/ Perfect Charging / Perfect Welding / Solar Energy

CMT Twin

Process description and

commissioning

User information

EN

System extension

42,0426,0138,EN 003-28082017

2

Dear reader,

Introduction Thank you for the trust you have placed in our company and congratulations on buying this

high-quality Fronius product. These instructions will help you familiarise yourself with the

product. Reading the instructions carefully will enable you to learn about the many different

features it has to offer. This will allow you to make full use of its advantages.

Please also note the safety rules to ensure greater safety when using the product. Careful

handling of the product will repay you with years of safe and reliable operation. These are

essential prerequisites for excellent results.

EN

3

4

Contents

General 7

General ...................................................................................................................................................... 9

System concept .................................................................................................................................... 9

Functional principle ............................................................................................................................... 9

Configurations....................................................................................................................................... 9

Dimensioning of the robot ..................................................................................................................... 10

Measures to increase system availability.............................................................................................. 10

Note for TimeTwin welding using a CMT Twin system ......................................................................... 10

System components required .................................................................................................................... 11

System components required ............................................................................................................... 11

Application example................................................................................................................................... 14

Application example.............................................................................................................................. 14

Installation and commissioning 15

Safety......................................................................................................................................................... 17

Safety.................................................................................................................................................... 17

Notes regarding the installation of Fronius system components ............................................................... 18

Installation and commissioning of Fronius system components ........................................................... 18

Setup regulations for the power sources .............................................................................................. 18

Fitting wearing parts to the torch neck ....................................................................................................... 19

Fitting wearing parts to the torch neck .................................................................................................. 19

Fitting the mounting bracket and torch neck .............................................................................................. 20

Fitting the mounting bracket to the robot .............................................................................................. 20

Screw the torch neck and drive units to the mounting bracket ............................................................. 20

Earth connection ........................................................................................................................................ 22

Earth connection ................................................................................................................................... 22

Recommendation to minimise arc blow ................................................................................................ 23

Connecting the LHSB-HUB with the power sources and wire-feed units .................................................. 24

Connecting the LHSB-HUB with the power sources and wire-feed units ............................................. 24

Connecting to the robot control.................................................................................................................. 25

Connecting to the robot control............................................................................................................. 25

Robot interfaces for CMT Twin ............................................................................................................. 25

Standard robot interfaces...................................................................................................................... 25

Twin fieldbus systems .......................................................................................................................... 26

Standard fieldbus systems.................................................................................................................... 27

Description of signal statuses .............................................................................................................. 28

Check compatibility of power sources and remote controls....................................................................... 29

Safety.................................................................................................................................................... 29

Checking power source compatibility.................................................................................................... 29

Checking the RCU 5000i database version .......................................................................................... 29

Checking the characteristics version ......................................................................................................... 31

Safety.................................................................................................................................................... 31

Checking the characteristics version .................................................................................................... 31

L/R alignment - aligning welding circuit inductivity and welding circuit resistance..................................... 33

Safety.................................................................................................................................................... 33

L/R alignment using RCU 5000i............................................................................................................ 33

Welding start-up......................................................................................................................................... 36

Welding start-up sequence ................................................................................................................... 36

Safety.................................................................................................................................................... 36

Welding start-up settings ...................................................................................................................... 36

Start delay parameter correction........................................................................................................... 37

Pulse/CMT welding .................................................................................................................................... 38

Process description pulse/CMT welding ............................................................................................... 38

CMT/CMT welding ..................................................................................................................................... 39

Process description CMT/CMT welding................................................................................................ 39

Single-wire welding ............................................................................................................

Special features and advantages.......................................................................................................... 40

........................ 40

EN

5

Material transfer .................................................................................................................................... 40

Applying the 'HD' ('Heavy Duty') configuration........................................................................................... 42

Available characteristics ....................................................................................................................... 42

Description of characteristics ................................................................................................................ 42

Configuring the system ......................................................................................................................... 42

Stick out ................................................................................................................................................ 44

Use 'Speed' configuration .......................................................................................................................... 45

Available characteristics ....................................................................................................................... 45

Description of characteristics ................................................................................................................ 45

Configuring the system ......................................................................................................................... 46

Stick out ................................................................................................................................................ 48

Use 'Root' configuration ............................................................................................................................. 49

Available characteristics ....................................................................................................................... 49

