Page 1

Operating

Instructions

Fronius Primo

3.0-1 / 3.5-1 / 3.6-1 / 4.0-1

4.6-1 / 5.0-1 AUS / 5.0-1

5.0-1 SC / 6.0-1 / 8.2-1

Operating Instructions

EN

Instructions de service

FR

Bedieningshandleiding

NL

42,0410,2148 027-20012023

Page 2

Page 3

Contents

Safety rules 5

General 5

Environmental conditions 5

Qualified personnel 5

Noise emission values 6

EMC measures 6

Disposal 6

Data protection 6

Copyright 6

General 8

Explanation of safety notices 8

Device concept 8

Proper use/intended purpose 9

Warning notices on the device 9

Data communication and Fronius Solar Net 11

Fronius Solar Net and data interface 11

Data communication area 11

Explanation of the multifunction current interface 12

Description of the "Fronius Solar Net" LED 13

Example 14

Installing option cards in the inverter 14

Dynamic power reduction by means of inverter 15

System monitoring 16

General 16

Fronius Datamanager during the night or when the available DC voltage is insufficient 16

Starting for the first time 16

Further information on Fronius Datamanager 2.0 18

Controls and indicators 19

Controls and displays 19

Display 20

The menu level 21

Activating display backlighting 21

Automatic deactivation of display backlighting / changing to the "NOW" menu item 21

Open menu level 21

The NOW, LOG and GRAPH menu items 22

NOW LOG GRAPH 22

Values displayed in the NOW and LOG menu items 22

SETUP menu item 24

Initial setting 24

SETUP 24

Navigating the SETUP menu item 24

Setting menu entries, general 25

Application example: Setting the time 26

The Setup menu items 28

Standby 28

WiFi Access Point 28

DATCOM 29

USB 29

Relay (floating contact switch) 31

Energy Manager(under Relay menu item) 32

Time / Date 33

Display settings 34

ENERGY YIELD 35

Fan 36

The INFO menu item 37

INFO 37

Measured values PSS status Grid status 37

Device information 38

Version 39

Switching the key lock on and off 40

EN

3

Page 4

General 40

Switching the key lock on and off 40

USB Stick as a Data Logger and for Updating Inverter Software 41

USB flash drive as a datalogger 41

Suitable USB flash drives 41

USB stick for updating the inverter software 42

Removing the USB flash drive 42

The Basic menu 43

General 43

Access the Basic menu 43

Menu items in the Basic menu 43

Switching off current supply and restarting the inverter 45

Switch off power to the inverter 45

Status diagnostics and troubleshooting 46

Status code display 46

Total failure of the display 46

Status codes in the e-Manual 46

Customer service 46

Operation in dusty environments 46

Technical data 47

General data and protection devices Fronius Primo 3.0-1 - 8.2-1 47

WLAN 50

Explanation of footnotes 51

Integrated DC disconnector 51

Applicable standards and guidelines 52

Warranty terms and conditions, and disposal 53

Fronius manufacturer's warranty 53

Disposal 53

4

Page 5

Safety rules

General The device has been manufactured in line with the state of the art and according

to recognized safety standards. If used incorrectly or misused, however, it can

cause:

Injury or death to the operator or a third party

-

Damage to the device and other material assets belonging to the operating

-

company.

All personnel involved in commissioning, maintenance, and servicing of the

device must:

Be suitably qualified

-

Have knowledge of and experience in dealing with electrical installations and

-

Have fully read and precisely followed these Operating Instructions

-

The Operating Instructions must always be at hand wherever the device is being

used. In addition to the Operating Instructions, attention must also be paid to

any generally applicable and local regulations regarding accident prevention and

environmental protection.

All safety and danger notices on the device:

Must be kept in a legible state

-

Must not be damaged

-

Must not be removed

-

Must not be covered, pasted or painted over

-

EN

Environmental

conditions

The terminals can reach high temperatures.

Only operate the device when all protection devices are fully functional. If the

protection devices are not fully functional, there is a danger of:

Injury or death to the operator or a third party

-

Damage to the device and other material assets belonging to the operating

-

company

Any safety devices that are not fully functional must be repaired by an authorised specialist before the device is switched on.

Never bypass or disable protection devices.

For the location of the safety and danger notices on the device, refer to the section headed "General remarks" in the Operating Instructions for the device.

Any equipment malfunctions which might impair safety must be remedied before

the device is turned on.

This is for your personal safety!

Operation or storage of the device outside the stipulated area will be deemed as

not in accordance with the intended purpose. The manufacturer accepts no liability for any damage resulting from improper use.

Qualified personnel

The servicing information contained in these operating instructions is intended

only for the use of qualified service engineers. An electric shock can be fatal. Do

not carry out any actions other than those described in the documentation. This

also applies to qualified personnel.

5

Page 6

All cables and leads must be secured, undamaged, insulated and adequately dimensioned. Loose connections, scorched, damaged or inadequately dimensioned

cables and leads must be immediately repaired by authorised personnel.

Maintenance and repair work must only be carried out by an authorised specialist.

It is impossible to guarantee that bought-in parts are designed and manufactured to meet the demands made on them, or that they satisfy safety requirements. Use only original spare parts (also applies to standard parts).

Do not carry out any alterations, installations, or modifications to the device

without first obtaining the manufacturer's permission.

Components that are not in perfect condition must be changed immediately.

Noise emission

values

EMC measures In certain cases, even though a device complies with the standard limit values for

Disposal To comply with the European Directive 2012/19/EU on Waste Electrical and Elec-

The inverter generates a maximum sound power level of < 65 dB(A) (ref. 1 pW)

when operating under full load in accordance with IEC 62109-1:2010.

The device is cooled as quietly as possible with the aid of an electronic temperature control system, and depends on the amount of converted power, the ambient

temperature, the level of soiling of the device, etc.

It is not possible to provide a workplace-related emission value for this device

because the actual sound pressure level is heavily influenced by the installation

situation, the power quality, the surrounding walls and the properties of the room

in general.

emissions, it may affect the application area for which it was designed (e.g., when

there is equipment that is susceptible to interference at the same location, or if

the site where the device is installed is close to either radio or television receivers). If this is the case, then the operator is obliged to take appropriate action to

rectify the situation.

tronic Equipment and its implementation as national law, electrical equipment

that has reached the end of its life must be collected separately and returned to

an approved recycling facility. Any device that you no longer require must be returned to your distributor, or you must locate the approved collection and recycling facilities in your area. Ignoring this European Directive may have potentially

adverse effects on the environment and your health!

Data protection The user is responsible for the safekeeping of any changes made to the factory

settings. The manufacturer accepts no liability for any deleted personal settings.

Copyright Copyright of these operating instructions remains with the manufacturer.

The text and illustrations are all technically correct at the time of printing. We

reserve the right to make changes. The contents of the operating instructions

shall not provide the basis for any claims whatsoever on the part of the purchaser. If you have any suggestions for improvement, or can point out any mis-

6

Page 7

takes that you have found in the instructions, we will be most grateful for your

comments.

EN

7

Page 8

General

Explanation of

safety notices

Indicates a potentially hazardous situation.

▶

Indicates a situation where damage could occur.

▶

Indicates a risk of flawed results and possible damage to the equipment.

If you see any of the symbols depicted in the "Safety rules" chapter, special care

is required.

