/ Perfect Welding / Solar Energy / Perfect Charging

FDV 50

Operating Instructions

EN

Carriage

42,0426,0097,EN V06 - 04072016

Table of contents

General ............................................................................................................................................................ 3

Principle......................................................................................................................................................3

Device concept ........................................................................................................................................... 3

Scope of supply .......................................................................................................................................... 3

Field of application ..................................................................................................................................... 3

Proper use .................................................................................................................................................. 4

Warning notices on the carriage .................................................................................................................4

Carriage components ...................................................................................................................................... 5

Standard equipment ................................................................................................................................... 5

Options and accessories ............................................................................................................................ 5

Controls and connections ................................................................................................................................ 6

FCU-9 control unit ...................................................................................................................................... 6

FRC-9 remote control ................................................................................................................................. 7

Welding positions ............................................................................................................................................8

Possible welding positions ......................................................................................................................... 8

Preparing the carriage ..................................................................................................................................... 8

Checking the surface of the workpiece and the carriage to ensure they are clean .................................... 8

Carriage strain relief ................................................................................................................................... 8

Commissioning ................................................................................................................................................ 9

Checking the connections .......................................................................................................................... 9

Switching on system components .............................................................................................................. 9

Dening parameters for the carriage .......................................................................................................... 9

Carrying out test run ................................................................................................................................. 10

Starting the welding process .................................................................................................................... 10

Troubleshooting ............................................................................................................................................. 11

General..................................................................................................................................................... 11

Basic requirements for the system to work .............................................................................................. 11

Carriage.................................................................................................................................................... 11

Control, remote control ............................................................................................................................. 11

Maintenance and care ................................................................................................................................... 13

Personnel ................................................................................................................................................. 13

Maintenance record ................................................................................................................................. 13

Maintenance operations and intervals ..................................................................................................... 13

Recommended lubricants ........................................................................................................................ 13

Carriage components ............................................................................................................................... 14

Technical data ............................................................................................................................................... 15

FDV 50 carriage ....................................................................................................................................... 15

FDV 50 dimensions .................................................................................................................................. 15

Options and accessories ............................................................................................................................... 16

System overview ...................................................................................................................................... 16

Installation kit ........................................................................................................................................... 16

Connecting cable ..................................................................................................................................... 16

Wiring diagram .............................................................................................................................................. 22

with one Powersource .............................................................................................................................. 22

with two Powersources ........................................................................................................................... 23

EU-Declaration of conformity ........................................................................................................................ 25

1

2

General

Principle The FDV 50 carriage is a straight-line carriage with a 2-wheel drive for welding mechani-

sed butt and llet welds in a horizontal welding position.

Device concept

Scope of supply

Field of

application

The FDV 50 carriage has been designed

for exibility and to improve productivity in

the execution of longitudinal weld seams.

Robust yet lightweight design allows quick

and easy positioning on the workpiece.

The carriage is powered by a mains cable.

It is controlled and operated by a remote

control.

FDV 50 carriage

FDV 50 carriage 8,045,099

FCU9 / M1 control unit 8,040,026

FRC9 remote control 8,046,016

The FDV 50 carriage can be used in all situations where a high degree of exibility is

required when executing longitudinal weld seams:

- Welding of longitudinal members

- Shipyards

- Bridge construction

- Workshops

- Production halls

- Building sites

3

Proper use

The FDV 50 carriage must only be used for welding mechanised butt and llet welds in a

horizontal welding position.

Any other use shall be deemed improper and the manufacturer will assume no

responsibility for any damages arising.

Can be used in the following welding processes:

- MIG / MAG process

Proper use also includes:

- Carrying out all maintenance work at the appropriate intervals

- Keeping a service book with the most important information (date, operator, activities

carried out)

- Using the spare parts stipulated by Fronius

- Following all the information in the operating instructions

- Using this document in combination with the operating instructions for the integrated

system components (power source, wire-feed unit, etc.)

NOTE! Any use of the machine other than for its intended purpose or any

unauthorised conversion or modications, shall be deemed improper use.

Any liability or warranty from the manufacturer is hereby invalidated.

