Fronius Galvo 1.5-1, Galvo 3.0-1, Galvo 2.0-1, Galvo 2.5-1, Galvo 3.1-1 Operating Instructions Manual

Page 1

/ Battery Charging Systems / Welding Technology / Solar Electronics

Fronius Galvo

1.5-1 / 2.0-1

2.5-1 / 3.0-1 / 3.1-1

Dummy

Operating Instructions

Grid-connected inverter

Istruzioni per l'uso

Inverter per impianti fotovoltaici collegati alla rete

Manual de instruções

Retificador alternado acoplado à

rede

EN

IT

PT-BR

www.youtube.com/FroniusSolar

LEARN MORE WITH

OUR HOW-TO VIDEOS

42,0410,1984 009-17092015

Page 2

0

Page 3

1

EN

Dear reader,

Introduction Thank you for the trust you have placed in our company and congratulations on buying this

high-quality Fronius product. These instructions will help you familiarise yourself with the

product. Reading the instructions carefully will enable you to learn about the many different

features it has to offer. This will allow you to make full use of its advantages.

Please also note the safety rules to ensure greater safety when using the product. Careful

handling of the product will repay you with years of safe and reliable operation. These are

essential prerequisites for excellent results.

Explanation of

safety symbols

If you see any of the symbols depicted in the "Safety rules" chapter, special care is required.

DANGER! Indicates immediate and real danger. If it is not avoided, death or serious injury will result.

WARNING! Indicates a potentially dangerous situation. Death or serious injury

may result if appropriate precautions are not taken.

CAUTION! Indicates a situation where damage or injury could occur. If it is not

avoided, minor injury and/or damage to property may result.

NOTE! Indicates a risk of flawed results and possible damage to the equipment.

IMPORTANT! Indicates tips for correct operation and other particularly useful information.

It does not indicate a potentially damaging or dangerous situation.

Page 4

2

Page 5

3

EN

Contents

Safety rules ................................................................................................................................................ 5

General ................................................................................................................................................. 5

Environmental conditions...................................................................................................................... 5

Qualified service engineers................................................................................................................... 6

Noise emission values .......................................................................................................................... 6

EMC measures ..................................................................................................................................... 6

Disposal ................................................................................................................................................ 6

Data protection...................................................................................................................................... 7

Copyright............................................................................................................................................... 7

General ...................................................................................................................................................... 8

Device concept ..................................................................................................................................... 8

Proper use ............................................................................................................................................ 8

Warning notices on the device.............................................................................................................. 9

Notes for a dummy device .................................................................................................................... 9

Data communication and Solar Net ........................................................................................................... 11

Fronius Solar Net and data interface .................................................................................................... 11

Data communication area..................................................................................................................... 11

Explanation of the multifunction current interface................................................................................. 12

Description of the 'Fronius Solar Net' LED............................................................................................ 13

Example................................................................................................................................................ 14

Installing option cards in the inverter .................................................................................................... 14

System monitoring ..................................................................................................................................... 15

General ................................................................................................................................................. 15

Fronius Datamanager during the night or when the available DC voltage is insufficient...................... 15

Starting for the first time........................................................................................................................ 15

Further information on Fronius Datamanager 2.0................................................................................. 17

Controls and indicators .............................................................................................................................. 18

Controls and indicators ......................................................................................................................... 18

Display .................................................................................................................................................. 19

The menu level .......................................................................................................................................... 20

Activate display backlighting................................................................................................................. 20

Automatic deactivation of display backlighting / choose 'NOW' menu item .......................................... 20

Open menu level................................................................................................................................... 20

The NOW, LOG and GRAPH menu items ................................................................................................. 21

NOW LOG GRAPH............................................................................................................................... 21

Values displayed in the NOW and LOG menu items............................................................................ 21

SETUP menu item ..................................................................................................................................... 23

Initial setting.......................................................................................................................................... 23

SETUP.................................................................................................................................................. 23

Navigating in the SETUP menu item .................................................................................................... 23

Setting entries on the Setup menu, general.......................................................................................... 24

Application example: Setting the time................................................................................................... 25

The Setup menu items............................................................................................................................... 26

Standby................................................................................................................................................. 26

WiFi Access Point................................................................................................................................. 26

DATCOM .............................................................................................................................................. 27

USB....................................................................................................................................................... 27

Relay..................................................................................................................................................... 29

Energy-Manager(in Relay menu item).................................................................................................. 29

Time / date ........................................................................................................................................... 30

Display settings..................................................................................................................................... 31

Energy yield .......................................................................................................................................... 32

Fan........................................................................................................................................................ 33

The INFO menu item ................................................................................................................................. 34

INFO ..................................................................................................................................................... 34

Measured values PSS status Grid status ............................................................................................. 34

Device information ................................................................................................................................ 34

Version.................................................................................................................................................. 36

Switching the key lock on and off............................................................................................................... 37

General ................................................................................................................................................. 37

Page 6

4

Switching the key lock on and off.......................................................................................................... 37

USB Stick as a Data Logger and for Updating Inverter Software .............................................................. 38

USB stick as a datalogger..................................................................................................................... 38

Suitable USB flash drives ..................................................................................................................... 38

USB stick for updating the inverter software......................................................................................... 39

Remove USB stick................................................................................................................................ 39

The Basic menu ......................................................................................................................................... 40

General ................................................................................................................................................. 40

Access the Basic menu......................................................................................................................... 40

Items on the Basic menu ...................................................................................................................... 41

Status diagnostics and troubleshooting ..................................................................................................... 43

Displaying status codes ........................................................................................................................ 43

Total failure of the display..................................................................................................................... 43

Class 1 status codes............................................................................................................................. 43

Class 3 status codes............................................................................................................................. 44

Class 4 status codes............................................................................................................................. 44

Class 5 status codes............................................................................................................................. 45

Class 6 status codes............................................................................................................................. 46

Class 7 status codes............................................................................................................................. 47

Customer service.................................................................................................................................. 48

Operation in dusty environments .......................................................................................................... 48

Technical data............................................................................................................................................ 49

Fronius Galvo 1.5-1 .............................................................................................................................. 49

Fronius Galvo 2.0-1 .............................................................................................................................. 50

Fronius Galvo 2.5-1 .............................................................................................................................. 51

Fronius Galvo 3.0-1 .............................................................................................................................. 52

Fronius Galvo 3.1-1 .............................................................................................................................. 53

Fronius Galvo Dummy .......................................................................................................................... 54

Explanation of footnotes ....................................................................................................................... 54

Applicable standards and guidelines .................................................................................................... 54

Warranty terms and conditions, and disposal ............................................................................................ 55

Fronius manufacturer's warranty .......................................................................................................... 55

Disposal ................................................................................................................................................ 55

Page 7

5

EN

Safety rules

General

Environmental

conditions

The device is manufactured using state-of-the-art technology and according

to recognised safety standards. If used incorrectly or misused, however, it can

cause:

- injury or death to the operator or a third party,

- damage to the device and other material assets belonging to the operator,

- inefficient operation of the device.

All persons involved in commissioning, maintaining and servicing the device

must

- be suitably qualified,

- have knowledge of and experience in dealing with electrical installations

and

- read and follow these operating instructions carefully.

The operating instructions must always be at hand wherever the device is being used. In addition to the operating instructions, attention must also be paid

to any generally applicable and local regulations regarding accident prevention and environmental protection.

All safety and danger notices on the device

- must be in a legible state,

- must not be damaged,

- must not be removed,

- must not be covered, pasted or painted over.

The terminals can reach high temperatures.

Only operate the device when all protection devices are fully functional. If the

protection devices are not fully functional, there is a risk of

- injury or death to the operator or a third party,

- damage to the device and other material assets belonging to the operator,

- inefficient operation of the device.

Any safety devices that are not functioning properly must be repaired by a suitably qualified engineer before the device is switched on.

Never bypass or disable protection devices.

For the location of the safety and danger notices on the device, refer to the

"General" section in the operating instructions for the device.

Before switching on the device, rectify any faults that could compromise safe-

ty.

This is for your personal safety!

Operation or storage of the device outside the stipulated area will be deemed

as "not in accordance with the intended purpose". The manufacturer shall not

be held liable for any damage arising from such usage.

For exact information on permitted environmental conditions, please refer to

the "Technical data" in the operating instructions.

Page 8

6

Qualified service

engineers

Noise emission

values

EMC measures

Disposal

The servicing information contained in these operating instructions is intended

only for the use of qualified service engineers. An electric shock can be fatal.

Do not perform any actions other than those described in the documentation.

This applies even if you are qualified to do so.

All cables and leads must be secure, undamaged, insulated and adequately

dimensioned. Loose connections, scorched, damaged or inadequately dimensioned cables and leads must be immediately repaired by authorised personnel.

Maintenance and repair work must only be carried out by authorised personnel.

It is impossible to guarantee that bought-in parts are designed and manufactured to meet the demands made of them, or that they satisfy safety requirements. Use only original spare parts (also applies to standard parts).

Do not carry out any modifications, alterations, etc. to the device without the

manufacturer's consent.

Components that are not in perfect condition must be changed immediately.

The inverter generates a maximum sound power level of < 59 dB(A)

(ref. 1 pW) when operating under full load in accordance with

IEC 62109-1:2010.

The device is cooled as quietly as possible with the aid of an electronic temperature control system, and depends on the amount of converted power, the

ambient temperature, the level of soiling of the device, etc.

It is not possible to provide a workplace-related emission value for this device

because the actual sound pressure level is heavily influenced by the installation situation, the power quality, the surrounding walls and the properties of

the room in general.

In certain cases, even though a device complies with the standard limit values

for emissions, it may affect the application area for which it was designed (e.g.

when there is sensitive equipment at the same location, or if the site where the

device is installed is close to either radio or television receivers). If this is the

case, then the operator is obliged to take appropriate action to rectify the situation.

To comply with the European Directive 2002/96/EC on Waste Electrical and

Electronic Equipment and its implementation as national law, electrical equipment that has reached the end of its life must be collected separately and returned to an approved recycling facility. Any device that you no longer require

must either be returned to your dealer or given to one of the approved collection and recycling facilities in your area. Ignoring this European Directive may

have potentially adverse affects on the environment and your health!

