Page 1

Operating

Instructions

Fronius Primo GEN24

8.0 Plus / 10.0 Plus

Operating Instructions

EN

42,0426,0419,EN 016-24042023

Page 2

Page 3

Contents

Safety rules 8

Explanation of safety notices 8

Safety 8

General 8

Environmental conditions 9

Qualified personnel 9

Noise emission values 9

EMC measures 10

Backup power 10

Data protection 11

Copyright 11

Protective earthing (PE) 11

General information 13

Fronius Primo GEN24 15

Device concept 15

Function overview 15

Fronius UP 16

Scope of supply 16

Intended use 16

Thermal concept 17

Fronius Solar.web 17

Local communication 18

The various operating modes 19

Operating modes – Explanation of symbols 19

Operating mode – Inverter with battery 20

Operating mode – Inverter with battery and several Smart Meters 20

Operating mode - inverter with battery, AC-coupled to another inverter 20

Operating mode – Inverter with battery and backup power function 21

Operating mode – Inverter with battery, Ohmpilot and backup power function 21

Operating mode – Inverter with battery, further inverter and backup power function 21

Energy flow direction of the inverter 22

Operating states (only for systems with a battery) 22

Energy saving mode 24

General 24

Switch-off conditions 24

Switch-on conditions 24

Special case 24

Indication of energy saving mode 25

Suitable batteries 26

General 26

Limitations in operation 26

BYD Battery-Box Premium 26

LG RESU FLEX 27

Manual system start 29

Requirements 29

Notification of system shutdown 29

Manual battery start after system shutdown 29

Starting backup power operation after a system shutdown 29

Protection of people and equipment 30

Central grid and system protection 30

WSD (wired shutdown) 30

RCMU 30

Safe state 30

Surge protective device 30

Control elements and connections 31

Connection area 31

Connection area divider 32

EN

3

Page 4

Ground electrode terminal 32

DC disconnector 33

Data communication area 33

Button functions and LED status indicator 35

Internal schematic connection diagram of the IOs 36

Backup power variant - PV Point (OP) 39

General 41

PV Point (OP) 41

Explanation - PV Point (OP) 41

Backup power variant - Full Backup 43

General 45

Prerequisites for backup power mode 45

Transitioning from feeding energy into the grid to backup power mode 45

Transitioning from backup power mode to feeding energy into the grid 45

Backup power and energy saving mode 46

Cabling variants including backup power circuits with 1-pin separation e.g. Austria or Australia

Functions 47

Transitioning from feeding energy into the grid to backup power mode 47

Transitioning from backup power mode to feeding energy into the grid 47

All-pin separation cabling variant e.g. Germany, France, Spain, UK 48

Functions 48

Transitioning from feeding energy into the grid to backup power mode 48

Transitioning from backup power mode to feeding energy into the grid 49

All-pin separation cabling variant, Italy 50

Functions 50

Transitioning from feeding energy into the grid to backup power mode 50

Transitioning from backup power mode to feeding energy into the grid 51

47

Installation 53

General 55

Quick-lock system 55

Warning notices on the device 55

System component compatibility 57

Installation location and position 58

Choosing the location of the inverter 58

Choosing the location of third-party batteries 59

Installation position of inverter 60

Install the mounting bracket and hang up the inverter 62

Selecting the fixing material 62

Properties of the mounting bracket 62

Do not deform the mounting bracket 62

Fitting the mounting bracket to a wall 62

Installing the mounting bracket on a mast or beam 63

Attaching the mounting bracket to mounting rails 64

Attaching the inverter to the mounting bracket 64

Prerequisites for connecting the inverter 65

Permissible cables for the electrical connection 65

Permitted cables for the data communication connection 66

Cross section of the AC cable 66

Cross section of the DC cable 67

Maximum alternating current fuse protection 67

Connecting the inverter to the public grid (AC side) 69

Safety 69

Connecting the inverter to the public grid (AC side) 69

Connecting solar module strings to the inverter 72

General comments regarding PV modules 72

Safety 72

Module array - general information 73

4

Page 5

Module array configuration 8 ‑ 10 kW 73

Connecting the solar module strings to the inverter 74

Connecting the battery to the inverter 78

Safety 78

Connecting the battery on the DC side 78

Connecting the LG RESU FLEX ground conductor 82

Connecting backup power - PV Point (OP) 83

Safety 83

Installation 83

Connecting backup power - Full Backup 88

Safety 88

Cabling variants including backup power circuits with 1-pin separation e.g. Austria or Aus-

tralia

All-pin separation cabling variant e.g. Germany, France, Spain 89

All-pin separation cabling variant, e.g. UK 90

All-pin separation cabling variant, e.g. Italy 91

Testing backup power mode 92

Connecting the data communication cable 93

Modbus participants 93

Routing data communication cables 94

Connecting the battery communication cable 96

Terminating resistors 96

Installing the WSD (wired shutdown) 98

Closing and commissioning the inverter 99

Closing the inverter's connection area/housing cover, and commissioning 99

Starting the inverter for the first time 99

Installation with the app 100

Installation using the web browser 100

Switching off current supply and restarting the inverter 102

De-energising the inverter and switching it on again 102

88

EN

Settings - user interface of the inverter 103

User settings 105

User login 105

Selecting the language 105

Device configuration 106

Components 106

Functions andI/Os 107

Demand Response Modes (DRM) 108

Inverter 108

Energy management 111

Energy management 111

Examples - Time-dependent battery control 112

Allowed battery control rules 114

PV power reduction 116

Load management 116

System 118

General 118

Update 118

Setup wizard 118

Restoring the factory settings 118

Event log 118

Information 118

Licence manager 119

Support 120

Communication 121

Network 121

Modbus 122

Remote control 123

Fronius Solar API 123

Safety and grid requirements 125

5

Page 6

Country setup 125

Feed-in limitation 125

Dynamic power regulation with several inverters 127

I/O power management 129

Connection diagram - 4 relay 130

I/O power management settings - 4 relays 131

Connection diagram - 3 relay 132

I/O power management settings - 3 relays 133

Connection diagram - 2 relay 134

I/O power management settings - 2 relays 135

Connection diagram - 1 relay 136

I/O power management settings - 1 relay 137

Autotest(CEI 0-21) 137

Options 139

Surge protective device (SPD) 141

General 141

Safety 141

Scope of supply 141

De-energising the inverter 142

Installation 143

Commissioning the inverter 148

DC Connector Kit GEN24 150

General 150

General comments regarding PV modules 150

Safety 150

Scope of supply 151

De-energising the inverter 151

Installation 152

Commissioning the inverter 156

Appendix 157

Care, maintenance and disposal 159

General 159

Cleaning 159

Maintenance 159

Safety 159

Operation in dusty environments 159

Disposal 160

Guarantee provisions 162

Fronius manufacturer's warranty 162

Components for automatic Full Backup backup power changeover 163

Components for automatic Full Backup backup power changeover 163

Status codes and remedy 165

Display 165

Status Codes 165

Technical data 166

Fronius Primo GEN24 8.0 / 8.0 Plus 166

Fronius Primo GEN24 10.0 / 10.0 Plus 169

WLAN 172

Technical data of surge protective device DC SPD type 1+2 GEN24 173

Explanation of footnotes 173

Integrated DC disconnector 174

Circuit diagrams 175

Circuit Diagram - PV Point (OP) 177

Circuit Diagram 177

Circuit Diagram - PV Point (OP) Australia 178

Circuit Diagram 178

Fronius Primo GEN24 and BYD Battery-Box Premium HV 179

Circuit Diagram 179

6

Page 7

Fronius Primo GEN24 with two BYD Battery-Box Premium HV connected in parallel 180

Circuit Diagram 180

Fronius Primo GEN24 with three BYD Battery-Box Premium HV connected in parallel 181

Circuit Diagram 181

Fronius Primo GEN24 and LG RESU FLEX 182

Circuit Diagram 182

Automatic switch to backup power 1-pin double separation - e.g. Austria 183

Circuit Diagram 183

Automatic switch to backup power 1-pin single separation - e.g. Australia 184

Circuit Diagram 184

Automatic switch to backup power 2-pin double separation - e.g. Germany 185

Circuit Diagram 185

Automatic switch to backup power 2-pin single separation - e.g. France, Spain 186

Circuit Diagram 186

Automatic switch to backup power 2-pin double separation - e.g. UK 187

Circuit Diagram 187

Automatic switch to backup power 2-pin double separation with ext. grid and system protection - e.g. Italy

Circuit Diagram 188

Fronius Primo GEN24 with Enwitec Box 189

Circuit Diagram 189

Wiring diagram - surge protective device SPD 190

Circuit Diagram 190

Dimensions of the inverter 191

188

EN

Fronius Primo GEN24 8 - 10 kW 193

Fronius Primo GEN24 8 - 10 kW 193

7

Page 8

Safety rules

Explanation of

safety notices

Safety

WARNING!

