.

- Components that are not in perfect condition must be changed immediately.

- When ordering, specify the exact name and part number according to the Spare

Parts List, as well as the serial number of your device.

In addition to a cable connection, the housing screws provide the protective conductor

connection for grounding the housing parts.

Always use original housing screws in the appropriate number with the specified torque.

EN-US

Safety inspection The manufacturer recommends that a safety inspection of the device be performed at

least every 12 months.

A safety inspection by a certified electrician is recommended:

- After changes

- After alterations

- After repair, service and maintenance

- At least every twelve months.

For the safety inspection, follow the appropriate national and international standards and

guidelines.

You can obtain more information about the safety inspection from your service center.

The service center will provide the necessary documents upon request.

Safety Symbols

Devices with the CE mark satisfy the essential requirements of the low-voltage and electromagnetic compatibility directives (e.g., relevant product standards of the EN 60974

series).

Devices marked with the CSA test mark satisfy the requirements of the relevant standards for Canada and the USA.

Copyright Copyright of these Operating Instructions remains with the manufacturer.

Text and illustrations were accurate at the time of printing. Fronius reserves the right to

make changes. The contents of the Operating Instructions shall not provide the basis for

any claims whatsoever on the part of the purchaser. If you have any suggestions for improvement, or can point out any mistakes that you have found in the Operating Instructions, we will be most grateful for your comments.

11

General information

Device concept

MagicCleaner 150

Intended use The MagicCleaner 150 is intended exclusively for the electrochemical cleaning of stain-

less steel. Any other use is deemed to be "not in accordance with the intended purpose."

The manufacturer shall not be liable for any damage resulting from such improper use.

Intended use also means

- Reading and understanding these Operating Instructions,

- Reading and understanding all safety data sheets of the cleaning and Print electrolytes,

- Carrying out all the specified inspection and maintenance work.

The MagicCleaner 150 is a device for the

electrochemical surface treatment of stainless steel.

The following surface treatments can be

carried out:

- Elimination of oxides and burns after

welding and cutting.

- Polishing of welds

- Printing - electrochemical surface

printing

(optional)

12

Scope of supply

*

(1)

(2)

(3)

(4) (5)

(6) (7) (10)(8)

(9)

(11) (12)

EN-US

(1) Brush insert

(2) Cleaning torch

(3) Cleaning torch holder

(4) Cleaning torch cable

(5) MagicCleaner 150

(6) Grounding cable with bayonet connector

(7) Cleaning electrode

(8) 3 x cleaning felt

(9) Cleaning electrode

(10) 3 x cleaning felt

(11) Adapter for cleaning brush

(12) Cleaning brush

* The cleaning electrolyte is not included in the scope of supply.

Not shown:

- 2.5 mm / 0.10 inch Allen key

- These Operating Instructions

- Small parts box

10 mm / 0.39 inch

10 mm / 0.39 inch

22 mm / 0.87 inch

22 mm / 0.87 inch

13

Options

(1) (2)

(3) (4)

(5)

(7) (8)

(9)

(6) (13)

(12)

(11)

(10) (14)

(15)

+

red

b

lue

(1) Adapter for cleaning brush

42,0510,0531

(2) 5 x cleaning brush

42,0510,0510

(3) Cleaning electrode

22 mm / 0.87 inch

42,0510,0500

(4) 10 x cleaning felt

22 mm / 0.87 inch

42,0510,0501

(5) Cleaning electrode

10 mm / 0.39 inch

42,0510,0506

(6) 10 x cleaning felt

10 mm / 0.39 inch

42,0510,0507

(7) Cleaning electrode

22 mm / 0.87 inch / 70°

42,0510,0502

(8) 10 x cleaning felt

22 mm / 0.87 inch / 70°

42,0510,0503

(9) Cleaning electrode

10 mm / 0.39 inch / 70°

42,0510,0508

(10) 10 x cleaning felt

10 mm / 0.39 inch / 70°

42,0510,0509

(11) Cleaning electrode

35 mm / 1.38 inch

42,0510,0504

(12) 10 x cleaning felt

35 mm / 1.38 inch

42,0510,0505

+

1 x O-ring

D=27.08 x d=23.52 mm /

D=1.07 x d=0.93 inch

14

(13) 6 x cleaning electrolyte blue 0.1 l

42,0510,0381

(14) 6 x cleaning electrolyte red 0.1 l

42,0510,0380

(15) Neutralizer

1 l spray bottle ...42,0510,0385

5 l canister ... 42,0510,0386

EN-US

15

(16)

(17) (18) (19)

(20) (21) (22)

(24)

(23)

(25)

ABC- 123

(26)

Print set 42,0510,0540

(16) Print film with Fronius logo

(for testing)

(17) Print electrolyte black 0.1 l

42,0510,0390

(18) Print electrolyte white 0.1 l

42,0510,0391

(19) Print torch holder

(20) Print torch

(21) Allen key

WAF 2.5 mm

(22) Print torch cable

(23) Print electrode

Transport information

16

(24) 5 x O-ring

(for attaching the Print felt to the Print electrode)

(25) 20 x Print felt

(26) Print film

(option, to be ordered separately from Fronius)

