Operating

www.youtube.com/FroniusSolar

LEARN MORE WITH

OUR HOW-TO VIDEOS

Instructions

Fronius Energy Package

Operating Instructions

EN

42,0426,0222,EN 024-14042023

Contents

Safety rules 7

Explanation of safety notices 7

General 7

Environmental conditions 8

Qualified personnel 8

Noise emission values 8

EMC measures 8

Emergency power 9

Copyright 9

Data protection 9

General information 11

Fronius Symo Hybrid 13

Device concept 13

Proper use 14

Warning notices on the device 14

Product registration 15

Fronius Solar Battery 17

Device concept 17

Proper use 17

Increase in storage capacity 18

State of charge (SOC) accuracy 18

Warning notices on the device 18

The various operating modes 20

Operating modes – Explanation of symbols 20

Operating mode: Inverter 20

Operating mode - Inverter plus battery 21

Operating mode - Inverter plus battery and multiple Smart Meters 22

Operating mode - inverter with battery, AC-coupled to another inverter 22

Operating mode - Inverter plus battery and emergency power function 22

Operating mode - Inverter plus battery, Ohmpilot and emergency power function 23

Operating mode - Inverter plus battery, additional inverter and emergency power function 24

Operating states (only for systems with a battery) 24

Emergency power mode 26

Prerequisites for emergency power mode 26

Transitioning from feeding energy into the grid to backup power mode 26

Transitioning from backup power mode to feeding energy into the grid 26

Restrictions in backup power mode 27

Backup power and energy saving mode 27

Fronius Ohmpilot and backup power mode 27

Energy saving mode 29

General 29

Fronius Solar Battery and Fronius Symo Hybrid switch-off conditions 29

Fronius Symo Hybrid and Fronius Solar Battery switch-on conditions 30

Special case 30

Indicators on the devices and user interfaces 30

Calibration charging for the Fronius Solar Battery 31

Benefits of calibration charging 31

General 31

Conditions for starting the calibration charge (Fronius Solar Battery) 31

Calibration charging procedure (Fronius Solar Battery) 31

Calibration process (Fronius Solar Battery) 32

Duration of calibration charging (Fronius Solar Battery) 32

Limitations during calibration (Fronius Solar Battery) 32

Display during calibration charge (Fronius Solar Battery) 32

Suitable third-party batteries for Fronius Symo Hybrid 34

LG Chem ResuH 34

BYD Battery-Box Premium 34

EN

3

Operation 37

Data communication 39

Data communication area 39

General 39

Controls, connections and indicators on the system monitoring unit 40

Fronius Hybrid inverter 44

Controls and indicators 44

Display 45

Fronius Solar Battery 46

Battery management module 46

Battery module 46

Display 46

Display types 47

Data converter connections 50

Data converter controls and indicators 50

Data converter LED displays 50

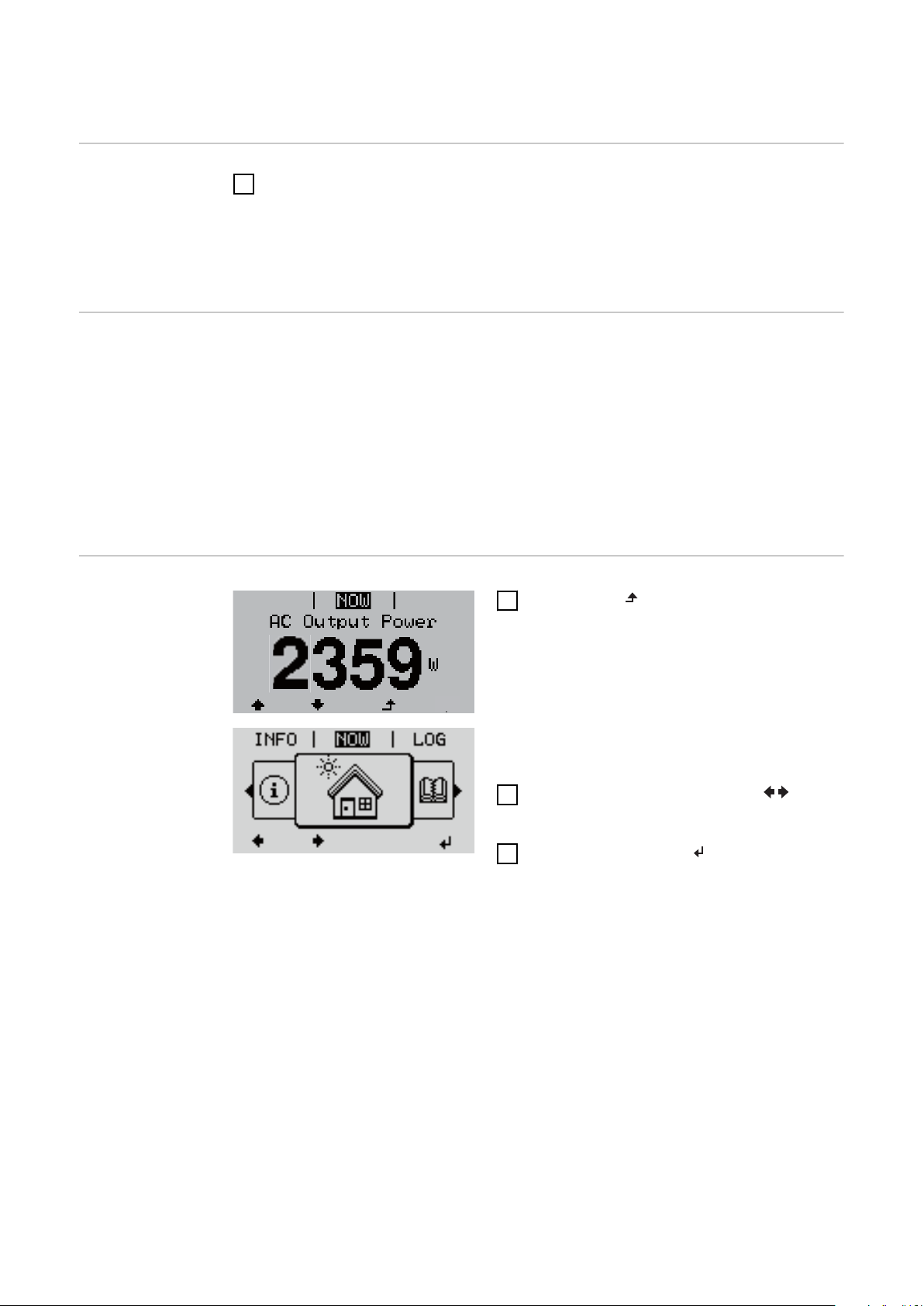

Navigation at the menu level 52

Activating display backlighting 52

Automatic deactivation of display backlighting / changing to the "NOW" menu item 52

Opening the menu level 52

Values displayed under the NOW menu item 53

Values displayed under the LOG menu item 53

Menu items in the Set-up menu 54

Standby 54

WiFi Access Point 54

Relay (floating contact switch) 55

Energy Manager(under "Relay" menu item) 56

Time / Date 57

Display settings 58

ENERGY YIELD 58

Fan 59

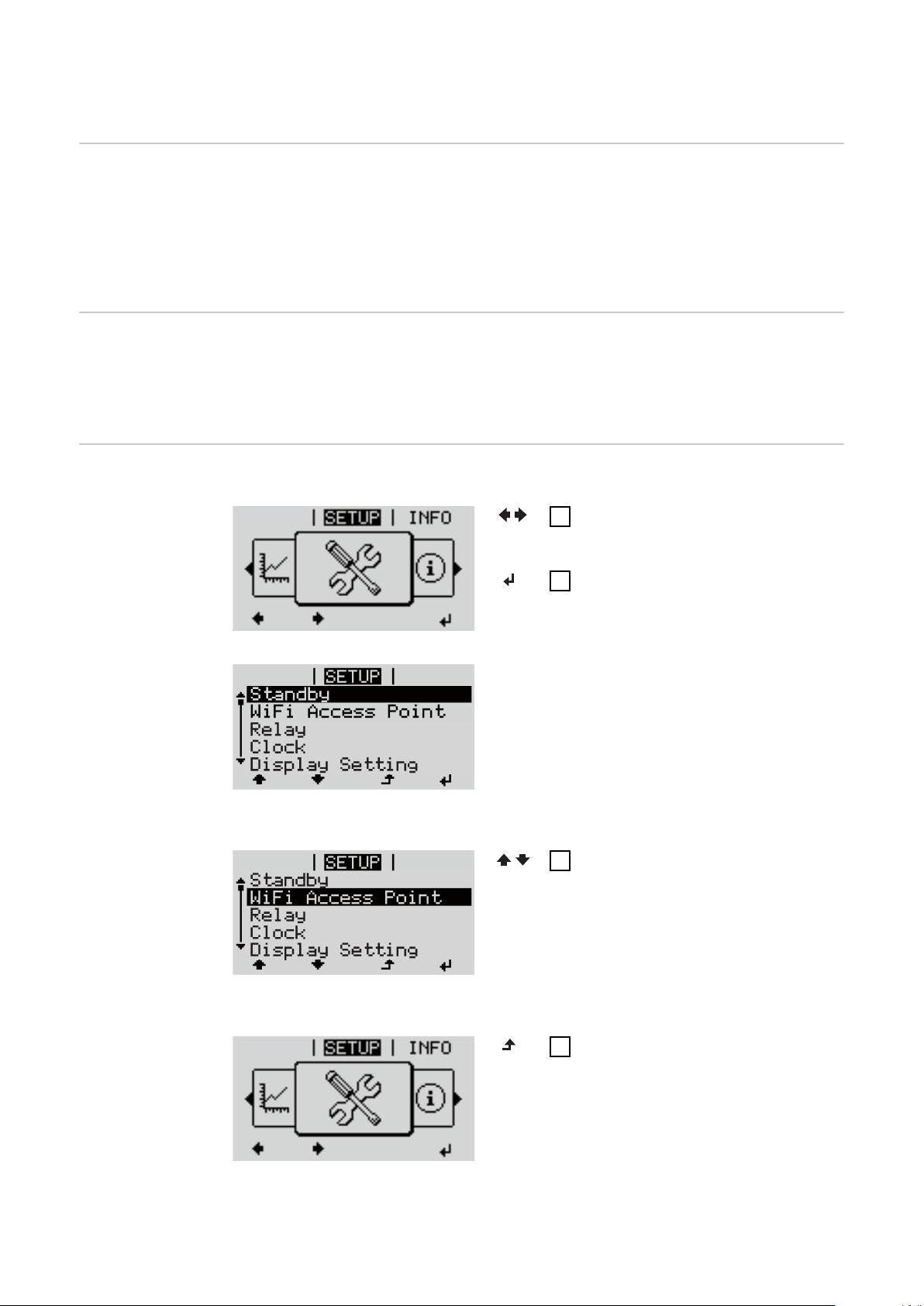

SETUP menu item 60

Initial setting 60

Software updates 60

Navigating the SETUP menu item 60

Setting menu entries, general 61

Application example: Setting the time 61

The INFO menu item 63

Measured values 63

PSS status 63

Grid status 63

Device information 63

Version 65

Switching the key lock on and off 66

General 66

Switching the key lock on and off 66

The Basic menu 67

Access the Basic menu 67

Items on the Basic menu 67

Fronius system monitoring 69

General 71

General 71

Prerequisites for operation 71

Calculating data volumes 72

General 72

Calculating data volumes 72

General information for the network administrator 74

Requirements 74

General firewall settings 74

4

Using Fronius Solar.web and sending service messages 75

Installing Fronius system monitoring – Overview 76

Safety 76

Starting for the first time 76

Information to help you work through the technician wizard 78

Testing backup power mode 79

Connecting to Fronius system monitoring via a web browser 80

General remarks 80

Prerequisites 80

Establishing a connection to Fronius system monitoring via a web browser 80

Connecting to Fronius system monitoring established via the Internet and Fronius Solar.web 81

General remarks 81

Functional description 81

Prerequisites 81

Accessing Fronius system monitoring data via the Internet and Fronius Solar.web 81

