Page 1

/ Battery Charging Systems / Welding Technology / Solar Electronics

MagicCleaner Fume Abstractor

Operating Instructions

Spare Parts List

EN

Miscellaneus

42,0426,0026,EN 002-04042012

Page 2

Page 3

Dear Reader

Introduction

Thank you for choosing Fronius - and congratulations on your new, technically highgrade Fronius product! This instruction manual will help you get to know your new

machine. Read the manual carefully and you will soon be familiar with all the many

great features of your new Fronius product. This really is the best way to get the most

out of all the advantages that your machine has to offer.

Please also take special note of the safety rules - and observe them! In this way, you

will help to ensure more safety at your product location. And of course, if you treat your

product carefully, this definitely helps to prolong its enduring quality and reliability - things

which are both essential prerequisites for getting outstanding results.

EN

ud_fr_st_et_00493 01/2012

Page 4

Page 5

Contents

General remarks ........................................................................................................................................... 2

Machine concept ...................................................................................................................................... 2

Intended use ............................................................................................................................................ 2

Area of use .............................................................................................................................................. 2

Functional diagram .................................................................................................................................. 2

Scope of supply ....................................................................................................................................... 3

Technical Specification............................................................................................................................. 3

Controls, connection sockets and mechanical components......................................................................... 4

Front of MC fume extractor ...................................................................................................................... 4

Rear of MC fume extractor ...................................................................................................................... 4

Before Initial Operation ................................................................................................................................. 5

Intended Use ........................................................................................................................................... 5

Set-up requirements ................................................................................................................................ 5

Mains supply ............................................................................................................................................ 5

Initial Operation ............................................................................................................................................. 6

Safety ....................................................................................................................................................... 6

Fit suction nozzle ..................................................................................................................................... 6

Connect to power source ......................................................................................................................... 6

Initial Operation ........................................................................................................................................ 7

Replace activated carbon filter ..................................................................................................................... 8

General remarks ...................................................................................................................................... 8

Change activated carbon filter ................................................................................................................. 8

Replace activated carbon filter ahead of schedule ................................................................................ 10

Disposal of spent cartridges .................................................................................................................. 10

EN

Maintenance and care .................................................................................................................................11

General remarks .....................................................................................................................................11

At every initial operation ......................................................................................................................... 11

If the activated carbon filter is full ........................................................................................................... 11

Every 6 months .......................................................................................................................................11

Fault diagnosis - Fault rectification ............................................................................................................. 12

General .................................................................................................................................................. 12

Fault diagnosis - Fault rectification ........................................................................................................ 12