Description of characteristics ................................................................................................................ 49

Configuring the system ......................................................................................................................... 49

Standard welding parameter values for fillet welds.................................................................................... 51

Standard welding parameter values for fillet welds............................................................................... 51

Alignment of welding torch relative to the workpiece ............................................................................52

Standard welding parameter values for lap joints ...................................................................................... 53

Standard welding parameter values for lap joints ................................................................................. 53

Alignment of welding torch relative to the workpiece ............................................................................53

Prerequisities for welding........................................................................................................................... 55

Safety.................................................................................................................................................... 55

Prerequisities for welding...................................................................................................................... 55

6

General

General

System concept CMT Twin is a high performance welding process that combines the advantages of CMT

welding and Twin welding. In addition to numerous other benefits, it offers a very high welding speed and simple control of the process.

EN

Functional principle

- The wire is fed by two separate wire-feed units and Robacta Drive CMT drive units

- The wire-feed units and drive units are supplied by two independent power sources

- The wire electrodes are brought together in the torch neck in such a way that two independent welding potentials are created

(4)

(5)

(1)

(2)

(3)

(2)

(1)

(4)

(5)

No. Explanation

(1) Wire-feed unit 1 and 2

(2) Wire electrode 1 and 2

(3) LHSB-HUB

(4) Power source 1 and 2

(5) Separate welding potential

Configurations CMT Twin can be used in a variety of configurations depending on requirements. The

available configurations comprise:

- wearing parts optimised for CMT Twin

- dedicated characteristics on the RCU 5000i

Refer to the "Installation and commissioning" section for more information about the individual configurations.

9

Dimensioning of

the robot

Dimension the robot so that it is able to accommodate the Robacta Twin Compact Pro

torch neck and associated mounting bracket plus 2 Robacta Drive CMT drive units and 1

metre of the relevant hosepacks.

NOTE! The total weight of these components is 7.5 kg (16.53 Ib.).

Measures to increase system

availability

Note for

TimeTwin welding using a CMT

Twin system

To increase system availability, we recommend the following welding torch cleaning devices:

Robacta Reamer Twin

Mechanical welding torch cleaner, suitable for all base materials, such as steel, aluminium, CrNi steels, copper, etc.

Robacta Reamer V Twin

Mechanical welding torch cleaner, suitable for all base materials, such as steel, aluminium, CrNi steels, copper, etc.

Robacta TC 1000 Twin

Electromagnetic welding torch cleaner for ferromagnetic base materials

NOTE! When welding the TimeTwin process using a CMT Twin system, the

"TimeTwin Digital" software needs to be enabled on both power sources.

NOTE! Pulse synchronous welding can only be performed using TimeTwin characteristics.

It is not possible with CMT Twin characteristics.

10

System components required

EN

System components required

FK 4000 R

- 2 TPS 5000 CMT

- with DSP software version

5.01.063 or higher

- 2 RCU 5000i

- with database version 908 or higher

Use 2 FK 4000 R or 1 FK 9000 for:

- hosepack lengths of up to 4.25 m

(14.76ft.)

- 100 % duty cycle (10min/40°C) at 360

A

FK 9000 R

Use 2 FK 9000 for:

- hosepack lengths from 4.25 m - 8.25 m

(14.76 ft. - 27.07 ft.)

- 100 % duty cycle (10min/40°C) at 360

A

11

VR 7000 CMT

VR 1550

- 2 VR 7000 CMT or 2 VR 1550

- 2 Robacta Drive CMT drive units with

wire buffer and hosepacks

- 1 LHSB-HUB

12

(1)

(2)

(3)

(4)

(5)

- 1 Robacta Twin Compact Pro torch

neck and mounting bracket

EN

(1) 2 inner liners

(2) 1 wrench for nozzle fitting and con-

tact tip

(3) 2 nozzle fittings

(4) 2 spatter guards

(5) 2 contact tips

(6) 1 gas nozzle

(7) 2 TCP tips

(8) 1 wrench for union nut on drive

units

(6)

(7)

(8)

- Robot interface for connecting power source to the robot control

13

Application example

Application example

(8)

(1)

(22)