Page 9

7

EN

Data protection

Copyright

The user is responsible for the safekeeping of any changes made to the factory settings. The manufacturer accepts no liability for any deleted personal

settings.

Copyright of these operating instructions remains with the manufacturer.

The text and illustrations are all technically correct at the time of printing. We

reserve the right to make changes. The contents of the operating instructions

shall not provide the basis for any claims whatsoever on the part of the purchaser. If you have any suggestions for improvement, or can point out any

mistakes that you have found in the instructions, we will be most grateful for

your comments.

Page 10

8

General

Device concept

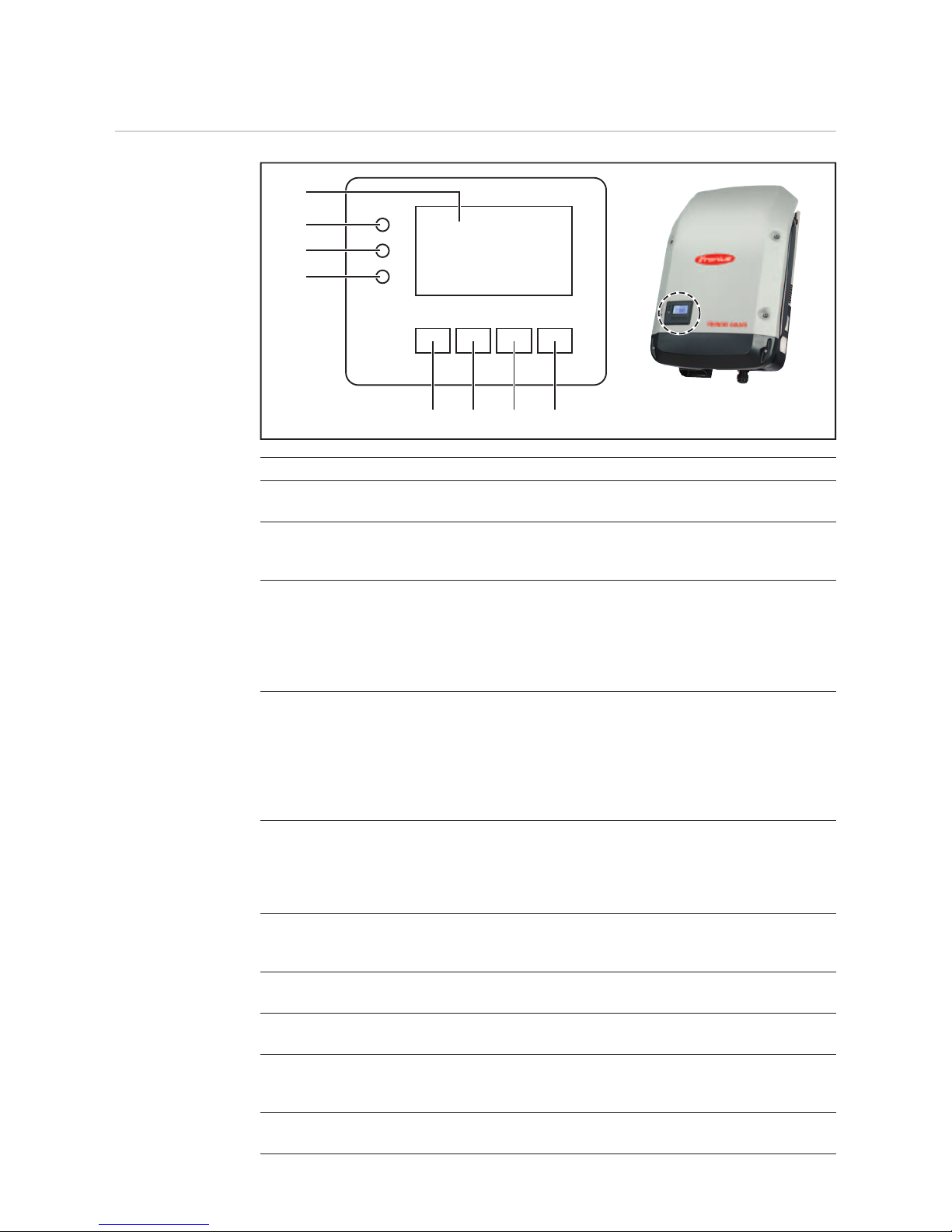

Device construction:

(1) Housing cover

(2) Inverter

(3) Wall bracket

(4) Connection area incl. DC main

switch

(5) Data communication area

(6) Data communication cover

The inverter transforms the direct current

generated by the solar modules into alternating into AC current. This alternating current is fed into your home system or into the

public grid and synchronized with the voltage that is used there.

The inverter has been designed exclusively for use in grid-connected photovoltaic systems. It cannot generate electric power independently of the grid.

The design and function of the inverter provide a maximum level of safety during both installation and operation.

The inverter monitors automatically the public grrid. Whenever conditions in the electric

grid are inconsistent with standard conditions (for example, grid switch-off, interruption),

the inverter will immediately stop operating and interrupt the supply of power into the grid.

Grid monitoring is carried out using voltage monitoring, frequency monitoring and monitoring islanding conditions.

The inverter is fully automatic. Starting at sunrise, as soon as the solar modules generate

enough energy, the inverter starts monitoring grid voltage and frequency. As soon as there

is a sufficient level of irradiance, the solar inverter starts feeding energy into the grid.

The inverter ensures that the maximum possible power output is drawn from the solar modules at all times.

As there is no longer sufficient energy available to feed power into the grid, the inverter

shuts down the grid connection completely and stops operating. All settings and recorded

data are saved.

If the inverter temperature exceeds a certain value, the inverter derates automatically the

actual output power for self protection.

The cause for a to high inverter temperature can be found in a high ambient temperature

or an inadequate heat transfer away (eg for installation in control cabinets without proper

heat dissipation).

Proper use The solar inverter is intended exclusively to convert direct current from solar modules into

alternating current and to feed this into the public grid.

Utilisation not in accordance with the intended purpose comprises:

- utilisation for any other purpose or in any other manner

- making any modifications to the inverter that have not been expressly approved by

Fronius

- the installation of parts that are not distributed or expressly approved by Fronius.

Fronius shall not be liable for any damage resulting from such action.

No warranty claims will be entertained.

(1) (2) (3)

(4)(5)(6)

Page 11

9

EN

Proper use includes:

- carefully reading and obeying all the instructions and all the safety and danger notices

in the operating instructions

- performing all stipulated inspection and maintenance work

- installation as specified in the operating instructions

When designing the photovoltaic system, ensure that all of its components are operated

within their permitted operating ranges at all times.

Observe all the measures recommended by the solar module manufacturer to ensure the

lasting maintenance of the properties of the solar module.

Obey the regulations of the energy supply company regarding feeding energy into the grid.

Warning notices

on the device

There are warning notices and safety symbols on and in the inverter. These warning notices and safety symbols must not be removed or painted over. They warn against operating

the device incorrectly, as this may result in serious injury and damage.

Text of the warning notices:

WARNING!

An electric shock can be fatal. Make sure that both the input side and output side of the

device are de-energised before opening the device. Wait for the capacitors to discharge (3

minutes).

Notes for a dummy device

A dummy device is not suitable for the operative connection to a photovoltaic system and

may only be taken into operation for demonstration purposes.

IMPORTANT! With a dummy device never connect live DC cables to the DC terminals.

Attaching not-energized cables or cable pieces for demonstration purposes is permitted.

A dummy device can be identified by the device rating plate:

Safety symbols:

Risk of serious injury and damage

due to incorrect operation

Do not use the functions described here until you have fully

read and understood the following

documents:

- these operating instructions

- all the operating instructions

for the system components of

the photovoltaic system, especially the safety rules

Dangerous electrical voltage

Wait for the capacitors to discharge.

Page 12

10

Device rating plate of a dummy device

Page 13

11

EN

Data communication and Solar Net

Fronius Solar Net

and data interface

Data communication area

Depending on the model, the inverter may be equipped with the Fronius Datamanager

plug-in card.

Fronius Solar Net was developed to make system add-ons flexible to use in a variety of

different applications. Fronius Solar Net is a data network that enables multiple inverters

to be linked up using system add-ons.

It is a bus system that uses a ring topology. One suitable cable is sufficient for communication between one or several inverters that are connected on the Fronius Solar Net using a system add-on.

Fronius Solar Net automatically recognises a wide variety of system add-ons.

In order to distinguish between several identical system add-ons, each one must be as-

signed a unique number.

Similarly, every inverter on the Fronius Solar Net must be assigned a unique number.

Refer to the section entitled 'The SETUP menu item' for instructions on how to assign a

unique number.

More detailed information on the individual system add-ons can be found in the relevant

operating instructions or on the internet at www.fronius.com

More detailed information on cabling DATCOM components can be found at:

http://www.fronius.com/QR-link/4204101938

(1) (2) (3) (4)

(5)

(6) (7) (8) (9)

IN

IN

OUT

OUT

PIN 2

PIN 1

PIN 1

PIN 2

PIN 3

Page 14

12

Explanation of

the multifunction

current interface

Various wiring variants can be connected to the multifunction current interface. However,

these cannot be operated simultaneously. For example, if an S0 meter is connected to the

multifunction current interface, it is not possible to connect a signal contact for overvoltage

protection (or vice versa).

Pin 1 = measurement input: max. 20 mA, 100 Ohm measurement resistor (load impedance)

Pin 2 = max. short circuit current 15 mA, max. open circuit voltage 16 V DC or GND

Item Designation

(1) Switchable multifunction current interface. For more details, refer to the section

below entitled "Explanation of the multifunction current interface"

Use the 2-pin mating connector supplied with the inverter to connect to the multifunction current interface.

(2)

(3)

Fronius Solar Net connection / interface protocol IN

Fronius Solar Net connection / interface protocol OUT

'Fronius Solar Net' / interface protocol input and output for connecting to other

DATCOM components (e.g. inverter, sensor box, etc.)

If several DATCOM components are linked together, a terminating plug must be

connected to every free IN or OUT connection on a DATCOM component.

For inverters with a Fronius Datamanager plug-in card, two terminating plugs are

supplied with the inverter.

