Operating

Instructions

Fronius Tauro 50-3

Fronius Tauro ECO 50-3

Fronius Tauro ECO 99-3

Fronius Tauro ECO 100-3

Operating Instructions

EN

42,0426,0307,EN 028-23022023

Contents

Safety rules 6

Explanation of safety notices 6

General 6

Environmental conditions 7

Qualified personnel 7

Safety measures at the installation location 7

Noise emission values 7

EMC measures 7

Data protection 8

Copyright 8

Protective earthing (PE) 8

Maintenance 8

General information 9

Description of the device 11

Description of the device 11

AC Daisy Chain 11

String fuses 11

Fronius Solar.web 12

Local communication 13

Protection of people and equipment 14

Safety 14

Warning notices and rating plate on the device 14

WSD (wired shutdown) 15

Central grid and system protection 15

RCMU 15

Surge protective device 16

Surge protective device (SPD) 16

AFCI – Arc Fault Circuit Interrupter (ArcGuard) 16

Safe state 17

Proper use 18

Intended use 18

Regulations governing the photovoltaic system 18

Functional principle 19

Functional principle 19

Cooling of the inverter through forced-air ventilation 19

Power derating 19

Control elements and connections 20

Controls and displays 20

PV connections - Tauro 50-3-D (direct) 20

PV connections - Tauro Eco 50-3-D (direct) 21

PV connections - Tauro 50-3-D (30A fuses) 21

PV connections - Tauro Eco 50-3-D (30A fuses) 21

PV connections - Tauro Eco 99-3-D / 100-3-D (direct, 20 A option) 22

PV connections - Tauro Eco 99-3-D / 100-3-D (direct, 30 A option) 22

PV connections - pre-combined 22

Optional DC disconnector lock 23

Mounting option for third-party components 23

Data communication area in the inverter 23

Data communication area 24

Internal schematic connection diagram of the IOs 25

Button functions and LED status indicator 26

EN

Installation and commissioning 29

General 31

System component compatibility 31

Installation location and position 32

Choosing the location of the inverter 32

3

Installation position 33

Transport 35

Crane transport 35

Transporting by counterbalanced lift truck or lift truck 35

Mounting the inverter 36

Selecting the fixing material 36

Mounting bracket dimensions 36

Mounting the inverter on the wall 36

Mounting the inverter on floor racks 38

Connecting the inverter to the public grid (AC side) 39

Monitoring the grid 39

AC connection area 39

Connecting aluminium cables 40

Permitted cables 40

Maximum alternating current fuse protection 41

Changing the clamping area for V-type terminal 42

Additional PE introduction for earthing 42

Safety 43

Opening the inverter 43

Switching off the AC disconnector option 44

Connecting the inverter to the public grid - Singlecore 44

Connecting the inverter to the public grid - Multicore 45

Connecting the inverter to the public grid - Daisy Chain 47

Connecting cables with a cable lug 48

Connecting the PV cable to the inverter 50

Safety 50

General comments regarding PV modules 51

Permitted cables 51

DC fuse protection - pre-combined 52

Example of Fronius Tauro Eco 50-3-P / 99-3-P / 100-3-P combiner box 53

Example Fronius Tauro 50-3-P combiner box 54

Distribution of the solar module strings for the direct version 54

Connecting PV cables - MC4 connector 55

MC4 connector cover 55

Connecting PV cables - Pre-combined 56

Connecting cables with a cable lug 57

Replacing the string fuses 58

Closing and switching on the inverter 60

Connecting the data communication cable 62

Modbus participants 62

Permitted cables for the data communication area 62

Multiple inverters in one network 63

Routing data communication cables 63

WSD (wired shutdown) 65

Using for the first time 67

Starting the inverter for the first time 67

Fronius system monitoring (Pilot) display 67

Installation with the app 67

Installation using the web browser 68

Switching off current supply and restarting the inverter 70

De-energising the inverter and switching it on again 70

Settings - user interface of the inverter 71

User settings 73

User login 73

Selecting the language 73

Device configuration 74

Components 74

Functions and IOs 74

"PSC editor - AUS - Demand Response Modes (DRM)" 75

Demand Response Modes (DRM) 75

4

Inverter 75

System 77

General 77

Update 77

Setup wizard 77

Restoring the factory settings 77

Event log 77

Information 77

Licence manager 78

Support 79

Communication 80

Network 80

Modbus 81

Remote control 82

Fronius Solar API 82

Safety and grid requirements 83

Country setup 83

Feed-in limitation 83

I/O power management 84

Connection diagram - 4 relay 85

I/O power management settings - 4 relays 86

Connection diagram - 3 relay 87

I/O power management settings - 3 relays 88

Connection diagram - 2 relay 89

I/O power management settings - 2 relays 90

Connection diagram - 1 relay 91

I/O power management settings - 1 relay 92

EN

Appendix 93

Status codes and remedy 95

Status Codes 95

Technical data 96

Tauro 50-3-D / 50-3-P 96

Tauro Eco 50-3-D / 50-3-P 98

Tauro Eco 99-3-D / 99-3-P 100

Tauro Eco 100-3-D / 100-3-P 102

WLAN 105

Explanation of footnotes 105

Integrated DC disconnector 105

Applicable standards and guidelines 107

CE mark 107

WLAN 107

Power failure 107

Service, warranty terms and conditions and disposal 108

Fronius SOS 108

Fronius manufacturer's warranty 108

Disposal 108

5

Safety rules

Explanation of

safety notices

Indicates a potentially hazardous situation.

▶

Indicates a situation where damage could occur.

▶

Indicates a risk of flawed results and possible damage to the equipment.

If you see any of the symbols depicted in the "Safety rules" chapter, special care

is required.

General The device has been manufactured in line with the state of the art and according

to recognised safety standards. In the event of incorrect operation or misuse,

there is a risk of:

-

-

WARNING!

If not avoided, death or serious injury may result.

CAUTION!

If not avoided, minor injury and/or damage to property may result.

NOTE!

Injury or death to the operator or a third party

Damage to the device and other material assets belonging to the operator

All personnel involved in commissioning and maintenance of the device must:

Be suitably qualified,

-

Have knowledge of and experience in dealing with electrical installations and

-

Read and follow these Operating Instructions carefully.

-

In addition to the Operating Instructions, all applicable local rules and regulations regarding accident prevention and environmental protection must also be

followed.

All safety and danger notices on the device:

Must be kept in a legible state

-

Must not be damaged

-

Must not be removed

-

Must not be covered, pasted or painted over

-

Only operate the device when all protection devices are fully functional. If the

protection devices are not fully functional, there is a risk of:

Injury or death to the operator or a third party

-

Damage to the device and other material assets belonging to the operator

-

Any safety devices that are not fully functional must be repaired by an authorized specialist before the device is switched on.

Never bypass or disable protection devices.

For the location of the safety and danger notices on the device, refer to the

chapter headed "Warning notices on the device" in the Operating Instructions for

your device.

6

Faults that could compromise safety must be remedied before switching on the

device.

EN

Environmental

conditions

Qualified personnel

Operation or storage of the device outside the stipulated area will be deemed as

not in accordance with the intended purpose. The manufacturer accepts no liability for any damage resulting from improper use.

The servicing information contained in these Operating Instructions is intended

only for the use of qualified service engineers. An electric shock can be fatal. Do

not carry out any actions other than those described in the documentation. This

also applies to qualified personnel.

All cables and leads must be secured, undamaged, insulated, and adequately dimensioned. Loose connections, scorched, damaged or inadequately dimensioned

cables and leads must be immediately repaired by authorised personnel.

Repair work must only be carried out by authorised personnel.

It is impossible to guarantee that bought-in parts are designed and manufactured to meet the demands made on them, or that they satisfy safety requirements. Use only original spare parts (also applies to standard parts).

Do not carry out any alterations, installations, or modifications to the device

without first obtaining the manufacturer's permission.

Components that are not in perfect condition must be changed immediately.

Safety measures

at the installation location

Noise emission

values

EMC measures In certain cases, even though a device complies with the standard limit values for

When installing devices with openings for cooling air, ensure that the cooling air

can enter and exit unhindered through the air ducts. Only operate the charger in

accordance with the degree of protection shown on the rating plate.

The sound power level of the inverter is specified in the Technical data.

The device is cooled as quietly as possible with the aid of an electronic temperature control system; this depends on the amount of converted power, the ambient

temperature, the level of soiling of the device, etc.

It is not possible to provide a workplace-related emission value for this device

because the actual sound pressure level is heavily influenced by the installation

situation, the grid quality, the surrounding walls and the properties of the room

in general.

emissions, it may affect the application area for which it was designed (e.g., when

there is equipment that is susceptible to interference at the same location, or if

the site where the device is installed is close to either radio or television receivers). If this is the case, then the operator is obliged to take appropriate action to

rectify the situation.

7

Data protection The user is responsible for the safekeeping of any changes made to the factory

settings. The manufacturer accepts no liability for any deleted personal settings.

Copyright Copyright of these operating instructions remains with the manufacturer.

The text and illustrations are all technically correct at the time of printing. We

reserve the right to make changes. The contents of the operating instructions

shall not provide the basis for any claims whatsoever on the part of the purchaser. If you have any suggestions for improvement, or can point out any mistakes that you have found in the instructions, we will be most grateful for your

comments.

Protective

earthing (PE)

Maintenance In principle, Tauro inverters are maintenance-free. If maintenance work is never-

Connection of a point in the device, system or installation to earth to protect

against electric shock in the event of a fault. When installing the Tauro inverter,

the PE connection is mandatory as it is a protection class 1 device. When connecting the PE conductor, ensure that it is secured against accidental disconnection. All points listed under "Connecting the inverter to the public grid (AC side)"

must be observed, including the use of washers, screw locks, and nuts with the

defined torque.

It must be ensured that when using the strain-relief devices, the ground conductor is the last to be disconnected in the event of a possible failure. When connecting the ground conductor, the minimum cross-section requirements specified by the respective national regulations must be observed. In addition, the

minimum cross-section of the PE conductor must be at least half of the phase

cross-sections according to the product standard IEC 62109-1, as a cross-section of at least 35 mm² (50 kW) or 70 mm² (99.99 / 100 kW) must be used for the

phases (L1 / L2 / L3).

theless carried out on the inverter, such as cleaning or replacing components,

this must be done in consultation with a Fronius-trained service technician. The

manufacturer accepts no liability for damage caused by improper use.

8

General information

9

10

Description of the device

EN

Description of

the device

AC Daisy Chain With the "AC Daisy Chain" inverter version, the AC lead can be fed directly from

The inverter transforms the direct current generated by the solar modules into

alternating current. This alternating current is fed into the public grid synchronously with the grid voltage.

The inverter has been developed exclusively for use in grid-connected photovoltaic systems; it is impossible to generate energy independently of the public grid.

Thanks to its design and the way it works, the inverter is extremely safe both to

install and to operate.

The inverter automatically monitors the public grid. In the event of abnormal grid

conditions, the inverter ceases operating immediately and stops feeding power

into the grid (e.g. if the grid is switched off, if there is an interruption, etc.).

The grid is monitored by monitoring the voltage, frequency and islanding conditions.

the inverter to another inverter. Several Tauro inverters, up to an output power of

max. 200 kW, can be thereby be quickly connected to one another.

The minimum cable cross-section is defined by the fuse at the mains connection

point. A larger cable cross-section can be selected at any time. The applicable

national standards must be taken into account and applied.

String fuses Only applies to device types Fronius Tauro 50-3-D / Eco 50-3-D / Eco 99-3-D /

Eco 100-3-D (direct):

String fuses are used in the Fronius Tauro to provide additional protection for the

solar modules.

The maximum short circuit current Isc, the maximum module return current IR or

the maximum string fuse rating specified in the module data sheet of the respective solar module is crucial in affording the solar modules the correct fuse

protection.

The national regulations regarding fuse protection must be observed. The electrical engineer carrying out the installation is responsible for the correct choice

of string fuses.