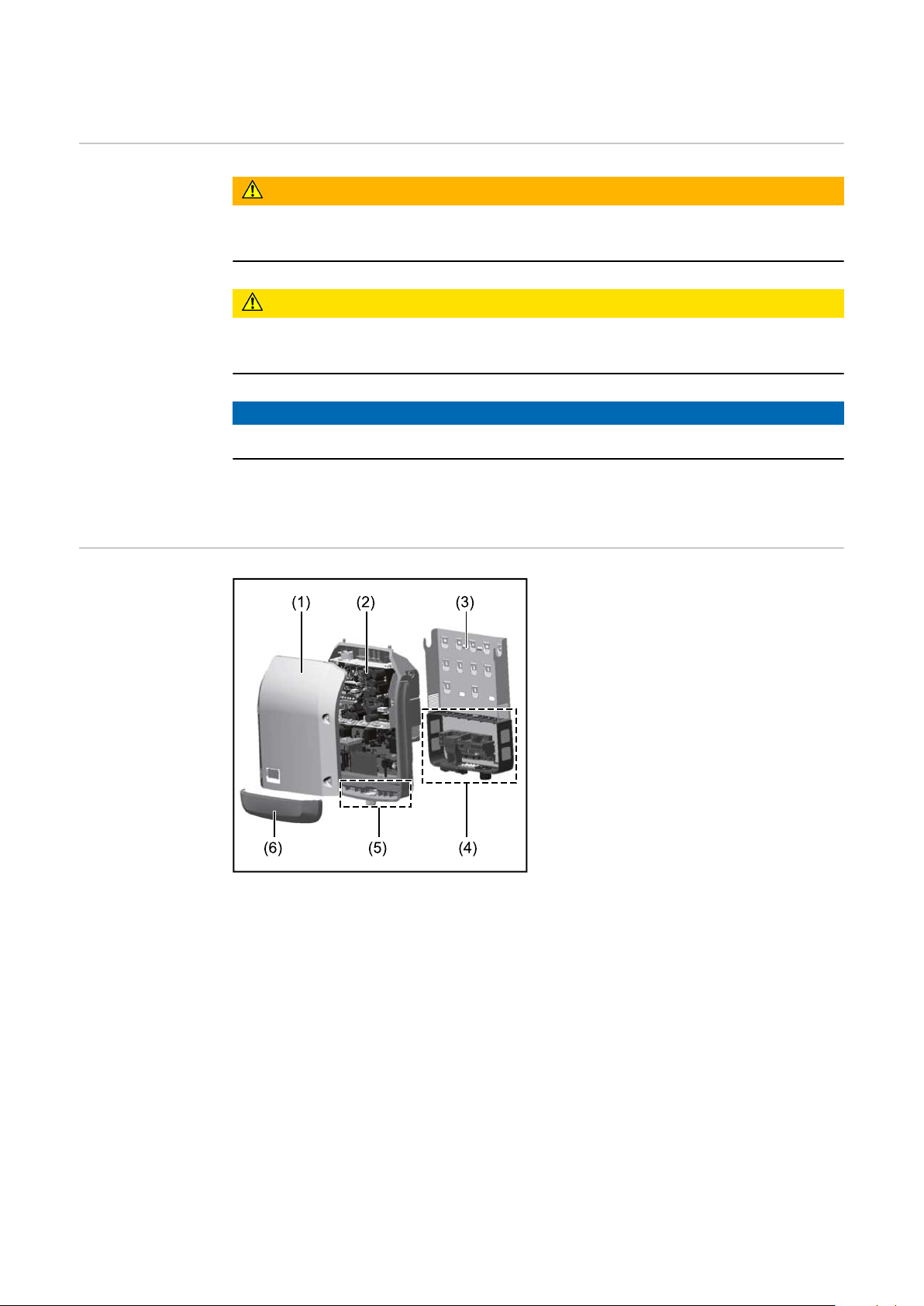

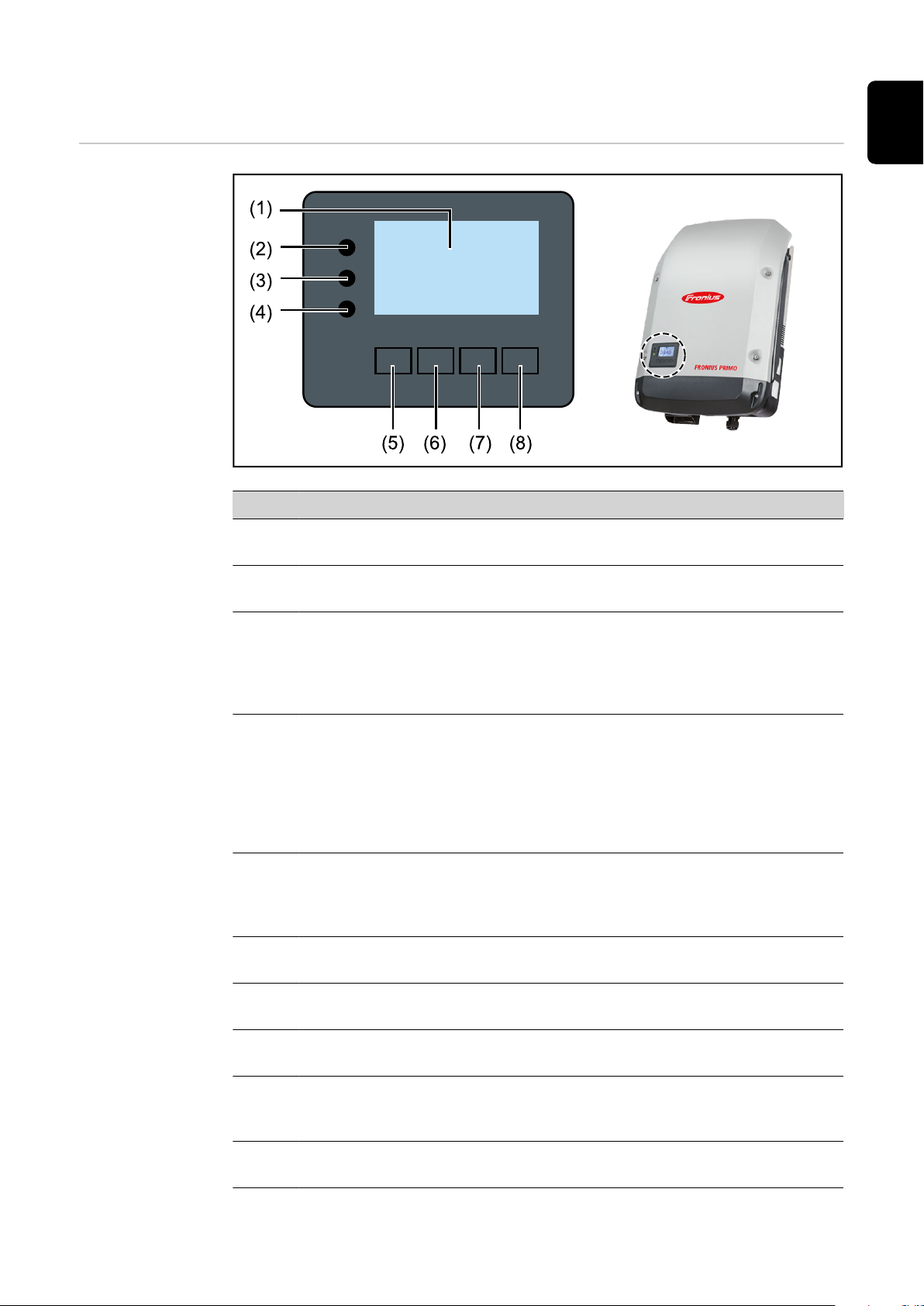

Device concept Device design:

WARNING!

If not avoided, death or serious injury may result.

CAUTION!

If not avoided, minor injury and/or damage to property may result.

NOTE!

(1) Housing cover

(2) Inverter

(3) Mounting bracket

(4) Connection area incl. DC main

switch

(5) Data communication area

(6) Data communication cover

The inverter transforms the direct current generated by the solar modules

into alternating current. This alternating current is fed into the public grid

synchronously with the grid voltage.

The inverter has been developed exclusively for use in grid-connected photovoltaic systems; it is impossible to generate energy independently of the public grid.

The inverter automatically monitors the public grid. In the event of abnormal grid

conditions, the inverter ceases operating immediately and stops feeding power

into the grid (e.g. if the grid is switched off, if there is an interruption, etc.).

The grid is monitored by monitoring the voltage, frequency and islanding conditions.

The inverter operates fully automatically. As soon after sunrise as there is sufficient energy available from the solar modules, the inverter starts monitoring the

grid. When insolation has reached a sufficient level, the inverter starts feeding

energy into the grid.

The inverter operates in such a way that the maximum possible amount of power

is obtained from the solar modules.

As soon as the power available has fallen below the level at which energy can be

8

Page 9

fed into the grid, the inverter disconnects the power electronics completely from

the grid and stops running. It retains all its settings and stored data.

If the inverter becomes too hot, it automatically reduces the current output

power in order to protect itself.

Reasons for the inverter becoming too hot include the ambient temperature being too high or inadequate heat dissipation (e.g. if it is installed in a switch cabinet

without suitable heat dissipation).

EN

Proper use/

intended purpose

The inverter is intended exclusively to convert direct current from solar modules

into alternating current and to feed this into the public grid.

Utilisation not in accordance with the intended purpose comprises:

Any use above and beyond this purpose

-

Making any modifications to the inverter that have not been expressly ap-

-

proved by Fronius

the installation of components that are not distributed or expressly ap-

-

proved by Fronius.

Fronius shall not be liable for any damage resulting from such action.

No warranty claims will be entertained.

Proper use also includes:

Carefully reading and obeying all the instructions and all the safety and

-

danger notices in the Operating Instructions and Installation Instructions

Performing all stipulated maintenance work

-

Installation as specified in the Installation Instructions

-

When designing the photovoltaic system, ensure that all components are operated within their permitted operating ranges at all times.

Observe all the measures recommended by the solar module manufacturer to

ensure that the solar module retains its properties in the long term.

Obey the regulations of the power supply company regarding connection methods and energy fed into the grid.

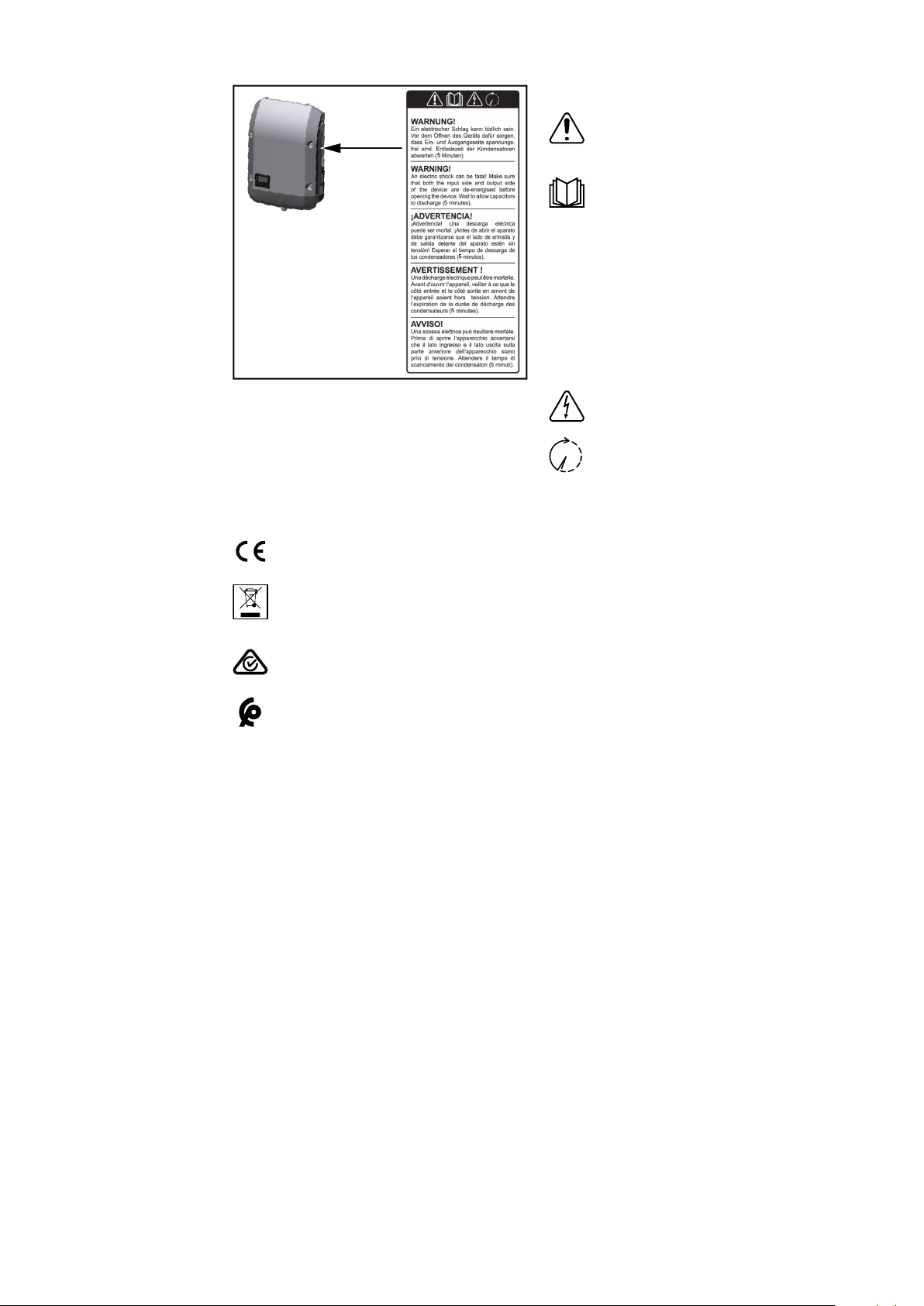

Warning notices

on the device

There are warning notices and safety symbols on and in the inverter. These warning notices and safety symbols must not be removed or painted over. They warn

against incorrect operation, as this may result in serious injury and damage.