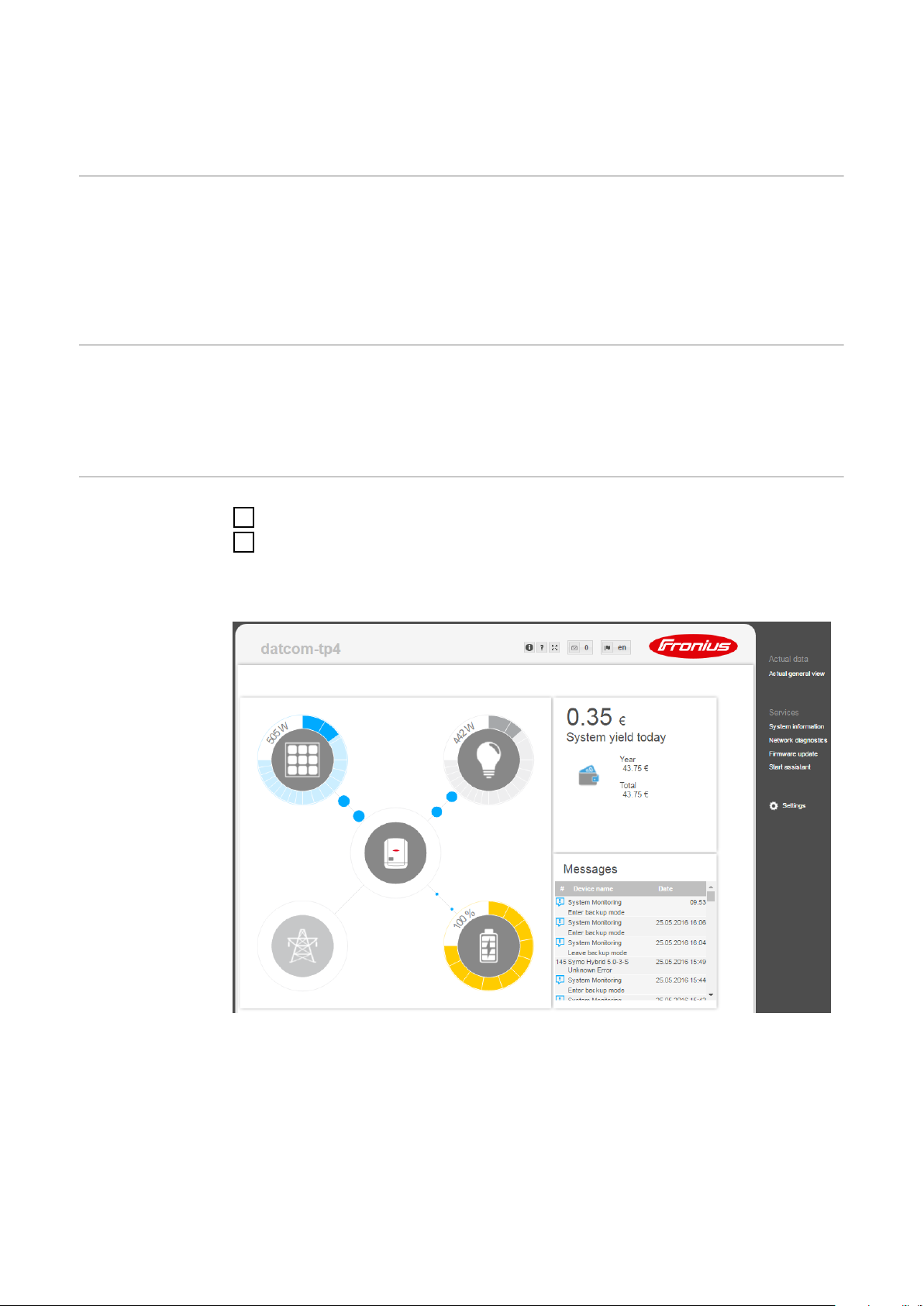

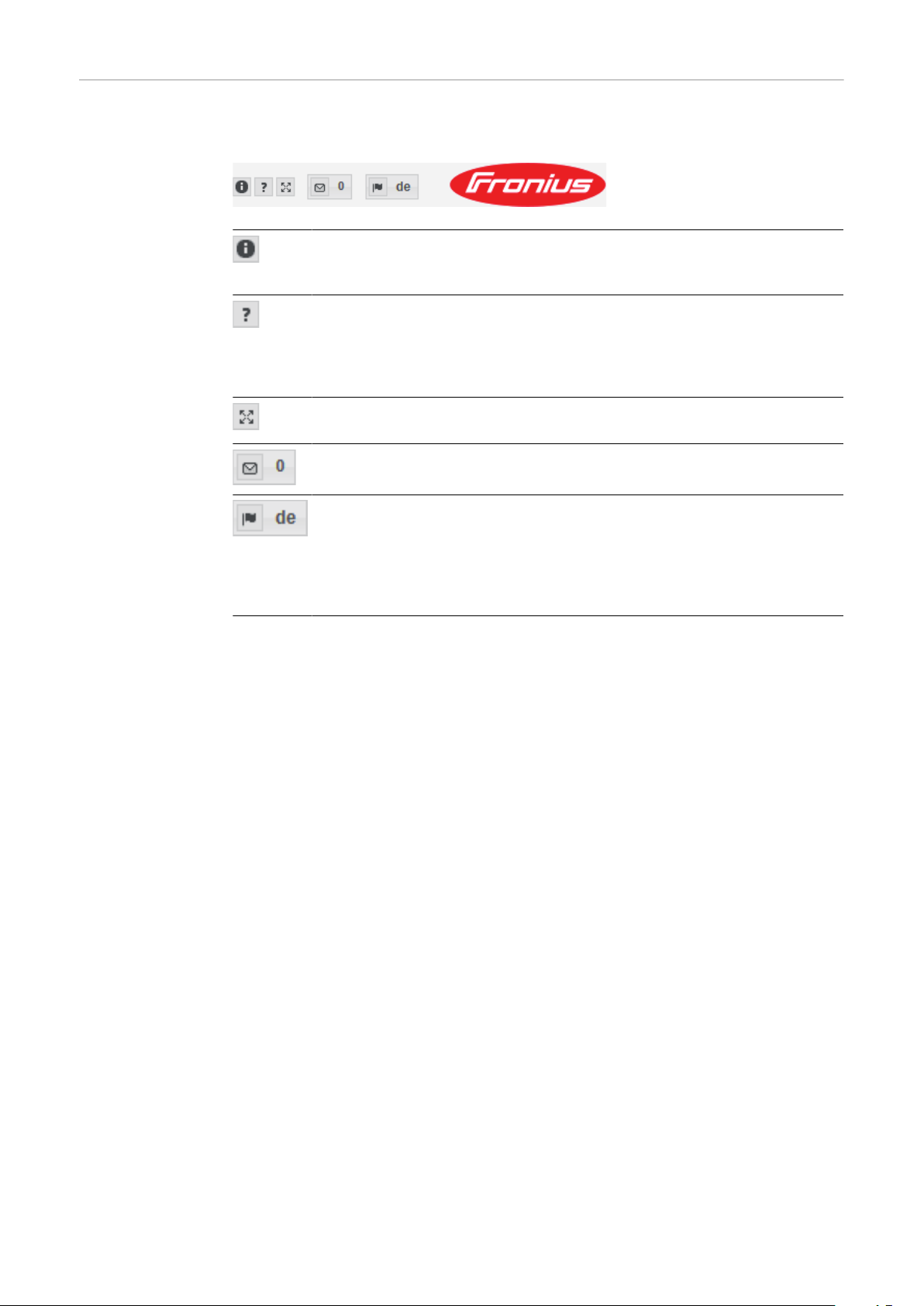

Current data, services and settings offered by Fronius system monitoring 83

The Fronius system monitoring web page 85

Fronius system monitoring web page – Overview 85

The Settings menu 85

Additional setting options 86

Services – System information 87

System information 87

Services – Network diagnostics 88

Network diagnostics 88

Services – Firmware update 89

General 89

Searching for updates automatically 89

Searching for updates manually 89

Updating the firmware via the Web 89

Services – Starting the wizard 90

Starting the wizard 90

Settings – General 91

General 91

Settings – Passwords 92

General remarks 92

Passwords 92

Settings – Network 93

Internet via WLAN 93

Internet via LAN 93

Local network via access point 93

Settings – Fronius Solar.web 95

Fronius Solar.web 95

Settings – IO mapping 96

General 96

Emergency power 96

Load management 96

IO control 96

AUS - Demand Response Modes (DRM) 96

Energy storage device 98

Settings - load management 99

Load management 99

Settings – Push Service 100

Push Service 100

Settings – Modbus 101

General remarks 101

Further information about the Modbus function 101

Exporting data via Modbus 101

Restricting control 102

Settings – Energy Manager 103

Energy management 103

Energy management examples 103

EN

5

Battery management 106

Permitted battery control parameters 107

PV power reduction 109

Settings – System overview 111

System overview 111

Settings - Meter 113

General 113

Fronius Smart Meter 113

Connection of the Fronius Smart Meter to Fronius system monitoring 113

Settings – DNO Editor 115

General 115

DNO Editor – IO control 115

Connection example 115

"PSC editor - AUS - Demand Response Modes (DRM)" 116

DNO Editor – Dynamic power reduction 116

DNO Editor – Control priorities 117

DNO Editor – Battery charge 118

Dynamic power regulation with several inverters 118

Settings – Battery 120

Battery 120

Troubleshooting and maintenance 121

Fronius Symo Hybrid 123

Status code display 123

Total failure of the display 123

Status codes – Class 1 123

Status codes – Class 3 124

Status codes – Class 4 125

Status codes – Class 5 127

Status codes – Class 6 129

Status codes – Class 7 129

Status codes – Class 9 130

Class 10 - 12 status codes 132

Customer service 132

Operation in dusty environments 132

Fronius Solar Battery 133

Status code display 133

Error messages – Battery management module 133

Error message – Data converter 133

Undefined operating statuses 134

Appendix 137

Technical data 139

System monitoring 141

Explanation of footnotes 142

Applicable standards and guidelines 142

Warranty terms and conditions, and disposal 144

Fronius manufacturer's warranty 144

Disposal 144

6

Safety rules

EN

Explanation of

safety notices

DANGER!

Indicates immediate danger.

If not avoided, death or serious injury will result.

▶

WARNING!

Indicates a potentially hazardous situation.

If not avoided, death or serious injury may result.

▶

CAUTION!

Indicates a situation where damage or injury could occur.

If not avoided, minor injury and/or damage to property may result.

▶

NOTE!

Indicates a risk of flawed results and possible damage to the equipment.

General The device has been manufactured in line with the state of the art and according

to recognized safety standards. If used incorrectly or misused, however, it can

cause:

Injury or death to the operator or a third party

-

Damage to the device and other material assets belonging to the operating

-

company.

All personnel involved in commissioning, maintenance, and servicing of the

device must:

Be suitably qualified

-

Have knowledge of and experience in dealing with electrical installations and

-

Have fully read and precisely followed these Operating Instructions

-

The Operating Instructions must always be at hand wherever the device is being

used. In addition to the Operating Instructions, attention must also be paid to

any generally applicable and local regulations regarding accident prevention and

environmental protection.

All safety and danger notices on the device:

Must be kept in a legible state

-

Must not be damaged

-

Must not be removed

-

Must not be covered, pasted or painted over

-

The terminals can reach high temperatures.

Only operate the device when all protection devices are fully functional. If the

protection devices are not fully functional, there is a danger of:

Injury or death to the operator or a third party

-

Damage to the device and other material assets belonging to the operating

-

company

7

Any safety devices that are not fully functional must be repaired by an authorised specialist before the device is switched on.

Never bypass or disable protection devices.

For the location of the safety and danger notices on the device, refer to the section headed "General remarks" in the Operating Instructions for the device.

Any equipment malfunctions which might impair safety must be remedied before

the device is turned on.

This is for your personal safety!

Environmental

conditions

Qualified personnel

Operation or storage of the device outside the stipulated area will be deemed as

not in accordance with the intended purpose. The manufacturer accepts no liability for any damage resulting from improper use.

The servicing information contained in these operating instructions is intended

only for the use of qualified service engineers. An electric shock can be fatal. Do

not carry out any actions other than those described in the documentation. This

also applies to qualified personnel.

All cables and leads must be secured, undamaged, insulated and adequately dimensioned. Loose connections, scorched, damaged or inadequately dimensioned

cables and leads must be immediately repaired by authorised personnel.

Maintenance and repair work must only be carried out by an authorised specialist.

It is impossible to guarantee that bought-in parts are designed and manufactured to meet the demands made on them, or that they satisfy safety requirements. Use only original spare parts (also applies to standard parts).

Do not carry out any alterations, installations, or modifications to the device

without first obtaining the manufacturer's permission.

Components that are not in perfect condition must be changed immediately.

Noise emission

values

EMC measures In certain cases, even though a device complies with the standard limit values for

8

The maximum sound power level of the inverter is specified in the Technical

Data.

The device is cooled as quietly as possible with the aid of an electronic temperature control system; this depends on the amount of converted power, the ambient

temperature, the level of soiling of the device, etc.

It is not possible to provide a workplace-related emission value for this device

because the actual sound pressure level is heavily influenced by the installation

situation, the power quality, the surrounding walls and the properties of the room

in general.

emissions, it may affect the application area for which it was designed (e.g., when

there is equipment that is susceptible to interference at the same location, or if

the site where the device is installed is close to either radio or television receivers). If this is the case, then the operator is obliged to take action to rectify the

situation.

Emergency

power

Copyright Copyright of these operating instructions remains with the manufacturer.

This system is equipped with an emergency power function. This means a backup

power supply is automatically established in the event of a power outage.

The emergency power sticker provided with the inverter must be attached to the

electrical distributor.

For maintenance and installation work, the system must both be isolated from

the grid, and backup power mode must be disabled by opening the integrated DC

disconnector on the inverter.

The emergency power supply is automatically activated and deactivated depending on the insolation conditions and the state of charge of the battery. This

means that emergency power can be re-established unexpectedly when in

standby mode. For this reason, when the emergency power supply is deactivated,

switch off all connected devices and do not undertake any installation work on

the household network.

The text and illustrations are all technically correct at the time of printing. We

reserve the right to make changes. The contents of the operating instructions

shall not provide the basis for any claims whatsoever on the part of the purchaser. If you have any suggestions for improvement, or can point out any mistakes that you have found in the instructions, we will be most grateful for your

comments.

EN

Data protection The user is responsible for the safekeeping of any changes made to the factory

settings. The manufacturer accepts no liability for any deleted personal settings.

9

10

General information

11

12

Fronius Symo Hybrid

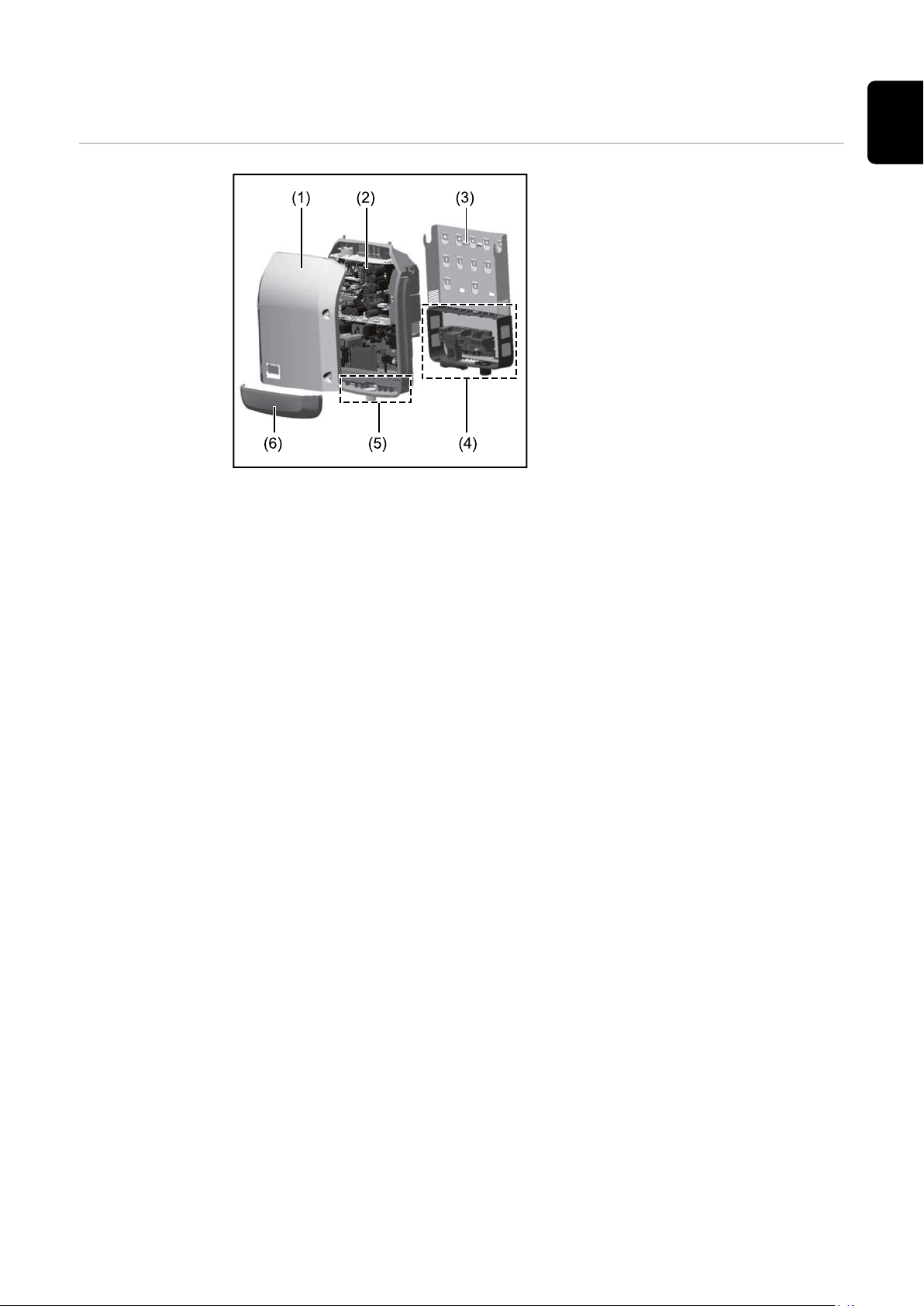

Device concept Device design:

(1) Housing cover

(2) Inverter

(3) Mounting bracket

(4) Connection area including DC

main switch

(5) Data communication area

(6) Data communication cover

The hybrid inverter converts the direct current generated by the PV modules into

alternating current. This alternating current is synchronized with the grid voltage

and fed into the public grid. Moreover, the solar energy can also be stored in a

connected battery for later use.