1

Page 6

General remarks

Machine concept

Intended use

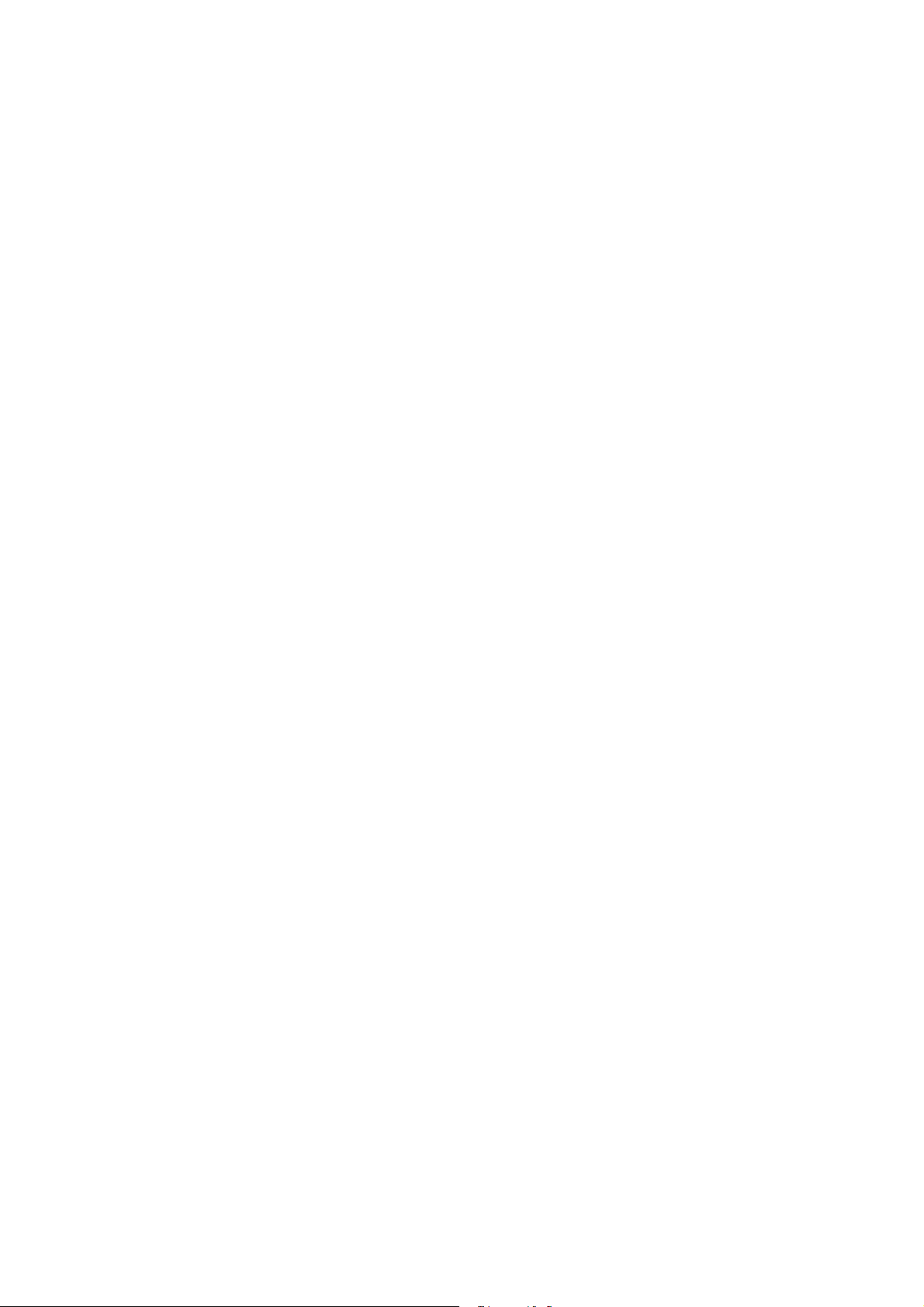

The fully automatic MagicCleaner fume

extractor (MC Fume Extractor) is an

additional device to the MagicCleaner

CrNi-cleaning device. The fume extractor

is fixed onto the cleaning device. This

results in a compact CrNi-cleaning system

with extraction.

The housing of the MC fume extractor

contains the control electronics and the

suction unit, consisting of pre-filter felt,

activated carbon filter and suction turbine.

The suction performance is regulated via

the cleaning device current conduction:

The suction turbine works at maximum

output if maximum current is used. If no

cleaning current flows then the suction

turbine does not work at all.

Fig. 1 MC fume extractor and cleaning device

The MC fume extractor is used for removal of acidic vapours that occur during electrochemical cleaning of welding seams.

Area of use

Functional

diagram

Note! The MC fume extractor only functions in conjunction with the MagicClea-

ner CrNi cleaning device.

The MC fume extractor can be used for a number of applications. Its low weight makes

it suitable above all for use on building sites.