(4) The 'Solar Net' LED

indicates whether the Fronius Solar Net power supply is available

(5) The 'Data transfer' LED

flashes while the USB flash drive is being accessed. The USB flash drive must

not be removed while recording is in progress.

(6) USB A socket

for connecting a USB flash drive with maximum dimensions of

65 x 30 mm (2.6 x 2.1 in.)

The USB flash drive can function as a datalogger for an inverter. The USB flash

drive is not included in the scope of supply of the inverter.

(7) Floating switch contact with mating connector

max. 250 V AC / 4 A AC

max. 30 V DC / 1 A DC

max. 1.5 mm² (AWG 16) cable cross-section

Pin 1 = NO contact (Normally Open)

Pin 2 = C (Common)

Pin 3 = NC contact (Normally Closed)

Use the mating connector supplied with the inverter to connect to the floating

switch contact.

(8) Fronius Datamanager with WLAN antenna

or

cover for option card compartment

(9) Cover for option card compartment

Page 15

13

EN

Wiring diagram variant 1: Signal contact for overvoltage protection

Depending on the setting in the Basic menu, the DC OVP Typ 2 option (overvoltage protection) either outputs a warning or an error on the display. Further information on the DC

OVP Typ 2 option can be found in the installation instructions.

Wiring diagram variant 2: S0 meter

A meter for recording the self-consumption of each S0 can be connected directly to the inverter.

IMPORTANT! In order to connect an S0 meter to the inverter, it may be necessary to update the inverter firmware.

Requirements for the S0 meter:

- Must comply with the IEC62053-31 Class B standard

- Max. voltage 15 V DC

- Max. current when ON 15 mA

- Min. current when ON 2 mA

- Max. current when OFF 0.15 mA

Recommended max. pulse rate of the S0 meter:

Description of the

'Fronius Solar

Net' LED

The 'Solar Net' LED is on:

the power supply for data communication within the Fronius Solar Net / interface protocol

is OK

The 'Solar Net' LED flashes briefly every 5 seconds:

data communication error in the Fronius Solar Net

- Overcurrent (current flow > 3 A, e.g. resulting from a short circuit in the Fronius Solar

Net ring)

- Undervoltage (not a short circuit, voltage in Fronius Solar Net < 6.5 V, e.g. if there are

too many DATCOM components on the Fronius Solar Net and not enough electrical

power is available)

In this case, power for the DATCOM components must be supplied by connecting an

additional power supply to one of the DATCOM components.

To detect the presence of an undervoltage, check some of the other DATCOM components for faults as required.

PV output kWp [kW] Max. pulse rate per kWp

30 1000

30 2000

10 5000

≤ 5.5 10000

Pin 1Pin 2

Pin 1

Pin 2 S0 +

S0 -

Page 16

14

After cutting out because of overcurrent or undervoltage, the inverter attempts to restore

the power supply in the Fronius Solar Net every 5 seconds while the fault is still present.

Once the fault is rectified, power to the Fronius Solar Net will be restored within 5 seconds.

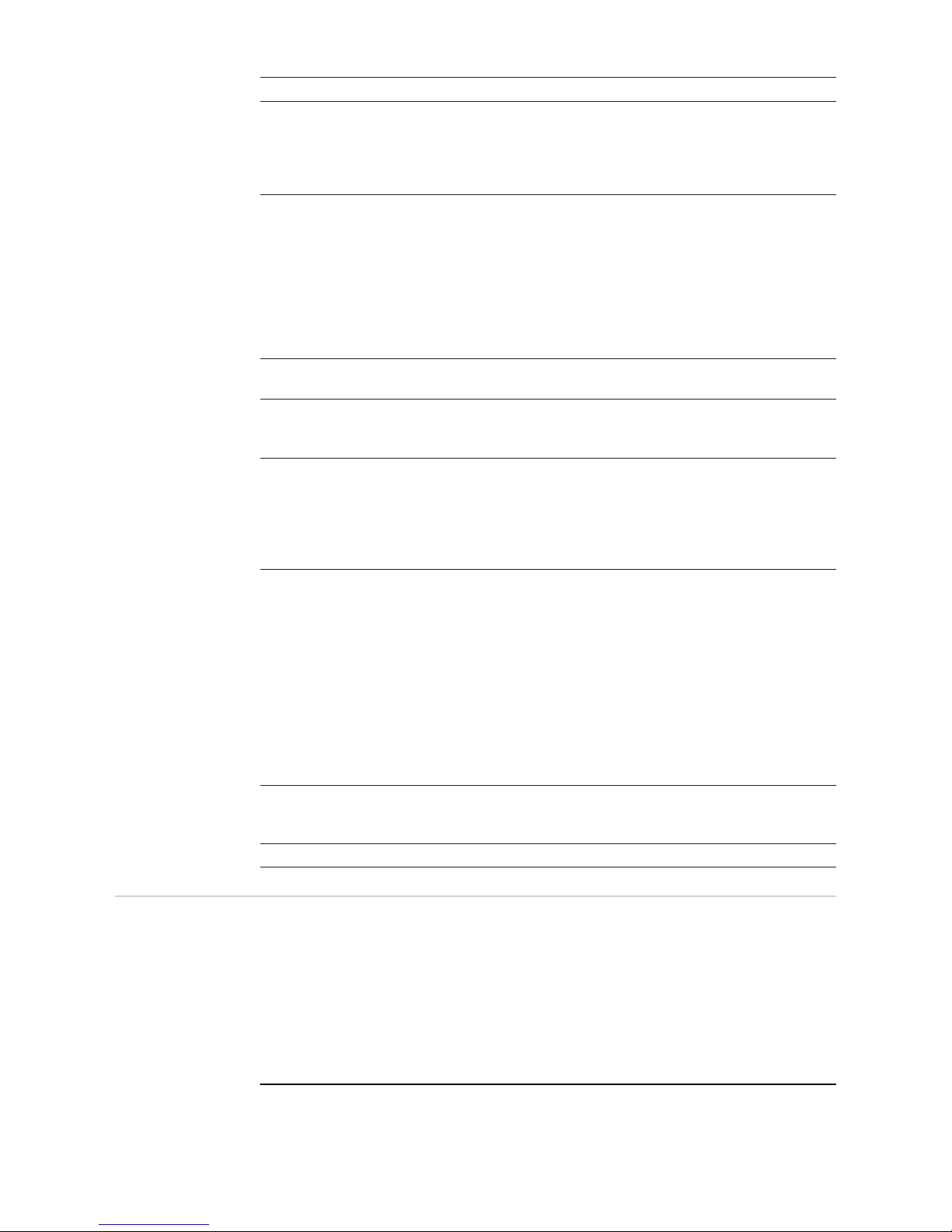

Example Recording and archiving data from the inverter and sensor using a Fronius Datamanager

and a Fronius Sensor Box:

Data network with 3 inverters and a Fronius Sensor Box:

- Inverter 1 with Fronius Datamanager

- Inverters 2 and 3 without Fronius Datamanager!

The external communication (Fronius Solar Net) takes place on the inverter via the data

communication area. The data communication area contains two RS 422 interfaces as inputs and outputs. RJ45 plug connectors are used to make the connection.

IMPORTANT! Since the Fronius Datamanager functions as a data logger, the Fronius Solar Net ring must not include any other data logger.

Only one Fronius Datamanager per Fronius Solar Net ring!

Any other Fronius Datamanagers must be removed and the unoccupied option card compartment sealed off using the blanking cover (42,0405,2020 - available from Fronius as an

optional extra); alternatively, use an inverter without Fronius Datamanager (light version).

Installing option

cards in the inverter

Information on installing option cards in the inverter and connecting the data communication cable can be found in the installation instructions.

= Terminating plug

12

3

IN

OUT

°C

W/m²

m/s

IN

OUT

IN

OUT

Sensor Box

WLAN

* Fronius Datamanager

*

IN OUT

Page 17

15

EN

System monitoring

General Where no special device model is present, the inverter is fitted with WLAN-compatible Fro-

nius Datamanager 2.0 system monitoring as standard.

Among other things, system monitoring includes the following functions:

- Own web page displaying current data and a wide range of different setting options

- Option of connecting directly to Fronius Solar.web

- Automatic sending of service messages by SMS or e-mail in the event of a fault

- Internet connection via WLAN or LAN

- Option of controlling the inverter by specifying power limit values, minimum or maximum running times or target running times

- Control of the inverter via Modbus (tcp / rtu)

- Assignment of control priorities

- Control of the inverter by means of connected meters (Fronius Smart Meter or S0 meter)

- Control of the inverter via a ripple control signal recipient (e.g. specification of reactive

power or effective power)

- Dynamic power reduction, taking self-consumption into account

Further information on Fronius Datamanager 2.0 can be found online in the Fronius Datamanager 2.0 operating instructions.

Fronius Datamanager during the

night or when the

available DC voltage is insufficient

The Night Mode parameter under "Display Settings" in the Setup menu is preset to OFF in

the factory.

For this reason the Fronius Datamanager cannot be accessed during the night or when the

available DC voltage is insufficient.

To nevertheless activate the Fronius Datamanager, switch the inverter off and on again at

the mains and press any key on the inverter display within 90 seconds.

See also the chapters on "The Setup menu items", "Display settings" (Night Mode).