Warning notices

on the carriage

A number of safety symbols can be seen on the rating plate axed to the carriage. The

safety symbols must not be removed or painted over.

FDV 50

A-4600 Wels

www.fronius.com

YM:2010

1~

50/60 Hz

max. load

Art.No.:

Ser.No.:

EN 12100

1

U

230 V

50 kg

1070 x 815 x 680 mm

0,8 A

weight

41 kg

L x W x H

8,045,099

1

I

max

v

199 cm/min

P

180 VA

FDV 50 rating plate

Do not use the functions until you have fully read all the operating instructions.

Do not dispose of used devices with domestic waste. Dispose of them according to

safety rules.

4

Carriage components

Standard

equipment

Options and

accessories

- 2-wheel drive via AC motor (drive can be uncoupled)

- Wheels with steel tread and groove

- Reinforcement with mounting pin for wire-feed unit

- Power supply and motor controller box integrated in the carriage

- Mains cable and plug (5 metres)

- Control line to power source (6.5 metres)

- FRC-9 remote control and cable (3 metres)

- Holder for remote control

- Mechanical weld tracking system

- Torch holder and adjustment units

- Steel guide rollers with / without groove (laterally adjustable)

- Rail system

- Limit position function I-kit

- VR holder for two wire-feed units

Wire-feed unit

FGU 4

FGU 1

FRC-9

FSU 7 + FTH

5

Controls and connections

FCU-9

control unit

WARNING! Operating the equipment incorrectly can cause serious injury and

damage. Do not use the functions described here until you have thoroughly

read and understood the following documents:

- These operating instructions

- All the operating instructions for the system components, especially the

safety rules

(2)

(3)

(1)

FDV 50 connections

No. Function

(1) Remote control connection

to connect manual remote control

(2) On/O mains switch

to switch the carriage and connected remote control on and o

(3) Power source control

to connect the power source

NOTE! Detailed information about using the FCU-9 control unit, plus information

about maintenance and troubleshooting, can be found in the FCU-9 operating

instructions that are enclosed with the technical documents for the carriage.

6

FRC-9 remote

control

(10)

(9)

(1)

(2)

No. Function

(1) Emergency Stop button

Stops all movements. The arc is

broken immediately.

(2) Start-up delay potentiometer

To set the time between igniting the

arc and starting the carriage.

(8)

(7)

(3)

(4)

(3) "Move manually" button

For manual ne positioning of the

carriage.

(4) "STOP" button

To stop the program sequence.

Combined with the "START" button,

used to determine the direction of

(5)(6)

FRC-9 remote control

rotation.

No. Function

(5) Preselect welding direction

To select the welding direction (direction of travel).

(6) START button

To start the welding process.

(7) Welding ON/OFF

Select program sequence with or without welding.

(8) Pneumatic ON/OFF

To control a pneumatic unit (e.g. lowering of torch).

(9) Welding speed potentiometer

To set the welding speed. This can also be changed during the welding process.

(10) Digital display of welding speed

Displays the carriage speed in [cm/min].

NOTE! Detailed information about using the remote control and setting

the desired welding parameters, plus information about maintenance and

troubleshooting, can be found in the FRC-9 operating instructions.

7

Welding positions

Possible

welding positions

Exceptional track consistency is assured by the wheels with grooves and the 2-wheel

drive, which can be uncoupled.

The following welding positions are possible:

- PA position

Preparing the carriage

Checking the

surface of the

workpiece and

the carriage to

ensure they are

clean

Carriage strain

relief

Before positioning the carriage, check the following:

- The surface of the workpiece must be clean (no sand, shavings, etc.)

- The tread and grooves of the drive wheels must not be damaged and must be free of

shavings, dirt and welding spatter

To attain optimum wirefeed, observe the following when connecting and routing the

hosepack:

- Do not allow the hosepack to become kinked

- Always lay the hosepack as straight as possible

- Suspend hosepack if necessary. Use balancer and hosepack holder.

