Fronius Galvo 208-240 1.5-1, Galvo 208-240 3.1-1, Galvo 208-240 2.0-1, Galvo 208-240 2.5-1 Operating Instructions Manual

Page 1

/ Battery Charging Systems / Welding Technology / Solar Electronics

LEARN MORE WITH

OUR HOW-TO VIDEOS

www.youtube.com/FroniusSolar

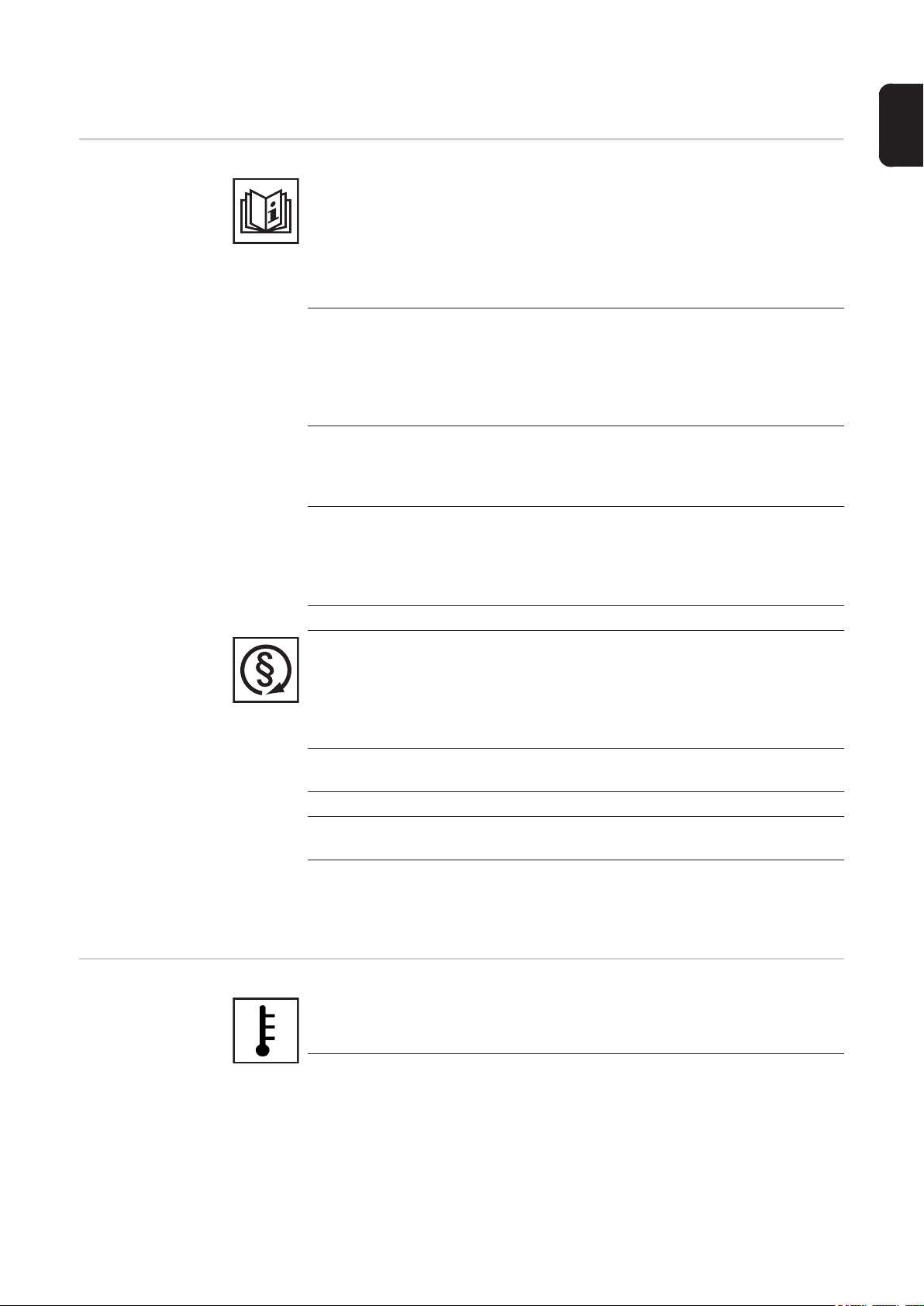

Fronius Galvo 208-240

1.5-1 / 2.0-1

2.5-1 / 3.1-1

Operating Instructions

Inverter for grid-connected photo-

EN-USEN-US

voltaic systems

Instructions de service

Onduleur pour installations photo-

FR ES

voltaïques connectées au réseau

Manual de instrucciones

Inversores para instalaciones fotovoltaicas acopladas a la red

42,0410,1934 011-18062015

Page 2

0

Page 3

Dear reader,

Introduction Thank you for the trust you have placed in our company and congratulations on buying this

high-quality Fronius product. These instructions will help you familiarize yourself with the

product. Reading the instructions carefully will enable you to learn about the many different

features it has to offer. This will allow you to make full use of its advantages.

Please also note the safety rules to ensure greater safety when using the product. Careful

handling of the product will repay you with years of safe and reliable operation. These are

essential prerequisites for excellent results.

EN-US

Explanation of

Safety Instructions

DANGER! Indicates an immediate danger. Death or serious injury may result if

appropriate precautions are not taken.

WARNING! Indicates a possibly dangerous situation. Death or serious injury may

result if appropriate precautions are not taken.

CAUTION! Indicates a situation where damage or injury could occur. Minor injury

or damage to property may result if appropriate precautions are not taken.

NOTE! Indicates the possibility of flawed results and damage to the equipment.

IMPORTANT! Indicates tips for correct operation and other particularly useful information.

It does not indicate a potentially damaging or dangerous situation.

If you see any of the symbols depicted in the "Safety Rules," special care is required.

1

Page 4

2

Page 5

Contents

Safety rules ................................................................................................................................................ 5

General ................................................................................................................................................. 5

Environmental Conditions..................................................................................................................... 5

Qualified Service Engineers.................................................................................................................. 6

Data Regarding Noise Emission Values............................................................................................... 6

EMC Measures ..................................................................................................................................... 6

Safety symbols...................................................................................................................................... 6

Disposal ................................................................................................................................................ 6

Backup.................................................................................................................................................. 7

Copyright............................................................................................................................................... 7

General ...................................................................................................................................................... 8

Device concept ..................................................................................................................................... 8

Intended Use......................................................................................................................................... 8

Information on "Field Adjustable Trip Points" and "Advanced Grid Features" ..................................... 9

FCC / RSS Compliance ........................................................................................................................ 9

Ground Fault Detector / Interrupter, Insulation Monitoring.................................................................... 10

Arc Detector / Interrupter ...................................................................................................................... 10

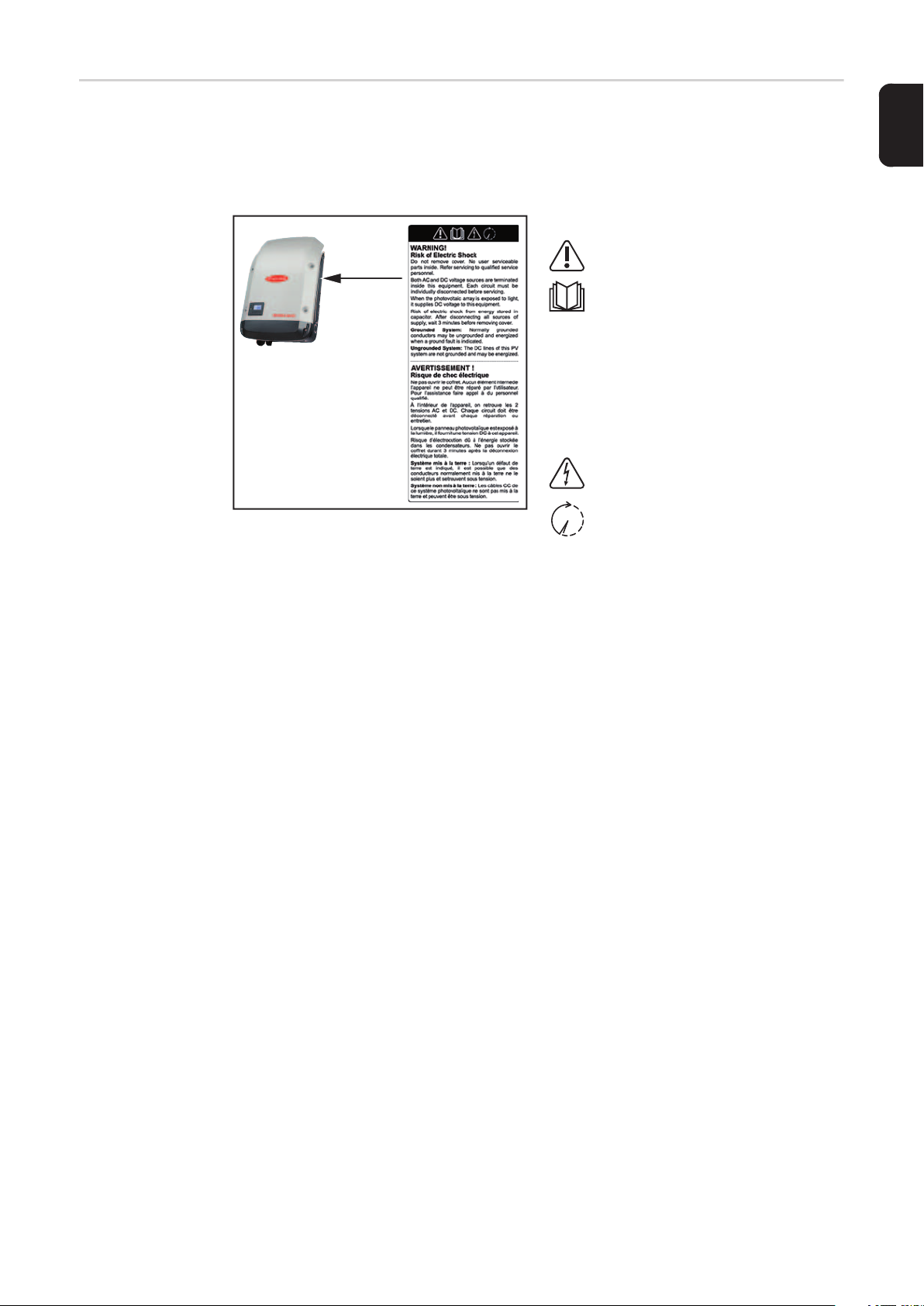

Warning Notices Affixed to the Device.................................................................................................. 11

Data Communication and Solar Net .......................................................................................................... 12

Fronius Solar Net and Data Interface ................................................................................................... 12