9

Page 10

Symbols on the rating plate:

CE mark – confirms compliance with applicable EU directives and

regulations.

Safety symbols:

Danger of serious injury and

damage due to incorrect operation

Do not use the functions de-

scribed here until you have

fully read and understood the

following documents:

These Operating Instruc-

-

tions

All the Operating In-

-

structions for the system

components of the

photovoltaic system, especially the safety rules

Dangerous electrical voltage

Wait for the capacitors to dis-

charge.

WEEE mark – waste electrical and electronic equipment must be

collected separately and recycled in an environmentally sound manner

in accordance with the European Directive and national law.

RCM mark – tested in accordance with the requirements of Australia

and New Zealand.

CMIM mark – tested in accordance with IMANOR requirements for

import regulations and compliance with Moroccan standards.

Text of the warning notices:

WARNING!

An electric shock can be fatal. Before opening the device, it must be disconnected at the input and output. Wait for the capacitors to discharge (5 minutes).

10

Page 11

Data communication and Fronius Solar Net

EN

Fronius Solar

Net and data interface

Fronius Solar Net was developed to make system add-ons flexible to use in a

variety of different applications. Fronius Solar Net is a data network that enables multiple inverters to be linked up using system add-ons.

It is a bus system that uses a ring topology. One suitable cable is sufficient for

communication between one or several inverters that are connected on the

Fronius Solar Net using a system add-on.

Similarly, every inverter on the Fronius Solar Net must be assigned a unique

number.

Refer to the section entitled "The SETUP menu item" for instructions on how

to assign a unique number.

Fronius Solar Net automatically recognises a wide variety of system add-ons.

In order to distinguish between several identical system add-ons, each one

must be assigned a unique number.

More detailed information on the individual system add-ons can be found in

the relevant operating instructions or on the internet at http://www.fronius.com

More detailed information on cabling Fronius DATCOM components can be

found at:

→ http://www.fronius.com/QR-link/4204101938

Data communication area

Depending on the model, the inverter may be equipped with the Fronius

Datamanager plug-in card (8).

11

Page 12

Ite

m Description

(1) Switchable multifunction current interface.

For more details, refer to the section below entitled "Explanation of the

multifunction current interface"

Use the 2-pin mating connector supplied with the inverter to connect to

the multifunction current interface.

(2)

(3)

(4) The "Fronius Solar Net" LED

(5) The "Data transfer" LED

(6) USB A socket

(7) Floating switch contact (relay) with mating connector

IN Fronius Solar Net connection / interface protocol IN

OUT Fronius Solar Net connection / interface protocol

"Fronius Solar Net" / interface protocol input and output for connecting

to other DATCOM components (e.g. inverter, Fronius sensor box, etc.)

If several DATCOM components are linked together, a terminating plug

must be connected to every free IN or OUT connection on a DATCOM

component.

For inverters with a Fronius Datamanager plug-in card, two terminating

plugs are supplied with the inverter.

indicates whether the Fronius Solar Net power supply is available

flashes while the USB flash drive is being accessed. The USB flash drive

must not be removed while recording is in progress.

for connecting a USB flash drive with maximum dimensions of

65 x 30 mm (2.6 x 2.1 in.)

The USB flash drive can function as a datalogger for any inverter that it

is connected to. The USB flash drive is not included in the scope of supply of the inverter.

Explanation of

the multifunction current interface

Max. 250 V AC / 4 A AC

Max. 30 V DC / 1 A DC

Max. 1.5 mm² (AWG 16) cable cross-section

Pin 1 = NO contact (normally open)

Pin 2 = C (common)

Pin 3 = NC contact (normally closed)

For a more detailed explanation, please see the "Menu items in the

Setup menu / Relay" section.

Use the mating connector supplied with the inverter to connect to the

floating switch contact.

(8) Fronius Datamanager with WLAN antenna

or

cover for option card compartment

(9) Cover for option card compartment

Various wiring variants can be connected to the multifunction current interface.

However, these cannot be operated simultaneously. For example, if an S0 meter

is connected to the multifunction current interface, it is not possible to connect

a signal contact for the surge protection device (or vice versa).

12

Page 13

Pin 1 = measurement input: max. 20 mA, 100 Ohm measurement resistor (load

impedance)

Pin 2 = max. short circuit current 15 mA, max. open-circuit voltage 16 V DC or

GND

Wiring diagram variant 1: Signal contact for surge protective device

Depending on the setting in the Basic menu (Signal Input submenu), the DC SPD

option (surge protective device) either outputs a warning or an error on the display. Further information on the DC SPD option can be found in the Installation

Instructions.

Wiring diagram variant 2: S0 meter

A meter for recording the self-consumption of each S0 can be connected directly to the inverter. This S0 meter can be positioned directly at the feed-in point

or in the consumption branch.

IMPORTANT! In order to connect an S0 meter to the inverter, it may be necessary to update the inverter firmware.

EN

Description of

the "Fronius Solar Net" LED

The S0 meter must comply with the IEC62053-31 Class B standard

Recommended max. pulse rate of the S0 meter:

PV output kWp [kW] Max. pulse rate per kWp

30 1000

20 2000

10 5000

≤ 5.5 10000

With this meter, dynamic power reduction can be performed in two ways:

Dynamic power reduction by means of inverter

-

For more information see chapter Dynamic power reduction by means of in-

verter on page 15

Dynamic power reduction by means of the Fronius Datamanager 2.0

-

for more info see: manuals.fronius.com/html/4204260191/

#0_m_0000017472

The "Fronius Solar Net" LED is on:

the power supply for data communication within the Fronius Solar Net / interface protocol is OK

The "Fronius Solar Net" LED flashes briefly every 5 seconds:

data communication error in the Fronius Solar Net

13

Page 14

Overcurrent (current flow > 3 A, e.g. resulting from a short circuit in the

1 2

3

IN

OUT

°C

W/m²

m/s

IN

OUT

IN

OUT

Sensor Box

WLAN

* Fronius Datamanager

*

IN

OUT

-

Fronius Solar Net ring)

Undervoltage (not a short circuit, voltage in Fronius Solar Net < 6.5 V, e.g. if

-

there are too many DATCOM components on the Fronius Solar Net and not

enough electrical power is available)

In this case, power for the Fronius DATCOM components must be supplied

by connecting an additional power supply (43,0001,1194) to one of the

Fronius DATCOM components.

To detect the presence of an undervoltage, check some of the other Fronius

DATCOM components for faults as required.

After cutting out because of overcurrent or undervoltage, the inverter attempts

to restore the power supply in the Fronius Solar Net every 5 seconds while the

fault is still present.

Once the fault is rectified, power to the Fronius Solar Net will be restored within

5 seconds.

Example Recording and archiving data from the inverter and sensor using a Fronius

Datamanager and a Fronius Sensor Box:

Installing option

cards in the inverter

14

Data network with 3 inverters and a Fronius Sensor Box:

- Inverter 1 with Fronius Datamanager

- Inverters 2 and 3 without Fronius Datamanager!

The external communication (Fronius Solar Net) takes place on the inverter via

the data communication area. The data communication area contains two RS 422

interfaces as inputs and outputs. RJ45 plug connectors are used to make the

connection.

IMPORTANT! Since the Fronius Datamanager functions as a data logger, the

Fronius Solar Net ring must not include any other data logger.

Only one Fronius Datamanager per Fronius Solar Net ring!

Any other Fronius Datamanagers must be removed and the unoccupied option

card compartment sealed off using the blanking cover (42,0405,2020 - available

from Fronius as an optional extra); alternatively, use an inverter without Fronius

Datamanager (light version).

Information on installing option cards (e.g.: Datamanager) in the inverter and

connecting the data communication cable can be found in the Installation Instructions.

= Terminating plug

Page 15

Dynamic power

reduction by

means of inverter

Energy companies or grid operators may impose feed-in limits on an inverter. Dynamic power reduction takes account of self-consumption by the household before the power of an inverter is reduced:

A counter for determining self-consumption of the S0 can be connected directly

to the inverter – see chapter Explanation of the multifunction current interface

on page 12

A feed-in limit can be set in the Basic menu under Signal input – S0 meter – see

chapter Menu items in the Basic menu on page 43.

Setting options for S0 meter:

Grid feed-in limit

-

Field for entering the maximum grid feed-in power in W. If this value is exceeded, the inverter regulates down to the set value within the time required

by national standards and regulations.

Pulses per kWh

-

Field for entering the pulses per kWh of the S0 meter.

Zero feed-in is possible with this configuration.

When using the S0 meter and power reduction by means of an inverter, the S0

meter must be installed in the consumption branch.

EN

S0 meter in the consumption branch

If dynamic power reduction is subsequently configured using the Fronius

Datamanager 2.0 (Inverter user interface - UC Editor menu - Dynamic power reduction), dynamic power reduction must be deactivated using the inverter (Inverter display - Basic menu - Signal input - S0 meter).

15

Page 16

System monitoring

General The inverter is fitted with the WLAN-enabled system monitoring Fronius

Datamanager 2.0 as standard.

