/ Perfect Welding / Solar Energy / Perfect Charging

FWT 1500 x 750

Operating Instructions

EN

Welding table

42,0410,1726 V04 - 10102016

Dear reader,

Introduction

These operating instructions will help you familiarise yourself with the welding table. It is

in your interest to read these instructions carefully and to observe the

directions contained herein. This will prevent faults and incorrect operation or possible

damage to installed system components.

Please also obey the safety rules; doing so will ensure greater safety when using the

product. Careful handling of the entire system will repay you with years of safe and

reliable operation. These are essential prerequisites for excellent results.

Table of contents

General information 3

About this document ........................................................................................................................................ 5

Function of this document .......................................................................................................................... 5

Qualied technicians .................................................................................................................................. 5

Copyright .................................................................................................................................................... 5

Safety 7

Operational reliability and tips for the user ...................................................................................................... 9

Proper use .................................................................................................................................................. 9

Operating instructions ................................................................................................................................ 9

Duty to instruct ........................................................................................................................................... 9

Third-party and untrained personnel .......................................................................................................... 9

Additional safety measures ...................................................................................................................... 10

Description 11

Danger points ................................................................................................................................................ 13

Danger points ........................................................................................................................................... 13

Description of the danger points .............................................................................................................. 13

Residual risk ............................................................................................................................................. 13

Transport and storage ...................................................................................................................................15

Handling and transporting items .............................................................................................................. 15

After delivery ............................................................................................................................................ 16

Temporary storage ...................................................................................................................................16

Transport and setup .................................................................................................................................16

Overview .................................................................................................................................................. 18

Machine data ........................................................................................................................................... 18

Description of controls and connections ........................................................................................................ 19

Safety ....................................................................................................................................................... 19

External controls and connections ........................................................................................................... 19

Maintenance unit ...................................................................................................................................... 19

Distributor ................................................................................................................................................. 20

Extractor ................................................................................................................................................... 20

Compressor .............................................................................................................................................. 20

Installation and start-up 21

Start-up .......................................................................................................................................................... 23

Properties of the installation site .............................................................................................................. 23

Space requirements ................................................................................................................................. 23

Troubleshooting and maintenance 25

Troubleshooting ............................................................................................................................................. 27

General.....................................................................................................................................................27

Safety ....................................................................................................................................................... 27

Basic requirements for the system to work .............................................................................................. 27

Maintenance, service .................................................................................................................................... 28

Safety ....................................................................................................................................................... 28

Maintenance engineers ............................................................................................................................ 28

Maintenance operations and intervals ..................................................................................................... 28

Recommended lubricants ........................................................................................................................ 29

1

Spare parts & accessories ............................................................................................................................ 30

Ordering

details ....................................................................................................................................................... 30

Spare parts ............................................................................................................................................... 30

Accessories .............................................................................................................................................. 31

Annex 33

Declaration of conformity ............................................................................................................................... 35

Pneumatic plan .............................................................................................................................................. 37

2

General information

3

4

About this document

Function of this

document

Qualied technicians

Copyright

These operating instructions tell you how to commission and operate the welding table

in conjunction with the installed system components. Look after the operating instructions

carefully; they must always be to hand at the location where the welding table is being

used. They can be used as a reference should any operational or functional problems

occur in the future.

Note: there are a large number of potential combinations of accessories, and for this rea-

son you may nd features described in these instructions that are not available on your

welding table.

These operating instructions are designed for trained technicians or persons with practi-

cal welding experience. Personnel must be trained through a veriable programme of

regular instruction.

Maintenance and repair of the welding table may also only be carried out by trained

technicians and in compliance with the specied maintenance activities and maintenance

intervals.

The manufacturer accepts no responsibility for damages caused by insucient knowledge of how to operate the system.

Copyright of these operating instructions remains with Fronius International GmbH. The

text and illustrations are all technically correct at the time of going to print. We reserve

the right to make changes. The contents of the operating instructions shall

not provide the basis for any claims whatsoever on the part of the purchaser.

5

6

Safety

7

8

Operational reliability and tips for the user

Proper use

Operating

instructions

The FWT 1500x750 welding table must only be used for welding demonstrations and training. Any other use shall be deemed improper and the manufacturer will assume no responsibility for any damages arising.

It can be used with the following welding processes:

- TIG process

- MIG/MAG process

Proper use also includes:

- following all the information in the operating instructions

- carrying out all maintenance work at the appropriate intervals

- using the spare parts stipulated by Fronius

- using this document in conjunction with the operating

instructions of the integrated system components (extractor, compressor, etc.)

The operating instructions help you to use the welding table safely and eciently, and

must therefore be to hand at all times.

- Keep the various sections of the operating instructions near the welding table at all

times.

- Clearly mark the place where the instructions are kept

- Ensure that all persons using the welding table know where the operating instructions are located.

- The operating instructions will only be able to help you if you can nd them when

there is a problem!

Important! The manufacturer shall not be liable for any damage arising from failure to

observe the operating instructions.

Duty to instruct Before personnel start working with the welding table, the plant operator is obliged to

instruct them about:

- the theoretical and practical aspects of using the welding table

- the relevant safety regulations.

Important! The duty to instruct applies in particular to those who only work occasionally

on the welding table (e.g. maintenance engineers, etc.)

Third-party and

untrained personnel

Do not allow third-party or untrained personnel unsupervised access to the welding table.

- Visitors or untrained personnel may only approach the welding table when accompanied by trained personnel

- Ensure that the welding table is never used unsupervised.

9

Operating

pneumatic

equipment

On welding accessories with integral pneumatic equipment, observe the following:

- The operating air pressure must not exceed 8 bar unless other operating pressure

values are specied in the operating instructions.

