Page 1

/ Perfect Welding / Solar Energy / Perfect Charging

FlexTrack 45

8,045,565

Operating instructions

Spare parts list

EN

Welding carriage

42,0426,0205,EN V03-03032015

Page 2

Page 3

Dear reader,

Introduction

These operating instructions will help you familiarise yourself with the device. It is in

your interest to read these instructions carefully and to observe the directions contained

in them. This will prevent faults and incorrect operation or possible damage to installed

components.

Please also obey the safety rules; doing so will ensure greater safety when using the

product. Careful handling of the entire system will repay you with years of safe and reliable operation. These are essential prerequisites for excellent results.

3

Page 4

4

Page 5

Contents

General information 7

About this document ........................................................................................................................................ 9

Function of this document .......................................................................................................................... 9

Explanation of safety symbols .................................................................................................................... 9

Qualied technicians .................................................................................................................................. 9

Copyright .................................................................................................................................................... 9

General .......................................................................................................................................................... 10

Principle....................................................................................................................................................10

Device concept and applications .............................................................................................................. 10

Safety 13

Operational reliability and tips for the user .................................................................................................... 15

Proper use ................................................................................................................................................ 15

Foreseeable misuse ................................................................................................................................. 15

Conversions or modications ................................................................................................................... 15

Duty to instruct ......................................................................................................................................... 15

Operating instructions .............................................................................................................................. 16

Personal protective equipment ................................................................................................................. 16

Local regulations ...................................................................................................................................... 16

Spare parts, wearing parts and auxiliary materials .................................................................................. 16

Transportation and storage ......................................................................................................................17

Description of the welding carriage 19

Scope of supply ............................................................................................................................................. 21

Basic conguration ................................................................................................................................... 21

Accessories and options .......................................................................................................................... 22

Welding carriage components ....................................................................................................................... 23

Conguration: welding carriage with oscillation unit ................................................................................. 23

Conguration: welding carriage without oscillation unit ............................................................................ 24

Operating elements and connections ............................................................................................................ 25

Connections ............................................................................................................................................. 25

Control box operating elements ............................................................................................................... 26

Welding carriage operating elements ....................................................................................................... 26

Remote control elements ......................................................................................................................... 27

Rails and bridges ........................................................................................................................................... 29

Weights of rails and bridges ..................................................................................................................... 29

Fittings ...................................................................................................................................................... 29

Rigid rails..................................................................................................................................................30

Flexible rails ............................................................................................................................................. 30

Bridge types ............................................................................................................................................. 31

Structure of a bridge ................................................................................................................................. 31

Conguration: rail and guide rings ........................................................................................................... 32

Welding position and weld seam tracking .....................................................................................................34

Possible welding positions ....................................................................................................................... 34

Commissioning 37

Preparing the welding carriage ...................................................................................................................... 39

Installing the welding carriage with oscillation unit ................................................................................... 39

Replacing oscillation unit with adjustment unit ......................................................................................... 40

Preparing and installing rails ......................................................................................................................... 41

Number of bridges required ..................................................................................................................... 41

Installing the bridges ................................................................................................................................ 41

Straight rails ............................................................................................................................................. 42

5

Page 6

Installing the contact cams ....................................................................................................................... 42

Securing the rail structure ........................................................................................................................ 43

Closed ring rail ......................................................................................................................................... 43

Closed ring rail ......................................................................................................................................... 44

Rigid ring segments ................................................................................................................................. 45

Flexible ring segments ............................................................................................................................. 47

Commissioning the welding carriage ............................................................................................................. 48

Placing the welding carriage on a straight rail .......................................................................................... 48

Placing the welding carriage on a ring rail ............................................................................................... 49

Regulating the pressure rollers ................................................................................................................ 50

Disengaging the welding carriage ............................................................................................................ 51

Operation 53

Creating and saving welding programs ......................................................................................................... 55

Switching on system components ............................................................................................................ 55

Setting the welding carriage parameters .................................................................................................. 55

Selecting additional functions ................................................................................................................... 56

Saving a program ..................................................................................................................................... 57

Loading a welding program ...................................................................................................................... 58

Changing the units of measurement ........................................................................................................ 58

Work procedure ............................................................................................................................................. 59

Working with or without oscillation ...........................................................................................................59

Performing a test run ................................................................................................................................ 59

Starting the welding process .................................................................................................................... 60

Maintenance and disposal 61

Troubleshooting ............................................................................................................................................. 63

General.....................................................................................................................................................63

Basic requirements for the system to work .............................................................................................. 63

Event codes ............................................................................................................................................. 63

Error codes ............................................................................................................................................... 63

Maintenance .................................................................................................................................................. 64

Maintenance personnel ............................................................................................................................ 64

Maintenance record ................................................................................................................................. 64

Recommended lubricants ........................................................................................................................ 64

Maintenance intervals and procedures .................................................................................................... 65

Technical data 67

Technical data ...............................................................................................................................................69

FlexTrack 45 welding carriage .................................................................................................................69

Control box ............................................................................................................................................... 69

Oscillation unit .......................................................................................................................................... 69

Dimensions...............................................................................................................................................69

Rating plates ............................................................................................................................................ 70

Weights of rails and bridges ..................................................................................................................... 71

Ring rail settings table .............................................................................................................................. 72

Flexible rail segments settings table ........................................................................................................ 73

Spare parts, circuit diagram 75

Spare parts .................................................................................................................................................... 77

Spare parts, wearing parts and auxiliary materials .................................................................................. 77

Ordering details ........................................................................................................................................ 77

Circuit diagram .............................................................................................................................................. 85

6

Page 7

General information

7

Page 8

8

Page 9

About this document

Function of this

document

Explanation of

safety

symbols

These operating instructions explain how to commission and operate the device in

conjunction with the installed system components. Look after the operating instructions

carefully; they must always be to hand at the location where the device is being used.

They can be used as a reference should any operational or functional problems occur in

the future.

DANGER! Indicates immediate and real danger. If it is not avoided, death or

serious injury will result.

WARNING! Indicates a potentially dangerous situation. Death or serious injury

may result if appropriate precautions are not taken.

CAUTION! Indicates a situation where damage or injury could occur. Minor

injury and/or damage to property may result if appropriate precautions are not

taken.

NOTE! Indicates a risk of awed results and possible damage to the equip-

ment.

Qualied

technicians

Copyright

IMPORTANT! Indicates tips for correct operation and other particularly useful informa-

tion. It does not indicate a potentially damaging or dangerous situation.

Special care is required if you see any of the symbols shown.

- These operating instructions are designed for trained technicians or persons with

practical welding experience. Personnel must be trained through veriable regular

instruction.

- Maintenance and repair of the device may likewise only be carried out by trained

technicians and in compliance with the specied maintenance activities and maintenance intervals.

- The manufacturer accepts no liability for damage caused by insufcient knowledge of

how to use the device.

Copyright of these operating instructions remains with Fronius International GmbH. The

text and illustrations are all technically correct at the time of going to

print. Fronius reserves the right to make changes. The contents of the operating instructions shall

not provide the basis for any claims whatsoever on the part of the purchaser.

9

Page 10

General

Principle

Device concept

and applications

The FlexTrack 45 welding carriage is intended for welding of butt and llet welds in the

MIG/MAG or CMT process, with or without oscillation.

It can be used on rigid or exible rails and on rigid or exible guide rings.

The compact welding carriage can be used in a wide range of applications. Three different rail types are available to suit differing requirements and surface geometries.

The carriage is entirely remote-controlled, making it perfect for universal use.

STRAIGHT application:

FLEXIBLE application:

min. 1500 mm

min. 1100 mm

10

Page 11

Device concept

and applications

(continued)

RING application:

200 - 6060 mm

11

Page 12

12

Page 13

Safety

13

Page 14

14

Page 15

Operational reliability and tips for the user

Proper use

Foreseeable

misuse

The FlexTrack 45 welding carriage must only be used for welding butt and llet welds in

a horizontal or vertical welding position.