Installing Option Cards in Inverters....................................................................................................... 12

System monitoring ..................................................................................................................................... 13

General ................................................................................................................................................. 13

Starting for the First Time via the Fronius Solar.web App .................................................................... 13

More Detailed Information on Fronius Datamanager 2.0...................................................................... 15

Keys and symbols...................................................................................................................................... 16

Keys and Symbols ................................................................................................................................ 16

Display .................................................................................................................................................. 17

Menu level.................................................................................................................................................. 18

Activating Display Illumination .............................................................................................................. 18

Automatic Deactivation of Display Illumination / Switching to the "NOW" Display Mode...................... 18

Accessing the Menu Level.................................................................................................................... 18

Menu items NOW, LOG, and GRAPH ....................................................................................................... 19

NOW LOG GRAPH............................................................................................................................... 19

Values Displayed in the Menu Items NOW and LOG ........................................................................... 19

The SETUP menu item .............................................................................................................................. 21

Presetting.............................................................................................................................................. 21

SETUP.................................................................................................................................................. 21

Navigation in the SETUP Menu Item .................................................................................................... 21

General Setup Menu Item Settings....................................................................................................... 22

Application Example: Setting the Feed-In Tariff.................................................................................... 23

The Setup menu item................................................................................................................................. 24

Standby................................................................................................................................................. 24

WiFi Access Point................................................................................................................................. 24

DATCOM .............................................................................................................................................. 25

USB....................................................................................................................................................... 25

Relay..................................................................................................................................................... 27

Time/Date ............................................................................................................................................ 28

Display Settings .................................................................................................................................... 28

Energy Yield.......................................................................................................................................... 30

Fan........................................................................................................................................................ 30

Arc Detection ........................................................................................................................................ 31

The INFO menu item ................................................................................................................................. 32

INFO ..................................................................................................................................................... 32

Measured values LT status Grid status ................................................................................................ 32

Device Information................................................................................................................................ 33

Version.................................................................................................................................................. 34

Switching the key lock on and off............................................................................................................... 35

General ................................................................................................................................................. 35

Switching the Key Lock On and Off ...................................................................................................... 35

EN-US

3

Page 6

USB Stick as a Data Logger and for Updating Inverter Software .............................................................. 36

USB Stick as a Data Logger ................................................................................................................. 36

Suitable USB Sticks.............................................................................................................................. 36

USB Stick for Updating Inverter Software............................................................................................. 37

Removing the USB Stick....................................................................................................................... 37

The Basic menu ......................................................................................................................................... 38

General ................................................................................................................................................. 38

Accessing the Basic menu.................................................................................................................... 38

Items in the Basic Menu........................................................................................................................ 39

Status Diagnosis and Troubleshooting ...................................................................................................... 41

Displaying Status Codes....................................................................................................................... 41

Total Failure of the Display ................................................................................................................... 41

Class 1 Status Codes ........................................................................................................................... 41

Class 2 Status Codes ........................................................................................................................... 41

Class 3 Status Codes ........................................................................................................................... 42

Class 4 Status Codes ........................................................................................................................... 43

Class 5 Status Codes ........................................................................................................................... 44

Class 7 Status Codes ........................................................................................................................... 45

Customer Service ................................................................................................................................. 46

Operation in dusty environments .......................................................................................................... 46

Technical Data ........................................................................................................................................... 47

Relevant standards and directives........................................................................................................ 50

Terms and conditions of warranty and disposal......................................................................................... 51

Fronius Manufacturer's Warranty.......................................................................................................... 51

Disclaimer ............................................................................................................................................. 51

Disposal ................................................................................................................................................ 51

CoC............................................................................................................................................................ 166

4

Page 7

Safety rules

EN-US

General

The device has been manufactured using state-of-the-art technology and according to recognized safety standards. If used incorrectly or misused, however, it can cause

- injury or death to the operator or a third party

- damage to the device and other material assets belonging to the operating company

- inefficient operation of the equipment

All persons involved in start-up operation, maintenance and servicing for the

device must

- be suitably qualified

- have knowledge of and experience in dealing with electrical installations

and

- have completely read and followed these operating instructions

The operating instructions must always be at hand wherever the device is being used. In addition to the operating instructions, all applicable local rules and

regulations regarding accident prevention and environmental protection must

also be followed.

All safety and danger notices on the device

- must be kept in a legible state

- must not be damaged/marked

- must not be removed

- must not be covered, pasted or painted over

The terminals can reach high temperatures.

Only operate the device when all protection devices are fully functional. If the

protection devices are not fully functional, there is a risk of

- injury or death to the operator or a third party

- damage to the device and other material assets belonging to the operating company

- inefficient operation of the device

Safety devices that are not fully functional must be repaired by an authorized

specialist before the device is turned on.

Never bypass or disable protection devices.

For the location of the safety and danger notices on the device, refer to the

section headed "General" in the operating instructions for the device.

Any equipment malfunctions which might impair safety must be remedied im-

mediately before the device is turned on.

Your personal safety is at stake!

Environmental

Conditions

Operation or storage of the device outside the stipulated area will be deemed

as "not in accordance with the intended purpose." The manufacturer is not responsible for any damages resulting from unintended use.

For exact information on permitted environmental conditions, please refer to

the "Technical data" in the operating instructions.

5

Page 8

Qualified Service

Engineers

The servicing information contained in these operating instructions is intended

only for the use of qualified service engineers. An electric shock can be fatal.

Do not perform any actions other than those described in the documentation.

This also applies to those who may be qualified.

All cables and leads must be secured, undamaged, insulated and adequately

dimensioned. Loose connections, scorched, damaged or inadequately dimensioned cables and leads must be immediately repaired by authorized personnel.

Maintenance and repair work must only be carried out by authorized personnel.

It is impossible to guarantee that externally procured parts are designed and

manufactured to meet the demands made on them, or that they satisfy safety

requirements. Use only original replacement parts (also applies to standard

parts).

Do not carry out any modifications, alterations, etc. without the manufacturer's

consent.

Components that are not in perfect condition must be changed immediately.

Data Regarding

Noise Emission

Values

EMC Measures

Safety symbols

The inverter generates a maximum sound power level of < 65 dB(A) (ref. 1

pW) when operating under full load in accordance with IEC 62109-1:2010.

The device is cooled as quietly as possible with the aid of an electronic temperature control system, and depends on the amount of converted power, the

ambient temperature, the level of soiling of the device, etc.

It is not possible to provide a workplace-related emission value for this device,

because the actual sound pressure level is heavily influenced by the installation situation, the power quality, the surrounding walls and the properties of

the room in general.

In certain cases, even though a device complies with the standard limit values

for emissions, it may affect the application area for which it was designed (e.g.,

when there is sensitive equipment at the same location, or if the site where the

device is installed is close to either radio or television receivers). If this is the

case, then the operator is obliged to take appropriate action to rectify the situation.

Devices marked with the CSA test mark satisfy the requirements of the relevant standards for Canada and the USA.

Disposal

6

Dispose of in accordance with the applicable national and local regulations.

Page 9

Backup

The user is responsible for backing up any changes made to the factory settings. The manufacturer accepts no liability for any deleted personal settings.

EN-US

Copyright

Copyright of these operating instructions remains with the manufacturer.

Text and illustrations are technically correct at the time of going to print. The

right to make modifications is reserved. The contents of the operating instructions shall not provide the basis for any claims whatsoever on the part of the

purchaser. If you have any suggestions for improvement, or can point out any

mistakes that you have found in the operating instructions, we will be most

grateful for your comments.

7

Page 10

General

Device concept

(1) (2) (3)

(4)(5)(6)

The inverter has been designed exclusively for use in grid-connected photovoltaic systems. It cannot generate electric power independently of the grid.

The design and function of the inverter provide a maximum level of safety during both installation and operation.

The inverter automatically monitors the public grid. Whenever conditions in the electric grid

are inconsistent with standard conditions (for example, grid switch-off, interruption), the inverter will immediately stop operating and interrupt the supply of power into the grid.

Grid monitoring is carried out using voltage monitoring, frequency monitoring and monitoring islanding conditions.

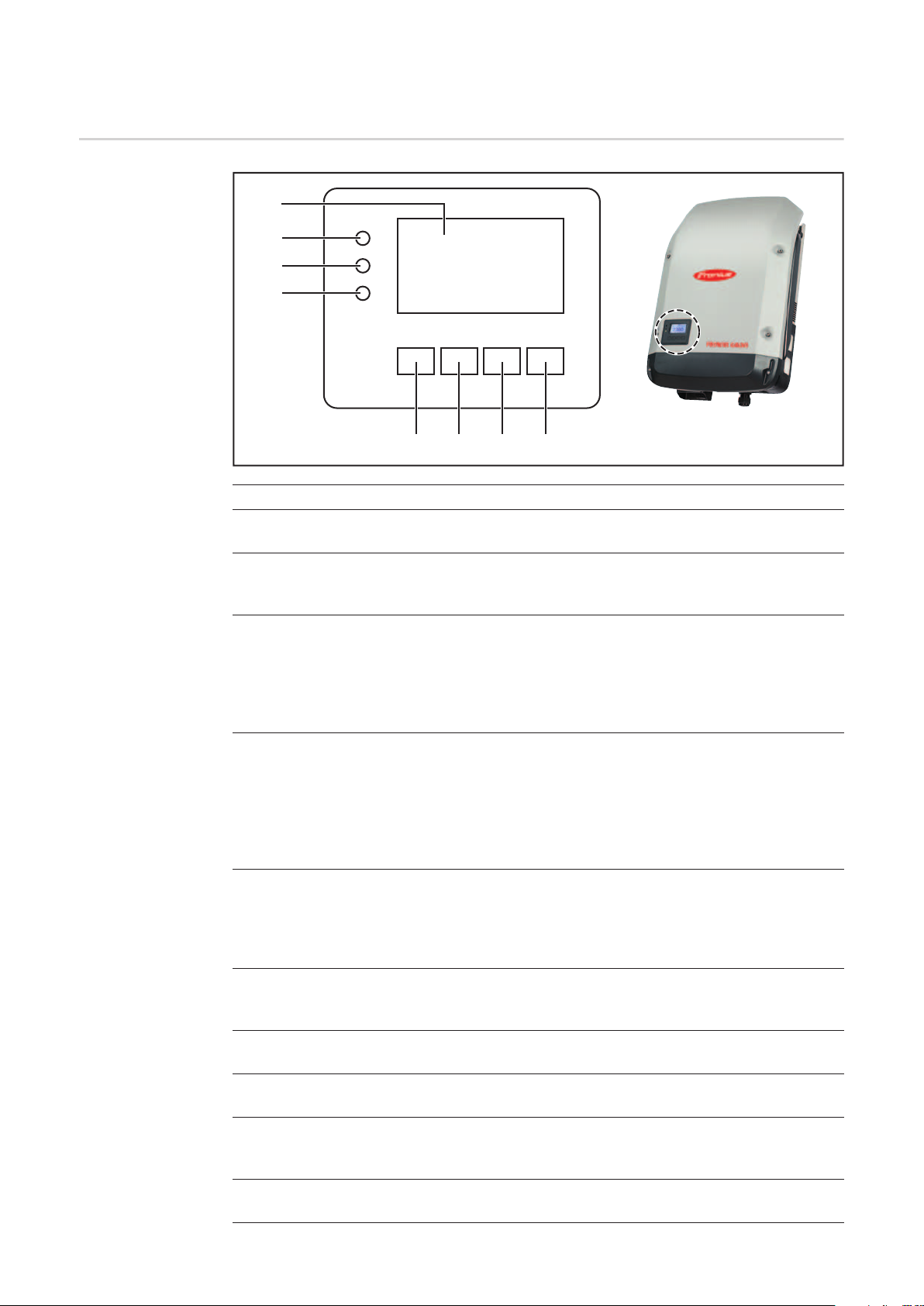

Device construction:

(1) Housing cover

(2) Inverter

(3) Wall bracket

(4) Connection area incl. DC main

switch

(5) Data communication area

(6) Data communication cover

The inverter transforms the direct current

generated by the solar modules into alternating AC current. This alternating current

is fed into your home system or into the public grid and synchronized with the voltage

that is used there.

