Page 1

Operating

Instructions

Fronius Smart Meter TS 5kA-3

Operating Instructions

EN

42,0426,0348,EN 013-25052022

Page 2

Page 3

Contents

Safety rules 5

Safety rules 7

Explanation of safety notices 7

General 7

Environmental conditions 8

Qualified personnel 8

Copyright 8

Data protection 8

General information 9

Fronius Smart Meter TS 5kA-3 11

Device description 11

Information on the device 12

Intended use 12

Scope of supply 13

Positioning 13

Measuring accuracy 14

Installation 15

Installation 17

Checklist for installation 17

Installation 18

Protective circuit 18

Auxiliary power supply cabling 18

Cabling 19

Selection criteria for current transformer 21

Connecting the current transformers 22

Suitable voltage transformers 22

Connecting the data communication cable to the inverter 23

Terminating resistors - Explanation of symbols 23

Connecting the terminating resistor 24

Terminating resistors 24

Mounting the connection cover 26

Multi-meter system - Explanation of symbols 26

Modbus participants - Fronius SnapInverter 27

Multi-meter system - Fronius SnapINverter 27

Modbus participants - Fronius GEN24 28

Multi-meter system - Fronius GEN24 inverter 29

Menu - Measured variables 30

Configuration menu - structure and parameters 33

Setting the transformation ratio of the current and voltage transformers 34

Setting the address on the Fronius Smart Meter TS 35

EN

Start-up 37

Fronius SnapINverter 39

General 39

Connecting to the Fronius Datamanager 39

Configuring the Fronius Smart Meter TS as the primary meter 39

Configuring the Fronius Smart Meter TS as a secondary meter 40

Fronius GEN24 inverter 41

General 41

Installation using the web browser 41

Configuring the Fronius Smart Meter TS as the primary meter 42

Configuring the Fronius Smart Meter TS as a secondary meter 42

Technical data 44

Technical data 44

3

Page 4

Fronius manufacturer's warranty 46

4

Page 5

Safety rules

5

Page 6

6

Page 7

Safety rules

EN

Explanation of

safety notices

DANGER!

Indicates immediate danger.

If not avoided, death or serious injury will result.

▶

WARNING!

Indicates a potentially hazardous situation.

If not avoided, death or serious injury may result.

▶

CAUTION!

Indicates a situation where damage or injury could occur.

If not avoided, minor injury and/or damage to property may result.

▶

NOTE!

Indicates a risk of flawed results and possible damage to the equipment.

General The device has been manufactured in line with the state of the art and according

to recognized safety standards. If used incorrectly or misused, however, it can

cause:

Injury or death to the operator or a third party

-

Damage to the device and other material assets belonging to the operating

-

company.

All personnel involved in commissioning, maintenance, and servicing of the

device must:

Be suitably qualified

-

Have knowledge of and experience in dealing with electrical installations and

-

Have fully read and precisely followed these Operating Instructions

-

The Operating Instructions must always be at hand wherever the device is being

used. In addition to the Operating Instructions, attention must also be paid to

any generally applicable and local regulations regarding accident prevention and

environmental protection.

All safety and danger notices on the device:

Must be kept in a legible state

-

Must not be damaged

-

Must not be removed

-

Must not be covered, pasted or painted over

-

The terminals can reach high temperatures.

Only operate the device when all protection devices are fully functional. If the

protection devices are not fully functional, there is a danger of:

Injury or death to the operator or a third party

-

Damage to the device and other material assets belonging to the operating

-

company

7

Page 8

Any safety devices that are not fully functional must be repaired by an authorised specialist before the device is switched on.

Never bypass or disable protection devices.

For the location of the safety and danger notices on the device, refer to the section headed "General remarks" in the Operating Instructions for the device.

Any equipment malfunctions which might impair safety must be remedied before

the device is turned on.

This is for your personal safety!

Environmental

conditions

Qualified personnel

Operation or storage of the device outside the stipulated area will be deemed as

not in accordance with the intended purpose. The manufacturer accepts no liability for any damage resulting from improper use.

The servicing information contained in these operating instructions is intended

only for the use of qualified service engineers. An electric shock can be fatal. Do

not carry out any actions other than those described in the documentation. This

also applies to qualified personnel.

All cables and leads must be secured, undamaged, insulated and adequately dimensioned. Loose connections, scorched, damaged or inadequately dimensioned

cables and leads must be immediately repaired by authorised personnel.

Maintenance and repair work must only be carried out by an authorised specialist.

It is impossible to guarantee that bought-in parts are designed and manufactured to meet the demands made on them, or that they satisfy safety requirements. Use only original spare parts (also applies to standard parts).

Do not carry out any alterations, installations, or modifications to the device

without first obtaining the manufacturer's permission.

Components that are not in perfect condition must be changed immediately.

Copyright Copyright of these operating instructions remains with the manufacturer.

The text and illustrations are all technically correct at the time of printing. We

reserve the right to make changes. The contents of the operating instructions

shall not provide the basis for any claims whatsoever on the part of the purchaser. If you have any suggestions for improvement, or can point out any mistakes that you have found in the instructions, we will be most grateful for your

comments.

Data protection The user is responsible for the safekeeping of any changes made to the factory

settings. The manufacturer accepts no liability for any deleted personal settings.

8

Page 9

General information

9

Page 10

10

Page 11

Fronius Smart Meter TS 5kA-3

EN

Device description

The Fronius Smart Meter TS is a bidirectional electricity meter which optimises

self-consumption and records the household's load curve. In conjunction with

the Fronius inverter, Fronius Datamanager and Fronius data interface, the Fronius Smart Meter TS provides a clear overview of a user's own power consumption.

The meter measures the power flow to the loads or to the grid and forwards the

information via the Modbus RTU/RS485 communication to the Fronius inverter

and the Fronius Datamanager.

CAUTION!

Observe and follow safety instructions!

Failure to observe the safety instructions will result in damage to personnel and

equipment.

Switch off the power supply before establishing a mains connection.

▶

Observe the safety instructions.

▶

11

Page 12

Information on

the device

Technical data, markings and safety symbols are located on the Fronius Smart

Meter TS. These must NOT be removed or painted over. They warn against incorrect operation which can lead to serious injury and damage.

Markings:

The devices comply with all the requisite and relevant standards and

guidelines that form part of the relevant EU Directive, and are therefore

permitted to display the CE mark.

Insulated (protection class II)

Regulatory Compliance Mark (RCM)

Complies with all applicable regulatory requirements in Australia and

New Zealand regarding safety and electromagnetic compatibility, as

well as specific requirements for radio equipment.

To comply with European Directive 2012/19/EU on Waste Electrical and

Electronic Equipment and its implementation as national law, electrical

equipment that has reached the end of its life must be collected separately and returned to an approved recycling facility. Any device that you

no longer require must be returned to your distributor or disposed of at

an approved collection and recycling facility in your area. Ignoring this

European Directive may have potentially adverse effects on the environment and your health!

RoHS (Restriction of Hazardous Substances)

The limited use of certain hazardous substances in electrical and electronic equipment has been complied with in accordance with EU Directive 2011/65/EU.