The MC fume extractor is frequently used in

- Tank construction

- Construction of large-scale catering institutions

- Swimming pool construction

- Dairy construction

- Plant construction for medicines and foodstuffs

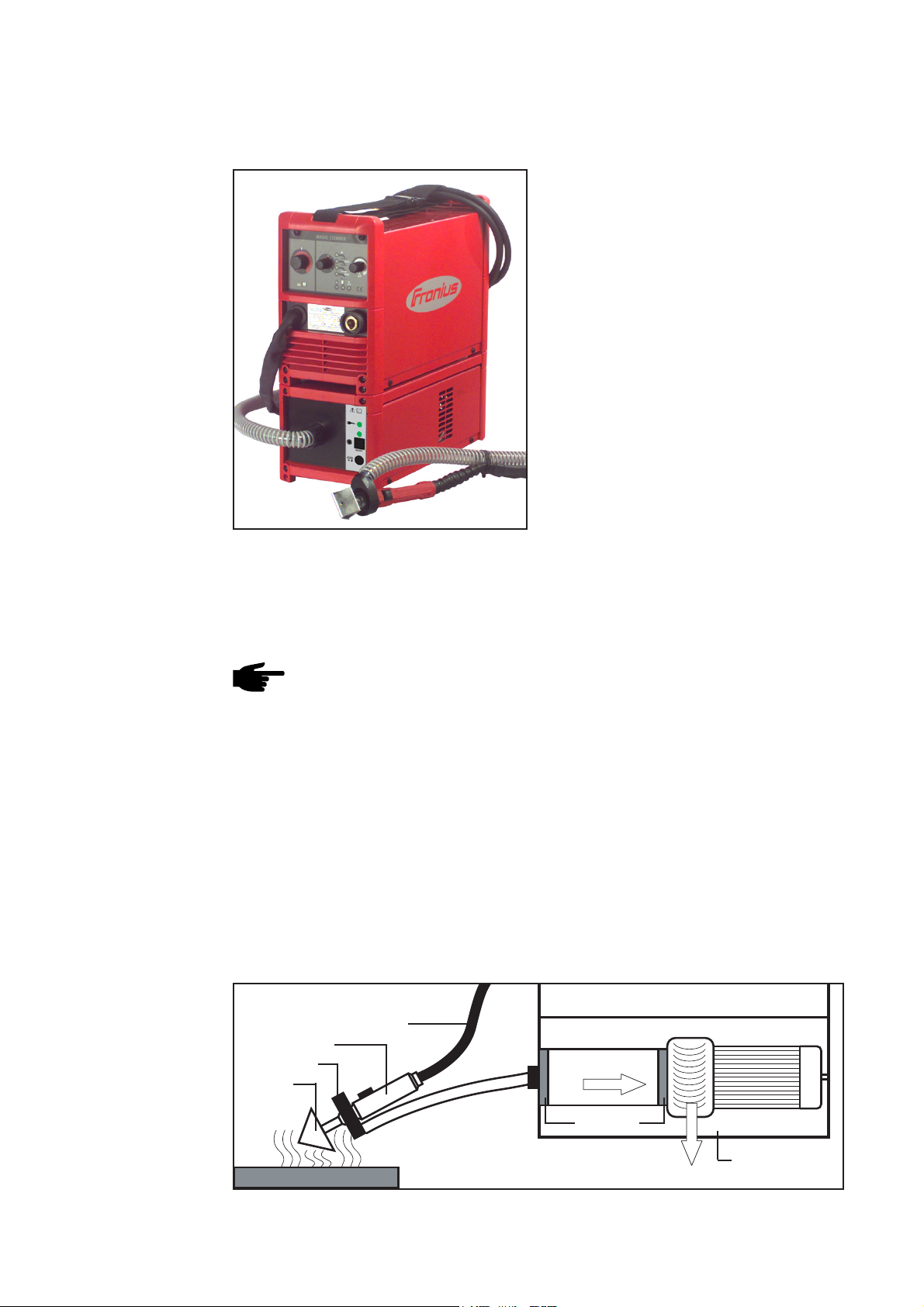

MagicCleaner CrNi-Cleaning Device

Hosepack to cleaning device

Cleaning handle

Suction nozzle

Cleaning

electrode

Suction hose

Activated

carbonfilter

Filter mats

Suction turbine

Turbine motor

Fig. 2 Functional diagram

Workpiece

Housing with

Exhaust air

2

control electronics

Page 7

Scope of supply

4 x Cable tie (can be reopened)

4 x M5 x 16 Extrude Tite Screw

EN

1 x MC fume extractor

1x suction hose 4 m incl. suction nozzle

Fig.3 Scope of supply MC fume extractor

Technical Specification

Supply voltage 230V

Mains voltage tolerance +/-15 %

Mains frequency 50 Hz

Rated power (incl. MagicCleaner cleaning device) 950 VA

Mains fuse protection 10 A slow-blow

Maximum suction power 110 m³/h

3928 cu.ft./h

Filter serviceable life approx. 300 hours

Net weight activated carbon filter 550 g

1.21 lb.

Type of protection IP 23

Dimensions l/w/h 430 / 180 / 180 mm

16.93 / 7.09 / 7.09 in.

Weight 5.5 kg

5.50 kg.

3

Page 8

Controls, connection sockets and mechanical components

Front of MC fume

extractor

Rear of MC fume

extractor

(1)

Fig. 4 Front of MC fume extractor

(6)

(1) Hose connection / filter fastening

(2) Mains supply display

(3) Filter display

(4) Reset button

(2)

(3)

(5) Turbine fuse

(4)

(5)

(6) Mains switch

(7) Socket with covering

Fig.5 Rear of MC fume extractor

(8) Power cable

(7)

(8)

4

Page 9

Before Initial Operation

Intended Use

Set-up requirements

The MC fume extractor must only be used for the removal of acidic vapours that arise

during electro-chemical cleaning of high-alloy steels.