The following functions are included with the system monitoring:

Dedicated web page displaying current data and a wide range of settings

-

Ability to connect to Fronius Solar.web using WLAN or LAN

-

Automatic sending of service messages by SMS or e-mail in the event of a

-

fault

Option of controlling the inverter by specifying power limit values, minimum

-

or maximum running times or target running times

Control of the inverter via Modbus (TCP / RTU)

-

Ability to assign control priorities

-

Ability to control the inverter by means of connected meters (Fronius Smart

-

Meter)

Ability to control the inverter via a ripple control signal receiver (e.g. by spe-

-

cifying the reactive power or effective power)

Dynamic power reduction, taking self-consumption into account

-

Further information on Fronius Datamanager 2.0 can be found online in the

Fronius Datamanager 2.0 Operating Instructions.

Fronius

Datamanager

during the night

or when the

available DC

voltage is insufficient

Starting for the

first time

The Night Mode parameter under "Display Settings" in the Setup menu is preset

to OFF in the factory.

For this reason the Fronius Datamanager cannot be accessed during the night or

when the available DC voltage is insufficient.

To nevertheless activate the Fronius Datamanager, switch the inverter off and on

again at the mains and press any function button on the inverter display within

90 seconds.

See also the chapters on "Menu items in the Setup menu", "Display settings"

(Night Mode).

Starting the Fronius Datamanager 2.0 for the first time is made considerably

easier with the Fronius Solar.start app. The Fronius Solar.start app is available in

the respective app stores.

16

When starting the Fronius Datamanager 2.0 for the first time,

the Fronius Datamanager 2.0 plug-in card must be installed in the inverter,

-

or

there must be a Fronius Datamanager Box 2.0 in the Fronius Solar Net ring.

-

IMPORTANT! In order to establish a connection to Fronius Datamanager 2.0,

"Obtain IP address automatically (DCHP)" must be activated on the end device in

question (e.g. laptop, tablet, etc.).

Page 17

NOTE!

Stand by

WiFi Access Point

DATCOM

USB

Clock

If the photovoltaic system has only one inverter, steps 1 and 2 below can be

skipped.

In this case, starting for the first time will commence with step 3.

Connect inverter with Fronius Datamanager 2.0 or Fronius Datamanager Box

1

2.0 to the Fronius Solar Net

When networking several inverters in Fronius SolarNet:

2

Set the Fronius Solar Net client/server switch on the Fronius Datamanager

2.0 plug-in card correctly

One inverter with Fronius Datamanager 2.0 = master

-

All other inverters with Fronius Datamanager 2.0 = slave (the LEDs on

-

the Fronius Datamanager 2.0 plug-in cards are not illuminated)

Switch the device to Service mode

3

Activate the WiFi Access Point via the Setup menu on the inverter

-

EN

The inverter establishes the WLAN access point. The WLAN access point remains open for 1 hour. The IP switch on the Fronius Datamanager 2.0 can remain

in switch position A due to the activation of the WiFi Access Point.

Installation using the Solar.start

Installation using a web browser

app

Download Fronius Solar.start

4

Connect the end device to the

4

WLAN access point

SSID = FRONIUS_240.xxxxx (5-8

digits)

Search for a network with the

-

name "FRONIUS_240.xxxxx"

Establish a connection to this

Run the Fronius Solar.start app

5

-

network

Enter the password 12345678

-

(Alternatively, connect the end

device and inverter using an Ethernet cable.)

Enter the following in the

5

browser:

http://datamanager

or

192.168.250.181 (IP address for

WLAN connection)

or

169.254.0.180 (IP address for

LAN connection)

17

Page 18

The Setup wizard start page is displayed.

The technician wizard is intended for the installer and contains standard-specific

settings. Running the technician wizard is optional.

If the technician wizard is run, it is vital to note the service password that is issued. This service password is necessary for setting the "DNO Editor" menu item.

If the technician wizard is not run, no specifications regarding power reduction

are set.

Further information on Fronius

Datamanager 2.0

Running the Fronius Solar.web wizards is mandatory.

Run the Fronius Solar.web wizards and follow the instructions

6

The Fronius Solar.web homepage is displayed,

or

the Fronius Datamanager 2.0 web page is displayed.

Where necessary, run the technician wizard and follow the instructions

7

Further information on the Fronius Datamanager 2.0 and other start-up options can be found at:

→ http://www.fronius.com/QR-link/4204260191DE

18

Page 19

Controls and indicators

Controls and displays

Item Description

(1) Display

For displaying values, settings and menus

EN

Monitoring and status LEDs

(2) General status LED (red) lights up

if a status message is being displayed on the monitor

-

If the process of feeding energy into the grid is interrupted

-

During error handling (the inverter waits for an acknowledge-

-

ment or for an error to be rectified)

(3) Startup LED (orange) lights up

If the inverter is in its automatic startup or self-test phase (as

-

soon after sunrise as the solar modules are delivering sufficient

power)

If the inverter has been switched to Standby mode in the Setup

-

menu (= feeding energy into the grid switched off manually)

If the inverter software is being updated

-

(4) Operating status LED (green) lights up

If the PV system is working correctly after the inverter's auto-

-

matic startup phase

all the time while energy is being fed into the grid

-

Function keys - allocated different functions depending on the selection:

(5) "Left/up" key

For navigating to the left and up

(6) "Down/right" key

For navigating down and to the right

(7) "Menu/Esc" key

For switching to the menu level

For quitting the Setup menu

(8) "Enter" key

For confirming a selection

19

Page 20

The keys are capacitive and any exposure to water can impair their function. Wipe

the keys dry with a cloth if necessary to ensure optimum functionality.

Display Power for the display comes from the mains voltage. Depending on the setting

selected in the Setup menu, the display can be kept on all day.

IMPORTANT! The display on the inverter is not a calibrated measuring device.

A slight inaccuracy in comparison with the energy meter used by the energy

company is intrinsic to the system. A calibrated meter will be needed to calculate

the bills for the power supply company.

Display areas in Display mode

Display areas in Setup mode

(*) Scroll bar

(**) The Energy Manager symbol

is displayed when the Energy Manager function is activated

(***) Inv. no. = Inverter DATCOM number,

Save symbol - appears briefly while set values are being saved,

USB connection - appears if a USB stick has been connected

20

Page 21

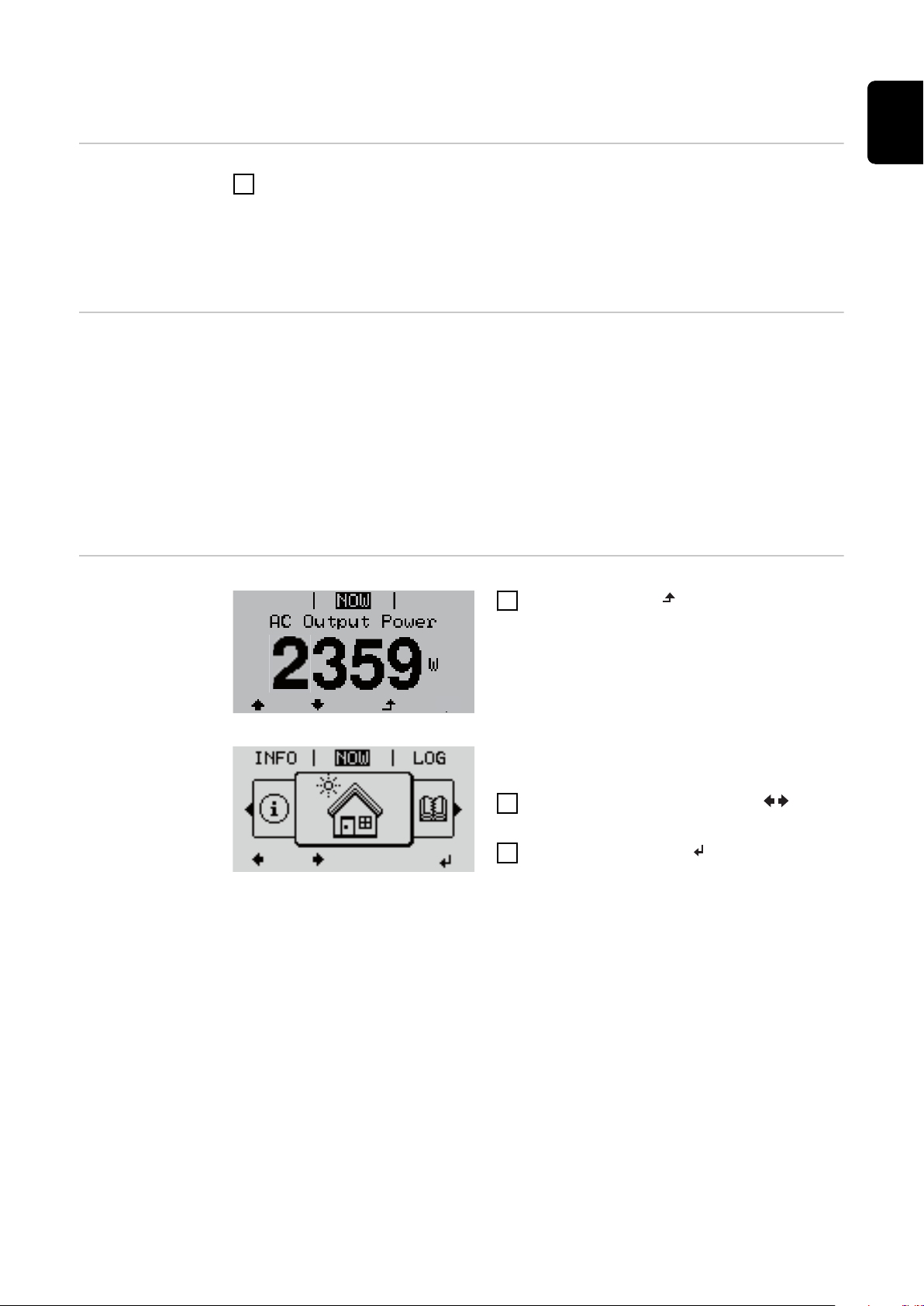

The menu level

EN

Activating display backlighting

Automatic deactivation of display backlighting / changing to

the "NOW" menu

item

Open menu level

Press any key

1

The display backlighting is activated.

There is an option under "Display Settings - Backlighting" in the SETUP menu

to set the display backlighting so that it is on all the time or off all the time.