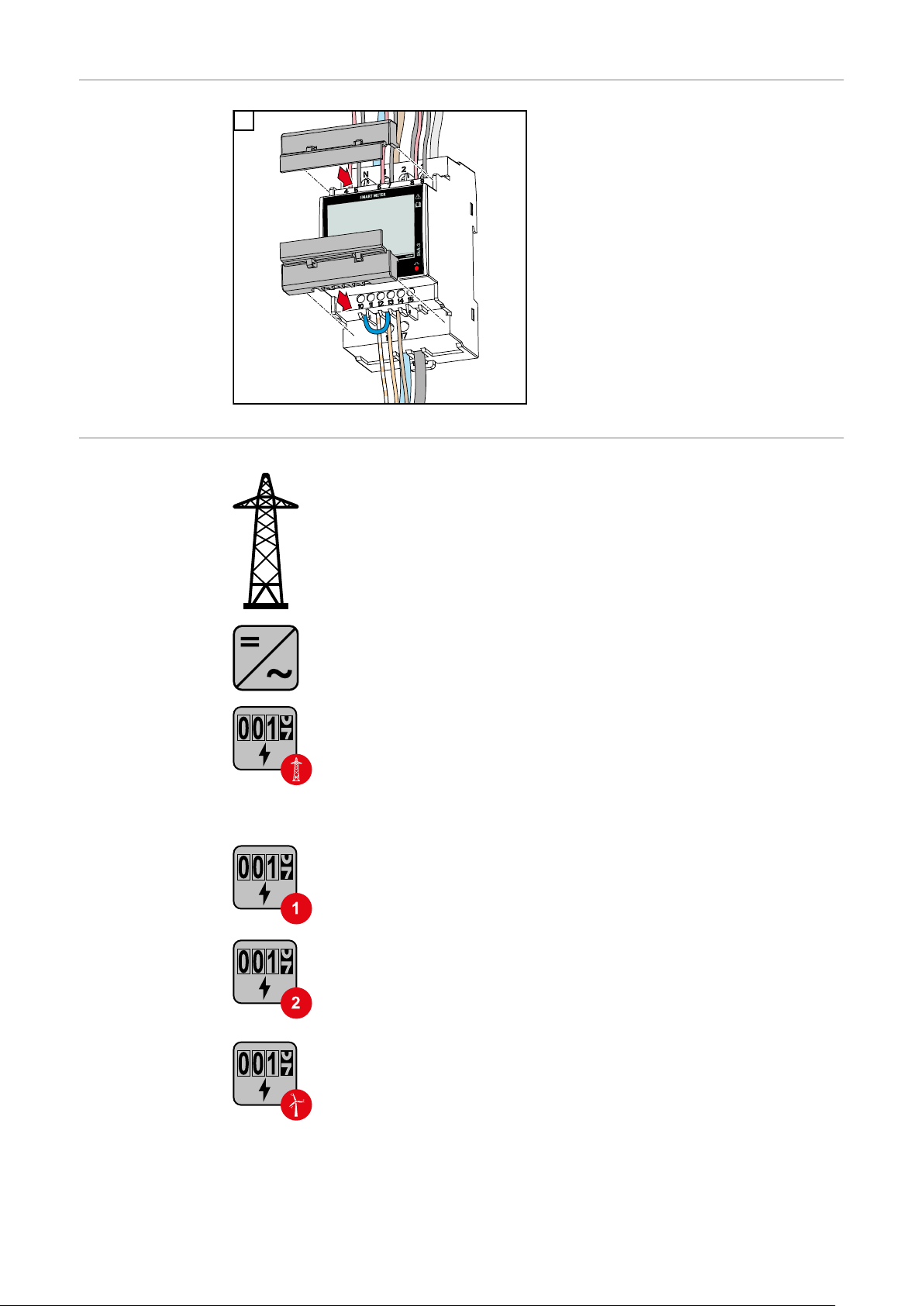

Safety symbols:

Danger of serious injury and property damage due to incorrect operation.

Dangerous electrical voltage.

Intended use The Fronius Smart Meter TS is a fixed piece of equipment for public grids of

TN/TT systems and records self-consumption and/or individual loads in the system. The Fronius Smart Meter TS is required for systems with a battery storage

12

Page 13

system and/or a Fronius Ohmpilot installed for communication between the individual components. The installation is carried out on an indoor DIN rail with corresponding back-up fuses, which are adapted to the cable cross-sections of the

copper conductors and to the maximum current of the meter. The Fronius Smart

Meter TS must only be operated in accordance with the specifications in the enclosed documentation and in accordance with local laws, regulations, provisions,

standards and within the limits of technical possibilities. Any use of the product

other than as described in the intended use shall be deemed to be not in accordance with the intended purpose. The available documentation forms part of the

product and must be read, observed and kept in good condition. It must also be

accessible at all times at the place of installation. The available documents do

not replace regional, state, provincial or national laws, or regulations or standards that apply to the installation, electrical safety and use of the product. Fronius International GmbH assumes no responsibility for compliance with or noncompliance with these laws or regulations in connection with the installation of

the product.

Interventions on the Fronius Smart Meter TS, e.g. modifications and alterations,

are not permitted. Unauthorised interventions will void the warranty and warranty claims and, as a rule, void the user's authority to operate the equipment.

The manufacturer shall not be liable for any damage resulting from such use.

Reasonably foreseeable misuse:

The Fronius Smart Meter TS is not suitable for the supply of life-sustaining medical devices or for the billing of subtenants.

EN

Scope of supply

Positioning The Fronius Smart Meter TS can be installed in the following positions in the sys-

tem:

Positioning at the feed-in point:

(1) 2x seal wire

(2) 2x connection cover

(3) Fronius Smart Meter TS 5kA-3

(4) Quick Start guide

13

Page 14

Positioning at consumption point:

For use as a secondary meter to measure individual loads and producers, see

chapter Multi-meter system - Fronius SnapINverter on page 27.

Measuring accuracy

14

The Fronius Smart Meter TS has accuracy class 1 when measuring active energy

(EN IEC 62053-21) in the voltage ranges 400 - 480 VLL or 230 -277 VLN. Within

the voltage ranges 173 - 400 VLL or 100 - 230 VLN the accuracy class is 2 (active

energy according to EN IEC 62053-21, reactive energy according to EN IEC

62053-23). For further details see Technical data on page 44.

Page 15

Installation

15

Page 16

16

Page 17

Installation

EN

Checklist for installation

For installation information, see the following chapters:

Switch off the power supply before establishing a mains connection.

1

Mount the Fronius Smart Meter TS (see Installation on page 18).

2

Connect automatic circuit breakers or automatic circuit breakers and discon-

3

nectors (see Protective circuit on page 18).

Connect the mains cable to the Fronius Smart Meter TS (see Cabling on

4

page 19).

Mount the current transformers on the conductors. Make sure that the cur-

5

rent transformers are pointing in the correct direction. An arrow either points

to the load or the source (public grid) (see Connecting the current trans-

formers on page 22).

Connect the current transformer and Fronius Smart Meter TS (see Connect-

6

ing the current transformers on page 22).

Make sure that the current transformer phases match the mains voltage

7

phases (see Connecting the current transformers on page 22).

Note down the nominal current of the current transformer for each meter.

8

These values will be required during setup.

Connect the data communication connections of the Fronius Smart Meter

9

TS to the Fronius system monitoring (see Connecting the data communica-

tion cable to the inverter on page 23).

If necessary, set terminating resistors (see Connecting the terminating res-

10

istor on page 24).

Tug on each wire and plug to make sure that they are securely connected to

11

the terminal blocks.

Switch on the power supply to the Fronius Smart Meter TS.

12

Check the firmware version of the Fronius system monitoring. To ensure

13

compatibility between the inverter and the Fronius Smart Meter TS, the software must always be kept up to date. The update can be started via the inverter web page or using Solar.web.

Set the transformation ratio of the current and voltage transformers (see

14

Setting the transformation ratio of the current and voltage transformers on

page 34).

If several Fronius Smart Meter TS are installed in the system, set the address

15

(see "Setting the address" under Setting the address on the Fronius Smart

Meter TS on page 35).

Configure and commission the meter (see Start-up on page 37).

