Page 1

/ Perfect Charging / Perfect Welding / Solar Energy

FIND YOUR

FIND YOUR

OPERATING MANUALS

OPERATING MANUALS

www.fronius-usa.com/inverter-manuals

www.fronius.com/energy-package-manuals

Fronius Symo Hybrid

with external battery

Installations instructions

EN

System monitoring

42,0426,0303,EN 015-12082019

Page 2

2

Page 3

Contents

Connecting the external battery to the Fronius Symo Hybrid .................................................................... 5

Components.......................................................................................................................................... 5

Fronius Checkbox 500V........................................................................................................................ 5

External battery..................................................................................................................................... 5

Fronius Checkbox 500V technical data ................................................................................................ 6

Fronius Checkbox 500V status LED ..................................................................................................... 6

Installing the Fronius Symo Hybrid with the external battery ..................................................................... 7

Tips before commissioning ................................................................................................................... 7

Commissioning .................................................................................................................................... 7

Maximum clearances between the components .................................................................................. 7

Modbus cabling and terminating resistors ............................................................................................ 8

Data cables in the third-party battery .................................................................................................... 8

Installing the Fronius Checkbox................................................................................................................. 9

Safety.................................................................................................................................................... 9

Mounting and connecting up the Fronius Checkbox 500V ................................................................... 10

Installing the ferrite ring for the data line............................................................................................... 10

Installing and configuring Fronius system monitoring ................................................................................ 11

Safety.................................................................................................................................................... 11

Starting for the first time........................................................................................................................ 11

Information to help you work through the technician wizard ................................................................. 13

Software version of the Fronius system monitoring ..............................................................................14

Updating the firmware via the Web....................................................................................................... 15

Performing a third-party battery software update.................................................................................. 15

Fronius system monitoring settings ........................................................................................................... 17

Settings on the Fronius system monitoring website..............................................................................17

Creating IO mapping............................................................................................................................. 17

System monitoring settings................................................................................................................... 17

Troubleshooting ......................................................................................................................................... 18

Troubleshooting .................................................................................................................................... 18

EN

3

Page 4

4

Page 5

Connecting the external battery to the Fronius Symo

Hybrid

Components

Solar module

Generates direct current

Inverter – Fronius hybrid

Converts the direct current into alternating current and charges the battery.

Thanks to the built-in system monitoring function, the inverter can be integrated into a network using WLAN technology.

Fronius Checkbox 500V

Needed to establish a secure connection between the inverter and the battery.

CHECKBOX 500V

Third-party battery

Connected on the DC side to the Checkbox and the inverter and stores

electrical energy.

Photovoltaic system consumers

The consumers connected to the PV system (single or three-phase)

EN

Fronius Checkbox 500V

Meter – Fronius Smart Meter

For optimum energy management. You can have the meter installed in a

switch cabinet by your electrical installer.

Grid

The Fronius Checkbox 500V connects the Fronius Symo Hybrid to an external battery. The

inverter and battery must never be directly connected to each other, as an error could lead

to surges that place the system in an unsafe state.

There are separate Installation Instructions for the battery and the Fronius Symo Hybrid.

This document is concerned only with the specifics of establishing a connection to the Fronius Checkbox 500V. The remaining steps for installing the equipment can be found in the

respective Installation Instructions. All Fronius documents are available at the following address: www.fronius.com/energy-package-manuals

External battery Fronius points out that the external batteries are not Fronius products. Moreover, Fronius

is not the distributor of these batteries. Therefore, Fronius does not assume any liability or

guarantee for these batteries.

5

Page 6

Fronius Checkbox 500V technical data

Environmental conditions

Degree of protection IP65

Permissible ambient temperature -25 °C - +60 °C

Maximum altitude 2000 m

Permitted humidity 0 - 100% (non-condensing)

Electrical specifications

Maximum input voltage

Inverter side

Battery side

Maximum current Idc max in / max out 16 A

Self-consumption @ 450 V 1.9 W

Dimensions and weight

Dimensions h x w x d (without packaging) 26 x 19 x 7.5 cm

Weight (without packaging) 1.4 kg

Dimensions h x w x d (with packaging) 36 x 30 x 13 cm

Weight (with packaging) 1.9 kg

Standards and directives

Applicable standards and directives LVD (2014/53/EU), IEC 62109-1

Udc max in_INV

Udc max out_BAT

1000 V

500 V

Fronius Checkbox 500V status

LED

When the status LED lights up green, an electrical connection has been

established between the inverter and the battery.