11

To replace the string fuses, see chapter Replacing the string fuses on page 58.

Eco 50-3-D

Eco 99-3-D / Eco 100-3-D Standard

F1.1 - F2.7

Eco 99-3-D / Eco 100-3-D

Standard

F3.1 - F3.8

50-3-D

F1.1 - F3.7

F3.1-

F3.1+

F3.2-

F3.2+

F3.3-

F3.3+

F3.4-

F3.4+

F3.5-

F3.5+

Eco 50-3-D

30A fuses F1.1 - F2.5

50-3-D / Eco 99-3-D / Eco 100-3-D

30A fuses F1.1 - F3.5

Fronius Solar.web

With Fronius Solar.web or Fronius Solar.web Premium, the PV system can be

easily monitored and analysed by the system owner and installer. If configured

accordingly, the inverter transmits data such as power, yields, load, and energy

balance to Fronius Solar.web. For more information see Solar.web - monitoring &

analysis.

Configuration is carried out via the setup wizard, see chapter Installation with

the app on page 67 or Installation using the web browser on page 68.

12

Prerequisites for configuration:

Internet connection (download: min. 512 kBit/s, upload: min. 256 kBit/s)*.

-

User account on solarweb.com.

-

Completed configuration via the setup wizard.

-

* The information given does not constitute an absolute guarantee of fault-

less function. High error rates in the transmission, reception fluctuations

or transmission drop-outs can have a negative effect on the data transfer.

Fronius recommends testing the Internet connection on site according to

the minimum requirements.

EN

Local communication

The inverter can be found via the Multicast DNS protocol (mDNS). It is recommended to search for the inverter by the assigned host name.

The following data can be retrieved via mDNS:

NominalPower

-

Systemname

-

DeviceSerialNumber

-

SoftwareBundleVersion

-

13

Protection of people and equipment

Safety

Warning notices

and rating plate

on the device

WARNING!

Danger due to incorrect operation and incorrectly performed work.

This can result in serious injury and damage to property.

All the work and functions described in this document must only be carried

▶

out by trained and qualified personnel.

Read and understand this document.

▶

Read and understand all the Operating Instructions for the system compon-

▶

ents, especially the safety rules.

WARNING!

Danger from electromagnetic fields. Electromagnetic fields are generated during operation.

Effects on the health of persons, e.g. those wearing a pacemaker can result.

Do not remain closer than 20 cm from the inverter for a prolonged period of

▶

time.

There are warning notices and safety symbols on and in the inverter. These warning notices and safety symbols must not be removed or painted over. They warn

against incorrect operation, as this may result in serious injury and damage.

Symbols on the rating plate:

CE mark – confirms compliance with applicable EU directives and

regulations.

UKCA mark – confirms compliance with applicable UK directives and

regulations.

A 4-digit number (coded production

date) is printed at the very bottom of

the rating plate, from which the production date can be calculated.

If you subtract the value 11 from the

first two digits, you get the production

year.

The last two digits represent the calendar week in which the device was produced.

Example: Value on rating plate = 3205

32 - 11 = 21 → Production year 2021

05 = Calendar week 05

14

WEEE mark – waste electrical and electronic equipment must be

collected separately and recycled in an environmentally sound manner

in accordance with the European Directive and national law.

RCM mark – tested in accordance with the requirements of Australia

and New Zealand.

ICASA mark – tested in accordance with the requirements of the

Independent Communications Authority of South Africa.

CMIM mark – tested in accordance with IMANOR requirements for

import regulations and compliance with Moroccan standards.

Safety symbols:

Risk of serious injury and property damage due to incorrect operation.

Do not use the functions described here until you have fully read and

understood the following documents:

These Operating Instructions.

-

All Operating Instructions for the system components of the

-

photovoltaic system, especially the safety rules.

Dangerous electrical voltage.

Before opening the machine, wait for the capacitors to discharge!

Text of the warning notices:

EN

WSD (wired

shutdown)

Central grid and

system protection

WARNING!

An electric shock can be fatal. Before opening the device, ensure that the input

and output sides are de-energised and insulated.

The wired shutdown (WSD) interrupts the inverter feeding energy into the grid if

the trigger device (switch, e.g. emergency stop or fire alarm switch) has been activated.

If an inverter (secondary device) fails, it is bypassed and the other inverters continue operating. If a second inverter (secondary device) or the inverter (primary

device) fails, the operation of the entire WSD chain is interrupted.

For installation, see WSD (wired shutdown) on page 65.

The inverter offers the option to use the integrated AC relays as coupling

switches in conjunction with a central grid and system protection unit (in accordance with VDE-AR-N 4105:2018:11 §6.4.1). For this purpose, the central trigger

device (switch) must be integrated into the WSD chain as described in the

chapter "WSD (Wired Shut Down)".

RCMU The inverter is equipped with a universal current-sensitive residual current monit-

oring unit (RCMU = Residual Current Monitoring Unit) in accordance with IEC

62109-2 and IEC63112.

This device monitors residual currents from the PV module to the AC output of

the inverter and disconnects the inverter from the grid in the event of unauthorised residual current.

15

Surge protective

device

The inverter is equipped with an integrated surge protective device on the DC

and AC side in accordance with IEC 62109-2. The surge protective device protects the system against damage in the event of a surge.

Surge protective

device (SPD)

AFCI – Arc Fault

Circuit Interrupter (ArcGuard)

The surge protective device (SPD) protects against temporary overvoltages and dissipates surge currents (e.g. lightning strike). Building on

an overall lightning protection concept, the SPD helps to protect your

PV system components.

If the surge protective device is triggered, the colour of the indicator

changes from green to red (mechanical display).

There is the option of a digital indication when an SPD has tripped. For

setting this function, see PDF "Temporary SPD Triggering" in the Service

& Support area at www.fronius.com

IMPORTANT!

After setting the function described above, the inverter will also respond if the 2pole signal cable of the surge protective device is interrupted or damaged.

Available ex works.

AFCI (Arc Fault Circuit Interrupter) protects against arcing faults and in the narrower sense is a protection device against contact faults. The AFCI evaluates any

faults that occur in the current and voltage curve with an electronic circuit and

switches off the circuit when a contact fault is detected. This prevents overheating on poor contacts and possible fires.

IMPORTANT!

Active solar module electronics can interfere with the function of the ArcGuard.

Fronius does not guarantee the correct functioning when using Fronius ArcGuard

in combination with active solar module electronics.

CAUTION!

Danger due to incorrect or unprofessional DC installation.

This can result in risk of damage and, in turn, risk of fire to the PV system due to

inadmissible thermal loads that arise with an arc.

Check that plug connections are in good condition.

▶

Repair incorrect insulation as appropriate.

▶

Complete connections as per the specifications.

▶

IMPORTANT!

Fronius will not accept any costs associated with production downtimes, installer

costs, etc., that may arise as the result of a detected arc and its consequences.

Fronius accepts no liability for damage that can occur despite the presence of

the integrated Arc Fault Circuit Interrupter/extinguishing system ( e.g. caused by

a parallel arc).

Automatic reconnection

To restart the AFCI, no manual procedure is required if a minimum interruption

time of 5 minutes is ensured before continuing operation.

When interrupting for the fifth time within a 24 h period, the AFCI is only allowed to be reset manually before the AFCI does reconnect. Afterwards, the

AFCI may return to automatic reconnection mode.

16

Safe state If one of the following safety devices trips, the inverter will change to a safe

state:

WSD

-

isolation measurement

-

RCMU and

-

AFCI

-

In the safe state, the inverter no longer feeds into the grid and is disconnected

from the grid by opening the AC relays.

EN

17

Proper use

Intended use The solar inverter is intended exclusively to convert direct current from solar

modules into alternating current and to feed this into the public grid.

Utilisation not in accordance with the intended purpose comprises:

Utilisation for any other purpose, or in any other manner

-

Making any modifications to the inverter that have not been expressly ap-

-

proved by Fronius

Installation of parts that are not distributed or expressly approved by Froni-

-

us

The manufacturer shall not be liable for any damage resulting from such use. All

warranty claims will be forfeited.

Intended use also includes complying with all the instructions in the Operating

Instructions.

Regulations governing the

photovoltaic system

The inverter is designed to be connected and used exclusively in conjunction with

solar modules.

Use of the inverter with other DC generators (e.g. wind generators) is not permitted.

When designing the photovoltaic system, ensure that all of its components are

operated within their permitted operating ranges at all times.

Observe all the measures recommended by the solar module manufacturer to

ensure that the solar module retains its properties in the long term.

18

Functional principle

EN

Functional principle

Cooling of the

inverter through

forced-air ventilation

The inverter operates fully automatically. As soon after sunrise as there is sufficient energy available from the solar modules, the inverter starts checking the

PV system (insulation measurement), and the grid (grid voltage and grid frequency). If all values are within the normative scope, automatic connection to the

grid and feeding of energy into the grid takes place.

The inverter works in a way that ensures the maximum power possible is obtained

from the solar modules. This is known as "Maximum Power Point Tracking"

(MPPT). In the event of shading of the solar modules, the function "Dynamic

Peak Manager" can be used to obtain the majority of the local maximum output

(LMPP) of the PV system.

After dusk, as soon as the power available has fallen below the level at which energy can be fed into the grid, the inverter disconnects the power electronics

completely from the grid and stops running. It retains all its settings and stored

data.

Cooling of the inverter is performed by a forced-air ventilation system via temperature-controlled fans. Air is sucked in from the front and fed, via a sealed

duct, through the AC and DC heat sink, before passing directly over the inductors and dissipating.

The sealed air duct prevents the electronics compartment from coming into contact with the ambient air. This approach largely prevents any contamination of

the electronics compartment.

The fan speed and temperature of the inverter are monitored.

The variable-speed, ball-bearing mounted fans in the inverter permit the following:

Optimum cooling of the inverter

-

Cooler components, therefore a longer service life

-

Lowest-possible energy consumption

-

High output power including in top temperature range of the inverter

-

Power derating If the inverter becomes too hot, it automatically reduces the current output

power in order to protect itself. Reasons for the inverter becoming too hot include too high an ambient temperature or inadequate heat dissipation (e.g. when

installed in containers without proper heat dissipation measures).

A power derating system restricts the output from the inverter in order to prevent the temperature from exceeding the permissible value.

If a maximum temperature is exceeded, the inverter switches off in a safe state

and does not resume feeding energy into the grid until the device has cooled

down.

19

Control elements and connections

Controls and displays

(1) DC disconnector

Disconnects the electrical connection from the solar modules

to the inverter. Depending on

the device type, 2 or 3 DC disconnectors are installed.

The DC disconnectors can be

secured against switching on

with a padlock.

(2) AC disconnector option

The optional AC disconnector

breaks the connection from the

inverter to the grid

(3) Button function

For further information about

the button function, see But-

ton functions and LED status

indicator

(4) LED status indicator

For further information about

the LED status indicator, see

Button functions and LED

status indicator

PV connections Tauro 50-3-D

(direct)

20

PV connections Tauro Eco 50-3D (direct)

PV connections Tauro 50-3-D

(30A fuses)

EN

PV connections Tauro Eco 50-3D (30A fuses)

21

PV connections Tauro Eco 99-3D / 100-3-D (direct, 20 A option)

PV connections Tauro Eco 99-3D / 100-3-D (direct, 30 A option)

PV connections pre-combined

22

Tauro Eco 50-3-P / 99-3-P / 100-3-P Tauro 50-3-P

Optional DC disconnector lock

With the optionally available DC disconnector lock, the inverter can be secured against unintentional switching

off.

EN

Mounting option

for third-party

components

Data communication area in the

inverter

Above the DC connection area there is

space for mounting third-party components. Components up to a maximum width of 14.5 cm (8 DU) can be

mounted on the DIN rail. The components must have a temperature resistance of ‑40 °C to +85 °C.

The data communication area (Pilot PC board) is located above the DC connections in the inverter.

23

Data communication area

Modbus terminal Push-in terminal for the installation of

Modbus 0, Modbus 1, 12 V and GND

(ground).