The inverter is fully automatic. Starting at sunrise, as soon as the solar modules generate

enough energy, the inverter starts monitoring grid voltage and frequency. As soon as there

is a sufficient level of irradiance, the solar inverter starts feeding energy into the grid.

The inverter ensures that the maximum possible power output is drawn from the solar modules at all times.

As there is no longer sufficient energy available to feed power into the grid, the inverter

shuts down the grid connection completely and stops operating. All settings and recorded

data are saved.

If the inverter temperature exceeds a certain value, the inverter derates automatically the

actual output power for self protection.

The cause for a to high inverter temperature can be found in a high ambient temperature

or an inadequate heat transfer away (eg for installation in control cabinets without proper

heat dissipation).

Intended Use The solar inverter is designed exclusively to convert direct current from solar modules into

alternating current and feed this power into the public grid.

The following are deemed not to be in conformity with its intended purpose:

- utilization for any other purpose, or in any other manner

- alterations to the inverter that are not expressly recommended by Fronius

- installation of components that are not expressly recommended or sold by Fronius.

The manufacturer is not responsible for any damage resulting from improper use.

All warranty claims are considered void in such cases.

8

Page 11

Proper use also means

- carefully reading and obeying all the instructions and safety and danger notices in the

operating instructions

- carrying out all the specified inspection and servicing work

- installation as per operating instructions.

When configuring the photovoltaic system, make sure that all photovoltaic system components are operating completely within their permitted operating range.

All measures recommended by the solar module manufacturer for maintaining solar module properties must be followed.

Utility company regulations regarding grid power feed must be followed.

EN-US

Information on

"Field Adjustable

Trip Points" and

"Advanced Grid

Features"

FCC / RSS Compliance

The inverter is equipped with field adjustable trip points and advanced grid features. For

further information, please contact Fronius technical support at the following e-mail address: pv-us-support@fronius.com.

FCC

This device corresponds to the limit values for a digital device of class B in

accordance with Part 15 of the FCC regulations. The limit values should provide adequate protection against harmful interference in homes. This device

creates and uses high frequency energy and can interfere with radio communications when not used in accordance with the instructions. However,

there is no guarantee against interference occurring in a particular installation.

If this device interferes with radio or television reception when turning the device on and off, it is recommended that the user solve this with one or more

of the following measures:

- adjust or reposition the receiving antenna

- increase the distance between the device and the receiver

- connect the device to another circuit, which does not include the receiver

- for further support, please contact the retailer or an experienced radio/

TV technician.

Industry Canada RSS

The device corresponds to the license-free Industry Canada RSS standards. Operation is subject to the following conditions:

(1) The device may not cause harmful interference

(2) The device must accept any interference received, including interference that may cause undesired operation.

9

Page 12

Ground Fault Detector / Interrupter, Insulation

Monitoring

The inverter is fitted with the following safety functions as required by UL 1741 and the National Electrical Code:

Ground fault detector / interrupter (GFDI)

In photovoltaic systems with negatively grounded solar modules, the negative cable from

the solar module is connected to the grounding system in the inverter. If a ground fault occurs in the DC wiring, the inverter disconnects from the grid.

Insulation monitoring

In photovoltaic systems with ungrounded solar modules, the inverter checks the resistance between the photovoltaic system's positive or negative pole and the ground potential. In the case of a short circuit between the DC+ or DC- cable and the ground (e.g., due

to poorly insulated DC cables or faulty solar modules) the inverter disconnects from the

grid.

Arc Detector / Interrupter

The inverter has an integrated arc detector / interrupter, which detects and deletes serial

arcs.

A serial arc may occur after the following example errors or situations:

- poorly connected DC plug

- defective solar module connection sockets

- high resistance solder connections between the cells of a solar module

- incorrect cable connected to the input terminal of an inverter

- defective DC cables that allow a connection to the ground.

If an arc is detected, the power is shut down and the grid power feed operation is interrupted. A status code appears on the display.

The status code on the display must be reset manually before the grid power feed operation can be resumed.

The power shut down also deletes the serial arc.

NOTE! Power optimizers for solar modules or data transfer via DC cables (PLC

– Power Line Communication) in the PV system can compromise the correct

function of the arc detector / interrupter.

When using such components, it is the responsibility of the system installer to ensure that the arc detector / interrupter functions correctly. Contact Fronius Technical Support for further information.

10

Page 13

Warning Notices

Affixed to the Device

The inverter contains and displays warning notices and safety symbols. These warning notices and safety symbols must NOT be removed or painted over. The notices and symbols

warn against operating the equipment incorrectly, as this may result in serious injury and

damage.

Safety Symbols:

Danger of serious injury or damage due to incorrect operation

Do not use the functions described until you have thoroughly

read and understood the following

documents:

- these operating instructions

- all operating instructions for

system components of the

photovoltaic system, especially the safety rules

Dangerous electrical voltages

You must wait until the capacitors

have discharged

Text of Warning Notices:

EN-US

WARNING!

Danger of electric shock

Do not remove lid. No parts are to be serviced by the user. Servicing must be carried out

by trained service technicians.

Both AC and DC power sources terminate within the device. Every circuit must be switched

off individually before carrying out maintenance work.

If the solar module field light is exposed it supplies the device with DC voltage.

Danger of electric shock from energy stored in the capacitors. Do not remove the lid until

three minutes have passed since all supply sources were switched off.

Grounded system: Normally grounded cables can be ungrounded and live due to a

ground fault.

Ungrounded system: The DC cables in this photovoltaic system are not grounded and

may be live.

11

Page 14

Data Communication and Solar Net

Fronius Solar Net

and Data Interface

Fronius developed Solar Net to make these system add-ons flexible and capable of being

used in a wide variety of different applications. Fronius Solar Net is a data network that

enables several inverters to be linked to the system add-ons.

Fronius Solar Net is a bus system with ring topology. Just one suitable cable is enough

to provide communication between one or more inverter connected to Fronius Solar Net

and a system add-on.

Different system add-ons are automatically recognized by Fronius Solar Net.

In order to distinguish between several identical system add-ons, each one must be as-

signed a unique number.

In order to clearly define each inverter in Fronius Solar Net, each inverter must also be

assigned an individual number.

You can assign individual numbers as per the "SETUP Menu" section in this manual.

More detailed information on individual system upgrades can be found in the relevant operating instructions or on the internet at http://www.fronius.com

More detailed information on cabling DATCOM components can be found at

http://www.fronius.com/QR-link/4204101938

Installing Option

Cards in Inverters

Information on installing option cards in the inverters and for connecting data communication cables can be found in the installation instructions.

12

Page 15

System monitoring

General If no device special version is present, the inverter is equipped with Wi-Fi enabled system

monitoring Fronius Data Manager 2.0.

The monitoring system includes inter alia the following functions:

- own website with display of actual data and a wide variety of settings

- direct connection-possibility to Fronius Solar.web

- automatic sending of service messages via SMS or e-mail in case of errors

- Internet connection via WiFi or LAN

- Possibility to control the inverter by setting of power limits, minimum or maximum operational times or target operational times

- Controlling the inverter via Modbus (tcp / rtu)

- Allocation of control priorities

- Controlling the inverter by connected meters (Fronius Smart Meter or S0 meter)

- Controlling the inverter via a ripple control signal receiver (eg reactive power setting

or power setting)

- dynamic power reduction considering the own consumption

Further information about the Fronius Data Manager 2.0 can be found online in the Fronius

Data Manager 2.0 operating instructions.

EN-US

Starting for the

First Time via the

Fronius Solar.web App

NOTE! The Fronius Solar.web App makes starting Fronius Datamanager 2.0 for

the first time significantly easier.

The Fronius Solar.web App is available in the relevant app store.

To start Fronius Datamanager 2.0 for the first time,

- the Fronius Datamanager 2.0 plug-in card must be installed in the inverter,

or

- there must be a Fronius Datamanager Box 2.0 in the Fronius Solar Net ring.

IMPORTANT! To establish a connection to Fronius Datamanager 2.0, the end device in

question (e.g., laptop, tablet) must be configured as follows:

- "Obtain an IP address automatically (DHCP)" must be activated

WARNING! An electric shock can be fatal. Danger from grid voltage and DC voltage from solar modules.

Before opening the inverter:

- You must wait until the capacitors have discharged.

- Follow the operating instructions when opening the inverter.

- Observe the safety rules and safety instructions contained in the inverter's

operating instructions.

Connect the inverters with Fronius Datamanager 2.0 or Fronius Datamanager Box 2.0

1

in Fronius Solar Net

IMPORTANT! Inverters Fronius IG, Fronius IG Plus, Fronius IG Plus V, Fronius IG

Plus A, Fronius CL, Fronius CL USA, and Fronius IG 300–500 must always be located

at the beginning or end of the Fronius Solar Net ring.