- Contaminated compressed air shortens the service life of pneumatic components.

A maintenance list for pneumatic components has therefore been included in the operating instructions.

- Keep the ambient air free from: dust, acids, corrosive gases or substances.

- Cylinders and other pneumatic components must only be dismantled by Froniustrained

service technicians.

- When commissioning, note that valves may have undened switching positions. This

may result in uncontrolled movements. Always remain at a safe distance!

- Before you start work on the pneumatic equipment, the compressed air should be

switched o, the system vented, and measures taken to prevent it being switched back

on.

Additional safety

measures

The plant operator bears sole responsibility for the work environment. The following

safety measures must be put in place and employed:

- Workplace must be enclosed

- Unless extraction and ltration equipment to reduce gas and vapour build-up is

integrated, it should be specied by a specialist company and implemented by the

customer.

- Eye protection must be worn when welding

- Workers must wear personal protective gear when welding

10

Description

11

12

Danger points

Danger points

(1)

(2)

(3)

Description of the

danger points

Residual risk

(1) Adjustable eye protector

Danger of an unexpected movement. Personnel standing nearby should be warned

before the eye protector is moved.

(2) Heat and hazardous fumes

Personal protective equipment is mandatory for welding demonstrations.

If there is no integrated fume extraction system (as illustrated above), then one

should be retro-tted by the plant operator.

(3) Adjustable eye protector poses risk of crushing

Moving parts of the eye protector must not be touched under any circumstances.

if the eye protector is extended (as shown in the picture above) when storing the welding

table for long periods, the eye protector will drop down due to the decrease in pressure

that occurs in the system.

13

14

Transport and storage

Handling and

transporting

items

CAUTION!

Danger of damage due to incorrect handling of the transport boxes.

If required the welding table will be delivered in a secure transport box. This

has various transport notices axed to it.

Observe the transport notices on the packaging or box.

Symbol Explanation

Protect from moisture! The shipping item must be kept dry.

Keep upright during transport. Always store and transport shipping items with the arrows pointing upwards. Shipping items must

not be laid on their side or upside-down. If these rules are not

observed, the shipping item may be damaged.

When lifting and transporting a shipping item, note its centre of

gravity. When lifting, always hold the item as close to this point as

possible. This will prevent it from tipping over unexpectedly.

Fragile! Shipping items must always be handled with care.

Attach here! The lifting tackle (lashing chain, hoisting belt) is to be

attached at the indicated points.

Avoid touching packages with this symbol when the relative

humidity is low, especially if wearing insulating footwear or the

oor is non-conductive. Low relative humidity is most common on

warm, dry summer days and very cold winter days.

15

After delivery

Inspect the transport packaging (container, box) for damage.

Important! Fronius International GmbH must be notied immediately of any

damage to the packaging. This will expedite the replacement of any damaged parts.

CAUTION!

Risk of damage to property due to the build-up of condensation.

If parts are not unpacked immediately after delivery, moisture can form on or

inside the parts (condensation). This can lead to serious damage as a result of

the corrosion of parts or to short circuits in electronic/electrical equipment.

Ensure that parts are at room temperature before commissioning. Do not attempt to accelerate this process by exposing the parts to a direct heat source.

If condensation occurs, the parts must not be used until they have dried out

completely (wait ve hours).

Temporary

storage

Transport and

setup

Store the parts in a sheltered place that is dry and free from dust.

Storage conditions:

- Never tip

- Avoid heavy impact

If storing for more than three months:

- Oil exposed parts monthly

- Protect parts from dust and moisture

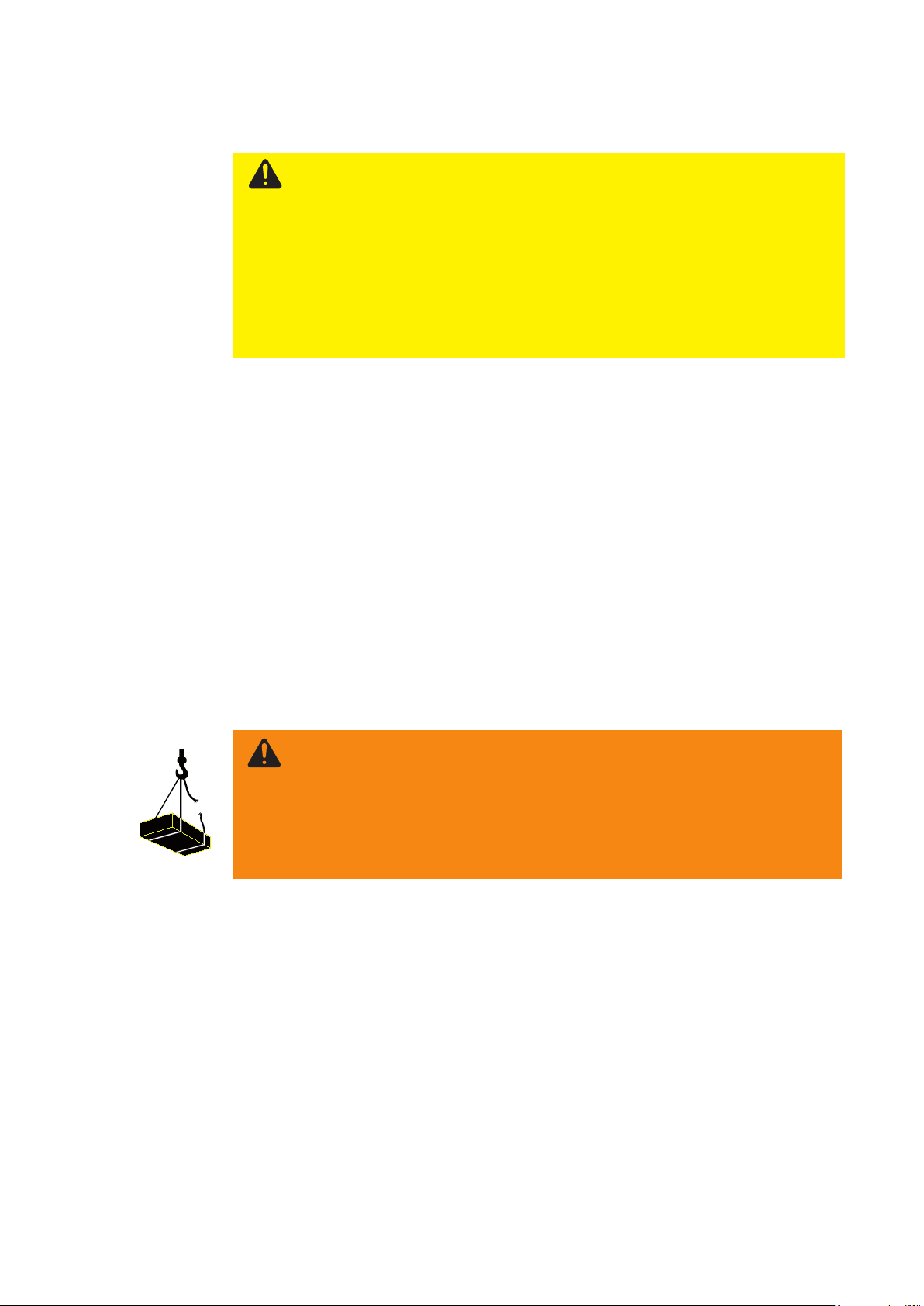

The total weight of the welding table and system components can be found in the "Machine data" section. The load-carrying equipment used must be designed for this weight.

Check its maximum load before lifting the table.

WARNING!

Danger of serious injury from standing under suspended loads

Hoisting, rigging and carrying equipment may be damaged. Falling loads can

cause death or serious injury. Body parts can be crushed, fractured or otherwise injured.

- Never stand under a freely suspended load.

- Make absolutely certain that all attachments are xed and secure before

moving the welding table.

- Only use lifting gear with sucient lifting capacity

- Never use damaged lifting gear

- Do not knot the carrying equipment or lay it over sharp edges

- Always use carrying equipment of the same length

- Move the welding table carefully, avoiding sudden movements

- Set the welding table down carefully

16

Transport and

setup

(continued)

WARNING!

Risk of serious injury and damage from

incorrect lifting and transportation procedures.

Incorrect procedures and unsuitable or incorrect devices can cause serious

injuries and/or damage.

- Observe national regulations when transporting; lifting equipment, ground

conveyors and load-carrying equipment must conform to specications.

- Use the correct load-carrying equipment for transport and assembly

- Only use the lifting lugs or lifting points specied by the manufacturer to

transport the welding table safely.

- Wear gloves and safety footwear when moving the welding table or system components

If the table needs to be moved, a forklift truck must be used to pick it up. Ensure that

all connecting leads have been removed. The welding table can also be moved using

(optional) wheels.