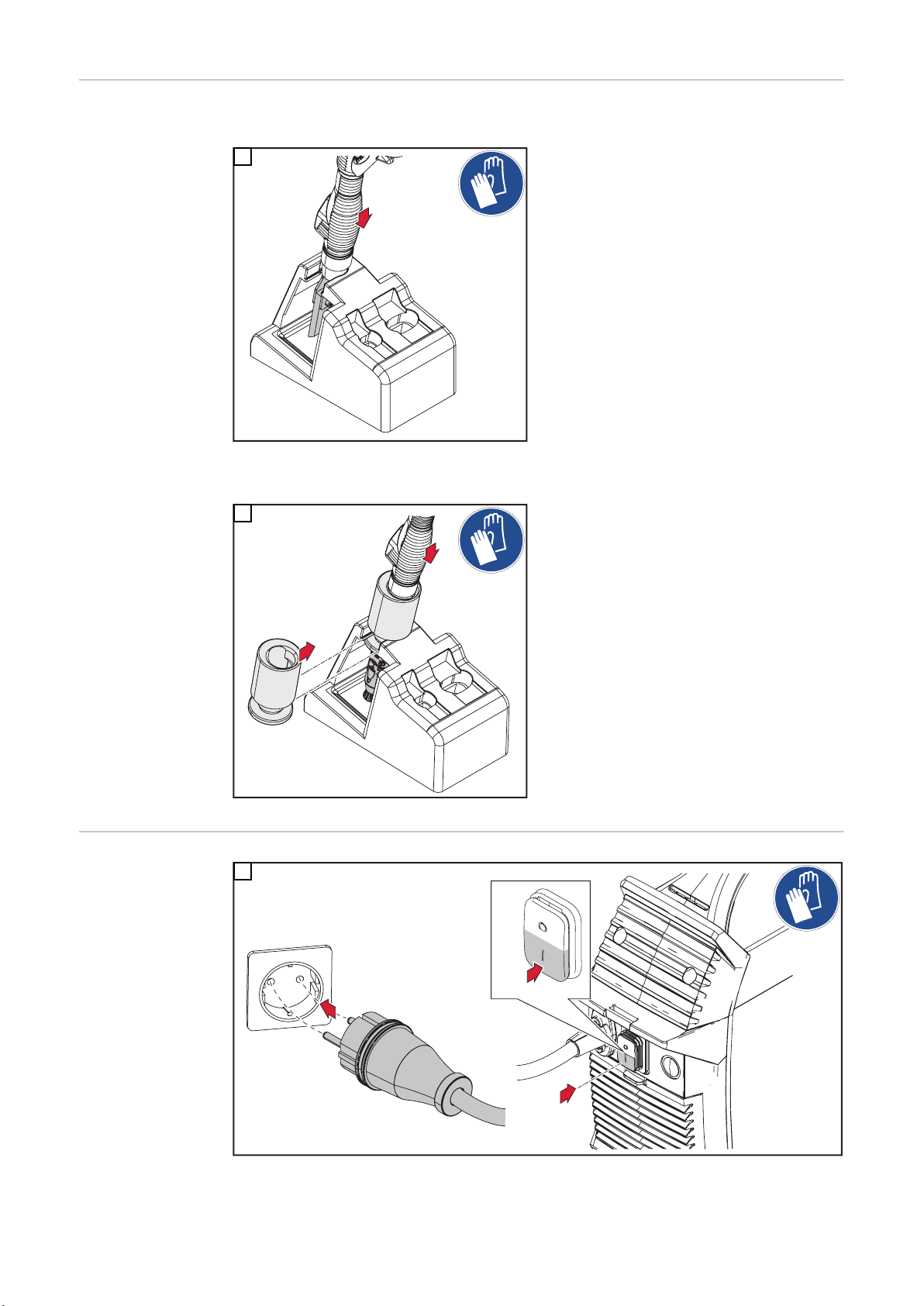

IMPORTANT! Before transport:

- Unscrew the cleaning electrolyte

- Empty hand pump

- Empty cleaning torch

- Remove used cleaning or Print felt

- Clean the cleaning and Print electrodes

Setup regulations Operation outdoors

Model No.

Part No.

Ser. No.

FRONIUS INTERNATIONAL GMBH

Froniusplatz 1, A-4600 Wels, Austria

Phone: +43 (0)7242 241-0

MAGIC CLEANER MC 150

.........................

.........................

CAN/CSA-E60974-1: 2012

ANSI/IEC 60974-1:2008

1~

50/60Hz

IP23

U0 = 30V AC Rms - 30V DC peak

U1 = 85-260V

U2 = 0 to 30V AC/DC

P1max = 450W

L1 max = 5A

L2 = 0 to 15A

Duty (%) = 0 to 80%

The device can be installed and operated outdoors in accordance with its degree of protection IP 23. However, the installed electrical parts must be protected from direct exposure to moisture, e.g. external wet cleaning.

Ambient temperature

IMPORTANT! The operating and storage temperature must not fall below the following

temperatures:

- without cleaning electrolyte: -25 °C / -13 °F

- with cleaning electrolyte: 0 °C / 32 °F

Install the device in such a way that it is not additionally heated by heat sources such as

radiators, heaters or annealing furnaces, direct sunlight, etc.

EN-US

Warning notices

on the device

The device is equipped with warning notices and a rating plate.

The warning notices and rating plate must not be removed or painted over.

Rating plate and warnings on the device

Use eye protection / safety goggles

Use respiratory protection

Use gloves

Use protective equipment according to the safety data sheet of the cleaning

electrolyte used!

Caution! Corrosive liquids

17

Operating controls, connections and mechanical

(1)

(2) (3) (4)

(5)

(6)

(7) (8)

-

+

components

Safety

Operating controls and connections

WARNING!

Danger due to incorrect operation.

This can result in severe personal injury and damage to property.

Do not use the functions described here until you have fully read and understood the

▶

Operating Instructions.

Do not use the functions described here until you have fully read and understood all

▶

of the Operating Instructions of the system components, especially the safety rules.

Control panel

(1) Controller cleaning power

1 ... low cleaning power

2 ... medium cleaning power

3 ... high cleaning power

The cleaning power can only be set on the cleaning power controller if the operating mode controller is set to the AC or DC position.

(2) LED overtemperature

Lights up if the device overheats;

Operation is interrupted and can only be continued after the device has cooled

down

(3) Power LED

Lights up when the mains supply is on and when the device is switched on

Front/back

18

(4) Controller operating mode

(15)

(14)

(13)

(12)

(11)

(10)

(9)

AC ... CLEAN - for cleaning welds

DC ... POLISH - for polishing welds

I ... BRUSH - to use the cleaning brush

(for example with narrow or difficult to access components)

• ... PRINT - dark print

o ... PRINT - light print

(5) (-) Current socket

for connecting the cleaning torch cable

(6) (+) Current socket

For connecting the grounding cable

(7) Mains cable with strain relief

Depending on the version of the device

(8) Power switch

EN-US

Cleaning torch + cleaning torch holder

(9) Cleaning electrolyte 0.1 l

For screwing onto the cleaning

torch

(10) Cleaning torch

or

Print torch

(11) Cleaning torch holder

or

Print torch holder

(12) Hand pump

For conveying the cleaning electrolyte (only at the cleaning torch)

(13) Fixing screw

(14) Cleaning electrode

or

Cleaning brush with adapter

Print electrode

(15) Cleaning felt

or

Print felt

19

Safety Instructions for commissioning, operation,

and maintenance

Read and follow

the Safety Instructions!

Safety Instructions for commissioning, operation, and maintenance

The following Safety Instructions provide information about dangers that occur when

working with and on the device.

IMPORTANT! Read and follow these Safety Instructions carefully before and during all

installation, cleaning, polishing, printing, and maintenance activities!

Follow the safety rules below when carrying out all tasks described in this document!

WARNING!

Danger due to incorrect operation.

This can result in severe personal injury and damage to property.

Do not use the functions described here until you have fully read and understood the

▶

Operating Instructions.