13

Page 16

For Fronius Galvo/Fronius Symo/Fronius Primo only and when linking multiple invert-

2

ers in Fronius Solar Net:

Set the Fronius Solar Net master/slave switch on the Fronius Datamanager 2.0 plugin card as required

- One inverter with Fronius Datamanager 2.0 = master

- All other inverters with Fronius Datamanager 2.0 = slave (the LEDs on the Fro-

nius Datamanager 2.0 plug-in cards are off)

Switch the device to service mode

3

Inverter with Fronius Datamanager 2.0 plug-in card:

- Switch the IP switch on the Fronius Datamanager 2.0 plug-in card to position A

or

- Activate the WIFI Access Point via the Setup menu of the inverter

(the performance of this function depends on the inverter software)

Stand by

WiFi Access Point

DATCOM

USB

Clock

Fronius Datamanager Box 2.0:

- Switch the IP switch on the Fronius Datamanager Box 2.0 to position A

The inverter/Fronius Datamanager Box 2.0 establishes the WLAN Access Point. The

WLAN Access Point stays open for one hour.

Download Fronius Solar.web App

4

14

Run Fronius Solar.web App

5

Page 17

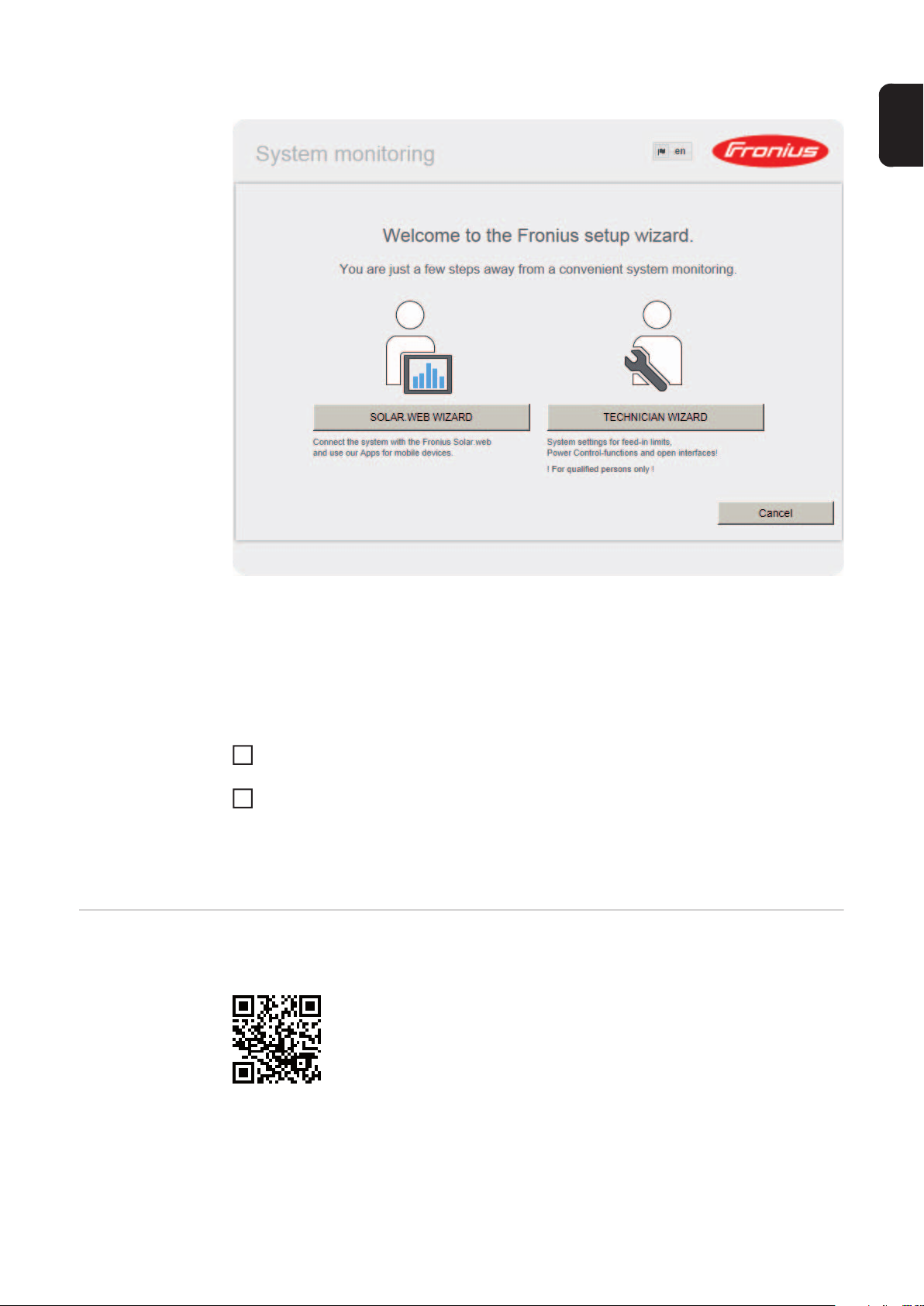

The start page of the Commissioning Wizard appears.

EN-US

More Detailed Information on Fronius

Datamanager 2.0

The Technician Wizard is designed for the installer and includes standard-specific settings.

Running the Technician Wizard is optional.

If the Technician Wizard is run, it is essential to note down the assigned service password.

This service password is required to configure the UC Editor and Counter menu items.

If the Technician Wizard is not run, no specifications for power reduction are set.

The Solar Web Wizard must be run.

If necessary, run the Technician Wizard and follow the instructions

6

Run the Solar Web Wizard and follow the instructions

7

The Fronius Solar.web start page appears.

or

The Fronius Datamanager 2.0 website opens.

More detailed information on Fronius Datamanager 2.0 and other start-up options can be

found at:

http://www.fronius.com/QR-link/4204260191EA

15

Page 18

Keys and symbols

Keys and Symbols

(1)

(2)

(3)

(4)

Item Description

(1) Display

for displaying values, settings, and menus

(5) (6) (7) (8)

Control and Status LEDs

(2) General Status LED (red)

indicates

- when a status code is shown on the display

- interruption of grid power feed operation

- during troubleshooting (the inverter is waiting to be reset or for an error to

be corrected).

(3) Startup LED (orange)

indicates

- if the inverter will enter the automatic startup or self test phase (as soon as

the solar modules yield sufficient power output after sunrise)

- if the inverter has been set to standby operation in the Setup menu (= manual shutoff of operation)

- when the inverter software is being updated.

(4) Operating Status LED (green)

indicates

- if the photovoltaic system is working fault-free following the automatic startup phase of the inverter

- when the grid power feed operation is taking place.

Function keys – each has a different function depending on the selection:

16

(5) "Left/Up" key

for navigating left and up

(6) "Down/Right" key

for navigating down and right

(7) "Menu/Esc" key

for switching to the menu level

to exit the Setup menu

(8) "Enter" key

for confirming a selection

Page 19

The keys are capacitive keys; if they become wet their function may be compromised.

Wipe the keys dry with a cloth if necessary to ensure optimal function.

Display Power for the display comes from the AC grid voltage. The display can be available all day

long depending on the setting in the Setup menu.

IMPORTANT! The inverter display is not a calibrated measuring instrument. Slight deviation from the utility company meter is intrinsic to the system. A calibrated meter is required

to make calculations for the utility company.

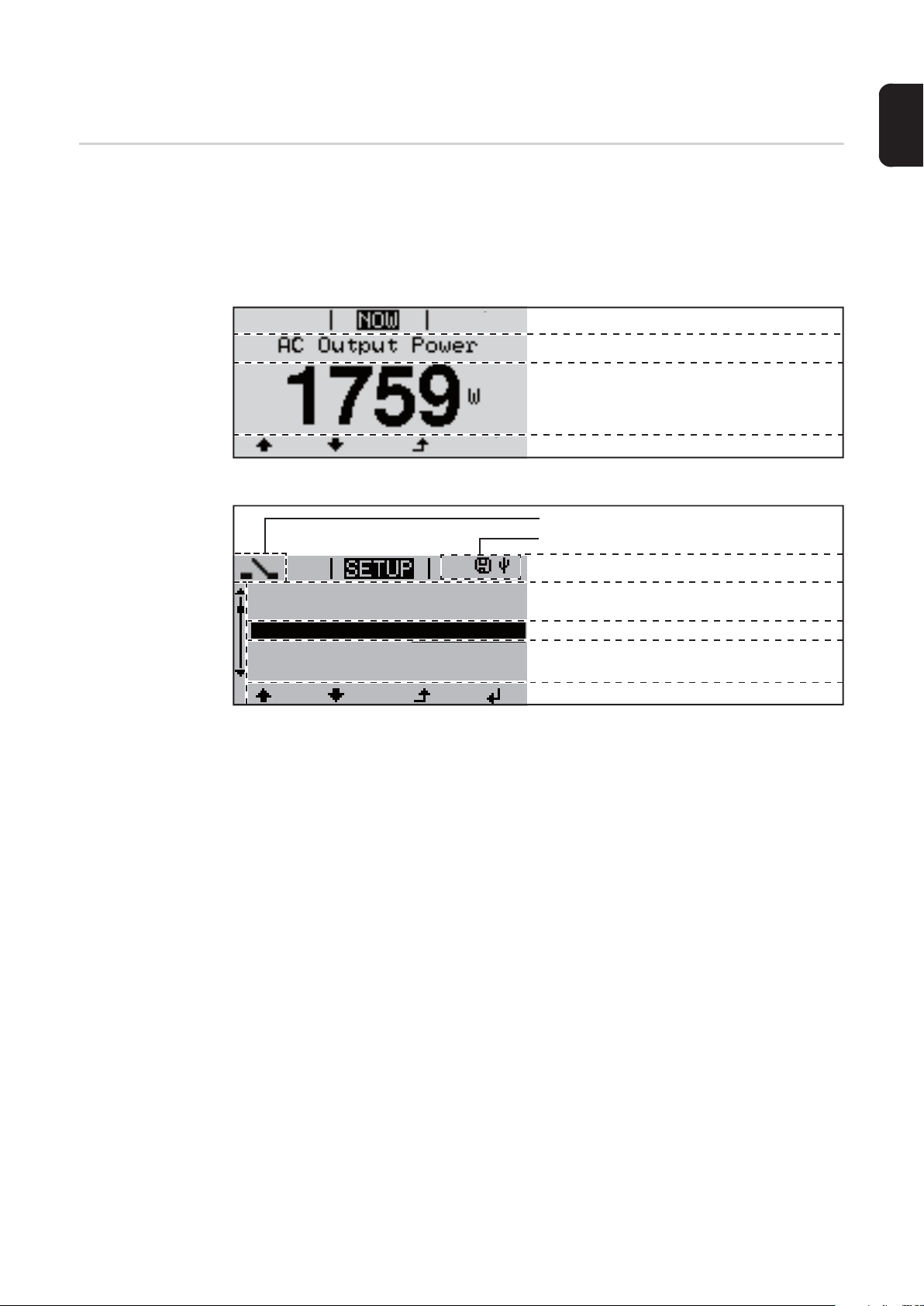

Menu item

Parameter declaration

Display of values, units and status codes

Function key functions

Display area, display mode

Energy-Manager (**)

Inv. no. | Save symbol | USB conn.(***)

EN-US

1

Standby

WiFi Access Point

DATCOM

USB

Relay

(*)

Display area, setup mode

(*) Scroll bars

(**) The Energy Manager symbol

is displayed if the Energy Manager function has been activated

(***) Inv. no. = Inverter DATCOM number,

Store icon – appears briefly when set values are stored,

USB connection – appears if a USB stick has been inserted

Menu item

Previous menu items

Currently selected menu item

Next menu items

Function key functions

17

Page 20

Menu level

Activating Display Illumination

Automatic Deactivation of Display

Illumination /

Switching to the

"NOW" Display

Mode

Accessing the

Menu Level

Press any key.