16

17

Page 18

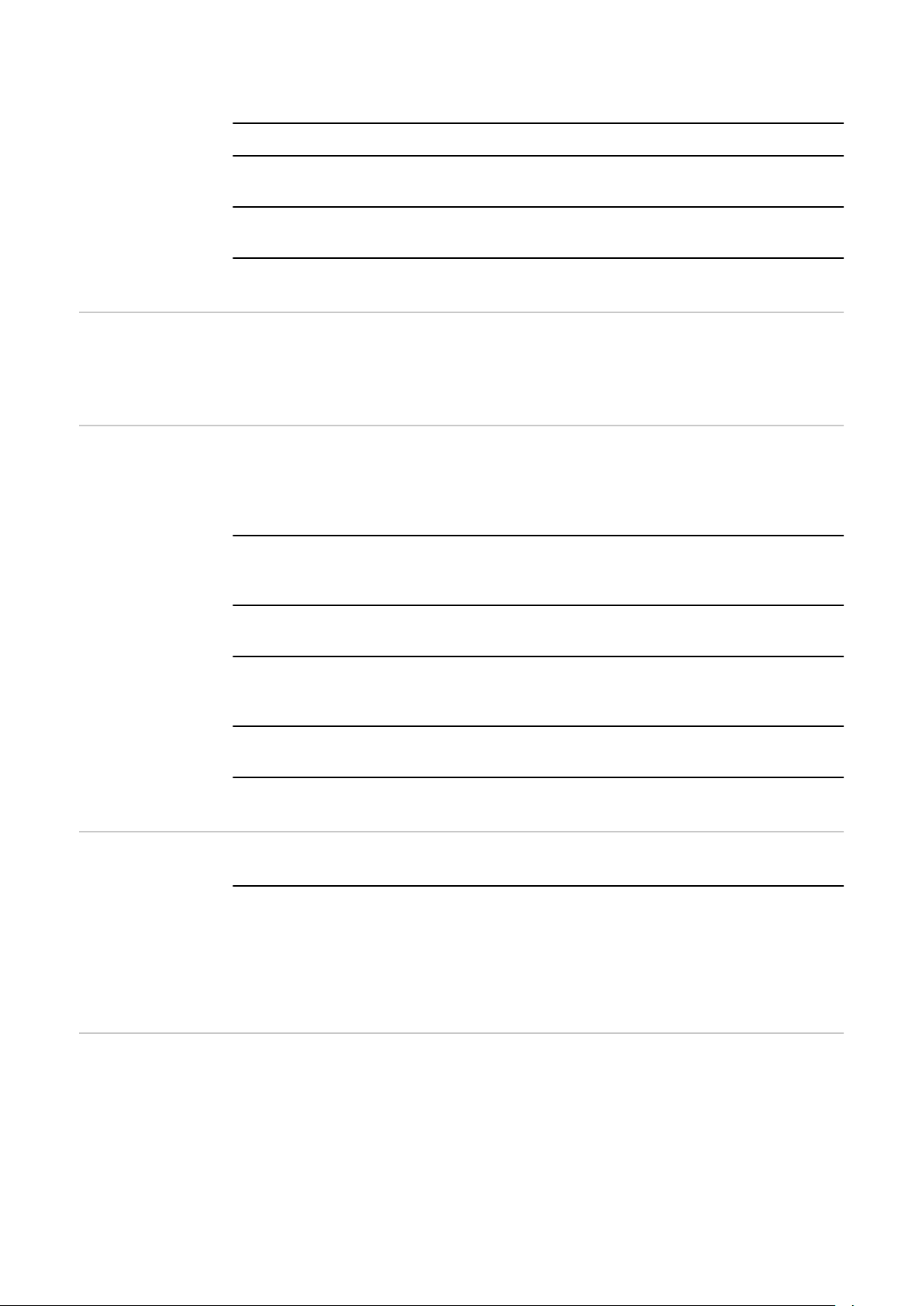

Installation The Fronius Smart Meter TS can be

mounted on a 35 mm DIN rail. The

housing comprises 3 modules according to DIN 43880.

Protective circuit

Auxiliary power

supply cabling

The Fronius Smart Meter TS is a hard-wired device and requires a disconnecting

device (circuit breaker, switch or disconnector) and overcurrent‑protection (automatic‑circuit breaker).

The Fronius Smart Meter TS consumes 10 - 30 mA, the nominal capacity of the

disconnecting devices and the overcurrent‑protection is determined by the wire

thickness, the mains voltage and the required breaking capacity.

Disconnecting devices must be mounted within sight and as close as possible

-

to the Fronius Smart Meter TS; they must also be easy to use.

The disconnecting devices must satisfy the requirements of IEC 60947-1

-

and IEC 60947-3, as well as all national and local regulations for electrical

systems.

To monitor more than one mains voltage, use connected‑automatic circuit

-

breakers.

The overcurrent‑protection must protect the mains terminals with the desig-

-

nations L1, L2 and L3. In rare cases, the neutral conductor has an overcurrent‑protection, which must interrupt both neutral and non-earthed cables

concurrently.

IMPORTANT!

An auxiliary power supply is required to operate the Fronius Smart Meter TS. The

fuse (F) must comply with the national standards and guidelines as well as the

dimensions of the conductors.

18

Page 19

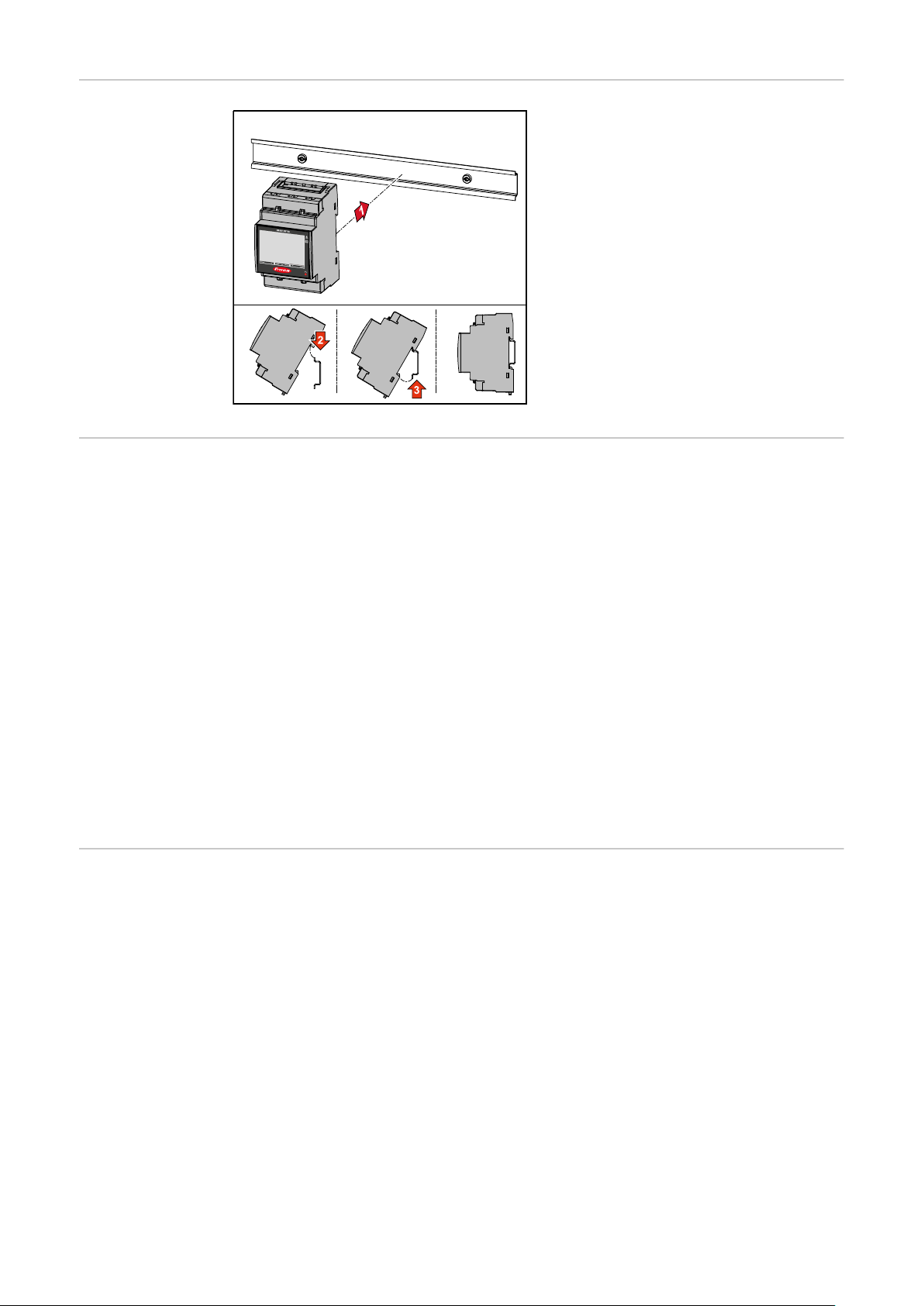

Cabling IMPORTANT!

Always switch off the power supply before connecting the mains voltage inputs

to the Fronius Smart Meter TS.

Recommended thickness of stranded mains voltage cables for the terminals of

the measuring input and measuring output:

Wire: 1 - 4 mm²

-

Recommended torque: max. 0.6 Nm

-

EN

The measuring inputs of the current transformers must be earthed on one side

as shown in the circuit diagram.

Connect each voltage cable to the terminal strip as shown in the graphics below.

1 phase, 2 conductors (CT connection)

1 phase, 2 conductors (VT/CT connection)

19

Page 20

2 phases, 3 conductors (CT connection)

2 phases, 3 conductors (VT/CT connection)

20

3 phases, 3 conductors (CT connection)

3 phases, 3 conductors (VT/CT connection)

Page 21

3 phases, 4 conductors (Aron CT connection)

3 phases, 4 conductors (CT connection)

EN

Selection criteria for current

transformer

3 phases, 4 conductors (VT/CT connection)

General

Do not use current transformers with a voltage output.