Indicates a potentially hazardous situation.

Death or serious injury may result if appropriate precautions are not taken.

▶

CAUTION!

Indicates a situation where damage could occur.

If not avoided, minor injury and/or damage to property may result.

▶

NOTE!

Indicates a risk of flawed results and possible damage to the equipment.

If you see any of the symbols depicted in the "Safety rules" chapter, special care

is required.

CAUTION!

Danger from crushing due to the incorrect handling of attachments and connection parts.

Injuries to limbs may result.

When lifting up, putting down and attaching the inverter, use the integrated

▶

grips.

When fitting attachments, ensure that no limbs are located between the at-

▶

tachment and the inverter.

Do not hold onto the individual poles on the terminals when locking and un-

▶

locking.

General The device has been manufactured in line with the state of the art and according

to recognised safety standards. In the event of incorrect operation or misuse,

there is a risk of

Injury or death to the operator or a third party

-

Damage to the device and other material assets belonging to the operating

-

company

All personnel involved in commissioning, maintenance, and servicing of the

device must:

Be suitably qualified

-

Have knowledge of and experience in dealing with electrical installations

-

Have fully read and precisely followed these Operating Instructions

-

In addition to the Operating Instructions, all applicable local rules and regulations regarding accident prevention and environmental protection must also be

followed.

8

Page 9

All safety and danger notices on the device:

Must be kept in a legible state

-

Must not be damaged

-

Must not be removed

-

Must not be covered, pasted, or painted over

-

Only operate the device when all protection devices are fully functional. If the

protection devices are not fully functional, there is a danger of

Injury or death to the operator or a third party

-

Damage to the device and other material assets belonging to the operating

-

company

Any safety devices that are not fully functional must be repaired by an authorized specialist before the device is switched on.

Never bypass or disable protection devices.

For the location of the safety and danger notices on the device, refer to the

chapter headed "Warning notices on the device" in the Operating Instructions for

your device.

Faults that could compromise safety must be remedied before switching on the

device.

EN

Environmental

conditions

Qualified personnel

Operation or storage of the device outside the stipulated area will be deemed as

not in accordance with the intended purpose. The manufacturer accepts no liability for any damage resulting from improper use.

The servicing information contained in these operating instructions is intended

only for the use of qualified service engineers. An electric shock can be fatal. Do

not carry out any actions other than those described in the documentation. This

also applies to qualified personnel.

All cables and leads must be secured, undamaged, insulated and adequately dimensioned. Loose connections, scorched, damaged or inadequately dimensioned

cables and leads must be immediately repaired by authorised personnel.

Maintenance and repair work must only be carried out by an authorised specialist.

It is impossible to guarantee that bought-in parts are designed and manufactured to meet the demands made on them, or that they satisfy safety requirements. Use only original spare parts (also applies to standard parts).

Do not carry out any alterations, installations, or modifications to the device

without first obtaining the manufacturer's permission.

Components that are not in perfect condition must be changed immediately.

Noise emission

values

The sound power level of the inverter is specified in the Technical data.

The device is cooled as quietly as possible with the aid of an electronic temperature control system; this depends on the amount of converted power, the ambient

temperature, the level of soiling of the device, etc.

It is not possible to provide a workplace-related emission value for this device

because the actual sound pressure level is heavily influenced by the installation

9

Page 10

situation, the grid quality, the surrounding walls and the properties of the room

in general.

EMC measures In certain cases, even though a device complies with the standard limit values for

emissions, it may affect the application area for which it was designed (e.g., when

there is equipment that is susceptible to interference at the same location, or if

the site where the device is installed is close to either radio or television receivers). If this is the case, then the operator is obliged to take action to rectify the

situation.

Backup power This system has backup power functions. This enables a replacement power sup-

ply to be established in the event of a failure in the public grid.

Where an automatic backup power supply is installed, a backup power warning

notice (https://www.fronius.com/en/search-page, item number: 42,0409,0275)

must be fitted on the electrical distributor.

Maintenance and installation work in the home network requires both disconnection on the utility side and deactivation of the replacement power mode by opening the integrated DC disconnector on the inverter.

Depending on the insolation conditions and the battery state of charge, the

backup power supply is automatically deactivated and activated. This can cause

the backup power supply to unexpectedly return from standby mode. Therefore,

installation work can only be performed on the home network when the backup

power supply is deactivated.

Influencing factors on the total power in backup power mode:

Reactive power

Electrical loads with a power factor not equal to 1 also require reactive power in

addition to effective power. The reactive power also loads the inverter. Therefore,

to correctly calculate the actual total power, it is not the rated power of the load

that is relevant, but the current caused by effective and reactive power.

Devices with a high reactive power are mainly electric motors such as:

Water pumps

-

Circular saws

-

Blowers and fans

-

High starting current

Electrical loads that need to accelerate a large mass usually require a high starting current. This can be up to 10 times higher than the nominal current. The maximum current of the inverter is available for the starting current. Loads with too

high starting currents therefore cannot be started/operated, even though the

nominal power of the inverter suggests that they can. When dimensioning the

backup power circuit, the connected load power and any starting current must

also be taken into account.

10

Devices with high starting currents are, for example:

Devices with electric motors (e.g. lifting platform, circular saws, planing

-

bench)

Devices with large transmission ratio and flywheel mass

-

Devices with compressors (e.g. compressed air compressors, air conditioning

-

systems)

IMPORTANT!

Very high starting currents can cause short-term distortion or a drop in output

Page 11

voltage. The simultaneous operation of electronic devices in the same backup

power supply system should be avoided.

IMPORTANT!

The inverter may only be operated within the limits of its technical capabilities.

Operation outside of its technical capabilities can cause the inverter to shut

down.

Data protection The user is responsible for the safekeeping of any changes made to the factory

settings. The manufacturer accepts no liability for any deleted personal settings.

Copyright Copyright of these operating instructions remains with the manufacturer.

The text and illustrations are all technically correct at the time of printing. We

reserve the right to make changes. The contents of the operating instructions

shall not provide the basis for any claims whatsoever on the part of the purchaser. If you have any suggestions for improvement, or can point out any mistakes that you have found in the instructions, we will be most grateful for your

comments.

EN

Protective

earthing (PE)

Connection of a point in the device, system or installation to earth to protect

against electric shock in the event of a fault. When installing a safety class 1 inverter (see Technical data), the ground conductor connection is required.

When connecting the ground conductor, ensure that it is secured against accidental disconnection. All the points listed in the chapter Connecting the invert-

er to the public grid (AC side) on page 69 must be observed. It must be ensured

that when using the strain relief devices, the ground conductor is the last to be

disconnected in the event of a possible failure. When connecting the ground conductor, the minimum cross-section requirements specified by the respective national standards and guidelines must be observed.

11

Page 12

12

Page 13

General information

13

Page 14

14

Page 15

Fronius Primo GEN24

Device concept The inverter transforms the direct current generated by the solar modules into

alternating current. This alternating current is fed into the public grid and synchronized with the grid voltage in use. Moreover, the solar energy can also be

stored in a connected battery for later use.

The inverter is intended for use in grid-connected photovoltaic systems. The inverter has backup power functions and switches to backup power mode if it has

been wired accordingly*.

The inverter automatically monitors the public grid. Whenever conditions in the

electric grid are inconsistent with standard conditions (for example, grid switchoff, interruption), the inverter will immediately stop producing power and interrupt the supply of power into the grid.

The grid is monitored by monitoring the voltage, frequency and islanding conditions.

After installation and commissioning, the inverter's operation is fully automatic;

the inverter draws the maximum possible power from the PV modules.

Depending on the operating point, this power is used in the home, stored in a battery* or fed into the grid.

EN

Function overview

As soon as the energy provided by the PV modules is no longer sufficient, the

power from the battery is fed into the home. Depending on the setting, power

may also be obtained from the public grid in order to charge the battery*.

When its temperature gets too high, the inverter automatically reduces the output or charging power, or switches off completely, in order to protect itself.