Any use above and beyond this purpose is deemed improper – the manufacturer shall not be responsible for any damage resulting from such

improper use.

The welding carriage can be used in the following welding processes:

- MIG/MAG process

- CMT process

Proper use also includes:

- Carrying out all maintenance work at the stipulated intervals

- Keeping a service book with the necessary information (date, operator, activities car-

ried out, etc.)

- Using the spare parts stipulated by Fronius

- Following all the instructions, particularly the safety instructions, in the operating

instructions

- Using this document in conjunction with the operating instructions for the integrated

system components (power source, etc.)

Any use other than for the intended purpose shall be deemed improper use. This includes:

- Riding on the welding carriage, transporting loads

- Using the exible (non-reinforced) rails on level surfaces

- Use above head height

- Hoisting processes (hoisting, manoeuvring of loads, animals or persons)

- Use as an aid to climbing

- Use as a tray for tools

- Use outside of the permitted technical operating limits (e.g. exceeding the max. per-

mitted load)

- Use in hazardous areas

Conversions or

modications

Duty to instruct Before they start work, the system operator must instruct or train all persons working with

Any unauthorised conversions or modications made to the welding carriage by the user

shall invalidate all liability or warranty obligations on the part of the manufacturer.

The electromagnetic characteristics of the welding carriage can be adversely affected by

additions or modications of any kind. No modications or upgrades should therefore be

undertaken without rst consulting the manufacturer and obtaining written approval.

the welding carriage in:

- the theoretical and practical aspects of operation

- the safety regulations.

IMPORTANT! The duty to instruct also applies in particular to those who only occasionally work with the welding carriage (e.g. during set-up, maintenance, etc.).

15

Page 16

Operating in-

structions

The operating instructions help you to use the welding carriage safely and efciently, and

must therefore be to hand at all times.

- Keep the various sections of the operating instructions at the location where the weld-

ing carriage is being used at all times.

- Clearly mark the place where the instructions are kept.

- Ensure that all persons working with the welding carriage know where the operating

instructions are located.

- The operating instructions will only be able to help you in the event of a problem if

they are at hand!

IMPORTANT! The manufacturer shall not be liable for any damage that arises from failure to observe the operating instructions.

Personal protective equipment

The operator alone is responsible for the immediate working environment.

The following safety measures must be put in place and employed:

- Welding goggles

- Welding shield

- Welding gloves

- Welding apparel

- Welding footwear

Local regulations In some countries, local statutory regulations may apply that are not included in these

operating instructions. It is the duty of the operator to be aware of and comply with any

local statutory regulations. This relates primarily to regulations concerning:

- Accident prevention

- Machine safety

- Protection of personnel (protective equipment)

- Environmental protection

- Electrical system

Spare parts,

wearing parts

and auxiliary

materials

Use of third-party spare and wearing parts may pose risks. Use approved Fronius original spare parts only.

The manufacturer cannot accept any liability for damage resulting from the use of spare

or wearing parts or auxiliary materials that are not approved by the manufacturer.

16

Page 17

Transportation

and storage

The complete system, including tool kit, is supplied in a specially designed metal transport box. The rails must be stored separately.

17

Page 18

18

Page 19

Description of the welding carriage

19

Page 20

20

Page 21

Scope of supply

Basic

conguration

(6)

(1)

(5)

(4)

(2)(7) (3)

(1) Control box

(2) FlexTrack welding carriage

(3) 2 connecting cables: 1x between carriage and control box, 1x between carriage

and remote control

(4) Hosepack holder

(5) Connecting cable, control box - power source

(6) Tool kit

(7) Remote control

21

Page 22

Accessories and

options

(8) Oscillation unit

(9) Adjustment unit

Torch holder, depending on welding process:

(10) FTH 18

(11) FTH 21

(8)

(10)

(11)

(9)

22

Page 23

Welding carriage components

Conguration:

welding carriage

with oscillation

unit

Carrying handles

Torch holder

Limit switch

Contact cam

Torch adjustment unit

Remote control

Oscillation unit

Rail

Coupling

Locking lever

Guide rollers

Hosepack

holder

Magnetic bridge

23

Page 24

Conguration:

welding

carriage without

oscillation unit

Hosepack

holder

Remote control

Carrying handles

Rail

Coupling

Limit switch

Magnetic bridge

Torch adjustment unit

Torch holder

Adjustment unit

24

Page 25

Operating elements and connections

Connections

4

3

1

2

5

(1) Control box mains cable

(2) Control line between welding carriage and control box

(3) Control line between welding carriage and remote control

(4) Connecting lead between control box and power source

(5) Connecting lead for oscillation unit

25

Page 26

Control box

operating

elements

Welding carriage

operating

elements

(1)

(1) ON/OFF switch

switches the control box on and off

(1)

(3)

(1) Coupling on/off

Locks/unlocks the welding carriage on the rail. Allows rapid positioning of the

carriage.

(2) Guide rollers locking lever

Fixes and releases the internal guide rollers.

(3) Limit switch (both sides, in and against direction of travel)

For automatic stopping or changing of direction.

(2)

26

Page 27

Remote control

elements

(1) (2)

(11)

(3a) (3b) (3c)

(10)

(9)

(8)

(1) Numerical display, 4 digits (metric / imperial)

Displays welding parameters and error codes.

(2) Limit switch function, change direction / stop

Depending on the switch position, the welding carriage changes direction or

stops as soon as the limit switch is activated.

(3a) White symbol: Oscillation dwell time, left

Regulates the oscillation dwell time on the left.

Yellow symbol: Return travel path

Return time at the end of the welding path in seconds [s].

(3b) White symbol: Oscillation dwell time, middle

Regulates the oscillation dwell time in the middle of the weaving motion.

Yellow symbol: Segment path with welding

Sets the length of the individual welding segments in [cm].

(3c) White symbol: Oscillation dwell time, right

Regulates the oscillation dwell time on the right.

Yellow symbol: Segment path without welding

Sets the distances between the individual segments in [cm].

(4) Oscillation speed

Regulates the oscillation speed.

(5) Offset

Regulates the offset during weaving.

(4)

(5)

(6)

(7)

27

Page 28

Remote control

elements

(continued)

(6) Traversing direction

Selects the traversing direction.

(7) Travel speed

Regulates the travel speed of the welding carriage.

(8) Welding mode

3 welding modes can be selected:

- Test

- Without arc (O)

- With arc (I)

(9) White symbols: Weaving mode

Four weaving modes can be selected:

- No weaving

- Trapezoidal weaving

- Box weaving

- Triangular weaving

Green marking: Preset path measurement

Preset to select the additional path measurement function (green symbol) on the

weaving path button (10).

Yellow marking: Preset segment welding

Preset to select the additional segment welding function (orange symbols).

IMPORTANT! The welding process cannot start until the weaving mode adjusting

knob (9) is set to one of the white function parameters.

(10) White symbol: Weaving path

Regulates the weaving path.

Green symbol: Total welding path

Total welding path in [cm].

(11) White symbol: End-crater lling time

Enables the weld seam to be nished smoothly.

IMPORTANT: Parameters must be entered via the power source and must be

either equal to or greater than the power source value.

Yellow symbol: Start-up delay / Flying-start

If value is positive – start-up delay [s]: Start welding -> Dwell time elapses ->

Carriage starts to move.

If value is negative – ying-start [s]: Carriage starts to move. The arc does not

ignite until the “ying start” time has expired.