The MC fume extractor must only be operated in conjunction with the MagicCleaner

CrNi cleaning device.

Any other form of use is seen as not the purpose for which the machine was intended.

The manufacturer will not be liable for damage arising from such improper use.

Intended use also comprises

- Following all information given in this manual

- Following all information given in the manual for the MagicCleaner CrNi-Cleaning

Device

- Performing all stipulated inspection and maintenance work

The MC fume extractor is tested to IP23, meaning:

- Protection from penetration by solid foreign bodies larger than Ø 12 mm

- Protection from water spray up to an angle of 60° to the vertical

In accordance with IP23 the MC fume extractor can be set up and operated outdoors.

The electrical parts fitted must be protected from direct moisture.

Important! Place the cleaning / extraction system on an even and firm floor in such a

way that it stands firmly.

EN

Mains supply

Air must be able to circulate freely around the air channels or air slots for turbine exhaust air. Any electroconductive metallic dust (e.g. from grinding work) must not be

allowed to be sucked into the machine.

The operating temperature and storage temperature for the cleaning/extraction system

must not drop below -10°C. Set up the cleaning/extraction system so that additional

heating due to heat sources such as radiators, heating or annealing furnaces, direct

insulation etc. is avoided.

The MC fume extractor is designed for the supply voltage given on the rating plate. If

the mains cable or mains plug are not fitted on your equipment model, then they must

be fitted in accordance with national standards. The technical specification provides

information regarding fuse protection for the mains cable.

Note! Inadequately dimensioned electrical installations can lead to serious

damage to property. The mains plug, mains supply lead, as well as their fuse

protection, must always be designed accordingly.

Any electrical intervention, including fitting or removal of the mains plug may only be

carried out by a qualified electrician.

5

Page 10

Initial Operation

Warning! Incorrect operation can cause serious personal injury and damage

to property. Only use the functions described when the following documents

have been read completely and understood:

- This Owner’s Manual

- All manuals for the system components ( MAGIC CLEANER CrNi-Cleaning Device), in particular the safety regulations

Safety

Fit suction nozzle

Connect to

power source

1. 2.

1

2

3

4

6

5

2

4

Fig.6 Preparation

3

2

1

Fig.7 Fit suction nozzle

3. Fasten the suction hose to the hosepack of the MagicCleaner CrNi Cleaning device

using 4 cable ties.

Note! The MagicCleaner CrNi Cleaning Device is not switched on at the same

time if main switch (6) of the MC fume extractor is operated.

1

The MagicCleaner CrNi-Cleaning Device

is ready to run when

2

Fig.8 Connect to power source

- the cleaning device power cable has

- the MC fume extractor power cable is

- the program switch for the cleaning

6

Caution! Danger of damage to

the workpiece and triangle due

to current conduction. As soon

as the mains cable from the MC

fume extractor is connected to

the mains supply, cleaning

current will flow if the program

switch is set to the appropriate

position.

Lay the cleaning handle down so

that it is insulated!

been inserted in the MC fume extractor socket,

connected to the mains supply and

device is set to the desired operating

mode.

Page 11

Initial Operation

Caution! The loud operating noise from the turbine can cause damage to

hearing. Use suitable ear protection!

1. Take protective measures for operating the MagicCleaner CrNi Cleaning Device

2. Switch main switch (6) into position „I“

The MC fume extractor is ready to run.

The fume extractor only works during the actual cleaning procedure using the

MagicCleaner CrNi Cleaning Device. The suction turbine is regulated via the

cleaning current:

Maximum cleaning current ..... Suction turbine working at full capacity

Cleaning current 50 % ........... Suction turbine working at half capacity

EN

7

Page 12

Replace activated carbon filter

Warning! An electric shock can be fatal. Before opening the machine

- Switch the mains switch into the “O” position

- Unplug the machine from the mains

- Display an easily understood sign warning against the danger of switching

the machine back on

- Using a suitable measuring device, ensure that the components under

electric charge (e.g. capacitors) have been discharged

General remarks

The degree of contamination of the activated carbon filter is shown on the filter display (2).

Filter display (2) off:

The activated carbon filter is clean or only

slightly dirty. The activated carbon filter

can absorb contaminants.

Filter display (2) on:

The activated carbon filter is very dirty or

(3)

full. The activated carbon filter cannot

absorb any more contaminants.

Important! When the filter display (2)

lights up the activated carbon filter and

the appropriate filter mat must be replaced within the next 12 operating hours.