FWT 1500x750 welding table, transportation points

17

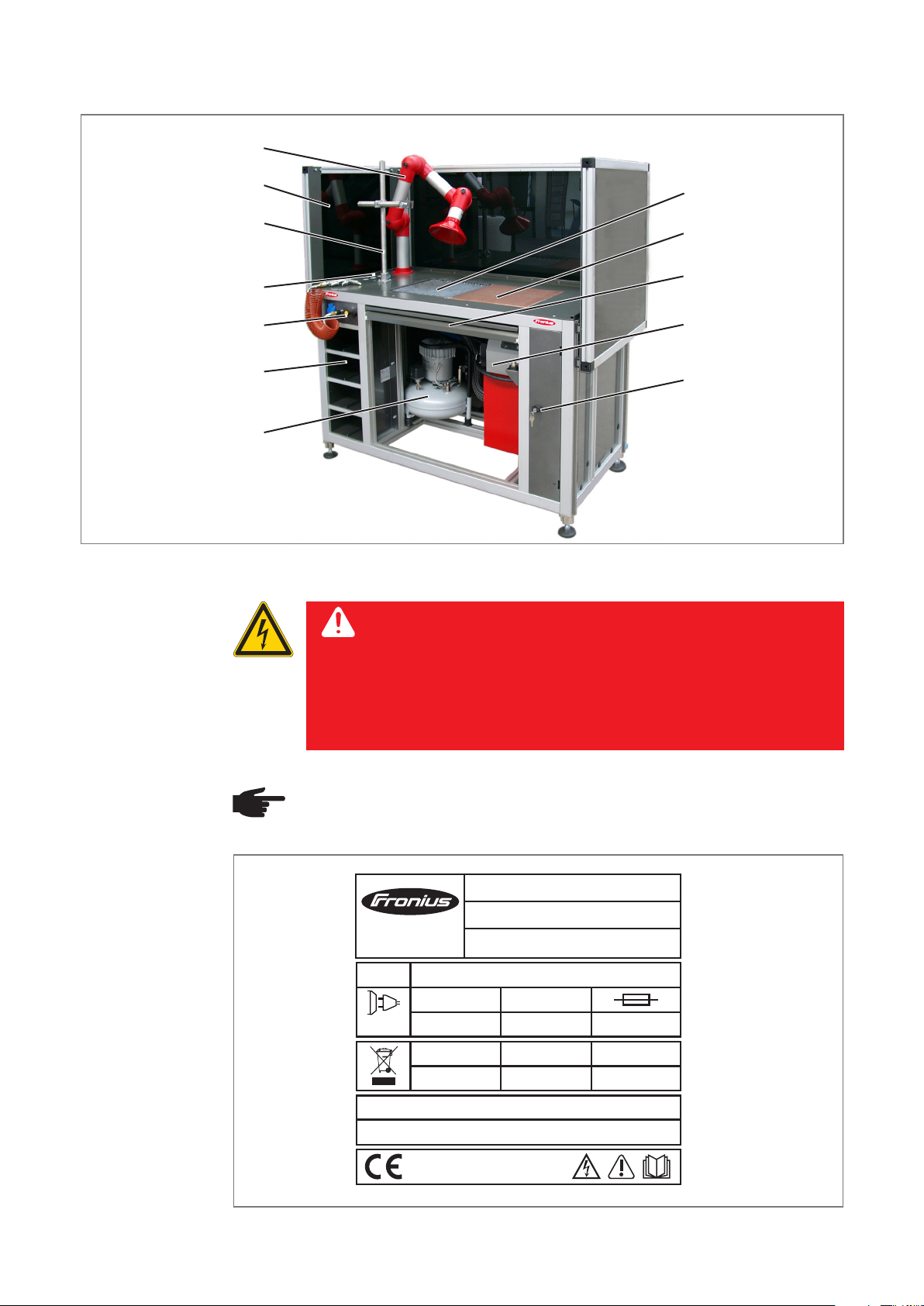

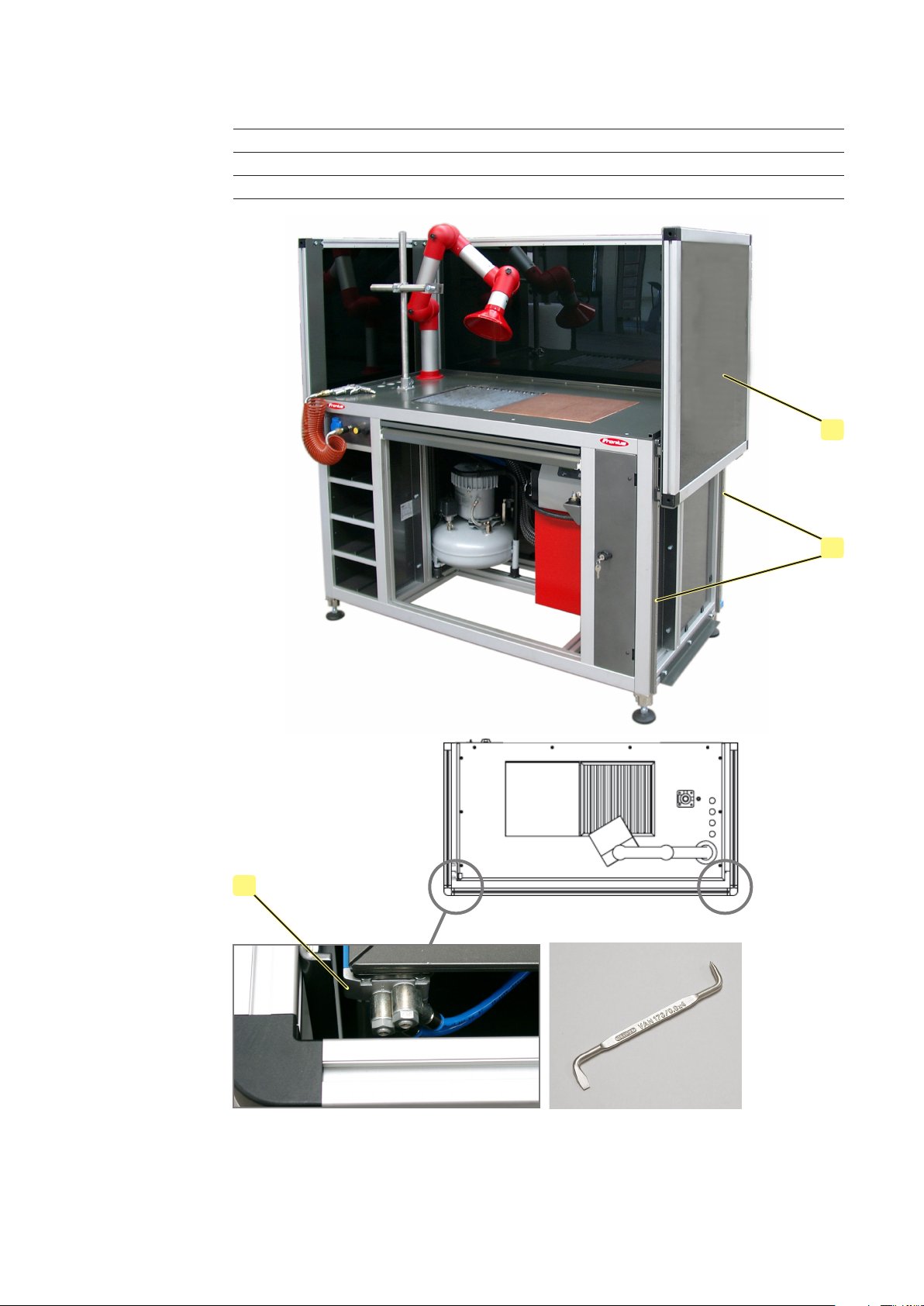

Overview

Overview of the most important functions and features:

Extractor arm

Overhead welding

Control panel

Compartments for

welding samples

Air compressor

Machine data

Welding lter

device

Wire holder

Welding grate

Copper plate

Slag drawer

Fume extractor

Storage area (lockable)

DANGER!