28

Page 29

Rails and bridges

Weights of rails

and bridges

Magnetic bridge 2.5 kg

Vacuum bridge (on request) 1.6 kg

Magnetic bridge with spacers 2.7 kg

Vacuum bridge with spacers (on request) 1.8 kg

Magnetic bridge with spacer and metric calibration unit 3.4 kg

Magnetic bridge with metric calibration unit 3.2 kg

Bridge with adjustable foot, spacer and metric calibration unit 1.5 kg

Bridge with adjustable foot and metric calibration unit 1.3 kg

Vacuum bridge with spacer and metric calibration unit (on request) 2.6 kg

Vacuum bridge with metric calibration unit (on request) 2.4 kg

Rigid guide rail 1884 mm 11 kg

Flexible guide rail 1884 mm 5.5 kg

Flexible guide rail 1695 mm 4.8 kg

Flexible guide rail 1130 mm 3.3 kg

Rigid guide ring Ø200-300 mm 8.8 kg

Rigid guide ring Ø300-480 mm 11 kg

Rigid guide ring Ø480-660 mm 14 kg

Rigid guide ring Ø660-840 mm 16 kg

Rail segment Ø840-1020 mm 19 kg

Rail segment Ø1020-1200 mm 22 kg

Rail segment Ø1200-1380 mm 24 kg

Rail segment Ø1380-1560 mm 27 kg

Fittings

Joining elements:

Two joining elements to extend the rails

are included with every rail.

Contact cam installation kit:

Two contact cams to trigger the limit switch at the beginning and end of the guide rail.

IMPORTANT! If contact cams are not used, there is a risk that the welding carriage

might travel beyond the end of the rail and fall off.

29

Page 30

Rigid rails

STRAIGHT

► Straight rails with aluminium reinforce-

ment

► For horizontal and vertical use

► With two joining elements to extend

the rail

Length: 1884 mm

Weight: 5.5 kg

RING (external use)

► Rigid rails with aluminium reinforce-

ment

► For external use on pipes

The following sizes are available:

For workpiece Ø 200-840 mm:

► Guide ring, rigid 200-300 mm

► Guide ring, rigid 300-480 mm

► Guide ring, rigid 480-660 mm

► Guide ring, rigid 660-840 mm

Flexible rails

For workpiece Ø 840-1560 mm:

► Guide ring, rigid 840-1020 mm

► Guide ring, rigid 1020-1200 mm

► Guide ring, rigid 1200-1380 mm

► Guide ring, rigid 1380-1560 mm

STRAIGHT/CURVED

► Can be mounted on straight or curved

components

► Internal welding:

min. internal radius 1500 mm

► External welding:

min. external radius 1100 mm

RING (internal and external use)

► From external diameter >1560 mm to

6060 mm

30

Different segment lengths for different

diameter ranges:

Segment type Length

I 1130 mm

II 1695 mm

III 1884 mm

Page 31

Bridge types

Magnetic bridge Bridge with adjustable feet

Structure of a

bridge

For magnetic components, heat-resistant

to 180°C.

Recommended for rigid rings up to 840

mm in diameter.

The magnetic force is controlled by a

lever.

Maximum holding force of a magnetic

bridge: 750 N

IMPORTANT! All bridges include a metric adjustment unit and a distance block.

Standard bridge with magnetic feet

Bridge with distance block

Standard bridge

Screws M6x20

Metric adjustment unit

(option)

Adjusting screw

M12x3

Bridge with metric

adjustment unit

Screws M6x20

Bridge with metric adjustment unit

and distance block

M6x14 screws

Screws M6x20

31

Page 32

Structure of a

l=1130 mm

Ø 1560 - 6060 mm

bridge

(continued)

Bridge with adjustable feet

Bridge with adjustable foot and

metric adjustment unit

M6x14 screws M6x14 screws

Bridge with adjustable foot, metric adjustment unit and distance block

M6x14 screws

Conguration:

rail and guide

rings

on request

on request

Ø200-840mm

Ø 840 - 1380mm Ø 1380 - 1560 mm

32

Page 33

Conguration:

rail and guide

rings

(continued)

on request

Ø 1560 - 6060 mm

l=1130 mm

l=1695 mm

l=1884 mm

33

Page 34

Welding position and weld seam tracking

Possible welding

positions

IMPORTANT! In vertical applications, the rail structure must be secured by a load arres-

tor with a locking function to prevent it from falling.

The load arrestor must be designed for the total weight of the welding carriage and rail

structure. The manufacturer accepts no liability for any damage to persons or property

resulting from vertical use of the welding carriage without a load arrestor.

Horizontal position on rigid rail:

Possible welding positions:

- PA (at position)

- PB (horizontal-vertical position)

- PC (horizontal position)

Vertical position on rigid rail:

Possible welding positions:

- PG (descending position)

- PF (ascending position)

34

Page 35

Possible welding

positions

(continued)

Positions on exible rail:

Possible welding positions:

- PA (at position)

- PB (horizontal-vertical position)

- PC (horizontal position)

PG (descending position)

- PF (ascending position)

Positions on ring rail (rigid or exible)

Possible welding positions:

- PA (at position)

- PB (horizontal-vertical position)

- PC (horizontal position)

PG (descending position)

- PF (ascending position)

35

Page 36

36

Page 37

Commissioning

37

Page 38

38

Page 39

Preparing the welding carriage

Installing the

welding carriage

with oscillation

unit

7

5

3

6

4

2

1

Assembling the welding carriage with oscillation unit:

1. Connect the oscillation unit to the welding carriage using the six screws supplied.

2. Connect the connecting lead for the oscillation unit to the carriage and lock it in

place.

3. Push the welding torch holder onto the oscillation unit.

4. Tighten the screws.

5. Fit the horizontal support onto the welding torch holder and tighten the screws.

6. Feed in the hosepack holder and x it in place with the clamp lever.

7. The remote control has a magnet which can be used to attach it to the welding

carriage.

39

Page 40

Replacing

oscillation unit

with adjustment

unit

1

3

2

Replacing the oscillation unit with an adjustment unit:

1. Disconnect the connecting lead for the oscillation unit from the welding carriage.

2. Undo the six M6 screws and remove the oscillation unit.

3. Place the protective cap onto the socket for the oscillation unit.

4. Fasten the adjustment unit to the welding carriage using four M6 screws.

IMPORTANT! Reverse this sequence when replacing the adjustment unit with the

oscillation unit.

4

40

Page 41

Preparing and installing rails

Number of

bridges required

Installing the

bridges

Straight, rigid rails:

► For a rail length of 1884 mm: use 3 bridges.

Straight, exible rails:

► For a rail length of 1884 mm: use 5 bridges.

► For a rail length of 1695 mm: use 4 bridges.

► For a rail length of 1130 mm: use 3 bridges.

Closed ring rails and ring rails made from rail segments:

► The number of bridges required depends on the ring diameter and should be taken

from the settings table.

Bridge without spacer and calibration unit:

Install the bridge on the rail using the two M6x65 screws and counter them with the two

M6 nuts.

IMPORTANT! The bridge installation positions on the rail are indicated by the hole in

the middle of the rail for the adjusting screw on the calibration unit.

Screw

M6x65

Nut M6

Bridge with adjustment unit:

Bridges with an adjustment unit are installed with the M6x14 screws supplied.

M6x14 screws

Screw

M4x10

41

The scale on the side of the adjustment

unit is xed in place using the M4x10

screw supplied.

Page 42

Straight rails Both rigid and exible straightw rails can easily be extended using the joining elements

supplied.

(3)

(4)

(1)

(2)

1. Set the levers on the magnetic bridges (1) to OFF.

2. Place the rail section on the workpiece and set the levers on the magnetic bridges

to ON.

3. Fit the joining element (2) at the end of the straight rail.

4. Loosen both M6 screws (3).

5. On the next section of rail, set the levers on the magnetic bridges to OFF.

6. Push the next section of rail with the groove (4) between the joining element (2)

and the screw (3).