Hosepack handling

8

Commissioning

Checking the

connections

WARNING! Operating the equipment incorrectly can cause serious injury and

damage. Do not use the functions described here until you have thoroughly

read and understood the following documents:

- These operating instructions

- all the operating instructions for the system components,

especially the safety rules

The following activities and work steps apply to the installed system. All connections

must be established. Before start-up, check the connections of the following system

components:

- Power source

- Cooling circuit

- Gas cylinder

- Wire-feed unit

- Welding torch with hosepack

- Workpiece

Precise information on the assembly and connection of the system components can be

found in the relevant system component operating instructions.

Switching on

system

components

Dening

parameters for

the carriage

IMPORTANT! There are no xed rules for the sequence in which the system

components are switched on. They can be switched on in any order.

On the following system components turn the main switch to the "ON - 1" position:

- Carriage control unit

- Power source

- Wire-feed unit (if power is not supplied from the power source)

Determine the following settings for the welding process:

- Start-up delay

- Welding direction

- Traversing speed

9

Carrying out

test run

welding process

Perform a test run to check that all system components work together correctly. This is

done without an arc and thus allows you to check all movements during the process.

1. Switch the "Welding ON / OFF" toggle switch to the OFF position.

2. Press the START button. The welding test sequence starts.

IMPORTANT! Never leave the machine unattended, particularly when it is moving

automatically.

3. Carry out a visual check during the process.

4. If necessary, make the relevant corrections (welding torch position, direction of travel

of carriage, traversing speed, etc.).

5. After the test, move the carriage back to its original position.

Start the welding process:Starting the

1. Switch the "Welding ON / OFF" toggle switch to the ON position.

2. Press the START button. The welding process starts.

IMPORTANT! Never leave the machine unattended, particularly when it is moving

automatically.

10

Troubleshooting

General

Basic

requirements for

the system to

work

Carriage

In the event of faults, note that the functioning of the entire system depends on many

additional components (power source, wire-feed unit, etc.) that are also potential sources

of problems.

- Connections established between separate system components

- System components are supplied with electricity and the mains voltage is as

specied (see rating plate)

Carriage is switched on but does not move

Cause: Carriage overloaded (e.g. the torch cables pull the carriage up)

Remedy: Relieve cable strain (suspend)

Cause: Wheels dirty (with oil)

Remedy: Clean the wheels

Play on the torch

Cause: Play on the handles

Remedy: Tighten handles

Control,

remote control

Cause: Play on the guide rails

Remedy: Tighten the pressure screws

Nothing happens, main switch does not light up

Cause: Main switch is switched o

Remedy: Switch the device on

Cause: No connection to the mains

Remedy: Check the mains lead, mains plug and mains cable

Cause: Mains fuse is faulty

Remedy: Replace the mains fuse: glass-tube fuse

No function, main switch lights up

Cause: Emergency Stop has been actuated

Remedy: Release the Emergency Stop button

Cause: No connection to the carriage

Remedy: Check the control line

Cause: Frequency converter error

Remedy: - Switch the device o

- Wait 15 seconds

- Switch the device on again

11

Control,

remote control

(continued)

Carriage does not move after start-up or when in inching mode

Cause: Emergency Stop has been actuated

Remedy: Release the Emergency Stop button

Cause: Frequency converter error

Remedy: - Switch the device o

- Wait 15 seconds

- Switch the device on again

Arc ignites, carriage does not move

Cause: Value too high for start-up delay

Remedy: Change the "Start-up delay time" parameter (start-up delay

potentiometer)

Carriage moves but arc does not ignite

Cause: Power source switched o

Remedy: Switch on the power source

Cause: Welding ON / OFF selector switch set to the OFF position

Remedy: Set the selector switch to ON

12

Maintenance and care

Personnel

Maintenance

record

Maintenance

operations and

intervals

WARNING! Risk of injury and damage from incorrectly performed

maintenance.

All maintenance work on the FDV 50 carriage must only be carried out by

trained technicians. It is essential to adhere

to the maintenance intervals and maintenance procedures. The manufacturer

accepts no liability for any damage caused by inadequate or poorly performed

maintenance.

The operator must put the following organisational measures in place with regard to

maintenance:

- keeping a service book with the most important data (date, operator, maintenance

activities carried out)

NOTE! Before beginning maintenance work, switch o device and disconnect

from mains supply.