1

The display illumination is activated.

The SETUP menu item offers the choice between a permanently lit or permanently

dark display under "Display Settings."

If no key is pressed for 2 minutes:

- the display illumination turns off automatically and the inverter switches to the "NOW"

display mode (if the display illumination is set to automatic)

- the inverter can be switched to the "NOW" display mode from any menu level, except

for the "Standby" menu item

- the current output power is displayed.

Press the "Menu" key

1

The display switches to the menu level

Select the desired menu item using

2

the "Left" or "Right" key

Access the desired menu item by

3

pressing the "Enter" key

18

Page 21

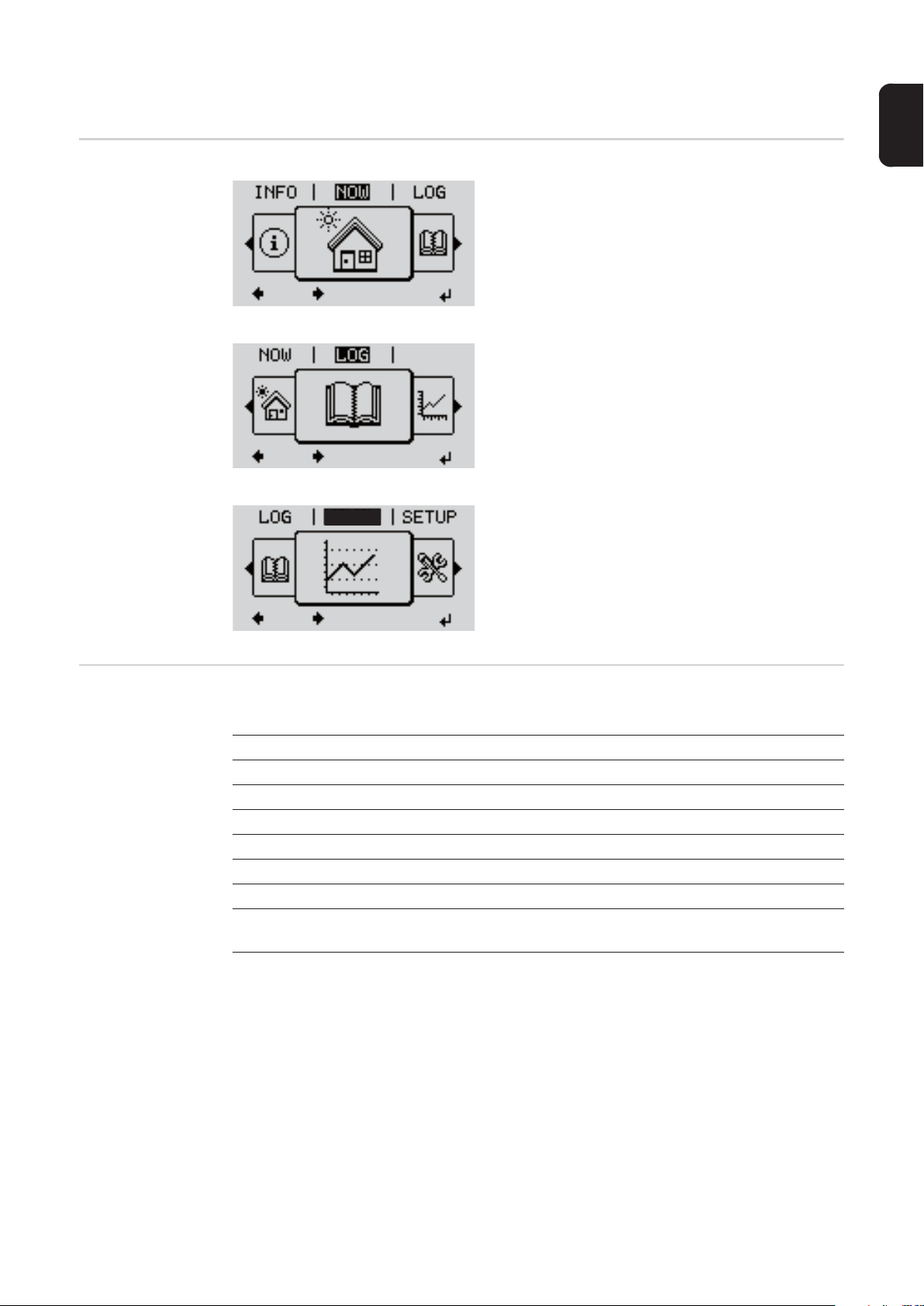

Menu items NOW, LOG, and GRAPH

EN-US

NOW

LOG

GRAPH

GRAPH

GRAPH

NOW

(displays real-time values)

LOG

(data logged on the current day, from the

current calendar year, and since using the

inverter for the first time)

GRAPH

graphically represents the course of the

output power during the day. The time

axis is automatically scaled

Press the "Back" key to close the display

Values Displayed

in the Menu Items

NOW and LOG

Data displayed in menu item NOW:

AC Output Power (W)

AC Reactive Power (VAr)

AC Voltage (V)

AC Output Current (A)

AC Frequency (Hz)

PV Array Voltage (V)

PV Array Current (A)

Time / Date

Time and date on the inverter or Fronius Solar Net ring

19

Page 22

Data displayed in menu item LOG:

(for the current day, the current calendar year, and since using the inverter for the first

time)

AC Energy Yield (kWh / MWh)

energy fed into the grid during the monitored period

Due to the variety of different monitoring systems, there can be deviations between the

readings of other metering instruments and the readings from the inverter. For determining the energy supplied to the grid, only the readings of the calibrated meter supplied by

the electric utility company are relevant.

AC Maximum output power (W)

highest power feeding in during the monitored period

Earnings

amount of money earned during the monitored period (currency can be selected in the

Setup menu)

As was the case for the output energy, readings may differ from those of other instruments.

"The Setup Menu" section describes how to set the currency and rate for the energy supplied.

The factory setting depends on the respective country-specific setup.

CO2 savings (g / kg)

CO2 emissions saved during the period in question

The value for CO2 savings depends on the power station facilities and corresponds to the

CO2 emissions that would be released when generating the same amount of energy. The

factory setting is 0.53 kg / kWh (source: DGS – Deutsche Gesellschaft für Sonnenenergie

e.V. (German Society for Solar Energy).

AC Max. Voltage L-N (V)

highest reading of voltage between the conductor and neutral conductor during monitored

period

PV Array Max. Voltage (V)

highest reading of solar module voltage during monitored period

Operating Hours

indicates how long the inverter has been operating (HH:MM)

IMPORTANT! The time must be set correctly for day and year values to be displayed

properly.

20

Page 23

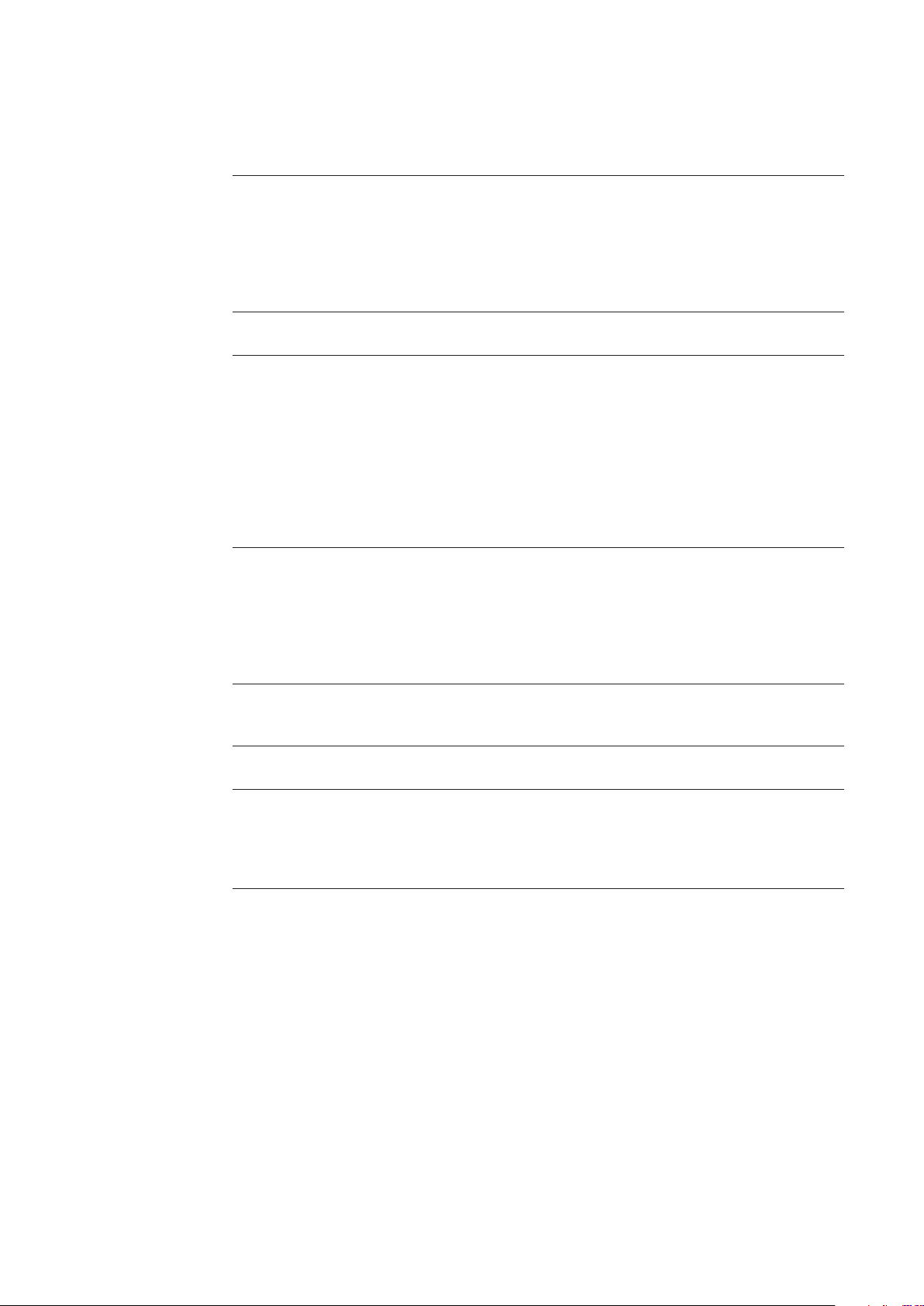

The SETUP menu item

Presetting Following commissioning, the inverter is preconfigured according to the country setup.