7. Tighten both M6 screws (3).

8. Align the rail if necessary, then set the levers on the magnetic bridges to ON.

9. Install further rail sections as described above until the rail has reached the required length.

10. Install a contact cam for the limit switch at the beginning and end of the rail.

Installing the

contact cams

IMPORTANT! If contact cams are not used, there is a risk that the welding carriage

might travel beyond the end of the rail and fall off.

In rail structures with open ends (not rings), contact cams (limit switch installation kit)

must be installed at both ends.

42

Page 43

Securing the rail

structure

IMPORTANT! In vertical applications, the rail structure must be secured by a load arres-

tor with a locking function to prevent it from falling.

The load arrestor must be designed for the total weight of the welding carriage and rail

structure. The manufacturer accepts no liability for any damage to persons or property

resulting from vertical use of the welding carriage without a load arrestor.

NOTE! Ensure that the cable on the load arrestor is kept permanently taut.

Closed ring rail

The closed ring rail is used for welding of pipes with a diameter of 200 to 840 mm.

Install the recommended number of bridges on the guide ring.

For the number of bridges, refer to the table below:

DIAMETER SEGMENTS BRIDGES

200 - 300 mm (7.9 - 11.8 in.) 2 3

300 - 480 mm (11.8 - 18.9 in.) 2 4

480 - 660 mm (18.9 - 26 in.) 2 6

660 - 840 mm (26 - 33.1 in.) 2 8

(a)

1. Open the locks on the ring rail:

- Loosen the M6 screws (a)

- Release the locking hook (b)

(b)

2. When using magnetic bridges: Set the levers on the magnetic bridges to OFF.

3. Using the adjusting screw (c), set the distance on the calibration units on the

bridges. Refer to the settings table for the recommended setting M plus 3 mm.

(c)

43

Page 44

Closed ring rail

4. Install the ring rail on the component.

5. Engage the locking hook (a), tighten the screws (b).

6. Using the adjusting screws (c) on the bridges, t the ring rail evenly around the

component.

(c)

(c)

(c)

7. When using magnetic bridges: Set all the levers on the magnetic bridges to the

ON position.

44

Page 45

Rigid ring

segments

Rigid ring segments can be joined to create guide rings with a maximum diameter of

1560 mm (4 segments). The individual segments are joined to form a guide ring using

locking catches and M6x20 socket screws:

1. Join two rail segments. Tighten the top

four M6x20 screws (a) slightly.

2. Lock the locking hook (b) on the lower

guide section.

Tighten the two lower M6x16 screws

(c) slightly.

(b)

(a)

(a)

(c)

3. Engage the upper locking hook (d). 4. If necessary, align the two segments

with one another.

Tighten all the M6 screws (4 at the top,

2 at the bottom).

The number of segments used and the bridges required for different pipe diameters are

set out in the table below:

DIAMETER SEGMENTS BRIDGES

840 - 1020 mm (33.1 - 40.2 in.) 3 9

1020 - 1200 mm (40.2 - 47.2 in.) 3 12

1200 - 1380 mm (47.2 - 54.3 in.) 3 15

1380 - 1560 mm (54.3 - 61.4 in.) 4 16

45

Page 46

Rigid ring

segments

(continued)

1. It is recommended that two people should work together when installing a guide

ring made from rail segments.

2. When using magnetic bridges: Set the lever on the bridges to OFF.

3. Use the adjusting screw (d) to set the distance on the calibration units on the

bridges. For the recommended setting M, please refer to the settings table. When

installing the rings, set them initially to 3 mm more than is shown on the calibration unit.

(d)

4. Install the guide ring on the component.

5. Using the adjusting screws (d) on the bridges, t the guide ring evenly around the

component.

6. When using magnetic bridges: set all the levers on the magnetic bridges to ON.

46

Page 47

Flexible ring

segments

Flexible ring segments can be joined to create guide rings with a diameter of 1560 mm

to 6060 mm (up to 11 segments). The individual segments are joined to form a guide ring

using M6x20 socket screws.

Flexible segments are available in the following lengths:

SEGMENT

LENGTH

TYPE

Type I 1130 mm

Type II 1695 mm

Type III 1884 mm

The number of segments depends on the pipe diameter and can be selected using the

table below:

Diameter Segments Bridges

1560 - 1740 mm

1740 - 1920 mm

1920 - 2100 mm

2100 - 2280 mm

3x type I

1x type II

3x type III

1x type I

3x type III

1x type II

3x type III

2x type I

18

18

20

21

2280 - 2460 mm 5x type II 25

2460 - 2640 mm

2640 - 2820 mm

3x type III

2x type II

5x type II

1x type I

25

25

2820 - 3000 mm 6x type II 28

3000 - 3180 mm

3x type III

3x type II

30

3180 - 3360 mm 6x type III 30

3360 - 3540 mm 7x type II 33

3540 - 3720 mm

3720 - 3900 mm

6x type III

1x type I

6x type III

1x type II

33

35

Diameter Segments Bridges

3900 - 4080 mm

6x type III

2x type I

36

6x type III

4080 - 4260 mm

1x type II

38

1x type I

4260 - 4440 mm

6x type III

2x type II

40

6x type III

4440 - 4620 mm

1x type II

41

2x type I

6x type III

4620 - 4800 mm

2x type II

43

1x type I

4800 - 4980 mm

6x type III

3x type II

45

4980 - 5160 mm 9x type III 45

6x type III

5160 - 5340 mm

3x type II

48

1x type I

5340 - 5520 mm

5520 - 5700 mm

5700 - 5880 mm

9x type III

1x type I

9x type III

1x type II

9x type III

2x type I

48

50

51

9x type III

5880 - 6060 mm

1x type II

53

1x type I

47

Page 48

Commissioning the welding carriage

Placing the

welding carriage

on a straight rail

1. Remove the remote control. The welding carriage must be installed on the guide

rail without the remote control.

2. Coupling and levers for the rollers in the "OFF" position.

3. Lift the welding carriage using the handles and place it on the rails.

4. Set the lever for the moving pressure rollers to the "ON" position.

5. Set the lever for the stationary pressure rollers to ON. (Reverse the procedure for

removal).

6. Manually pull the welding carriage along the full length of the rail once to check

whether the welding torch remains at a constant distance from the workpiece. If

the distance is not constant, set the correct distance "M" on the relevant bridges.

7. Push the welding carriage along the rail. At the same time, set the coupling to the

"ON" position to engage the gearbox unit with the openings on the guide rail.

8. Check the following switches on the remote control:

- Welding mode switch in position "0"

- Change direction / stop switch in the central position.

9. Connect the cables:

- Plug in the connecting lead to the power source (1) at the control box and

power source.

- Connect the remote control to the control box using the control line (2) (purple

cable).

- Connect the welding carriage to the control box using the control line (3) (purple cable).

- Connect the control box to the grid (4).

10. Set the mains switch on the control box to ON.

1

2

4

3

48

Page 49

Placing the

welding carriage

on a ring rail

1. Remove the remote control. The welding carriage must be installed on the guide

rail without the remote control.

2. Coupling and levers for the rollers in the "OFF" position.

3. Loosen the three M6x20 holding the pressure rollers in place, on both sides.

4. Place the welding carriage horizontally on the rail above the centre of the workpiece and hold it by the handle.

5. Set the lever for the moving pressure rollers to the "ON" position.

6. Set the lever for the stationary pressure rollers to ON. (Reverse the procedure for

removal).

7. Tighten the three M6 mounting screws on both sides.

8. Manually pull the welding carriage along the full length of the rail once to check

whether the welding torch remains at a constant distance from the workpiece. If

the distance is not constant, set the correct distance "M" on the relevant bridges.

9. Push the welding carriage along the rail. At the same time, set the coupling to the

"ON" position to engage the gearbox unit with the openings on the guide rail.

10. Check the following switches on the remote control:

- Welding mode switch in position "0"

- Change direction / stop switch in the central position.

49

Page 50

Placing the

welding carriage

on a ring rail

(continued)

11. Connect the cables:

- Plug in the connecting lead to the power source (1) at the control box and

power source.