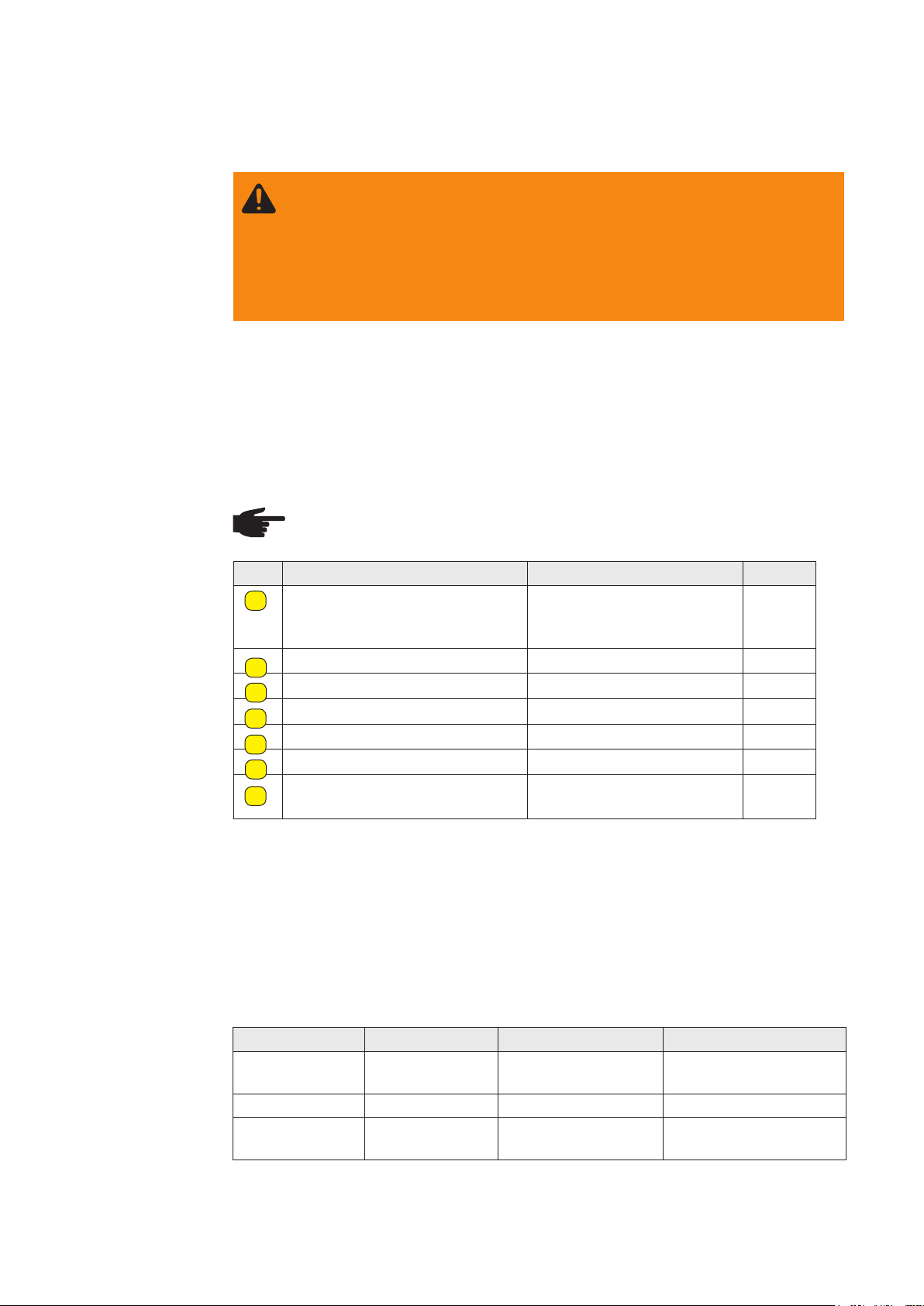

Item Part Action Interval

Linear guides Clean, check oil lm, elimi-

A

nate play: tighten pressure

screws with Allen key

Thread play Clean, regrease M

B

Rack and pinion Clean, regrease M

C

Rollers and rails Clean, check position M

D

Ventilation openings Clean W

E

Terminal contacts Clean W

F

Wheels, underbody, guide

G

wheels, guide rails

Clean D

M

Recommended

lubricants

D Daily

W Weekly

M Monthly

1/2 y Half-yearly

Y Yearly

IMPORTANT! Lubricants with solid lubricant additives (e.g.: MoS2, graphite and PTFE)

are not suitable for guiding systems.