The data connection to the connected

components is established via the

Modbus terminal. The inputs M0 and

M1 can be selected for this purpose.

Max. 4 Modbus participants per input,

see chapter Modbus participants on

page 62.

WSD (wired shutdown) switch Defines the inverter as a WSD primary

device or WSD secondary device.

Position 1: WSD primary device

Position 0: WSD secondary device

Modbus 0 (MB0) switch Switches the terminating resistor for

Modbus 0 (MB0) on/off.

Position 1: Terminating resistor on

(factory setting)

Position 0: Terminating resistor off

Modbus 1 (MB1) switch Switches the terminating resistor for

Modbus 1 (MB1) on/off.

Position 1: Terminating resistor on

(factory setting)

Position 0: Terminating resistor off

Optical sensor

Communication LED

To operate the inverter. See chapter

Button functions and LED status indicator on page 26.

Indicates the inverter connection

status.

24

Operating status LED

Indicates the inverter operating

status.

LAN 1 Ethernet connection for data commu-

nication (e.g. WLAN router, home network or for commissioning with a

laptop see chapter Installation using

the web browser on page 68).

LAN 2 Reserved for future functions. Only

use LAN 1 to avoid malfunctions.

WSD terminal Push-in terminal for the WSD installa-

tion. See chapter "WSD (wired shut-

down)" on page 65.

IOs terminal Push-in terminal for digital inputs/

outputs. See chapter Permitted

cables for the data communication

area on page 62.

The designations (RG0, CL0, 1/5, 2/6,

3/7, 4/8) on the terminal refer to the

Demand Response Mode function, see

chapter "PSC editor - AUS - Demand

Response Modes (DRM)" on page 75.

EN

Internal schematic connection

diagram of the

IOs

On the V+/GND pin, it is possible to feed in a voltage of around 12.5–24 V (+ max.

20%) with an external power supply. The outputs IO 0–5 can then be operated

with the external voltage. A maximum of 1 A can be drawn per output, with a

maximum of 3 A allowed in total. The fuse protection must be located externally.

CAUTION!

Risk of polarity reversal at the terminals due to improper connection of external

power supplies.

This may result in severe damage to the inverter.

Check the polarity of the external power supply with a suitable measuring

▶

device before connecting it.

Connect the cables to the V+/GND outputs with the correct polarity.

▶

IMPORTANT!

If the total output (6 W) is exceeded, the inverter switches off the entire external

power supply.

25

12 V DC

500 mA

V+ V+

GND

IO0

IO1

IN8

IN9

IN10

IN11

IN6

IN7

IO4

IO5

IO2

IO3

GND

(1)

12 V

USB

TYP A

5 V

IO4

V+

V+

IO0

IO2

IN6

IN8

IN10IN11

IN9

IN7

IO5

IO3

IO1

GND

GND

M0-

M0+

M1-

M1+

SHIELD

SHIELD

V+ V+

GND GND

V+

V+

M0+

SHIELD

M1+

GND

M1-

SHIELD

M0-

GND

(1) Power limitation

Ok

Standby

Uncritical Error

(flashing)

Critical Error

Network Error

Connecting

(flashing)

Connected

1x WLAN access point

2x WPS

3-6 sec. Quit Service Message

Button functions

and LED status

indicator

Sensor functions

The status of the inverter is

shown via the operating status

LED. In the event of faults,

carry out the individual steps

in the Fronius Solar.web live

app.

The optical sensor is actuated

by touching with a finger.

The status of the connection is

shown via the communication

LED. To establish the connection, carry out the individual

steps in the Fronius Solar.web

live app.

1x = WLAN access point (AP) is opened.

Flashing blue

26

2x = WLAN Protected Setup (WPS) is activated.

Flashing green

3 seconds (max. 6 seconds) = the service notification is

terminated.

Lights up yellow

LED status indicator

The inverter is operating correctly.

Lights up green

The inverter starts.

Flashing green

The inverter is in standby, is not operational (e.g. no

feed-in at night) or is not configured.

Lights up yellow

The inverter indicates a non-critical status.

Flashing yellow

The inverter indicates a critical status and there is no

grid power feed process.

Lights up red

The network connection is being established via WPS.

2x = WPS search mode.

EN

Flashing green

The network connection is being established via

WLAN AP.

1x = WLAN AP search mode (active for 30 minutes).

Flashing blue

The network connection is not configured.

Lights up yellow

The inverter is operating correctly, a network fault is in-

dicated.

Lights up red

The inverter is performing an update.

/ Flashing blue

27

28

Installation and commissioning

29

30

General

EN

System component compatibility

All installed components in the photovoltaic system must be compatible and

have the necessary configuration options. The installed components must not restrict or negatively influence the functioning of the photovoltaic system.

CAUTION!

Risk due to components in the photovoltaic system that are not compatible

and/or have limited compatibility.

Incompatible components may limit and/or negatively affect the operation

and/or functioning of the photovoltaic system.

Only install components recommended by the manufacturer in the photovol-

▶

taic system.

Before installation, check the compatibility of components not expressly re-

▶

commended with the manufacturer.

31

Installation location and position

min.

50 cm

min. 50 cm

min.

50 cm

min.

50 cm

-30 °C - +65 °C - Option AC-Disconnect

0 - 100 %

-40 °C - +65 °C

Choosing the

location of the

inverter

Please note the following criteria when choosing a location for the inverter:

Only install on a solid, non-flammable surface

Max. ambient temperatures: -40 °C / +65 °C

* with built-in AC disconnector option: -30 °C / +65 °C

Relative humidity: 0 - 100%

When installing the inverter in a switch cabinet or similar closed environment, it

is necessary to make sure that the hot air that develops will be dissipated by

forced-air ventilation.

When installing the inverter on the outer walls of cattle sheds, it is important to

keep a minimum clearance of 2 m between all sides of the inverter and air vents

and building openings.

The following surfaces are permissible for installation:

Walls (corrugated metal walls [mounting rails], brick walls, concrete walls, or

-

other non-flammable surfaces sufficiently capable of bearing loads)

Poles (installed using mounting rails, behind the solar modules directly on

-

the PV mounting system)

Flat roofs (if this is for a film roof, make sure that the films comply with the

-

fire protection requirements and are not highly flammable. Observe the na-

tional regulations.)

Covered car park roofs (no overhead installation)

-

The DC disconnectors must always be freely accessible after installation of the

inverter.

The inverter is suitable for indoor installation.

32

flame-resistant

The inverter is suitable for outdoor installation.

Because of its IP 65 protection class, the inverter is resistant to

water jets from any direction and can also be used in damp environments.

The inverter is suitable for outdoor installation.

To keep the heating of the inverter as low as possible, it is better

not to expose the inverter to direct sunlight. Mount the inverter

in a protected location, for example below the solar modules or

under a roof overhang.

IMPORTANT! The inverter must not be installed or used at altitudes above 4000 m.

Do not install the inverter in:

Areas where it may be exposed to ammonia, corrosive gases,

-

acids or salts (e.g. fertiliser storage areas, vent openings for

livestock stables, chemical plants, tanneries, etc.)

Due to the noise generated by the inverter under certain operating conditions, it should not be installed close to living areas.

EN

Installation position

Do not install the inverter in:

Areas where there is an increased risk of accidents from

-

farm animals (horses, cattle, sheep, pigs, etc.)

Stables or adjoining areas

-

Storage areas for hay, straw, chaff, animal feed, fertilizers,

-

etc.

Storage or processing areas for fruit, vegetables or viticul-

-

ture products

Areas used in the preparation of grain, green fodder or an-

-

imal feeds

The inverter is designed to be dust-tight (IP 65). However, in

areas with high dust accumulation, the cooling surfaces may collect dust and this may impair the thermal performance. In such

cases, regular cleaning is required. Consequently, we do not recommend installation in places and environments with strong

dust formation.

The inverter is designed to be installed vertically on a vertical

wall. The optional floor racks must not be used for vertical

mounting.

33

The inverter should have a minimum inclination of 3° in a horizontal installation position so that water can run off. Mounting

of the optional floor racks is recommended. The floor racks may

only be used on an installation position of 0 - 45°.

The inverter is suitable for installation on a sloping surface.

Do not install the inverter on a sloping surface with its connection sockets at the top.

Do not install the inverter at an angle on a vertical wall or

column.

Do not install the inverter horizontally on a vertical wall or pillar.

Do not install the inverter on a vertical wall or pillar with its connection sockets facing upwards.

Do not install the inverter overhanging with the connection

sockets at the top.

Do not install the inverter overhanging with the connection

sockets at the bottom.

34

Do not install the inverter on the ceiling.

Transport

EN

Crane transport

Transporting by

counterbalanced

lift truck or lift

truck

WARNING!

Danger of serious injury and damage

from articles being dropped or falling

over.

When transporting by crane:

Hook chains and ropes onto the

▶

suspension points only

Always hook chains and ropes onto

▶

both suspension points

WARNING!

Equipment that falls or topples over can cause serious or even fatal injury.

Secure the inverter to prevent it from falling over when transporting on a

▶

counterbalanced lift truck or lift truck.

Avoid sudden changes in direction, braking or acceleration

▶

35

Mounting the inverter

Selecting the fixing material

Mounting bracket dimensions

Use the corresponding fixing materials depending on the subsurface and observe

the screw dimension recommendations for the mounting bracket.

The installer is responsible for selecting the correct type of fixing.

Dimensions of the mounting bracket - all dimensions in mm.

Mounting the inverter on the

wall

36

1 2

EN

3

5

4

Observe the local regulations for lifting heavy

loads or use a crane to lift the device (attach to

crane-hoisting lugs)

To attach the inverter to the mounting

bracket, use only the screws included

in the scope of delivery.

37

Mounting the inverter on floor

racks

1

The floor racks can be ordered as an

optional accessory.

Mounting the inverter on a horizontal

mounting surface is not mandatory,

but recommended.

Depending on the surface, different

wall plugs and screws are required for

floor mounting the floor racks. Wall

plugs and screws are therefore not included in the scope of supply of the inverter. The installer is responsible for

selecting the correct wall plugs and

screws.

Mount the inverter and floor racks

2

securely to a suitable surface using

the appropriate installation materials

Do not climb onto the device!

38

Connecting the inverter to the public grid (AC

side)

Monitoring the

grid

AC connection

area

IMPORTANT! To provide the best possible grid monitoring, the resistance in the

leads to the mains connections should be as low as possible.