Reasons for the temperature being too high include a high ambient temperature

or insufficient heat dissipation (for example, inadequate heat dissipation when installed in switch cabinets).

* Depending on the device variant, suitable battery, appropriate wiring, set-

tings and local standards and guidelines.

Function Primo GEN24 Primo GEN24 Plus

Backup power variant - PV Point

(OP)

Battery connection*

Backup power variant - Full Backup

Available as an op-

tion**

Available as an op-

tion**

* For suitable batteries, see chapter Suitable batteries.

** The functions are optionally available via Fronius UP (see chapter Fronius

UP).

15

Page 16

Fronius UP With Fronius UP*, the inverter can be expanded by the authorised specialist to

include optionally available functions (see chapter Function overview).

* The availability of Fronius UP varies from country to country. For more in-

formation on Fronius UP and availability, see Installation guide: Fronius

GEN24 & GEN24 Plus.

Scope of supply

Intended use The inverter is designed to convert direct current from PV modules into alternat-

ing current and feed this power into the public grid. A backup power mode* is

possible provided that appropriate cabling has been installed.

The following are considered improper use:

Utilisation for any other purpose, or in any other manner

-

Alterations to the inverter are not permitted unless expressly recommended

-

by Fronius

Installation of components is not permitted unless expressly recommended

-

or sold by Fronius

(1) Housing cover

(2) Inverter

(3) Mounting bracket (illustration)

(4) Quick Start guide

16

The manufacturer is not responsible for any damage resulting from improper use.

All warranty claims are considered void in such cases.

Intended use also means:

Carefully reading and obeying all the instructions, as well as safety

-

and danger notices in the Operating Instructions

Installation in accordance with chapter "Installation" from page 53.

-

When designing the photovoltaic system, ensure that all components of the

photovoltaic system are operated exclusively within their permissible operating

range.

Take into account the grid operator's regulations for energy fed into the grid and

connection methods.

Page 17

The Fronius GEN24 inverter is a grid-connected inverter with a backup power

function – it is not a stand-alone inverter. The following restrictions must therefore be observed in backup power mode:

Backup power mode may be in operation for at max. 2000 hours

-

Backup power mode may be in operation for more than 2000 operating hours

-

if 20% of the duration of the inverter's grid power feed operation is not exceeded at the relevant time.

* Depending on the device variant, suitable battery, appropriate wiring, set-

tings, and local standards and guidelines.

Thermal concept Ambient air is drawn in by the fan on

the front side and blown out at the

device sides. The even heat dissipation

allows several inverters to be installed

next to each other.

EN

Fronius Solar.web

NOTE!

Risk due to insufficient cooling of the inverter.

This may result in a loss of power in the inverter.

Do not block the fan (for example, with objects that protrude through the

▶

touch guard).

Do not cover the ventilation slots, even partially.

▶

Make sure that the ambient air can always flow through the inverter's ventila-

▶

tion slots unimpeded.

With Fronius Solar.web or Fronius Solar.web Premium, the PV system can be

easily monitored and analysed by the system owner and installer. If configured

accordingly, the inverter transmits data such as power, yields, load, and energy

balance to Fronius Solar.web. For more information see Solar.web - monitoring &

analysis.

Configuration is carried out via the setup wizard, see chapter Installation with

the app on page 100 or Installation using the web browser on page 100.

Prerequisites for configuration:

Internet connection (download: min. 512 kBit/s, upload: min. 256 kBit/s)*.

-

User account on solarweb.com.

-

Completed configuration via the setup wizard.

-

* The information given does not constitute an absolute guarantee of fault-

less function. High error rates in the transmission, reception fluctuations

or transmission drop-outs can have a negative effect on the data transfer.

17

Page 18

Fronius recommends testing the Internet connection on site according to

the minimum requirements.

Local communication

The inverter can be found via the Multicast DNS protocol (mDNS). It is recommended to search for the inverter by the assigned host name.

The following data can be retrieved via mDNS:

NominalPower

-

Systemname

-

DeviceSerialNumber

-

SoftwareBundleVersion

-

18

Page 19

The various operating modes

EN

Operating modes

– Explanation of

symbols

PV module

generates direct current

Fronius GEN24 inverter

converts direct current into alternating current and charges the battery (battery charging is only possible with Fronius GEN24 Plus inverters). The integrated system monitoring enables the inverter to be integrated into a network by means of WLAN.

Additional inverter in the system

converts the direct current into alternating current. However, it cannot charge a battery, and is not available in backup power mode.

Battery

is coupled to the inverter on the direct current side, and stores electrical energy.

Fronius Ohmpilot

for using excess energy to heat water.

Primary meter

records the system's load curve and provides measurement data for

energy profiling in Fronius Solar.web. The primary meter also controls

the dynamic feed-in control.

Secondary meter

records the load curve of individual loads (e.g. washing machine,

lamps, TV, heat pump, etc.) in the consumption branch and provides

measurement data for energy profiling in Fronius Solar.web.

Loads in the PV system

are the loads connected in the system.

Additional loads and generators in the system

are connected to the system by means of a Smart Meter.

PV Point

is a non-uninterruptible 1‑phase backup power circuit which supplies

electrical devices with up to 3 kW if sufficient power is available from

the PV modules or the battery.

Full Backup

the inverter is prepared for backup power mode. The backup power

mode must be implemented in the switch cabinet by the electrician

performing the installation. The PV system operates in a stand-alone

manner in backup power mode.

Grid

supplies the loads in the system if insufficient power is being generated by the PV modules or supplied by the battery.

19

Page 20

Operating mode

00

1

6

1

00

1

6

1

00

1

6

2

+

-

00

1

6

1

– Inverter with

battery

Operating mode

– Inverter with

battery and several Smart

Meters

In order to be able to obtain the highest rate of self-consumption with your PV

system, a battery can be used to store excess energy. The battery is coupled to

the inverter on the direct current side. Multiple current conversion is therefore

not required, and the efficiency is increased.

Operating mode

- inverter with

battery, ACcoupled to another inverter

20

Page 21

Operating mode

+

-

00

1

6

1

+

-

00

1

6

1

– Inverter with

battery and

backup power

function

IMPORTANT!

In backup power mode, an increased nominal frequency is used in order to prevent undesired parallel operation with other power generators.

In the fully equipped hybrid PV system, the inverter can:

Supply loads in the house

-

Store excess energy in the battery and/or feed it into the grid

-

Supply connected loads in the event of a power failure

-

EN

Operating mode

– Inverter with

battery, Ohmpilot and backup

power function

Operating mode

– Inverter with

battery, further

inverter and

backup power

function

IMPORTANT!

In the fully equipped hybrid PV system with a Fronius Ohmpilot, the Ohmpilot

cannot be operated in the event of a power failure for regulatory reasons. It is

therefore sensible to install the Ohmpilot outside of the backup power branch.

In the hybrid photovoltaic system, batteries must only be connected to one inverter with battery support. Batteries cannot be split between multiple inverters

with battery support. However, depending on the battery manufacturer, several

batteries can be combined on one inverter.

21

Page 22

+

-

00

1

6

1

Energy flow dir-

AC~DC=

DC=

(1)

(2)

(4)

(3)

+

-

ection of the inverter

In the case of hybrid inverters, there are four different energy flow directions:

(1) PV module – inverter – load/grid

Operating states

(only for systems

with a battery)

22

(2) PV module – inverter – battery*

(3) Battery – inverter – load/grid*

(4) Grid – inverter – battery*

* depending on the settings and local standards and regulations.

Battery systems distinguish different operating states. In this case, the relevant

current operating state is displayed on the user interface of the inverter or in

Solar.web.

Operating state Description

Normal operation Energy is stored or drawn, as required.

Page 23

Operating state Description

Min. state of charge (SOC)

achieved

Energy saving mode

(standby)

Start The storage system starts from energy saving

Forced re-charging The inverter re-charges the battery, in order to

Deactivated The battery is not active. It has either been deac-

Battery has reached the minimum SOC set or

specified by the manufacturer. The battery cannot

be discharged any further.

The system has been put into energy saving mode.

Energy saving mode is automatically ended as

soon as sufficient excess energy is available again.

mode (standby).

maintain the set minimum SOC (state of charge)

or the SOC specified by the manufacturer (protection against deep discharge).

tivated/switched off, or an error means that no

communication with the battery is possible.

EN

23

Page 24

Energy saving mode

General Energy saving mode (standby mode) is used to reduce the self-consumption of

the system. Both the inverter and the battery automatically switch to energy saving mode under certain conditions.