Starting for the

first time

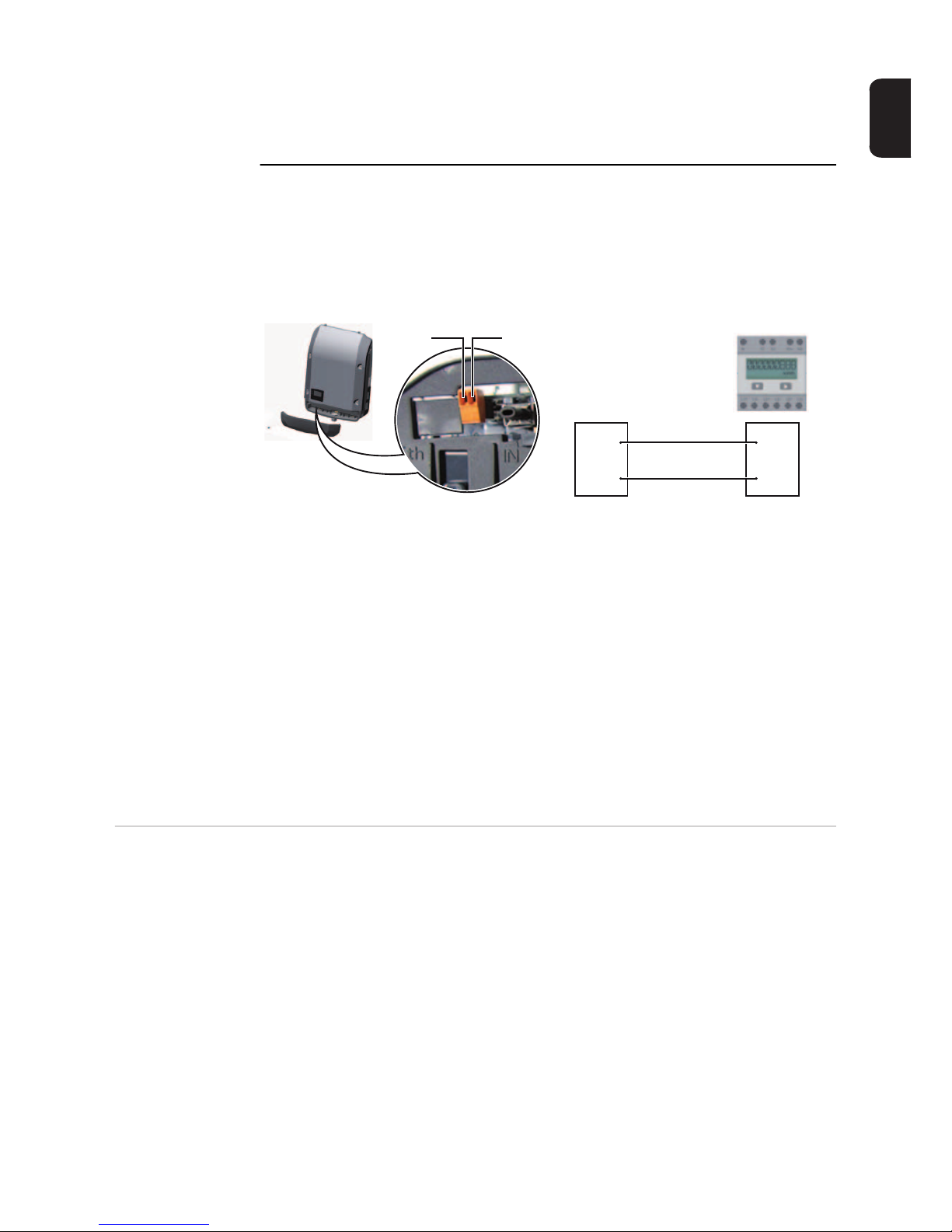

When starting Fronius Datamanager 2.0 for the first time,

- the Fronius Datamanager 2.0 plug-in card must be installed in the inverter,

or

- there must be a Fronius Datamanager Box 2.0 in the Fronius Solar Net ring.

IMPORTANT! In order to establish a connection to Fronius Datamanager 2.0, the end device in question (e.g. laptop, tablet, etc.) must be set up as follows:

- "Obtain IP address automatically (DHCP)" must be activated

NOTE! Starting the Fronius Datamanager 2.0 for the first time can be made significantly easier with the aid of the Fronius Solar.web App.

The Fronius Solar.web App is available in the relevant App store.

NOTE! If the photovoltaic system has only one inverter, steps 1 and 2 below can

be skipped. In this case, starting for the first time will commence with step 3.

Page 18

16

Connect inverter with Fronius Datamanager 2.0 or Fronius Datamanager Box 2.0 to

the Fronius Solar Net

When networking several inverters together in Fronius Solar Net:

Set the Fronius Solar Net master / slave switch on the Fronius Datamanager 2.0 plugin card correctly

- One inverter with Fronius Datamanager 2.0 = master

- All other inverters with Fronius Datamanager 2.0 = slave (the LEDs on the Fronius

Datamanager 2.0 plug-in cards are not illuminated)

Switch the device into service mode

- Activate the WLAN access point via the Setup menu on the inverter

The inverter establishes the WLAN access point. The WLAN access point remains open

for 1 hour.

The Setup wizard start page is displayed.

Installation using the Solar.web App Installation using a web browser

Download the Fronius Solar.web App

Run the Fronius Solar.web App

Connect the end device to the WLAN

access point

SSID = Fronius_240.xxxxx (5-8 digits)

- Search for a network with the

name "Fronius_240.xxxxx"

- Establish a connection to this

network

- Enter password 12345678

(or connect the end device and inverter using an Ethernet cable)

Entry in browser:

http://datamanager

or

192.168.250.181 (IP address for

WLAN connection)

or

169.254.0.180 (IP address for LAN

connection)

1

2

3

Stand by

WiFi Access Point

DATCOM

USB

Clock

4

5

4

5

Page 19

17

EN

The technician wizard is intended for the installer and contains standard-specific settings.

Running the technician wizard is optional.

If the technician wizard is run, it is vital to note the service password that is issued. This

service password is necessary for setting the EVU Editor menu item.

If the technician wizard is not run, no specifications regarding power reduction are set.

Running the Solar Web wizard is mandatory.

Run the Solar Web wizard and follow the instructions

The Fronius Solar.web homepage is displayed,

or

the Fronius Datamanager 2.0 web page is displayed.

Where necessary, run the technician wizard and follow the instructions

Further information on Fronius

Datamanager 2.0

6

7

Further information on the Fronius Datamanager 2.0 and other start-up options can be

found at:

http://www.fronius.com/QR-link/4204260191EA

Page 20

18

Controls and indicators

Controls and indicators

Item Description

(1) Display

showing values, settings and menus

Monitoring and status LEDs

(2) General status LED (red)

on steady,

- if a status message is being displayed on the monitor

- if the process of feeding energy into the grid is interrupted

- while error handling (the inverter waits for an acknowledgement or for an

error to be rectified)

(3) Startup LED (orange)

on steady if

- the inverter is in its automatic startup or self-test phase (as soon after sunrise as the solar modules are delivering sufficient power)

- the inverter has been switched to standby mode in the setup menu (= feeding energy into the grid switched off manually)

- the inverter software is being updated

(4) Operating status LED (green)

on steady,

- if the PV system is working correctly after the inverter's automatic startup

phase

- all the time while energy is being fed into the grid

Function keys - allocated different functions depending on the selection:

(5) 'Left/up' key

for navigating to the left and up

(6) 'Down/right' key

for navigating down and to the right

(7) 'Menu/Esc' key

for switching to the menu level

for quitting the Setup menu

(8) 'Enter' key

for confirming a selection

(1)

(2)

(3)

(4)

(5) (6) (7) (8)

Page 21

19

EN

The keys are capacitive, and any exposure to water can impair their function. Wipe the

keys dry with a cloth if necessary to ensure optimum functionality.

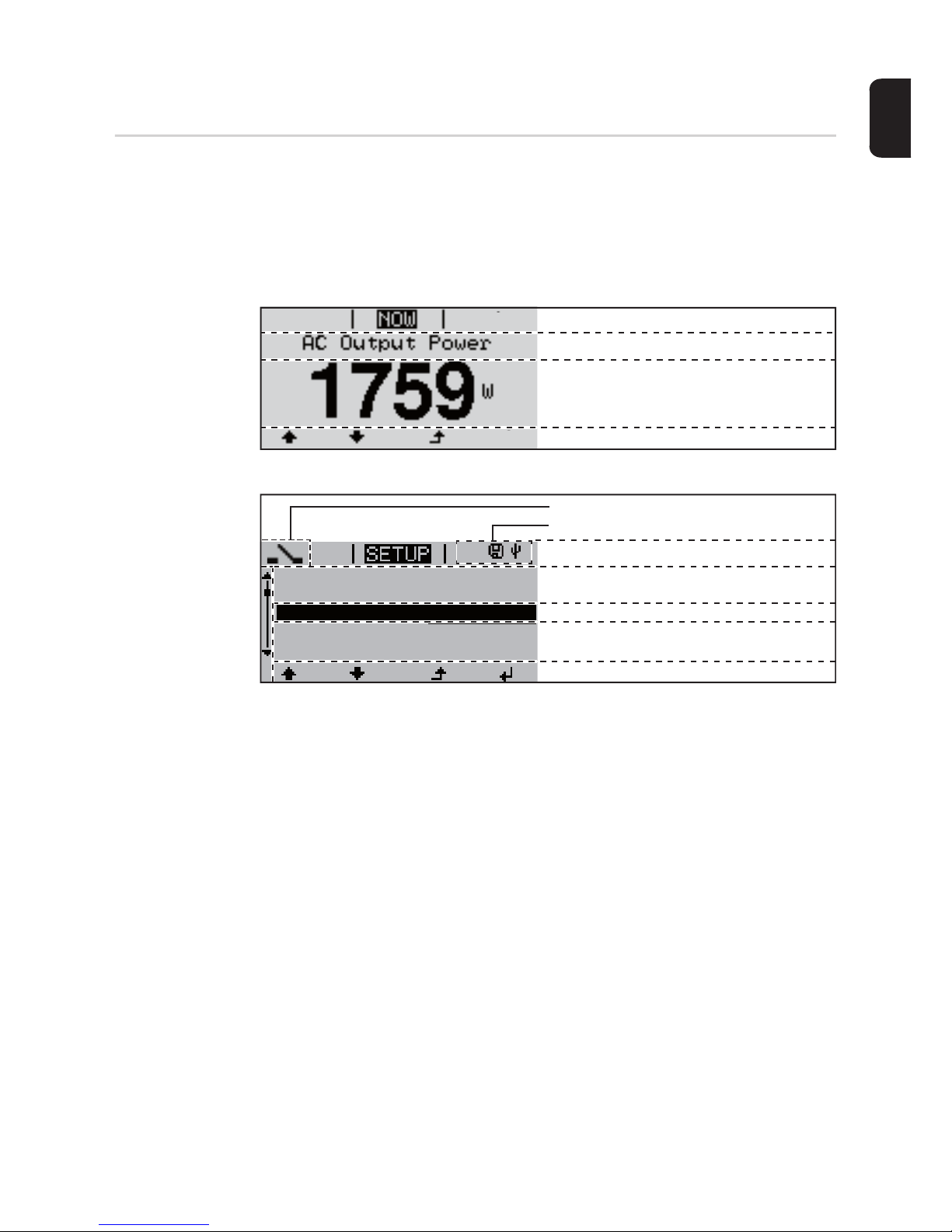

Display Power for the display comes from the mains voltage. Depending on the setting selected in

the Setup menu, the display can be kept on all day.