EN

The hybrid inverter has been developed specifically for use in grid-connected

photovoltaic systems. A backup power mode is possible if the cabling is set up

accordingly.

Thanks to its design and operating principle, the inverter is extremely safe both

to install and to operate.

The inverter monitors the public grid automatically. In the event of abnormal grid

conditions, the inverter ceases operating immediately and stops feeding power

into the grid (e.g. if the grid is switched off, if there is an interruption, etc.).

The grid is monitored by monitoring the voltage, frequency and islanding conditions. The inverter switches to backup power mode if it has been cabled up accordingly.

Operation of the inverter is fully automatic.

The inverter is designed to draw as much power from the PV modules as possible.

Depending on the operating point, this power is either stored in the battery, fed

into the grid or used for the household network in backup power mode.

As soon as the energy provided by the PV modules is no longer sufficient, the

power from the battery is fed into the home. Depending on the setting, power

may also be obtained from the public grid in order to charge the battery.

If the inverter becomes too hot, it automatically reduces the current output

power or charging power, or switches to backup power mode in order to protect

itself.

Reasons for the inverter becoming too hot include the ambient temperature being too high or inadequate heat dissipation (e.g. if it is installed in a switch cabinet

without suitable heat dissipation).

IMPORTANT! The battery must only be switched on when the inverter is in

Standby mode.

13

Proper use The solar inverter is exclusively intended for charging a battery with direct cur-

rent from solar modules, or for converting this direct current into alternating

current and feeding it into the public grid or the household network in emergency power mode.

The following actions constitute improper use:

Any use above and beyond this purpose

-

Making any modifications to the inverter that have not been expressly ap-

-

proved by Fronius

Installing components that are not distributed or expressly approved by

-

Fronius

Operating the device with a battery that has not been approved by Fronius

-

Operating the equipment with an energy meter that has not been approved

-

by Fronius

Fronius shall not be liable for any damage resulting from such action.

No warranty claims will be entertained.

Proper use also includes:

Carefully studying and obeying the Installation and Operating Instructions

-

Performing all stipulated inspection and maintenance work

-

When designing the photovoltaic system, ensure that all of its components are

operated within their permitted operating ranges at all times.

Observe all the measures recommended by the solar module manufacturer to

ensure that the solar module retains its properties in the long term.

Warning notices

on the device

Observe the stipulations of the power supply company concerning energy fed into the grid, emergency power mode and the operation of storage systems.

The Fronius Symo Hybrid is a grid-connected inverter with an emergency power

function – it is not a stand-alone inverter. The following restrictions must therefore be observed in emergency power mode:

Emergency power mode may be in operation for at least 1500 hours

-

Emergency power mode may be in operation for more than 1500 operating

-

hours if 15% of the duration of the inverter's grid power feed operation is not

exceeded at the relevant time

There are warning notices and safety symbols on and in the inverter. These warning notices and safety symbols must not be removed or painted over. They warn

against incorrect operation, as this may result in serious injury and damage.

14

6

6

6

6

6

Safety symbols:

Danger of serious injury and dam-

age due to incorrect operation

Do not use the functions described

here until you have fully read and

understood the following documents:

These Operating Instructions

-

All the Operating Instructions

-

for the system components of

the photovoltaic system, especially the safety rules

Dangerous electrical voltage

Wait for the capacitors to dis-

charge.

Text of the warning notices:

WARNING!

Danger from electric current.

This can result in serious injury or death.

Before opening the device, it must be disconnected at the input and output.

▶

Wait for the capacitors to discharge (6 minutes).

▶

EN

Product registration

Symbols on the rating plate:

CE mark – confirms compliance with applicable EU directives and

regulations.

WEEE mark – waste electrical and electronic equipment must be

collected separately and recycled in an environmentally sound manner

in accordance with the European Directive and national law.

RCM mark – tested in accordance with the requirements of Australia

and New Zealand.

Why do I need to register?

By registering easily and for free, you will benefit from additional years of warranty. You only need to fill out a few details and confirm the registration.

Who can register a device?

The warranty agreement is concluded between Fronius and the warranty holder

(owner of the installed system). For this reason, the system must be registered by

the warranty holder using their Solar.web login credentials. Registration may only

be performed by third parties if they have been authorised to do so. Non-compliance may result in a penalty. The warranty will be invalid if incorrect details are

provided.

How can I register?

Log in to the website www.solarweb.com and click on the "Product registration"

field. More information can be found in the product registration area.

15

Where can I find the serial number for my product?

The serial number can be found on the rating plate of the Fronius device.

For the Solar Battery, only use the serial number shown in the picture. The serial

numbers of the individual battery modules are not relevant.

16

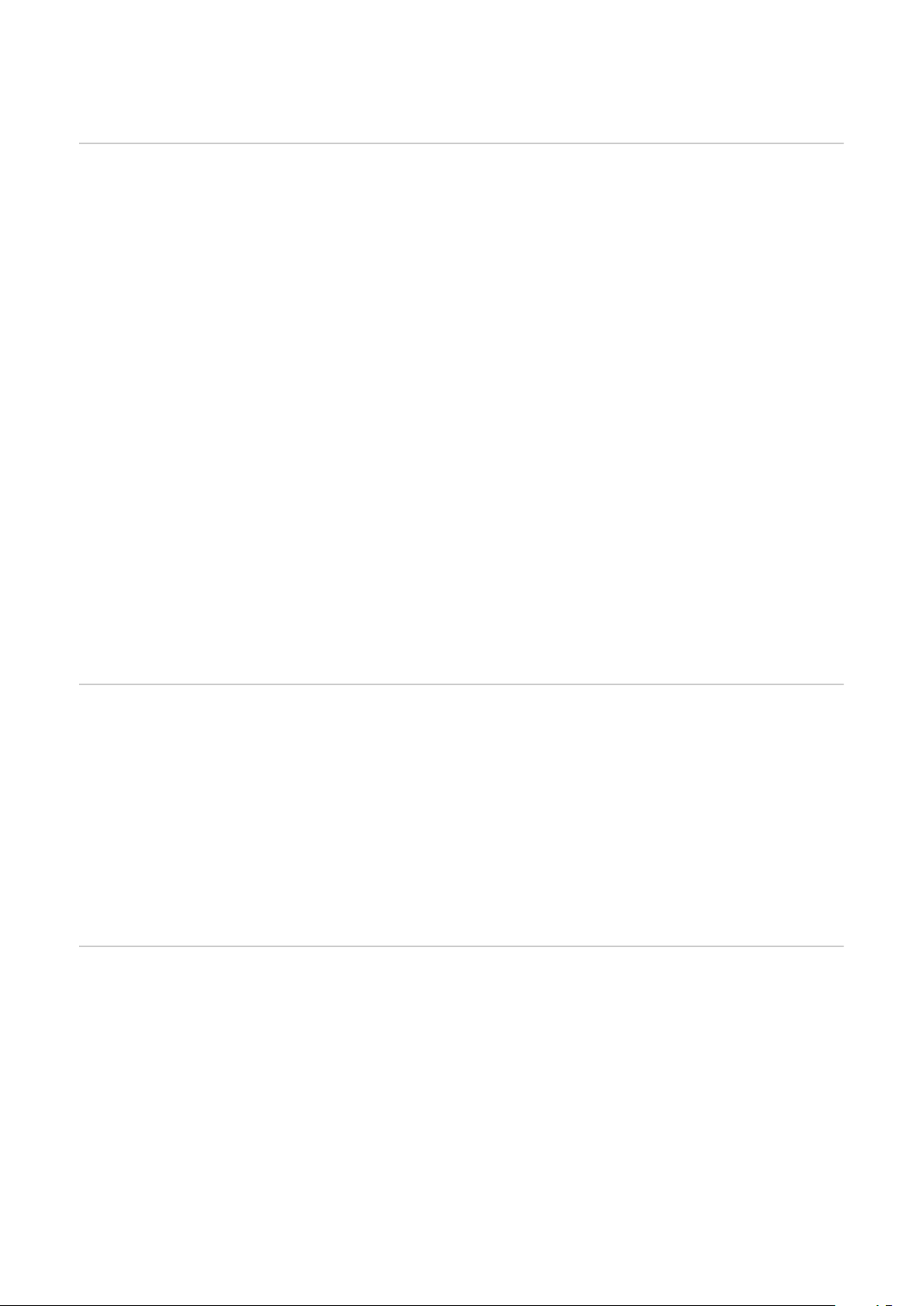

Fronius Solar Battery

(1)

(2)

(3)

(4)

(5)

(6)

EN

Device concept

Device design:

(1) Battery management module

(2) Side panel

(3) Lid

(4) Fuses

(5) Data converter

(6) Battery module (1.2 kWh usable

capacity)

With the market launch of its new Fronius Energy Package, Fronius is introducing

an inverter that can be used to store energy. One of the key components is the

Fronius Solar Battery, which contains a lithium-ion rechargeable cell. The Fronius

Solar Battery supplements the Fronius hybrid inverter by adding storage functionality. This means that the solar energy from the solar modules can be stored

for later use.

The storage system is only suitable for operation in conjunction with Fronius hybrid inverters.

Thanks to its design and operating principle, the storage system is extremely safe

both to install and to operate. A high-performance lithium-ion phosphate battery

is used (LiFePO4), which is based on the latest technology and complies with the

highest safety standards.

When used in conjunction with the Fronius inverter, operation of the storage system is fully automatic.

If proper charging of the batteries in the Fronius Energy Package cannot be

guaranteed for an extended period of time (over several weeks or months) for any

reason, we strongly recommend that the following steps are undertaken to prevent the deep discharge of the battery modules:

switch off the main switch of the Fronius Solar Battery

-

remove the DC fuses from the fuse holder

-

remove the orange power connector from the individual battery modules

-

Proper use The Fronius Solar Battery is exclusively intended for taking direct current from a

Fronius hybrid inverter and storing it for later use.

The following actions constitute improper use:

Any use above and beyond this purpose

-

Making any modifications to the storage system that have not been expressly

-

approved by Fronius

Installing components that are not distributed or expressly approved by

-

Fronius

Operating the system with an inverter that has not been approved by Fronius

-

Operating the equipment with an energy meter that has not been approved

-

by Fronius

17

Fronius shall not be liable for any damage resulting from such action.

No warranty claims will be entertained.

Proper use also includes:

Carefully studying and obeying the installation and operating instructions

-

performing all stipulated inspection and maintenance work

-

Observe the stipulations of the power supply company concerning energy fed into the grid and the operation of storage systems.

Increase in storage capacity

State of charge

(SOC) accuracy

The storage capacity of the Fronius Solar Battery can also be increased after

purchase to a maximum capacity of 9.6 kWh of usable energy.

The capacity is increased by adding additional battery modules and this must be

carried out by a qualified electrician.

Capacity can be expanded within 2 years from the date of purchase, but a maximum of 30 months following dispatch from Fronius Austria.

The capacity cannot be increased after this for technical reasons. Observe the

stipulations of the distribution network operator concerning energy fed into the

grid and the operation of storage systems.

Adding or replacing a memory module can lead to inaccuracies when calculating

the state of charge (SOC). Straight lines and jumps can occur, in particular immediately after the upgrade. These only affect the display of the state of charge

and do not affect operation of the device.

SOC jump

Warning notices

on the device

SOC straight line

Warning notices and safety symbols are affixed to the battery. These warning notices and safety symbols must not be removed or painted over. They warn against

incorrect operation, as this may result in serious injury and damage.

18

Safety symbols – Text of the warning notices:

CAUTION!

Incorrect handling or failing to observe these notices and the operating

instructions is extremely dangerous. It may give rise to thermal/electrical or fire hazards, thereby resulting in serious injuries.

Please read the Operating Instructions carefully while also ensuring

compliance with the safety instructions during use!

To avoid electric shocks:

Do not dismantle or modify the device

-

Do not allow any water to enter the device

-

Do not allow any foreign substances or material to enter the device

-

Do not touch any connections directly

-

EN

To avoid overheating, fire, electric shocks or injuries:

Do not use any unspecified charging devices

-

Do not use in room temperatures of 35 °C or above

-

Do not use in unstable environments

-

Do not expose to any strong vibrations

-

To avoid the risk of fire:

Do not short-circuit individual connections

-

Avoid overheating

-

What to do in an emergency:

Fire:

a)

Suitable extinguishing agents: CO2 or powder extinguisher; fire extin-

-

guishing equipment that involves the use of water can result in electric

shocks.