If two minutes pass without any button being pressed, the display backlighting

switches off automatically and the inverter goes to the "NOW" menu item (assuming the display backlighting is set to AUTO).

The automatic selection of the "NOW" menu item can happen from any position

on the menu level, unless the inverter was manually switched into the "Standby"

operating mode.

After automatically selecting the "NOW" menu item, the current power of feeding in is displayed.

1

Press the "Menu" key

The display switches to the menu level.

2

Using the "Left" or "Right" keys select the desired menu item

3

Press the "Enter" key to select the

desired menu item

21

Page 22

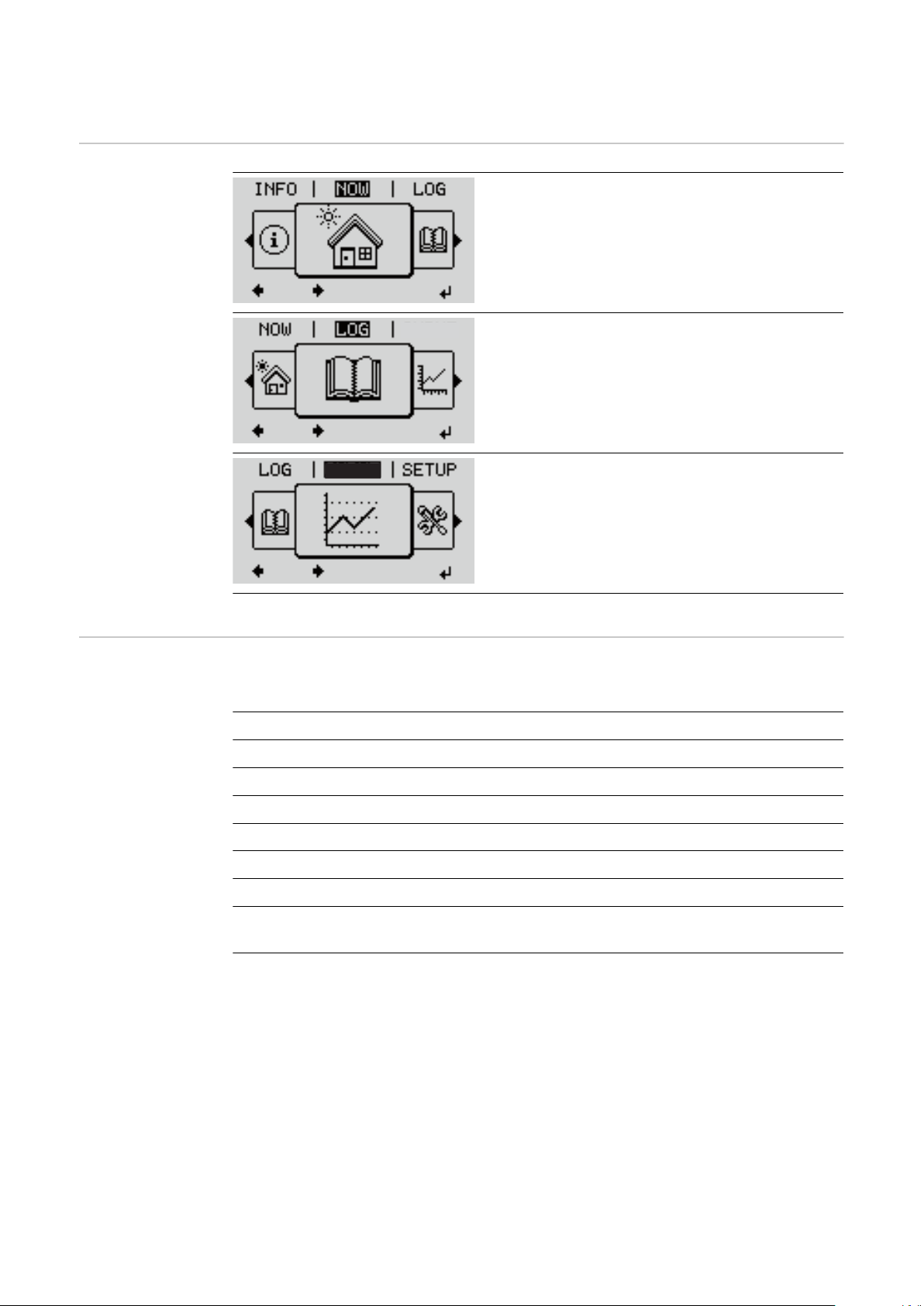

The NOW, LOG and GRAPH menu items

GRAPH

GRAPH

NOW

LOG

GRAPH

NOW

(Displays real-time values)

LOG

(Data recorded today, during the current calendar year and since the inverter was first

commissioned)

GRAPH

Day characteristic

displays a plot showing the output power

during the day. The time axis is scaled automatically.

Press the "Back" key to close the display

Values displayed

in the NOW and

LOG menu items

Values displayed in the NOW menu item:

AC Output power (W)

AC Reactive power (V Ar)

AC Voltage (V)

AC Output current (A)

AC Frequency (Hz)

PV Array Voltage (V)

PV Array Current (A)

Time / date

Time and date on the inverter or in the Fronius Solar Net ring

22

Page 23

Values displayed in the LOG menu item:

(for today, during the current calendar year and since the inverter was started

for the first time)

AC Energy Yield (kWh / MWh)

Energy fed into the grid during the period in question

There may be discrepancies with values displayed on other measuring instruments because of differences in measuring methods. As far as the billing of

the energy fed in is concerned, the only binding display values are those produced by the calibrated measuring device provided by the electricity supply

company.

AC Max. Output Power (W)

Largest amount of power fed into the grid during the period in question

Earnings

Amount of money earned during the period in question (currency can be selected in the Setup menu)

Like the energy supplied figure, the yield figure may also exhibit discrepancies

with other measured values.

The 'Setup Menu' section explains how to select a currency and charge rate.

The factory setting depends on the respective country setup.

EN

CO2 savings (g / kg)

CO2 emissions saved during the period in question

The value for CO2 savings depends on the power station facilities and corresponds to the CO2 emissions that would be released when generating the same

amount of energy. The factory setting is 0.53 kg / kWh (source: DGS –

Deutsche Gesellschaft für Sonnenenergie e.V. (German Society for Solar Energy).

AC Max. Voltage L-N (V)

Highest voltage measured between the conductor and neutral conductor during the period in question

PV Array Max. Voltage (V)

Highest solar module voltage measured during the period in question

Operating Hours

Length of time the inverter has been working (HH:MM).

IMPORTANT! A prerequisite for the correct display of day and year values is

that the time is set correctly.

23

Page 24

SETUP menu item

GRAPH

GRAPH

Relay

Initial setting The inverter is pre-configured after commissioning has been completely carried

out (e.g. using the Installation Wizard) according to the country setup.

The SETUP menu item allows the initial settings of the inverter to be changed

easily to bring it in line, as closely as possible, with the preferences and requirements of the user.

SETUP

Navigating the

SETUP menu

item

SETUP

(Setup menu)

NOTE!

As a result of software updates, you may find that your device has certain functions that are not described in these Operating Instructions, or vice versa.

Certain illustrations may also differ slightly from the actual controls on your

device, but these controls function in exactly the same way.

Entering the SETUP menu item

At the menu level, use the "Left" or

1

"Right" keys to select the "SETUP"

menu item

2

Press the "Enter" key

Menu level, "SETUP" selected

The first entry under the SETUP menu item

is displayed:

"Standby"

"Standby" entry

Scrolling between the entries

24

Page 25

Relay

3

GRAPH

Use the "Up" and "Down" keys to

scroll between the available entries

Example: "WiFi Access Point" menu item

Exiting an entry

To exit a menu entry, press the "Back"

4

key

The menu level appears

If no key is pressed for 2 minutes:

The inverter switches from wherever it is on the menu level back to the

-

"NOW" display mode (exception: "Standby" Setup menu entry),

The display backlighting goes out.

-

The amount of power currently being fed in is displayed.

-

EN

Setting menu

entries, general

Open the desired menu

1

2

Use the 'Up' or 'Down' keys to select the desired menu item

3

Press "Enter"

The available settings are displayed: The first digit of a value to be set

flashes:

Use the 'Up' or 'Down' buttons to

4

select the desired setting

Press the 'Enter' key to save and

5

Use the 'Up' or 'Down' keys to se-

4

lect a value for the first digit

5

Press "Enter"

apply the setting.

The second digit of the value flashes.

To discard the setting, press the

Repeat steps 4 and 5 until ...

'Esc' key.

6

the whole value to be set flashes.

7

Press "Enter"

Repeat steps 4 - 6 as required for

8

units or other values that are to

be set until the appropriate unit

or the value flashes.

Press the 'Enter' key to save and

9

apply the changes.

To discard the changes, press the

'Esc' key.

25

Page 26

The currently selected menu item is

displayed.

The currently selected menu item is

displayed.

Application example: Setting

the time

Select "Clock" from the Setup menu

1

.

2

Press the "Enter" key

An overview of the values that can be

changed is displayed.

3

Use the "Up" and "Down" keys Select

"Set time"

4

Press the "Enter" key

The current time appears. (HH:MM:SS, 24hour clock), the "tens" digit for the hour will

flash.

5

Use the "Up" and "Down" keys to select a value for the first digit of the code

6

Press the "Enter" key

The "units" digit for the hour will flash.

Repeat steps 5 and 6 to set the "units"

7

digit for the hour, for the minutes and for

the seconds until...

the set time starts flashing.

8

Press the "Enter" key

The time is applied and the overview of values that can be changed is displayed.

4

Press the "Esc" key

26

Page 27

The "Clock" item on the Setup menu appears.

EN

27

Page 28

The Setup menu items

Standby Manual activation / deactivation of Standby mode

No energy is fed into the grid.

-

The Startup LED will show steady orange.

-

In the display, STANDBY / ENTER are alternately displayed

-

In Standby mode, no other menu item at menu level can be accessed or ad-

-

justed.

The automatic switchover into the "NOW" display mode after 2 minutes of

-

keyboard inactivity does not occur.

Standby mode can only be terminated manually by pressing the "Enter" key.