6

Page 7

Installing the Fronius Symo Hybrid with the external

battery

Tips before commissioning

Commissioning

EN

It can take up to two hours to update the inverter. During this time the inverter must be connected to an AC power source. To save time during installation, work may still be carried

out in a non-live area of the system while the update is in progress.

More information on the update process can be found under "Software version of the

Fronius system monitoring" on page 14

IMPORTANT!

Failure to follow these steps in the correct order will not only invalidate the warranty,

but also risks a deep discharge of the battery.

IMPORTANT!

If the installation cannot be completed in one attempt, precautions must be taken to

prevent a deep discharge of the battery (see the battery Installation Instructions).

Maximum clearances between

the components

Observe the enclosed complete circuit diagram for the entire system during commissioning.

Set up the entire system in the following order:

1. Install the inverter (Fronius Hybrid series)

2. Install the Fronius Smart Meter

3. Install the Fronius Checkbox and external battery

(for more information on installing the Fronius Checkbox, see section Installing the

Fronius Checkbox on page 9)

4. Launch and complete the Setup wizard (wizard on the inverter)

5. Configure communication between the battery and the inverter

6. Carry out a function test

max. 1 m max. 9 m

7

Page 8

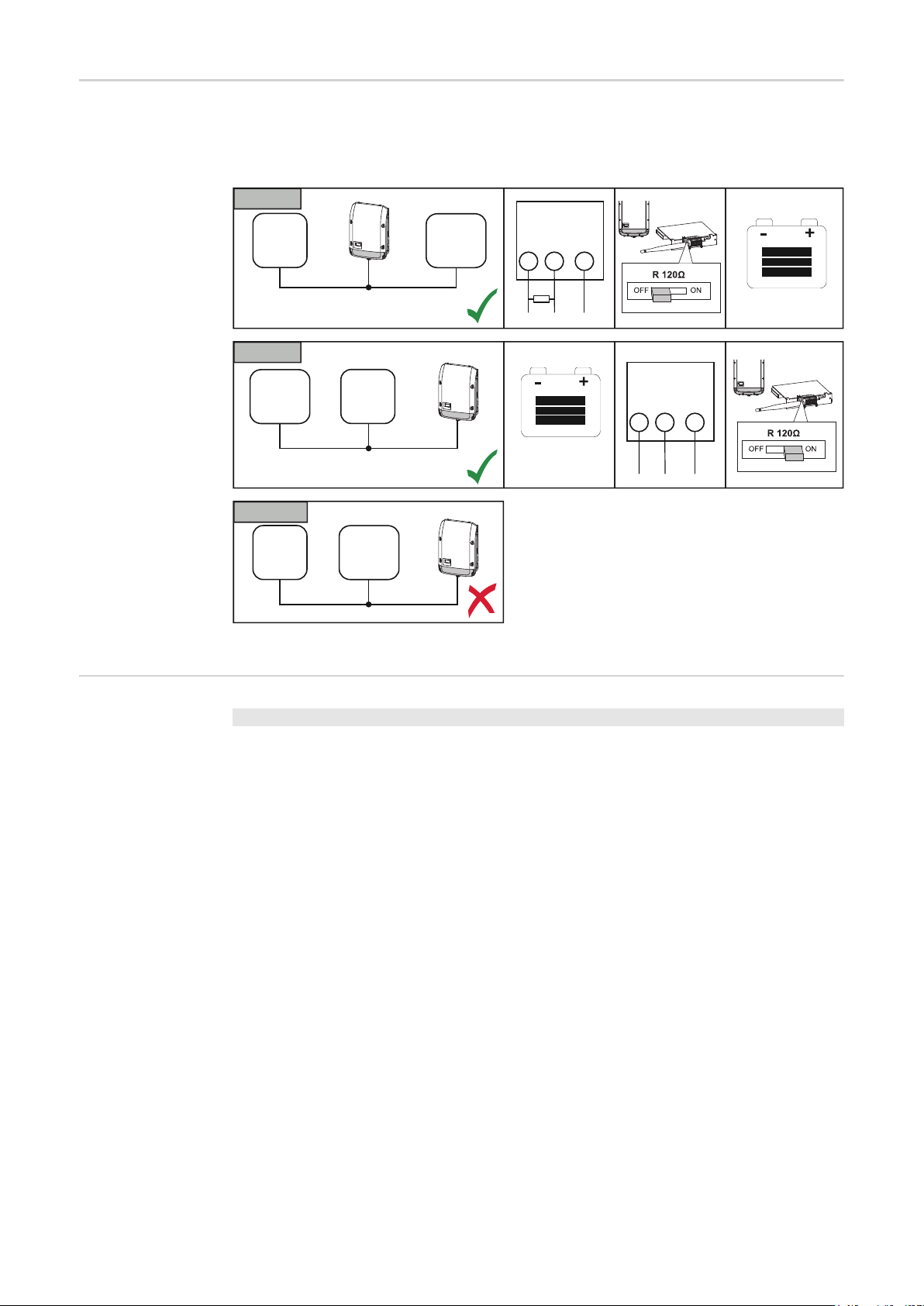

Modbus cabling

OPTION 1

NO OPTION

OPTION 2

and terminating

resistors

A terminating resistor must be used on the outer components of the Modbus cabling. The

location of the terminating resistor on the external battery is fixed, meaning that the battery

cannot be installed in the middle of the Modbus.

OPTION 1

Fronius

Smart

Meter

OPTION 2

Battery

Battery

Data (Recommended cable:

Li2YCY(TP) or CAT6a)

Fronius

Smart

Meter

OUTPUT

RS 485

D+ / D- -

33 34 35

120 Ω

*)

OUTPUT

RS 485

D+ / D- -

33 34 35

Data (Recommended cable:

Li2YCY(TP) or CAT6a)

NO OPTION

Fronius

Smart

Meter

*) The R 120 Ohm terminating resistor is supplied with the Fronius Smart Meter

Battery

Data cables in the

third-party battery

LG Chem ResuH Fronius Symo Hybrid Fronius Smart Meter