The inverter switches to energy saving mode if the battery is flat and no PV

power is available. Only the inverter's communication with the Fronius Smart

Meter and Fronius Solar.web is maintained.

Switch-off conditions

Switch-on conditions

If all the switch-off conditions are met, the battery switches into energy saving

mode within ten minutes. This time delay ensures that the inverter can at least be

restarted.

The battery state of charge is less than or equal to the input

minimum state of charge.

The current charging or discharging power of the battery is

less than 100 W.

Less than 50 W is available for charging the battery. The

power of feeding into the public grid is at least 50 W less than

the power currently required in the home network.

The inverter automatically switches into energy saving mode, following the battery.

If one of the following conditions is met for at least 30 seconds, energy saving

mode is ended:

Energy saving mode is no longer permissible owing to a changed setting on

-

the user interface of the inverter.

If dynamic power reduction of 0 is set, or if the system is operating in backup

-

power mode, the power of feeding into the public grid is always less than the

required power in the home network.

There is a separate condition for this case (dynamic power reduction < 300 W

or active backup power mode):

If the PV power is above a specified threshold, energy saving mode is

-

ended.

Battery charging from the public grid is requested via the user interface of

-

the inverter.

The battery is being recharged in order to restore the minimum state of

-

charge or perform calibration.

Special case If the inverter does not operate for 12 minutes (e.g. fault), or there is an interrup-

tion in the electrical connection between the inverter and the battery and there

is no backup power mode, the battery switches to energy-saving mode in any

case. This reduces self discharge of the battery.

24

Page 25

Indication of en-

5

%

Energy-saving mode

ergy saving

mode

During energy saving mode:

Operating LED for the inverter lights up orange (see Button functions and

-

LED status indicator on page 35).

The user interface of the inverter can be reached.

-

All the available data is saved and transmitted to Solar.web.

-

The real-time data can be seen on Solar.web.

-

Energy saving mode is shown on the

user interface of the inverter and in

Solar.web by an "i" beside the battery

symbol in the system overview.

EN

25

Page 26

Suitable batteries

General Fronius explicitly points out that the third-party batteries are not Fronius

products. Fronius is not the manufacturer, distributor or retailer of these batteries. Fronius accepts no liability and offers no service or guarantees for these batteries.

Obsolete firmware/software states may lead to incompatibilities between the inverter and the battery. In this case, the following steps are to be performed:

Update battery software – see the battery documentation.

1

Update inverter firmware – see Update on page 118.

2

Read this document and the Installation Instructions before installing and commissioning the external battery. The documentation is either enclosed with the

external battery or can be obtained from the battery manufacturer or their service partners

All documents associated with the inverter can be found at the following address:

https://www.fronius.com/en/solar-energy/installers-partners/service-support/

tech-support

Limitations in

operation

BYD BatteryBox Premium

If the DC voltage exceeds 520 V, the battery can no longer be charged or discharged. The voltage of 520 V is rarely exceeded during normal operation of the

inverter.

When the output power of the inverter is reduced, the operating point shifts towards higher DC voltages. The following conditions during normal operation can

lead to the DC voltage of 520 V being exceeded:

Overdimensioning of the PV generator.

-

Feed-in limitation (e.g. zero feed-in).

-

Specifications of the grid operator (e.g. mains voltage-dependent power re-

-

duction).

Backup power mode. If the 520 V voltage is exceeded during backup power,

-

backup power operation may be restricted. Therefore, an open circuit voltage

of max. 520 V is recommended.

BYD Battery-Box Premium HVS 5.1 7.7 10.2 12.8

Fronius Primo GEN24 8.0 - 10.0*

Fronius Primo GEN24 8.0 - 10.0 Plus

Number of battery modules 2 3 4 5

26

Battery parallel operation**

BYD Battery-Box Premium HVM 8.3 11.0 13.8 16.6 19.3 22.1

Fronius Primo GEN24 8.0 - 10.0*

Page 27

BYD Battery-Box Premium HVM 8.3 11.0 13.8 16.6 19.3 22.1

Fronius Primo GEN24 8.0 - 10.0 Plus

Number of battery modules 3 4 5 6 7 8

Battery parallel operation**

* Battery support optionally available.

** Max. 3 batteries with the same capacity can be combined.

IMPORTANT!

According to the manufacturer's specifications, the max. DC cable length is 20

m. More detailed information can be found in the manufacturer's documents.

IMPORTANT!

To ensure reliable operation with a BYD Battery-Box Premium, the following

switch-on sequence for the system must always be observed.

1

Switch on the battery.

EN

LG RESU FLEX

2

Set the DC disconnector to the "On"

switch position. Switch on the automatic circuit breaker.

LG RESU FLEX 8.6 12.9 17.2

Fronius Primo GEN24 3.0 - 10.0*

27

Page 28

LG RESU FLEX 8.6 12.9 17.2

Fronius Primo GEN24 3.0 - 10.0 Plus

Number of battery modules 2 3 4

* Battery support optionally available.

IMPORTANT!

According to the manufacturer's specifications, the max. DC cable length is 30

m. More detailed information can be found in the manufacturer's documents.

Switching on the battery

1

Pull off the cover to the right.

2

Pull off the cover of the DC disconnector to the front. Set the DC disconnector to the "On" switch position.

To refit the battery, follow the steps listed above in reverse order.

28

Page 29

Manual system start

Requirements There is no energy available from the PV modules or from the public grid. If

backup power operation or battery operation are not possible (e.g. deep discharge protection of the battery), the inverter and battery switch off.

EN

Notification of

system shutdown

Manual battery

start after system shutdown

Starting backup

power operation

after a system

shutdown

Status codes about the inactive state of the battery are displayed on the user interface of the inverter or sent via Solar.web by means of SMS or e-mail (only if

notification via Solar.web is configured accordingly).

As soon as energy is available again, the inverter starts operation automatically;

however the battery must be started manually. The switch-on sequence must be

observed for this, see chapter Suitable batteries on page 26.

The inverter requires energy from the battery to start backup power operation.

This is done manually on the battery; further information on the power supply for

restarting the inverter via the battery can be found in the battery manufacturer's

Operating Instructions.

29

Page 30

Protection of people and equipment

Central grid and

system protection

WSD (wired

shutdown)

RCMU The inverter is equipped with a universal current-sensitive residual current monit-

The inverter offers the option to use the integrated AC relays as coupling

switches in conjunction with a central grid and system protection unit (in accordance with VDE-AR-N 4105:2018:11 §6.4.1). For this purpose, the central trigger

device (switch) must be integrated into the WSD chain as described in the

chapter "WSD (Wired Shut Down)".

The wired shutdown (WSD) interrupts the inverter feeding energy into the grid if

the trigger device (switch, e.g. emergency stop or fire alarm switch) has been activated.

If an inverter (secondary device) fails, it is bypassed and the other inverters continue operating. If a second inverter (secondary device) or the inverter (primary

device) fails, the operation of the entire WSD chain is interrupted.

For installation, see Installing the WSD (wired shutdown) on page 98.

oring unit (RCMU = Residual Current Monitoring Unit) in accordance with IEC

62109-2 and IEC63112.

This device monitors residual currents from the PV module to the AC output of

the inverter and disconnects the inverter from the grid in the event of unauthorised residual current.

Safe state If one of the following safety devices trips, the inverter will change to a safe

state:

WSD

-

insulation measurement and

-

RCMU

-

In the safe state, the inverter no longer feeds into the grid and is disconnected

from the grid by opening the AC relays.

Surge protective

device

The inverter is equipped with an integrated surge protective device on the DC

and AC side in accordance with IEC 62109-2. The surge protective device protects the system against damage in the event of a surge.