Display areas in display mode

Display areas in setup mode

(*) Scroll bar

(**) The Energy Manager symbol

is displayed when the Energy Manager function is activated

(***) Inv. no. = Inverter DATCOM number,

Save symbol - appears briefly while set values are being saved,

USB connection - appears if a USB flash drive has been connected

IMPORTANT! The display on the inverter is not a calibrated measuring device. A slight inaccuracy in comparison with the energy meter used by the energy supply company is intrinsic to the system. A calibrated meter will be needed to calculate the bills for the energy

supply company.

Function key functions

Menu item

Parameter declaration

Display of values, units and status codes

Function key functions

Next menu items

Currently selected menu item

Previous menu items

Menu item

Inv. no. | Save symbol | USB conn.(***)

(*)

1

Energy-Manager (**)

Standby

WiFi Access Point

DATCOM

USB

Relay

Page 22

20

The menu level

Activate display

backlighting

Press any key

The display backlighting is activated.

There is an option under 'Display Settings' in the SETUP menu to set the display backlighting so that it is on all the time or off all the time.

Automatic deactivation of display

backlighting /

choose 'NOW'

menu item

If no key is pressed for 2 minutes,

- the display backlighting switches off automatically and the inverter goes to the 'NOW'

menu item (assuming the display backlighting is set to automatic).

- The selection of the 'NOW' menu item can happen from any position on the menu level

with the exception of the item 'Standby' on the Setup menu.

- The amount of energy currently fed in is displayed.

Open menu level

1

Press the 'Menu' key

The display switches to the menu level

Use the 'Left' or 'Right' keys to select

the desired menu item

Press the 'Enter' key to select the desired menu item

1

2

3

Page 23

21

EN

The NOW, LOG and GRAPH menu items

NOW

LOG

GRAPH

Values displayed

in the NOW and

LOG menu items

NOW

(Displays real-time values)

LOG

(Data recorded today, during the current

calendar year and since the inverter was

first commissioned)

GRAPH

Day characteristic

displays a plot showing the power output

during the day. The time axis is scaled automatically.

Press the 'Back' key to remove the display

GRAPH

GRAPH

Values displayed in the NOW menu item:

AC Output power (W)

AC Reactive power (V Ar)

AC Voltage (V)

AC Output current (A)

AC Frequency (Hz)

PV Array Voltage (V)

PV Array Current (A)

Time / date

Time and date on the inverter or in the Fronius Solar Net ring

Page 24

22

Values displayed in the LOG menu item:

(for today, during the current calendar year and since the inverter was started for the first

time)

AC Energy Yield (kWh / MWh)

Energy fed into the grid during the period in question

There may be discrepancies with values displayed on other measuring instruments because of differences in measuring methods. As far as the billing of the energy fed in is

concerned, the only binding display values are those produced by the calibrated measuring device provided by the electricity supply company.

AC Max. Output Power (W)

Largest amount of power fed into the grid during the period in question

Earnings

Amount of money earned during the period in question (currency can be selected in the

Setup menu)

Like the energy supplied figure, the yield figure may also exhibit discrepancies with other

measured values.

The 'Setup Menu' section explains how to select a currency and charge rate.

The factory setting depends on the respective country setup.

CO2 savings (g / kg)

CO2 emissions saved during the period in question

The value for CO2 savings depends on the power station facilities and corresponds to the

CO2 emissions that would be released when generating the same amount of energy. The

factory setting is 0.53 kg / kWh (source: DGS – Deutsche Gesellschaft für Sonnenenergie

e.V. (German Society for Solar Energy).

AC Max. Voltage L-N (V)

Highest voltage measured between the conductor and neutral conductor during the period in question

PV Array Max. Voltage (V)

Highest solar module voltage measured during the period in question

Operating Hours

Length of time the inverter has been working (HH:MM).

IMPORTANT! A prerequisite for the correct display of day and year values is that the time

is set correctly.

Page 25

23

EN

SETUP menu item

Initial setting The inverter is pre-configured and ready to use. There is no need to enter any initial set-

tings before using it to feed energy into the grid, as this is a fully-automated process.

The SETUP menu item allows the initial settings of the inverter to be changed easily to

bring it in line, as closely as possible, with the preferences and requirements of the user.

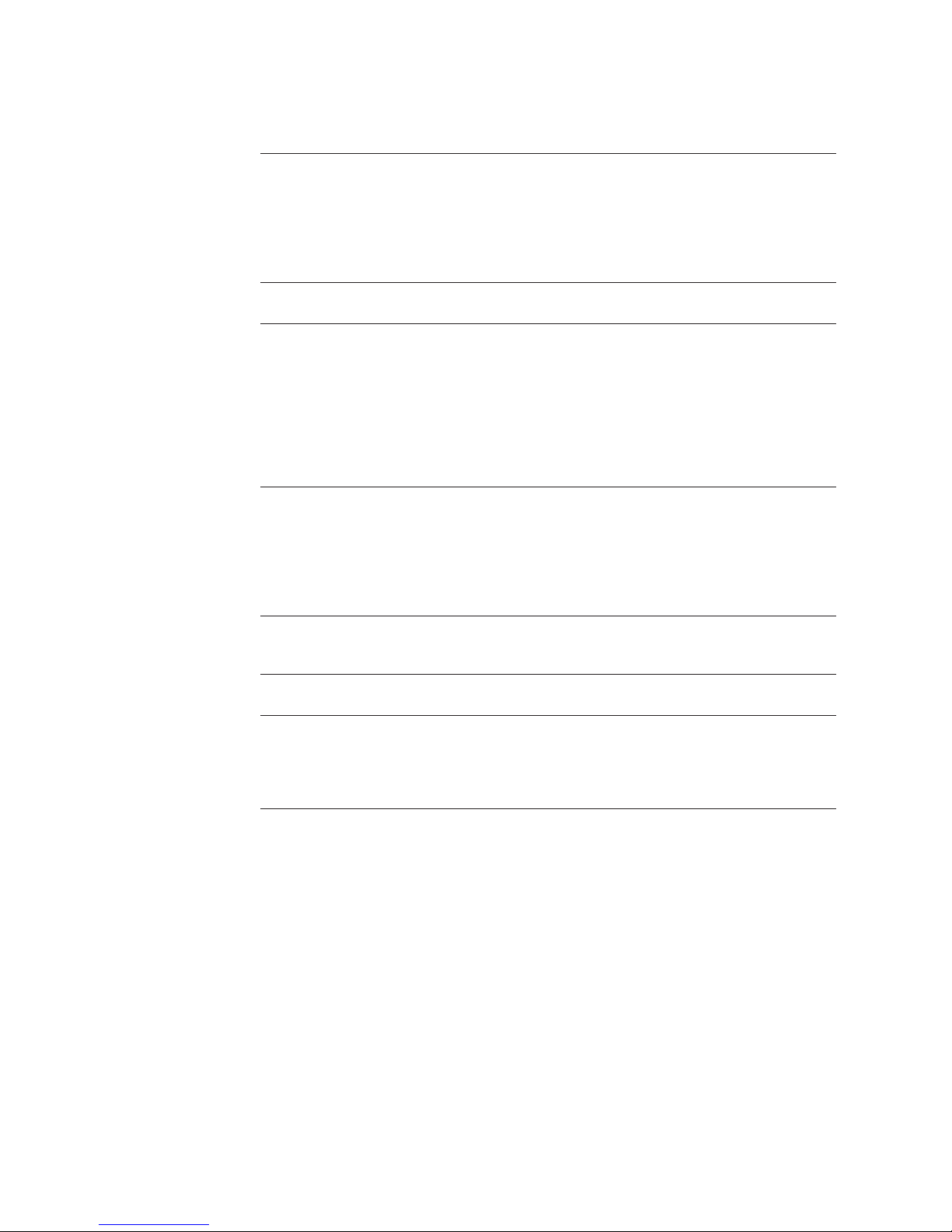

SETUP

Navigating in the

SETUP menu item

Enter the SETUP menu item

Scrolling between the entries

Exiting an entry

SETUP

(Setup menu)

NOTE! As a result of software updates, you may find that your device has certain

functions that are not described in these operating instructions, or vice versa. Certain illustrations may also differ slightly from the actual controls on your device.

but these controls function in exactly the same way.

GRAPH

Menu level, 'SETUP' selected

In the menu level, use the 'Left' or

'Right' keys to select the 'SETUP'

menu item

Press the 'Enter' key

'Standby' entry

The first entry under the SETUP menu

item is displayed:

'Standby'

Example: 'WiFi Access Point' menu item

Use the 'Up' and 'Down' keys to move

between the available entries

GRAPH

1

2

Relay

Relay

3

Page 26

24

If no key is pressed for 2 minutes,

- The inverter switches from wherever it is on the menu level back to the 'NOW' display

mode (exception: 'Standby' Setup menu entry),

- the display backlighting goes out.

- The amount of energy currently being fed in is displayed.

Setting entries on

the Setup menu,

general

Enter the SETUP menu item

Use the 'Up' or 'Down' keys to select the desired menu item

Press 'Enter'

To exit a menu entry, press the 'Back'

key

The menu level appears

GRAPH

4

The first digit of a value to be set flashes:

The available settings are displayed:

Use the 'Up' or 'Down' keys to select

a value for the first digit

Press 'Enter'

The second digit of the value flashes.

Repeat steps 4 and 5 until ...

the whole value to be set flashes.

Press 'Enter'

Repeat steps 4 - 6 as required for

units or other values that are to be set

until the appropriate unit or the value

flashes.

Press the 'Enter' key to save and apply the changes.