Do not use the functions described here until you have fully read and understood all

▶

of the Operating Instructions for the system components, especially the safety rules

and the safety data sheets for the cleaning electrolyte.

WARNING!

Danger from electrical current!

This can result in serious personal injury and damage to property.

Before starting the installation work, switch off the device and disconnect it from the

▶

grid.

Secure the device to prevent it from being switched back on again.

▶

WARNING!

Danger due to harmful vapors!

When working with the device, vapors are produced which are severely harmful to the

human body and can cause respiratory problems, respiratory diseases, and further personal injury.

Do not breathe in vapors produced.

▶

While working with the device, keep your head away from the working area and the

▶

vapors produced

Use extraction and respiratory protection

▶

20

CAUTION!

Danger from escaping cleaning or Print electrolyte!

Personal injury and damage to property may result.

Observe the safety data sheets of the cleaning and Print electrolytes

▶

Always screw the cleaning electrolyte onto the cleaning torch with the opening fa-

▶

cing upwards

Use protective equipment according to the safety data sheet of the cleaning or Print

▶

electrolytes used

Make sure that the cleaning or Print electrolyte does not come into contact with

▶

clothing or body parts

CAUTION!

Danger from spilled, leaked or uncollected chemicals!

Personal injury and damage to property or

the environment may result.

For cleaning, polishing or Print work,

▶

provide an acid-resistant drip tray.

Make sure that cleaning or Print elec-

▶

trolytes cannot escape in an uncontrolled manner.

EN-US

CAUTION!

Danger from live cleaning electrodes, cleaning brushes, and Print electrodes!

Damage to the workpiece and cleaning electrode or Print electrode may result.

As soon as the mains cable of the MagicCleaner 150 is connected to the grid and the

device is switched on, current flows through the cleaning electrode, cleaning brush or

Print electrode.

Store the cleaning or Print torch in an insulated place, e.g. in the cleaning torch hold-

▶

er!

CAUTION!

Risk of injury from hot workpiece surfaces and hot cleaning or print electrodes!

Workpiece surfaces, cleaning electrodes, and Print electrodes can reach temperatures of

over 100 °C / 212 °F during operation. This can result in burns.

Do not touch workpiece surfaces, cleaning and Print electrodes during operation

▶

Only touch workpiece surfaces, cleaning and Print electrodes when they have

▶

cooled down

21

NOTE!

A short circuit between the bare cleaning or print electrode and the workpiece can

impair the cleaning result, the print result, and/or the surface of the workpiece!

Make sure that the cleaning or Print felt does not have any holes or chafed areas

▶

Push the cleaning or Print felt completely onto the cleaning or print electrode

▶

Make sure that the tip of the cleaning or Print electrode is completely covered by the

▶

cleaning or print felt

If necessary, always fix the cleaning or Print felt with an O-ring or rubber ring (see

▶

also from page 26onwards)

NOTE!

Cleaning felt or cleaning brush must always be soaked with cleaning electrolyte,

otherwise the service life will be reduced.

If burns or cracks are visible on the cleaning felt or cleaning brush, replace them.

▶

Do not make contact between cleaning electrode and workpiece without cleaning

▶

felt.

NOTE!

To prevent damage to the workpiece to be treated and burning of the cleaning felt

due to excessive cleaning power:

Perform preliminary tests on material samples

▶

Always use sufficient cleaning electrolyte

▶

NOTE!

An improper Print procedure can result in damage to the workpiece surface!

During the Print process, make sure that the Print electrode is not in direct contact

▶

with the workpiece.

The Print electrode may only be moved on the Print film.

Do not mixPrint electrolytes.

▶

After performing the Print process, do not place the Print torch with the Print elec-

▶

trode on the workpiece - place the print torch on the print torch holder or switch off

the device beforehand!

22

Mounting the cleaning electrode

22 mm / 0.87 inch

22 mm / 0.87 inch / 70°

35 mm / 1.38 inch

10 mm / 0.39 inch

10 mm / 0.39 inch / 70°

Overview The following cleaning electrodes are available for cleaning and polishing:

EN-US

23

Mounting the

1

1

*

**

1

2

2,5 Nm

1.84 lb-ft

cleaning electrode

1

IMPORTANT! When inserting the cleaning electrode, make sure that the plastic tube (*)

is inserted into the hole (**) on the cleaning torch.

2

24

3

Attaching the

supplied cleaning

felt to the cleaning electrode

The MagicCleaner 150 is supplied with 3 cleaning felts each for the two cleaning electrodes in sizes 10 mm / 0.39 inch and 22 mm / 0.87 inch.

These cleaning felts are manufactured in the form of a pocket and are slid over the

cleaning electrodes. Fixing by means of an O-ring or rubber ring is not necessary.

EN-US

1

Attach cleaning felt to cleaning electrode 10 mm /

0.39 inch

The cleaning felt is attached to the 22

mm / 0.87 inch cleaning electrode in the

same way.

25

Mounting the optionally available cleaning felt

1

1

1

1

Mounting cleaning felt by means

of torch holder 22 mm / 0.87 inch

cleaning electrode

Alternative mounting option if cleaning felt other than the felt supplied is used for the 22

mm / 0.87 inch cleaning electrode.

1

3

2

4

26

5

Other cleaning felt, O-rings, and wide rubber rings are optionally available from

Fronius.

Mounting clean-

1

1

1

1

ing felt by means

of torch holder 10 mm / 0.39 inch

cleaning electrode

Alternative mounting option if cleaning felt other than the felt supplied is used for the 10

mm / 0.39 inch cleaning electrode.

1

2

EN-US

3

5

4

Other cleaning felt, O-rings, and wide rubber rings are optionally available from

Fronius.

27

Mounting cleaning felt by means

of O-ring - 35

mm / 1.38 inch

cleaning electrode

Mounting option of the cleaning felt for the 35 mm / 1.38 inch cleaning electrode.

1 2

Other cleaning felt, O-rings, and wide rubber rings are optionally available from Fronius.