Risk of fatal injury from dangerous electrical voltage.

The areas bearing this symbol contain parts that are under dangerous electrical voltages. An electric shock can be fatal.

Work on the electrical system must only be carried out by qualied

electrical engineers.

NOTE! The rating plates may not be removed or modied without the consent

of Fronius International GmbH. Ensure that the rating plates remain legible.

A-4600 Wels

www.fronius.com

U

3~

50 Hz

FWT 1500x750 welding table, rating plate

400 V

weight

400 kg

Art.No.:

Art.No.:

Ser.No.:

EN 12100-1/-2

1

L x W x H

1600 x 830 x 1140 mm

I1

16 A

max

p

6 bar

FWT 1500

8,045,282

16 A

P1max

11 kVA

18

Description of controls and connections

Safety

External controls

and connections

WARNING!

Operating the equipment incorrectly can cause serious injury and damage.

Do not use the functions described until you have thoroughly read and understood the following documents:

- these operating instructions

- all operating instructions for the system components

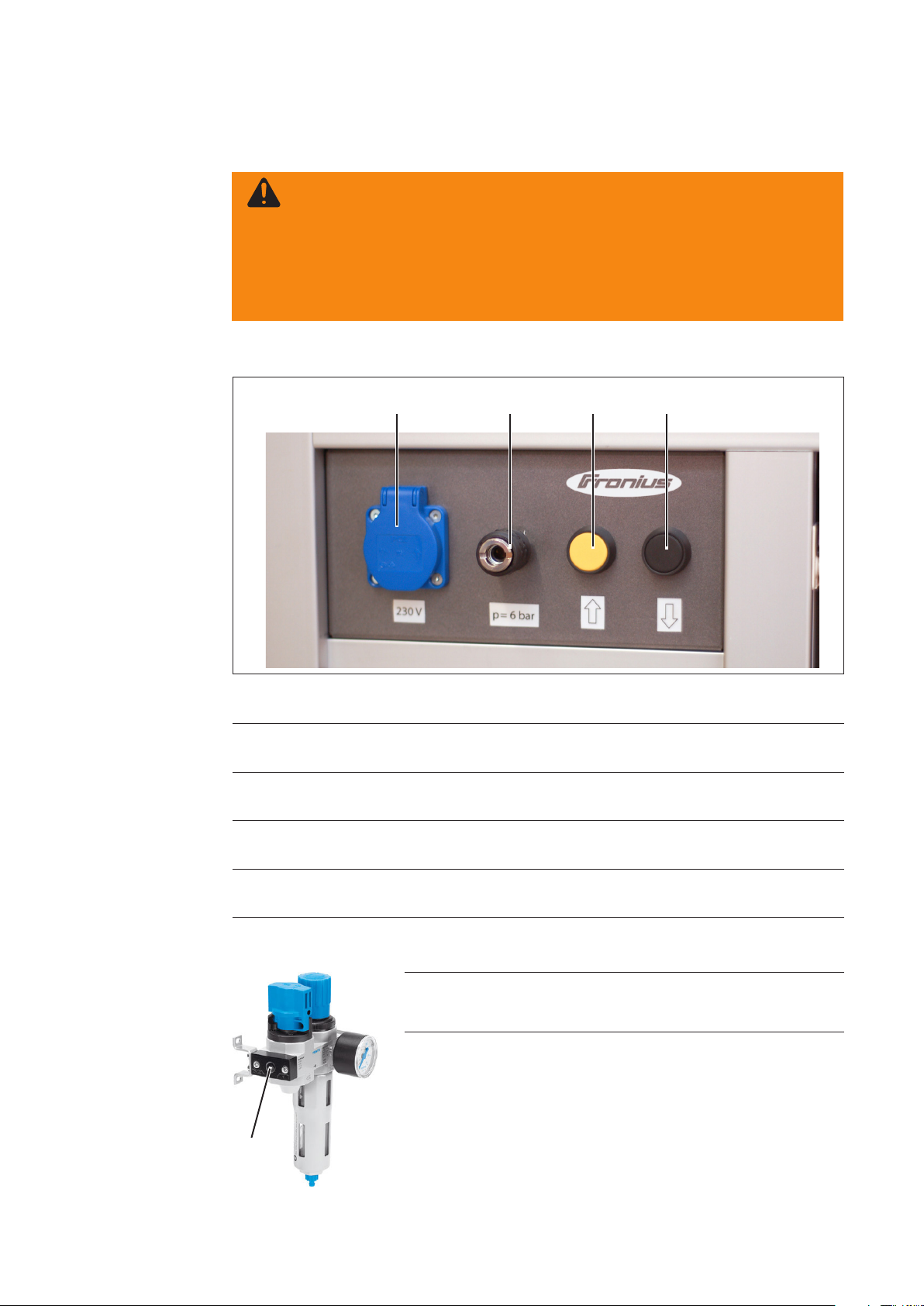

(1)

(2) (3) (4)

Maintenance unit

Control panel

(1) 230V socket

For operating additional tools, such as a portable grinder.

(2) Compressed air

Allows a compressed-air gun to be connected easily using a quick-release coupling.

(3) UP key

For raising the eye protector.

(4) DOWN key

For lowering the eye protector.