Current transformers are directional. If they are mounted backwards or with

swapped wires, the measured power will be negative.

Primary current

Maximum current per phase. A current converter with a primary current greater

than the maximum expected current per phase should be selected. The closer

the expected current is to this value, the more precise the measurement will be.

Secondary current

The current transformer must supply alternating current at a nominal current of

1 or 5 A. The nominal values for the current transformer are listed in the current

transformer data sheet.

Power

The Fronius Smart Meter TS needs 0.5 VA to carry out its measurements. Losses

also occur on the outgoing and return leads. The power of the current converter

21

Page 22

must be greater than the sum total of the power of the Fronius Smart Meter TS

and the leads. The higher the power, the better.

Line resistances at different cross-sections (copper wires)

Secondary cur-

rent

[A]

Cross-section

[mm²]

Line resistances at different lead lengths

(outgoing and return lead)

0.5 m 1.0 m 2.5 m 5 m 10 m

5 1.5 0.3 VA 0.6 VA 1.5 VA 2.9 VA 5.8 VA

5 2.5 0.2 VA 0.4VA0.9 VA 1.8 VA 3.6 VA

5 4 - - 0.6 VA 1.1 VA 2.2 VA

Example

The length of the outgoing and return lead (0.5 m each) between the Fronius

Smart Meter TS and the current transformer is a total of 1 m and has a copper

cable cross-section of 1.5 mm²; the line resistance is therefore 0.6 VA according

to the table above. The self-consumption of the Fronius Smart Meter TS is 0.5

VA.

Line resistance 0.6 VA + self-consumption 0.5 VA = 1.1 VA

→ A current transformer with a rating of 1.5 VA, 5 VA or higher is suitable here.

Accuracy class

Use Class 1 or better (Class 0.5 / 0.2, etc.). Class 1 is equivalent to a deviation of

± 1% of the secondary current at maximum power.

Mounting

Rigid or hinged

"Rigid" is usually cheaper with better power and accuracy values. Hinged current

transformers can be opened for attachment to the conductor. To prevent it being

opened inadvertently, a plastic cable tie can be secured to the current transformer. Hinged current transformers can be installed in a system without interrupting the voltage.

Connecting the

current transformers

Suitable voltage

transformers

Make sure that the current transformers match the voltage phases. Make

1

sure that current transformer L1 measures the current on the same phase

that is monitored by voltage input L1. The same applies for phases L2 and L3.

Make sure that the current transformers are pointing in the correct direction.

2

Observe the data sheet for the current transformer.

Note down the nominal current of the current transformer for each meter.

3

These values will be required for setup.

Attach the current transformers to the conductor to be measured and con-

4

nect the cables of the current transformer to the Fronius Smart Meter TS.

IMPORTANT!

Always switch off the power supply before disconnecting live conductors.

The current transformers are connected to connections 4 and 5; 6 and 7; 8

5

and 9. If necessary, excessively long cables can be shortened accordingly.

Observe the sequence in which the phases are connected. Accurate power

measurement is only ensured if the mains voltage phases match the current

phases.

Only voltage transformers with a voltage range from 220 to 480 V (phase phase) and from 100 to 277 V (phase - neutral conductor) may be used. The

22

Page 23

voltage transformers must be connected to terminals 1, 2, 3 and N at the point of

direct voltage measurement.

EN

Connecting the

data communication cable to

the inverter

Connect the data communication connections of the Fronius Smart Meter TS to

the Modbus interface of the Fronius inverter using a network cable (type CAT5

or higher).

Several Smart Meters can be installed in the system, see chapter Multi-meter

system - Fronius SnapINverter on page 27.

To avoid interference, the terminating

resistor must be used (see chapter

Connecting the terminating resistor

on page 24).

Terminating resistors - Explanation of symbols

IMPORTANT!

More information on successful commissioning.

Note the following information about connecting the data communication cable

to the inverter.

Use network cables of type CAT5 or higher.

-

Use a mutual twisted cable pair for corresponding data lines (D+/D-, M1+/

-

M1-).

If the data lines are close to the mains cabling, use wires or cables that are

-

designed for 300 to 600 V (never less than the operating voltage).

Use double-insulated or sheathed data lines when they are close to bare con-

-

ductors.

Use shielded twisted pair cables to avoid faults.

-

Two wires can be installed in each terminal; the wires are twisted first, inser-

-

ted into the terminal and tightened.

Note: A loose wire can disable an entire area of the network.

The data communication connections of the Fronius Smart Meter TS are

-

electrically isolated from hazardous voltages.

Inverter in the system

e. g. Fronius Symo

Meter - Fronius Smart Meter TS

Terminating resistor R 120 Ohm is set with a wire jumper between

M- and T.

23

Page 24

Modbus RTU slave

e. g. Fronius Ohmpilot, Fronius Solar Battery, etc.

Terminating resistor

R 120 Ohm

Connecting the

terminating resistor

Terminating resistors

The terminating resistor is integrated

in the Fronius Smart Meter TS and is

manufactured with a bridge between

the M and T connections (T = termination).

Due to interference, it is recommended that terminating resistors are used as illustrated below to ensure proper functioning.

24

Page 25

EN

* The terminating resistor is integrated in the Fronius Smart Meter TS and is

manufactured with a bridge between the M and T connections (T = termination).

25

Page 26

Mounting the

connection cover

1

Insert the connection covers into the

guides and press firmly.

IMPORTANT!

When fitting the connection covers,

ensure that the cables are not kinked,

pinched, crushed or otherwise damaged.

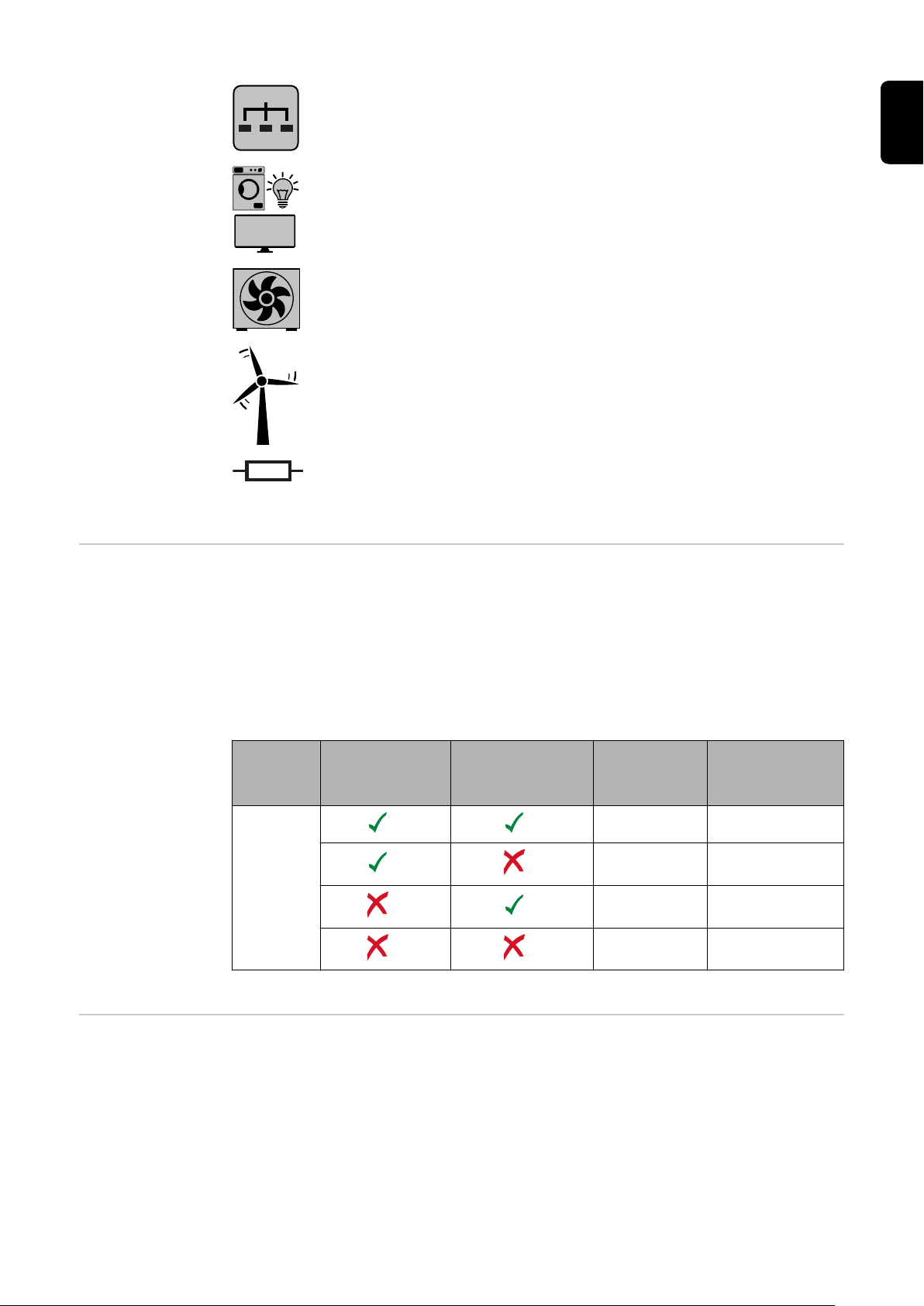

Multi-meter system - Explanation of symbols

Grid

supplies the loads in the system if insufficient power is being generated by the PV modules or supplied by the battery.