28

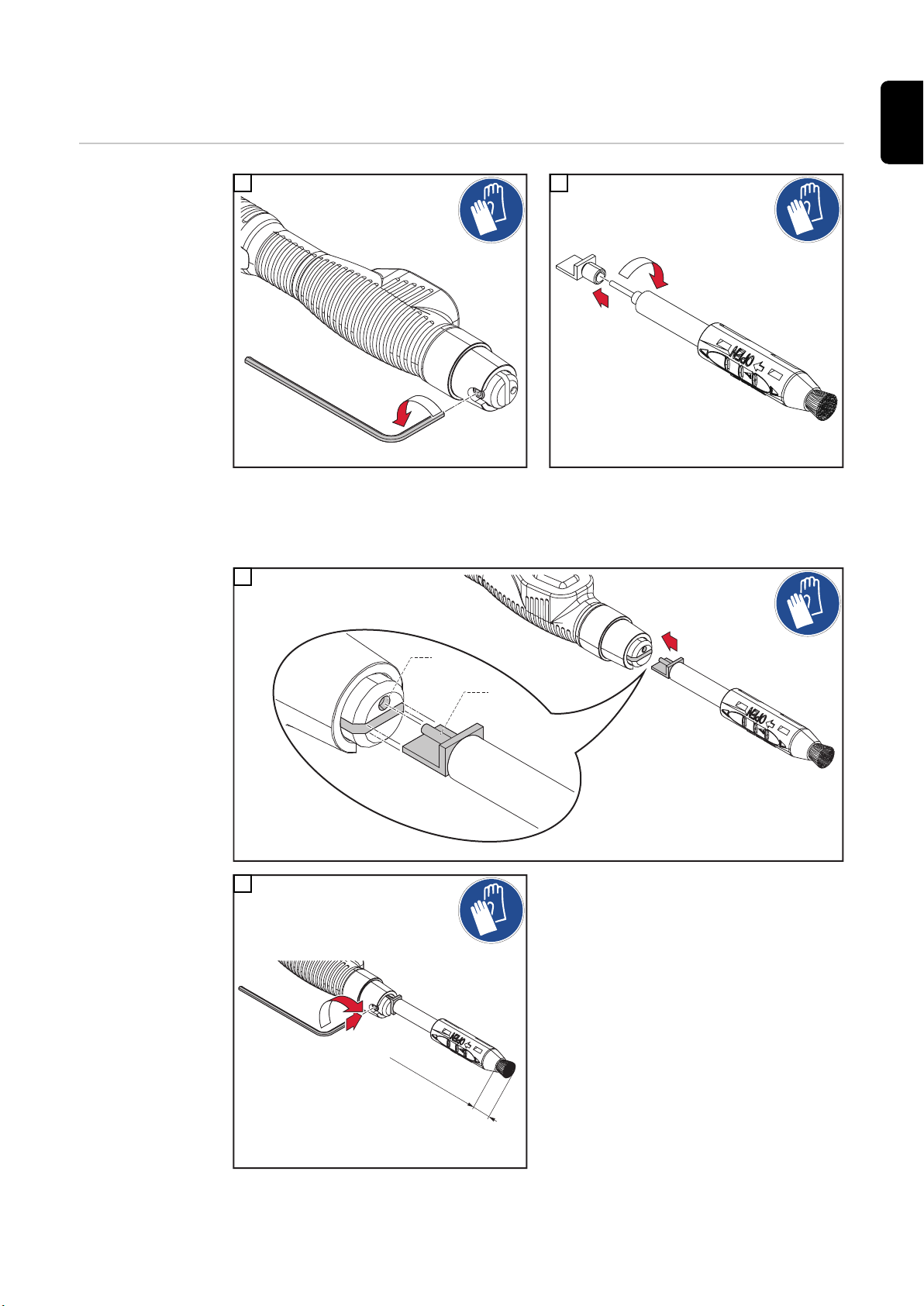

Mounting the cleaning brush

1

1

2

1

*

**

1

2

max. 15 mm

max. 0.59 inch

2,5 Nm

1.84 lb-ft

EN-US

Mounting the

cleaning brush

1

2

IMPORTANT! When inserting the cleaning brush, make sure that the plastic tube (*) is

inserted into the hole (**) on the cleaning torch.

3

4

IMPORTANT! The fibers of the cleaning

brush must not protrude more than 15

mm / 0.59 inch from the brush housing.

29

Readjusting the

max. 15 mm

max. 0.59 inch

1

cleaning brush

1

NOTE!

If the fibers are worn or short, push the

brush housing towards the cleaning

torch.

Only push the brush housing back

▶

when the cleaning brush is mounted

on the cleaning torch.

The first few times you push the brush

▶

housing back this may require more

force.

The fibers of the cleaning brush must

▶

not protrude more than 15 mm / 0.59

inch from the brush housing.