- Connect the remote control to the control box using the control line (2) (purple

cable).

- Connect the welding carriage to the control box using the control line (3) (purple cable).

- Connect the control box to the grid (4).

12. Set the mains switch on the control box to ON.

Regulating the

pressure rollers

The four pressure rollers are non-positively connected with the guide rails by means of

disk springs.

IMPORTANT! The minimum play of 0.6 mm (maximum force) is achieved by tightening

the M8 screw to its maximum extent and then loosening it by a half turn.

The pressing force of the rollers is set as follows:

1. Loosen the M8 nuts (a).

2. Tighten the M8 adjusting screws

(b) to their maximum extent. Then

release them by a half turn.

3. Tighten the M8 nuts (a).

(b)

(a)

(b)

(a)

50

Page 51

Disengaging the

welding carriage

To attain optimum wirefeed, observe the following when laying the hosepack:

- Do not kink the hosepack

- Always lay the hosepack as straight as possible

1. Undo the knurled screw (a) on the

clamp.

(a)

2. Insert the hose pack as illustrated

IMPORTANT! Do not kink the hosepack. This can cause wirefeed problems.

3. Tighten the knurled screw (a)

NOTE! Observe the maximum tensile load on the hosepack holder (see the

"Technical data" section). This value must not be exceeded.

51

Page 52

52

Page 53

Operation

53

Page 54

54

Page 55

Creating and saving welding programs

Switching on

system

components

Setting the

welding carriage

parameters

WARNING!

Danger of injury from premature arc ignition.

The arc may be ignited accidentally. This can cause serious eye injuries.

- Before switching on the system components, ensure that the "Welding

mode" toggle switch on the welding carriage remote control is set to the "O"

position.

IMPORTANT! There are no xed rules for the sequence in which the system components are switched on. They can be switched on in any order.

On the following system components turn the main switch to the "ON - 1" position:

- Welding carriage control box

- Power source

- Wire-feed unit (if power is not supplied from the power source)

NOTE! The oscillation unit must be connected to the welding carriage when

saving programs with weaving parameters.

The remote control can be used to congure 9 welding programs with the following parameters:

With oscillation:

- Travel speed

- Weaving path

- Oscillation speed

- Dwell time, left

- Dwell time, middle

- Dwell time, right

- End-crater lling time

Without oscillation:

- Travel speed

- End-crater lling time

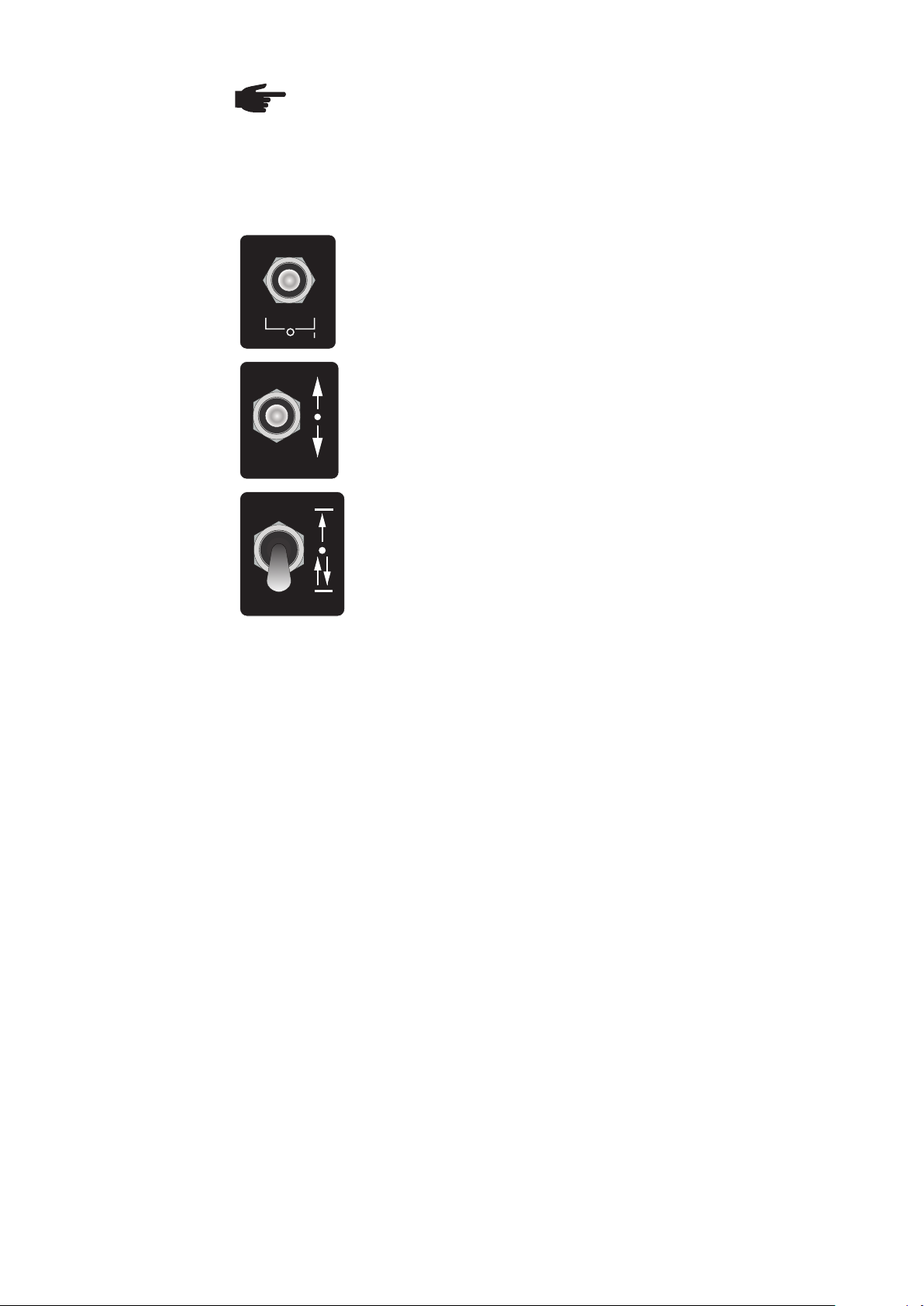

To set a parameter, turn the corresponding adjusting knob:

to the right to increase the value

to the left to reduce the value

When a setting has been adjusted, the value of the parameter is shown on the display.

Press the adjusting knob to save the value for the setting.

Additional functions:

- Path measurement (green markings)

- Segment welding (yellow markings)

55

Page 56

Selecting

additional

functions

IMPORTANT! After adjusting settings for the additional functions, turn the weaving mode

knob (1) back to the weaving mode required (white markings), otherwise the welding

process cannot start.

Additional function - path measurement:

1. Set the weaving mode knob to the GREEN marking.

2. Turn the weaving path knob and set the welding path required.

3. Turn the knob back to the white function parameter required.

Additional function - segment welding:

1. Set the weaving mode knob to the YELLOW marking.

2. Set the segment welding function parameter:

Start-up delay / ying-start:

If value is positive – start-up delay [s]: Start welding -> Dwell

time elapses -> Carriage starts to move.

If value is negative – ying-start [s]: Carriage starts to move.

The arc does not ignite until the “ying start” time has expired.

Return travel path:

Return time at the end of the welding path.

Segment path with welding:

Length of the individual welding segments.

Segment path without welding:

Length of the distances between the individual welding segments.

56

Page 57

Saving a program

Before saving a program:

Set the toggle switch for the "Change direction/stop" limit switch

functions to the lower position (change direction).

Set the welding mode toggle switch to the 0 position.

TEST

Set the traversing direction toggle switch to the central position 0.

Saving a program:

- Press the travel speed knob and end-crater lling time knob at the same time and

hold for 4 seconds.