IMPORTANT! Only the following cables may be connected to V-type terminals:

RE (solid round conductor)

-

RM (stranded round conductor)

-

SE (solid sector conductor)

-

SM (stranded sector conductor)

-

Fine-core cables only in conjunction with ferrules

-

Fine-core cables without ferrules may only be connected to the M10 threaded

bolts of the grid connections using a suitable M10 cable lug;

torque = 18 Nm

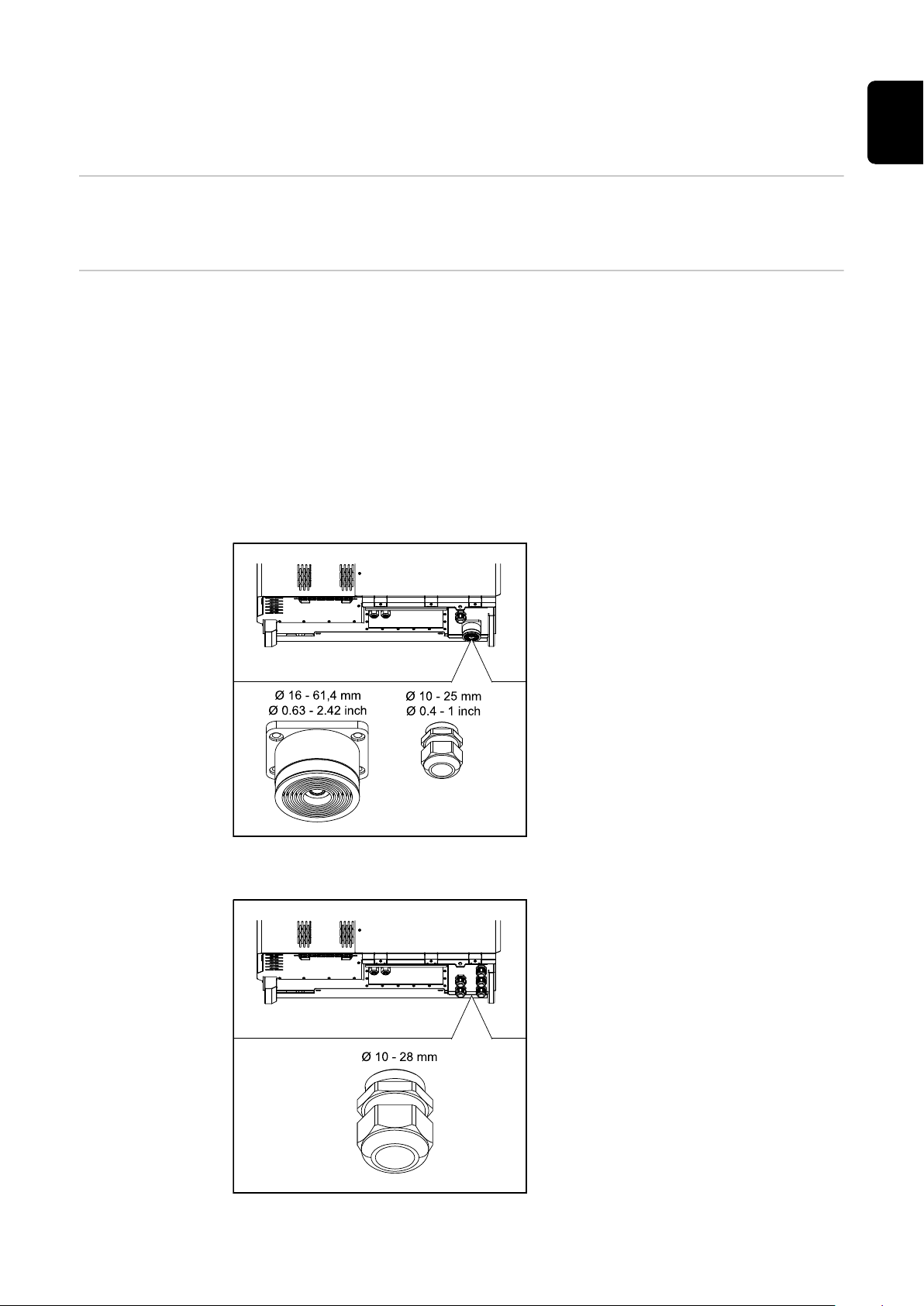

Cable gland "Multicore" version

The following cable outer diameters

are compatible with the larger bushing:

16 - 27.8 - 36.2 - 44.6 - 53 - 61.4 mm

EN

Cable gland "Singlecore" version

For the small bushing (M32 PG gland),

earth cables of 10 - 25 mm can be fed

through.

5 M40 bushings

39

Cable gland "AC Daisy Chain" version

10 M32 bushings

Connecting aluminium cables

Permitted cables For the pre-combined variant, the temperature resistance of the AC cables must

Aluminium cables can be connected to the mains connections.

NOTE!

When connecting aluminium cables:

Observe national and international guidelines regarding the connection of

▶

aluminium cables

To protect the aluminium strands from oxidation, grease them with a suitable

▶

grease.

Follow the instructions of the cable manufacturer

▶

be at least 90 C.

If cables are used that do not meet this temperature requirement, pass the protective hose (item number: 4,251,050) over the phases (L1 / L2 / L3) and neutral

conductor (N). The earthing PE does not have to be protected with a protective

hose.

With the AC Daisy Chain option, all phases and neutral conductors must be protected with the protective hose. Thus, two sets of protective hoses are required

for the AC Daisy Chain option.

40

Grid connections

Select sufficiently high cable cross sections depending on the power category

and connection option!

Power category Connection option Cable cross section

Tauro 50-3

Tauro Eco 50-3

Singlecore/Multicore

Optional AC disconnector

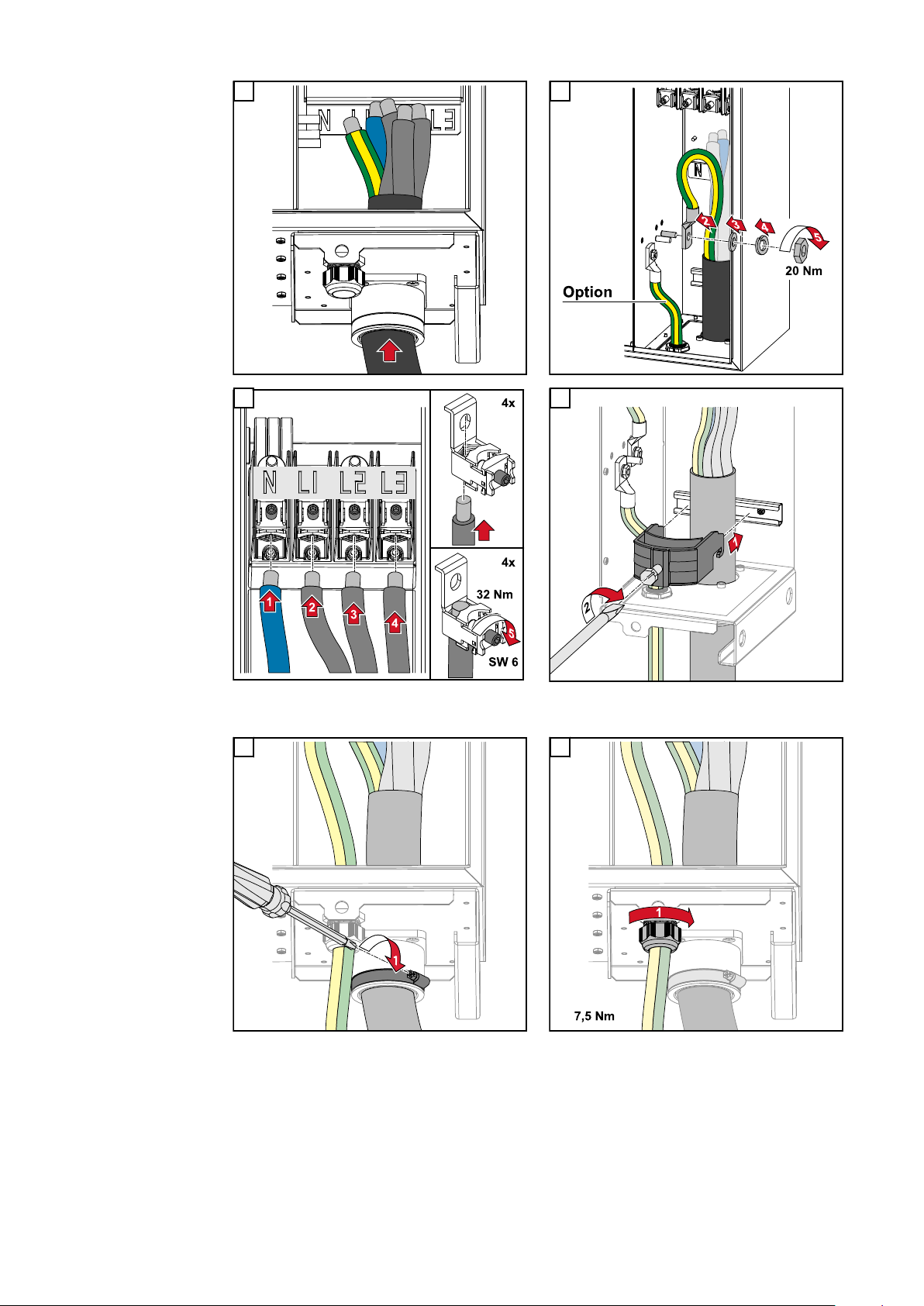

Daisy Chain (without AC discon-

nector)

35–240 mm2 *

35–240 mm2 *

35–240 mm2 *

Grid connections

Maximum alternating current

fuse protection

Select sufficiently high cable cross sections depending on the power category

and connection option!

Power category Connection option Cable cross section

Singlecore/Multicore

Tauro Eco 99-3

Tauro Eco 100-3

* The cable cross-section of the neutral conductor can be reduced to 25 mm² if

no local directives or standards require otherwise.

NOTE!

There is no general requirement to use a residual current device.

If a residual current device (RCD) is nevertheless used, a type B with a tripping

current of at least 1000 mA must be used.

NOTE!

Optional AC disconnector

Daisy Chain (without AC discon-

nector)

70–240 mm2 *

70–240 mm2 *

70–240 mm2 *

EN

The inverter can be used with an automatic circuit breaker of a maximum of

355 A.

Recommended output overcurrent protection [A]

for 50 kW output power

Recommended output overcurrent protection [A]

for 100 kW output power

(example: Daisy Chaining)

Recommended output overcurrent protection [A]

for 150 kW output power

(example: Daisy Chaining)

Tauro Eco 99-3-P

Tauro 50-3-D / 50-3-P

Tauro Eco 50-3-D / 50-3-P

80 80 - - - -

160 160 160 160 160 160

250 250 250 250 250 250

Tauro Eco 99-3-D

Tauro Eco 100-3-P

Tauro Eco 100-3-D

Recommended output overcurrent protection [A]

for 200 kW output power

(example: Daisy Chaining)

355 355 355 355 355 355

41

Changing the

clamping area

for V-type terminal

The clamping range of the V-type terminal is 35 - 150 mm² when delivered. The

clamping range can be changed to 185 - 240 mm² by a simple modification of the

V-type terminal.

Additional PE introduction for

earthing

An optional hole can be made on the right side of the housing at the bottom for

an additional PE introduction.

CAUTION!

Danger from faulty or incorrect holes.

This may lead to injuries to the eyes and hands as a result of flying debris and

sharp edges, as well as damage to the inverter.

When drilling, wear suitable protective goggles.

▶

Only use a step drill when drilling.

▶

Ensure that nothing is damaged inside the device (for example connection

▶

block).

Adapt the diameter of the hole to match the corresponding connection.

▶

Deburr the holes using a suitable tool.

▶

Remove the drilling residues from the inverter.

▶

1

42

2

Insert the screw connection in the hole

and secure to the torque specified by

the manufacturer.

The opening must be sealed in accordance with the protection class of the

inverter!

EN

Safety

WARNING!

Danger due to grid voltage and DC voltage from solar modules.

An electric shock can be fatal.

Ensure that both the AC side and the DC side of the inverter are de-ener-

▶

gised before carrying out any connection work.

Only an authorised electrical engineer is permitted to connect this equip-

▶

ment to the public grid.

CAUTION!

Risk of damage to the inverter as the result of incorrectly tightened cable connections.

Incorrectly tightened cable connections can cause heat damage to the inverter

that may result in a fire.

When connecting AC and DC cables, ensure that all the cables are tightened

▶

to the inverter terminals with the specified torque.

IMPORTANT! For PE connection, the requirements defined under "Safety rules"

for a safe connection of the PE conductor must also be observed.