The SETUP menu item enables you to easily customize the inverter’s preset parameters

to your needs.

EN-US

SETUP

Navigation in the

SETUP Menu Item

GRAPH

NOTE! Because of software updates, certain functions may be available for your

device but not described in these operating instructions or vice versa. In addition,

individual figures may also differ slightly from the operating elements of your device. However, the function of these operating elements is identical.

Accessing the SETUP menu item

GRAPH

SETUP

(Setup menu)

Select the "Setup" menu item at

1

menu level using the "Left" or "Right"

key

Press the "Enter" key

2

"SETUP" menu level selected

Standby

WiFi Access Point

DATCOM

USB

Relay

"Standby" item

Scrolling through the items

Example: "WiFi Access Point" menu item

The first SETUP menu item is displayed:

"Standby"

Scroll through the available menu

3

items using the "Up" and "Down" keys

21

Page 24

Exiting a menu item

To exit a menu item, press the "Back"

GRAPH

4

key

The menu level is displayed

If no key is pressed for 2 minutes

- the inverter switches to the "NOW" menu item from anywhere within the menu level

(exception: Setup menu item "Standby")

- the display illumination turns off

- the current power of feeding in is displayed.

General Setup

Menu Item Settings

Accessing the SETUP menu item

1

Use the "Up" and "Down" keys to select the desired menu item

2

Press the "Enter" key

3

The first digit of a value to be set flash-

The available settings are displayed:

es:

Use the "Up" and "Down" keys to se-

4

lect a value for the first digit

Press the "Enter" key

5

Use the "Up" and "Down" keys to se-

4

lect the desired setting.

Press the "Enter" key to save and ap-

5

ply the selection.

The second digit of the value flashes.

Repeat steps 4 and 5 until...

6

Press the "Esc" key to discard the selection.

the entire value flashes.

Press the "Enter" key

7

Repeat steps 4–6 for units or other

8

values to be set until the unit or value

to be set flashes.

Press the "Enter" key to save and ap-

9

ply the changes.

22

Press the "Esc" key to discard the

changes.

The currently selected item is displayed. The currently selected item is displayed.

Page 25

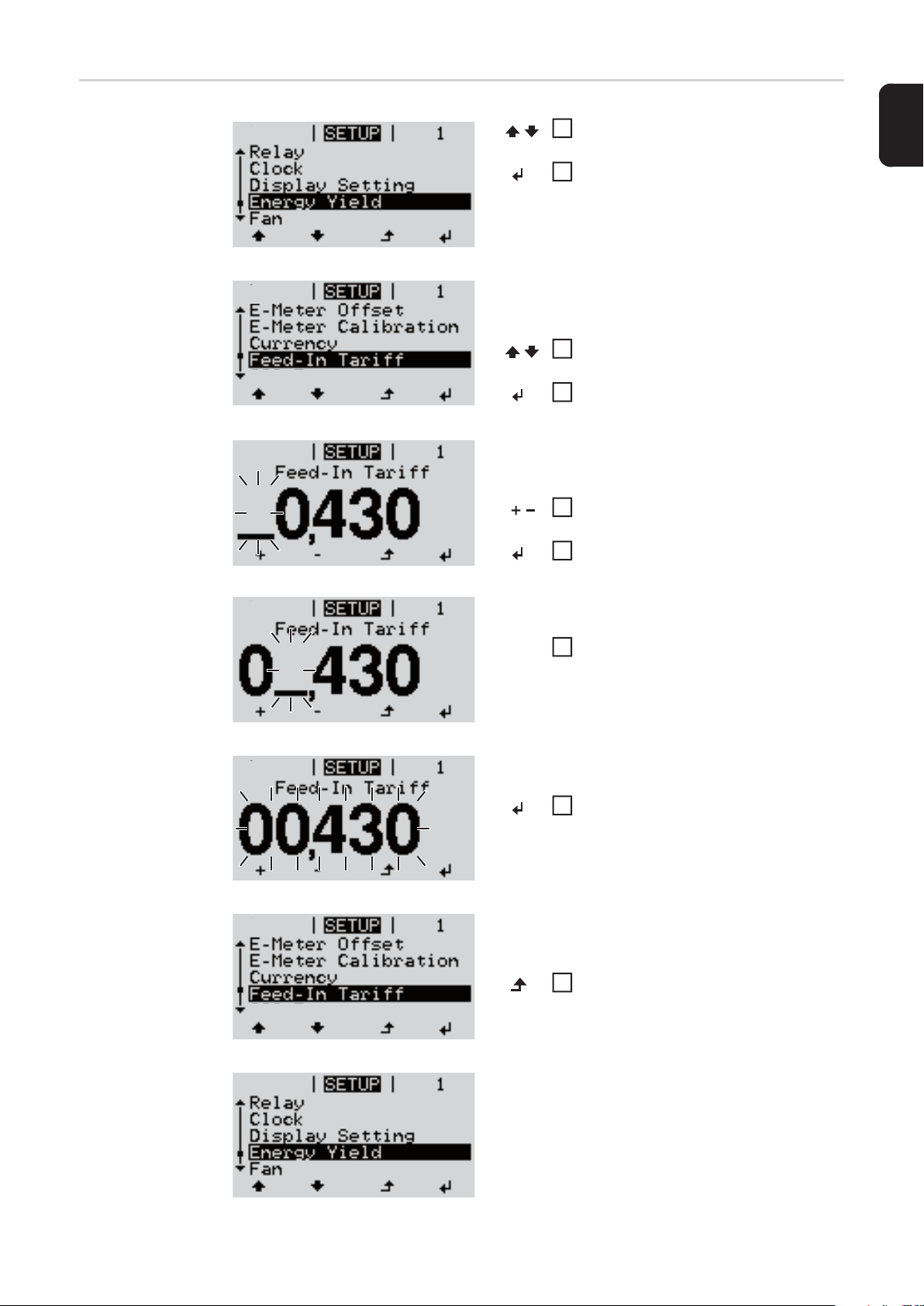

Application Example: Setting

the Feed-In Tariff

Select the Setup menu item "Energy

1

yield"

Press the "Enter" key

2

The overview of values that can be selected is displayed.

Use the "Up" or "Down" keys to select

3

"Energy yield"

Press the "Enter" key

4

The feed-in tariff is displayed.

The tens digit flashes.

Use the "Up" and "Down" keys to se-

5

lect a value for the tens digit.

Press the "Enter" key

6

EN-US

The units digit flashes.

Repeat steps 5 and 6 for the units dig-

7

it and for the three digits after the decimal point until ...

the set feed-in tariff flashes.

Press the "Enter" key

8

The feed-in tariff is applied; the overview

of the values that can be set is displayed.

Press the "Esc" key

9

The Setup menu item "Energy yield" is

shown.

23

Page 26

The Setup menu item

Standby Manual activation/deactivation of the standby mode

- No power is fed into the grid.

- The Startup LED lights up orange.

- In standby mode, no other menu item can be accessed or set in the menu level.

- The automatic switching to the "NOW" menu item after 2 minutes if no key is pressed

is not activated.

- The Standby mode can only be deactivated manually by pressing the "Enter" key.

- Grid supply operation can be resumed at any time (deactivate "Standby").

Setting standby mode (manual shutoff for feeding energy into the grid):

Select the "Standby" item

1

Press the "Enter" key

2

The display alternates between "STANDBY" and "ENTER."

The Standby mode is now activated.

The Startup LED lights up orange.

Restoring the grid feed:

WiFi Access

Point

In Standby mode, the display alternates between "STANDBY" and "ENTER."

Press "Enter" to restore the grid power feed operation

1

The "Standby" item is displayed.

The inverter also switches to the Startup phase.

After the grid power feed operation is restored, the Operation Status LED lights up green.

For activating / deactivating of the WiFi Access Point (e.g. to set a system monitoring)

Adjustment range WiFi Access Point

[stopped]

Activate WiFi ?

To activate the WiFi Access Point press the Enter key.

WiFi Access Point

[active]

24

The SS-ID (SS) and the password (PW) are displayed.

Deactivate WiFi AP ?

To deactivate the WiFi Access Point press the Enter

key.

Page 27

***

WiFi Access Point

[not available]

Is displayed, when no system monitoring is present at the inverter.

DATCOM Check of a data communication, entry of the inverter number, DATCOM night mode, pro-

tocol settings

Setting range Status / Inverter number / Protocol type

Status

Displays data communication available via Solar Net or an error that occurred in data communication

Inverter Number

Number setting (address) of the inverter in a setup where multiple solar inverters are linked

together

Setting range 00 – 99 (00 = 100 inverter)

Factory setting 01

EN-US

IMPORTANT! Each inverter must be assigned its own address when using multiple invert-

ers in a data communications system.

Protocol type

Defines the communication protocol used to transmit data:

Setting range Solar Net / Interface Protocol *

Factory setting Solar Net

* The protocol type Interface Protocol only works without the Datamanager card. Available

Datamanager cards must be removed from the inverter.

USB Value settings when using a USB stick

Setting range Safely remove hardware / software update / logging interval

Safely remove hardware

To remove a USB stick from the USB A socket on the data communication rack without

losing data.

The USB stick can be removed:

- when OK is displayed

- when the "Data Transfer" LED is no longer flashing or illuminated

Software update

For updating inverter software using a USB stick.

IMPORTANT! Firmware may only be updated by Fronius Service Technicians or Fronius

Service Partners.

25

Page 28

Procedure:

Download the "froxxxxx.upd" update file

1

(e.g., at http://www.fronius-usa.com; xxxxx stands for the respective version number)

NOTE! To ensure problem-free updates of inverter software, the USB stick

should have no hidden partitions and no encryption (see section "Suitable USB

Sticks).

Save the update file to the highest data level of the USB stick

2

Open the data communication area

3

Insert the USB stick with the update file into the USB socket in the data communication

4

area

In the Setup menu, select the menu item "USB" and then "Update Software"

5

Press the "Enter" key

6

Wait until a comparison of the current software version on the inverter and the new

7

software version is displayed:

- Page 1: Recerbo software (LCD), key controller software (KEY), country-setup

version (SET)

- Page 2: Power stage set software

Press the "Enter" key after every page

8

The inverter begins copying the data.