Notify fire brigade

-

Notify anyone who is in danger

-

Switch off main switch

-

Open residual current-operated circuit breaker

-

Flooding:

b)

Switch off main switch

-

Open residual current-operated circuit breaker

-

Protect system from water, pump water away

-

Undefined operating status (see also section titled "Undefined operating

c)

statuses" on page 134):

Ensure adequate ventilation

-

Switch off main switch

-

Open residual current-operated circuit breaker

-

19

The various operating modes

Operating modes

– Explanation of

symbols

Solar module

Generates direct current

Inverter – Fronius hybrid

Converts the direct current into alternating current and charges

the battery. Thanks to the built-in system monitoring function, the

inverter can be integrated into a network using WLAN technology.

Battery

Connected to the inverter on the DC side and used to store electrical energy.

Photovoltaic system consumers

The consumers connected to the PV system (single or threephase)

Meter – Fronius Smart Meter

For optimum energy management. You can have the meter installed in a switch cabinet by your electrical installer. Energy profiling is possible through the use of several Smart Meters. Additional consumers or generators in the system can be measured

and monitored.

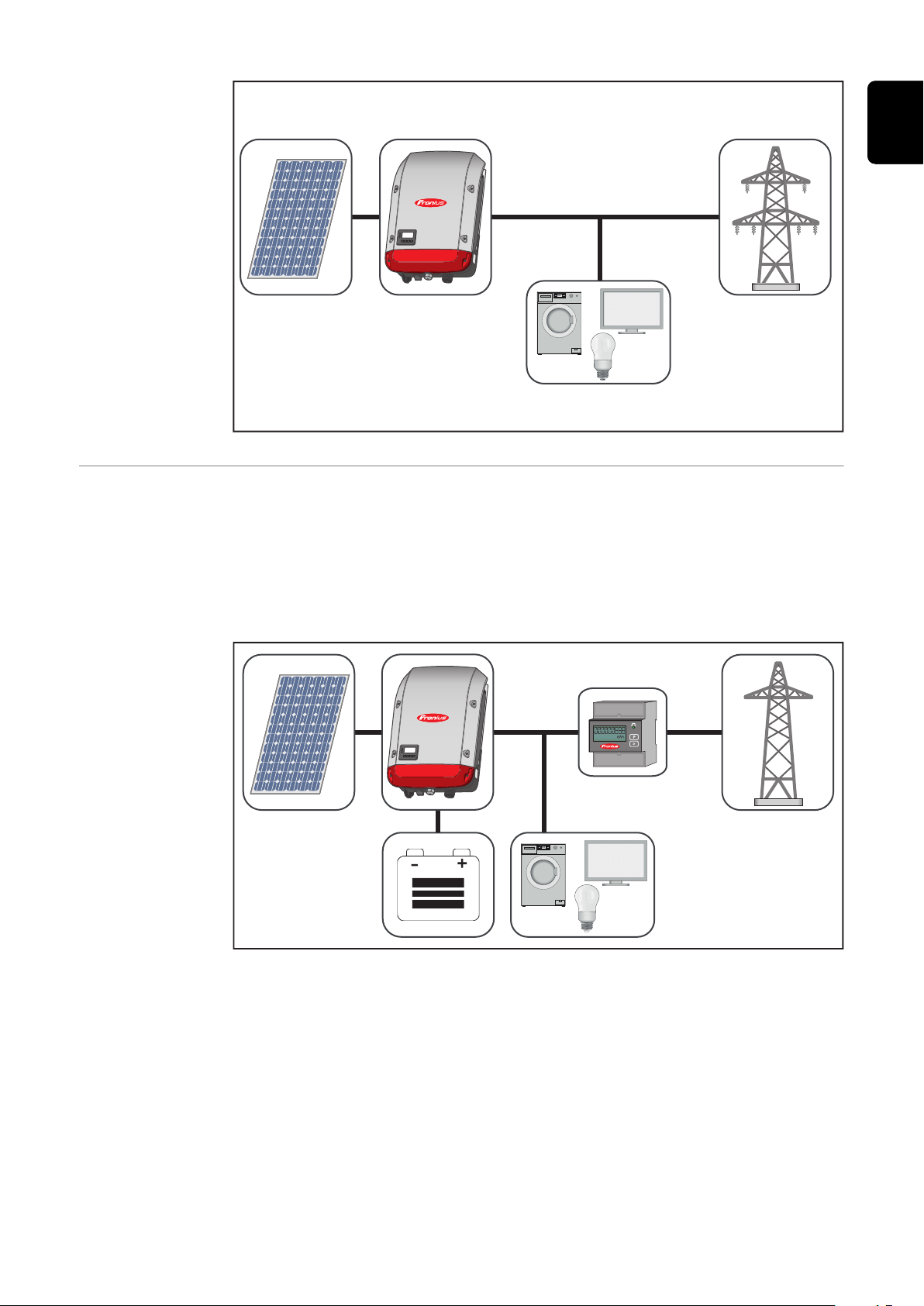

Operating mode:

Inverter

Emergency power function

The inverter is delivered ready for supplying emergency power.

However, the electrical installer must set up the emergency power

function in the switch cabinet. In emergency power mode, the PV

system operates as a stand-alone island.

Fronius Ohmpilot

To use surplus energy to heat water.

Additional inverter in the system (e.g. Fronius Symo)

Converts the direct current into alternating current. Cannot,

however, be used to charge batteries and is not available to

provide emergency power.

Grid

The Fronius hybrid inverter can be used purely as an inverter without a battery

connected to it.

20

EN

Operating mode

- Inverter plus

battery

To ensure fault-free regulation, parallel operation of several batteries is not permitted.

To optimise self-consumption in your PV system, you can use a battery as a storage system. The battery is connected to the inverter on the DC side. As a result,

there is no need for multiple current conversion processes, which results in

greater efficiency.

21

Operating mode

- Inverter plus

battery and multiple Smart

Meters

Operating mode

- inverter with

battery, ACcoupled to another inverter

Operating mode

- Inverter plus

battery and

emergency

power function

22

IMPORTANT! In emergency power mode, an increased nominal frequency is

used in order to avoid parallel operation with other generators.

To ensure fault-free regulation, parallel operation of several batteries is not permitted.

When the hybrid PV system is equipped with all the available features, the inverter can:

Feed energy into the grid

-

Supply the devices that are connected to the PV system with power in the

-

event of a power failure

Use any excess energy to charge the battery.

-

EN

Operating mode

- Inverter plus

battery, Ohmpilot and emergency power

function

IMPORTANT! In a hybrid PV system with Fronius Ohmpilot and all the system

features, the Ohmpilot cannot be operated in the event of a power failure for

control-related reasons. Therefore, it makes sense to install the Ohmpilot outside

of the emergency power circuit.

23

Operating mode

- Inverter plus

battery, additional inverter

and emergency

power function

Operating states

(only for systems

with a battery)

Battery system distinguishes different operating states. The current operating

state is displayed on the system monitoring website or in Solar.web.

Operating state Description

The battery is not active. It has either been deac-

Deactivated

tivated, or no communication with the battery or

meter is possible due to a fault.

Normal operation The system is in normal operation

Service mode has been activated. The battery is

Service mode

1)

automatically charged or discharged to a defined

SOC value and then kept at this value until service

mode is ended manually.

The Fronius Symo Hybrid recharges the battery to

Forced re-charging

counteract self discharge and maintain the set

minimum SOC (protection against deep discharge).

The battery has reached the set minimum SOC.

Min. SOC reached

The battery cannot be discharged further until

charging takes place again.

The system has been put into energy saving mode.

Energy saving mode

None of the LEDs or the battery display light up1).

Energy saving mode is automatically ended as

soon as sufficient excess energy is available again.

24

Calibration mode

1)

Deep discharge protec-

1)

tion

The system is in calibration mode. When there is

insufficient PV energy available to reach 100%,

the battery is cyclically charged to 100% for internal calibration. Under certain conditions (depending on weather, microcycles, temperature,

etc.), this can take an extended period of time.

The Fronius Symo Hybrid recharges the battery to

counteract self discharge and maintain the minimum state of charge.

Operating state Description

Start

1) Only available for the Fronius Solar Battery.

The storage system starts from energy saving

mode (standby).

EN

25

Emergency power mode

Prerequisites for

emergency

power mode

In order to use the hybrid inverter's emergency power function, the following

prerequisites must be fulfilled:

Correct cabling of the emergency power system in the electrical installation

-

(see document "Fronius Energy Package - Examples of emergency power

switchover").

The Fronius Smart Meter must be installed at the feed-in point and con-

-

figured.

Latest firmware on the inverter - if required, perform a firmware update.

-

The emergency power sticker provided with the inverter must be attached to

-

the electrical distributor.

Select Alternative (emergency power) setup in the CONFIG menu on the in-

-

verter (see Installation Instructions).

Change the required settings in the emergency power area in the IO mapping

-

menu (Fronius system monitoring web page → Settings → IO mapping →

Emergency power).

Set the emergency power to "Auto" in the system overview (Fronius system

-

monitoring web page → Settings → System overview → Emergency power operating mode).

If there are additional inverters in the system, these should be installed outside

of the emergency power circuit, but within that for the Fronius Smart Meter, see

Operating mode - Inverter plus battery, additional inverter and emergency

power function on page 24.

NOTE! Emergency power mode is not possible with the batteries from the LG

Chem ResuH series.

Transitioning

from feeding energy into the grid

to backup power

mode

Transitioning

from backup

power mode to

feeding energy

into the grid

The public grid is monitored by the inverter's internal grid and system pro-

1.

tection unit and by the Fronius Smart Meter connected to it.

The public grid fails or specific grid parameters are dropped below or ex-

2.

ceeded.

The inverter carries out the measures necessary according to the country

3.

standard and then switches off.

The inverter starts backup power mode after a checking period.

4.

All loads in the household that are in the backup power circuit are supplied

5.

by the battery and the PV modules. The remaining loads are not supplied

with power and are safely isolated.

The inverter is operating in backup power mode.

1.

The public grid is functioning correctly again.

2.

The Fronius Smart Meter monitors the grid parameters on the public grid

3.

and passes this information to the inverter.

The stability of the returned public grid is determined by checking the meas-

4.

ured values of the Fronius Smart Meter.

The inverter ends backup power mode.

5.

All circuits are reconnected to the public grid and are supplied by the grid.

6.

The inverter can start feeding energy into the grid again after performing the

7.

grid checks required by the relevant standard.

26

Restrictions in

backup power

mode

In backup power mode, some electrical appliances cannot function properly as

the starting currents are too high (e.g. fridges and freezers). It is recommended

to switch off non-essential loads during backup power mode.

Switching from grid-connected operation to backup power mode takes a little

while. For this reason, the battery system with backup power function cannot be

used as an uninterruptible power supply, for example for computers.

If no energy is available from the battery or the PV modules during backup

power mode, this mode is automatically ended, irrespective of whether power is

available from the public grid or not.

Fronius Solar Battery: If sufficient energy becomes available from the PV modules once again, backup power mode starts again automatically.

BYD Battery-Box Premium: The system must be restarted manually as soon as

sufficient energy from the PV modules or the public grid is available again. For

the correct power-up sequence, see chapter BYD Battery-Box Premium on page

34.

If consumption is too high, backup power mode is interrupted and status code

"143 - Backup power overload" appears. The maximum power in backup power

mode according to the technical data must be observed!

EN

Backup power

and energy saving mode

Fronius Ohmpilot and backup

power mode

If the inverter is operating in backup power mode, energy saving mode is automatically active. Under the following conditions, the battery and the inverter are

switched to energy saving mode after a waiting time of 8 - 12 minutes:

The battery is discharged to the minimum state of charge and no energy is

-

coming from the PV modules.

The inverter is in an error state that is not acknowledged automatically (e.g.

-

multiple overload).

The inverter is set to energy saving mode (standby mode) using the display

-

setting.

If the battery and inverter are in energy saving mode, the system is reactivated

by the following actions (applies only for Fronius Solar Battery):

Enough energy is available from the PV modules.

-

The public grid is functioning again.

-

The battery's POWER switch is switched off and on.

-

More information on energy saving mode can be found in chapter Energy saving

mode on page 29

The Fronius Ohmpilot is not suitable for backup power mode. If a Fronius Ohmpilot is used, it should be installed outside of the backup power circuit (see Oper-

ating mode - Inverter plus battery, Ohmpilot and emergency power function on

page 23).

NOTE!

Risk from an active Ohmpilot in backup power mode.

This may result in loss of the backup power supply.

Never turn on boost mode on the Ohmpilot.

▶

Switch off the automatic circuit breaker on the Fronius Ohmpilot (if fitted).

▶

Before a power outage occurs, any function that would exceed the power

▶

limits in backup power mode must be disabled.

27

Disable functions that would exceed the power limits in backup power mode:

Set measuring of heating rod to manual on the Ohmpilot (under "General -

1

General Settings - Heating 1 - Manual").

Disable the "Legionella prevention (h)" and "Adapt day curve" settings (under

2

"General - General Settings - Heating 1").

28

Energy saving mode

General Energy saving mode (standby) is used to reduce the self-consumption of the sys-

tem. It is available from version 1.4.1-11 of the system monitoring software. Both

the inverter and the battery automatically switch into energy saving mode under

certain conditions.

Fronius Symo Hybrid

If the battery is flat and no PV energy is available, the inverter switches to energy

saving mode. Only the inverter's communication with the Fronius Smart Meter

and Fronius Solar.web is maintained.

Fronius Solar Battery

When the battery is in energy saving mode, the display remains dark. In Solar.web, energy saving mode is indicated by an "i" next to the battery symbol. In

the energy balance view, the SOC (State of Charge) of the Fronius Solar Battery

is not displayed for the duration of energy saving mode.

BYD Battery-Box Premium

In Solar.web, energy saving mode is indicated by an "i" next to the battery symbol.