-

Pressing "Enter" at any time will cause energy to resume feeding into the

-

grid, as long as there is no error (state code)

Switching off Standby mode (manually switching off feeding energy into the

grid):

Select the "Standby" item

1

2

Press "Enter" function key

"STANDBY" and "ENTER" appear alternately on the display.

Standby mode is now active.

The Startup LED shows steady orange.

WiFi Access

Point

Resuming feeding energy into the grid:

In standby mode, the display alternates between 'STANDBY' and 'ENTER'.

1

Press the "Enter" function key to resume feeding energy into the grid

The "Standby" menu item is displayed.

At the same time, the inverter enters the startup phase.

The operating state LED shows steady green when feeding energy into the grid

has been resumed.

Activating / deactivating the WiFi Access Point. This is necessary for setting up

or adjusting system monitoring using the Datamanager web interface, for example. If no Datamanager is detected by the inverter, [not available] is displayed

Setting range WiFi Access Point

[stopped]

Activate WiFi AP?

To activate the WiFi Access Point Press the "Enter"

key

WiFi Access Point

[active]

28

The SS-ID (SS) and password (PW) are displayed.

Deactivate WiFi AP?

To deactivate the WiFi Access Point Press the

"Enter" key

Page 29

DATCOM Checking data communications, entering the inverter number, protocol settings

Setting range Status / inverter number / protocol type

Status

Indicates data communication is taking place via Fronius Solar Net or that a

data communications error has occurred

Inverter number

Sets the number (= address) of the inverter in a system with several inverters

Setting range 00 - 99 (00 = inverter address 100)

Factory setting 01

WiFi Access Point

[not available]

Displayed if there is no system monitoring present on

the inverter.

EN

IMPORTANT! If a number of inverters are linked together in a data communic-

ations system, assign a unique address to each one.

Protocol type

Specifies the communications protocol to be used to transfer the data:

Setting range Solar Net / Interface *

Factory setting Fronius Solar Net

* The protocol type "Interface" only functions when there is no Datamanager

card in the inverter. All Fronius Datamanager cards should be removed from

the inverter.

USB Running firmware updates or saving detailed information from the inverter to the

USB flash drive

Setting range Safely remove hardware / Software update / Logging in-

terval

Safely remove hardware

To remove a USB flash drive from the USB A socket on the plug-in data communications card without losing any data.

The USB flash drive can be removed:

If the OK message appears

-

when the "Data transfer" LED stops flashing or comes on steady

-

Software update

To update the inverter firmware using a USB flash drive.

29

Page 30

Procedure:

Download the relevant firmware update file "froxxxxx.upd"

1

(e.g. from http://www.fronius.com; xxxxx stands for the version number)

NOTE!

To successfully update the inverter software, the USB flash drive provided for

the purpose must not have a hidden partition or any encryption (see chapter

"Suitable USB flash drives").

Save the firmware update file to the highest data level of the USB flash drive

2

Open the lid of the data communication area on the inverter

3

Plug the USB flash drive containing the firmware update file into the USB

4

socket in the inverter's data communication area

Select "USB" from the Setup menu, followed by "Software update"

5

Press the "Enter" key

6

Wait until the version currently installed on the inverter and the new firm-

7

ware version are displayed for comparison:

First Page: Recerbo software (LCD), key controller software (KEY), coun-

-

try setup version (Set)

Second Page: Power stage set software (PS1/PS2)

-

Press the "Enter" function button after each page

8

The inverter starts copying the data.

"BOOT" and the progress of storing the individual tests expressed in % are displayed until all the data for all the electronic modules has been copied.

Once copying is complete, the inverter updates the electronic modules as required in sequence.

"BOOT", the affected modules and the update progress in % are displayed.

The final step is for the inverter to update the display.

The display remains dark for approx. 1 minute while the monitoring and status

LEDs flash.

Once the firmware update is complete, the inverter enters its start-up phase before going on to start feeding energy into the grid. Unplug the USB flash drive using the "Safely remove hardware" function.

When the inverter firmware is updated, any custom settings that were configured

in the Setup menu are retained.

30

Page 31

Logging interval

Activate / deactivate the USB logging function and specify a logging interval

Unit Minutes

Setting range 30 min. / 20 min./ 15 min./ 10 min./ 5 min./ No log

Factory setting 30 min.

30 min. The logging interval is 30 minutes; every 30 minutes new

logging data will be saved to the USB flash drive.

20 min.

15 min.

10 min.

5 min. The logging interval is 5 minutes; every 5 minutes new

logging data will be saved to the USB flash drive.

No log No data is saved

IMPORTANT! In order for the USB logging function to work correctly the time

must be set correctly. Setting the time is discussed in the section "Menu items in

the Setup menu" - "Clock".

EN

Relay (floating

contact switch)

Status codes (state codes), the status of the inverter (e.g. feeding energy into the

grid) or Energy Manager functions can be displayed using the floating switch contact (relay).

Setting range Relay mode / Relay test / Switch-on point* / Switch-off

point*

* these are only shown if the "E-Manager" function has been activated under "Relay mode".

Relay mode

The following functions can be shown using relay mode:

Alarm function (Permanent / ALL / GAF)

-

Active output (ON / OFF)

-

Energy Manager (E-Manager)

-

Setting range ALL / Permanent / GAF / OFF / ON / E-Manager

Factory setting ALL

Alarm function:

ALL / Permanent:

Switching the floating switch contact for permanent and temporary service codes (e.g. brief interruption to energy being

fed into the grid, a service code occurs a certain number of

times a day - can be adjusted in the "BASIC" menu)

31

Page 32

GAF As soon as GAF mode is selected, the relay is switched on.

The relay opens as soon as the power stage set registers an

error and goes from normally feeding energy into the grid to

being in an error state. This means that the relay can be used

for fail-safe functions.

Application example

It may be necessary to perform phase compensation when using a single-phase inverter at a multiphase site. If an error occurs on one or several inverters and the connection to the grid

is broken, the other inverters must also be disconnected to

maintain the phase balance. The "GAF" relay function can be

used in conjunction with the Datamanager or an external protection device to recognise or signal that an inverter is not

feeding in or is disconnected from the grid and to then disconnect the remaining inverters from the grid using a telecontrol command.

Active output:

ON: The floating NO contact is on all the time the inverter is in op-

eration (as long as the display is not dark or is displaying

something).

OFF: The floating NO contact is off.

Energy Manager:

E-Manager: Further details on the "Energy Manager" function may be

found in the "Energy Manager" section.

Relay test

Function test to determine whether the floating switch contact switches

Switch-on point (only if "Energy Manager" function is activated)

for setting the effective power limit beyond which the floating switch contact is

switched on

Factory setting 1000 W

Setting range Set switch-off point up to the maximum nominal output

of the inverter (W or kW)

Switch-off point (only if "Energy Manager" function is activated)

for setting the effective power limit beyond which the floating switch contact is

switched off

Factory setting 500

Setting range 0 to the set switch-on point of the inverter (W or kW)

Energy Manager

(under Relay

menu item)

32

The "Energy Manager" (E-Manager) function can be used to activate the floating

switch contact in such a way that it functions as an actuator.

Thus, a consumer that is connected to the floating switch contact can be controlled by specifying a switch-on or switch-off point that depends on the feed-in

power (effective power).

The floating switch contact is automatically switched off:

If the inverter is not feeding any power into the grid

-

If the inverter is manually switched to Standby mode

-

If the effective power is set to < 10% of the nominal output of the inverter.

-

Page 33

To activate the Energy Manager function, select the "E-Manager" item and press

the "Enter" key.

When the "Energy Manager" function is running, the "Energy Manager" symbol

will appear in the top left corner of the display:

When the floating NO contact is off (open contact)

When the floating NC contact is on (closed contact)

To deactivate the Energy Manager function, select a different function (ALL /

Permanent / OFF / ON) and press the "Enter" key.

NOTE!

Notes on setting up the switch-on and switch-off points

If the difference between the switch-on and switch-off points is too small, or if

there are fluctuations in effective power, the result may be multiple switching

cycles.

To avoid switching on and off frequently, the difference between the switch-on

and switch-off points should be at least 100 - 200 W.

When choosing the switch-off point, the power consumption of the connected

consumer should be taken into account.

EN

When choosing the switch-on point, the weather conditions and anticipated insolation should be taken into account.

Application example

Switch-on point = 2000 W, switch-off point = 1800 W

If the inverter is outputting 2000 W or above, then the floating switch contact on

the inverter is switched on.

If the inverter output falls to below 1800 W, the floating switch contact is

switched off.

This allows useful applications, such as operating a heat pump or an air-conditioning system using as much self-generated power as possible, to be implemented quickly

Time / Date Set the time, date, the display format and automatic changeover between sum-

mer and winter time

Setting range Set time / Set date / Time display format / Date display

format / Summer/winter time

Set time

Set the time (hh:mm:ss or hh:mm am/pm – depending on the setting for the

time display format)

Set date

Set the date (dd.mm.yyyy or mm/dd/yyyy - depending on the setting for the

date display format)

Time display format

For specifying the time display format

33

Page 34

Setting range 12hrs / 24hrs

Factory setting Depends on country setup

Date display format

for specifying the date display format

Setting range mm/dd/yyyy or dd.mm.yy

Factory setting Depends on country setup

Summer/winter time

Activate/deactivate automatic changeover between summer and winter time

IMPORTANT! Only use the automatic summer/winter time changeover function if the Fronius Solar Net ring does not include any LAN- or WLAN-compatible system components (e.g. Fronius Datalogger Web, Fronius Datamanager or

Fronius Hybridmanager).

Setting range on / off

Factory setting on

IMPORTANT! The time and date must be set accurately in order for the day

and year values and for the day characteristic to be displayed correctly.

Display settings

Setting range Language / Night mode / Contrast / Illumination

Language

Set language for display

Setting range English, German, French, Spanish, Italian, Dutch,

Czech, Slovakian, Hungarian, Polish, Turkish, Por-

tuguese, Romanian

Night mode

Night mode controls Fronius DATCOM and inverter display operation during

the night or when the DC voltage is insufficient

Setting range AUTO / ON / OFF

Factory setting OFF

AUTO: Fronius DATCOM mode is always in effect as long as there is a

Fronius Datamanager connected in an active and uninterrupted

Fronius Solar Net.