(1) Connection to robot control (12) Robot

(2) Robot interface (13) Drum coil

(3) Connection to robot interface (14) Drum coil

(4) Interconnecting hosepack (15) FK 9000 R or FK 4000 R cooling

(5) VR 7000 CMT or VR 1550 (16) TPS 5000 CMT power source

(6) VR 7000 CMT or VR 1550 (17) LHSB-HUB

(7) Wire buffer (18) FK 9000 R or FK 4000 R cooling

(8) Wire buffer (19) TPS 5000 CMT power source

(9) Robacta Drive CMT drive unit (20) RCU 5000i

(10) Robacta Drive CMT drive unit (21) RCU 5000i

(11) Robacta Twin Compact Pro torch

neck

(21)

(20)

(2)

(3) (4)

(19)

(18)

(17)

(5)

(16) (14) (13)

(15)

(6)

(22) Robot control

(7)

(9)

(10)

(12)

(11)

unit

unit

14

Installation and commissioning

Safety

Safety Observe the following safety instructions for all work described in these operating instruc-

tions.

WARNING! Work that is carried out incorrectly can cause serious injury or damage. All the work described below must only be carried out by trained and qualified personnel. Do not carry out any of the work described below until you have

fully read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

WARNING! Machines that start up automatically can cause serious injury and

damage. In addition to these operating instructions, the safety rules issued by the

manufacturers of the robot and welding systems must also be observed. For your

personal safety, ensure that all protective measures have been taken and will remain in place while you are in the working area of the robot.

WARNING! Work that is carried out incorrectly can cause serious injury or damage. Before starting the work listed below:

- turn the mains switch of both power sources to the "O" position

- disconnect both power sources from the mains

- put up an easy-to-understand warning sign to stop anybody inadvertently

switching it back on again

EN

WARNING! Risk of serious injury and damage from articles being dropped. All

the screw connections described below:

- must be checked after fitting to ensure they are tight

- must be checked after unusual events (e.g. a crash) to ensure they are tight

- must be checked regularly to ensure they are tight

17

Notes regarding the installation of Fronius system

components

Installation and

commissioning of

Fronius system

components

Setup regulations

for the power

sources

NOTE! Install and commission Fronius system components (power source, wire-

feed unit, cooling unit, hosepack, RCU 5000i, LHSB-HUB, etc.) according to the

operating instructions of the relevant device.

NOTE! If the power sources are used with two FK 4000 R, ensure a minimum gap

of 1000 mm (39.07 in.) between the power sources in order to guarantee a sufficient supply of fresh air to the cooling units.

NOTE! If the power sources are used with two FK 9000 R, ensure a minimum gap

of 1000 mm (39.07 in.) between the power sources in order to guarantee a sufficient supply of fresh air to the cooling units.

1000 mm

(39.37 in.)

18

Fitting wearing parts to the torch neck

EN

Fitting wearing

parts to the torch

neck

1 2

1

3

3

2

19

Fitting the mounting bracket and torch neck

Fitting the mounting bracket to the

robot

Screw the torch

neck and drive

units to the

mounting bracket

1

1

1 2

1

2

3x M6x12

2

1

2x

M6x12

8Nm

3

3

3

20

4

4

5 6

5 6

* Only screw in loosely to begin with -

do not tighten. Only tighten the

screws once all components have

been properly aligned with each

other - step 6.

This will avoid placing the drive

units under excessive strain.

EN

21

Earth connection

Earth connection

NOTE! Each power source must have its own dedicated earthing cable routed as

shown.

Separate earthing cable Shared earthing cable, earthing socket

22

Separate earthing cable laid in a loop Earthing cable coiled

Recommendation to minimise

arc blow

NOTE! To minimise arc blow,

weld away from the earthing connections.

EN

23

Connecting the LHSB-HUB with the power sources

and wire-feed units

Connecting the

LHSB-HUB with

the power sources and wire-feed

units

Connect the lead power source to connection (1) on the LHSB-HUB

1

Connect the wire-feed unit of the lead power source to connection (2) on the LHSB-

2

HUB

Connect the trail power source to connection (3) on the LHSB-HUB

3

Connect the wire-feed unit of the trail power source to connection (4) on the LHSB-

4

HUB

Connect the LHSB-HUB to the LocalNet port on the lead power source

5

(1) (2)

(3) (4)

24

Connecting to the robot control

EN

Connecting to the

robot control

Robot interfaces

for CMT Twin

Use one of the following configurations to connect the welding system to the robot con-

1

trol.