30

Page 31

Control elements and connections

Connection area

EN

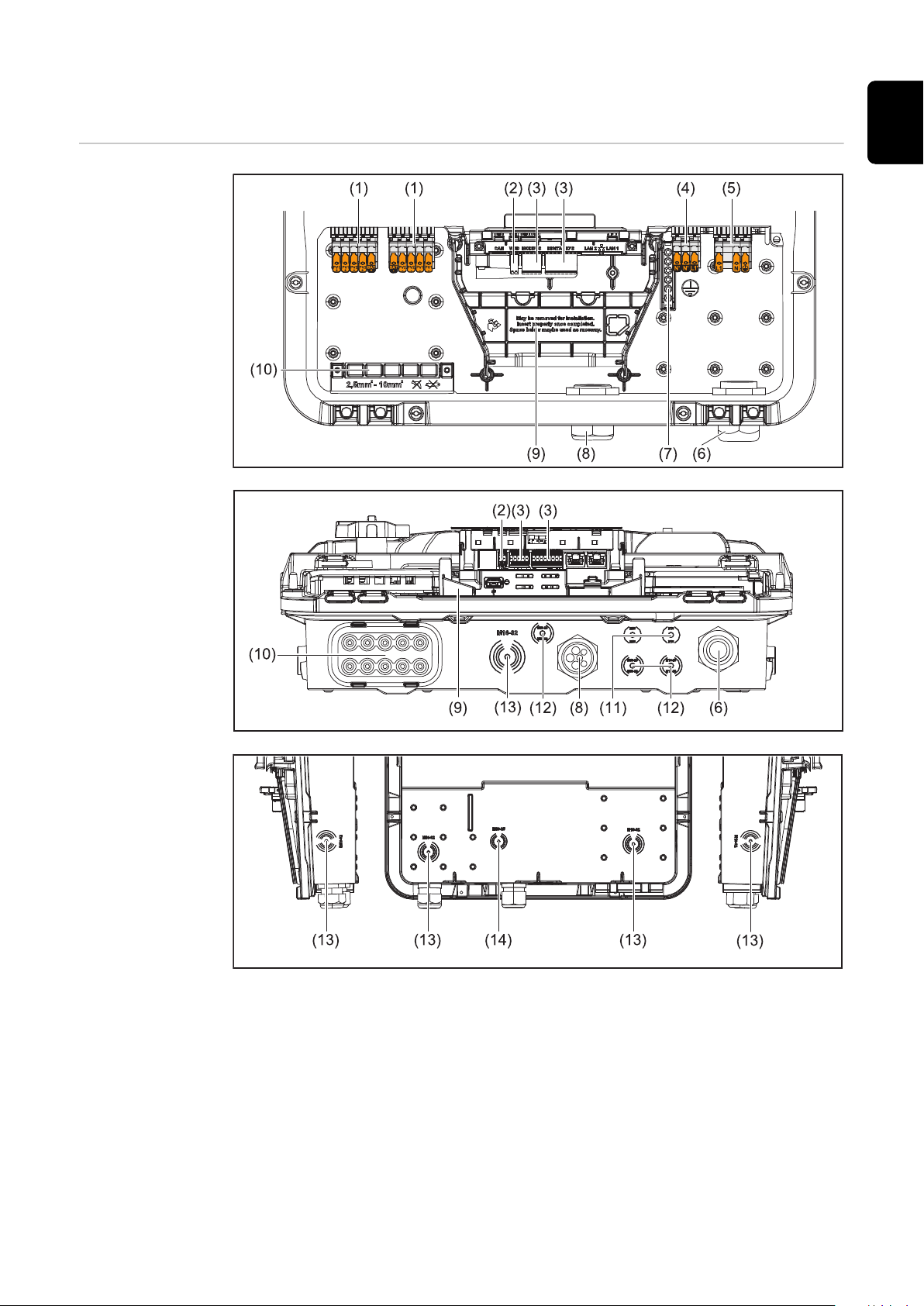

(1) 2 x 5-pin DC push-in terminal

(2) Push-in WSD (wired shutdown) terminal

(3) Push-in terminals in the data communication area (Modbus, digital inputs

and outputs)

(4) 3-pin push-in terminal for PV Point (OP)

(5) 3-pin AC push-in terminal

(6) Cable gland/strain-relief device AC

(7) 6-pin ground electrode terminal

(8) Cable gland/strain-relief device in the data communication area

31

Page 32

(9) Connection area divider

(10) 10 x DC cable glands

(11) Optional cable gland (M16)

(12) Optional cable gland (M16 - M20)

(13) Optional cable gland (M16 - M32)

(14) Optional cable gland (M16 - M25)

Connection area

divider

Ground electrode terminal

The connection area divider separates the high-voltage conductors (DC and AC)

from the signal lines. To make it easier to reach the connection area, the divider

can be removed for the connection work, and must be re-inserted.

(1) Integrated cable duct

(2) Recesses for removing the con-

nection area divider

(3) Snap tabs for locking/unlocking

(4) Defined breaking point for the

Datcom connection

The integrated cable duct (1) allows for

the lines to be laid from one area of

the inverter to the other. As a result,

multiple inverters can be easily installed next to each other.

The ground electrode terminal allows additional components to be

earthed, such as:

AC cable

-

Module mounting system

-

Ground rod

-

32

Page 33

DC disconnector The DC disconnector has 3 switch set-

tings:

(1) Locked/off (turned to the left)

(2) Off

(3) On

IMPORTANT!

In switch settings (1) and (3), a conventional padlock can be used to secure

the inverter against being switched on/

off. The national guidelines must be

complied with in this respect.

Data communication area

EN

Modbus terminal Push-in terminal for the installation of

Modbus 0, Modbus 1, 12 V and GND

(ground).

The data connection to the connected

components is established via the

Modbus terminal. The inputs M0 and

M1 can be selected for this purpose.

Max. 4 Modbus participants per input,

see chapter Modbus participants on

page 93.

WSD (wired shutdown) switch Defines the inverter as a WSD primary

device or WSD secondary device.

Position 1: WSD primary device

Position 0: WSD secondary device

33

Page 34

Modbus 0 (MB0) switch Switches the terminating resistor for

Modbus 0 (MB0) on/off.

Position 1: Terminating resistor on

(factory setting)

Position 0: Terminating resistor off

Modbus 1 (MB1) switch Switches the terminating resistor for

Modbus 1 (MB1) on/off.

Position 1: Terminating resistor on

(factory setting)

Position 0: Terminating resistor off

Optical sensor

Communication LED

Operating status LED

LAN 1 Ethernet connection for data commu-

LAN 2 Reserved for future functions. Only

WSD terminal Push-in terminal for the WSD installa-

IOs terminal Push-in terminal for digital inputs/

To operate the inverter. See chapter

Button functions and LED status indicator on page 35.

Indicates the inverter connection

status.

Indicates the inverter operating

status.

nication (e.g. WLAN router, home network or for commissioning with a

laptop see chapter Installation using

the web browser on page 100).

use LAN 1 to avoid malfunctions.

tion. See chapter "WSD (wired shut-

down)" on page 30.

outputs. See chapter Permitted

cables for the data communication

connection on page 66.

The designations (RG0, CL0, 1/5, 2/6,

3/7, 4/8) on the terminal refer to the

Demand Response Mode function, see

chapter Functions andI/Os on page

107.

34

Page 35

Button functions

Ok

Standby

Uncritical Error

(flashing)

Critical Error

Network Error

Connecting

(flashing)

Connected

1x WLAN access point

2x WPS

3-6 sec. Quit Service Message

and LED status

indicator

Sensor functions

The status of the inverter is

shown via the operating status

LED. In the event of faults,

carry out the individual steps

in the Fronius Solar.start app.

The optical sensor is actuated

by touching with a finger.

The status of the connection is

shown via the communication

LED. To establish the connec-

tion, carry out the individual

steps in the Fronius Solar.start

app.

1x = WLAN Access Point (AP) is opened.

Flashing blue

EN

LED status indicator

2x = WLAN Protected Setup (WPS) is activated.

Flashing green

3 seconds (max. 6 seconds) = the service message is

terminated.

Lights up yellow

The inverter is operating correctly.

Lights up green

The inverter starts.

Flashing green

The inverter is in standby, is not operational (e.g. no

feed-in at night) or is not configured.

Lights up yellow

The inverter indicates a non-critical status.

Flashing yellow

The inverter indicates a critical status and there is no

grid power feed process.

Lights up red

35

Page 36

LED status indicator

The inverter indicates a back-up power overload.

Flashing red

The network connection is being established via WPS.

2x = WPS search mode.

Flashing green

The network connection is being established via

WLAN AP.

1x = WLAN AP search mode (active for 30 minutes).

Flashing blue

The network connection is not configured.

Lights up yellow

The inverter is operating correctly, a network fault is indicated.

Lights up red

Internal schematic connection

diagram of the

IOs

The inverter is performing an update.

/ Flashing blue

On the V+/GND pin, it is possible to feed in a voltage of around 12.5–24 V (+ max.

20%) with an external power supply. The outputs IO 0–5 can then be operated

with the external voltage. A maximum of 1 A can be drawn per output, with a

maximum of 3 A allowed in total. The fuse protection must be located externally.