EN GND - (GND) C

ENABLE_H IO 1

RS485_L D- B

RS485_H D+ A

8

Page 9

Installing the Fronius Checkbox

EN

Safety

WARNING!

Operating the equipment incorrectly or poor workmanship can cause serious injury

or damage.

Commissioning of the hybrid system may only be carried out by trained personnel in accordance with the technical regulations. Read the Installation Instructions and the Operating Instructions of the Fronius Symo Hybrid and the battery before carrying out any

installation or commissioning work.

WARNING!

An electric shock can be fatal.

Danger due to DC voltage from the inverter and the battery.

► Always make sure the inverter is disconnected and de-energised before carrying out

any connection work.

► Check that the battery is de-energised. The battery should be de-energised when it is

delivered.

► Only an authorised electrical engineer is permitted to connect this equipment to the

public grid.

IP65

NH

3

Possible assembly positions when using outdoors:

> 2000 m

2000 m

0 m

9

Page 10

Mounting and

6 mm

connecting up the

Fronius Checkbox 500V

NOTE!

Risk of damage to the device.

Do not mix up the DC connections of the battery and the inverter.

Observe the enclosed complete circuit diagram when connecting up the Fronius checkbox.

Mount the supplied mounting bracket to the wall using suitable screws and wall plugs

1

Attach the Fronius Checkbox, push it down, and secure using the screw supplied

2

1 2

3

4

only original MC4

Installing the ferrite ring for the

data line

min 4 mm²

2

1

4

3

min 2,5 mm²

double insulated

-

1

1000 V

+

2

3

4

+

-

The data line between the inverter and the battery must be fitted with a ferrite ring as close

as possible to each of the two terminal connections in order to avoid electromagnetic interference.

One ferrite ring is supplied with the Fronius Symo Hybrid and one is supplied with the Fronius Checkbox (Würth ferrite ring - item number: 74271132S).

Fit a ferrite core to the data line ahead of the terminal connection in the inverter

1

Remove the insulation from the data line ahead of the battery terminal connection and

2

loop the line through the ferrite core twice

10

Page 11

Installing and configuring Fronius system monitoring

Safety

Starting for the

first time

EN

WARNING!