Inverter in the system

e. g. Fronius Primo, Fronius Symo, etc.

Utility meter

Measures the measurement data relevant for billing amounts of

energy (in particular kilowatt hours of energy sourced from the

grid and energy fed into the grid). Based on the relevant billing

data, the electricity retailer will invoice the energy sourced from

the grid and the purchaser of the surplus energy will reimburse

the energy fed into the grid.

Primary meter

Records the system's load curve and provides measurement data

for energy profiling in Fronius Solar.web. The primary meter also

controls the dynamic feed-in control.

26

Secondary meter

Records the load curve of individual loads (e.g. washing machine,

lamps, TV, heat pump, etc.) in the consumption branch and

provides measurement data for energy profiling in Fronius Solar.web.

Producer meter

Records the load curve of individual producers (e.g. wind power

plant) in the consumption branch and provides measurement data

for energy profiling in Fronius Solar.web.

Page 27

Modbus RTU slave

e. g. Fronius Ohmpilot, Fronius Solar Battery, etc.

Loads in the system

e. g. washing machine, lamps, TV, etc.

Additional loads in the system

e. g. heat pump

Additional producers in the system

e. g. wind power plant

Terminating resistor

R 120 Ohm

EN

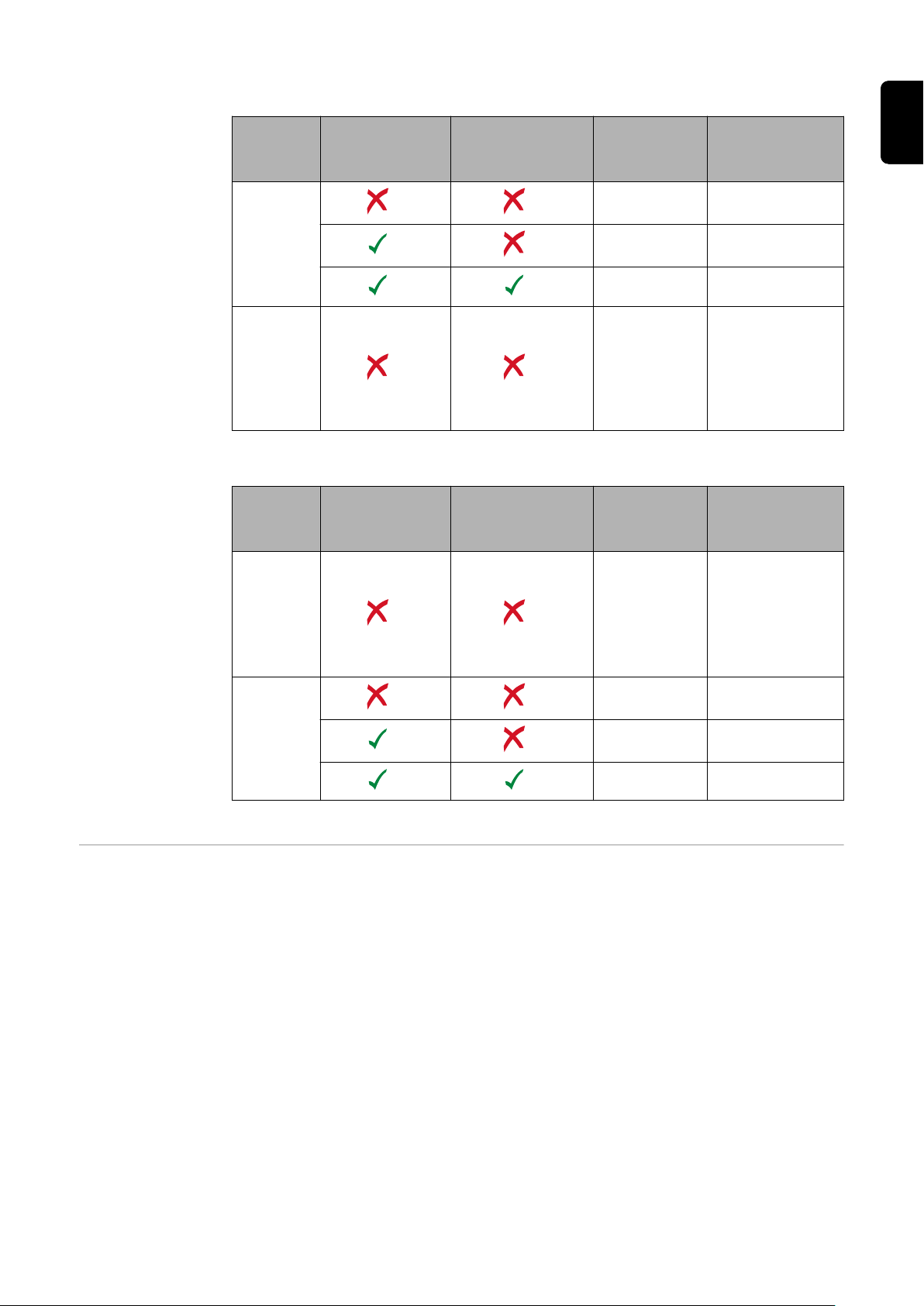

Modbus participants - Fronius

SnapInverter

A maximum of 4 Modbus participants can be connected to the Modbus terminal.

IMPORTANT!

Only one primary meter, one battery and one Ohmpilot can be connected per inverter. Due to the high data transfer of the battery, the battery occupies 2 participants.

Example:

Input Battery

Modbus

Fronius

Ohmpilot

Quantity

Primary

meter

1 0

1 1

1 2

1 3

Quantity

Secondary

meter

Multi-meter system - Fronius

SnapINverter

If several Fronius Smart Meter TS are installed, a separate address must be set

for each (see Setting the address on the Fronius Smart Meter TS on page 35).

The primary meter is always assigned address 1. All the other meters are

numbered consecutively with the address range from 2 to 14. Different Fronius

Smart Meter power categories can be used in combination.

IMPORTANT!

Max. Use 3 secondary meters in the system. To avoid interference, it is recom-

27

Page 28

mended to install the terminating resistors according to chapter Connecting the

terminating resistor on page 24.

Location of the primary meter in the consumption branch. *Terminating resistor R 120 Ohm

Modbus participants - Fronius

GEN24

Location of the primary meter at the feed-in point. *Terminating resistor R 120 Ohm

The following must be observed in a multi-meter system:

Only assign each Modbus address once.

-

Terminating resistors must be positioned individually for each channel.

-

The inputs M0 and M1 can be selected for this purpose. A maximum of 4 Modbus

participants can be connected to the Modbus terminal on inputs M0 and M1.

IMPORTANT!

Only one primary meter, one battery and one Ohmpilot can be connected per inverter. Due to the high data transfer of the battery, the battery occupies 2 participants.