CAUTION!

Risk of polarity reversal at the terminals due to improper connection of external

power supplies.

This may result in severe damage to the inverter.

Check the polarity of the external power supply with a suitable measuring

▶

device before connecting it.

Connect the cables to the V+/GND outputs with the correct polarity.

▶

IMPORTANT!

If the total output (6 W) is exceeded, the inverter switches off the entire external

power supply.

36

Page 37

12 V DC

500 mA

V+ V+

GND

IO0

IO1

IN8

IN9

IN10

IN11

IN6

IN7

IO4

IO5

IO2

IO3

GND

(1)

12 V

USB

TYP A

5 V

IO4

V+

V+

IO0

IO2

IN6

IN8

IN10IN11

IN9

IN7

IO5

IO3

IO1

GND

GND

M0-

M0+

M1-

M1+

SHIELD

SHIELD

V+ V+

GND GND

V+

V+

M0+

SHIELD

M1+

GND

M1-

SHIELD

M0-

GND

(1) Power limitation

EN

37

Page 38

38

Page 39

Backup power variant - PV Point

(OP)

39

Page 40

40

Page 41

General

PV Point (OP) IMPORTANT!

If several backup power variants are available, please note that only one backup

power variant may be installed and configured.

EN

With the PV Point, in the event of a

failure of the public grid, electrical

devices can be connected to the Opportunity Power (OP) terminal and

supplied with a maximum power of

3 kW, if enough power is available from

the PV modules or an optional battery.

In grid-connected operation, the OP

terminal is not supplied with voltage,

therefore the connected loads will not

be supplied with power in this operating mode.

IMPORTANT!

A relay-based network switching setup

is not possible.

Explanation - PV

Point (OP)

The inverter can provide 220 ‑ 240 V at the PV Point. A corresponding configuration must be set up during commissioning.

At 220 ‑ 240 V output voltage, max. 13 A AC continuous current is available.

Example:

230 V *13 A = 2860 W

240 V *13 A = max. 3 kW

In backup power mode, some electrical appliances cannot function properly as

starting currents are too high (for example, fridges and freezers). It is recommended to switch off non-essential loads during backup power mode. Overload capacity of 35% is possible for a duration of 5 seconds, depending on the capacity of

the PV modules and/or the battery at that moment in time.

There is a brief interruption when switching from grid-connected mode to backup

power mode. For this reason, the backup power function cannot be used as an

uninterruptible power supply, for example for computers.

If no energy from the battery or the solar modules is available in backup power

mode, backup power mode ends automatically. If sufficient energy becomes

available from the solar modules once again, backup power mode starts again

automatically.

In the event of excessive consumption, backup power mode is stopped and the

"backup power overload" status code is displayed on the inverter's LED status indicator. The maximum power in backup power mode according to the technical

data must be observed.

41

Page 42

42

Page 43

Backup power variant - Full Backup

43

Page 44

44

Page 45

General

EN

Prerequisites for

backup power

mode

IMPORTANT!

If several backup power variants are available, please note that only one backup

power variant may be installed and configured.

In order to use the inverter's backup power function, the following prerequisites

must be fulfilled:

The inverter must support the backup power variant – Full Backup (see

-

chapter Function overview on page 15).

A battery suitable for backup power use must be installed and configured.

-

Correct cabling of the backup power system in the electrical installation or

-

usage of a switch box from Enwitec (see chapter Components for automatic

Full Backup backup power changeover on page 163 or Circuit diagrams on

page 175).

Mount and configure the Fronius Smart Meter at the feed-in point.

-

Attach a warning notice for the backup power supply (https://www.froni-

-

us.com/en/search-page, item number: 42,0409,0275) on the electrical distributor.

Apply the necessary settings in the "Devices and system components" →

-

"Functions and pins" → "Backup power" menu area and activate backup

power.

Follow the backup power checklist (https://www.fronius.com/en/search-

-

page, item number: 42,0426,0365) step by step and confirm.

Transitioning

from feeding energy into the grid

to backup power

mode

Transitioning

from backup

power mode to

feeding energy

into the grid

The public grid is monitored by the inverter's internal grid and system pro-

1.

tection unit and by the Fronius Smart Meter connected to it.

The public grid fails or specific grid parameters are dropped below or ex-

2.

ceeded.

The inverter carries out the measures necessary according to the country

3.

standard and then switches off.

The inverter starts backup power mode after a checking period.

4.

All loads in the household that are in the backup power circuit are supplied

5.

by the battery and the PV modules. The remaining loads are not supplied

with power and are safely isolated.

The inverter is operating in backup power mode.

1.

The public grid is functioning correctly again.

2.

The Fronius Smart Meter monitors the grid parameters on the public grid

3.

and passes this information to the inverter.

The stability of the returned public grid is determined by checking the meas-

4.

ured values of the Fronius Smart Meter.

The inverter ends backup power mode.

5.

All circuits are reconnected to the public grid and are supplied by the grid.

6.

The inverter can start feeding energy into the grid again after performing the

7.

grid checks required by the relevant standard.

45

Page 46

Backup power

and energy saving mode

Under the following conditions, the battery and the inverter are switched to energy saving mode after a waiting time of 8 - 12 minutes and backup power mode

is ended:

The battery is discharged to the minimum state of charge and no energy is

-

coming from the PV modules.

The inverter is set to energy saving mode (standby mode).

-

If the battery and inverter are in energy saving mode, the system is reactivated

by the following:

Enough energy is available from the PV modules.

-

The public grid is functioning again.

-

The battery is switched off and on.

-

46

Page 47

Cabling variants including backup power circuits

with 1-pin separation e.g. Austria or Australia

Functions

Transitioning

from feeding energy into the grid

to backup power

mode

Measuring and transferring the required parameters for energy management

-

and Solar.web by the Fronius Smart Meter.

Disconnecting from the public grid to enable operation in backup power

-

mode if the grid parameters are outside the country-specific standards.

Reconnecting to the public grid when the grid parameters are within the lim-

-

its specified by the country-specific standards.

Option of having a separate backup power circuit or several backup power

-

circuits that are supplied even during failure of the public grid. The total load

of the backup power circuits must not exceed the nominal output of the inverter. Furthermore, the performance of the connected battery must also be

considered.

The public grid is monitored by the inverter's internal grid and system pro-

1.

tection unit and by the Fronius Smart Meter connected to it.

Failure of the public grid.

2.

The inverter carries out the necessary measures according to the country

3.

standard and then switches off.

Contactors K1 and K2 (K2 - optional in Australia) drop out. This disconnects

the backup power circuits and the inverter from the rest of the home network and from the public grid, as the main contacts of the contactors K1 and

K2 1-pin open. The inverter activates relay K3, which interrupts the supply to

contactors K1 and K2. This prevents unintentional activation of contactors

K1 and K2 and thus a grid connection when voltage is restored in the grid.

The NC auxiliary contacts of contactors K1 and K2 send feedback to the inverter that the contactors are open (a condition for starting backup power

mode).

The NO contact of relay K3 gives additional feedback to the inverter on

4.

whether the locking was successfully performed by relay K3.

The inverter decides based on the contactors' feedback as well as the meas-

5.

urements on the inverter terminals and the Smart Meter that backup power

mode can be started.

After all the required activation tests have been carried out, the inverter

6.

starts backup power mode.

All loads in the backup power circuits are supplied with power. The remaining

7.

loads are not supplied with power and are safely isolated.

EN

Transitioning

from backup

power mode to

feeding energy

into the grid

The inverter is operating in backup power mode. The contactors K1 and K2 to

1.

the public grid are open.

Public grid available again.

2.

The Fronius Smart Meter monitors the grid parameters on the public grid

3.

and passes this information to the inverter.

The stability of the returned public grid is determined by checking the meas-

4.

ured values of the Fronius Smart Meter.

The inverter ends backup power mode and disconnects the outputs.

5.

The inverter deactivates K3. The contactors K1 and K2 are reactivated.

6.

All circuits are reconnected to the public grid and are supplied by the grid.

7.

The inverter does not feed anything into the grid at this time.

The inverter can start feeding energy into the grid again after performing the

8.

grid checks required by the relevant standard.

47

Page 48

All-pin separation cabling variant e.g. Germany,

France, Spain, UK

Functions

Transitioning

from feeding energy into the grid

to backup power

mode

Measuring and transferring the required parameters for energy management

-

and Solar.web by the Fronius Smart Meter.