Lubricant DIN DIN number Comment

Lubricating

grease

Lubricating oil CLP32-100 51517 Part 3 ISO VG 32-100

Conductive

paste

KP 2-K 51502 / 51825 Lithium soap-based

grease

-- -- Item no. 48,0009,0157

13

Carriage

components

F

G

F

G

G

G

G

G

C

G

14

Technical data

FDV 50

carriage

FDV 50

dimensions

Mains voltage/frequency 230 V / 50-60 HZ

Control voltage 24 V DC

Power consumption 180 VA

Max. load 50 kg

Track width 370 mm

Welding position PA

Horizontal speed (load = 50 N) 0-199 cm/min

Net weight (without remote control and weld tracking) 41 kg

H

C

E

G

A 792 mm

B 437 mm

C 345 mm

D 592 mm

D

AB

F

E 370 mm

F 1069 mm

G max. 379.5 mm

H 678 mm

15

Options and accessories

F

C

U

9

/

M

1

FDV 50

TUCHEL

FRC-9

System overview

1

Pneumatic cylinder

FPT 100 8,045,228

or

FPT 150 8,045,227

38,0100,008 1

24V + DC

Installation kit

Start/Stop second power source I-kit

Item number: 8,100,107

Including 3 m Tuchel connecting cable

TUCHEL

38,0100,0018

Power source

A

Installation kits FTV 20 / FTV 50:

1

I-Kit Start-Stop Power source 2:

8,100,107

Power source

B

LEGEND:

--------- Option

______ Standard

(included in delivery)

Connecting

cable

5 m connecting cable to FTP (pneum. torch positioning)