28

Page 29

Example 1:

Input Battery

Modbus 0 (M0)

Modbus 1 (M1)

Example 2:

Input Battery

Fronius

Ohmpilot

Fronius

Ohmpilot

Quantity

Primary

meter

0 4

0 2

0 1

1 3

Quantity

Primary

meter

Quantity

Secondary

meter

Quantity

Secondary

meter

EN

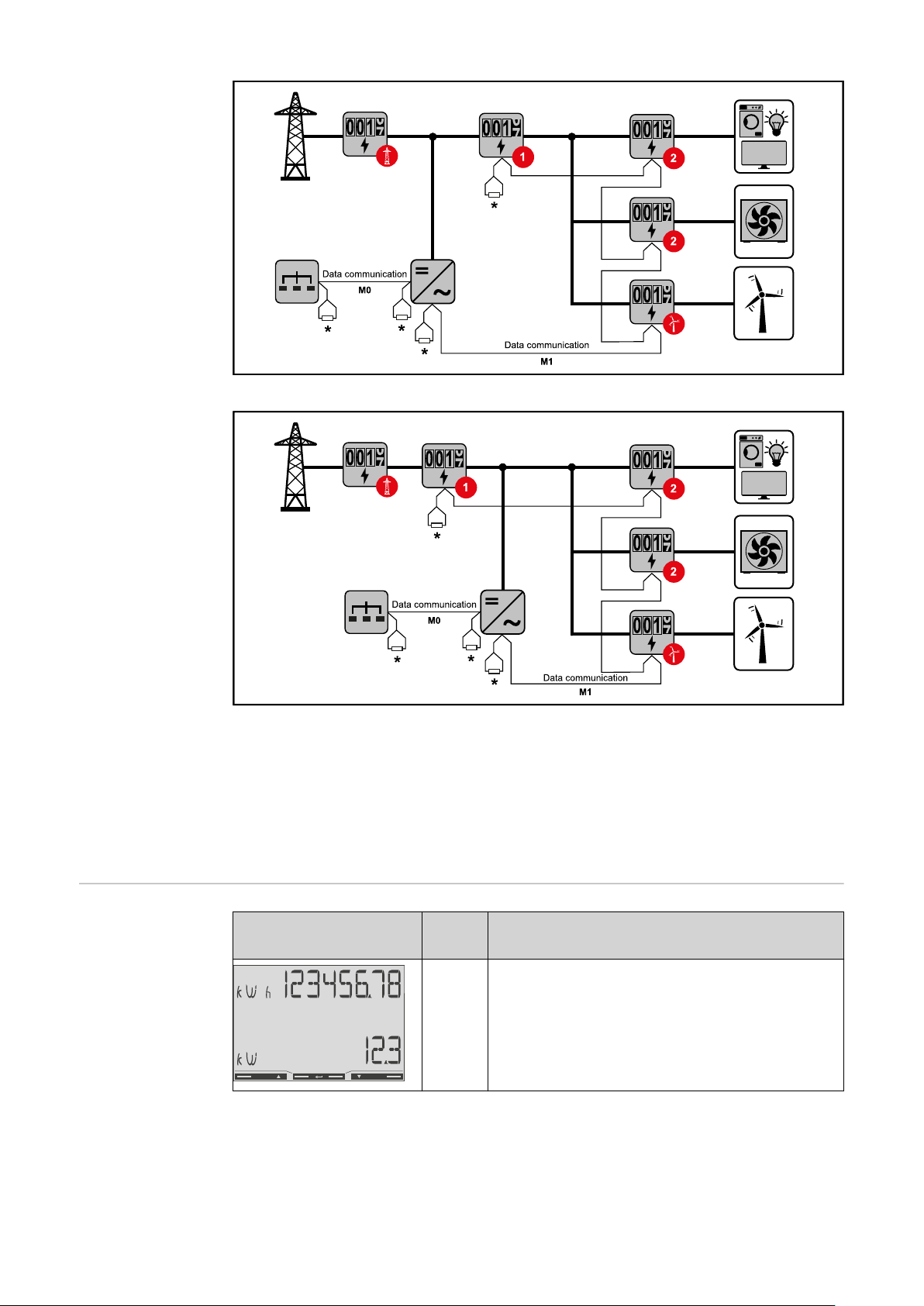

Multi-meter system - Fronius

GEN24 inverter

1 3

Modbus 0 (M0)

0 4

0 2

Modbus 1 (M1)

If several Fronius Smart Meter TS are installed, a separate address must be set

for each (see Setting the address on the Fronius Smart Meter TS on page 35).

The primary meter is always assigned address 1. All the other meters are

numbered consecutively with the address range from 2 to 14. Different Fronius

Smart Meter power categories can be used in combination.

IMPORTANT!

Max. Use 7 secondary meters in the system. To avoid interference, it is recommended to install the terminating resistors according to chapter Connecting the

terminating resistor on page 24.

0 1

29

Page 30

Location of the primary meter in the consumption branch. *Terminating resistor R 120 Ohm

Location of the primary meter at the feed-in point. *Terminating resistor R 120 Ohm

The following must be observed in a multi-meter system:

Connect the primary meter and the battery to different channels (recom-

-

mended).

The remaining Modbus participants must be distributed equally.

-

Only assign each Modbus address once.

-

Terminating resistors must be positioned individually for each channel.

-

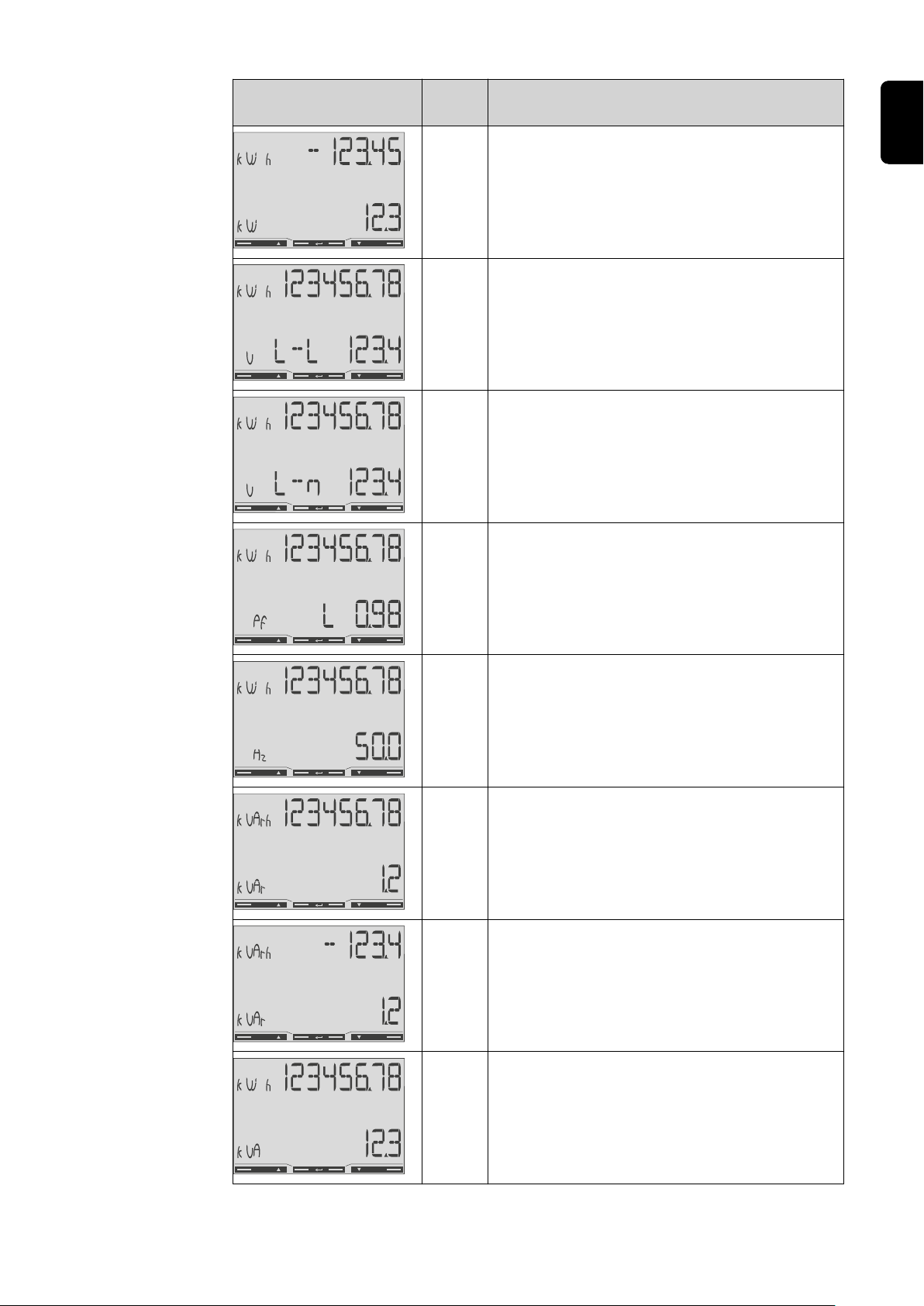

Menu - Measured

variables

30

Image ScreenDescription

00

Total active energy drawn*

1.