The inverter display remains dark during the night, but can be activated by pressing any function button.

34

Page 35

ON: Fronius DATCOM mode is always in effect. The inverter supplies 12

V of DC voltage continuously to power the Fronius Solar Net. The

display is always active.

IMPORTANT! If Fronius DATCOM night mode is set to ON or

AUTO when there are Fronius Solar Net components connected,

the inverter's current consumption during the night will increase to

around 7 W.

OFF: Fronius DATCOM will not run at night, the inverter therefore does

not require any power during the night to supply the Fronius Solar

Net with energy.

The inverter display is switched off during the night and the Fronius

Datamanager is not available. To nevertheless activate the Fronius

Datamanager, switch the inverter off and on again at the mains and

press any function button on the inverter display within 90

seconds.

Contrast

Set the contrast on the inverter display

Setting range 0 - 10

Factory setting 5

EN

Since the contrast is temperature-dependent, it may be necessary to adjust

the setting under the "Contrast" menu item when the environmental conditions

change.

Illumination

Initial setting for inverter display illumination

The "Illumination" menu item only relates to the inverter display backlighting.

Setting range AUTO / ON / OFF

Factory setting AUTO

AUTO: The inverter display backlighting is activated by pressing any key. If

no key is pressed for 2 minutes, the display backlighting will go off

again.

ON: The inverter display backlighting remains permanently on when the

inverter is active.

OFF: The inverter display backlighting is permanently switched off.

ENERGY YIELD The following settings can be changed/set here:

Counter deviation / Calibration

-

Currency

-

Feed-in tariff

-

CO2 factor

-

Setting range Currency / Feed-in tariff

35

Page 36

Counter deviation / calibration

Calibrating the counter

Currency

Set the currency

Setting range 3 characters, A-Z

Feed-in tariff

Set the remuneration rate for energy fed into the grid

Setting range 2 digits, 3 decimal places

Factory setting (depends on country setup)

CO2 factor

Setting the CO2 factor of the energy fed into the grid

Fan To check that the fan is working correctly

Setting range Test fan #1 / Test fan #2 (depending on the device)

Use the "Up" and "Down" keys to select the desired fan

-

Testing of the selected fan is initiated by clicking "Enter".

-

The fan will continue to run until the operator exits the menu by pressing

-

"Esc".

IMPORTANT! Nothing will show on the inverter display if the fan is working. The

only way to check how the fan is working is by listening and feeling.

36

Page 37

The INFO menu item

EN

INFO

Measured values

PSS status

Grid status

Measured values

INFO

(Information about the device and the software)

Display range: PV ins. / Ext. lim. / U PV1 / U PV2 /

GVDPR / Fan #1

PV ins.

Insulation resistance of the PV system

(with unearthed solar modules and solar modules with negative pole earthing)

Ext. lim.

External power reduction in per cent e.g. specified by grid operator

U PV1

Current DC voltage on the terminals, even if the inverter is

feeding no power into the grid whatsoever (from the 1st MPP

tracker)

PSS status The status of the most recent inverter fault can be displayed.

Grid status The five most recent grid faults can be displayed:

U PV2

Current DC voltage on the terminals, even if the inverter is

feeding no power into the grid whatsoever (from the 2nd MPP

tracker)

GVDPR

Grid voltage-dependent power reduction

Fan #1

Percentage of target output for fan

IMPORTANT! Due to the low level of insolation early in the

morning and in the evening, the status codes 306 (Power low)

and 307 (DC low) are displayed routinely at these times of

day. These status codes do not indicate any kind of fault.

Press the "Enter" key to see the status of the power stage

-

set and the most recent fault

Use the "Up" and "Down" keys to scroll through the list

-

Press the "Back" key to close the status and fault list

-

Press the 'Enter' key to see the five most recent grid

-

faults

Use the "Up" and "Down" keys to scroll through the list

-

Press the 'Back' key to close the grid fault display

-

37

Page 38

Device information

Display area General / Country-specific setting / MPP tracker / Grid monitoring / Grid

General: Device type - the exact name of the inverter

For displaying the settings that will be of relevance to a power supply company.

The values shown will depend on the country setup or the device-specific settings of the inverter.

voltage limits / Grid frequency limits / Q-mode / AC power limit / AC voltage

derating / Fault Ride Through

fam. - inverter family of the inverter

serial number - serial number of the inverter

Country-specific

setting:

MPP Tracker: Tracker 1 - indicates the set tracking behaviour (MPP AUTO / MPP USER /

Grid monitoring: GMTi - Grid Monitoring Time - start-up time of the inverter in sec (seconds)

Setup - specified country setup

Version - version of country setup

Origin activated - indicates that the normal country-specific setup is activated.

Alternat. activated - indicates that the alternative country-specific setup is

activated (for Fronius Symo Hybrid only)

Group - group for updating the inverter software

FIX)

Tracker 2 (only on Fronius Symo except for Fronius Symo 15.0-3 208) - indicates the set tracking behaviour (MPP AUTO / MPP USER / FIX)

GMTr - Grid Monitoring Time reconnect - reconnection time in sec (seconds)

after a grid fault

ULL - U (voltage) Longtime Limit - voltage limit value in V (volts) for the 10minute average voltage value

LLTrip - Longtime Limit Trip - trip time for ULL monitoring, how fast the inverter should switch off

Grid voltage limits

inner limit value:

38

UImax - upper inner grid voltage in V (volts)

TTMax - Trip Time Max - trip time for exceeding the upper inner grid voltage

limit value in cyl*

UMin - lower inner grid voltage in V (volts)

TTMin - Trip Time Min - trip time for falling below the lower inner grid

voltage limit value in cyl*

*cyl = grid periods (cycles); 1 cyl corresponds to 20 ms at 50 Hz or 16.66 ms

at 60 Hz

Page 39

Grid voltage limits

outer limit value

UMax - upper outer grid voltage in V (volts)

TTMax - Trip Time Max - trip time for exceeding the upper outer grid voltage

limit value in cyl*

UMin - lower outer grid voltage in V (volts)

TTMin - Trip Time Min - trip time for falling below the lower outer grid

voltage limit value in cyl*

*cyl = grid periods (cycles); 1 cyl corresponds to 20 ms at 50 Hz or 16.66 ms

at 60 Hz

EN

Grid frequency limits:

Q-mode: Indicates which reactive power setting is currently active on the inverter (e.g.

AC power limit including SoftStart indicator and/or AC

grid frequency derating:

AC voltage derating: GVDPRe - Grid Voltage Depending Power Reduction enable limit - threshold

FILmax - upper inner grid frequency in Hz (Hertz)

FILmin - lower inner grid frequency in Hz (Hertz)

FOLmax - upper outer grid frequency in Hz (Hertz)

FOLmin - lower outer grid frequency in Hz (Hertz)

OFF, Q / P, etc.)

Max P AC - maximum output power, which can be changed using the "Manual Power Reduction" function

GPIS - Gradual Power Incrementation at Startup - indicates (%/sec) whether the SoftStart function is active on the inverter

GFDPRe - Grid Frequency Dependent Power Reduction enable limit - indicates the set grid frequency in Hz (Hertz) from when power derating takes

place

GFDPRv - Grid Frequency Dependent Power Reduction derating gradient indicates the set grid frequency in %/Hz, how strong power derating is

value in V from which voltage-dependent power derating starts

GVDPRv - Grid Voltage Depending Power Reduction derating gradient - derating gradient %/V with which the power is reduced

Message - indicates whether the dispatch of an info message via Fronius Solar Net is active

Version Displays the version and serial numbers of the PC boards in the inverter (e.g. for

service purposes)

Display area Display / Display Software / Integrity Checksum /

Memory Card / Memory Card #1 / Power Stage / Power

Stage Software / EMI Filter / Power Stage #3 / Power

Stage #4

39

Page 40

Switching the key lock on and off

Acess Code

General The inverter has a key lock function.

When the key lock is active, the Setup menu is not accessible, i.e. the setup data

cannot be changed accidentally (or maliciously).

The code 12321 has to be entered in order to activate / deactivate the key lock.

Switching the

key lock on and

off

1

Press the "Menu" key

The menu level appears.

Press the unassigned "Menu / Esc" key

2

5 times

"Access Code" is displayed in the "CODE"

menu; the first digit starts flashing.

Enter the code 12321: Use the "Plus" and

3

"Minus" keys to select a value for the

first digit of the code

4

Press the "Enter" key

The second digit flashes.

Repeat steps 3 and 4 for the second,

5

third, fourth and fifth digits of the access

code until...

the selected code starts flashing.

6

Press the "Enter" key

"Setup Menu Lock" is displayed in the

"LOCK" menu.

7

Use the "Plus" and "Minus" keys to

turn the key lock on or off:

ON = key lock is on (the Setup menu is

not accessible)

OFF = key lock is off (the Setup menu is

accessible)

8

Press the "Enter" key

40

Page 41

USB Stick as a Data Logger and for Updating Inverter Software

USB flash drive

as a datalogger

If a USB flash drive is connected to the USB A socket it can function as a datalogger for an inverter.

At any time, the logging data stored on the USB flash drive can be

imported into the Fronius Solar.access software using the FLD file that was

-

logged at the same time,

viewed directly in third-party programs (e.g. Microsoft® Excel) using the CSV

-

file logged at the same time.

Older versions (before Excel 2007) are limited to a maximum of 65,536 rows.

Further information on "Data on a USB flash drive", "Data volume and storage

capacity" as well as "Buffer memory" can be found at:

EN

® http://www.fronius.com/QR-link/4204260204DE

Suitable USB

flash drives

Due to the variety of USB flash drives available on the market, it cannot be guaranteed that every USB flash drive will be detected by the inverter.

Fronius recommends that only certified, industry-grade USB flash drives are

used (look out for the USB-IF logo).

The inverter supports USB flash drives with the following file systems:

FAT12

-

FAT16

-

FAT32

-

Fronius recommends that the USB flash drive employed should only be used for

recording logging data or updating the inverter software. The USB flash drives

should not contain any other data.

41

Page 42

USB symbol on the inverter display, e.g. in display mode 'NOW':

AC Output Power

NOW

Do not disconnect

USB-Stick

while LED is flashing!