EN

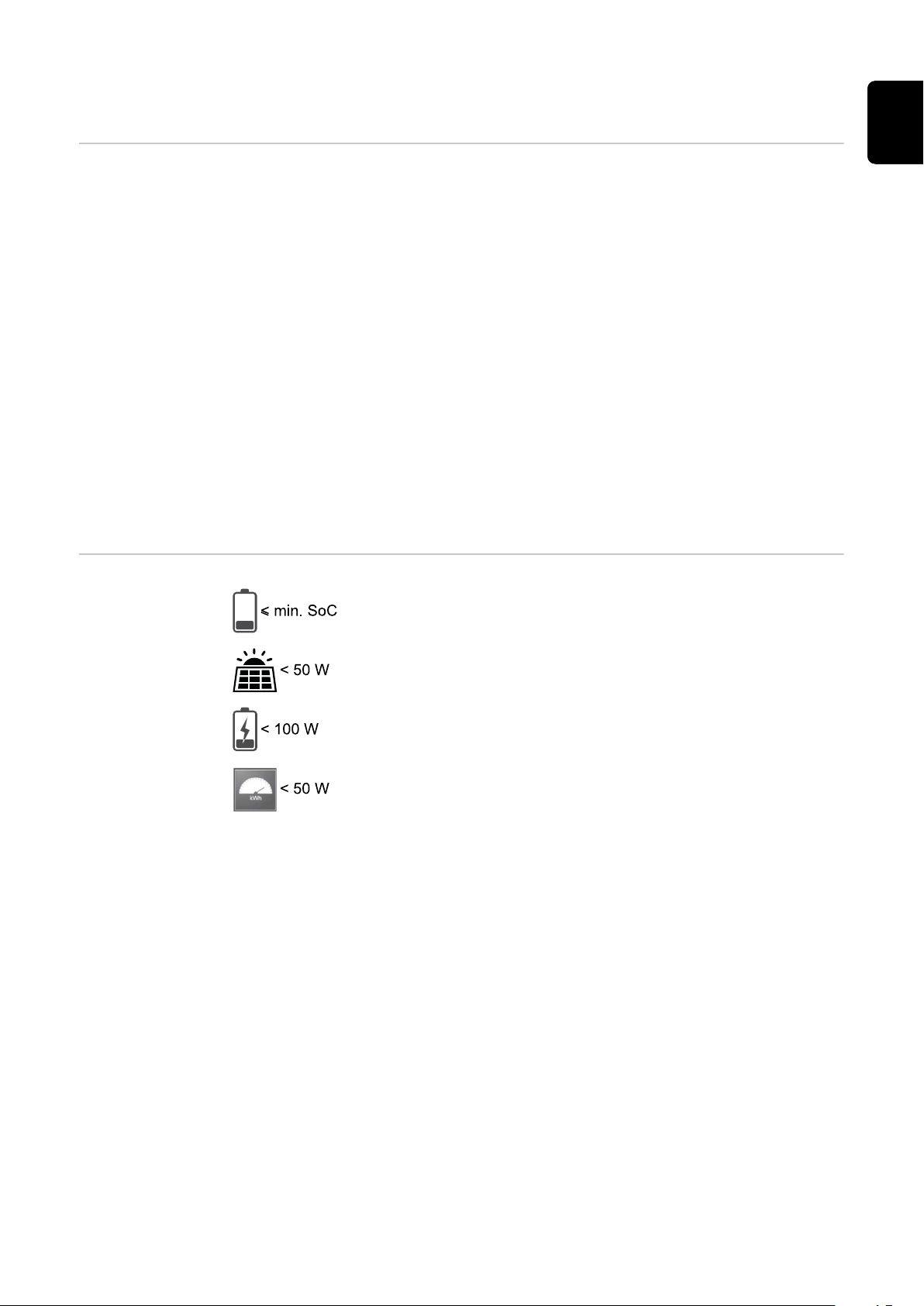

Fronius Solar

Battery and

Fronius Symo

Hybrid switchoff conditions

The battery state of charge is less than or equal to the input

minimum state of charge.

The power from the PV modules is less than 50 W.

The current charging or discharging power of the battery is

less than 100 W.

Less than 50 W is available for charging the battery. The

power of feeding in for the public grid is at least 50 W less

than the power currently required in the home network.

If all the switch-off conditions are met, the battery switches into energy saving

mode within six minutes. This time delay ensures that the inverter can be restarted at least once.

The inverter automatically switches into energy saving mode after the battery.

Backup power:

If the backup power function has been activated, the battery in grid operation

does not switch to energy saving mode. Otherwise, the dark start (start without

grid and PV supply) of the hybrid system cannot be ensured.

During backup power mode and when the state of charge falls below the minimum limit, the battery switches to energy saving mode.

29

Fronius Symo

Hybrid and

Fronius Solar

Battery switchon conditions

Special case If the inverter does not operate for 8–12 minutes (e.g.: error), or if there is an in-

If one of the following conditions is met for at least 30 seconds, energy saving

mode is ended:

Energy saving mode is no longer permissible owing to a changed setting on

-

the user interface of the inverter.

More than 50 W is available for charging the battery. The power of feeding in

-

for the public grid is at least 50 W greater than the power currently required

in the home network.

If a dynamic power reduction of 0 is set, or if the system is operating in

-

backup power mode, the power of feeding in for the public grid is always less

than the required power in the home network.

There is a separate condition for this case (dynamic power reduction < 300 W

or active backup power mode): If the PV power is above a specified threshold

(50 W), the energy saving mode is ended.

Battery charging from the public grid is requested via the website.

-

The battery is recharged to restore the minimum state of charge or to per-

-

form a calibration.

The Fronius Solar Battery is woken up as soon as the Symo Hybrid is generat-

-

ing PV power. This guarantees reliable operation of the battery.

terruption in the electrical connection between the inverter and battery, the battery switches into energy saving mode in any case. This reduces self discharge of

the battery.

Indicators on the

devices and user

interfaces

During energy saving mode:

Orange status LED lights up steady

-

The inverter website can be accessed

-

All available data is saved and sent to Solar.web

-

The current available data can be viewed on Solar.web

-

Energy saving mode is shown on the website of the inverter and in Solar.web by

an "i" beside the battery symbol in the system overview.

30

Calibration charging for the Fronius Solar Battery

EN

Benefits of calibration charging

General Determining the exact state of charge (SOC) of the battery is important for oper-

Natural differences in the individual cell capacities and the small amount of self

discharge that occurs in all batteries cause the cell voltages to diverge. This

makes the SOC value less accurate, which affects the operation. If no steps are

taken, the battery will become damaged.

Periodic calibration charging brings all cells of the battery to the same state of

charge, and calibrates the SOC value. This ensures a longer service life of the

battery cells.

ation management. To ensure this happens, the battery must regularly be

charged to 100%. This allows the SOC value to be calibrated.

Fronius Solar Battery:

Calibration charging occurs automatically during operation after several charge

and discharge cycles. When calibration charging is carried out depends on two

crucial factors:

Average state of charge

-

Energy throughput of the battery

-

As these factors are extremely weather dependent, the time of a calibration

charge can vary depending on the time of year.

Conditions for

starting the calibration charge

(Fronius Solar

Battery)

Calibration charging procedure

(Fronius Solar

Battery)

The following description of calibration charging is valid from version 1.4.1-12 of

the Fronius system monitoring software.

One charge and discharge cycle of the Fronius Solar Battery corresponds to an

energy throughput of 48 Ah per battery module. Calibration charging occurs cyclically according to the following conditions:

After 3 full charge and discharge cycles and a SOC of 80%

-

After 5 full charge and discharge cycles and a SOC of 50%

-

After 7 full charge and discharge cycles, independent of the SOC

-

For newly installed systems and for module replacement or expansion, a calibration charge is started automatically after 30 minutes.

Calibration charging primarily occurs with the entire PV power. If insufficient PV

energy is available, energy is drawn from the public grid. This is also the case

even if the "Battery charging from DNO grid" function is deactivated, as this is a

critical requirement.

The SOC is calculated per battery module. For this reason, each battery module

must reach a SOC of 100%.

31

Calibration process (Fronius

Solar Battery)

The start conditions must be fulfilled

1.

The battery is charged to 100% with a minimum current of 6.5 A or the total

2.

PV power.

So that a SOC of 100% can be reached for each battery module, one of the

3.

following two conditions must be fulfilled for at least 2 minutes (for each cell

in every battery module):

Minimum cell voltage ³ 3.45 V and current < 100 mA

-

Minimum cell voltage > 3.5 V independent of current

-

When a battery module reaches one of these conditions, the current is lim-

4.

ited to prevent an overload. A current in the two-digit mA range flows over a

bypass resistor

Unneeded PV power is reused directly

5.

Once all cells in all battery modules have fulfilled one of the two conditions,

6.

the SOC is set to 100% and calibration charging is complete.

Duration of calibration charging

(Fronius Solar

Battery)

Limitations during calibration

(Fronius Solar

Battery)

Due to tolerances in the cells, they are not always charged and discharged at the

same rate. As cells and battery modules are connected in series and the slowest

cell determines the charging and discharging duration, some calibration charges

need more or less time.

In rare cases, calibration charges or full charge cycles (depending on the time of

year, e.g. in the winter months) can lead to large variations in the cell voltages in

the battery modules. In calibration mode, one cell charges more quickly than the

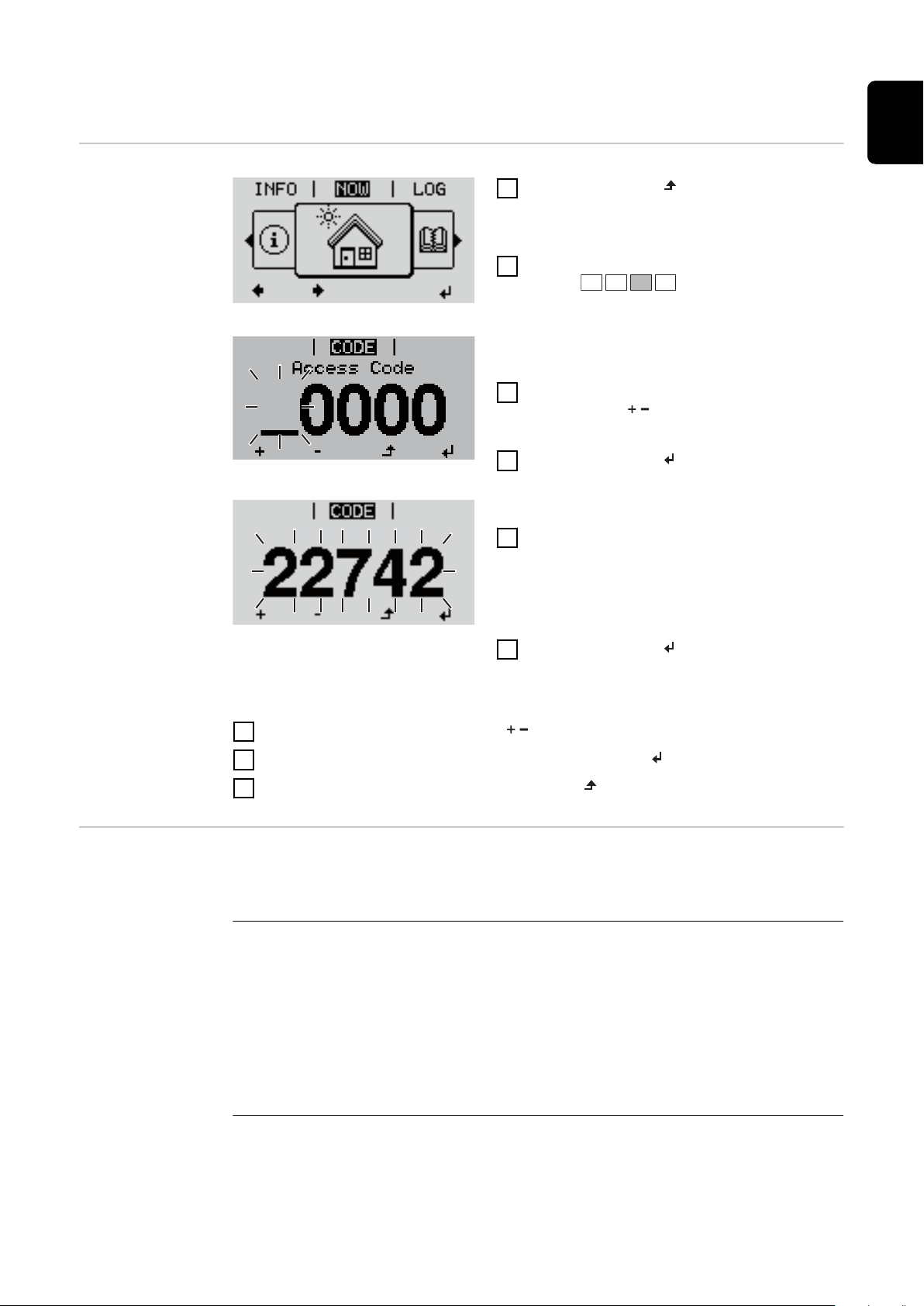

others. This cell then begins redistribution. The other cells can then only be

charged with a reduced charging current. It takes longer for these cells to reach

the target value.

If the battery is regularly charged completely, calibration charges are rarely required. The cells are calibrated during every charge with 100% SOC.

In the winter months. where there are few full charges and a lower energy

throughput, calibration charges can take longer, as higher variations between the

battery modules must be redistributed.

Drawing energy from the battery (discharging) is not possible

-

Self-consumption optimisation is disabled while calibration charging is in

-

progress

Charging from the grid can still occur if the "Battery charging from DNO

-

grid" function is not activated, as this process concerns system-relevant service charging

Zero feed-in continues according to the standard and service charging can

-

even be started if you wish to expand or replace battery modules during calibration

Emergency power mode can be started – calibration charging is interrupted

-

Display during

calibration

charge (Fronius

Solar Battery)

32

As soon as calibration charging starts, it becomes visible in Fronius Solar.web

(current and energy balance view) or on the web interface of the Fronius Symo

Hybrid inverter.

In Fronius Solar.web or on the web interface of the inverter,

the calibration charge information is displayed in the overview. Clicking on the battery symbol (see the image on the

left) displays the information "The battery is in calibration

mode"

In the energy balance display in Solar.web, both the start and end of the calibration charge is displayed by changing the battery status ("Battery Mode: Normal

→ Calibrate" and "Battery Mode: Calibrate → Normal")

The following graphic shows calibration charging of the Fronius Solar Battery in

the energy balance view. At the start of calibration charging, the total PV production is used to charge the battery. From the point where one cell is fully

charged, only a certain charging current is drawn by the battery. This charging

current decreases towards 0 A as the cell voltage increases.

EN

As during normal operation, the status "charging" (CHG) is shown on the battery

display and the relevant charging current in ampere is displayed. If the charging

current drops to below 0.3 A, 0 A is shown on the display, even though calibration

charging continues.

In Fronius Solar.web, the SOC value for the entire battery is displayed. On the

battery display, the SOC values of the individual battery modules can be viewed.