Opening the inverter

1 2

43

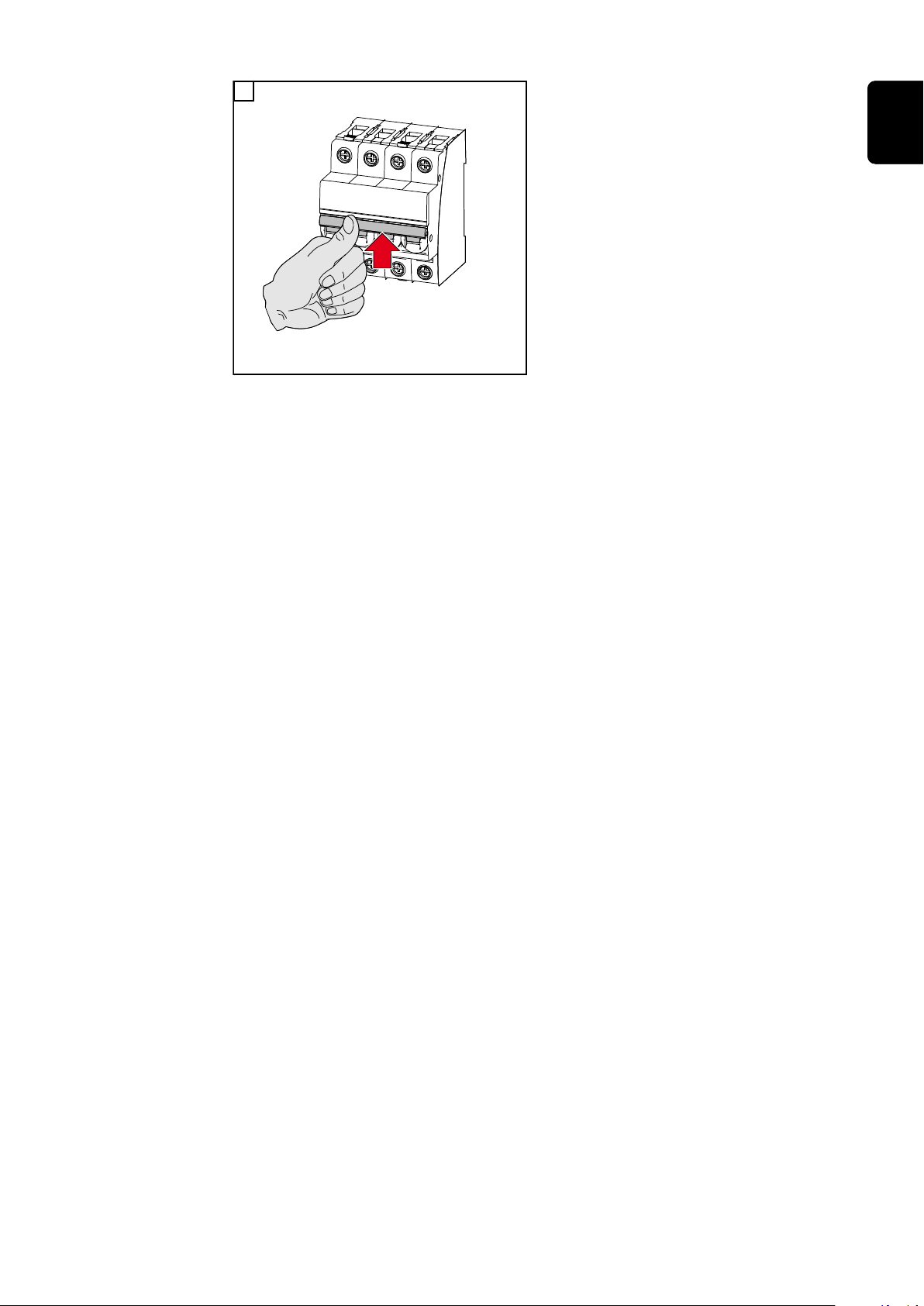

Switching off the

AC disconnector

option

1

Connecting the

inverter to the

public grid Singlecore

Ensure that the phases are connected in the right order: PE, N, L1, L2 and L3.

1 2

3 4

44

5 6

7

EN

Connecting the

inverter to the

public grid - Multicore

When connecting, ensure that the phases are in the correct order: PE, N, L1, L2

and L3.

1 2

45

3 4

5

7 8

6

Secure to the torque specified by the manufacturer of the strain-relief device. The strain-relief

device is not part of the scope of supply.

46

Secure to the torque specified by the manufacturer

9

EN

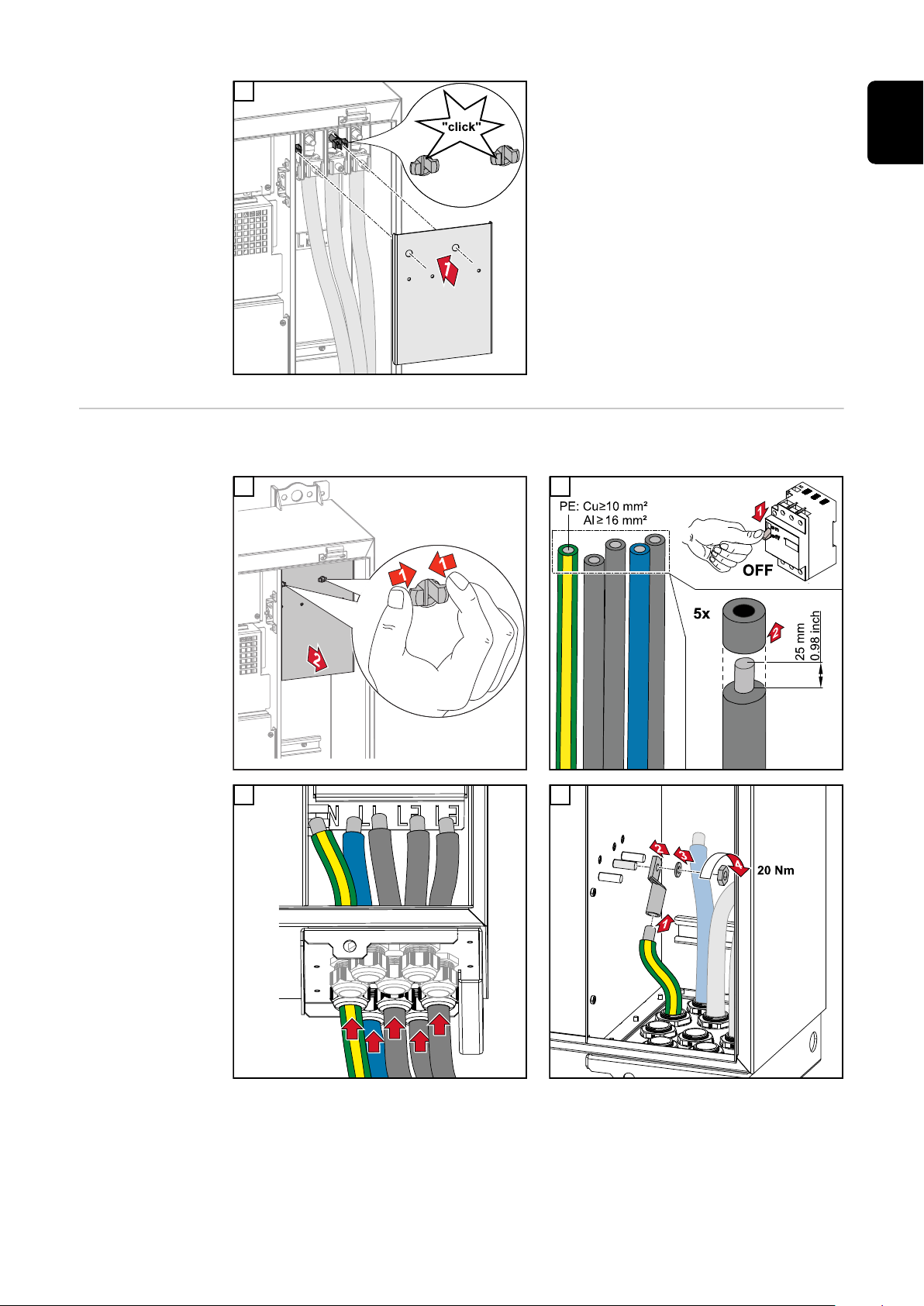

Connecting the

inverter to the

public grid Daisy Chain

Ensure that the phases are connected in the right order: PE, N, L1, L2 and L3.

1 2

3 4

47

5 6

7 8

Connecting

cables with a

cable lug

9 10

Alternatively, a cable with a cable lug can be connected to the M12 threaded

bolts on the grid connections in order to connect the cables to the V-type terminals.

48

EN

49

Connecting the PV cable to the inverter

Safety

WARNING!

Danger due to grid voltage and DC voltage from solar modules that are exposed

to light.

An electric shock can be fatal.

Prior to any connection work, disconnect the inverter on the AC side and the

▶

DC side.

Only an authorised electrical technician is permitted to connect this equip-

▶

ment to the public grid.

WARNING!

Danger of electric shock due to incorrectly connected terminals / PV plug connectors.

An electric shock can be fatal.

When connecting version D ("direct string"), ensure that every pole of a

▶

string is fed across the same PV input, e.g.:

'+ pole string 1' at input PV 1.1+ and '- pole string 1' at input PV 1.1-

WARNING!

Danger from DC voltage. Even when the DC disconnectors are switched off, the

fuse boards (100-3-D / 99-3-D) / fuse board (50-3-D) and everything before the

DC disconnectors are live.

An electric shock can be fatal.

Prior to any connection work, disconnect the inverter on the AC side and the

▶

DC side.

CAUTION!

Risk of damage to the inverter as the result of incorrectly tightened terminals.

Incorrectly tightened terminals can cause heat damage to the inverter that may

result in a fire.

When connecting AC and DC cables, ensure that all the terminals are

▶

tightened to the specified torque.

CAUTION!

Risk of damage to the inverter as the result of incorrectly tightened terminals.

Incorrectly tightened terminals can cause heat damage to the inverter that may

result in a fire.

When connecting AC and DC cables, ensure that all the terminals are

▶

tightened to the specified torque.

50

CAUTION!

General comments regarding

PV modules

Risk of damage to the inverter due to PV modules that are not connected with

the correct polarity.

PV modules that are not connected with the correct polarity can cause thermal

damage to the inverter.

Measure the DC cables from the PV modules and connect them to the in-

▶

verter with the correct polarity.

CAUTION!

Risk of damage to the inverter by exceeding the maximum input current per

string.

Exceeding the maximum input current per string can cause damage to the inverter.

Observe the maximum input current per string for the inverter according to

▶

the technical data.

The maximum input current must not be exceeded even when using Y or T

▶

connectors.

To enable suitable PV modules to be chosen and to use the inverter as efficiently

as possible, it is important to bear the following points in mind:

If insolation is constant and the temperature is falling, the open-circuit

-

voltage of the PV modules will increase. The open-circuit voltage must not

exceed the maximum permissible system voltage. If the open-circuit voltage

exceeds the specified values, the inverter will be destroyed and all warranty

claims will be forfeited.

The temperature coefficients on the data sheet of the PV modules must be

-

observed.

Exact values for sizing the PV modules can be obtained using suitable calcu-

-

lation tools, such as the Fronius Solar.creator.

EN

IMPORTANT!

Before connecting up the PV modules, check that the voltage for the PV modules specified by the manufacturer corresponds to the actual measured voltage.

IMPORTANT!

The PV modules connected to the inverter must comply with the IEC

61730 Class A standard.

IMPORTANT!

Solar module strings must not be

earthed.

Permitted cables The temperature resistance of the DC cables must be at least 90 °C.

51

DC connections

Select sufficiently high cable cross sections depending on the device type!

Power category Device type Cable cross section

Tauro 50-3 / Eco 50-3 /

Eco 99-3 / Eco 100-3

pre-combined

direct

25 - 95 mm

2,5 - 10 mm² (see

data sheet for con-

nector)

2

DC fuse protection - pre-combined

CAUTION!

Risk of damage to the inverter as the result of incorrectly fused PV lines.

PV lines for the "pre-combined" model that are not fused can cause damage to

the inverter.

PV lines must be fused in a combiner box before the inverter ("pre-com-

▶

bined" version).

52

Example of

PV 1.1 PV 1.2 PV 1.n

* SPD

PV 1

breaker

* DC

PV 2.1 PV 2.2 PV 2.n

* SPD

PV 2

breaker

* DC

PV 1 PV 2

... ...