30

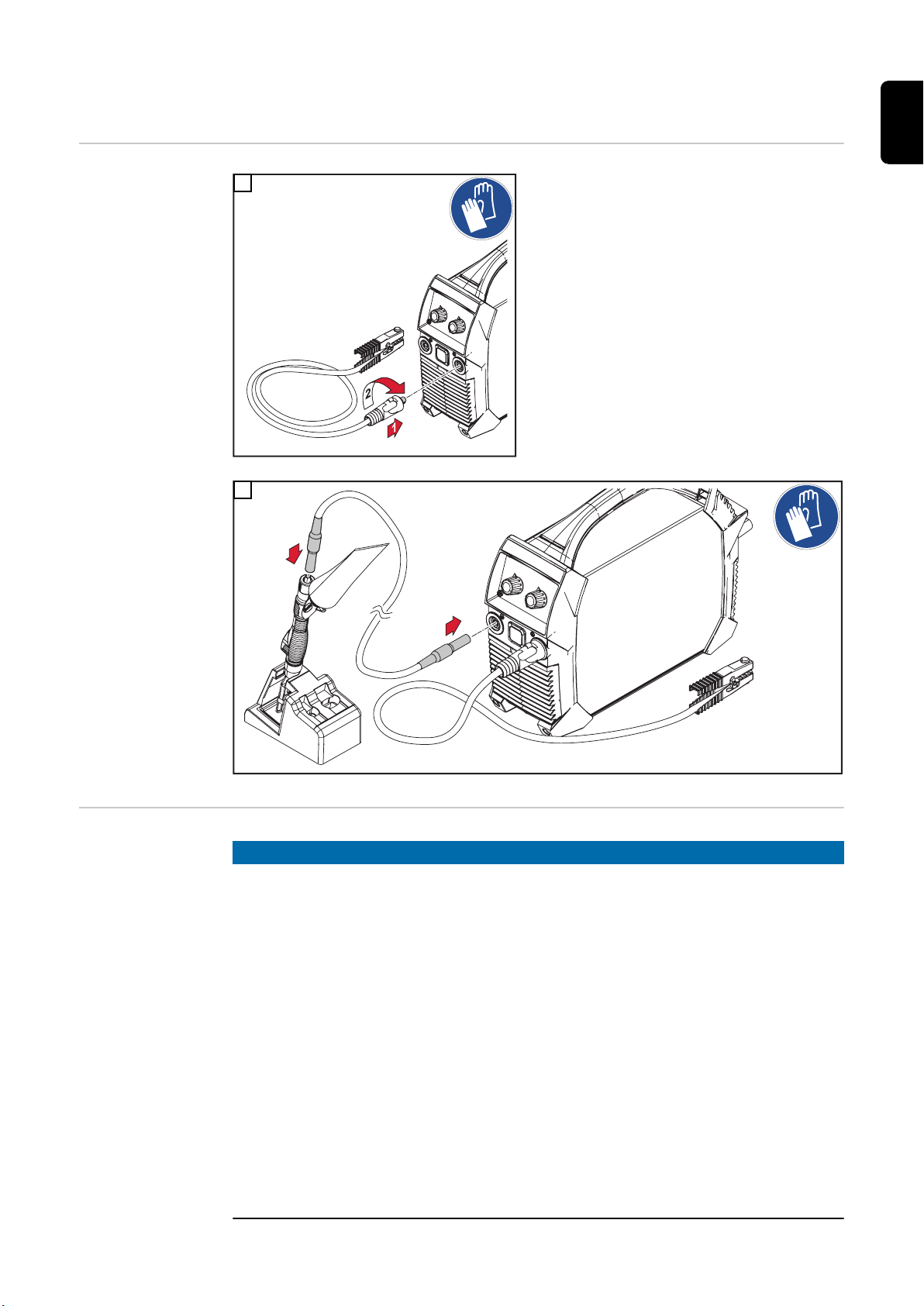

Preparing the workstation

1

2

EN-US

Connecting the

grounding cable

and cleaning

torch cable

1

2

Preparing the

workstation

NOTE!

Prepare the workstation in such a way that the cleaning, polishing or Print process

and the final operations do not have to be interrupted.

Prepare an acid-resistant collection tray for excess or dripping cleaning or Print elec-

▶

trolyte

Provide / put on protective equipment

▶

Provide cleaning or Print electrolyte, also for changing

▶

Ensure that cleaning or Print electrolytes cannot escape in an uncontrolled manner

▶

Provide suitable cleaning felt or Print felt, also for changing

▶

Keep neutralizer within easy reach

▶

Prepare cloths (for removing excess cleaning or Print electrolyte as well as for the

▶

final cleaning)

Prepare containers for the disposal of the cloths wetted with cleaning or Print elec-

▶

trolyte and the used cleaning or Print felt

Set up the extraction system

▶

Mount the cleaning electrode and cleaning felt or Print electrode and Print felt

▶

Make sure there is an active power supply, check distance to mains socket (provide

▶

extension cable if necessary)

31

Before using the

cleaning torch for

the first time

NOTE!

The cleaning torches are tested and filled with glycol before delivery.

Before using for the first time, pump out the cleaning torch well with the hand pump

▶

to remove any glycol residues.

32

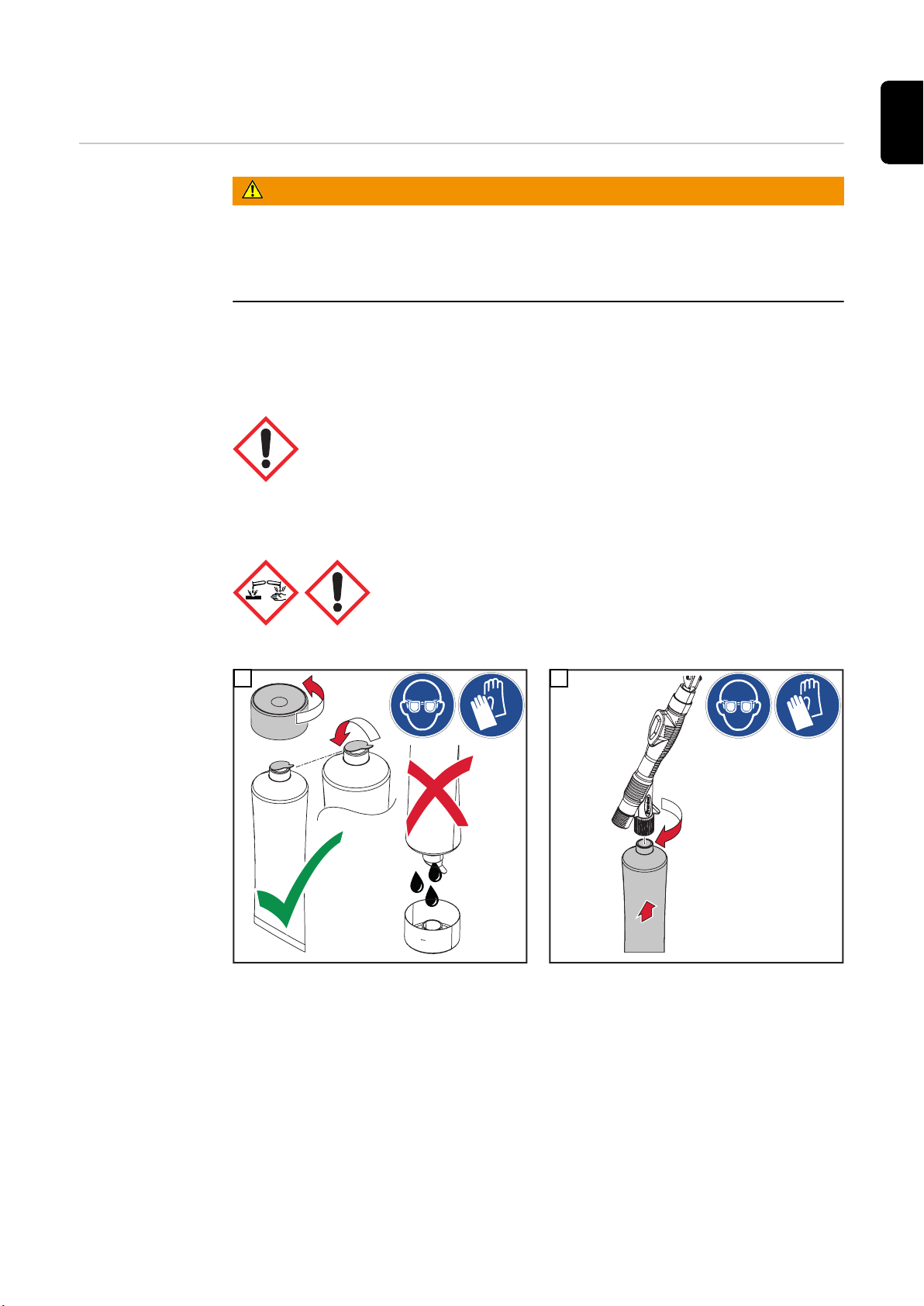

Cleaning

2

1

2

1

EN-US

Screwing the

cleaning electrolyte onto the

cleaning torch

WARNING!