X

If the inverter detects a USB flash

drive, the USB symbol will appear in

the top right corner of the display.

When inserting a USB flash drive,

check whether the USB symbol is displayed (it may also flash).

Note! Please note for outdoor applications that conventional USB flash drives

are often only guaranteed to work within a restricted temperature range.

For outdoor applications ensure that the USB flash drive also functions, for example, at low temperatures.

USB stick for updating the inverter software

Removing the

USB flash drive

With the help of the USB stick, end customers can also update the inverter software via the USB item on the SETUP menu: the update file is first saved to the

USB stick, from where it is then transferred to the inverter. The update file must

be saved in the root directory on the USB stick.

Safety instruction concerning the removal of a USB flash drive:

IMPORTANT! To avoid any loss of

data, a USB flash drive may only be

removed if the following conditions

are met:

Only remove a USB flash drive

-

via the 'Safely remove USB /

HW' item on the SETUP menu

The 'Data transmission' LED has

-

stopped flashing or comes on

steady.

42

Page 43

The Basic menu

Access Code

General The Basic menu is used to set the following parameters, which are important for

installing and operating the inverter:

EN

Access the Basic

menu

DC operating mode

-

Fixed voltage

-

MPPT1 / MPPT2 start voltage

-

USB logbook

-

Event counter

-

Grounding mode / grounding

-

monitoring

Insulation settings

-

TOTAL reset

-

1

Press the "Menu” button

The menu level appears.

Press the unassigned "Menu / Esc" key

2

5 times

"Access Code" is displayed in the "CODE"

menu; the first digit starts flashing.

Enter the code 22742: Use the "Plus" and

3

"Minus" keys to select a value for the

first digit of the code

4

Press the "Enter" button

Menu items in

the Basic menu

The second digit flashes.

Repeat steps 3 and 4 for the second,

5

third, fourth and fifth digits of the access

code until...

the selected code starts flashing.

6

Press the "Enter" button

The Basic menu appears.

7

Use the "Plus" and "Minus" keys to select the desired entry

8

Edit the desired menu item by pressing the "Enter" button

9

Press the "Esc" key to exit the Basic menu

The Basic menu is used to set the following parameters, which are important

for installing and operating the inverter:

43

Page 44

MPP Tracker 1 / MPP Tracker 2

MPP Tracker 2: ON / OFF (only for devices with multiple MPP trackers)

-

DC operating mode: MPP AUTO / FIX / MPP USER

-

MPP AUTO: normal operating status; the inverter automatically

-

searches for the ideal operating point

FIX: for entering a fixed DC voltage at which the inverter will operate

-

MPP USER: for entering a lower MP voltage above which the inverter

-

will search for its ideal operating point

Dynamic Peak Manager: ON / OFF

-

Fixed voltage: for inputting a fixed voltage (80–800 V)

-

MPPT start-up input voltage: for entering the start-up input voltage (80–

-

800 V)

USB log book

Activates or deactivates the function for saving all error messages to a USB

flash drive

AUTO / OFF / ON

Input signal

Ext Sig. / S0-Meter / OFF operating mode

-

Ext Sig. operating mode:

Triggering method: Warning (warning shown on display) / Ext. Stop

-

(inverter switches off)

Connection type: N/C (normally closed contact) / N/O (normally open

-

contact)

S0 meter operating mode – see chapter Dynamic power reduction by

means of inverter on page 15.

Grid feed-in limit

-

Field for entering the maximum grid feed-in power in W. If this value

is exceeded, the inverter regulates down to the set value within the

time required by national standards and regulations.

Pulses per kWh

-

Field for entering the pulses per kWh of the S0 meter.

SMS / relay

Event delay:

-

for entering the time delay after which an SMS is sent or the relay is to

switch

900–86,400 seconds

Event counter:

-

for entering the number of events that lead to signalling:

10–255

Isolation setting

Isolation warning: ON / OFF

-

Threshold warning: for entering a threshold that leads to a warning

-

TOTAL Reset

Under the LOG menu item, this setting resets the max. and min. voltage values

and the max. power of feeding in to zero.

Once the values have been reset, this action cannot be undone.

44

To reset the values to zero, press the ‘Enter’ key.

‘CONFIRM’ is displayed.

Press ‘Enter’ again.

The values are reset and the menu is displayed

Page 45

Switching off current supply and restarting the

inverter

Switch off power

to the inverter

EN

Turn off the automatic circuit

1

1.

breaker.

Turn the DC disconnector to the

2.

"Off" switch position.

To start up the inverter again, follow

the steps listed above in reverse order.

45

Page 46

Status diagnostics and troubleshooting

manuals.fronius.com/html/4204102165/#0_t_0000

000061

STATE CODES

Fronius Primo

Status code display

Total failure of

the display

Status codes in

the e-Manual

The inverter performs a system self-diagnosis that automatically detects many

faults that may occur and shows them on the display. This means you are

promptly made aware of malfunctions in the inverter or the photovoltaic system,

or of any installation or operating faults.

If the system self-diagnosis has detected a specific fault, the associated status

code will be shown on the display.

IMPORTANT! Status codes may sometimes appear briefly as a result of the in-

verter's control response. If the inverter then continues working with no sign of

any problem, this means that there was no fault.

If the display fails to come on some time after sunrise:

Check the AC voltage ON the inverter connections:

-

the AC voltage must be 230 V (+ 10 % / - 5 %)*.

* The mains voltage tolerance depends on the country setup

The latest status codes can be found in the e-Manual version of these Operating

Instructions:

Customer service

manuals.fronius.com/html/4204102165/#0_t_0000000061

IMPORTANT! Contact your Fronius dealer or a Fronius-trained service techni-

cian if

an error appears frequently or all the time

-

an error appears that is not listed in the tables

-

Operation in

dusty environments

46

When operating the inverter in extremely dusty environments:

when necessary, clean the cooling elements and fan on the back of the inverter

as well as the air intakes at the mounting bracket using clean compressed air.

Page 47

Technical data

EN

General data and

protection

devices Fronius

Primo 3.0-1 -

8.2-1

Self-consumption at night 0.6 W

Cooling Controlled forced-air ventila-

tion

Protection class IP 65

Dimensions h x w x d 628 x 428 x 205 mm

Weight 21.6 kg

Permitted ambient temperature -40 °C – +55 °C

Permissible humidity 0 - 100%

EMC emission class B

DC / AC overvoltage category

Inverter topology Non-insulated transformer-

less

Voltage classification

Decisive Voltage Classification

(DVC rating)

Protection devices

AC DVC-C

DC DVC-C

Data DVC-A

DC isolation measurement

Manifestation of DC overload Operating point shift, power

DC disconnector Integrated

Active anti-islanding method Frequency conversion meth-

Fronius Primo 3.0-1 3.5-1 3.6-1

Input data

MPP voltage range 200 - 800 V

Max. input voltage

at 1000 W/m²/14 °C in an open circuit

Max. input current (MPPT 1 / MPPT 2) 12.0 A

Max. short circuit current of the solar modules

(MPPT1 / MPPT2)

Max. inverter backfeed current to the array

8)

3)

Warning/shutdown 2) at R

< 1 MOHM

limiter

od

1000 V

24 / 24 A

18 A

ISO

Output data

47

Page 48

Fronius Primo 3.0-1 3.5-1 3.6-1

Rated power (P

) 3000 W 3500 W 3680 W

nom

Max. output power 3000 W 3500 W 3680 W

Rated apparent power 3000 VA 3500 VA 3680 VA

Nominal grid voltage 1 ~ NPE 220 / 230 / 240 V

Min. grid voltage

Max. grid voltage

Inverter topology 150 V

270 V

1)

1)

Max. output current 13.7 A 16.0 A 16.8 A

Nominal frequency

50 / 60 Hz

1)

Total harmonic distortion < 3%

Power factor (cos phi)

Max. permitted mains impedance Z

Current (inrush)

5)

max

at PCC

0.85 - 1 ind./cap.

None

36 A / 2.2 ms

2)

Max. output fault current / duration 38 A / 172 ms

Efficiency

Maximum efficiency 98.0% 98.0% 98.0%

European efficiency 96.1% 96.8% 96.8%

Fronius Primo 4.0-1 4.6-1 5.0-1

Input data

MPP voltage range 210 - 800 V 240 - 800 V 240 - 800 V

Max. input voltage

at 1000 W/m²/14 °C in an open circuit

1000 V

Max. input current (MPPT 1 / MPPT 2) 12.0 A

Max. short circuit current of the solar modules

(MPPT1 / MPPT2)

Max. inverter backfeed current to the array

8)

3)

24 / 24 A

18 A

Output data

Rated power (P

) 4000 W 4600 W 5000 W

nom

Max. output power 4000 W 4600 W 5000 W

Rated apparent power 4000 VA 4600 VA 5000 VA

Nominal grid voltage 1 ~ NPE 220 / 230 / 240 V

Min. grid voltage

Max. grid voltage

150 V

270 V

1)

1)

Max. output current 18.3 A 21.1 A 22.9 A

48

Page 49

Fronius Primo 4.0-1 4.6-1 5.0-1

Nominal frequency

50 / 60 Hz

1)

Total harmonic distortion < 3 %

Power factor (cos phi)

0.85 - 1 ind./cap.

2)

EN

Max. permitted mains impedance Z

Current (inrush)

5)

max

at PCC

None

36 A / 2.2 ms

Max. output fault current / duration 38 A / 172 ms

Efficiency

Maximum efficiency 98.1% 98.1% 98.1%

European efficiency 97.0% 97.0% 97.1%

Fronius Primo 5.0-1 AUS 6.0-1 8.2-1

Input data

MPP voltage range 240 - 800 V 240 - 800 V 270 - 800 V

Max. input voltage

at 1000 W/m²/14 °C in an open circuit

1000 V

Max. input current (MPPT 1 / MPPT 2) 18.0 A

Max. short circuit current of the solar modules

(MPPT1 / MPPT2)

Max. inverter backfeed current to the array

8)

3)

36 A / 36 A

27,0 A

Output data

Rated power (P

) 4600 W 6000 W 8200 W

nom

Max. output power 5000 W 6000 W 8200 W