Total efficiency

2.

Page 31

Image ScreenDescription

01

02

03

04

Total active energy supplied**

1.

Total efficiency

2.

Total active energy drawn*

1.

Average conductor voltage in the system

2.

Total active energy drawn*

1.

Average phase voltage in the system

2.

Total active energy drawn*

1.

Power factor (L = inductive, C = capacit-

2.

ive)

EN

05

06

07

08

Total active energy drawn*

1.

Frequency

2.

Total active energy drawn*

1.

Total reactive power

2.

Total reactive energy supplied**

1.

Total reactive power

2.

Total active energy drawn**

1.

Total apparent power

2.

31

Page 32

Image ScreenDescription

09

10

11

12

Total active energy drawn*

1.

Average demanded power (P = demand),

2.

calculated for the set interval. The value

remains unchanged for the entire interval. It is "0" in the first interval after the

start.

Maximum demanded power (dMd = Peak

3.

demand) that has been reached since

the last reset.

Not used

-

Not used

-

Active energy drawn*

1.

13

14

15

Apparent power

1.

Reactive energy drawn

1.

Power factor (L = inductive, C = capacit-

1.

ive)

32

Page 33

Image ScreenDescription

16

18

19

20

Phase voltage

1.

Operating hours counter

1.

Neutral current

2.

Current

1.

Effective power

1.

EN

Configuration

menu - structure

and parameters

* Displayed when easy connection mode is activated (measurement = A).

This value indicates the total energy without considering the direction.

** Factory setting - displayed when drawn and delivered energy are meas-

ured separately (measurement = b).

Screen Code Description Values

PASS*** P1 Enter the current password 2633*

nPASS P2 Password change ** Four digits (0000-9999)

SYStEM P3 Type of system 3Pn*: three-phase system,

4-core

3P: three-phase system, 3core

2P: two-phase system, 3core

Ct rAtIo P4 Current transformer ratio from 1* to 1000

Ut rAtIo P5 Voltage transformer ratio from 1* to 1000

MEASurE P6 Measurement mode ** A: easy connection, meas-

ures all energy without taking the direction into account.

B*: measures imported and

exported energy separately.

33

Page 34

Screen Code Description Values

InStALL P7 Connection check On: activated

Off*: deactivated

P int P8 Average power calculation

interval (minutes)

MOdE P9 Display mode ** Full*: full display

tArIFF P10 Tariff management ** On: activated

HoME P11 Screen showing measured

variables displayed at startup and after 120 seconds

of inactivity **

AddrESS***

bAUd P15 Baud rate (kBit/s) ** 9.6* / 19.2 / 38.4 / 57.6 /

PArITY P16 Parity ** Even/No*

STOP bit P16-2Only if parity = No. Stop bit.**1* / 2

rESET P17 Activation of the reset func-

P14 Modbus address 1* - 247

tion for energy tariffs, maximum requested power and

part values of active and reactive energy (the latter are

only transmitted via the

serial interface) **

1* - 30

Easy: reduced display. The

values that are not displayed are still transmitted

via the serial interface.

Off*: deactivated

For full display (Mode =

Full): 0* - 19

115.2

No*: reset function deactivated.

Yes: reset function activated.

Setting the

transformation

ratio of the current and voltage

transformers

End P18 Returns to the measured

variables start screen

* Factory settings

** The settings can be protected by changing the default password (pass-

word cannot be reset).

*** Settings that need to be configured.

Only the transformation ratio of the current and voltage transformers must be

set. All other parameters are preset at the factory.

Symbol Name Event Function

Up

Down

Enter

1 x

1 x

2 seconds

Scroll one screen forward, increase the

value by 1

Scroll one screen back, decrease the value

by 1

Call up settings, confirm value

None

34

Page 35

Press and hold "Enter" for 2

1

seconds.

Use "Up" or "Down" to access the

2

P1 screen.

Set password "2633" with "Up" and

3

"Down" and confirm each individual

value with "Enter".

Note down the password.

4

IMPORTANT!

The password cannot be reset.

Use "Up" or "Down" to access the

1

P4 screen.

Press and hold "Enter" for 2

2

seconds.

Set the transformation ratio with

3

"Up" and "Down" and confirm each

individual value with "Enter".

Press "Up" to access screen P18

4

and press and hold "Enter" for 2

seconds to exit the settings.

EN

Setting the address on the

Fronius Smart

Meter TS

Ratio of current transformers1) (0001 - 10002)).

Ratio of voltage transformers

1)

Important! Changing the transformation ratios will reset the counters in the

1), 3)

(001.0 - 10002)).

Fronius Smart Meter TS to 0.

2)

Transformation ratio in the current transformer x Transformation ratio of the

voltage transformers = max. 1000

3)

Changeover only when using voltage transformers (direct voltage measurement

VT = 1)

Symbol Name Event Function

Up

1 x

Scroll one screen forward, increase the

value by 1

Down

1 x

Scroll one screen back, decrease the value

by 1

Enter

2 seconds

Call up settings, confirm value

35

Page 36

Press and hold "Enter" for 2

1

seconds.

Use "Up" or "Down" to access the

2

P1 screen.

Set password "2633" with "Up" and

3

"Down" and confirm each individual

value with "Enter".

Use "Up" or "Down" to access the

1

P14 screen.

Press and hold "Enter" for 2

2

seconds.

Set the address with "Up" and

3

"Down" and confirm each individual

value with "Enter".

Press "Up" to access screen P18

4

and press and hold "Enter" for 2

seconds to exit the settings.

36

Page 37

Start-up

37

Page 38

38

Page 39

Fronius SnapINverter

General IMPORTANT! Settings under the "Meter" menu item are only to be made by

trained and qualified personnel!

The service password must be entered in order to access the "Meter" menu item.

Three-phase or single-phase Fronius Smart Meter TS can be used. In both cases,

the selection is made under the "Fronius Smart Meter" item. The Fronius

Datamanager automatically identifies the meter type.

A primary meter and several secondary meters can be selected. The primary

meter needs to be configured first before a secondary meter can be selected.

EN

Connecting to

the Fronius

Datamanager

Configuring the

Fronius Smart

Meter TS as the

primary meter

Access point:

Select the "Setup" menu on the inverter display and enable the "Wi-Fi Access

1

Point".

Establish the connection to the inverter in the network settings (the inverter

2

is displayed with the name "Fronius_240.XXXXXX").

Password: Enter 12345678 and confirm.

3

In the browser address bar, enter and confirm the IP address http://

4

192.168.250.181 and confirm.

The Fronius Datamanager start page is displayed.

LAN:

Connect the Fronius Datamanager and computer to a LAN cable.

1

Place the Fronius Datamanager IP switch in the 'A' position.

2

In the browser address bar, enter and confirm the IP address http://

3

169.254.0.180 and confirm.

Go to the Fronius Datamanager website.

1

Open the web browser.

-

In the address bar of the browser, enter the IP address (IP address for

-

WLAN: 192.168.250.181, IP address for LAN: 169.254.0.180) or the host

and domain name of the Fronius Datamanager and confirm.

The Fronius Datamanager website will be displayed.

-

Click the "Settings" button.

2

Log in to the login area with the "service" user and the service password.

3

Call up the "Meter" menu area.

4

Select the primary meter from the drop-down list.

5

Click the "Settings" button.

6

In the pop-up window, set the position of the meter (feed-in point or con-

7

sumption point). For more information on the position of the Fronius Smart

Meter TS, see Positioning on page 13.

Click the "Ok" button when the OK status is displayed. If the Timeout status

8

is displayed, try again.

39

Page 40

9

Click the button to save the settings.

The Fronius Smart Meter TS is configured as a primary meter.

The "Current general view" menu area displays the power of the PV modules,

self-consumption, the energy fed into the grid and the battery charge (if available).

Configuring the

Fronius Smart

Meter TS as a

secondary meter

Go to the Fronius Datamanager website.

1

Open the web browser.

-

In the address bar of the browser, enter the IP address (IP address for

-

WLAN: 192.168.250.181, IP address for LAN: 169.254.0.180) or the host

and domain name of the Fronius Datamanager and confirm.

The Fronius Datamanager website will be displayed.

-

Click the "Settings" button.

2

Log in to the login area with the "service" user and the service password.

3

Call up the "Meter" menu area.

4

Select the secondary meter from the drop-down list.

5

Click the "Add" button.

6

Enter the name of the secondary meter in the "Name" input field.