Disconnecting from the public grid to enable operation in backup power

-

mode if the grid parameters are outside the country-specific standards.

Reconnecting to the public grid when the grid parameters are within the lim-

-

its specified by the country-specific standards.

Establishing a proper ground connection for backup power mode to ensure

-

the protection devices function correctly.

Option of having a separate backup power circuit or several backup power

-

circuits that are supplied even during failure of the public grid. The total load

of the backup power circuits must not exceed the nominal output of the inverter. Furthermore, the performance of the connected battery must also be

considered.

The public grid is monitored by the inverter's internal grid and system pro-

1.

tection unit and by the Fronius Smart Meter connected to it.

Failure of the public grid.

2.

The inverter carries out the necessary measures according to the country

3.

standard and then switches off.

Contactors K1, K2 (K2 - optional in France and Spain), K4 and K5 drop out.

This disconnects the backup power circuits and the inverter from the rest of

the home network and from the public grid, as the main contacts of the contactors K1 and K2 all-pin open. The NC auxiliary contacts of contactors K1

and K2 send feedback to the inverter that the contactors are open (a condition for starting backup power mode).

The NC main contacts of contactors K4 and K5 are closed, establishing a

4.

connection between the neutral conductor and the ground conductor. The

two other NC main contacts of contactors K4 and K5 give feedback to the

inverter that the ground connection has been established correctly (a condition for starting backup power mode).

The inverter activates relay K3, which interrupts the supply to contactors K1,

5.

K2, K4 and K5. This prevents unintentional activation of contactors K1, K2,

K4 and K5 and thus a grid connection when voltage is restored in the grid.

The NO contact of relay K3 gives additional feedback to the inverter on

6.

whether the locking was successfully performed by relay K3.

The inverter decides based on the contactors' feedback as well as the meas-

7.

urements on the inverter terminals and the Smart Meter that backup power

mode can be started.

After all the required activation tests have been carried out, the inverter

8.

starts backup power mode.

All loads in the backup power circuits are supplied with power. The remaining

9.

loads are not supplied with power and are safely isolated.

48

Page 49

Transitioning

from backup

power mode to

feeding energy

into the grid

The inverter is operating in backup power mode. The contactors K1 and K2 to

1.

the public grid are open.

Public grid available again.

2.

The Fronius Smart Meter monitors the grid parameters on the public grid

3.

and passes this information to the inverter.

The stability of the returned public grid is determined by checking the meas-

4.

ured values of the Fronius Smart Meter.

The inverter ends backup power mode and disconnects the outputs.

5.

The inverter deactivates K3. Power is restored to contactors K1, K2, K4 and

6.

K5.

All circuits are reconnected to the public grid and are supplied by the grid.

7.

The inverter does not feed anything into the grid at this time.

The inverter can start feeding energy into the grid again after performing the

8.

grid checks required by the relevant standard.

EN

49

Page 50

All-pin separation cabling variant, Italy

Functions

Transitioning

from feeding energy into the grid

to backup power

mode

Measuring and transferring the required parameters for energy management

-

and Solar.web by the Fronius Smart Meter.

Monitoring of the voltage and frequency grid parameters by the inverter.

-

Disconnecting from the public grid to enable operation in backup power

-

mode if the grid parameters are outside the country-specific standards.

Reconnecting to the public grid when the grid parameters are within the lim-

-

its specified by the country-specific standards.

Establishing a correct ground connection for backup power mode.

-

Option of having a separate backup power circuit or several backup power

-

circuits that are supplied even during failure of the public grid. The total load

of the backup power circuits must not exceed the nominal output of the inverter. Furthermore, the performance of the connected battery must also be

considered.

The public grid is monitored by the inverter's internal grid and system pro-

1.

tection unit and by an external grid and system protection unit.

Failure of the public grid

2.

The inverter carries out the measures necessary according to the country

3.

standard and then switches off.

The external grid and system protection unit opens contactors K1 and K2 for

4.

grid monitoring. This disconnects the backup power circuits and the inverter

from the rest of the home network and from the public grid, as the main contacts of the contactors K1 and K2 all-pin open. To ensure that the public grid

has definitely been disconnected, the NC auxiliary contacts of contactor K1

give feedback to the external grid and system protection unit.

The NC main contacts of contactors K4 and K5 are closed, establishing a

5.

connection between the neutral conductor and the ground conductor. The

two other NC main contacts of contactors K4 and K5 give feedback to the

inverter that the ground connection has been established correctly.

The inverter activates relay K3, which activates the remote input of the ex-

6.

ternal grid and system protection unit via an NC contact. This prevents a

connection to the public grid when voltage is restored in the grid.

The NO contact of relay K3 gives additional feedback to the inverter on

7.

whether the locking was successfully performed by relay K3.

The inverter decides based on the contactor's feedback as well as the meas-

8.

urement on the inverter terminals and the Smart Meter that the emergency

power mode can be activated.

The inverter starts backup power mode after a defined checking period.

9.

All loads in the backup power circuits are supplied with power. The remaining

10.

loads are not supplied with power and are safely isolated.

50

Page 51

Transitioning

from backup

power mode to

feeding energy

into the grid

The inverter is operating in backup power mode. The contactors K1 and K2 to

1.

the public grid are open.

Public grid available again.

2.

The Fronius Smart Meter monitors the grid parameters on the public grid

3.

and passes this information to the inverter.

The stability of the returned public grid is determined by checking the meas-

4.

ured values of the Fronius Smart Meter.

On the basis of adjustments that have been carried out, the inverter ends

5.

backup power mode and disconnects the outputs.

The inverter deactivates K3. Power is restored to contactors K1, K2, K4 and

6.

K5.

All circuits are reconnected to the public grid and are supplied by the grid.

7.

The inverter does not feed anything into the grid at this time.

The inverter can start feeding energy into the grid again after performing the

8.

grid checks required by the relevant standard.

EN

51

Page 52

52

Page 53

Installation

53

Page 54

54

Page 55

General

EN

Quick-lock system

A quick-lock system (3) is used to

mount the connection area cover and

front cover. The system is opened and

closed with a half-rotation (180°) of

the captive screw (1) into the quicklock spring (2).

The system is independent of torque.

NOTE!

Danger when using a drill driver.

This may result in the destruction of the quick-lock system due to overtorque.

Use a screwdriver (TX20).

▶

Do not turn the screws more than 180°.

▶

Warning notices

on the device

Technical data, warning notices and safety symbols are affixed to the inverter.

These warning notices and safety symbols must not be removed or painted over.

They warn against incorrect operation which can lead to serious injury and damage.

55

Page 56

A 4-digit number (coded production date) is printed on the rating plate at the

very bottom, from which the production date can be calculated.

If you subtract the value 11 from the first two digits, you get the production year.

The last two digits stand for the calendar week in which the device was produced.

Example:

Value on rating plate = 3205

32 - 11 = 21 → Production year 2021

05 = Calendar week 05

Symbols on the rating plate:

CE mark – confirms compliance with applicable EU directives and

regulations.

UKCA mark – confirms compliance with applicable UK directives and

regulations.

WEEE mark – waste electrical and electronic equipment must be

collected separately and recycled in an environmentally sound manner

in accordance with the European Directive and national law.

RCM mark – tested in accordance with the requirements of Australia

and New Zealand.

CMIM mark – tested in accordance with IMANOR requirements for

import regulations and compliance with Moroccan standards.

56

Safety symbols:

Risk of serious injury and property damage due to incorrect operation.

Do not use the functions described here until you have fully read and

understood the following documents:

These Operating Instructions.

-

All the Operating Instructions for the photovoltaic system compon-

-

ents, especially the safety rules.

Dangerous electrical voltage.

Allow the capacitors of the inverter to discharge (2 minutes).

Warning notice text:

Page 57

WARNING!

An electric shock can be fatal. Before opening the device, it must be disconnected and de-energized at the input and output.

EN

System component compatibility

All installed components in the photovoltaic system must be compatible and

have the necessary configuration options. The installed components must not restrict or negatively influence the functioning of the photovoltaic system.

NOTE!

Risk due to components in the photovoltaic system that are not compatible

and/or have limited compatibility.

Incompatible components may limit and/or negatively affect the operation

and/or functioning of the photovoltaic system.

Only install components recommended by the manufacturer in the photovol-

▶

taic system.

Before installation, check the compatibility of components not expressly re-

▶

commended with the manufacturer.