Danger from incorrect operation

This can result in severe personal injury and damage to property.

► Do not use the functions described here until you have fully read and understood the

Operating Instructions of every system component:

► Do not use the functions described here until you have read and understood all the

safety rules.

IMPORTANT! Knowledge of networking systems is required in order to install Fronius system monitoring.

IMPORTANT! Starting up the Fronius system monitoring function for the first time is made

considerably easier with the Fronius Solar.web app. The Fronius Solar.web app is available in the respective app stores.

Or visit

https://wizard.solarweb.com

IMPORTANT! In order to establish a connection to Fronius system monitoring, the end device in question (e.g. laptop, tablet, etc.) must be set up as follows:

- "Obtain IP address automatically (DHCP)" must be activated

Switch the device to Service mode

1

- Activate the WLAN Access Point via the Setup menu on the inverter

Standby

WiFi Access Point

Relay

Clock

Relay

Display Setting

The inverter establishes the WLAN access point. The WLAN access point remains open

for 1 hour.

11

Page 12

Installation using the Solar.web app Installation using a web browser

Download the Fronius Solar.web App

2

Run the Fronius Solar.web app

3

The Setup wizard start page is displayed.

Connect the end device to the WLAN

2

access point

SSID = FRONIUS_239.xxxxx (4-8

digits)

- Search for a network with the

name "FRONIUS_239.xxxxx"

- Establish a connection to this

network

- Enter the password 12345678

(Alternatively, connect the end device

and inverter using an Ethernet cable.)

Enter the following in the browser:

3

http://datamanager

or

192.168.250.181 (IP address for

WLAN connection)

or

169.254.0.180 (IP address for LAN

connection)

12

If you run the technician wizard, always remember to make a note of the assigned service

password. This service password is required to enter settings in the "System overview" and

"DNO Editor" menus as well as for advanced battery settings.

If the technician wizard is not run, no specifications regarding power reduction are set and

hybrid mode is not possible (charging and discharging of the battery)

Run the technician wizard and follow the instructions

4

Page 13

IMPORTANT!

Information to

help you work

through the technician wizard

Danger of deep discharge of an unactivated battery

This may result in permanent damage to the battery.

► The Solar Web wizard needs to be run in order to activate the battery and, if necessary,

the Smart Meter.

Run the solar web wizard and follow the instructions

5

The Fronius Solar.web homepage

or

the Fronius system monitoring web page is displayed.

The description below only applies to technician wizards for inverters with software version

1.9.x-x or higher. Thus, IO and battery mapping are not possible. Only once the software

has been updated (see "Updating the firmware via the Web" on page 15) can the settings be changed in the web interface under "IO mapping" (see "Creating IO mapping" on

page 17) and "System overview" (see "System monitoring settings" on page 17).

The technician wizard consists of 5 steps:

1. General

General system data (e.g. system name) is entered here

EN

2. Service password

Enter (and make a note of) the service password.