Item number: 38,0100,0081

16

/ Battery Charging Systems / Welding Technology / Solar Electronics

FDV-50

Spare parts list,

circuit diagram

EN

Carriage

17

18

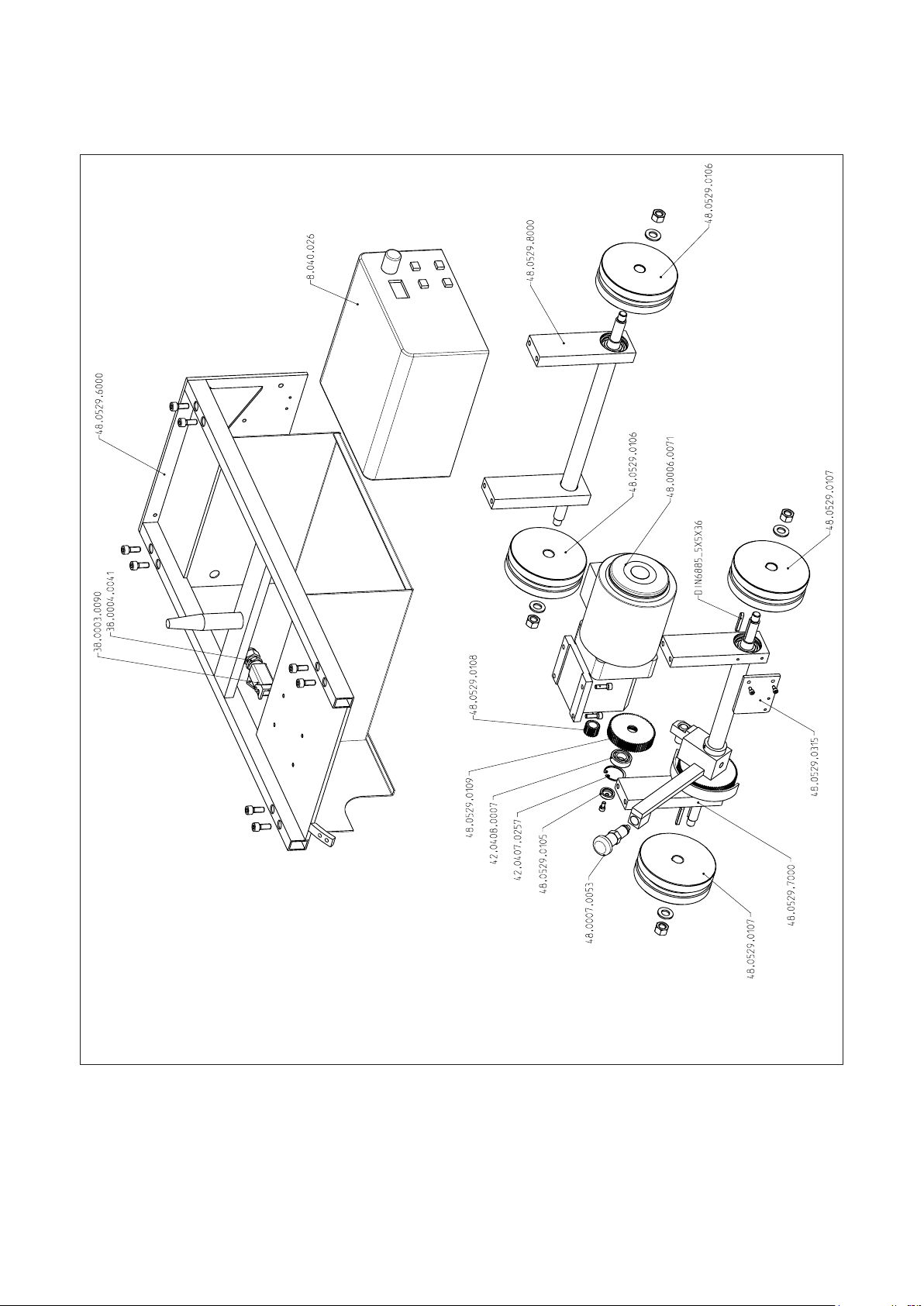

48,0529,0000 FDV 50 carriage

19

48,0529,0000 FDV 50 carriage

Designation: Item number:

Thrust washer 48,0529,0105

Impeller 48,0529,0106

Impeller drive 48,0529,0107

Drive pinion 48,0529,0108

Intermediate cog 48,0529,0109

Limit switch plate 48,0529,0315

Base frame, complete 48,0529,6000

Drive axis, complete 48,0529,7000

Front axis, complete 48,0529,8000

Base housing 38,0003,0090

Cable gland 38,0004,0041

Spur gear motor 48,0006,0071

Stop bolt without locking nut, with button 48,0007,0053

FCU-9M1 8,040,026

Locking ring 42,0407,0257

Bearing 42,0408,0007

Spring DIN6885_5x5x36

FRC-9 remote control 8,046,016

48-0385-C000 I-kit Limit switch

Designation: Item number:

Limit switch 90° 38,0002,0166

Cable connection 38,0004,0090

20

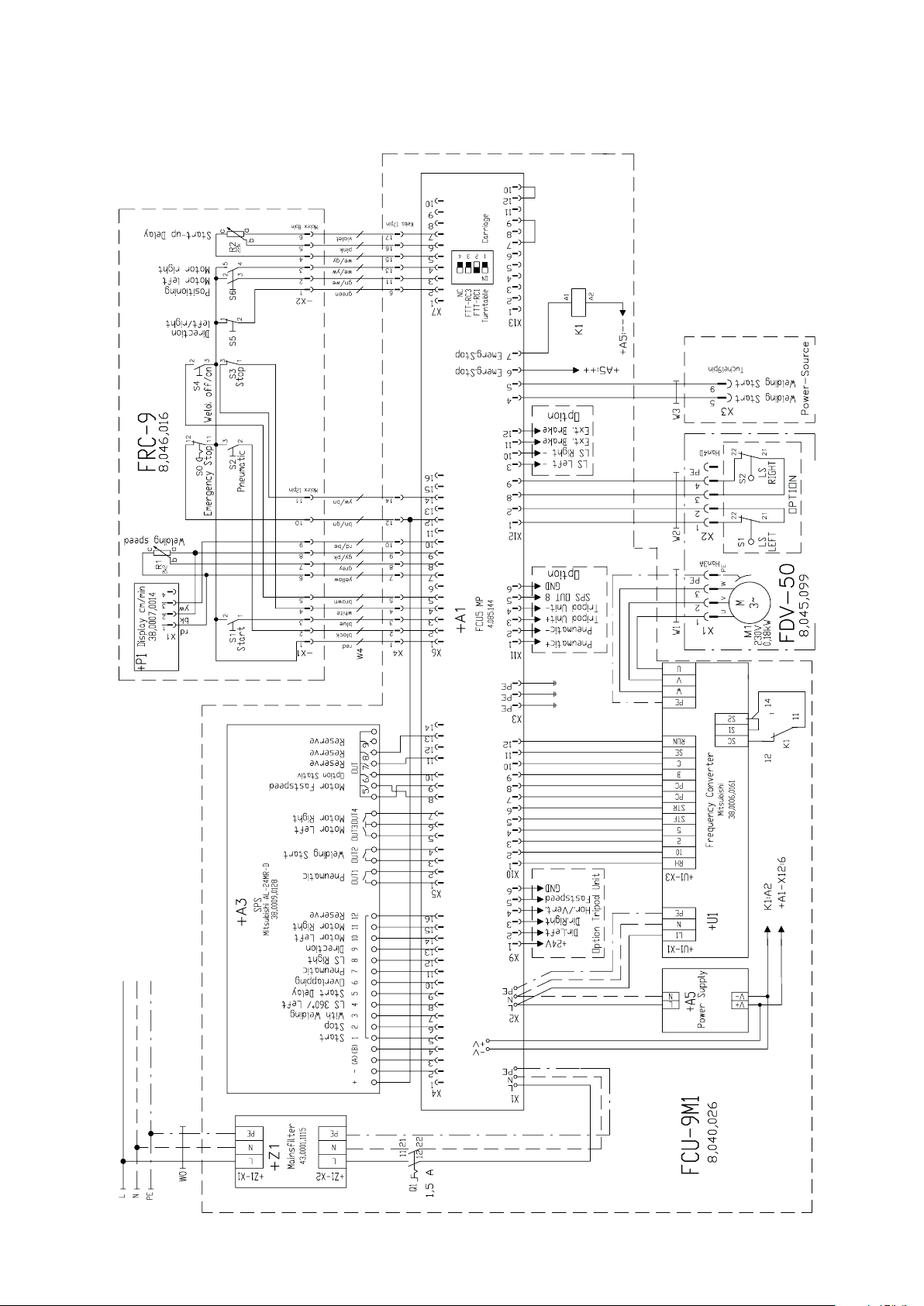

8,040,026 FCU-9M1

38,0102,0017

38,0006,0043

43,0001,1397

43,0001,1115

38,0006,0087

38,0102,0031

4,085,0144

43,0003,0002

43,0003,0001

43,0003,0148

38,0003,0089

43,0003,0235

43,0004,3206

38,0003,0089

Item no. Name

4,085,144 MP-Print

38,0006,0087 Mains switch

38,0102,0017 Frequency converter

38,0102,0031 PLC

38,0006,0043 Relay 24VDC 1Wl

43,0001,1115 Line lter

43,0001,1397 24 VDC mains adapter

43,0004,3206 5 m mains cable

43,0003,0001 Handle cap

43,0003,0002 Plug connector

43,0003,0148 Plug insert

38,0003,0089 Connector housing

43,0003,0235 Plug insert

21

Wiring diagram

with one Powersource

22

24VDC 0,4A

43,0001,1397

with two Powersources

23

24VDC 0,4A

43,0001,1397

24

EU-Declaration of conformity

25

FRONIUS INTERNATIONAL GMBH

TechSupport Automation

www.fronius.com

www.fronius.com/addresses

26

Loading...

Loading...