Combiner Box

GAK

-F1.1.1

-F1.1.2

-F1.2.1

-F1.2.2

-F1.n.1

-F1.n.2

-F2.1.1

-F2.1.2

-F2.2.1

-F2.2.2

-F2.n.1

-F2.n.2

* Fuses

* Fuses

Fronius Tauro

Eco 50-3-P /

99-3-P / 100-3-P

combiner box

EN

* DC fuse optional depending on national standard / DC breaker optional / DC SPD optional

53

Example Fronius

PV 1.1 PV 1.2 PV 1.n

* SPD

PV 1

breaker

* DC

PV 2.1 PV 2.2 PV 2.n

* SPD

PV 2

breaker

* DC

PV 3.1 PV 3.2 PV 3.n

* SPD

PV 3

breaker

* DC

PV 1 PV 2 PV 3

... ... ...

Combiner Box

GAK

-F1.1.1

-F1.1.2

-F1.2.1

-F1.2.2

-F1.n.1

-F1.n.2

-F2.1.1

-F2.1.2

-F2.2.1

-F2.2.2

-F2.n.1

-F2.n.2

-F3.1.1

-F3.1.2

-F3.2.1

-F3.2.2

-F3.n.1

-F3.n.2

* Fuses

* Fuses

* Fuses

Tauro 50-3-P

combiner box

Distribution of

the solar module

strings for the

direct version

* DC fuse optional depending on national standard / DC breaker optional / DC SPD optional

Divide the existing solar module strings evenly between the PV inputs (PV1 /

PV2 / PV3) of the inverter.

Start with the odd inputs first and only then fill up the even inputs to divide the

power as evenly as possible and extend the service life of the fuses, e.g.: (1.1, 2.1,

3.1, 1.3, 2.3...)

54

Connecting PV

cables - MC4

connector

1

Connect the PV cables from the solar

modules to the MC4 connectors as la-

EN

belled

Unused MC4 connectors on the inverter must be covered with the cover

plates supplied with the inverter.

MC4 connector

cover

To protect the MC4 connectors, a cover plate can be mounted on the inverter.

The cover plate can be ordered as an optional accessory together with the floor

racks.

55

Connecting PV

cables - Precombined

Solar module strings that are combined in a DC combiner box, must, according

to the applicable national regulations, be fused per string in the DC combiner

box!

Before working in the connection area of the inverter, the DC

voltage must be switched off. This can also be done in the DC

combiner box.

1 2

3 4

56

5 6

7 8

EN

Connecting

cables with a

cable lug

Alternatively, a cable with a cable lug can be connected to the M12 threaded

bolts on the grid connections in order to connect the cables to the V-type terminals.

57

Replacing the

string fuses

CAUTION!

Danger due to faulty fuses.

This can lead to fires.

Only replace faulty fuses with new ones of the same rating.

▶

Do not replace faulty fuses with bolts.

▶

CAUTION!

Danger due to incorrectly dimensioned string fuses

Incorrectly dimensioned string fuses can cause damage to the inverter for these

connected components.

The following string fuses should be used for the -D (direct) version of the Fronius Tauro:

Max. 10 A per string → use of 15 A gPV fuse 1000 V possible (Fronius item

▶

number: 41,0007,0230 - fuse 15 1000 F PV 15A)

Max. 14.5 A per string → use of 20 A gPV fuse 1000V required (Fronius item

▶

number: 41,0007,0233 - fuse-HL 20A 1KV fast)

Max. 22 A per string → use of 30 A gPV fuse 1000V required (Fronius item

▶

number: 41,0007,0241 - fuse-HL 30A 1KV fast)

Replacing fuses:

Fronius Tauro 50-3-D string 1.1 - 3.7 /

Fronius Tauro 50-3-D (30A fuses) string 1.1 - 3.5 /

Fronius Tauro Eco 50-3-D string 1.1 - 2.7 /

Tauro Eco 50-3-D (30A fuses) string 1.1 - 2.5 /

Fronius Tauro Eco 99 / 100-3-D string 1.1 - 2.7 /

Fronius Tauro Eco 99 / 100-3-D (30A fuses) string 1.1 - 3.5

Check values! Only replace faulty fuses with new ones of the same rating.

1

58

Replacing fuses:

Fronius Tauro Eco 99 / 100-3-D string 3.1 - 3.8

Check values! Only replace faulty fuses with new ones of the same rating.

1 2

3 4

EN

5

59

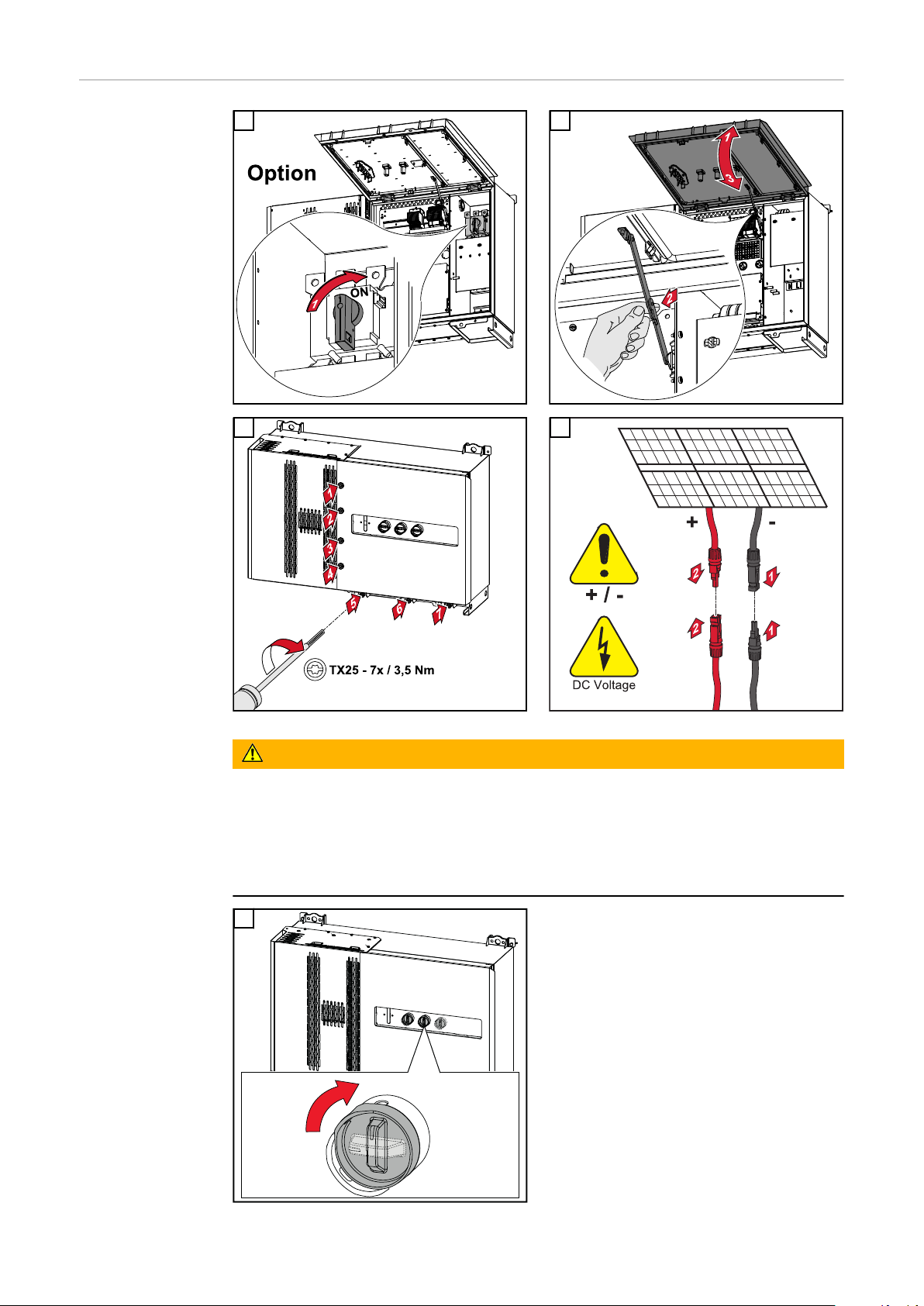

Closing and

OFF

ON

2

2-3x

switching on the

inverter

1 2

3 4

WARNING!

Danger due to DC disconnectors that are not switched on properly

This can result in serious injury and damage to property.

Turn all existing DC disconnectors to the ON position before turning on the

▶

AC connection.

The DC disconnectors may only ever be actuated simultaneously (one imme-

▶

diately after the other).

5

The WLAN access point can be opened

with the optical sensor, see chapter

Button functions and LED status indicator on page 26

60

AC~

ON

1

6

EN

61

Connecting the data communication cable

Modbus participants

The inputs M0 and M1 can be freely selected. A maximum of 4 Modbus participants can be connected to the Modbus terminal on inputs M0 and M1..

IMPORTANT!

If the function „Inverter control via Modbus“ is activated in the menu area

„Communication“ → „Modbus“, no Modbus participants are possible. It is not

possible to send and receive data at the same time.

Permitted cables

for the data

Cables with the following design can be connected to the terminals of the inverter:

communication

area

Copper: round, solid

-

Copper: round, fine-stranded

-

WSD connections with push-in terminal

Distance

max.

Stripping

length

Solid

Fine-stran-

ded

Fine-stran-

ded with fer-

rules with

collar

Fine-stran-

ded with fer-

rules

without col-

lar

Cable re-

commenda-

tion

100 m

10 mm

0.14 - 1.5

2

mm

Modbus connections with push-in terminal

Distance

max.

300 m

Stripping

length

10 mm

Solid

0.14 - 1.5

2

mm

Fine-stran-

IO connections with push-in terminal

Distance

max.

30 m

Stripping

length

10 mm

Solid

0.14 - 1.5

2

mm

Fine-stran-

0.14 - 1.5

2

mm

ded

0.14 - 1.5

2

mm

ded

0.14 - 1.5

2

mm

0.14 - 1 mm

Fine-stran-

ded with fer-

rules with

collar

0.14 - 1 mm

Fine-stran-

ded with fer-

rules with

collar

0.14 - 1 mm

0.14 - 1.5

2

mm

Fine-stran-

ded with fer-

rules

without col-

0.14 - 1.5

2

mm

Fine-stran-

ded with fer-

rules

without col-

0.14 - 1.5

2

mm

lar

lar

2

UTP

Cable re-

commenda-

tion

min. CAT 5

min. CAT 5

2

STP

Cable re-

commenda-

tion

Single con-

2

ductor pos-

sible

62

LAN connections

Fronius recommends at least CAT 5 STP (Shielded Twisted Pair) cables and a maximum distance of

100 m.

Multiple inverters in one net-

The network cabling of the inverters must be in a star arrangement. Observe the

maximum lengths and requirements for the cable!

work

EN

Routing data

communication

cables

To use the connection to Fronius Solar.web or Modbus TCP, each Tauro must be

connected directly to the network via LAN.

IMPORTANT! If data communication cables are wired into the inverter, observe

the following points:

Depending on the number and cross section of the wired data communica-

-

tion cables, remove the corresponding blanking plugs from the sealing insert

and insert the data communication cables.

Make sure that you insert the corresponding blanking plugs into any free

-

openings on the sealing insert.

Note! Should the blanking plugs be missing or improperly fitted, then protection

class IP65 cannot be guaranteed.