13

Page 14

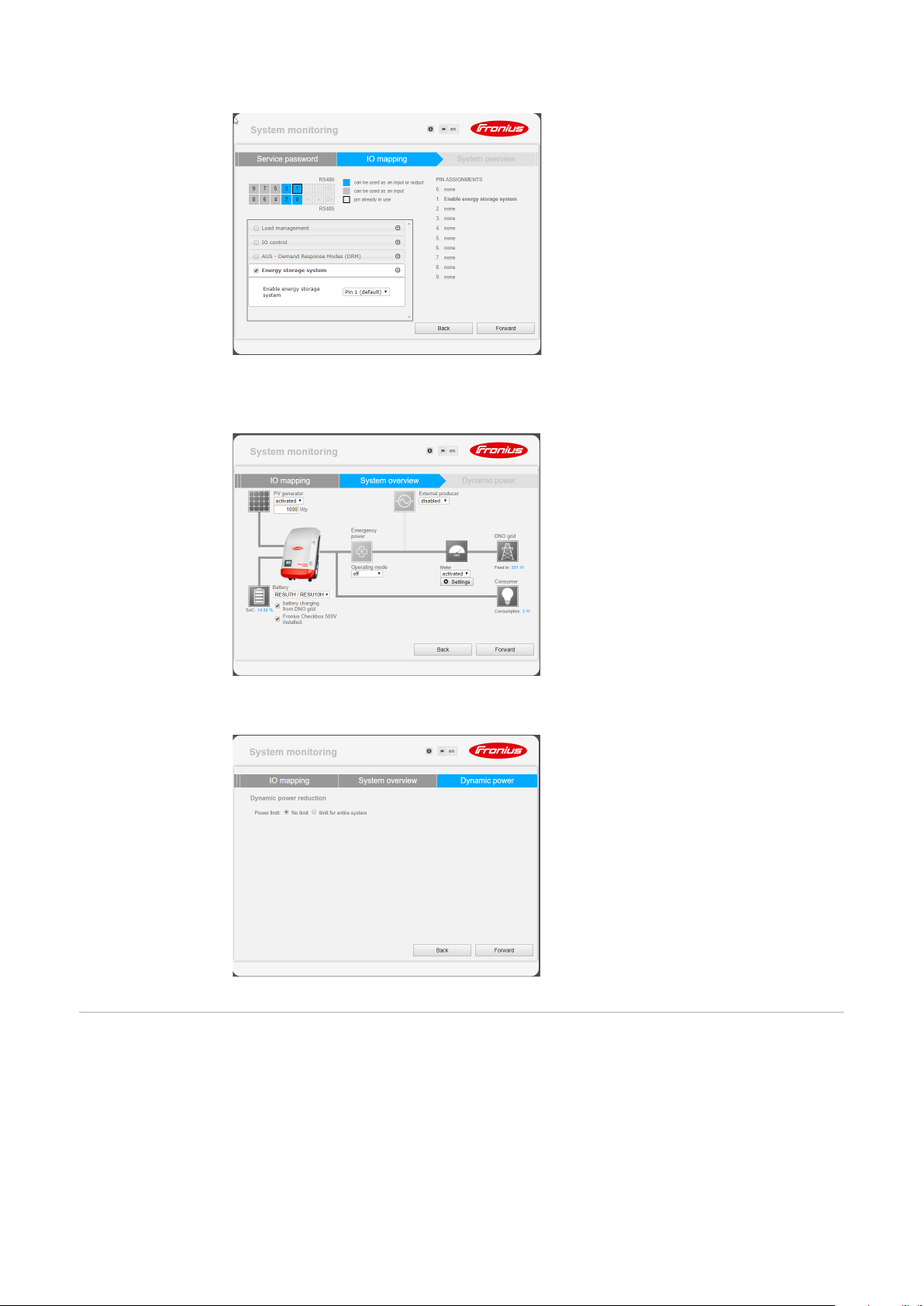

3. IO mapping

Settings for the IO interface are entered (also see Creating IO mapping on page 17)

4. System overview

Settings for the entire PV system are entered (see also System monitoring settings on

page 17)

Software version

of the Fronius

system monitoring

5. Dynamic power

Enter the settings for the dynamic power reduction

Software version 1.9.x-x or higher is required to support third-party batteries. There must

be an internet connection for the duration of the update process. The current version of the

system monitoring software can be viewed by clicking on the info symbol:

14

Page 15

Regardless of the software version shown in the web interface, it may take several update

steps before the software is updated to the latest version. Both the inverter and the battery

can be updated at the same time.

EN

Updating the firmware via the Web

Performing a

third-party battery software update

Use your web browser to open the Fronius system monitoring web page.

1

Open “Firmware update” under “Services”.

2

Select 'Update via Web'

3

Click the 'Run update' button.

4

A confirmation prompt for the update is displayed.

Click the 'Yes' button

5

The update is performed and progress is indicated in the form of a bar and as a percentage.

If the connection to the server fails:

- Deactivate the firewall for the amount of time required to complete the update.

- Try again.

IMPORTANT! If a proxy server is being used to establish the Internet connection:

- You must activate the “Use proxy server for Web update” option.

- You must enter the data required.

CAUTION!

Risk of damage to the battery! If the battery software update process is interrupted,

this may result in damage to the battery.

In order to avoid this, during the update:

► Do not switch off the inverter

► Do not switch off the battery

► Maintain the recommended state of charge (SoC) of over 50% on the battery

► Ensure a steady mains supply

► Ensure and do not interrupt Modbus communication

CAUTION!