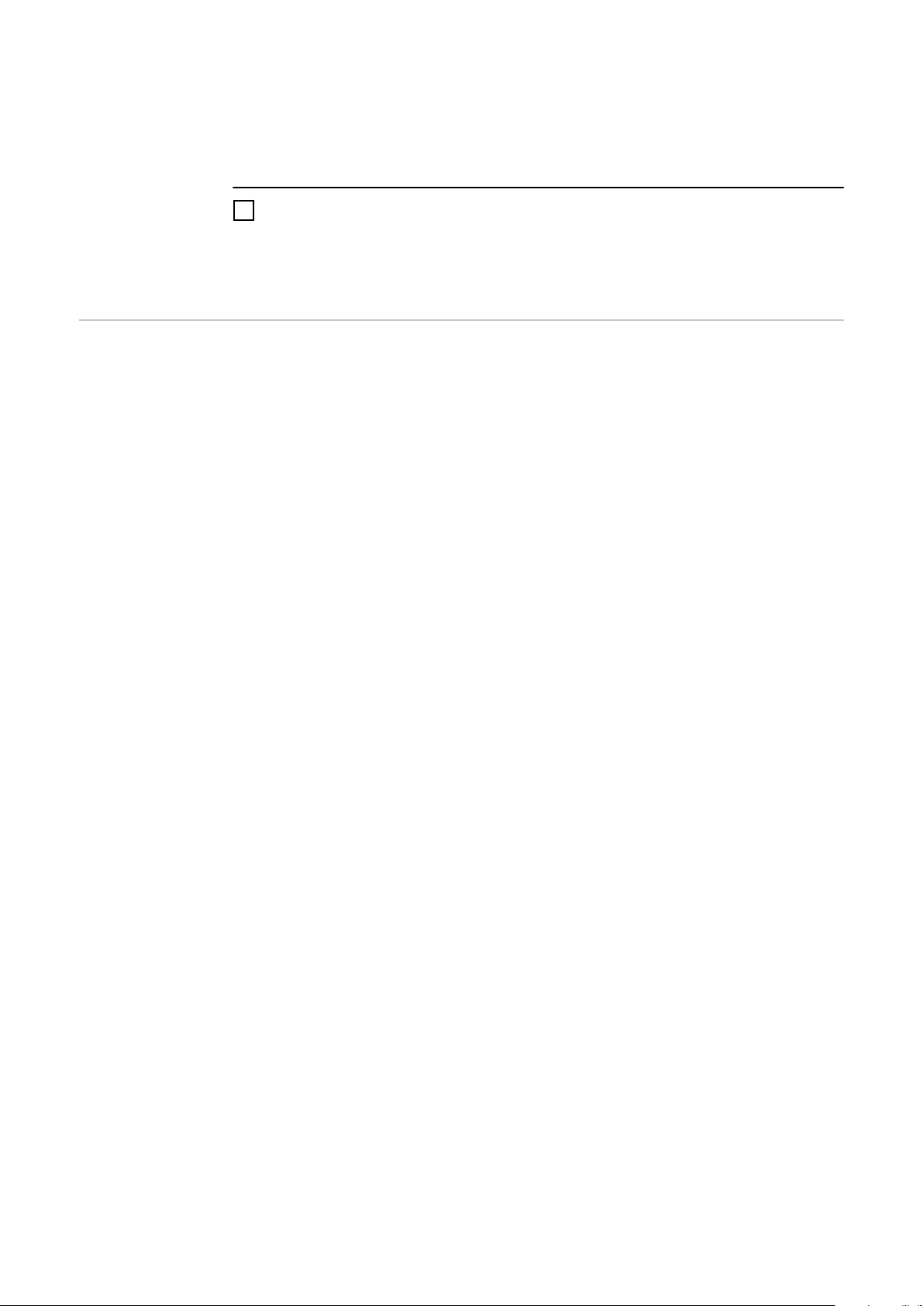

33

Suitable third-party batteries for Fronius Symo

Hybrid

LG Chem ResuH Fronius expressly points out that third-party batteries are not Fronius products

and that Fronius is not a trader or distributor of these batteries. This means that

Fronius accepts no liability for these batteries and cannot offer any kind of warranty.

The Fronius Symo Hybrid can be operated with an LG Chem type RESU7H(TypeR) or RESU10H(Type-R) high-voltage battery.

A Fronius Checkbox 500V is required to connect an LG battery to a hybrid inverter. Backup power mode is not possible when operating the LG Chem high-voltage

battery.

Read this document and the Installation Instructions for the Fronius Symo Hybrid, the Fronius Checkbox 500V and the third-party battery before installation

and commissioning.

All Fronius documents are available at the following address:

www.fronius.com/photovoltaics/infocentre/tech-support/how-to-install

BYD BatteryBox Premium

The documentation for the LG Chem ResuH is enclosed with the third-party battery, or you can acquire it from the third-party manufacturer.

WARNING!

Danger due to DC voltage from the inverter and battery.

This can result in serious injury or death.

The Fronius Checkbox 500V must be installed in the system in accordance

▶

with the Installation Instructions.

Read and follow the "Fronius Checkbox 500V" Installation Instructions. The

▶

Installation Instructions are supplied with the Fronius Checkbox 500V.

Wire the "Third-party battery with Fronius Symo Hybrid and Fronius Check-

▶

box 500V" in accordance with the Circuit Diagram. The Circuit Diagram is

supplied with the Fronius Checkbox 500V.

Fronius expressly points out that third-party batteries are not Fronius products

and that Fronius is not a trader or distributor of these batteries. This means that

Fronius accepts no liability for these batteries and cannot offer any kind of warranty.

The Fronius Symo Hybrid can be operated with the following BYD Battery-Box

Premium variants:

HVM 8.3*

-

HVM 11.0

-

HVM 13.8

-

HVM 16.6

-

HVM 19.3

-

HVM 22.1

-

34

Parallel operation of up to three BYD HVM batteries is possible in compliance

with BYD specifications. A combination of three HVM 22.1 is not permitted.

* Note for systems with backup power switchover with Fronius Symo Hybrid and

ON

OFF

1

BYD Battery-Box Premium HVM 8.3:

If there is a power failure, there is no energy available from the PV system and

the battery has a low state of charge (SOC typically < 20%), the system may no

longer be able to switch to backup power mode.

Read this document and the Installation Instructions for the Fronius Symo Hybrid and the third-party battery before installation and commissioning.

All Fronius documents are available at the following address:

www.fronius.com/photovoltaics/infocentre/tech-support/how-to-install

Obsolete software states may lead to incompatibilities between the inverter and

the battery. If a corresponding message is displayed:

Update inverter software - see Services – Firmware update on page 89

-

Update battery software - see the battery documentation

-

The documentation for the BYD Battery-Box Premium is enclosed with the thirdparty battery, or you can acquire it from the third-party manufacturer.

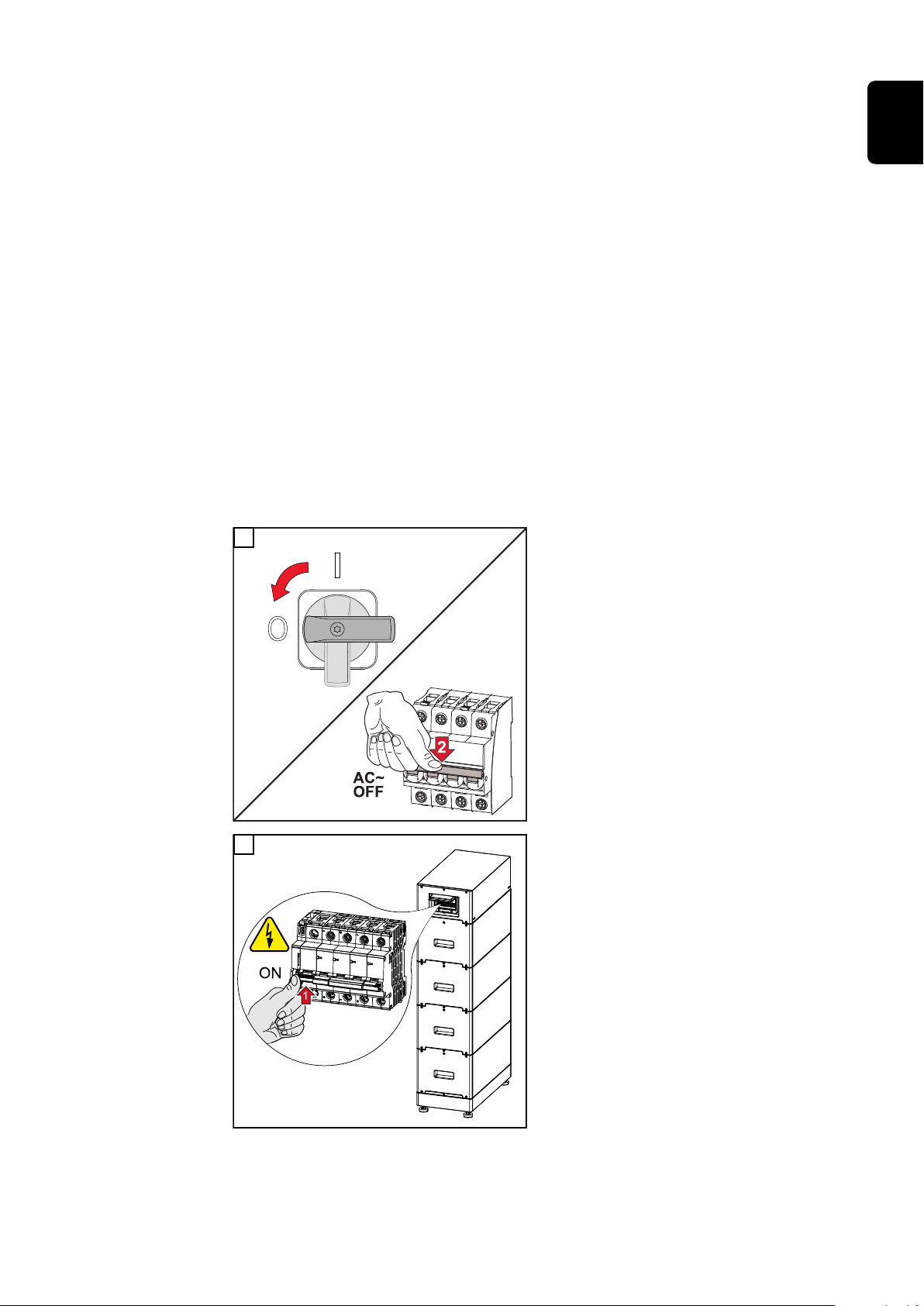

IMPORTANT!

To ensure reliable operation with a BYD Battery-Box Premium HVM, the following

switch-on sequence for the system must always be observed.

EN

1

Set the DC disconnector to the "Off"

switch position. Turn off the automatic

circuit breaker.

2

Switch on the battery.

35

ON

OFF

2

3

Switch on the automatic circuit breaker. Set the DC disconnector to the

"On" switch position.

36

Operation

37

38

Data communication

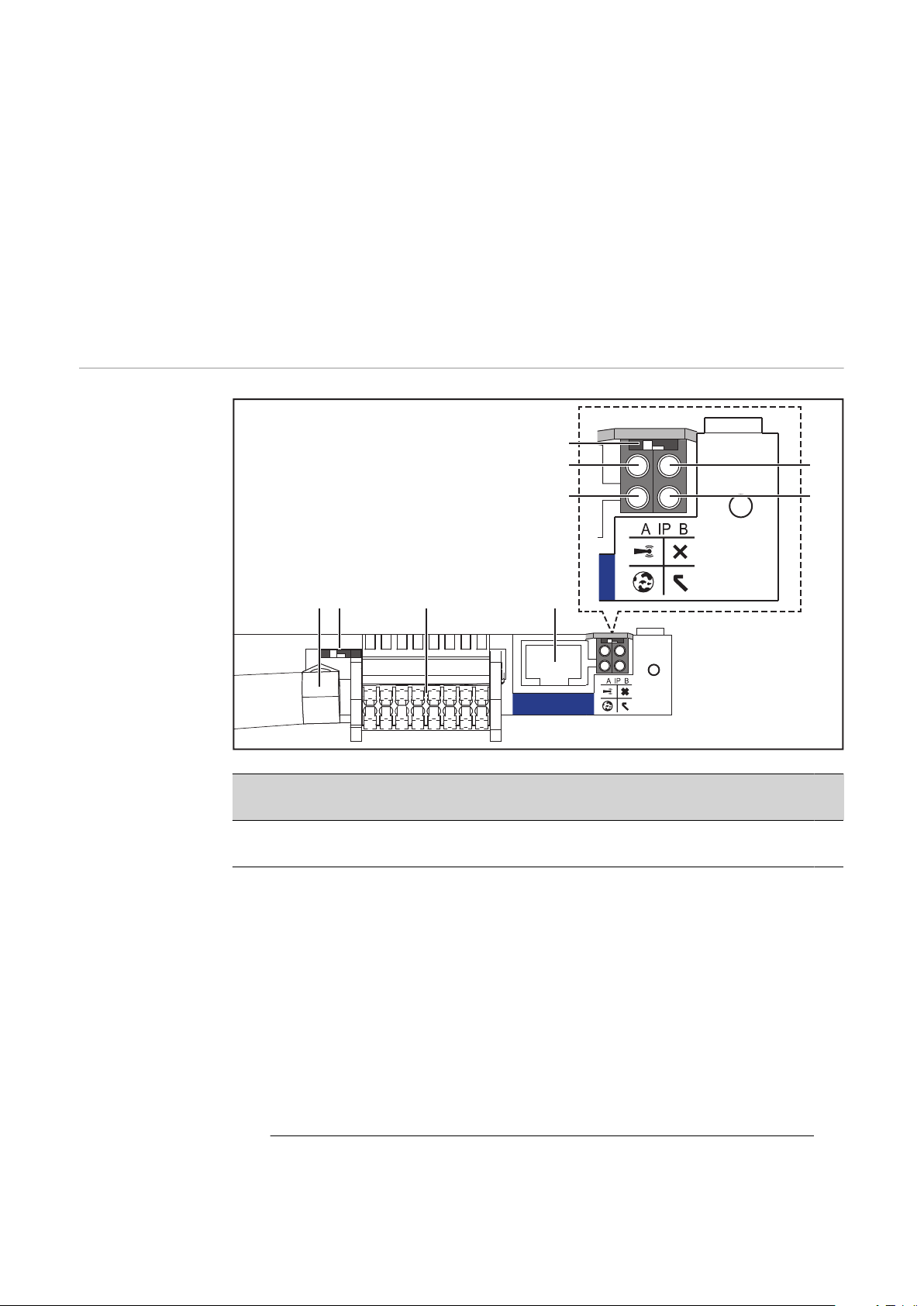

(2)

PIN 1

PIN 2

PIN 1

PIN 2

PIN 3

(3)

(1)

Data communication area

Ite

m Designation

EN

(1) Switchable multifunction current interface

Use the 2-pin mating connector supplied with the inverter to connect to

the multifunction current interface.