Fig. 9 Filter display

Note! Always replace used activated carbon filters and associated filter mats

with new filters and filter mats,

- never re-use used filters and filter mats,

- dispose of used filters and filter mats in accordance with official regulati-

ons.

Change activated

carbon filter

1. Switch main switch (6) into position „0“

2. Unplug the mains cable (8) from the mains supply

3.

2

1

Fig.10 Remove the left-hand side panel and

remove the suction hose

3

4

8

Caution! Risk of injury due to

acid in the suction hose. Wear

suitable safety glasses and

safety gloves when pulling the

suction hose off.

Caution! Inadequate protective

conductor connection can cause

serious personal injury and

damage to property. The housing

screws represent a suitable

protective conductor connection

for earthing the housing and

must not be replaced by other

screws without a reliable protective conductor connection.

Page 13

Replace activated carbon filter

(continued)

4.

Caution! Risk of injury due to

acid. Use suitable safety gloves

when touching the filter cartridge

or the filter mats.

2

Filter cartridge

3

2 x Filter mat

Fig.11 Remove the filter cartridge and the filter

mats (2x)

5.

1

1

1

Note! Place the filter cartridge or

the filter mats in an acid resistant

EN

container and ensure that it is not

possible for other persons to

access the filter cartridge or the

filter mats.

Important! Insert the filter mats in the

following manner :

- on the turbine end: the blue side must

face the filter cartridge

- on the hose connection end: the blue

side must face the hose connection /

filter mount

2

Fig.12 Insert the new filter cartridge and the new

filter mats (2x)

3

6.

1

2

Fig.13 Fit the left-hand side panel and insert

suction hose

3

Caution! Risk of injury due to

acid in the suction hose. Wear

suitable safety glasses and

safety gloves when putting the

suction hose in place.

4

9

Page 14

Replace activated carbon filter

(continued)

7. Connect mains cable (8) to mains power supply

8. Set mains switch (6) to “I” position - filter indicator (3) lights up

9. Press “Reset” button (4) and hold approx. 10 secs until filter indicator (3) goes off

Caution! Suction efficiency is impaired if activated carbon filter is full. Only

press “Reset” button (4) if the activated carbon filter has actually been

replaced!

Replace activated carbon filter

ahead of schedule

Disposal of spent

cartridges

Procedure in the event that the activated carbon filter has to be replaced ahead of

schedule e.g. if the activated carbon filter has suffered mechanical damage (filter

indicator (3) fails to light up):

1. Replace the activated carbon filter and the associated filter mats

Note! Always replace used activated carbon filters and associated filter mats

with new filters and filter mats,

- never re-use used filters and filter mats,

- dispose of used filters and filter mats in accordance with official regulations.

2. Connect mains cable (8) to mains power supply

3. Set mains switch (6) to “I” position

4. Press “Reset” button (4)

Filter indicator (3) lights up

5. Press “Reset” button (4) and hold approx. 10 secs until filter indicator (3) goes off

Important! Acidic materials may only be disposed off in line with official national and

international guidelines.

The composition of the activated carbon filter means that it can be incinerated completely for disposal purposes.

Fig. 14 Composition of the activated carbon filter

Filter pipe and perforated plates made from PVC

Filter material made from impregnated activated carbon

Non-woven filter fabric made from polyolefin

Electrolyte:

Maximum 180 g phosphoric acid (P2O5) per cartridge

Maximum 50 g sulphuric acid (P2O4) per cartridge

Filter mats made from latex bonded natural fibres and

animal hair

10

Page 15

Maintenance and care

General remarks Under normal operating conditions the MC fume extractor only requires a minimum of

care and maintenance. However it is imperative that a few points are followed in order

to keep the system operational over many years.

Warning! An electric shock can be fatal. Before opening, switch the device off,

remove the mains plug and fit a clearly legible and easily understood warning

sign against switching the machine back on - discharge the electrolytic capacitators if necessary. The screws for the case represent a suitable conductor

connection for earthing the case. The screws must NOT be replaced by any

other screws without a reliable PE conductor connection.

EN

At every initial

operation

If the activated

carbon filter is

full

Every 6 months

Check the following parts for possible damage:

- Socket, mains plug and mains cable

- Mains plug and mains cable for the MagicCleaner CrNi Cleaning Device

- Cleaning handle and cleaning handle hosepack for the MagicCleaner CrNi Cleaning Device

Check the ventilation flaps or air slots for turbine exhaust air and that air circulation is

unimpeded. The ventilation flaps or the air slots for the turbine exhaust air must not be

covered in any way, not even partially.