Refer to the operating instructions for the respective interface for instructions on connecting the welding system to the robot control.

There are two special robot interfaces for CMT Twin available for connecting to the robot

control:

- Twin Standard I/O Job (0-24 V digital)

- Twin Standard I/O Synergic / Job (0-24 V digital, 0-10 V analogue)

Each of these "Twin interfaces" features an integral programmable logic controller (PLC).

The signals are connected logically by the PLC. Both power sources are therefore triggered simultaneously by a signal from the robot control. Only one "Twin interface" is required for two power sources. The "Twin interface" in installed in the switch cabinet.

Example setup:

No. Part/device No. Part/device

(1) LocalNet connection (5) Twin interface

(2) LocalNet connection (6) Connection to robot control

(3) Power source (7) Robot control

(4) Power source

Standard robot

interfaces

(1)

(2)

(3)

(4)

(5)

(6)

(7)

The following standard robot interfaces can be used to connect to the robot control for Twin

processes:

- ROB 3000 (0-24 V digital)

- ROB 4000 (0-24 V digital, 0-10 V analogue)

- ROB 5000 (0-24 V digital, 0-10 V analogue)

Signals must be connected logically by the robot control when standard robot interfaces

are used. Two identical robot interfaces are required for two power sources. The two standard robot interfaces are installed in the switch cabinet. Robot interfaces "1" and "2" are connected to power sources "1" and "2" via LocalNet.

25

Application example:

No. Part/device No. Part/device

(1) Standard interface (5) Power source

(2) Standard interface (6) Power source

(3) LocalNet connection (7) Connection to robot control

(4) LocalNet connection (8) Robot control

Twin fieldbus

systems

(1) (3)

(2) (4)

(6)

(8)

The following Twin fieldbus systems can be used to connect to the robot control for Twin

processes:

- Twin DeviceNet fieldbus robot interface

- Twin CANopen fieldbus robot interface

- Twin Interbus CU fieldbus robot interface

- Twin Profibus fieldbus robot interface

An integral PLC is also a feature of the "Twin fieldbus systems" as well as the "Twin interfaces". The signals are connected logically by this PLC. Both power sources are therefore

triggered simultaneously by a signal from the robot control. Only one "Twin fieldbus system" is required for two power sources. The "Twin fieldbus system" is fitted to one of the

power sources. The connection to the second power source is established via LocalNet

and the connection to the robot control via the fieldbus.

(5)

(7)

26

Application example:

No. Part/device No. Part/device

(1) Robot control (5) Power source

(2) Fieldbus connection (6) LHSB-HUB

(3) Twin fieldbus system (7) Power source

(4) LocalNet connection

(1)

(2) (3) (4)

EN

(5)(7) (6)

Standard fieldbus

systems

The following standard fieldbus systems can be used to connect to the robot control for

Twin processes:

- DeviceNet fieldbus robot interface

- CanOpen fieldbus robot interface

- Interbus CU fieldbus robot interface

- Interbus LWL fieldbus robot interface

- Profibus 1.5 MB fieldbus robot interface

Signals must be connected logically by the robot control when standard fieldbus systems

are used. Two identical standard fieldbus systems are required for two power sources. The

two standard fieldbus systems are fitted to the power sources. The robot control is connected to the power sources via the fieldbus.

Application example:

No. Part/device No. Part/device

(1) Fieldbus connection (5) Power source

(2) Standard fieldbus system (6) LHSB-HUB

(3) Fieldbus connection (7) Power source

(4) Standard fieldbus system (8) Robot control

(1) (2) (3) (4)

(5)(7) (6)(8)

27

Description of

signal statuses

NOTE! During twin-wire welding (CMT Twin), the signal statuses have no influ-

ence on which power source operates as the lead or trail power source.

This is decided by the characteristic selection on the RCU 5000i.

Description of "Twin master selection" signal statuses

Power source 1 Power source 2 Effect

0 0 Power source 1 welds,

power source 2 is inactive

1 0 Both power sources weld

0 1 Both power sources weld

1 1 Power source 2 welds,

power source 1 is inactive

28

Check compatibility of power sources and remote

controls

Safety

EN

WARNING! If the equipment is used or tasks are carried out incorrectly, serious

injury or damage may result. All the work described below must only be carried

out by trained and qualified personnel. Do not carry out any of the work described

below until you have fully read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

CAUTION! The power sources must be switched on for the following work. This

poses a risk of injury and material damage due to:

- welding current

- unintentional ignition of an arc

- emerging wire electrodes

Until all work is completed, ensure that:

- welding is not initiated by any power source

- the wire electrodes are not fed out

Checking power

source compatibility

Checking the

RCU 5000i database version

NOTE! Check the compatibility of both power sources.