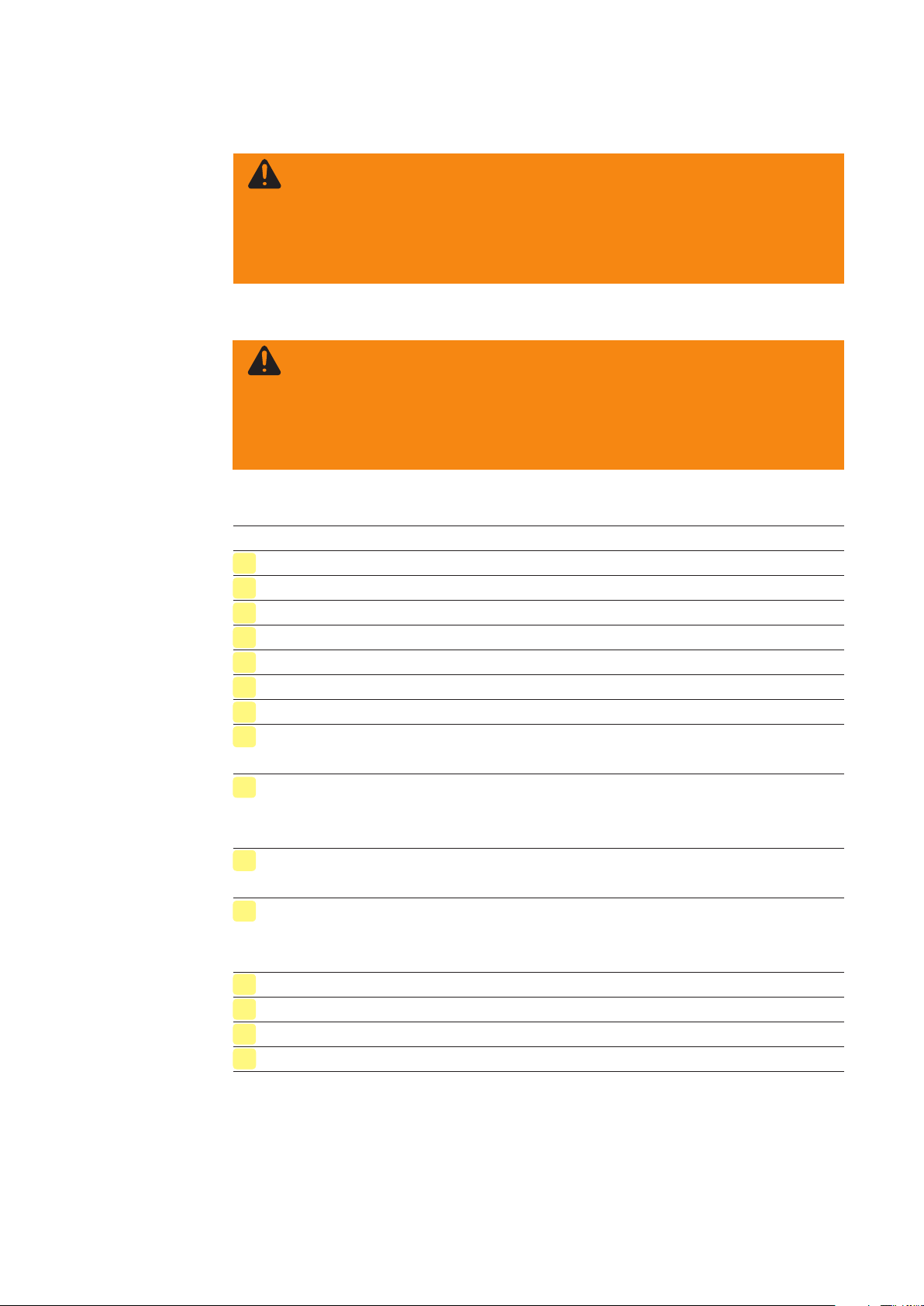

(1) Connection on both sides G1/4

Operating pressure 6 bar

(1)

19

Distributor

(1) (2)

(1) 380V socket

Main connection for the welding table

(2) 230V sockets

For operating installed equipment, such as an extractor or compressor

Extractor

Compressor

See extractor operating instructions

See compressor operating instructions

20

Installation and start-up

21

22

Start-up

Properties of the

installation site

Space requirements

Foundations:

- even and rm

Environment:

- not outdoors

- not in a hazardous area

- not in an area of increased electrical risk (including working in boilers, narrow spaces,

in restricted areas, between or on electrically conductive parts, in damp or hot rooms).

E

F

D

C

A

Dimensions

• A 1500 mm

• B 750 mm

• C 945 mm

• D 1780 mm upper position (eye protector)

• D 1140 mm lower position (eye protector)

• E 1600 mm

• F 830 mm

B

23

24

Troubleshooting and maintenance

25

26

Troubleshooting

General

Safety

Basic requirements for the

system to work

In the event of faults, note that the function of the entire system depends on many additional components that are also potential sources of problems.

NOTE! Faults may only be corrected by qualied technicians or by Fronius

service personnel.

WARNING!

An electric shock can be fatal.

Unplug device from the mains before opening it

- Connections established between separate system components

- System components are supplied with electricity and the mains voltage for each

component complies with the rating plate

- Pneumatic system is supplied with compressed air at the correct pressure (see rating

plate)

27

Maintenance, service

Safety

Maintenance

engineers

Maintenance

operations and

intervals

WARNING!

Risk of injury and damage during maintenance work.

Before commencing maintenance work:

- Unplug the welding table from the mains

- Switch o all system components and unplug them from the mains

- Ensure that all moving parts are stationary

WARNING!

Risk of injury and damage from incorrectly performed maintenance.

Maintenance work on the welding table must only be carried out by trained

specialist technicians. It is essential to adhere to the maintenance operations

and intervals. The manufacturer accepts no liability for any damage caused by

inadequate or poorly performed maintenance.