"UPDATE" and the saving progress of the individual tests is displayed in % until the data

for all electronic assemblies is copied.

After the copying is complete the inverter updates the required electronic assemblies one

after the other.

"UPDATE", the relevant assembly, and the update progress are displayed in %.

The inverter updates the display in the last step.

The display remains dark for approx. 1 minute, the control and status LEDs flash.

When the software update is complete, the inverter switches to the startup phase and then

to grid power feed operation. The USB stick can be removed.

Individual settings in the Setup menu are retained when the inverter software is updated.

Logging Interval

Activating / deactivating the logging function, as well as setting the logging interval

Unit Minutes

Setting range 30 Min. / 20 Min. / 15 Min. / 10 Min. / 5 Min. / No Log

Factory setting 30 Min.

30 Min. The logging interval is 30 minutes; new logging data are saved

to the USB stick every 30 minutes.

20 Min.

15 Min.

10 Min.

5 Min. The logging interval is 5 minutes; new logging data are saved to

the USB stick every 5 minutes.

26

No Log No data are saved

Page 29

IMPORTANT! The time must be set correctly in order for the logging function to work properly.

Relay Activate Relay, Relay Settings, Relay Test

Setting range Relay Mode / Relay Test / Switch on Point* / Switch off Point*

* only shown if the 'E-manager' function has been activated under "Relay Mode."

Relay Mode

For selection of the various functions of the potential-free switching contact in the data

communications area:

- Alarm function

- Active output

- Energy manager

Setting range ALL / Permanent / OFF / ON / E-manager

Factory setting ALL

Alarm function:

Permanent /

ALL:

Active output:

ON: The potential-free switching contact NO is switched on at all times

OFF: The potential-free switching contact NO is switched off

Energy manager:

E-manager: You can find additional information on the "Energy manager" function

Switches the potential-free switching contacts for continual and temporary service codes (e.g., brief interruption of grid power feed operation, a service code occurs a set number of times per day – can be set

in the "BASIC" menu)

while the inverter is operating (as long as the display lights up or appears)

in the "Energy Manager" section below

EN-US

Relay test

Functional test to check if the potential-free switching contact works

Switch on point (only if "Energy manager" function is activated )

for setting the effective power limit from which the potential-free switching contact will be

switched on

Factory setting 1000 W

Setting range Switch off point – max. power rating of the inverter / W / kW

Switch off point (only if the "Energy manager" function is activated)

for setting the effective power limit from which the potential-free switching contact will be

switched off

Factory setting 500

Setting range 0 – switch on point / W / kW

27

Page 30

Time/Date Setting the time, date and automatic adjustment for daylight saving time

Setting range Set time / Set date / Time display format / Date display format /

Daylight saving time

Set time

Setting the time (hh:mm:ss or hh:mm am/pm, depending on the setting under Time display

format)

Set date

Setting the date (dd.mm.yyyy or mm/dd/yyyy, depending on the setting under Date display

format)

Time display format

For specifying the format in which the time is displayed

Setting range 12 hrs / 24 hrs

Factory setting depends on the country setup

Date display format

For specifying the format in which the date is displayed

Setting range mm/dd/yyyy / dd.mm.yy

Factory setting depends on the country setup

Display Settings

Daylight saving time

Activating/deactivating the automatic adjustment for daylight saving time

NOTE! Only use the function for automatic daylight savings adjustment when

there are no LAN or WLAN-compatible system components in a Fronius Solar Net

Ring (e.g., Fronius Datalogger Web, Fronius Datamanager or Fronius Hybridmanager).

If there are LAN or WLAN-compatible system components, set this function on

the web interface for the system component.

Setting range on/off

Factory setting on

IMPORTANT! The time and date must be set correctly for day and year values to be displayed properly.

Setting range Language / Night mode / Contrast / Illumination

Language

Setting the display language

28

Setting range German, English, French, Dutch, Italian, Spanish, Czech, Slo-

vak, etc.

Page 31

Night Mode

DATCOM night mode; controls DATCOM and display operation at night or when there is

insufficient DC voltage available

Setting range AUTO / ON / OFF

Factory setting OFF

AUTO: DATCOM operation is constant as long as a Datalogger is connected to an

active, uninterrupted Solar Net.

The display is dark during the night and can be activated by pressing any

key.

ON: DATCOM operation is constant. The inverter provides 12 V constantly to

supply Solar Net with power. The display is always active.

IMPORTANT! The power consumption of the inverter is increased at night

to approximately 7 W when the DATCOM night mode is ON or on AUTO and

Solar Net components are connected.

OFF: No DATCOM operation at night, the inverter requires no AC power to supply

Solar Net.

The display is deactivated at night; the Fronius Datamanager is not available.

EN-US

Contrast

set contrast on the display

Setting range 0–10

Factory setting 5

Since contrast depends on temperature, it may be necessary to adjust the "Contrast" menu

item when environmental conditions change.

Illumination

Initial setting for display illumination

The "Illumination" menu item only applies to the display background illumination.

Setting range AUTO / ON / OFF

Factory setting AUTO

AUTO: The display illumination is activated by pressing any key. If no key is pressed

for 2 minutes, the display backlight goes out.

ON: The display illumination will be permanently on when the inverter is active.

OFF: The display illumination will be permanently off.

29

Page 32

Energy Yield Setting

- an OFFSET value for the Total energy display

- a measurement correction value for the day, year and total energy display

- the currency

- the feed-in tariff

Setting range E-meter offset/E-meter calibration/Currency/Feed-in tariff

E-meter offset

Specification of a value for the energy supplied that is added to the currently supplied energy (e.g., the transfer value when an inverter is replaced)

Unit Wh/kWh/MWh

Setting range 5-digit

Factory setting 0

E-meter calibration

Specification of a correction value so that the data shown on the inverter display correspond to the calibrated data shown on the electric meter

Unit %

Setting range -5.0 to +5.0

Factory setting 0

Currency

Currency setting

Setting range 3-digit, A-Z

Feed-in tariff

Charge rate setting for the energy fed into the grid

Setting range 2-digit, 3 decimal places

Factory setting (depends on the country setup)

Fan for checking the fan functionality

Setting range Test fan 1 / Test fan 2 (depends on device)

- Use the "Up" and "Down" keys to select the desired fan

- Press the "Enter" key to start testing the selected fan

- The fan runs until the menu is exited by pressing the "Esc" key

30

Page 33

Arc Detection for checking arc detection/interruption

Setting range ArcDetector Status/Start Self-test

Arc.det. Status

displays the current status of arc detection/interruption

Start Self-test

self-test to check whether the inverter interrupts grid power feed operation when an arc

is detected.

Test procedure:

Select "Arc Detection" in the Setup menu

1

Press the "Enter" key

2

Use the up and down keys to select "Start Self-test"

3

Press the "Enter" key

4

The self-test starts. The arc detection/interruption function simulates an arc and sends

the corresponding signal to the inverter.

If the test is successful, the inverter disconnects from the grid and stops grid power feed

operation.

EN-US

The message "Self-test completed and Start AFCI" is shown on the display.

Confirm the indication by pressing the "Enter" key

5

31

Page 34

The INFO menu item

INFO

Measured values

LT status

Grid status

INFO

(information on device and software)

Measured values Display range: PV Ins. / Fan #1 / U PV1

PV Ins.

Insulation resistance of the PV system

(for ungrounded solar modules and for solar modules grounded at the

negative pole)

Fan #1

Percentage value of the fan's target power

U PV1

Current DC voltage at the terminal, also if the inverter is not feeding

in at all (from the first MPP Tracker)

LT status The status display of the last error that occurred in the inverter can be

shown.

IMPORTANT! Status codes 306 (Power low) and 307 (DC low) appear naturally every morning and evening due to low solar irradiance.

These status codes are not the result of a fault.

- After pressing the "Enter" key, the power stage set status and the

last error that occurred are displayed

- Use the "Up" and "Down" keys to scroll through the list

- Press the "Back" key to exit the status and error list

Grid status The last 5 grid errors that occurred can be displayed:

- After pressing the "Enter" key, the last 5 grid errors that occurred

are displayed

- Use the "Up" and "Down" keys to scroll through the list

- Press the "Back" key to exit the grid error display

32

Page 35

Device Information

The device is used to display settings relevant to a power supply company. The displayed

values depend on the respective country setup or device-specific inverter settings.

Display range General / Country Setup / MPP Tracker / AC Monitoring / AC

Voltage Limits / AC Frequency limits / Q-Mode / AC Power Limits / AC Voltage Derating / Fault Ride Through

General: Device type

Fam.

Country Setup: Setup

Country setup

Version

Country setup version

Group

Inverter software update group

MPP Tracker: Tracker 1

AC Monitoring: GMTi

Startup time of the inverter in s

GMTr

Restart time in s after a grid error

EN-US

ULL

Grid voltage average value over 10 minutes in V

LLTrip

Detection time for long-term voltage monitoring

AC Voltage Limits: UILmax

Upper inner grid voltage value in V

UILmin

Lower inner grid voltage value in V

AC Frequency Limits: FILmaw

Upper inner grid frequency value in Hz

FILmin

Lower inner grid frequency value in Hz

Q-Mode: Current power factor cos phi

(e.g., constant cos(phi) / constant Q / Q(U) characteristic / etc.)

AC Power limits: Max. P AC

manual power reduction

33

Page 36

AC Voltage Derating: Status

ON / OFF voltage-dependent power reduction

GVDPRe

Threshold from which the voltage-dependent power reduction

begins

GVDPRv

Reduction gradient used to reduce the power, e.g.: 10% per volt

above the GVDPRe threshold.

Message

Activates the dispatch of an info message via Fronius Solar Net

Fault Ride Through: Status – default setting: OFF

If the function is activated, the inverter does not switch off im-

mediately when a short-term interruption to the AC voltage oc-

curs (outside of the limits set by the grid supplier); instead it

continues to supply power for a defined time.

DB min – default setting: 90%

"Dead Band Minimum" setting (%)

DB max – default setting: 120%

"Dead Band Maximum" setting (%)

k-Fac. default setting: 0

Version Display of version number and serial number of the PC boards installed in the inverter (e.g.,

for service purposes)

Display range Display/Display Software/Integrity Checksum/Memory Card/

Memory Card #1/Power Stage/Power Stage Software/EMI Fil-

ter/Power Stage #3/Power Stage #4

34

Page 37

Switching the key lock on and off

General The inverter comes equipped with a ‘Key lock’ function.

When the ‘Keylock’ function is active, the Setup menu cannot be accessed, e.g., to protect

against setup data being changed by accident.

You must enter code 12321 to activate / deactivate the ‘Key lock’ function.