To discard the changes, press the

'Esc' key.

Use the 'Up' or 'Down' keys to select

the desired setting

Press the 'Enter' key to save and apply the setting.

To discard the setting, press the 'Esc'

key.

The currently selected menu item is displayed.

The currently selected menu item is displayed.

1

2

3

4

5

6

7

8

9

4

5

Page 27

25

EN

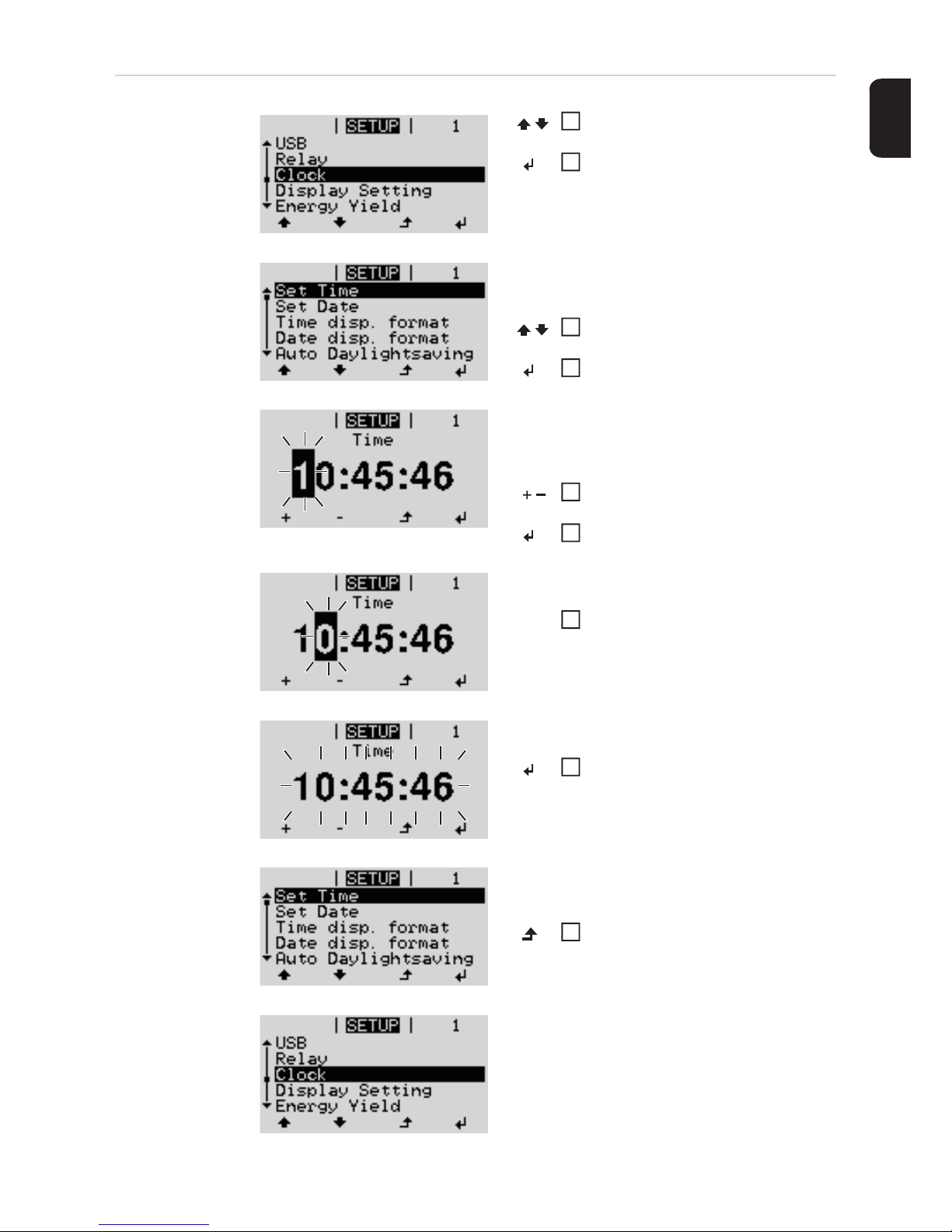

Application example: Setting

the time

Select 'Time / Date' from the Setup

menu

Press the 'Enter' key

An overview of the values that can be

changed is displayed.

Use the 'Up' or 'Down' keys to select

'Set time'

Press the 'Enter' key

The current time appears.

(HH:MM:SS, 24-hour clock),

the 'tens' digit for the hour will flash.

Use the 'Up' and 'Down' keys to select

a value for the 'tens' digit for the hour

Press the 'Enter' key

The 'units' digit for the hour will flash.

Repeat steps 5 and 6 for the 'units'

digit for the hour, for the minutes and

seconds until...

the set time starts flashing.

Press the 'Enter' key

The time is applied and the overview of

values that can be changed is displayed.

Press the 'Esc' key

The 'Time / Date' item on the Setup menu

appears.

1

2

3

4

5

6

7

8

4

Page 28

26

The Setup menu items

Standby Manual activation / deactivation of Standby mode

- No energy is fed into the grid.

- The Startup LED will show steady orange.

- In Standby mode, no other menu item at menu level can be accessed or adjusted.

- The automatic switchover into the 'NOW' display mode after 2 minutes of keyboard inactivity does not occur.

- Standby mode can only be terminated manually by pressing the 'Enter' key.

- Feeding energy into the grid can be resumed at any time (deactivate 'Standby').

Switching off Standby mode (manually switching off feeding energy into the grid):

Select the 'Standby' item

Press the 'Enter' key

'STANDBY' and 'ENTER' appear alternately on the display.

Standby mode is now active.

The Startup LED shows steady orange.

Resuming feeding energy into the grid:

'STANDBY' and 'ENTER' appear alternately on the display when in Standby mode.

Press the 'Enter' key to resume feeding energy into the grid

The 'Standby' menu item is displayed.

At the same time, the inverter enters the startup phase.

The operating state LED shows steady green when feeding energy into the grid has been

resumed.

WiFi Access

Point

For activating / deactivating the WLAN access point (e.g. to set up system monitoring)

1

2

1

Setting range WiFi Access Point

[stopped]

Activate WiFi AP?

To activate the WLAN access point Press the 'Enter' key

WiFi Access Point

[active]

The SS-ID (SS) and password (PW) are displayed.

Deactivate WiFi AP?

To deactivate the WLAN access point Press the 'Enter'

key

Page 29

27

EN

DATCOM Checking data communications, entering the inverter number, DATCOM night mode, pro-

tocol settings

Status

Indicates data communication is taking place via a Fronius Solar Net or that a data communications error has occurred

Inverter number

Sets the number (= address) of the inverter in a system with several solar inverters

Protocol type

Specifies the communications protocol to be used to transfer the data:

* The protocol type 'interface protocol' only functions when there is no Datamanager card

in the inverter. All Datamanager cards must be removed from the inverter.

USB Specification of values in conjunction with a USB stick

Safely remove hardware

To remove a USB stick from the USB A socket on the plug-in data communications card

without losing any data.

The USB stick can be removed:

- when the OK message appears

- when the 'Data transfer' LED stops flashing or comes on steady

Software Update

To update the inverter software via a USB stick.

Procedure:

Download the relevant update file 'froxxxxx.upd'

(e.g. from http://www.fronius.com; xxxxx stands for the version number)

***

WiFi Access Point

[not available]

Displayed if there is no system monitoring present on the inverter.

Setting range Status / inverter number / protocol type

Setting range 00 - 99 (00 = 100th inverter)

Factory setting 01

IMPORTANT! If a number of inverters are linked together in a data communications system, assign a unique address to each one.

Setting range Fronius Solar Net / interface protocol *

Factory setting Fronius Solar Net

Setting range Safely remove hardware / Software update / Logging interval

1

Page 30

28

Save the update file to the highest data level of the USB stick

Open the data communication area

Plug the USB stick containing the update file into the USB socket in the data commu-

nication area

Select 'USB' from the Setup menu, followed by 'Update software'

Press the 'Enter' key

Wait until the version currently installed on the inverter and the new software version

are displayed for comparison:

- 1st page: Recerbo software (LCD), key controller software (KEY), country setup

version (Set)

- 2nd page: Power stage set software

Press the 'Enter' key after each page

The inverter starts copying the data.

'UPDATE' and the progress of storing the individual tests expressed in % are displayed until all the data for all the electronic modules has been copied.

Once copying is complete, the inverter updates the electronic modules as required in sequence.

'UPDATE', the affected modules and the update progress in % are displayed.

The final step is for the inverter to update the display.

The display remains dark for approx. 1 minute while the monitoring and status LEDs flash.

Once the software update is complete, the inverter enters its startup phase before going

on to start feeding energy into the grid. The USB stick can be unplugged.

When the inverter software is updated, any custom settings that were configured in the

Setup menu are retained.

IMPORTANT! In order for the logging function to work correctly the time must be set correctly.

NOTE! To successfully update the inverter software, the USB stick provided for

the purpose must not have a hidden partition or any encryption (see chapter "Suitable USB sticks").

Logging interval

Activate / deactivate the logging function and specify a logging interval

Unit Minutes

Setting range 30 min. / 20 min./ 15 min./ 10 min./ 5 min./ No log

Factory setting 30 min.

30 min. The logging interval is 30 minutes; every 30 minutes new log-

ging data will be saved on the USB stick.

20 min.

15 min.

10 min.

5 min. The logging interval is 5 minutes; every 5 minutes new logging

data will be saved on the USB stick.

No log No data is saved

2

3

4

5

6

7

8

Page 31

29

EN

Relay Activate relay, relay settings, relay test

* these are only shown if the 'E-Manager' function has been activated under 'Relay mode'.

Relay mode

for selecting the different functions of the floating switch contact in the data communication

area:

- Alarm function

- Active output

- Energy-Manager

Relay test

Function test to determine whether the floating switch contact switches

Switch-on point (only if 'Energy-Manager' function is activated)

for setting the effective power limit beyond which the floating switch contact is switched on

Switch-off point (only if 'Energy-Manager' function is activated)

for setting the effective power limit beyond which the floating switch contact is switched off

Energy-Manager

(in Relay menu

item)

The 'Energy-Manager' function can be used to activate the floating switch contact in such

a way that it functions as an actuator.