(2) Floating switch contact with mating connector

Max. 250 V AC / 4 A AC

Max. 30 V DC / 1 A DC

Max. 1.5 mm² (AWG 16) cable cross-section

Pin 1 = NO contact (normally open)

Pin 2 = C (common)

Pin 3 = NC contact (normally closed)

Use the mating connector supplied with the inverter to connect to the

floating switch contact.

(3) System monitoring with WLAN antenna

General The inverter is fitted with the WLAN-enabled system monitoring and energy

management unit (Fronius Datamanager) as standard.

Various functions are included with the Fronius system monitoring, such as:

39

Controls, con-

(5)

(1)

(6)(7)(8)(9)

(4)

(2)

(3)

LAN

nections and indicators on the

system monitoring unit

Dedicated web page displaying current data and a wide range of settings

-

Option of connecting directly to Fronius Solar.web

-

Internet connection via WLAN or LAN

-

Ability to control the inverter load by specifying power limit values, minimum

-

or maximum running times or target running times

Ability to control the inverter via Modbus (TCP)

-

Ability to assign control priorities

-

Ability to control the inverter by means of connected meters (Fronius Smart

-

Meter)

Ability to control the inverter via a ripple control signal receiver (e.g. by spe-

-

cifying the reactive power or effective power)

Dynamic power reduction, taking self-consumption into account

-

Ability to control battery charging in line with the control targets set

-

Ability to control emergency power mode

-

No

. Function

(1) IP switch

For switching the IP address:

Switch position A

Default IP address with activating of the WLAN access point

Setting the IP switch to position A also opens an access point to enable a direct WLAN connection to system monitoring.

Access data for this access point:

Network name: FRONIUS_239.XXXXXX

Key: 12345678

System monitoring can be accessed by:

Using the DNS name "http://datamanager"

-

Using the IP address 169.254.0.180 for the LAN interface

-

Using the IP address 192.168.250.181 for the WLAN access point

-

40

No

. Function

Switch position B

Assigned IP address

System monitoring uses an assigned IP address (factory setting: dynamic (DHCP))

The IP address can be set on the system monitoring web page.

(2) WLAN LED

Flashing green: System monitoring is in Service mode

-

(IP switch on the system monitoring plug-in card is in position A or

Service mode has been activated via the inverter display, the WLAN

access point is open)

Lights up green: WLAN connection established

-

Flashing green/red (alternately): WLAN access point has timed out

-

following activation (1 hour)

Lights up red: no WLAN connection

-

Flashing red: faulty WLAN connection

-

(3) Solar.web connection LED

Lights up green: Fronius Solar.web connection established

-

Lights up red: Fronius Solar.web connection is required but has not

-

been established

Not lit: no Fronius Solar.web connection is required or the option for

-

sending data to Fronius Solar.web has been deactivated

EN

(4) Supply LED

Lights up green: internal communication system is providing an ad-

-

equate power supply; system monitoring is ready for use

Not lit: no power is being supplied by the internal communication sys-

-

tem

Flashing red: update in progress

-

IMPORTANT! Never interrupt the power supply while an update is in

progress.

Lights up red: update failed

-

(5) Connection LED

Lights up green: good connection within the internal communication

-

system

Lights up red: connection within the internal communication system

-

has been interrupted

(6) LAN connection

Ethernet interface, colour-coded blue, for connecting the Ethernet cable

41

No

D-

-

-

1

3

5

7

9

D+

+

+

0

2

4

6

8

I IO RS485

. Function

(7) I/Os

Digital inputs and outputs

Modbus RTU 2-wire (RS485):

D- Modbus data D+ Modbus data +

Int./ext. power supply

- GND

+ U

int

/ U

ext

Internal voltage output 12.8 V

or

input for an external supply voltage

>12.8 - 24 V DC (+ 20%)

Digital inputs: 0 - 3, 4 - 9

Voltage level: low = min. 0 V - max. 1.8 V; high = min. 3 V - max. 24 V DC (+

20%)

Input currents: dependent on input voltage; input resistance = 46 kOhm

Digital outputs: 0 - 3

Switching capacity when power is supplied by the system monitoring plugin card: 3.2 W in total for all 4 digital outputs

Switching capacity when power is supplied by an external power supply

delivering min. 12.8 - max. 24 V DC (+ 20%), connected to Uint / Uext and

GND: 1 A, 12.8 - 24 V DC (depending on external power supply) for each

digital output

42

The connection to the I/Os is established via the mating connector supplied.

(8) Antenna socket

This is where the WLAN antenna is connected

No

. Function

(9) Modbus termination switch (for Modbus RTU)

Internal bus terminator with 120 ohm resistor (yes/no)

Switch in "on" position: 120 ohm terminating resistor active

Switch in "off" position: no terminating resistor active

IMPORTANT! On an RS485 bus, the terminating resistor on the first and

last device must be active. For a detailed description, see the Installation

Instructions.

EN

43

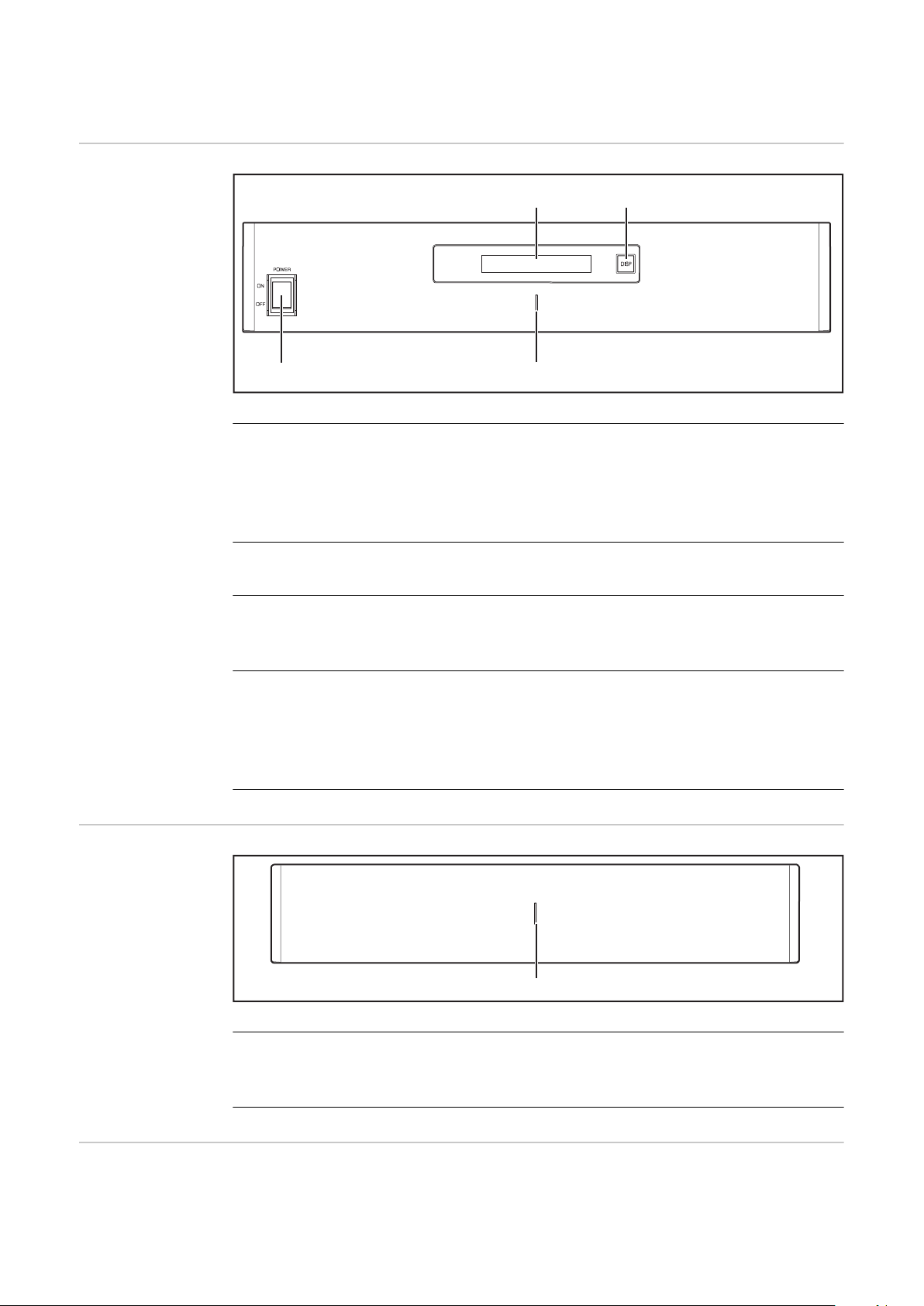

Fronius Hybrid inverter

(1)

(2)

(3)

(4)

(5) (6) (7) (8)

Controls and indicators

Item Description

(1) Display

For displaying values, settings and menus

Monitoring and status LEDs

(2) General status LED

Lights up steady:

If a status code is being displayed on the monitor (red for error,

-

orange for warning)

If the process of feeding energy into the grid is interrupted

-

During error handling (the inverter waits for an acknowledgement

-

or for an error to be rectified)

(3) Startup LED (orange)

Lights up steady:

If the inverter is in its automatic startup or self-test phase (as

-

soon after sunrise as the solar modules are delivering sufficient

power)

If the inverter has been switched to Standby mode in the Setup

-

menu (= feeding energy into the grid switched off manually)

If the inverter software is being updated

-

(4) Operating status LED (green)

Lights up steady:

If the PV system is working correctly after the inverter's automat-

-

ic startup phase

When system is feeding energy into the grid or is in Storage mode

-

Function keys – Allocated different functions depending on what has been selected:

44

(5) “Left/up” key

For navigating to the left and up

(6) “Down/right” key

For navigating down and to the right

(7) “Menu/Esc” key

For switching to the menu level

For quitting the Setup menu

Item Description

Standby

Relay

Clock

Display Setting

Energy Yield

(*)

(8) “Enter” key

For confirming a selection

The keys operate capacitively. Exposure to water may impair their function. If necessary, wipe the keys dry with a cloth to ensure optimum functionality.

Display The display is supplied with power via the AC grid voltage and via the PV and bat-

tery side. Depending on the setting selected in the Setup menu, the display can

be kept on all day.

IMPORTANT!

The display on the inverter is not a calibrated measuring device.

A slight inaccuracy in comparison with the utility meter used by the energy company is intrinsic to the system. A calibrated meter will be needed to calculate the

bills for the energy company.

EN

Display areas, display mode

Save symbol

Previous menu items

Currently selected menu item

Next menu items

Function key functions

(*) Scroll bar

Save symbol – Appears briefly while the set values are being saved

45

Fronius Solar Battery

(1)

(3)

(4)

(2)

(1)

Battery management module

(1) LCD display

Provides information about the status of a module (charging/discharging,

total voltage, total current strength, total remaining capacity, number of

connected modules, remaining capacity of each module, voltage/temperature etc. of the cell block)

Battery module

(2) DISP switch

Changes the information shown on the display

(3) Indicator LED

Normal status: Green

Error: Flashing red

(4) POWER ON/OFF switch

POWER ON: Switches on battery modules and battery management module (operation)

POWER OFF: Switches off battery modules and battery management

module (power supply interrupted)

(1) Indicator LED

Normal status: Green

Error: Flashing red

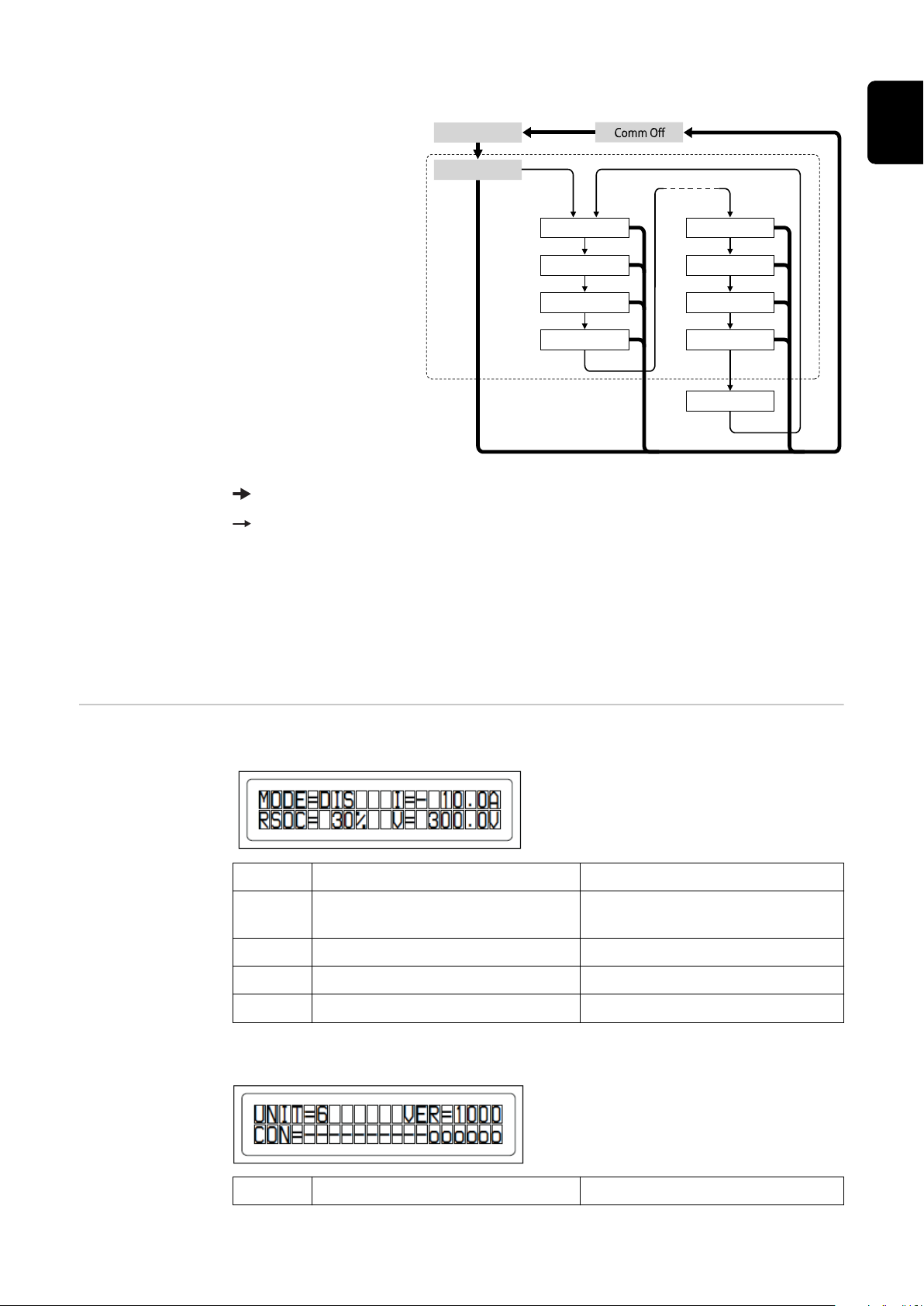

Display Press the DISP key to display information.