- Replace activated carbon filter

- Replace filter mats

Note! Always replace used activated carbon filters and associated filter mats

with new filters and filter mats,

- never re-use used filters and filter mats,

- dispose of used filters and filter mats in accordance with official regulati-

ons.

Caution! Risk of injury due to acid or acidic materials. When cleaning the MC

fume extractor using compressed air, use suitable safety gloves and suitable

eye protection.

Do not point the MC fume extractor in the direction of other people when

cleaning it with compressed air.

- Dismantle the extractor‘s side panels and blow the inside of the device clean

using dry, pressure-reduced compressed air

Note! Electronic components may be damaged by compressed air. Do not

aim airjets at electronic components from too close a range.

- Clean ventilation flaps or air slots for turbine exhaust air

11

Page 16

Fault diagnosis - Fault rectification

General All faults detected by the MC fume extractor are displayed by way of MC mains indica-

tor (2) and filter indicator (3) .

After switching on the extractor, both indicators light up for approx. 1 sec during the

start-up phase. During the start-up phase, the MC fume extractor checks the mains

voltage present .

Fault diagnosis Fault rectification

Mains supply indicator (1) is not lit

Mains switch in “I” position

Cause: Fault in the power feed

Remedy: Check mains cable, mains plug, and mains protection

Mains indicator (2) flashes

Mains switch in “I” position

Cause: Inadmissible mains fluctuations when device is switched on

Remedy: Check mains for voltage and frequency, switch device on again

Mains indicator (2) flashes

Suction turbine not working

Cause: Turbine fuse (3) faulty

Remedy: Replace turbine fuse (3):

- Set mains switch (6) to “0” position

- Disconnect mains cable (8) from mains supply

- Replace turbine fuse (3)

- Connect mains cable (8) to mains supply

- Set mains switch (6) to “I” position - mains indicator (2) goes off

Cause: Temperature in device too high

Remedy: Allow device to cool down

Filter display (2) on

Cause: Activated carbon filter is full

Remedy: Replace activated carbon filter and filter mats

Suction power not achieved

Cause: Bend in the suction hose; suction hose or suction nozzle are installed

incorrectly

Remedy: Remove bend from suction hose, check suction hose and suction nozzle

for foreign bodies, remove foreign bodies

12

Page 17

Ersatzteilliste

DEENFRITESPT-BRNLNOCSRUSKSVTR

Spare Parts List

Liste de pièces de rechange

Lista parti di ricambio

Lista de repuestos

Lista de peças sobresselentes

Onderdelenlijst

Reservdelsliste

Seznam náhradních dílù

Список запасных частей

Zoznam náhradných dielov

Reservdelslistan

ud_fr_st_tb_00150 012012

Parça Listesi

Czyszczenie palnika

PL

Page 18

Exhaust device MagicCleaner 4,045,884

AM2,0201,1727

AM2,0201,1726

AM2,0201,1725

* gewünschte Länge angeben

* Specify the length required

* Indiquer la longueur désirée

* Indicar la longitud deseada

* Indicare la lunghezza desiderat

* indicar o comprimento desejado

* uved'te požadovanou délku

42,0300,2602

42,0300,2568

42,0100,1146

43,0006,0180

43,0003,0316

43,0003,0315

44,0001,1337

42,0300,2602

42,0100,1145

42,0405,0367

42,0100,1147

42,0405,0193

43,0002,0360

41,0007,0047 - 250V/4A

41,0007,0076

41,0007,0169

45,0200,1191

41,0007,0079

43,0002,0295

42,0300,0648

42,0405,0367

43,0004,0519

4,070,849

44,0350,2295

40,0001,0431 - *

42,0407,0558

Exhaust device MagicCleaner

Ersatzteilliste / Spare parts list / Listes de pièces de rechange / Lista de repuestos / Lista de pecas sobresselentes / Lista dei Ricambi

el_fr_st_so_00873 012004

1/1

Page 19

FRONIUS INTERNATIONAL GMBH

Froniusplatz 1, A-4600 Wels, Austria

Tel: +43 (0)7242 241-0, Fax: +43 (0)7242 241-3940

E-Mail: sales@fronius.com

www.fronius.com

Under http://www.fronius.com/addresses you will find all addresses

www.fronius.com/addresses

of our Sales & service partners and Locations.

ud_fr_st_so_00082 012011

Loading...

Loading...