57

Page 58

Installation location and position

≥ 200 mm

(≥ 7.87 inch)

≥ 200 mm

(≥ 7.87 inch)

≥ 445 mm

(≥ 17.52 inch)

≥ 250 mm

(≥ 9.84 inch)

≥ 225 mm

(≥ 8.86 inch)

≥ 275 mm

(≥ 10.83 inch)

≥ 150 mm

(≥ 5.91 inch)

≥ 100 mm

(≥ 3.94 inch)

-40°C - +60°C

-40°F - +140°F

0 - 100%

Choosing the

location of the

inverter

Please note the following criteria when choosing a location for the inverter:

Only install on a solid, non-flam-

mable surface.

Max. ambient temperatures:

-40 °C - +60 °C

-40 °F - +140 °F

Relative humidity:

0-100%

If the inverter is installed in a switch

cabinet or similar enclosed space,

ensure sufficient heat dissipation

with forced-air ventilation.

For detailed information on the dimensions of the inverter, see chapter

Dimensions of the inverter on page

191.

When installing the inverter on the outer walls of cattle sheds, it is important

to maintain a minimum clearance of 2 m between the inverter and the ventilation and building openings on all sides.

The following substrates are permissible for installation:

Walls (corrugated metal walls [mounting rails], brick walls, concrete walls,

-

or other non-flammable surfaces sufficiently capable of bearing loads)

Mast or support (installed using mounting rails, behind the PV modules

-

directly on the PV mounting system)

Flat roofs (if installing on a film roof, make sure that the films comply

-

with the fire protection requirements and are not highly flammable. En-

sure compliance with the national provisions.)

Covered car park roofs (no overhead installation)

-

58

The inverter is suitable for indoor installation.

The inverter is suitable for outdoor installation.

Because of its IP 66 protection class, the inverter is resistant to

water jets from any direction and can also be used in damp environments.

In order to minimise the heating up of the inverter, do not expose it to direct insolation.

Page 59

The inverter should be installed in a protected location, for ex-

4001 m

0 m

ample, below the PV modules or under an overhanging roof.

The inverter must not be installed or used at altitudes above

4000 m.

Do not install the inverter in:

Areas where it may be exposed to ammonia, corrosive

-

gases, acids or salts (e.g. fertiliser storage areas, vent openings for livestock stables, chemical plants, tanneries, etc.)

During certain operating phases the inverter may produce a

slight noise. For this reason it should not be installed in an occupied living area.

Do not install the inverter in:

Areas where there is an increased risk of accidents from

-

farm animals (horses, cattle, sheep, pigs, etc.)

Stables or adjoining areas

-

Storage areas for hay, straw, chaff, animal feed, fertilizers,

-

etc.

EN

Choosing the

location of thirdparty batteries

The inverter is designed to be dustproof (IP 66). In areas of high

dust accumulation, dust deposits may collect on the cooling

surfaces, and thus impair the thermal performance. Regular

cleaning is required in this case, see chapter Operation in dusty

environments on page 159. We therefore recommend not in-

stalling the device in areas and environments with high dust accumulation.

Do not install the inverter in:

Greenhouses

-

Storage or processing areas for fruit, vegetables or viticul-

-

ture products

Areas used in the preparation of grain, green fodder or an-

-

imal feeds

IMPORTANT!

Refer to the manufacturer's documents for the suitable location for third-party

batteries.

59

Page 60

Installation position of inverter

The inverter is suitable for vertical installation on a vertical wall

or column.

The inverter is suitable for installation on a sloping surface (min.

slope to underside 10°).

Do not install the inverter on a sloping surface with its connection sockets at the top.

Do not install the inverter at an angle on a vertical wall or

column.

Do not install the inverter horizontally on a vertical wall or pillar.

Do not install the inverter on a vertical wall or pillar with its connection sockets facing upwards.

Do not install the inverter overhanging with the connection

sockets at the top.

Do not install the inverter overhanging with the connection

sockets at the bottom.

60

Page 61

Do not install the inverter on the ceiling.

EN

61

Page 62

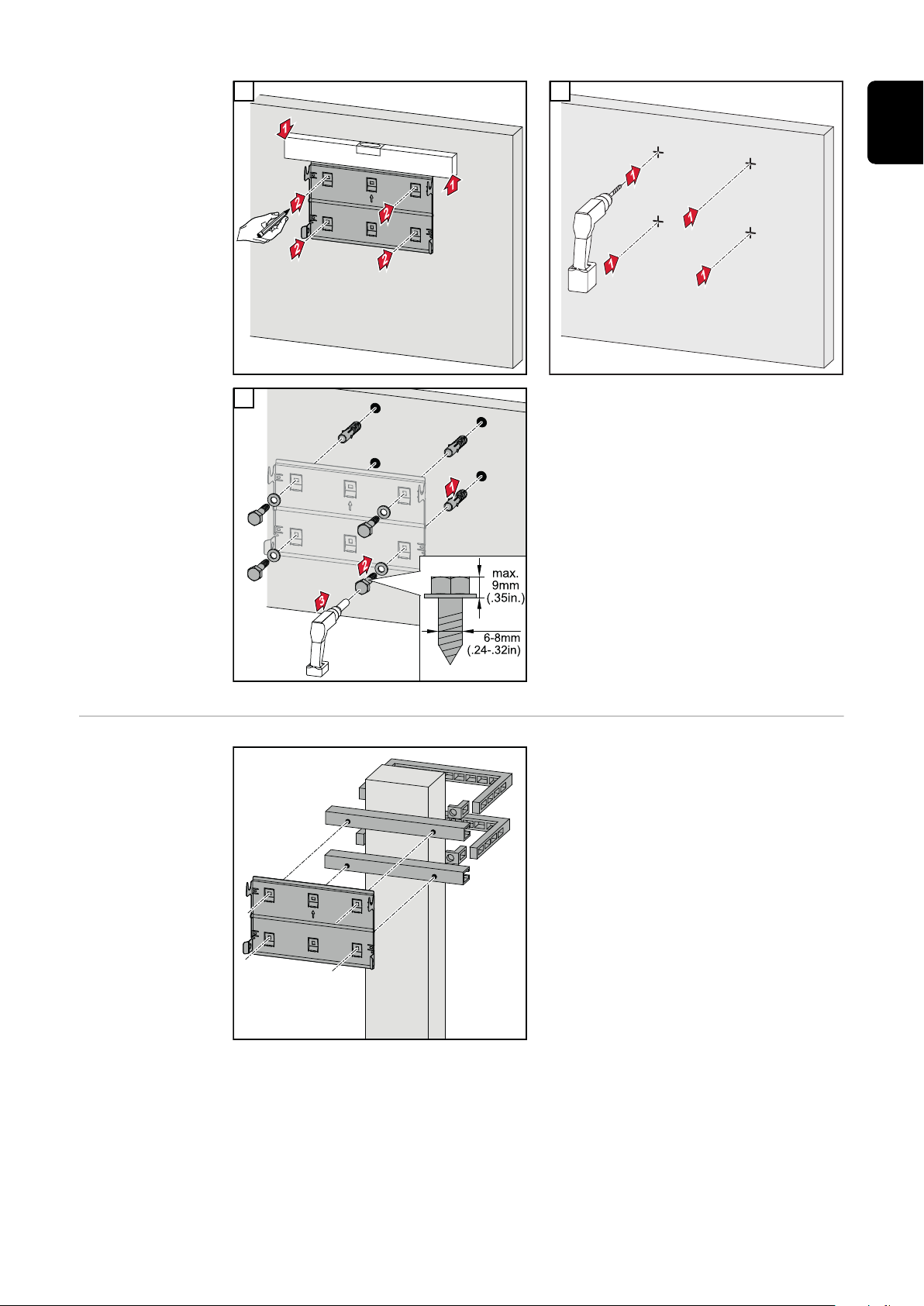

Install the mounting bracket and hang up the inverter

Selecting the fixing material

Properties of the

mounting bracket

Use the corresponding fixing materials depending on the subsurface and observe

the screw dimension recommendations for the mounting bracket.

The installer is responsible for selecting the correct type of fixing.

The mounting bracket (illustration) can

also be used as a guide.

The pre-drilled holes on the mounting

bracket are intended for screws with a

thread diameter of 6-8 mm (0.24-0.32

inches). The distance from the left to

the right pre-drilled hole is 406 mm

(16 inches).

Unevenness on the mounting surface

(such as coarse-textured plaster) is

largely compensated by the mounting

bracket.