Thus a consumer that is connected to the floating switch contact can be controlled by specifying a switch-on or switch-off point that depends on the feed-in power.

Setting range Relay mode / Relay test / Switch-on point* / Switch-off point*

Setting range ALL / Permanent / OFF / ON / E-Manager

Factory setting ALL

Alarm function:

Permanent /

ALL:

Switch the floating switch contact for permanent and temporary service codes (e.g. brief interruption to energy being fed into the grid, a

service code occurs a certain number of times a day - can be adjusted

in 'BASIC' menu)

Active output:

ON: The floating NO contact is on all the time the inverter is in operation

(as long as the display is not dark and is displaying something).

OFF: The floating NO contact is off.

Energy-Manager:

E-Manager: Further details on the 'Energy-Manager' function may be found in the

"Energy-Manager" section.

Factory setting 1000 W

Setting range Switch-off point - max. nominal output of inverter / W / kW

Factory setting 500

Setting range 0 - Switch-on point / W / kW

Page 32

30

The floating switch contact is automatically switched off,

- if the inverter is not feeding any power into the grid,

- if the inverter is manually switched into standby mode,

- if the effective power is < 10% of nominal output,

- in the event of insufficient insolation.

To deactivate the 'Energy-Manager' function, select a different function and press the 'Enter' key.

Notes on setting up the switch-on and switch-off points

If the difference between the switch-on and switch-off points is too small, or if there are fluctuations in effective power, the result may be multiple switching cycles.

To avoid switching on and off frequently, the difference between the switch-on and switchoff points should be at least 100 - 200 W.

When choosing the switch-off point the power consumption of the connected consumer

should be taken into account.

When choosing the switch-on point, the weather conditions and anticipated insolation

should also be taken into account.

Application example

Switch-on point = 2000 W, switch-off point = 1800 W

If the inverter is outputting 2000 W or above, then the floating switch contact on the inverter

is switched on.

If the inverter output falls to below 1800 W, the floating switch contact is switched off.

Possible applications:

operating a heat pump or an air-conditioning system using as much self-generated power

as possible

Time / date Set the time, date and automatic changeover between summer and winter time

Set time

Set the time (hh:mm:ss or hh:mm am/pm - depending on the setting in the time display format)

Set date

Set the date (dd.mm.yyyy or mm/dd/yyyy - depending on the setting in the date display format)

To activate the 'Energy-Manager' function, select 'E-Manager' and press the 'Enter' key.

When the 'Energy-Manager' function is running, the 'Energy-Manager' symbol will appear

in the top left corner of the display:

when the floating NO contact is off (open contact)

when the floating NO contact is on (closed contact)

Setting range Set time / set date / time display format / date display format /

summer/winter time

Time display format

for specifying the time display format

Page 33

31

EN

Summer/winter time

Activate / deactivate automatic changeover between summer and winter time

IMPORTANT! The correct time and date is a prerequisite for the correct display of day and

year values and the day characteristic.

Display settings

Language

Set language for display

Night mode

DATCOM night mode; controls the DATCOM and display operation during the night or

when the DC voltage is insufficient

Setting range 12hrs / 24hrs

Factory setting Depends on country setup

Date display format

for specifying the date display format

Setting range mm/dd/yyyy / dd.mm.yy

Factory setting Depends on country setup

NOTE! Only use the automatic summer/winter time changeover function if the

Fronius Solar Net ring does not include any LAN- or WLAN-compatible system

components (e.g. Fronius Datalogger Web, Fronius Datamanager or Fronius Hybridmanager).

If it does include such system components, then this function should be switched

on using the system component's web interface.

Setting range on / off

Factory setting on

Setting range Language / Night mode / Contrast / Lighting

Setting range German, English, French, Dutch, Italian, Spanish, Czech, Slo-

vak, etc.

Setting range AUTO / ON / OFF

Factory setting OFF

AUTO: DATCOM mode is always in effect as long as there is a Datalogger connect-

ed in an active and uninterrupted Fronius Solar Net.

The display remains dark during the night, but can be activated by pressing

any key.

Page 34

32

Contrast

Set the contrast on the display

Since the contrast is temperature-dependent, when the ambient conditions change it may

be necessary to adjust the 'Contrast' menu item.

Illumination

Initial setting for display illumination

The 'Illumination' menu item only relates to the display backlighting.

Energy yield Setting

- of an OFFSET value for the total energy display

- of a measuring offset factor for the day, year and total energy display

- of the currency

- of the feed-in tariff

ON: DATCOM mode is always in effect. The inverter supplies 12 V continuously

to power the Fronius Solar Net. The display is always active.

IMPORTANT! If DATCOM night mode is set to ON or AUTO when there are

Fronius Solar Net components connected, then the inverter's current consumption during the night will increase to around 7 W.

OFF: DATCOM will not run at night, the inverter will not need any AC current in

order to supply power to the Fronius Solar Net.

The display is switched off during the night and the Fronius Datamanager is

not available.

Setting range 0 - 10

Factory setting 5

Setting range AUTO / ON / OFF

Factory setting AUTO

AUTO: Display backlighting is activated by pressing any key. If no key is pressed for

2 minutes, the display backlighting will go off again.

ON: The display backlighting remains permanently on when the inverter is

switched on.

OFF: The display backlighting is permanently switched off.

Setting range Meter deviation / Meter calibration / Currency / Feed-in tariff

Meter deviation

Input of a value for the fed-in energy that will be added to the energy currently fed in (e.g.

carry-over value when replacing an inverter)

Unit Wh / kWh / MWh

Setting range Five digits

Factory setting 0

Page 35

33

EN

Fan To check that the fan is working correctly

- Use the 'Up' and 'Down' keys to select the desired fan

- Testing of the selected fan is initiated by clicking 'Enter'.

- The fan will continue to run until the operator exits the menu by pressing 'Esc'.

Meter calibration

Input of a correction value to ensure that the value shown on the inverter display corresponds with the calibrated display on the electricity meter

Unit %

Setting range -5.0 - +5.0

Factory setting 0

Currency

Set the currency

Setting range 3 characters, A-Z

Feed-in tariff

Set the remuneration rate for energy fed into the grid

Setting range 2 digits, 3 decimal places

Factory setting (depends on country setup)

Setting range Test fan #1 / Test fan #2 (depending on the device)

Page 36

34

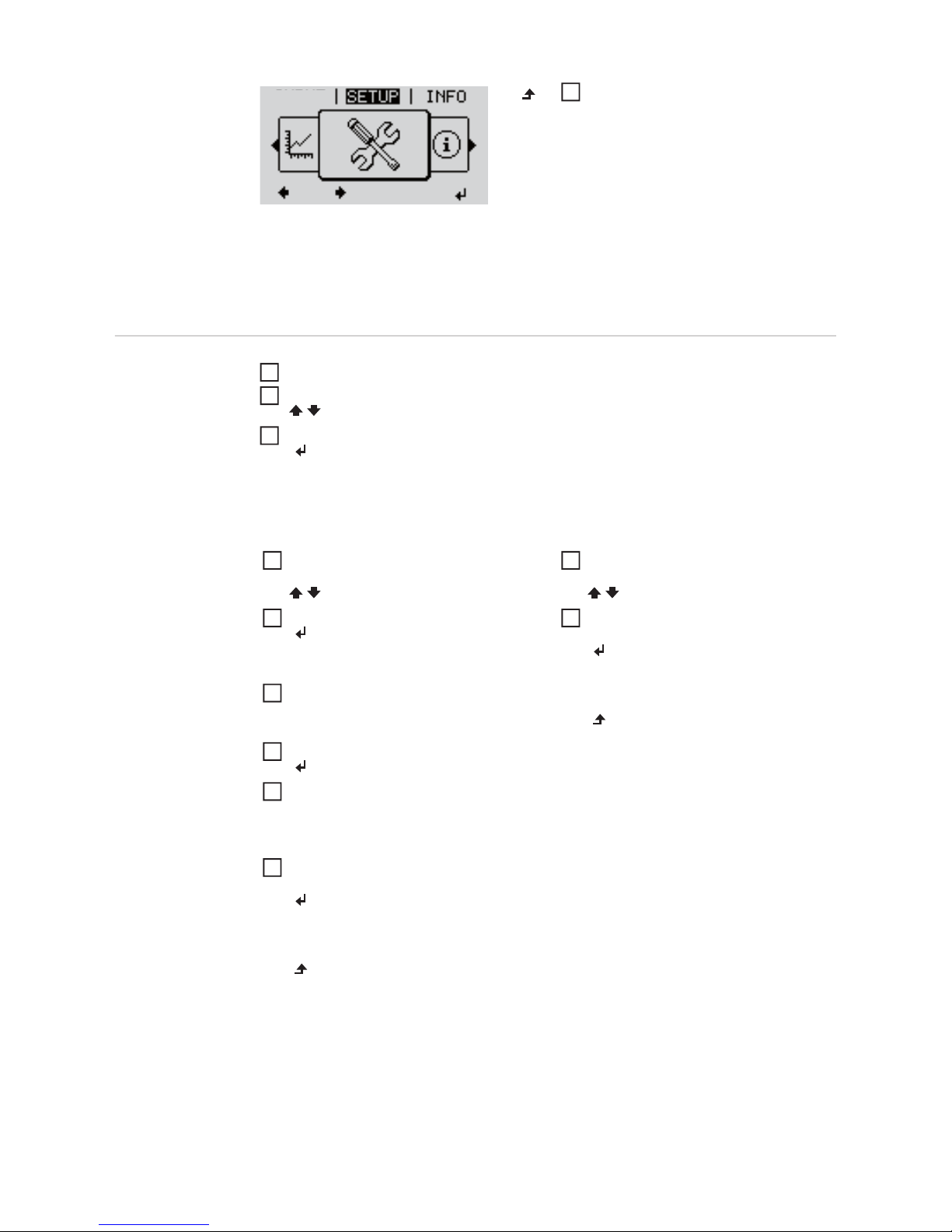

The INFO menu item

INFO

Measured values

PSS status

Grid status

Device information

For displaying the settings that will be of relevance to an energy supply company. The values shown will depend on the country setup or the device-specific settings of the inverter.