Item Part Action Interval

Linear guides Clean, check oil lm M

A

Threaded spindle Clean, regrease M

B

Rack and pinion Clean, regrease M

C

D

Toothed belt Pretension, check for tears M

Current collector Clean, apply conductive paste M

E

Earth cable Check connection M

F

Rollers and rails Clean, check position M

G

H

Maintenance units Check lter element and M

If dirty, change; check liquid level

Pneumatic/hydraulic systems Check interconnecting hosepacks and M

I

connections, Check guide rods for dirt and check

oil lm, check maintenance unit

J

Linear and Clean, function test M

rotating components

Safety measures: Function test D

K

(EMERGENCY STOP, limit switches,

safety strips)

L

Bearing units, bearing blocks Regrease M

M

Lubricating nipple Regrease M

N

Filter mats, ventilation slots Clean W

O

Safety glass Check for damage, replace if necessary M

D ..........Daily

W .........Weekly

M .........Monthly

½Y.......Twice per year

Y .........Annually

28

Recommended

lubricants

Important! Lubricants with solid lubricant additives (e.g. MoS2, graphite and PTFE) are

not suitable for guiding systems.

Lubricant DIN DIN number Remarks

Lubricating grease KP 2-K 51502 / 51825 Lithium soap-based grease

Lubricating oil CLP32-100 51517 Part 3 ISO VG 32-100

O

Safety glass speed can be

adjusted by repositioning

the exhaust air choke using

an angled screwdriver

I

A

Angled screwdriver

Important! The maintenance activities and maintenance intervals of the following system

components can be found in the relevant operating instructions:

- Compressor

- Fume extractor

29

Spare parts & accessories

Ordering

details

Spare parts

NOTE! Only trained technicians may change parts and may only do so after

consulting the installation and dismantling instructions supplied.

When ordering spare parts, please provide the following data:

- Exact designation of the spare part

- Associated item number as per spare parts list

- Model name of the device

- Serial number (shown on the rating plate)

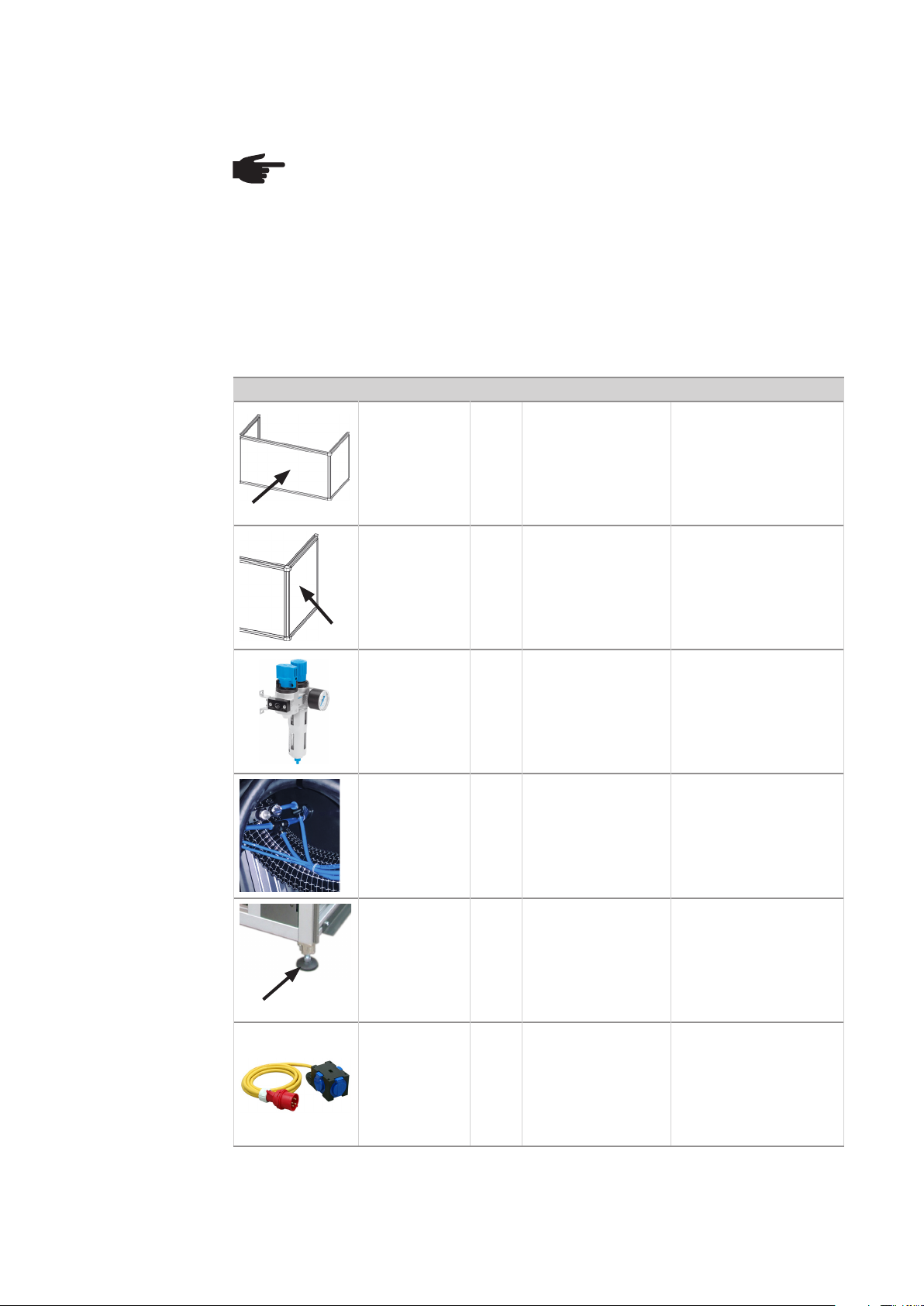

Photo Item no. No. Type Description

58,0223,2411 1 Safety glass, front

58,0223,2410 1 Safety glass, side

48,0001,0083 1 0.3-10 G1/4 Maintenance unit

38,0003,0266 1 0.3-10 G1/4

48,0007,0202 1 80 / M16x68 Machine foot

38,0008,0030 1 16A / 400V Current distribution box

Pressure regulating

valve

30

Spare parts

(continued)

Photo Item no. No. Type Description

48,0002,0198 1 Copper plate

58,0223,4000 1 Welding grate

Accessories

48,0007,0199 1

Lever cylinder lock

(incl. 2 keys)

48,0001,0114 1 Blow-through gun

48,0001,0113 1 DM6 7.5m

Spiral hose (pneumatic)

Photo Item no. No. Type Description

Fume extractor (incl.