46

Display switching diagram

Overall

Connection

Modul Nr. 00 Modul .Nr. N

Status

Mode

Cell temp

Status

Mode

Cell temp.

Alarm bits Alarm bits

Heatsink

Display overall status

of system

Display status of individual modules

Press and hold DISP key

Press DISP key

Nr.N. Means the nth storage module

EN

Tips:

Hold down DISP key for longer than 3 seconds

-

Pressing the DISP key on the “Connection” display takes you back to the

-

“Overall” display.

“Comm Off Mode” is used for maintenance purposes.

-

Display types

"Overall" display

Display Details Display

MODE Charging/discharging and stop

RSOC Remaining system capacity 0% - 100%

I Total system current strength -999.9 A to +999.9 A

V Total system voltage 0.0 V to +999.9 V

"Connection" display

status

DIS: Discharging

CHG: Charging

Display Details Display

47

UNIT Number of connected modules 1 - 16

VER Version XXXX

CON Status of connected modules In the above example, there are

6 connected modules (no. 00 no. 05).

"Status" display

Display Details Display

M_NO Number of modules displayed 00 - 15

STAT Module status YX (Y: Current status, X: Previ-

ous status)

1X [Pre Charge]: Pre-charging

2X [Initial]: Status at beginning

3X [Normal Chg]: Normal charging

4X [Terminate]: End charging

5X [Normal Dis]: Normal discharging

6X [Over Volt]: Overvoltage

7X [Over Dis]: Deep discharge

8X

9X [Over Temp C]: Overtemperature charging

AX [Over Curr C]: Overcurrent

charging

BX [Over Temp D]: Overtemperature discharging

CX [Over Curr D]: Overcurrent

discharging

DX [Unbalance]: Cell imbalance

EX [Chg Suspend]: Charging

suspended

FX

"Mode, Current, SOC, Voltage" display

Display Details Display

M_NO Number of modules displayed 00 - 15

RSOC Remaining module capacity 0% - 100%

I System module current strength -999.9 A to +999.9 A

48

V System module voltage 0.0 V to +999.9 V

"Cell Temp., Cycle Count" display

Display Details Display

M_NO Number of modules displayed 00 - 15

CYCL Number of cycles 0000 - 9999

T Average temperature of all cells -99.9 °C to +99.9 °C

"Alarm bits" display

Display Details Display

M_NO Number of modules displayed 00 - 15

ALRM Module status 8000 [Over Volt]: Overvoltage

4000 [Terminate]: End charging

2000 [Under Volt]: Undervoltage

1000 [Over Curr]: Overcurrent

0800 [Over Temp]: Overtemperature

0400 [0]:

0200 [Resistor]: Resistor alarm

0100 [Unbalance]: Cell imbalance

Details displayed if multiple

alarms are triggered

Example: If both "Over Current"

and "Over Temp" are detected,

the following message is displayed. A higher bit level takes

priority over messages in brackets: "ALRM=1800 [Over Curr]"

EN

"Heatsink Temp" display

Display Details Display

HEATSINK_T

MP

COMM_QLInternal communication quality 0% - 100%

Temperature of the heat sink -40 °C to +119 °C

49

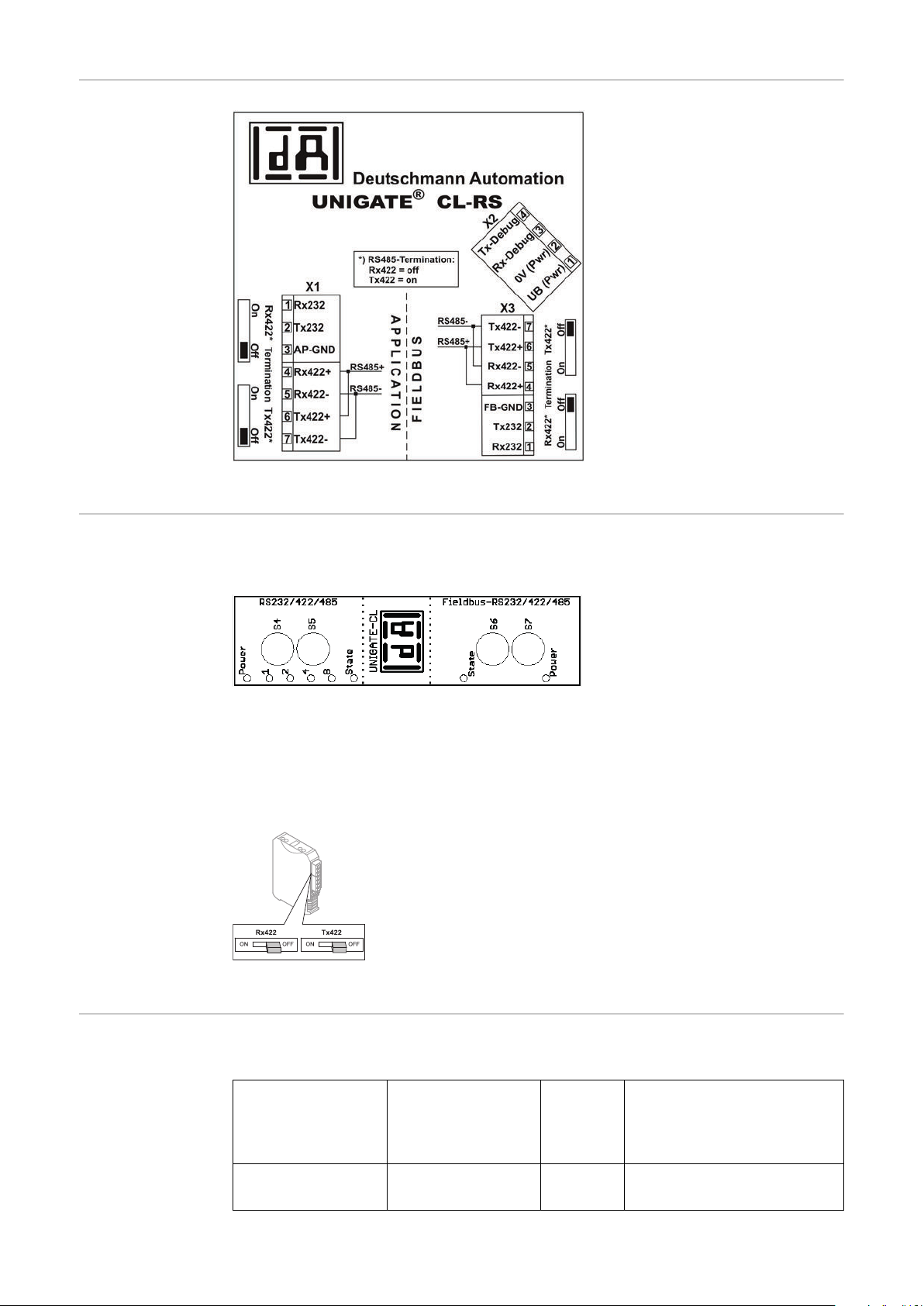

Data converter

connections

Data converter

controls and indicators

Connection to Fronius Solar Battery

Factory settings:

S4 = 0x0 (hex) = 0000 (binary)

S5 = 0x0 (hex) = 0000 (binary)

S6 = 0x1 (hex) = 0001 (binary)

S7 = 0x4 (hex) = 0100 (binary)

Connection to Fronius hybrid inverter

RS485 terminal

Rx422 = off

Tx422 = off

Data converter

LED displays

50

The data converter features 8 LEDs, the meaning of which is explained below:

Fronius Solar Battery

RS232/422/485

Power LED Green Supply voltage on storage

Fronius hybrid inverter

Fieldbus

RS232/422/485

side

LED 1/2/4/8 (Error No / Selected

ID)

Green General gateway error

EN

State LED Red/

green

State LED Red/

green

Power LED Green Inverter supply voltage

"Power" LED(Fronius Solar Battery)

This LED is connected directly to the supply voltage of the 1st serial interface

(electrical isolation is optionally available for this supply).

"1/2/4/8 (Error No / Selected ID)" LED

If these 4 LEDs and the "State" LED all light up steady red at the same time, the

error number is indicated in binary format in accordance with the table in the

"Troubleshooting" section.

"State" LED(Fronius Solar Battery)

Lights up green Status OK

Flashing green Status OK

Flashing

green/red

Lights up red General gateway error (see "Error No." LEDs)

Status OK

General gateway error

Inverter interface state

Flashing red Data converter is in configuration/test mode

"State" LED (Fronius hybrid inverter)

Lights up green Initialised and started

Flashing green Initialised

Flashing

green/red

Lights up red General bus error (system error 10)

Flashing red Starts to flash straight after "BusStart" -> Initialisation

"Power" LED (Fronius hybrid inverter)

This LED is connected directly to the supply voltage of the interface.

-

failed

Starts to flash during actual operation -> Data error

51

Navigation at the menu level

Activating display backlighting

Automatic deactivation of display backlighting / changing to

the "NOW" menu

item

Opening the

menu level

Press any key

1

The display backlighting is activated.

There is an option under "Display Settings - Backlighting" in the SETUP menu

to set the display backlighting so that it is on all the time or off all the time.

If two minutes pass without any button being pressed, the display backlighting

switches off automatically and the inverter goes to the "NOW" menu item (assuming the display backlighting is set to AUTO).

The automatic selection of the "NOW" menu item can happen from any position

on the menu level, unless the inverter was manually switched into the "Standby"

operating mode.

After automatically selecting the "NOW" menu item, the current power of feeding in is displayed.

1

Press "ESC"

The display switches to the menu level.

2

Using the "Left" or "Right" keys select the desired menu item

3

Press the "Enter" key to select the

desired menu item

The menu items

NOW

-

Displays real-time values

LOG

-

Data recorded today, during the current calendar year and since the inverter

was started for the first time

GRAPH

-

Day characteristic displays a plot showing the output power during the day.

The time axis is scaled automatically. Press the "Back" key to close the display

SETUP

-

Setup menu

INFO

-

Information about the device and the software

52

Values displayed

under the NOW

menu item

Output power (W)

AC reactive power (VAr)

Grid voltage (V)

Output current (A)

Grid frequency (Hz)

Solar voltage (V) – Of U PV

Solar current (A) – Of I PV

Time Date

EN

Values displayed

under the LOG

menu item

Energy fed in (kWh / MWh)

Energy delivered by the inverter over the period in question

There may be discrepancies compared with values displayed on other measuring instruments because of differences in measuring methods. As far as the

billing of the energy fed in is concerned, the only binding display values are

those produced by the calibrated measuring instrument provided by the utility

company.

Max. output power (W)

Largest amount of energy delivered by the inverter during the period in question

Yield

Amount of money earned during the period in question (currency and conversion factor can be selected in the Setup menu)

Like the "Energy fed in" figure, the yield figure may also exhibit discrepancies

compared with other measured values.

The "Setup menu" section explains how to select a currency and charge rate.

The factory setting depends on the respective country setup.

Max. grid voltage (V)

Highest grid voltage measured during the period in question

Maximum solar voltage (V)

Highest solar module voltage measured during the period in question

Operating hours

Length of time the inverter has been working (HH:MM)

IMPORTANT! In order for the day and year values to be displayed correctly,

the time must be set accurately.

Alternative operating hours

Operating time of the inverter (HH:MM) in alternative mode (emergency power

mode).

53

Menu items in the Set-up menu

Standby Manual activation / deactivation of Standby mode

No energy is fed into the grid.

-

The Startup LED will show steady orange.

-

In the display, STANDBY / ENTER are alternately displayed

-

In Standby mode, no other menu item at menu level can be accessed or ad-

-

justed.

The automatic switchover into the "NOW" display mode after 2 minutes of

-

keyboard inactivity does not occur.

Standby mode can only be terminated manually by pressing the "Enter" key.

-

Pressing "Enter" at any time will cause energy to resume feeding into the

-

grid, as long as there is no error (state code)

Switching off Standby mode (manually switching off feeding energy into the

grid):

Select the "Standby" item

1

2

Press "Enter" function key

"STANDBY" and "ENTER" appear alternately on the display.

Standby mode is now active.

The Startup LED shows steady orange.

WiFi Access

Point

Resuming feeding energy into the grid:

In standby mode, the display alternates between 'STANDBY' and 'ENTER'.

1

Press the "Enter" function key to resume feeding energy into the grid

The "Standby" menu item is displayed.

At the same time, the inverter enters the startup phase.

The operating state LED shows steady green when feeding energy into the grid

has been resumed.

Activating / deactivating the WiFi Access Point. This is necessary for setting up

or adjusting system monitoring using the Datamanager web interface, for example. If no Datamanager is detected by the inverter, [not available] is displayed

Setting range WiFi Access Point

[stopped]

Activate WiFi AP?

To activate the WiFi Access Point Press the "Enter"

key

WiFi Access Point

[active]

54

The SS-ID (SS) and password (PW) are displayed.

Deactivate WiFi AP?

To deactivate the WiFi Access Point Press the

"Enter" key

WiFi Access Point

[not available]

EN

Displayed if there is no system monitoring present on

the inverter.

Relay (floating

contact switch)

Status codes (state codes), the status of the inverter (e.g. feeding energy into the

grid) or Energy Manager functions can be displayed using the floating switch contact (relay).

Setting range Relay mode / Relay test / Switch-on point* / Switch-off

point*

* these are only shown if the "E-Manager" function has been activated under "Relay mode".

Relay mode

The following functions can be shown using relay mode:

Alarm function (Permanent / ALL / GAF)

-

Active output (ON / OFF)

-

Energy Manager (E-Manager)

-

Setting range ALL / Permanent / GAF / OFF / ON / E-Manager

Factory setting ALL

Alarm function:

ALL / Permanent:

Switching the floating switch contact for permanent and temporary service codes (e.g. brief interruption to energy being

fed into the grid, a service code occurs a certain number of

times a day - can be adjusted in the "BASIC" menu)

GAF As soon as GAF mode is selected, the relay is switched on.