Risk of damage to the battery! If, despite safety precautions, the update process is

still interrupted, follow the steps for turning off the battery as outlined by the thirdparty battery manufacturer and in the correct order. Then immediately consult the

third-party battery manufacturer

to avoid long-term damage. A battery in standby mode can become permanently damaged

in just a few days due to self discharge.

As soon as the battery software needs to be updated, a message will appear on the system

monitoring website.

Click the message stating that the battery software needs to be updated

1

15

Page 16

A page containing a variety of setting options appears.

2

Under "Update", select "Local" and click on "Run update"

The update will start and run to completion. This can take up to an hour.

3

Wait until the end of the update.

A message will appear stating that the update was successful.

4

Confirm the message by clicking "OK".

16

Page 17

Fronius system monitoring settings

EN

Settings on the

Fronius system

monitoring website

Creating IO mapping

If the battery is installed at a later date or the inverter was only updated to software version

1.9.x-x after the system had already been commissioned, several settings will need to be

changed on the system monitoring website. In the "IO mapping" section, a pin must be selected under "Energy storage system". The battery must be selected in the "System overview" area.

Enable "Energy storage system" under Settings - IO mapping. The pin assignment

1

must match the cabling.

System monitoring settings

Select "RESU7H / RESU10H" in the Battery field under Settings - System overview

1

Select "activated" in the Meter field. The meter position must be selected under Set-

2

tings depending on the installation (consumption branch or feed-in point)

If the Checkbox has been installed correctly, check the box next to "Fronius Checkbox

3

500V installed"

17

Page 18

Troubleshooting

Troubleshooting Battery is permanently in energy saving mode (error message 65000)

Behaviour The battery goes into energy saving mode and can no longer be activated by

the inverter

Remedy Check if the DC main switch on the battery has been switched on

Remedy Check if the DC main switch on the inverter has been switched on

Remedy Check the cabling between the inverter, Checkbox and battery

Remedy Restart the Datalogger (click the "Datalogger restart" button on the system

monitoring website under "System information") - the ON LED on the battery

goes green. When switching on, check that the green LED on the Checkbox

also comes on.

Remedy Using the display, place the inverter in standby mode for ten seconds - the ON

LED on the battery will go green. When switching on, check that the green

LED on the Checkbox also comes on.

18

Page 19

EN

19

Page 20

Other Languages

Deutsch

Deutsch www.fronius.com/QR-link/4204260303DE

English www.fronius.com/QR-link/4204260303EN

Ceština www.fronius.com/QR-link/4204260303CS

Italiano www.fronius.com/QR-link/4204260303IT

Français www.fronius.com/QR-link/4204260303FR

Español www.fronius.com/QR-link/4204260303ES

Dansk

Dansk www.fronius.com/QR-link/4204260303DA

Svensk www.fronius.com/QR-link/4204260303SV

Polski www.fronius.com/QR-link/4204260303PL

Português www.fronius.com/QR-link/4204260303PB

Magyar www.fronius.com/QR-link/4204260303HU

Türk www.fronius.com/QR-link/4204260303TR

English

Svensk

Ceština

Polski

Italiano

Português

Français

Magyar

Español

Türk

Slovenský

Slovenský www.fronius.com/QR-link/4204260303SK

Nederlands www.fronius.com/QR-link/4204260303NL

İȜȜȘȞȚțȐ www.fronius.com/QR-link/4204260303EL

Român www.fronius.com/QR-link/4204260303RO

Nederlands

İȜȜȘȞȚțȐ

Român

Fronius Worldwide - www.fronius.com/addresses

Fronius International GmbH

4600 Wels, Froniusplatz 1, Austria

E-Mail: pv-sales@fronius.com

http://www.fronius.com

Fronius USA LLC Solar Electronics Division

6797 Fronius Drive, Portage, IN 46368

E-Mail: pv-us@fronius.com

http://www.fronius-usa.com

8QGHUKWWSZZZIURQLXVFRPDGGUHVVHV\RXZLOO¿QGDOODGGUHVVHVRIRXUVDOHVEUDQFKHVDQGSDUWQHU¿UPV

Loading...

Loading...