Danger due to improper use!

This can result in serious personal injury, damage to property and the environment.

Observe the safety data sheets of the cleaning electrolytes!

▶

Observe Safety Instructions from page 20!

▶

The following cleaning electrolytes are available for cleaning purposes:

Cleaning electrolyte blue 0.1 l

for cleaning welds

Cleaning electrolyte red 0.1 l

for cleaning welds at higher cleaning speeds

1

2

33

Placing the clean-

1

1

2

2

1

2

ing torch in the

cleaning torch

holder

Place the cleaning torch with mounted cleaning electrode in the cleaning torch holder

1

Place cleaning torch with mounted cleaning brush in cleaning torch holder

1

Cleaning

34

1

1

1

1

1

2

1

1

1

2

4 - 5 x / 2 - 3 se

c.

2 - 3 sec.

2

1

2

2

1

2

2 - 3 sec.

3

EN-US

AC / CLEAN ... for cleaning by means of cleaning

electrode

BRUSH ... for cleaning by means of a cleaning brush

4

6

With increasing cleaning power, higher cleaning

speeds are possible.

5

Press the hand pump 4 to 5 times at intervals of 2 to

3 seconds each time it is used for the first time

Cleaning electrode | Cleaning brush

35

NOTE!

1

1

2

1

Observe the following points for smooth cleaning operation:

Press the hand pump every 2 to 3 seconds to deliver cleaning electrolyte.

▶

More cleaning electrolyte is required with a higher cleaning power, because the

cleaning electrode and workpiece become hotter and the cleaning electrolyte evaporates more quickly.

When cleaning with the cleaning felt, apply slight pressure to the weld.

▶

If the operating noise ("crackling") is increased, insufficient cleaning electrolyte is be-

▶

ing used; it is better to clean in a puddle than too dry.

Always hold the cleaning brush perpendicular to the weld, and always moistened

▶

with cleaning electrolyte.

Apply light pressure to the area to be cleaned.

When cleaning with the cleaning brush, sparking, foaming, and increased operating

▶

noise may occur - this is normal.

After cleaning

1

Place cleaning electrode | cleaning brush ...

in the cleaning torch holder

2

Switching off the device

36

3

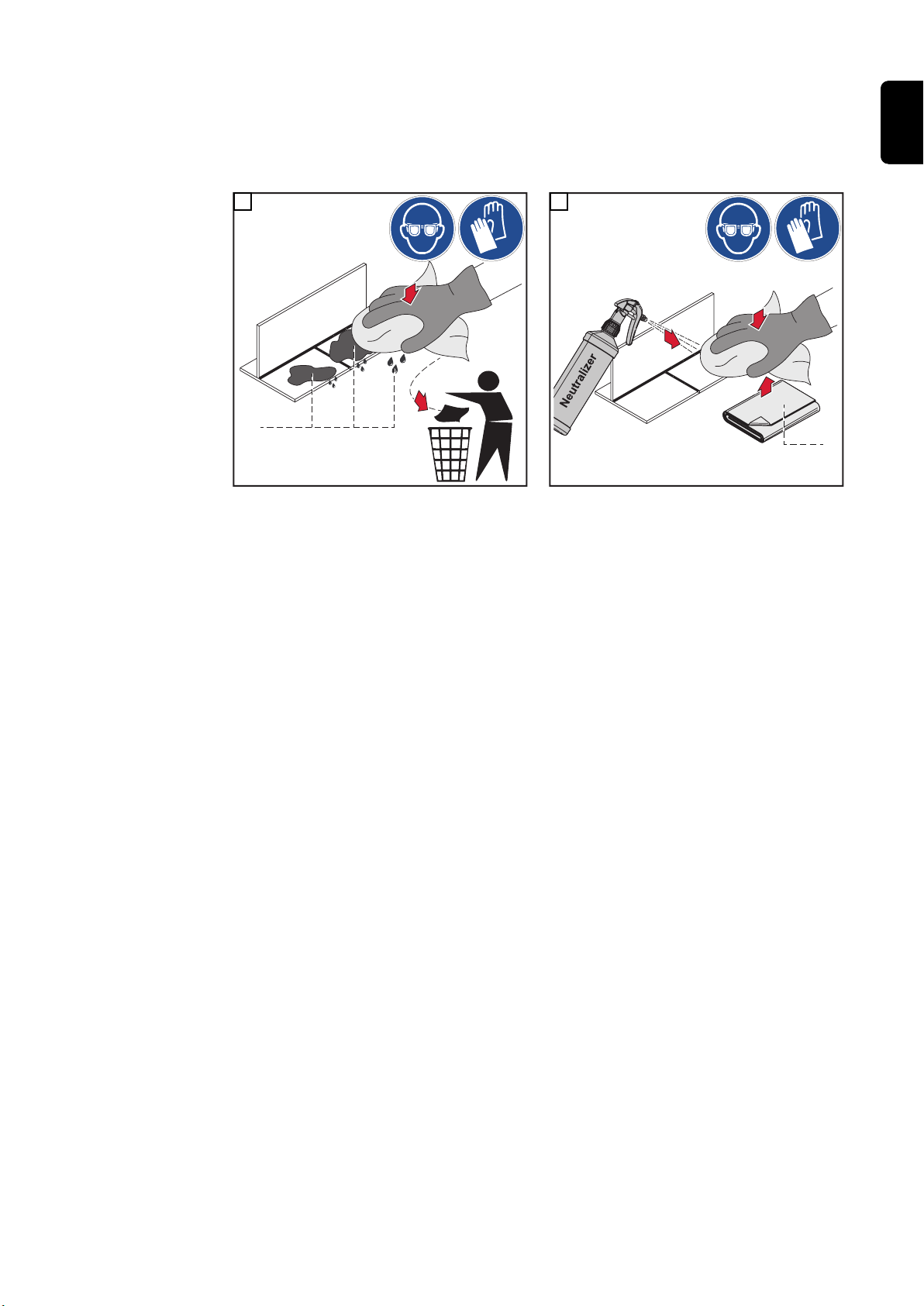

IMPORTANT! For an optimal cleaning result, remove the excess cleaning electrolyte to

1

2

*

**

1

2

avoid white spots due to cleaning electrolyte residues.

Subsequently clean the surface with the neutralizer.

EN-US

4

* Excess cleaning electrolyte

5

** New microfiber cloth

IMPORTANT!

- Do not dispose of cloths wetted with cleaning electrolyte in household waste!

- Dispose of cloths wetted with cleaning electrolyte in accordance with regional regulations!

Observe the safety data sheets of the cleaning electrolytes!