7

Enter the previously assigned address in the “Modbus address” input field.

8

Add meter description.

9

10

Click the button to save the settings.

The Fronius Smart Meter TS is configured as a secondary meter.

40

Page 41

Fronius GEN24 inverter

General IMPORTANT! Settings under the "Device configuration" menu item are only to be

made by trained and qualified personnel!

The service password must be entered in order to access the "Device configuration" menu item.

Three-phase or single-phase Fronius Smart Meter TS can be used. In both cases,

the selection is made under the "Components" menu area. The meter type is determined automatically.

A primary meter and several secondary meters can be selected. The primary

meter needs to be configured first before a secondary meter can be selected.

EN

Installation using the web

browser

WLAN:

1

Open the access point by touching the sensor once → Communication LED:

flashes blue.

Establish the connection to the inverter in the network settings (the inverter

2

is displayed with the name "FRONIUS_PILOT" and the serial number of the

device).

Password: enter 12345678 and confirm.

3

IMPORTANT!

To enter the password on a Windows 10 operating system, the link "Connect

using a security key instead" must first be activated to establish a connection

with the password: 12345678.

In the browser address bar, enter and confirm the IP address

4

192.168.250.181. The installation wizard is opened.

Follow the installation wizard in the individual sections and complete the in-

5

stallation.

Add system components in Solar.web and start up the PV system.

6

The network wizard and the product setup can be carried out independently of

each other. A network connection is required for the Solar.web installation wizard.

Ethernet:

41

Page 42

Establish a connection to the inverter (LAN1) with a network cable (CAT5

1

STP or higher).

2

Open the access point by touching the sensor once → Communication LED:

flashes blue.

In the browser address bar, enter and confirm IP address 169.254.0.180. The

3

installation wizard is opened.

Follow the installation wizard in the individual sections and complete the in-

4

stallation.

Add system components in Solar.web and start up the PV system.

5

The network wizard and the product setup can be carried out independently of

each other. A network connection is required for the Solar.web installation wizard.

Configuring the

Fronius Smart

Meter TS as the

primary meter

Configuring the

Fronius Smart

Meter TS as a

secondary meter

Access the inverter website.

1

Open the web browser.

-

In the address bar of the browser, enter the IP address (IP address for

-

WLAN: 192.168.250.181, IP address for LAN: 169.254.0.180) or the host

and domain name of the inverter and confirm.

The inverter website is displayed.

-

Click the "Device configuration" button.

2

Log in to the login area with the "Technician" user and the technician pass-

3

word.

Access the "Components“ menu area.

4

Click the "Add component" button.

5

In the "Position" drop-down list, set the position of the meter (feed-in point

6

or consumption point). For more information on the position of the Fronius

Smart Meter TS, see Positioning on page 13.

Click the "Add" button.

7

Click the "Save" button to save the settings.

8

The Fronius Smart Meter TS is configured as a primary meter.

Access the inverter website.

1

Open the web browser.

-

In the address bar of the browser, enter the IP address (IP address for

-

WLAN: 192.168.250.181, IP address for LAN: 169.254.0.180) or the host

and domain name of the inverter and confirm.

The inverter website is displayed.

-

Click the "Device configuration" button.

2

Log in to the login area with the "Technician" user and the technician pass-

3

word.

Access the "Components“ menu area.

4

Click the "Add component" button.

5

In the "Position" drop-down list, select the meter type (producer/load meter).

6

Enter the previously assigned address in the “Modbus address” input field.

7

Enter the name of the meter in the "Name" input field.

8

In the "Category" drop-down list, select the category (producer or load).

9

Click the "Add" button.

10

Click the "Save" button to save the settings.

11

42

Page 43

The Fronius Smart Meter TS is configured as a secondary meter.

EN

43

Page 44

Technical data

Technical data Modbus transmission speed: 9600 baud

Parity bit:none

Software version:

Fronius Datamanager 2.0 (from version 3.16.1 onwards)

-

Fronius Symo Hybrid (from version 1.16.1 onwards)

-

Measuring input

Nominal voltage (3-phase)

Operating range (class 1)

Operating range (class 2)

Nominal voltage (1-phase)

Operating range (class 1)

Operating range (class 2)

Voltage transformer ratio (kVT) 1 - 1000

Self-consumption - voltage path

(max. voltage)

Nominal frequency

Tolerance

Nominal current, l

Maximum current, I

Starting current 10 mA

Current transformer ratio (kCT) 1 - 1000

Short-time overload

(EN IEC 62053-21, EN IEC 62053-23)

b

max

400 - 480 V

320 - 552 V

173 - 400 VLL ± (2 % RDG/accuracy)

230 - 277 V

184 - 318.55 V

100 - 230 VLN ± (1 % RDG/accuracy)

e. g. VT 20000/400V kVT = 50

for direct connection: kVT = 1

10 VA

50 - 60 Hz

45 - 65 Hz

1 A + 5 A

6 A

e. g. TC 800/5A kCT = 160

for direct connection: kCT = 1

5 l

/ 0.5 s

max

44

Self-consumption - current path (max.

current)

Maximum value kVT x kCT 1000 (CT/5A)

Current distortion factor in acc. with EN IEC 62053-21

Power factor

Operating range

(EN IEC 62053-21, EN IEC 62053-23)

Energy

Max. display As per table

Resolution As per table

LED indicator 1 pulse / 0.1 Wh

Active energy accuracy

(EN IEC 62053-21)

0.3 W per phase

active cosφ 0.5 ind - 0.8 cap,

reactive sinφ 0.5 ind - 0.5 cap

Class 1

Class 2: 100 - 230 VLN (173 - 400

VLL)

Page 45

Energy

Reactive energy accuracy

(EN IEC 62053-23)

Response time after switch-on

(EN IEC 62053-21, EN IEC 62053-23)

kCT x kVT Maximum display Resolution

1 - 9.9 9 9 9 9 9 9 . 9 9 kWh / kvarh 10 Wh / varh

10 - 99.9 9 9 9 9 9 9 9 . 9 kWh / kvarh 100 Wh /

100 - 999.9 9 9 9 9 9 9 9 9 kWh / kvarh 1 kWh / varh

≥ 1000 9 9 9 9 9 9 . 9 9 MWh / kvarh 10 kWh /

Average power

Measured variable Effective power

Calculation Average value over set period of time

Integration time 5 / 8 / 10 / 15 / 20 / 30 / 60 minutes

Output

Class 2

< 5 s

varh

varh

EN

RS485 communication

Electrically isolated from input and auxiliary voltage

Standard RS485 - 3 conductors

Transmission Serial, asynchronous

Protocol Modbus RTU

Addresses 1 - 255

Number of bits 8

Stop bit 1

Parity bit None - even - odd

Baud rate 9600, 19200, 38400 bit/s

Response time ≤ 200 ms

Insulation (EN IEC 62052-11, EN IEC 62053-21)

Installation category III

Pollution degree 2

Insulation voltage 4 kV RMS

Impulse withstand voltage

Test circuit

4 kV 1.2/60 µs

Voltage input, current input, pulse

output, communication

Test voltage

Test circuit

Test voltage

Test circuit

2.75 kV RMS. 50 Hz/1 min

Voltage input, current input, pulse

output, communication

4 kV RMS. 50 Hz/1 min

All circuits and earth

45

Page 46

Electromagnetic compatibility

Test in acc. with EN IEC 62052-11

Operating conditions

Reference temperature 25 °C (± 5 °C)

Operating range -25 to +65 °C

Temperature limit for storage and

transport

Max. power loss (for thermal dimensioning of the switch cabinet)

Housing

Housing 3 modules according to DIN 43880

Sealable housing/terminal cover

Connection Screw connection

Mounting Can be snapped onto 35 mm DIN rail

Housing material Noryl, self-extinguishing

Degree of protection (EN 60529) IP54 housing, IP20 connections

Weight 240 grams

Terminals

Measuring input

Wire min. 1 mm² / max. 4 mm²

Recommended torque max. 0.6 Nm

-30 to +80 °C

≤ 2.8 W

Fronius manufacturer's warranty

Data output and auxiliary power supply

Wire min 0.05 mm² / max. 2.5 mm²

Recommended torque max. 0.4 Nm

Detailed, country-specific warranty terms are available on the internet:

www.fronius.com/solar/warranty

To obtain the full warranty period for your newly installed Fronius inverter or

storage system, please register at: www.solarweb.com.

46

Page 47

EN

47

Page 48

-

-

Loading...

Loading...