INFO

(Information about the device and the software)

Measured values Display range: PV ins. / Ext. lim. / U PV1 / GVDPR / Fan

#1

PV Iso.

Insulation resistance of the PV system (with ungrounded solar modules and solar modules with negative pole grounding)

Ext. lim.

External power reduction in percent e.g. specified by grid operator

U PV1

Current DC voltage on the terminals, even if the inverter is not feeding

any power into the grid whatsoever (from the 1st MPP tracker)

GVDPR

Grid voltage-dependent power reduction

Fan #1

Percentage of target output for fan

PSS status The status of the most recent inverter fault can be displayed.

IMPORTANT! Due to the low level of insolation early in the morning

and in the evening, the status codes 306 (Power low) and 307 (DC

low) are displayed routinely at these times of day. These status codes

do not indicate any kind of fault.

- Press the 'Enter' key to see the status of the power stage set and

the most recent fault

- Use the 'Up' and 'Down' keys to scroll through the list

- Press the 'Back' key to close the status and fault list

Grid status The five most recent grid faults can be displayed:

- Press the 'Enter' key to see the five most recent grid faults

- Use the 'Up' and 'Down' keys to scroll through the list

- Press the 'Back' key to close the grid fault display

Page 37

35

EN

Display range General / Country-specific setting / MPP tracker / Grid monitor-

ing / Grid voltage limits / Grid frequency limits / Q-mode / AC

power limit / AC voltage derating / Fault Ride Through

General: Device type

Fam.

Country-specific setting:

Setup

Specified country setup

Version

Version of country setup

Group

Group for updating the inverter software

MPP Tracker: Tracker 1

Monitoring the grid: GMTi

Startup time of inverter in s

GMTr

Reconnection time in s following a grid fault

ULL

Mean grid voltage over 10 minutes in V.

LLTrip

Trip time for long-term voltage monitoring

Grid voltage limits: UILmax

Upper inner grid voltage in V

UILmin

Lower inner grid voltage in V

Grid frequency limits: FILmax

Upper inner grid frequency in Hz

FILmin

Lower inner grid frequency in Hz

Q-mode: current power factor setting cos phi

(e.g. Constant Cos(phi) / Constant Q / Q(U)-characteristic / etc.)

AC power limit: Max. P AC

manual power reduction

Page 38

36

Version Displays the version and serial numbers of the PC boards in the inverter (e.g. for service

purposes)

AC voltage derating: Status

ON / OFF voltage-dependent power reduction

GVDPRe

Threshold from which the voltage-dependent power reduction

begins

GVDPRv

Reduction gradient used to reduce the power, e.g.: 10% per volt

above the GVDPRe threshold.

Message

Activates the dispatch of an info message via Fronius Solar Net

Fault Ride Through: Status - default setting: OFF

If the function is activated, the inverter does not switch off im-

mediately in the event of a short-term AC voltage interruption

(outside of the limits specified by the grid supplier), but instead

continues to feed in power for a defined period.

DB min - default setting: 90%

"Dead Band Minimum" setting in percent

DB max - default setting: 120%

"Dead Band Maximum" setting in percent

k-Fac. - default setting: 0

Display area Display / Display Software / Integrity Checksum / Memory Card

/ Memory Card #1 / Power Stage / Power Stage Software / EMI

Filter / Power Stage #3 / Power Stage #4

Page 39

37

EN

Switching the key lock on and off

General The inverter has a key lock function.

When the key lock is active, the Setup menu is not accessible, i.e. the setup data cannot

be changed accidentally (or maliciously).

The code 12321 has to be entered in order to activate / deactivate the key lock.

Switching the key

lock on and off

Press the 'Menu' key

The menu level appears.

Press the unassigned 'Menu / Esc'

key

5 times

"Access Code" is displayed in the "CODE"

menu; the first digit starts flashing.

Enter the code 12321: use the 'Up'

and 'Down' keys to select a value for

the first digit of the code.

Press the 'Enter' key

The second digit starts flashing.

Repeat steps 3 and 4 for the second,

third, fourth and fifth digit of the access code until ...

the selected code starts flashing.

Press the 'Enter' key

'Key Lock' is displayed in the 'LOCK'

menu.

Use the 'Up' and 'Down' keys to turn

the key lock on or off:

ON = key lock is on (the Setup menu

is not accessible)

OFF = key lock is off (the Setup menu

is accessible)

Press the 'Enter' key

1

2

3

4

Acess Code

5

6

7

8

Page 40

38

USB Stick as a Data Logger and for Updating Inverter Software

USB stick as a datalogger

If a USB stick is connected to the USB A socket it can function as a datalogger for an inverter.

At any time, the logging data stored on the USB stick can be

- imported into the Fronius Solar.access software using the FLD file that was logged at

the same time,

- viewed directly in third-party programs (e.g. Microsoft® Excel) using the CSV file

logged at the same time.

Older versions (before Excel 2007) are limited to a maximum of 65,536 rows.

Suitable USB

flash drives

Due to the variety of USB flash drives available on the market, it cannot be guaranteed that

every USB flash drive will be detected by the inverter.

Fronius recommends that only certified USB flash drives suitable for building sites are used

(look out for the USB-IF logo).

The inverter supports USB flash drives with the following file systems:

- FAT12

- FAT16

- FAT32

Fronius recommends that the USB flash drives employed should only be used for recording logging data or updating the inverter software. The USB flash drives should not contain

any other data.

Further information on "Data on a USB stick", "Data volume and storage capacity" as well

as "Buffer memory" can be found at:

http://www.fronius.com/QR-link/4204260171EN

Page 41

39

EN

USB stick for updating the inverter software

With the help of the USB stick, end customers can also update the inverter software via the

USB item on the SETUP menu: the update file is first saved to the USB stick, from where

it is then transferred to the inverter. The update file must be saved in the root directory on

the USB stick.

Remove USB

stick

USB symbol on the inverter display, e.g. in display mode 'NOW':

If the inverter detects a USB flash drive,

the USB symbol will appear in the top right

corner of the display.

When inserting a USB flash drive, check

whether the USB symbol is displayed (it

may also flash).

NOTE! Please note for outdoor applications that conventional USB flash drives

are often only guaranteed to work within a restricted temperature range. For outdoor applications ensure that the USB flash drive also functions, for example, at

low temperatures.

AC Output Power

NOW

Security note concerning the removal of a USB stick:

IMPORTANT! To avoid any loss of data, a

USB stick may only be removed if the following conditions are met:

- only remove a USB stick via the

'Safely remove USB / HW' item on the

SETUP menu

- the 'Data transmission' LED has

stopped flashing or comes on steady.

Do not disconnect

USB-Stick

while LED is flashing!

X

Page 42

40

The Basic menu

General The Basic menu is used to set the following parameters, which are important for installing

and operating the inverter:

Access the Basic

menu

- DC operating mode

- Fixed voltage

- MPPT1 initial voltage

- USB logbook

- Insulation settings

- TOTAL reset

- Event counter

Press the 'Menu' key

The menu level appears.

Press the unassigned 'Menu / Esc'

key

5 times

"Access Code" is displayed in the "CODE"

menu; the first digit starts flashing.

Enter the code 22742: Use the 'Up'

and 'Down' keys to select a value for

the first digit of the code

Press the 'Enter' key

The second digit starts flashing.

Repeat steps 3 and 4 for the second,

third, fourth and fifth digit of the access code until ...

the selected code starts flashing.

Press the 'Enter' key

The Basic menu appears.

Use the 'Up' or 'Down' keys to select

the desired menu item

Press the 'Enter' key to open the desired menu item

Press the 'Esc' key to exit the Basic

menu

1

2

3

4

Access Code

5

6

MPP Tracker 1

USB Eventlog

Input signal

SMS / Relay

Grounding Settings

7

8

9

Page 43

41

EN

Items on the Basic menu

The Basic menu contains the following items:

MPP Tracker 1

- DC operating mode:

MPP AUTO

FIX

MPP USER

- Fixed voltage:

for inputting a fixed voltage, 120 - 440 V

- MPPT1 initial voltage:

for inputting the MPPT1 initial voltage, 120 - 440 V

USB log book

Activates or deactivates the function for saving all error messages to a USB flash drive

AUTO / OFF / ON

Input signal

- How it works:

Ext Sig. / S0 meter / OFF

- Triggering method (with "Ext. Sig." mode of operation):

Warning / Ext. Stop

- Connection type (with "Ext. Sig." mode of operation):

N/C / N/O

SMS / relay

- Event delay

for inputting the time delay after which an SMS is sent or the relay is to switch

900 - 86,400 seconds

- Event counter:

for entering the number of errors after which an SMS is sent or the relay is to switch:

10 - 255

Grounding setting

- Grounding mode:

Off / Positive / Negative

- Ground monitoring:

Off / Warn Err / Error / Warning

Insulation mode

- Insulation warning:

for activating and deactivating insulation monitoring, with display of a warning without

interruption of feed-in if there is an insulation fault

ON / OFF (depends on the country setup)

- Threshold warning:

for setting an insulation threshold at which the inverter produces a warning (without

interruption of feed-in)

0 - 1000 kOhm (depends on the country setup)

Page 44

42

- Insulation fault:

for activating and deactivating insulation monitoring, with error message and immediate shutdown of the inverter if there is an insulation fault

ON / OFF (depends on the country setup)

- Threshold error:

for setting an insulation threshold at which the inverter produces an error message

and interrupts the feeding of energy into the grid

0 - 1000 kOhm (depends on the country setup)

Temperature warning

for activating / deactivating the overtemperature warning for each event;

the overtemperature warning is sent and displayed on the monitor.

ON / OFF

TOTAL Reset

in the LOG menu item, resets the max. and min. voltage values and the max. power of

feeding in to zero.

Once values have been reset, this action cannot be undone.

To reset the values to zero, press the 'Enter' key.

"CONFIRM" is displayed.

Press 'Enter' again.

The values are reset and the menu is displayed

Page 45

43

EN

Status diagnostics and troubleshooting

Displaying status

codes

The inverter performs a system self diagnosis that automatically detects many faults that