- memX appears on the display. X stands for the program number that has not yet

been selected.

- Turn the travel speed knob to select the program number required.

- Press the travel speed knob to save the program with this number.

57

Page 58

Loading a

welding program

NOTE! The remote control has a factory-saved, read-only program "mem0",

which contains the working parameters for the welding carriage and oscillation

unit.

The value “mem0” cannot be overwritten.

To load a saved program, "mem" and the number of the last used program must be

shown on the display.

Set the welding mode toggle switch to the 0 position.

TEST

Set the traversing direction toggle switch to the central position 0.

Set the change direction/stop toggle switch to the change direction

position.

Changing the

units of

measurement

Press the travel speed button and the weaving path / total

welding path button at the same time for at least 4 seconds.

Turn the travel speed button to select a program.

To load the program selected, press the travel speed button briey

once.

Measurements can be displayed in either metric (cm) or imperial (inch) units.

To change the units, proceed as follows:

- Set the main switch on the control box to 0 (off).

- Press and hold the left and right dwell time buttons at the same time.

- Switch on the main switch on the control box. The unit of measurement selected (cm

or inch) is shown on the display.

- Select the setting required using the travel speed knob.

- Press the travel speed knob once to conrm and apply the setting.

58

Page 59

Work procedure

Working with

or without

oscillation

Performing a test

run

The welding carriage can work with and without oscillation. If the oscillation unit is not

required, it should be removed according to the instructions in the "Preparing the welding

carriage " section under "Replacing the oscillation unit with an adjustment unit".

After the control box has been switched on, it automatically checks whether the oscillation unit is connected and the current status appears on the display.

Perform a test run to check that all system components are working together correctly.

The test run is carried out without an arc and allows you to check all the movements during the program sequence.

Set the welding mode toggle switch to the 0 position.

TEST

Move the traversing direction toggle switch forwards.

The welding carriage moves according to the programmed parameters, but without welding.

The welding carriage's current speed is then shown on the display.

All parameters can be changed during operation.

When the welding carriage reaches the limit switch:

If the change direction/stop toggle switch is forwards or in the central position:

► The welding carriage stops when it triggers the limit switch.

If the toggle switch is in the change direction position:

► After triggering the limit switch, only the oscillation unit stops

and the welding carriage starts to move back in the opposite

direction. In this situation, the travel speed can be increased

to the maximum for the return journey: press the travel speed

knob and hold for 2 seconds.

NOTE! If the traversing direction toggle switch is in the central position and the

welding mode toggle switch is in the "test" position, this position causes the

arc to light up briey. To activate the welding function, move the welding mode

toggle switch to the "I" position.

59

Page 60

Starting the

welding process

Set the welding mode toggle switch to the "I" position.

TEST

Set the change direction/stop toggle switch to the position required.

Set the traversing direction toggle switch to the position required

(forwards or backwards). The welding process starts.

IMPORTANT! Never leave the device unattended during the welding process.

To stop the welding carriage early, move the traversing direction

toggle switch to the central position.

60

Page 61

Maintenance and disposal

61

Page 62

62

Page 63

Troubleshooting

General

Basic

requirements for

the system to

work

Event codes

In the event of faults, note that the functioning of the entire system depends on many

additional components (power source, wire-feed unit, etc.) that are also potential sources

of problems.

If an error occurs, "Err" and the error number are shown on the display.

► Connections have been established between the separate system components

► System components are supplied with electricity and the mains voltage for each

component complies with the rating plate.

Indication Description Remedy

cLs- / cLs+ Welding carriage has reached one

of the contact cams on the rail.

oLs- / oLs+ The oscillation arm has reached a

limit position.

cm Metric system selected. To change the setting: see the "Cre-

inch Imperial system selected.

mem0 mem9

Save or load a

welding program.

Release the limit switch using the

traversing direction toggle switch.

Release the limit switch using the

offset knob.

ating and saving welding programs"

section under "Changing the units

of measurement".

--

Error codes

Indication Description Remedy

err1 Error during initiation of the CAN

communication system.

err2 Communication error between car-

riage and remote control.

err3 Communication error between re-

mote control and oscillation unit.

err4 Communication error between

remote control and control box.

err5 Error while saving or reading,

memory error on the remote control.

err6 Operating temperature exceeded

or ambient temperature too high.

err7 Error in motor control unit. Contact your FRONIUS service

err8 Error in oscillation control unit. Contact your FRONIUS service

err9 Error in the control unit in the con-

trol box.

Rectify short circuit between the

lines or communication ports.

Check connections, tighten if necessary.

If necessary, replace damaged

control lines.

Contact your FRONIUS service

engineer.

Allow device to cool down. Operate

in a lower ambient temperature.

engineer.

engineer.

Contact your FRONIUS service

engineer.

63

Page 64

Maintenance

Maintenance

personnel

WARNING!

Risk of injury and damage if maintenance work is not carried out correctly.

It is essential to adhere to the maintenance intervals and maintenance procedures. The manufacturer accepts no liability for any damage caused by inadequate or poorly performed maintenance.

- All maintenance work on the welding carriage must be carried out by trained

technicians.

Electrically qualied person / technician:

Is a person who is able to evaluate the working steps, based on his specic technical

training, experiences and the well known relevant standards / regulations to recognize

possible risks / hazards.

Electrically instructed person:

Is a person who was trained by an electrically qualied person and was instructed

of the possible risks that can appear due to improper use / behaviour as well as the

necessary protective measures.

Notice: instruction has to be recorded

Electrically ordinary person:

Is a layperson who is neither an electrically qualied person nor a electrically instructed

person.

Maintenance

record

Recommended

lubricants

The following measures regarding maintenance must be put in place by the system

operator:

- a service book containing the required information (date, operator, maintenance work

carried out) must be kept.

IMPORTANT! Lubricants with solid lubricant additives (e.g.: MoS2, graphite and PTFE)

are not suitable for guiding systems.

Lubricant DIN DIN number Comment

Grease KP 2-K 51502 / 51825 Lithium soap grease

Lubricating oil CLP32-100 51517 Part 3 ISO VG 32-100

64

Page 65

Maintenance

intervals and

procedures

NOTE! Use a dry cleaning cloth to clean the machine components. Only

use a cleaning agent if this is indicated in the maintenance procedure for a

specic part.

Item Component Procedure Interval

Linear guides Clean, check oil lm M

A

Gearbox Clean, regrease M

B

Rack and pinion Clean, regrease M

C

Rollers, underbody & rails Clean, check position M

D

Safety devices:

E

Function test D

- Limit switch

Grease nipples Regrease M

F

Connection contacts Cleaning W

G

D Daily

W Weekly

M Monthly

1/2 y Half-yearly

Y Yearly

Daily care:

After every use:

► Remove the welding carriage from the guide rail.

► Using a brush or a soft cloth, clean the guide rails for the oscillation unit, the guide

rollers and the gearbox.

► Carry out maintenance work as shown in the illustration below.

IMPORTANT! Do not use compressed air.

E

65

C

G

G

Page 66

Maintenance

intervals and

procedures

(continued)

Clean and lubricate the gearbox:

IMPORTANT! The gearbox must be

cleaned and lubricated once a month

(B):

D

1. Undo four M5 screws and remove

the wheel cover.

D

B

2. Clean the gearbox with a brush.

3. Lubricate with grease.

D

D

Maintenance on the underside of the

welding carriage:

Clean the guide rollers (D)

M5 screws

Maintenance on the oscillation unit

IMPORTANT! The toothed rack on the oscillation unit must be lubricated once a

month.

The guide rail must be lubricated every six months.

(a) 3x

C

F

1. Fully extend the oscillation arm.

2. Undo the three M5 screws (a) and remove the guide rail cover.

3. Clean the toothed rack with a brush (C).

4. Lubricate the toothed rack on the side of the oscillation unit housing with

lubricant.