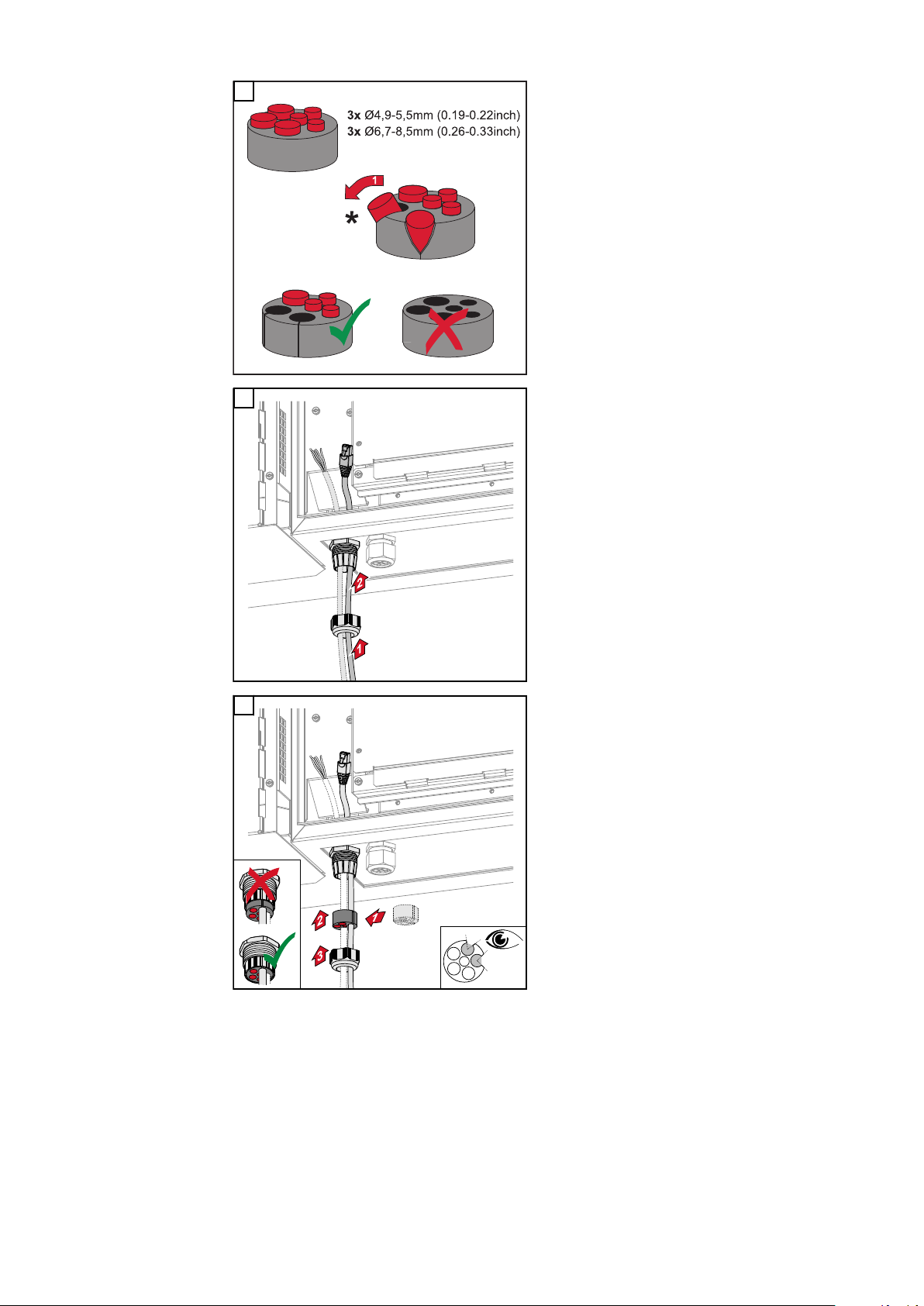

1

Undo the strain-relief device cap nut

and push out the sealing ring and the

blanking plug from the inside of the

device.

63

2

Open up the sealing ring at the location where the blanking plug is to be

removed.

* Liberate the blanking plug by moving

it sideways.

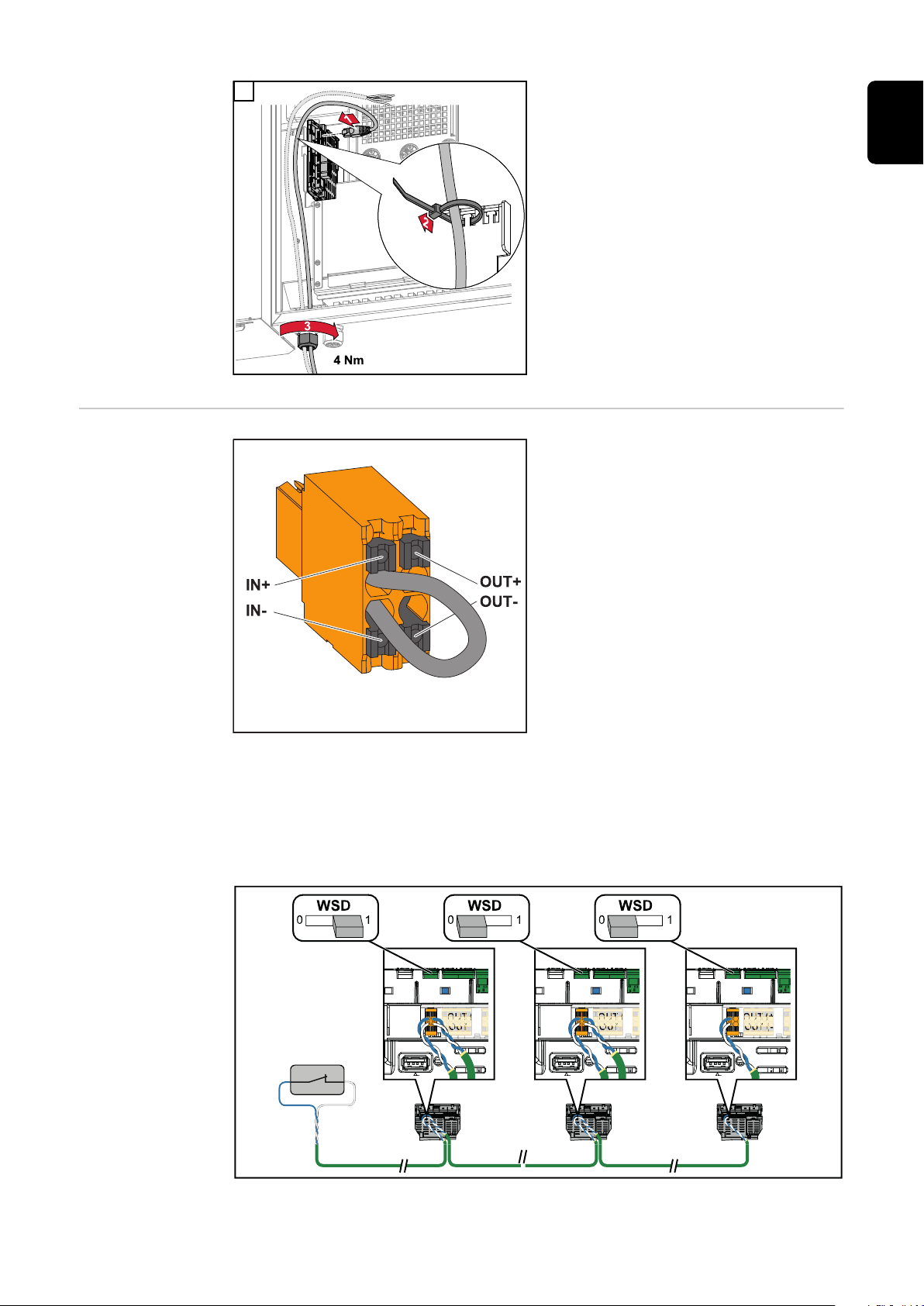

3

Guide the data cables first through the

strain-relief device cap nut and then

through the housing opening.

4

Insert the sealing ring between the cap

nut and the housing opening. Press the

data cables into the seal's cable guide.

Then press in the seal until it reaches

the underside of the strain-relief

device.

64

5

IN (+)

IN (-)

OUT (+)

OUT (-)

IN (+)

IN (-)

OUT (+)

OUT (-)

IN (+)

IN (-)

OUT (+)

OUT (-)

CAT 5/6/7

*

Connect the data cables to the data

communication area using a movement

loop, and fasten the cap nut with min.

EN

2.5 to max. 4 Nm.

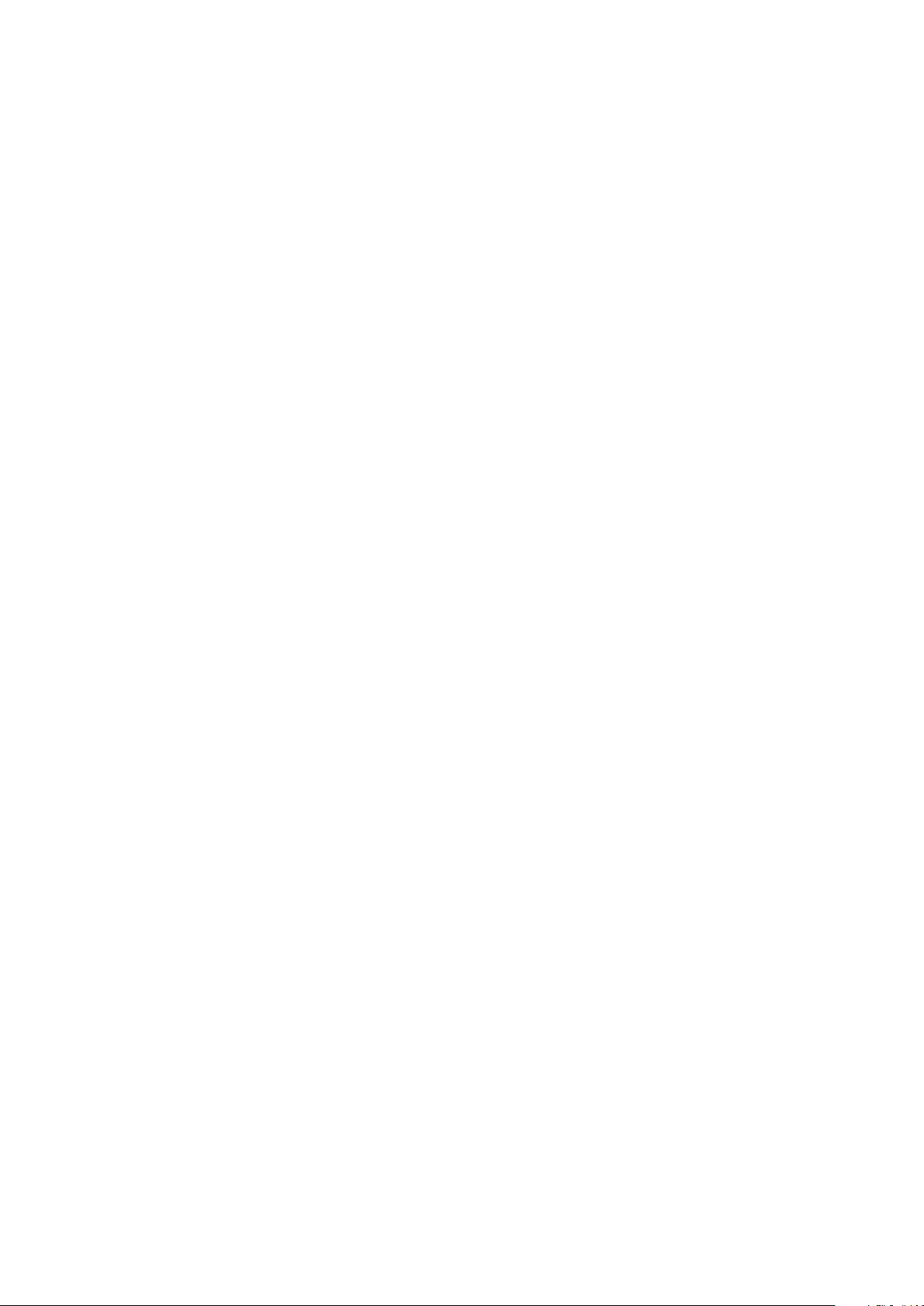

WSD (wired

shutdown)

IMPORTANT!

The push-in WSD terminal in the inverter's connection area is delivered

with a bypass ex works as standard.

The bypass must be removed when installing a trigger device or a WSD

chain.

The WSD switch of the first inverter with connected trigger device in the WSD

chain must be in position 1 (primary device). The WSD switch of all other inverters should be in the 0 (secondary device) position.

Max. distance between two devices: 100 m

Max. number of devices: 28

65

* Floating contact of the trigger device (e.g. central grid and system protection).

If several floating contacts are used in a WSD chain, they must be connected in

series.