- Do not refill empty cleaning electrolyte tubes!

- Unscrew the cleaning electrolyte tubes from the cleaning torch after use, close them

such that they are airtight, and label the container.

- After finishing work, remove the cleaning felt from the cleaning electrode.

37

Polishing

1

General

WARNING!

Danger due to improper use!

This can result in serious personal injury, damage to property and the environment.

Observe the safety data sheets of the cleaning electrolytes!

▶

Observe Safety Instructions from page 20!

▶

Electrochemical polishing of welds is carried out with:

Cleaning electrolyte red 0.1 l

42,0510,0380

Supply of the cleaning electrolyte via the cleaning torch and the hand pump.

NOTE!

The same cleaning electrodes are used for polishing as for cleaning.

The cleaning electrode and cleaning felt are mounted as described from page 24

▶

onwards.

Preparation of the workstation for polishing is the same as for cleaning (see page

▶

31).

Placing the cleaning torch in the

cleaning torch

holder

Place the cleaning torch with mounted cleaning electrode in the cleaning torch holder

1

38

Polishing Requirement:

2

1

2

1

1

1

1

1

1

2

4 -

5

x / 2 - 3 sec.

- Cleaning electrode and cleaning felt mounted on the cleaning torch

(see from page 24)

- Cleaning electrolyte red 0.1 l screwed onto the cleaning torch

(see from page 33)

1

EN-US

2

DC / POLISH ... Polishing

4

3

Polishing with maximum power

5

39

2 - 3 sec.

1

2

2

6

1

1

1

2

*

**

1

2

NOTE!

When polishing with the cleaning elec-

▶

trode, apply slight pressure to the

weld.

After polishing

1

Switching off the device

3

2

IMPORTANT! For an optimal cleaning result, subsequently remove the excess cleaning

electrolyte to avoid white spots due to cleaning electrolyte residues.

Finally, clean the surface with the neutralizer.

4

5

40

* Excess cleaning electrolyte

** New microfiber cloth

IMPORTANT!

- Do not dispose of cloths wetted with cleaning electrolyte in household waste!

- Dispose of cloths wetted with cleaning electrolyte in accordance with regional regulations!

Observe the safety data sheets of the cleaning electrolytes!

EN-US

41

Printing

(1)

(2)

(3) (4)

(5) (6)

(7)

(9)

(8)

(10)

ABC- 123

(11)

General

WARNING!

Danger due to improper use!

This can result in serious personal injury, damage to property and the environment.

Observe the safety data sheets of the print electrolytes!

▶

Observe Safety Instructions from page 20!

▶

With the MagicCleaner 150, it is possible to apply electrochemical surface prints to stainless steel. Logos, graphics, texts, numbers, etc. can be printed on the surface using a

customizable Print film.

The print on stainless steel can be either light or dark.

For printing on stainless steel, the Print set is required:

Print set 42,0510,0540

(1) Print film with Fronius logo

(for testing)

(2) Print electrolyte black 0.1 l

42,0510,0390

(3) Print electrolyte white 0.1 l

42,0510,0391

(4) Print torch holder

(5) Print torch

(6) Allen key

WAF 2.5 mm

(7) Print torch cable

(8) Print electrode

42

(9) O-ring

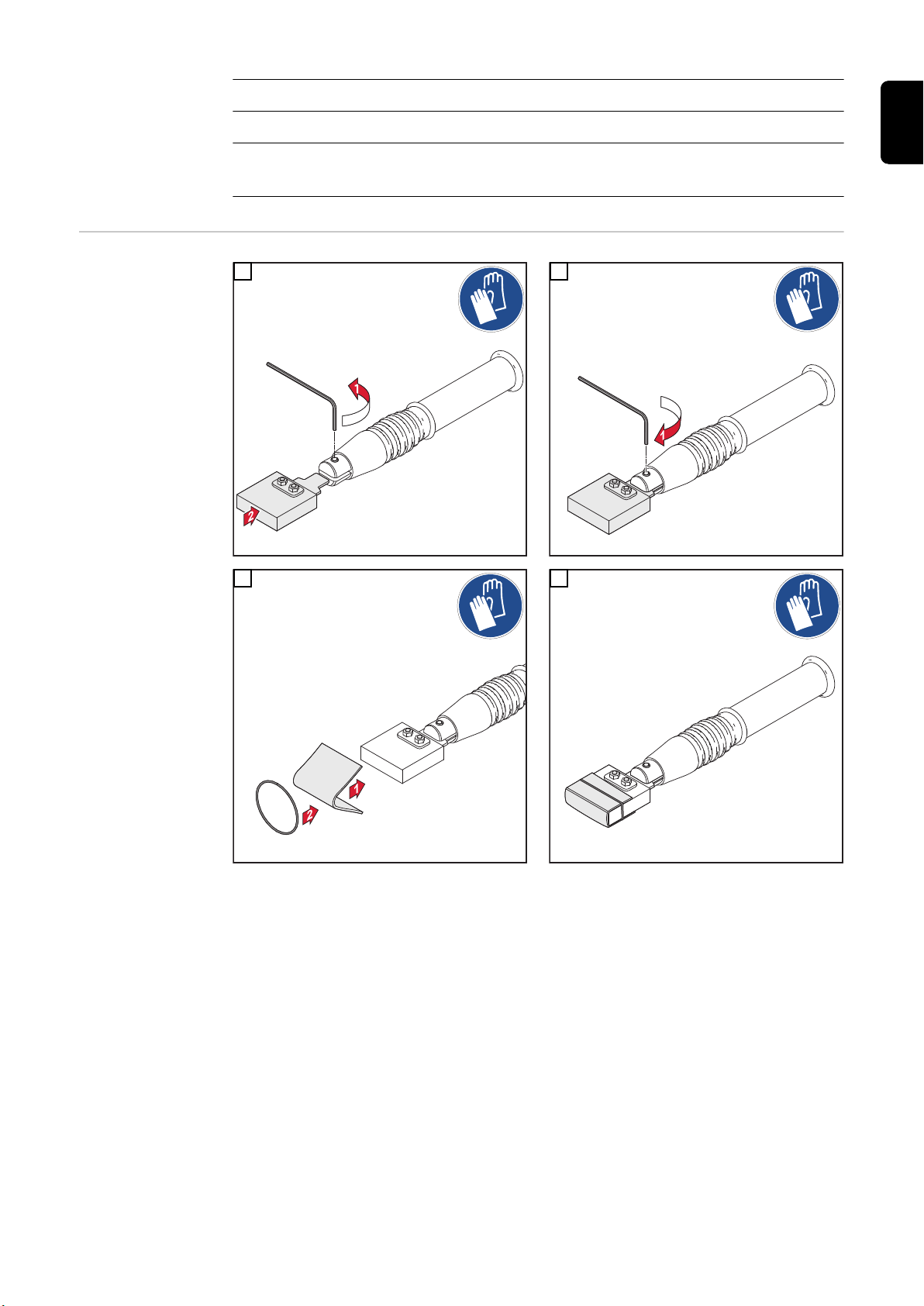

Mounting the

Print electrode

and Print felt

(10) 20 x Print felt

EN-US

(11) Print film

(option, to be ordered separately from Fronius)

1 2

3 4

43

Preparing the

workstation for

Printing

For further preparation steps, see "Preparing the workstation" from page 31.