5. Add approximately 2 g of lubricant to the grease cup via the Ø 12 mm grease

nipple (F).

66

Page 67

Technical data

67

Page 68

68

Page 69

Technical data

FlexTrack 45

welding carriage

Control box

Welding position PA, PB, PC, PF, PG

Material thickness min. 4 mm

Traversing speed, horizontal 5 - 150 cm/min

Traversing speed, vertical 5 - 135 cm/min

End-crater lling time 0 - 5 seconds

Max. load, horizontal/vertical 45/30 kg

Weight (without welding torch holder) 12.5 kg

Protection class IP23

Mains voltage 50 - 60 Hz 115/230 V

Supply voltage 24 V DC

Weight (without cable) 5.3 kg

Remote control

Cable length 3 m

Weight (without cable) 1.5 kg

Oscillation unit

Dimensions

Oscillation speed 5 - 400 cm/min

Weaving path 2 - 30 mm

Offset 0 - 50 mm

Dwell time 0 - 3 seconds

Weight (without welding torch holder) 2 kg

E

B

A

D

C

F

69

G H

Page 70

Dimensions

(continued)

A (with oscillation)

A (without oscillation)

B (with oscillation)

B (without oscillation)

C (with oscillation)

C (without oscillation)

543 - 623 mm

480 - 560 mm

97 - 201 mm

119 - 223 mm

352 mm

334 mm

D (welding carriage with remote control) 304 mm

E (welding carriage without remote control) 230 mm

F (overall height with straight, rigid

rails)

318 mm

G (overall height with magnetic bridge) 317 - 415 mm

H (overall height with adjustable foot bridge) 317 - 415 mm

Rating plates

NOTE! The rating plates may not be removed or modied without the consent

of Fronius International GmbH. Ensure that the rating plates remain legible.

Type:

A-4600 Wels

www.fronius.com

U

24 VDC

Rating plate, welding carriage

weight

14,5 kg

A-4600 Wels

www.fronius.com

U

24 VDC

weight

1,5 kg

Art.No.:

Ser.No.:

IP23

Type:

Art.No.:

Ser.No.:

45 kg

FlexTrack 45

8,045,565

max. load

8,046,036

30 kg

FRC 45

A-4600 Wels

www.fronius.com

U

1

230 VAC

Rating plate, control box

U

2

24 VDC

IP23

A-4600 Wels

www.fronius.com

U

24 VDC

weight

2 kg

Type: E-Cabinet

Art.No.:

Ser.No.:

I2

4 A 13 A

Type:

Art.No.:

Ser.No.:

max. load

10 kg

41,100,000

FOU 30/ML10

8,045,579

IP23

Rating plate, remote control Rating plate, oscillation unit

IP23

All illustrations of rating plates are representative images.

70

Page 71

Weights of rails

and bridges

Magnetic bridge 2.5 kg

Vacuum bridge (on request) 1.6 kg

Magnetic bridge with distance block 2.7 kg

Vacuum bridge with distance block (on request) 1.8 kg

Magnetic bridge with distance block and metric adjustment unit 3.4 kg

Magnetic bridge with metric adjustment unit 3.2 kg

Bridge with adjustable foot, distance block and metric adjustment unit 1.5 kg

Bridge with adjustable foot and metric adjustment unit 1.3 kg

Vacuum bridge with distance block and metric adjustment unit (on request) 2.6 kg

Vacuum bridge with metric adjustment unit (on request) 2.4 kg

Rigid rail 1884 mm 11 kg

Flexible rail 1884 mm 5.5 kg

Flexible rail 1695 mm 4.8 kg

Flexible rail 1130 mm 3.3 kg

Rigid ring Ø200-300 mm 8.8 kg

Rigid ring Ø300-480 mm 11 kg

Rigid ring Ø480-660 mm 14 kg

Rigid ring Ø660-840 mm 16 kg

Rail segment Ø840-1020 mm 19 kg

Rail segment Ø1020-1200 mm 22 kg

Rail segment Ø1200-1380 mm 24 kg

Rail segment Ø1380-1560 mm 27 kg

71

Page 72

Ring rail settings table

IMPORTANT! A quick-reference summary of the settings table, showing the most important

settings, can be found on the inside of the transport box lid.

workpiece

* Vw / D

rail

= D

carriage

[cm/min]

Vw = welding speed [cm/min]

V

718*Vw/Dp

-

ment unit

on adjust

Distance M

of

bridges

Number

285-0.5*Dp

195-0.5*Dp 537*Vw/Dp

4

3

-

[mm]

max

block

Max. Ø for

bridges with

Dp

out distance

-

[mm]

min

Min. Ø for

block

Dp

out distance

bridges with

900*Vw/Dp

1080*Vw/Dp

375-0.5*Dp

365-0.5*Dp

6

8

1260*Vw/Dp

1440*Vw/Dp

455-0.5*Dp

545-0.5*Dp

9

12

1620*Vw/Dp

1800*Vw/Dp

635-0.5*Dp

725-0.5*Dp

15

16

[mm]

Max. Ø for

Dp

bridges with

distance block

[mm]

Min. Ø for

Dp

bridges with

distance block

Dp [mm]

Ø Workpiece

[mm]

Ø Round

guide rail

max

min

300-400 295.6 411.6

200-300 192 308

300-480

200-300

380-480 375.6 491.6 245-0.5*Dp

480-580 475.5 591.5

560-660 555.5 671.5 335-0.5*Dp

480-660

660-760 655.5 771.5

740-840 735.5 851.5 325-0.5*Dp

660-840

840-940 835.4 951.4

920-1020 915.4 1031.4 415-0.5*Dp

840-1020

1020-1120 1015.3 1131.3

1100-1200 1095.3 1211.3 505-0.5*Dp

1200-1300 1195.2 1311.2

1020-1200

1280-1380 1275.2 1391.2 595-0.5*Dp

1380-1480 1375.1 1491.1

1200-1380

1380-1560

72

1460-1560 1455.1 1571.1 685-0.5*Dp

Page 73

Flexible rail segments settings table

workpiece

* Vw / D

rail

= D

carriage

V

[cm/min]

Vw = welding speed [cm/min]

ment unit

on adjust-

Distance M

1980*Vw/Dp 1640-1740 1635 1751 915-0.5*Dp

2160*Vw/Dp 18290-1920 1815 1931 1005-0.5*Dp

2340*Vw/Dp 2000-2100 1995 2111 1095-0.5*Dp

of

bridges

Number

2520*Vw/Dp 2180-2280 2175 2291 1185-0.5*Dp

2700*Vw/Dp 2360-2460 2355 2471 1275-0.5*Dp

2880*Vw/Dp 2540-2640 2535 2651 1365-0.5*Dp

3060*Vw/Dp 2720-2820 2714 2830 1455-0.5*Dp

3240*Vw/Dp 2900-3000 2894 3010 1545-0.5*Dp

3420*Vw/Dp 3080-3180 3074 3190 1635-0.5*Dp

3600*Vw/Dp 3260-3360 3254 3370 1725-0.5*Dp

3780*Vw/Dp 3440-3540 3434 3550 1815-0.5*Dp

3960*Vw/Dp 3620-3720 3614 3730 1904-0.5*Dp

4140*Vw/Dp 3800-3900 3794 3910 1994-0.5*Dp

4320*Vw/Dp 3980-4080 3974 4090 2084-0.5*Dp

block

Max. Ø for

out distance

bridges with-

block

Min. Ø for

out distance

bridges with-

[mm]

Max. Ø for

Dp

bridges with

distance block

[mm]

Min. Ø for

Dp

bridges with

distance block

[mm]

max

Dp

[mm]

min

Dp

max

min

Dp [mm]

Ø Workpiece

[mm]