66

Using for the first time

1 2

open access point

Setup your PV system in a few minutes.

START INSTALLATION

LOGIN

Log in with your Fronius credentials (email adress

& password) in order to get the most out of the

PV System. Installing a new product does not

require a Login.

Imprint & Contact Terms & ConditionsData Privacy

Fronius Solar.start

EN

Starting the inverter for the

first time

Fronius system

monitoring (Pilot) display

When starting the inverter for the first time, various setup settings must be configured.

If the setup process is cancelled before the process is complete, any data that

has been input up to this point is lost and the start screen with the installation

wizard is shown again. If the process is interrupted, such as in the event of a

power outage, the data is saved. Commissioning may be continued from the point

at which the process was interrupted once the power supply has been restored. If

the setup was interrupted, the inverter feeds energy into the grid at maximum

500 W and the operating status LED flashes yellow.

The country setup can only be set when starting the inverter for the first time. If

the country setup needs to be changed at a later date, please contact your installer / Technical Support team.

To simplify the display, the vertical installation position of the Pilot pc board

(LED display) is shown horizontally below.

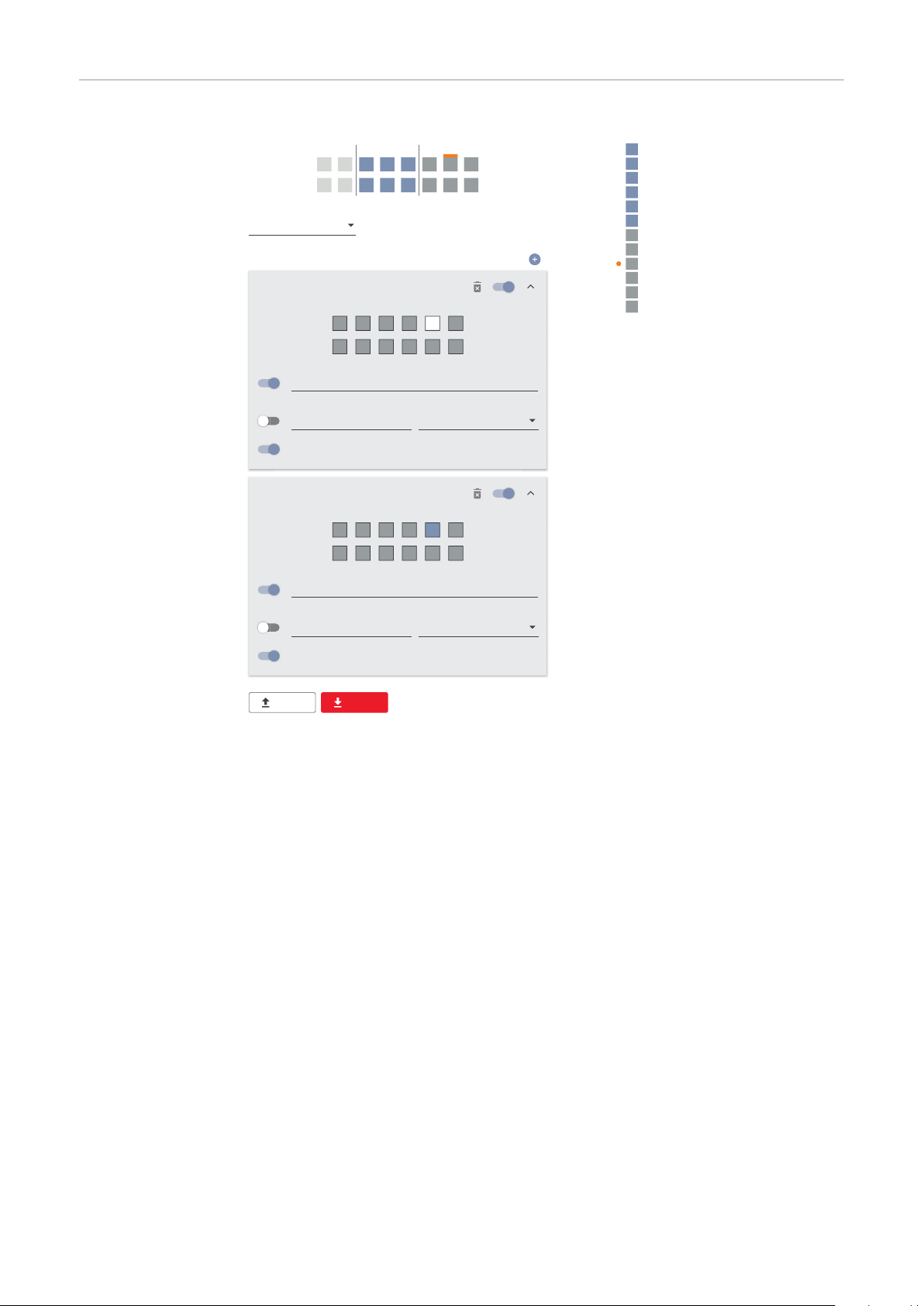

Installation with

the app

The "Fronius Solar.start" app is required for this installation method. Depending

on the end device with which the installation will be carried out, download the

app for the respective platform.

Start the installation in the app.

1

Select the product to which the connection should be established.

2

3

Open the access point by touching the sensor once → Communication LED:

flashes blue.

Follow and complete the installation wizard in the individual sections.

4

Add system components in Solar.web and start up the PV system.

5

67

The network wizard and the product setup can be carried out independently of

open access point

1

FRONIUS_PILOTxxx

Secured

Password:

12345678

2

192.168.250.181

169.254.0.180

21

open access point

each other. A network connection is required for the Solar.web installation wizard.

Installation using the web

browser

WLAN:

1

Open the access point by touching the sensor once → Communication LED:

flashes blue.

Establish the connection to the inverter in the network settings (the inverter

2

is displayed with the name "FRONIUS_PILOT" and the serial number of the

device).

Password: enter 12345678 and confirm.

3

IMPORTANT!

To enter the password on a Windows 10 operating system, the link "Connect

using a security key instead" must first be activated to establish a connection

with the password: 12345678.

In the browser address bar, enter and confirm the IP address

4

192.168.250.181. The installation wizard is opened.

Follow the installation wizard in the individual sections and complete the in-

5

stallation.

Add system components in Solar.web and start up the PV system.

6

The network wizard and the product setup can be carried out independently of

each other. A network connection is required for the Solar.web installation wizard.

Ethernet:

Establish a connection to the inverter (LAN1) with a network cable (CAT5

1

STP or higher).

2

Open the access point by touching the sensor once → Communication LED:

flashes blue.

In the browser address bar, enter and confirm IP address 169.254.0.180. The

3

installation wizard is opened.

Follow the installation wizard in the individual sections and complete the in-

4

stallation.

Add system components in Solar.web and start up the PV system.

5

68

The network wizard and the product setup can be carried out independently of

each other. A network connection is required for the Solar.web installation wizard.

EN

69

Switching off current supply and restarting the

inverter

De-energising

the inverter and

switching it on

again

Turn off the automatic circuit

1

1.

breaker.

Turn the DC disconnector to the

2.

"Off" switch position.

To start up the inverter again, follow

the steps listed above in reverse order.

70

Settings - user interface of the in-

verter

71

72

User settings

EN

User login

Selecting the

language

Open the user interface of the inverter in your browser.

1

In the "Login" menu, log in using your user name and password, or go to the

2

"User" menu and click on the "User login" button and then log in with your

user name and password.

IMPORTANT!

Depending on the user's authorization, settings can be executed in the individual

menus.

In the “User” menu, click on the “Language” button and select the desired

1

language.

73

Device configuration

Components Select "Add component+" to add all available components to the system.

PV generator

Activate the particular PV generator and enter the connected PV power in the

associated field.

Primary meter

To ensure smooth operation in conjunction with other energy producers, it is important to install the Fronius Smart Meter at the feed-in point. The inverter and

other producers must be connected to the public grid via the Fronius Smart

Meter.

This setting also affects how the inverter behaves overnight. If the function is deactivated, the inverter switches to standby mode as soon as there is no more PV

power available. The message "Power low" is displayed. The inverter starts again

as soon as sufficient PV power is available.

After connecting the meter, the position must be configured.

Several Fronius Smart Meters can be installed in the system. A different address

needs to be set for each Smart Meter.

The Watt value on the generator meter is the sum of all generator meters. The

Watt value on the consumption meter is the value of all consumption meters.

Functions and

IOs

Ohmpilot

All Ohmpilots available in the system are displayed. Select the desired Ohmpilot

and add it to the system via “Add”.

Load management

Up to four pins can be selected here for load management. Other load management settings are available in the Load Management menu item.

Default: Pin 1

OFF - Demand Response Mode (DRM)

The pins for control via DRM can be set here:

De-

fault

Mode Description Information

DRM0 Inverter disconnects itself

from the grid

REF GEN RG0

COM LOAD CL0

Open grid relay

pin

74

DRM0 occurs if there is an interruption or short circuit on

the REF GEN or COM LOAD

leads. Or if the combinations

DRM1 - DRM8 are invalid.

IMPORTANT!

If the Demand Response Mode (DRM) function is enabled and no DRM control is

connected, the inverter switches to Standby mode.

EN

"PSC editor AUS - Demand

Response Modes

(DRM)"

Demand Response Modes

(DRM)

Inverter "Enforce Standby"

A value for the apparent power consumption and apparent power output can be

entered here for the Australia country setup.

Here you can enter a value for the apparent power input and the apparent power

output for the Australia country setup.

When the function is activated, the feed-in mode of the inverter is interrupted.

This enables a powerless shutdown of the inverter and protects its components.

When the inverter is restarted, the standby function is automatically deactivated.

"PV 1" and "PV 2"

Parameter Value range Description

"Mode" Off The MPP tracker is deactivated.

Auto The inverter uses the voltage at which the

max. possible power of the MPP tracker is

possible.

Fix The MPP tracker uses the voltage defined

in the "UDC fix".

"UDC fix" 80 ‑ 530 V The inverter uses the fixed preset voltage

used at the MPP tracker.

"Dynamic Peak

Manager"

"Ripple Control"

Ripple control signals are signals sent out by the energy company to switch controllable loads on and off. Depending on the installation situation, ripple control

signals may be attenuated or amplified by the inverter. The settings below can be

used to counteract this if necessary.

Parameter Value range Description

"Reduction of

Influence"

"Frequency of

Ripple Control

Signal"

Off The function is deactivated.

On The entire solar module string is checked

for optimisation potential and determines

the best possible voltage for feed-in mode.

Off The function is deactivated.

On The function is activated.

100 ‑ 3000 Hz The frequency specified by the energy

company must be entered here.

"Grid Inductance"

0.00001 ‑ 0.00

5 H

The value measured at the feed-in point

must be entered here.

75

"Measures against RCD/RCMU false trips"

(when using a 30 mA residual current circuit breaker)

Parameter Value range Description

"Inverter shutdown before

30 mA RCD

trips"

"Iso Warning"

Parameter Value range Description

"Iso Warning" Off The isolation warning is deactivated.

"Iso Alternative

Mode"

"Isolation

Warning

Threshold"

0 No measures to prevent false tripping.

1 The inverter switches off at 15 mA before

the residual current circuit breaker trips.

On The isolation warning is activated.

A warning is issued in the event of an isolation fault.

Accurate Isolation monitoring is performed with the

highest accuracy and the measured insulation resistance is displayed on the user interface of the inverter.

Fast Isolation monitoring is performed with

lower accuracy, which shortens the duration of the isolation measurement, and the

isolation value is not displayed on the user

interface of the inverter.

10 ‑

10,000 kΩ

If this threshold is undershot, status code

1083 is displayed on the user interface of

the inverter.

76

System

General General settings

In the "System name" input field, enter the name of the system (max. 30

1

characters).

"Synchronize time automatically" enabled → select "Area time zone" and

2

"Location time zone". The date and time are applied from the time zone

entered.

"Synchronize time automatically" disabled → enter or select "Date", "Time",

2