8,100,119 1

extractor arm, extractor hood, automatic

start/stop)

8,100,120 1

8,100,0121 1

31

2x castors

2x castors with

locks

Air compressor (incl.

blow-through gun and

spiral hose)

Wheels incl. installation materials

Accessories

(continued)

Photo Item no. No. Type Description

no image

38,0008,0027 1 32A / 400V

38,0100,0189 1

48,0009,0038 1

on request 1

country-specic

version

Current connection

distributor

Earth cable distributor

(x5)

Swivel stool (symbol

photo)

Transport box

58,0223,F000 1

Ramp (for transport

box)

32

Annex

33

34

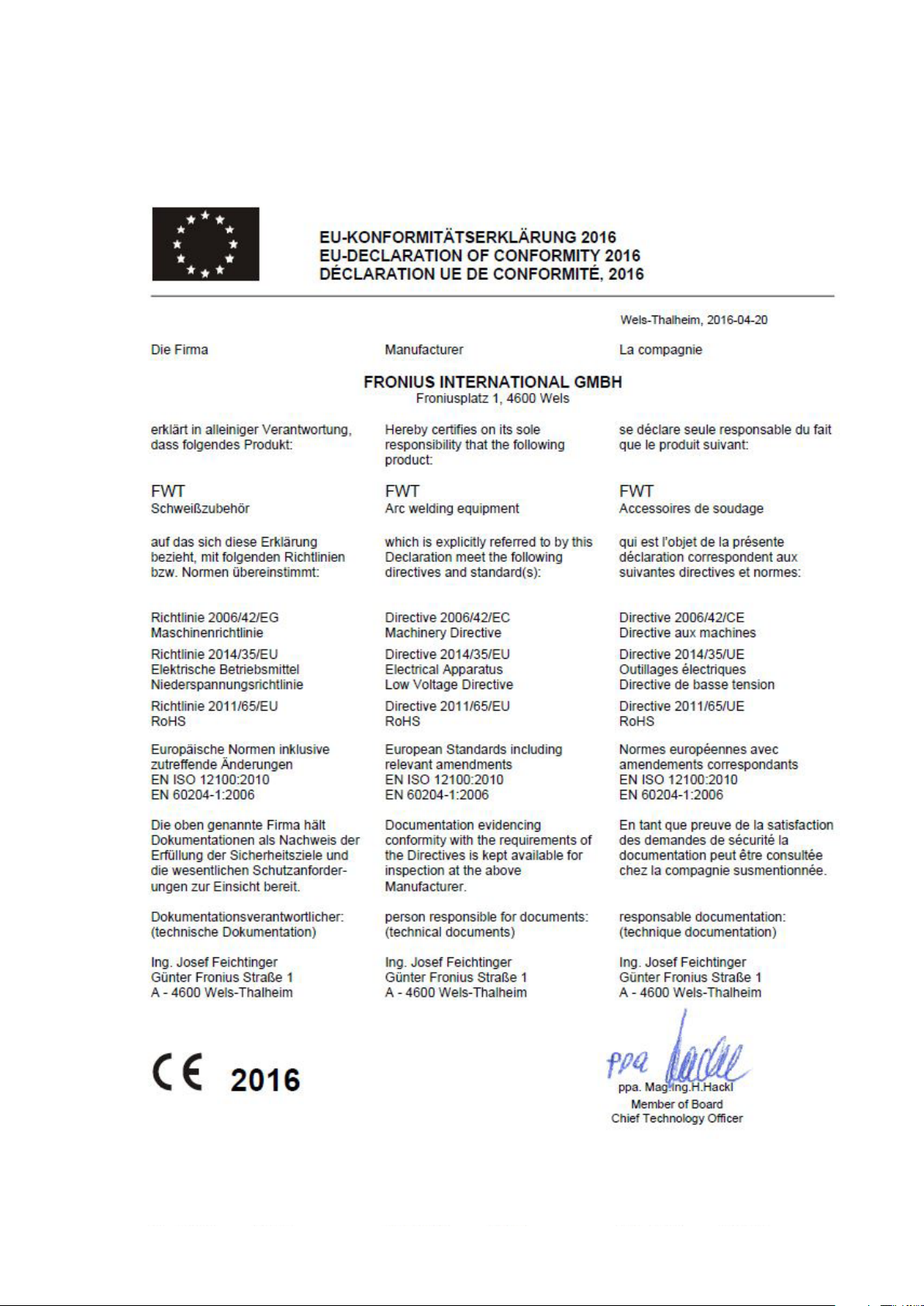

Declaration of conformity

35

36

Pneumatic plan

37

38

'*&.339$*.

=.%

33/

*5/$46'

26%

/50$46

9/%

6926

7*(

696

76:

39

FRONIUS INTERNATIONAL GMBH

TechSupport Automation

www.fronius.com

www.fronius.com/addresses

40

Loading...

Loading...