Ø Round

guide rail

1560-1660 1555 1671 18 875-0.5*Dp

1740-1840 1735 1851 18 965-0.5*Dp

1560-1740

1740-1920

1920-2020 1915 2031 20 1055-0.5*Dp

2100-2200 2095 2211 21 1145-0.5*Dp

1920-2100

2100-2280

2280-2380 2275 2391 25 1235-0.5*Dp

2460-2560 2455 2571 25 1325-0.5*Dp

2280-2460

2460-2640

73

2640-2740 2634 2750 28 1415-0.5*Dp

2820-2920 2814 2930 30 1505-0.5*Dp

2640-2820

2820-3000

3000-3100 2994 3110 30 1595-0.5*Dp

3180-3280 3174 3290 30 1685-0.5*Dp

3000-3180

3180-3360

3360-3460 3354 3470 33 1775-0.5*Dp

3540-3640 3534 3650 33 1864-0.5*Dp

3360-3540

3540-3720

3720-3820 3714 3830 35 1954-0.5*Dp

3900-4000 3894 4010 36 2044-0.5*Dp

3720-3900

3900-4080

Page 74

Flexible rail segments settings table (continued)

workpiece

* Vw / D

rail

= D

carriage

V

[cm/min]

Vw = welding speed [cm/min]

ment unit

on adjust-

Distance M

4500*Vw/Dp 4160-4260 4154 4270 2174-0.5*Dp

4680*Vw/Dp 4340-4440 4334 4450 2264-0.5*Dp

4860*Vw/Dp 4520-4620 4514 4630 2354-0.5*Dp

5040*Vw/Dp 4700-4800 4693 4809 2444-0.5*Dp

5220*Vw/Dp

2534-0.5*Dp

5400*Vw/Dp 5060-5160 5053 5169 2624-0.5*Dp

5580*Vw/Dp 5240-5340 5233 5349 2714-0.5*Dp

5760*Vw/Dp 5420-5520 5413 5529 2808-0.5*Dp

5940*Vw/Dp 5600-5700 5593 5709 2894-0.5*Dp

6120*Vw/Dp 5780-5880 5773 5889 2984-0.5*Dp

6300*Vw/Dp 5960-6060 5953 6069 3074-0.5*Dp

of

bridges

Number

block

Max. Ø for

out distance

bridges with-

block

Min. Ø for

out distance

bridges with-

[mm]

Max. Ø for

Dp

bridges with

distance block

[mm]

max

Dp

[mm]

min

Dp

max

Min. Ø for

bridges with

distance block

Dp [mm]

Ø Workpiece

[mm]

Ø Round

guide rail

[mm]

min

Dp

4080-4180 4074 4190 38 2134-0.5*Dp

4260-4360 4254 4370 40 2224-0.5*Dp

4080-4260

4260-4440

4440-4540 4434 4550 41 2314-0.5*Dp

4620-4720 4613 4729 43 2404-0.5*Dp

4440-4620

4620-4800

4800-4900 4793 4909 45 2494-0.5*Dp

4880-4980 4873 4989

4980-5080 4973 5089 45 2594-0.5*Dp

4800-4980

4980-5160

74

5160-5260 5153 5269 48 2674-0.5*Dp

5340-5440 5333 5449 48 2764-0.5*Dp

5160-5340

5340-5520

5520-5620 5513 5629 50 2854-0.5*Dp

5700-5800 5693 5809 51 2944-0.5*Dp

5520-5700

5700-5880

5880-5980 5873 5989 53 3034-0.5*Dp

5880-6060

Page 75

Spare parts, circuit diagram

75

Page 76

76

Page 77

Spare parts

Spare parts,

wearing parts

and auxiliary

materials

Ordering details

Use of third-party spare and wearing parts may pose risks. Use approved Fronius original spare parts only.

The manufacturer cannot accept any liability for damage resulting from the use of spare

or wearing parts or auxiliary materials that are not approved by the manufacturer.

NOTE! Only trained technicians may change parts and may only do so after

having read the installation and dismantling instructions supplied.

When ordering spare parts, you should provide the following data:

- Item number as per spare parts list

- Model name of the device

- Serial number of the device (shown on the rating plate)

77

Page 78

Order numbers for welding carriage, rails and accessories:

8,045,565 FlexTrack 45

8,045,578 FGU 8/SD80-28

8,045,579 FOU 30/ML10

8,045,581 FGU 9/SD28

8,046,036 FRC-45

8,100,224 I-kit, contact cam

48,0005,1752 FTH 18/D16-25

48,0005,1753 FTH 19/D22-35

48,0005,1754 Rail, straight 1884mm incl. joining elements

48,0005,1755 Magnetic bridge /1

48,0005,1756 Rail, exible 1130mm incl. joining elements

48,0005,1757 Rail, exible 1695mm incl. joining elements

48,0005,1758 Rail, exible 1884mm incl. joining elements

48,0005,1759 Magnetic bridge /2

48,0005,1760 Rigid ring, 200-300mm

48,0005,1761 Rigid ring, 300-480mm

48,0005,1762 Rigid ring, 480-660mm

48,0005,1763 Rigid ring, 660-840mm

48,0005,1764 Point support, adjustable

48,0005,1765 Rigid ring, 840-1020mm

48,0005,1766 Rigid ring, 1020-1200mm

48,0005,1767 Rigid ring, 1200-1380mm

48,0005,1768 Rigid ring, 1380-1560mm

48,0005,1769 Magnetic bridge, adjustable /1

48,0005,1770 Magnetic bridge, adjustable /2

48,0005,1771 Vacuum bridge (on request)

48,0005,1776 FTH 18

48,0005,1777 FTH 21

48,0005,1792 Vacuum bridge with support

(on request)

48,0005,1793 Point support, adjustable /2

38,0100,0433 Control line

78

Page 79

FlexTrack 45 welding carriage Item no.: 8,045,565

48,0005,1820

48,0005,1811

48,0005,1800

48,0005,1812

48,0005,1799

48,0005,1806

48,0005,1802

48,0005,1798

48,0005,1804

48,0005,1809

48,0005,1805

48,0005,1808

48,0005,1807

48,0005,1810

48,0005,1813

48,0005,1814

48,0005,1818

38,0100,0433

48,0005,1815

48,0005,1817

48,0005,1816

48,0005,1819

79

Page 80

8,045,578

8,045,581

FGU 8/SD80-28 Item no.: 8,045,578

48,0005,1823

FGU 9 / SD28 Item no.: 8,045,581

80

Page 81

48,0005,1839

48,0005,1843

48,0005,1845

FOU 30 / ML 10 Item no.: 8,045,579

48,0005,1840

48,0005,1841

48,0005,1842

48,0005,1798

48,0005,1846

81

Page 82

Remote control Item no.: 8,046,036

48,0005,1853

48,0005,1816

48,0005,1854

82

Page 83

FTH 18/D16-25 Item no.: 48,0005,1752

48,0005,1752

FTH 21 Item no.: 48,0005,1777

48,0005,1777

83

Page 84

48,0005,1838

48,0005,1838

48,0005,1825

48,0005,1838

Closed rings

48,0005,1826

48,0005,1827

48,0005,1824

Straight rails (rigid and exible)

84

Page 85

Circuit diagram

85

Page 86

86

Page 87

87

Page 88

FCP 600 - II

Spare parts recommendation,

D

Mechanical spare parts

Page 89

FRONIUS INTERNATIONAL GMBH

TechSupport Automation

)URQLXVSODW]$:HOV$XVWULD

7HO)D[

(0DLOVDOHV#IURQLXVFRP

www.fronius.com

8QGHUKWWSZZZIURQLXVFRPDGGUHVVHV\RXZLOOIiQGDOODGGUHVVHV

www.fronius.com/addresses

RIRXU6DOHVVHUYLFHSDUWQHUVDQG/RFDWLRQV

Page 90

FCP 600 - II

Spare parts recommendation,

D

Mechanical spare parts

Loading...

Loading...