EN-US

Switching the Key

Lock On and Off

Press the "Menu" key.

1

The menu level is displayed.

Press the unassigned "Menu / Esc"

2

key

5 x.

In the "CODE" menu, the "Access Code"

is displayed; the first digit flashes.

Enter code 12321: Use the "Up" and

3

"Down" keys to select a value for the

first digit of the code.

Press the "Enter" key.

4

The second digit flashes.

Repeat steps 3 and 4 for the second,

5

third, fourth and fifth digit in the code

until...

...the set code flashes.

Press the "Enter" key.

6

In the "LOCK" menu, the "Key lock" function is displayed.

Use the "Up" and "Down" keys to

7

switch the key lock on or off:

ON = the key lock function is activated (the SETUP menu item cannot be

accessed)

OFF = the key lock function is deactivated (the SETUP menu item can be

accessed).

Press the "Enter" key.

8

35

Page 38

USB Stick as a Data Logger and for Updating Inverter Software

USB Stick as a

Data Logger

Suitable USB

Sticks

A USB stick connected to the USB A socket can act as a data logger for an inverter.

Logging data saved to the USB stick can at any time

- be imported into the Fronius Solar.access software via the included FLD file

- be viewed directly in third-party applications (e.g., Microsoft® Excel) via the included

CSV file.

Older versions (up to Excel 2007) have a row limit of 65536.

Further information on "Data on a USB stick", "Data volume and storage capacity" as well

as "Buffer memory" can be found at:

http://www.fronius.com/QR-link/4204260171EN

Due to the number of USB sticks on the market, we cannot guarantee that every USB stick

will be recognized by the inverter.

Fronius recommends using only certified, industrial USB sticks (look for the USB-IF logo).

The inverter supports USB sticks using the following file systems:

- FAT12

- FAT16

- FAT32

Fronius recommends that the USB stick only be used for recording logging data or for updating the inverter software. USB sticks should not contain any other data.

USB symbol on the inverter display, e.g., in the "NOW" display mode:

When the inverter recognizes a USB stick,

the USB symbol will appear at the top right

of the display.

When inserting the USB stick, make sure

that the USB symbol is displayed (it may

also be flashing).

NOW

AC Output Power

36

Page 39

NOTE! Please be aware that in outdoor applications the USB stick may only function in a limited temperature range. Make sure, for example, that the USB stick

will also function at low temperatures for outdoor applications.

EN-US

USB Stick for Updating Inverter

Software

Removing the

USB Stick

The USB stick can be used to help end customers update inverter software via the USB

menu item in the SETUP menu item: the update file is first saved on the USB stick and then

transferred to the inverter. The update file must be saved in the USB stick root directory.

Safety information for removing a USB stick

IMPORTANT! To prevent a loss of data,

X

Do not disconnect

USB-Stick

while LED is flashing!

the connected USB stick should only be

removed under the following conditions:

- via the SETUP and "Safely remove

USB / hardware" menu items

- when the "Data Transfer" LED is no

longer flashing or illuminated.

37

Page 40

The Basic menu

General The following important parameters are set in the Basic menu for the installation and op-

eration of the inverter:

Accessing the

Basic menu

- DC operating mode

- Fixed voltage

- MPPT1 initial voltage

- USB logbook

- Insulation settings

- TOTAL reset

- Event meter

Press the "Menu" key.

1

The menu level is displayed.

Press the unassigned "Menu / Esc"

2

key

5 x.

In the "CODE" menu, the "Access Code"

is displayed; the first digit flashes.

Enter code 22742: Use the "Up" and

3

"Down" keys to select a value for the

first digit of the code.

Press the "Enter" key.

4

Access Code

MPP Tracker 1

USB Eventlog

SMS / Relay

Grounding Settings

Insulation Settings

The second digit flashes.

Repeat steps 3 and 4 for the second,

5

third, fourth and fifth digit in the code

until...

...the set code flashes.

Press the "Enter" key.

6

The Basic menu is shown.

Use the "Up" and "Down" keys to se-

7

lect the desired item.

Edit the selected item by pressing the

8

"Enter" key.

Press "Esc" to exit the Basic menu.

9

38

Page 41

Items in the Basic

Menu

The Basic menu contains the following items:

EN-US

MPP Tracker 1

- DC operating mode:

MPP AUTO

FIX

MPP USER

- Fixed voltage:

For entering the fixed voltage, 120–440 V

- MPPT1 initial voltage:

For entering the MPPT1 initial voltage, 120–440 V

USB logbook

Activating or deactivating the function to save all error messages to a USB stick

AUTO / OFF / ON

SMS / Relay

- Event delay:

For entering the delay time from when an SMS is sent or from when the relay should

switch

900–86400 seconds

- Event meter:

For entering the number of errors following which an SMS is sent or the relay should

switch:

10–255

Ground Settings

- Ground mode:

Off / Positive / Negative

- Ground monitoring

(only displayed if the ground mode is set to Positive or Negative):

Warn Err / Error / Warning

Insulation settings

(only displayed if the ground mode is set to Negative or Off)

- Insulation warning:

to activate and deactivate the insulation monitoring with display of a warning without

interrupting feed-in in the event of an insulation error

ON / OFF (depends on the country setup)

- Threshold warning:

to set an insulation threshold below which the inverter displays a warning (without

interrupting feed-in)

0–1000 kOhm (depends on the country setup set)

- Threshold error:

to set an insulation threshold under which the inverter displays an error message

and interrupts feed-in

0–1000 kOhm (depends on the country setup)

39

Page 42

TOTAL Reset

resets the max. and min. voltage values and the max. power of feeding in in the LOG

menu item to zero.

Once you have reset the values, this cannot be undone.

To reset the values to zero, press the "Enter" key.

"CONFIRM" is displayed.

Press the "Enter" key again.

The values are reset and the menu is displayed.

40

Page 43

Status Diagnosis and Troubleshooting

EN-US

Displaying Status Codes

Total Failure of

the Display

Class 1 Status

Codes

Your inverter is equipped with a self diagnostic system that automatically identifies a large

number of possible operation issues by itself and displays them on the screen. This enables you to know immediately if there are any malfunctions in the inverter, the photovoltaic

system or any installation or operating errors.

Whenever the self diagnostic system has identified a particular issue, the respective status

code is shown on the screen.

IMPORTANT! Status codes may sometimes appear briefly as a result of the control response from the inverter. If it subsequently continues to operate normally, there has not

been a system error.

If the display remains dark for a long time after sunrise:

- check the AC voltage at the inverter's connections:

the AC voltage must be 208–240 V (+10% / -12%) according to the grid.

Status codes in class 1 are typically temporary. Their cause lies in the grid.

Your inverter's first reaction is to disconnect from the grid. Thereafter, the grid will be

checked for the duration of the observation period stipulated. If, after the end of this period,

no further defect is identified, your inverter resumes grid power feed operation.

Code Description Details Rectification

102 AC voltage too high

103 AC voltage too low

105 AC frequency too high

106 AC frequency too low

107 AC grid outside of tolerances

108 Stand alone operation detect-

ed

Class 2 Status

Codes

Code Description Details Rectification

212 Overvoltage at L1-N Grid conditions are being test213 Undervoltage at L1-N

222 Overvoltage at L2-N

223 Undervoltage at L2-N

240 Arc detected

Grid conditions are being tested and as soon as they are

back within the permissible

range, the inverter will resume

grid power feed operation.

ed and as soon as they are

back within the permissible

range, the inverter will resume

grid power feed operation.

The status code is displayed

for approx. 4 seconds.

Check grid connections.

If this status code keeps recurring, contact your system installer.

Check grid connections. If this

status code keeps recurring,

contact your system installer.

-

41

Page 44

Code Description Details Rectification

If an arc has been detected,

241 Arc detected

242 Arc detected

245 Arc detector self test failed

247

249 Arc detector defective

Arc detector current sensor defective

The status code 241 is displayed directly after 240; the

inverter disconnects from the

grid for safety reasons.

Status code 242 is displayed

after resetting status code 241.

The inverter disconnects from

the grid.

The inverter disconnects from

the grid.

check the entire affected PV

system for damage before resetting the inverter.

Reset status code by pressing

the "Enter" key.

Reset the status code by

pressing the "Enter" key.

The inverter resumes grid

power feed operation.

If the status code keeps recurring, contact your system installer.

Reset AC.

The test is repeated.

If the status code persists:

contact a Fronius-trained service technician.

If status code persists: contact

a Fronius-trained service technician.

Class 3 Status

Codes

Code Description Details Rectification

301 Over-current (AC)

302 Over-current (DC)

303

304 Interior temperature too high

Power stage set over temperature

Class 3 includes status codes that may appear during grid power feed operation and do

not cause permanent interruption of the grid power feed operation.

After automatic disconnection from the grid and waiting for its conditions to return to those

stipulated, your inverter will try to resume grid power feed operation.

Brief interruption of grid power

feed operation due to overcurrent in the inverter.

The inverter returns to the

startup phase.

Brief interruption of grid power

feed operation due to over

temperature.

The inverter returns to the

startup phase.

Error is automatically rectified;

if status code persists: contact

a Fronius-trained service technician.

If required, clean cool air vents

and cooling elements with

compressed air.

The fault is rectified automatically.

If this status code keeps recurring, contact your system installer.

42

Page 45

Code Description Details Rectification

LOW PV POWER

Intermediate circuit voltage

306

307

IMPORTANT! Status codes 306 (LOW PV POWER) and 307 (LOW PV VOLTAGE) appear naturally every

morning and evening due to low solar irradiance. These status codes are not the result of a fault.

has dropped below permissible

threshold value for grid power

feed operation.

LOW PV VOLTAGE

DC input voltage has dropped

below permissible threshold

value for grid power feed operation.

Brief interruption of grid power

feed operation.

The inverter returns to the

Startup phase.

The fault is rectified automatically.

If this status code keeps recurring with sufficient solar irradiance, contact your system

installer.

EN-US

308 Intermediate circuit overvolt-

age

309 DC input voltage too high

Class 4 Status

Codes

Code Description Details Rectification

401

406

407

408 DC feed-in detected

412

415

416

425

445

448

No internal communication

with power stage set.

Power stage set temperature

sensor defective

Internal temperature sensor

defective

The "fixed voltage" setting has

been selected instead of MPP

voltage operation and the voltage is set to a value that is too

low or too high.

Safety cut-out has been triggered by option card or RECERBO

No communication between

power stage set and control

unit

Communication with the power

stage set is not possible

Limit value setting not permitted

Neutral conductor not connected

Class 4 status codes may require the intervention of a trained Fronius service technician.

Brief interruption of grid power

feed operation.

The inverter returns to the

Startup phase.

The inverter will automatically