1

2

3

44

Printing

2

1

2

1

1

1

1

Printing

electrolyte

1

EN-US

2

Print - dark print

Print - light print

The power for the Print process is automatically preset by the device; the settings

on the cleaning power control have no influence on the Print process.

IMPORTANT! Use the correct Print electrolyte depending on the Print process:

- Print electrolyte black 0.1 l ... for dark printing

- Print electrolyte white 0.1 l ... for light printing

- Do not mix Print electrolytes

3

Wetting the Print felt once is sufficient for a

maximum of 15 Print operations in succession.

45

NOTE!

1

2

1

When using a new Print film or when changing the Print operating mode, carry out

a test print!

After the Print

process

4

Position and secure the Print film on the

workpiece to be printed

Pass the Print electrode with Print felt several times over the Print film

1

46

2

1

3

3

Neutr

a

lizer

*

**

EN-US

4

* As an alternative to the neutralizer, a microfiber cloth moistened with clear water

can be used.

5

** New, dry microfiber cloth

47

2

Neutralizer

**

6

** New, dry microfiber cloth - clean both sides of the Print film;

clear water can be used as an alternative to the neutralizer.

48

Service, maintenance and disposal

General The MagicCleaner 150 requires minimal service and maintenance under normal operat-

ing conditions. However, several points must be observed in order for the device to remain operational for years to come.

WARNING!

Danger due to improper use!

This can result in serious personal injury, damage to property and the environment.

Observe the safety data sheets of cleaning and/or Print electrolytes!

▶

Observe Safety Instructions from page 20!

▶

WARNING!

Danger from electrical current.

An electric shock can be fatal. Before any maintenance activities

Set the power switch to - O -

▶

Unplug the device from grid power

▶

Attach a clear warning sign advising others not to switch the power source back on

▶

EN-US

At every start-up - Check mains cable, grounding cable, and torch cable for damage

- Check cleaning electrodes and cleaning felt, cleaning brushes as well as Print electrodes and Print felt for wear and burns and replace if necessary;

only use original spare parts and accessories from the manufacturer.

NOTE!

The air inlet and outlet openings on the device must not be blocked or even partially covered.

At the end of

each shift

Disposal Used cleaning felts are considered hazardous waste.

- In case of residues of cleaning agent or Print electrolyte, clean the device with neutralizer and clean cloths

- Remove cleaning felt, cleaning brushes or Print felt and rinse with clean water;

replace worn or burnt cleaning felt / cleaning brushes / Print felt

- After cooling down, rinse the cleaning and Print electrodes with clear water

- Unscrew the cleaning electrolyte from the cleaning torch and close it

- Pump the cleaning torch empty

During cleaning and polishing, heavy metals are deposited in the cleaning electrolyte

used. Used cleaning electrolytes are therefore considered hazardous waste.

Materials should be disposed of according to valid local and national regulations.

Waste electrical and electronic equipment must be collected separately and recycled in

an environmentally sound manner in accordance with the European Directive and national law. Used equipment must be returned to the distributor or through a local authorized

49

collection and disposal system. Proper disposal of the used device promotes sustainable

recycling of material resources. A failure to observe this may lead to potential health/

environmental impacts

50

Technical data

EN-US

MagicCleaner

150 /EF

150 /CN

150 /np

Grid voltage ~ 1 x 230 V

Mains voltage tolerance -15 / +10%

Grid frequency 50 / 60 Hz

Mains fuse protection 6.3 A slow-blow

Max. primary power 500 VA

Output current Max. 15 A

Output voltage

AC

DC

Output power 450 W

Open circuit voltage 30 V

Detergent content 0.1 l

Protection class IP 23

Dimensions l / w / h 365 / 130 / 285 mm

14.37 / 5.12 / 11.22 inch

Weight 4.5 kg

Noise generation > 10 dB (A)

10 V

30 V

9.92 lb.

Ambient temperature 0 - +40 °C / 32 - 104 °F

Bearing temperature

Max. altitude above sea level 2000 m

Overvoltage category III

Pollution degree according to IEC60664 3 3

EMC emission class A

Toxic emissions during operation

(measured according to UNI EN 689/97

part 5)

Safety symbols CE, S, CCC

(1)

without cleaning electrolyte

(1)

Standard MAK 1 mg/m³ < 0.31 mg/m³

-20 - +55 °C / -4 - 131 °F

6561 feet 8.16 inch

Industry

51

MagicCleaner

150 MV/B

150 MV/np

Grid voltage ~ 1 x 100 - 110 V

Mains voltage tolerance -15 / +10%

Grid frequency 50 / 60 Hz

Mains fuse protection 6.3 A slow-blow

Max. primary power 500 VA

Output current Max. 15 A

Output voltage

AC

DC

10 V

30 V

Output power 450 W

Open circuit voltage 30 V

Detergent content 0.1 l

Protection class IP 23

Dimensions l / w / h 365 / 130 / 285 mm

14.37 / 5.12 / 11.22 inch

Weight 4.5 kg

Noise generation > 10 dB (A)

Ambient temperature 0 - +40 °C / 32 - 104 °F

Bearing temperature

(1)

-20 - +55 °C / -4 - 131 °F

Max. altitude above sea level 2000 m

6561 feet 8.16 inch.

Overvoltage category III

Pollution degree according to IEC60664 3 3

EMC emission class A

Industry

Toxic emissions during operation

Standard MAK 1 mg/m³ < 0.31 mg/m³

(measured according to UNI EN 689/97

part 5)

Safety symbols CE, S, CCC

(1)

without cleaning electrolyte

52

EN-US

53

54

EN-US

55

Fronius International GmbH

Froniusstraße 1

4643 Pettenbach

Austria

contact@fronius.com

www.fronius.com

Under www.fronius.com/contact you will find the adresses

of all Fronius Sales & Service Partners and locations.

spareparts.fronius.com

SPAREPARTS

ONLINE

Loading...

Loading...