Open "Machine pre-sets" on the RCU

1

5000i menu

Select the "Version" screen

2

Check that the power source DSP soft-

3

ware version is 5.01.063 or higher

- If not, the power source cannot be

used for CMT Twin applications

NOTE! Check the database version of both RCU 5000i devices.

29

Open "Machine pre-sets" on the RCU

1

5000i menu

Select the "Version" screen

2

Check that the RCU 5000i database

3

version is DB 0908 or higher

If not, update the RCU 5000i firmware

4

30

Checking the characteristics version

EN

Safety

Checking the

characteristics

version

WARNING! If the equipment is used or tasks are carried out incorrectly, serious

injury or damage may result. All the work described below must only be carried

out by trained and qualified personnel. Do not carry out any of the work described

below until you have fully read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

CAUTION! The power sources must be switched on for the following work. This

poses a risk of injury and material damage due to:

- welding current

- unintentional ignition of an arc

- emerging wire electrodes

Until all work is completed, ensure that:

- welding is not initiated by any power source

- the wire electrodes are not fed out

NOTE! The welding start-up configured for CMT Twin is only available with characteristics version V2.9.4. Check the characteristics version to ensure that the

welding start-up configured for CMT Twin is available for the respective welding

system.

Use the adjusting dial to select "MIG/

1

MAG synergic welding" from the RCU

5000i menu

Press the OK button

2

31

- The last "Data" screen called up appears

In the relevant "Data" screen, press F4

3

"Filler metal"

- The 1st screen in the wizard appe-

ars ("Select a filler metal")

Apply the desired CMT Twin settings

4

depending on the application

- The "Welding program" screen is displayed again once the relevant settings

have been made

Check that characteristics version

5

V2.9.4 or higher is displayed

If not, update the RCU 5000i firmware

6

32

L/R alignment - aligning welding circuit inductivity

and welding circuit resistance

Safety

WARNING! If the equipment is used or tasks are carried out incorrectly, serious

injury or damage may result. All the work described below must only be carried

out by trained and qualified personnel. Do not carry out any of the work described

below until you have fully read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

CAUTION! The power sources must be switched on for the following work. This

poses a risk of injury and material damage due to:

- welding current

- unintentional ignition of an arc

- emerging wire electrodes

Until all work is completed, ensure that:

- welding is not initiated by any power source

- the wire electrodes are not fed out

EN

L/R alignment using RCU 5000i

NOTE! Optimum welding results are only achieved up to a welding circuit induc-

tivity of 30 μH (at a mains voltage of 400 V). Welding circuit inductivity in excess

of 30 μH must be reduced.

The following measures may be taken to reduce welding circuit inductivity:

- Keep the torch hosepack, interconnecting hosepack and earthing cable as

short as possible

- Lay the torch hosepack, interconnecting hosepack and earthing cable parallel to each other

Open "Machine pre-sets" on the RCU

1

5000i menu

Select the "MIG/MAG" screen

2

Press F4 "L/R alignment"

3

Machine pre-sets: e.g. "MIG/MAG" screen

33

"Actual values" screen

- The 1st screen in the wizard appears

("Actual values")

Press F2 "Forward"

4

- The 2nd screen in the wizard appears

("Preparations")

Follow the instructions given in the

5

"Preparations" screen

NOTE! The contact between the

earthing clamp and workpiece

must take place on a cleaned

workpiece surface.

"Preparations" screen

"L/R alignment" screen

Press F2 "Forward":

6

- LR alignment is started, the 3rd screen

in the wizard appears ("L/R alignment")

34

"Confirmation" screen

- Once the L/R alignment is complete,

the values obtained for welding circuit

resistance (R) and inductivity (L) appear in the 4th screen of the wizard

("Confirmation").

Press F2 "Done"

7

- The last "Data" screen called up appears.

EN

Machine pre-sets: e.g. "MIG/MAG" screen

35

Welding start-up

Welding start-up

sequence

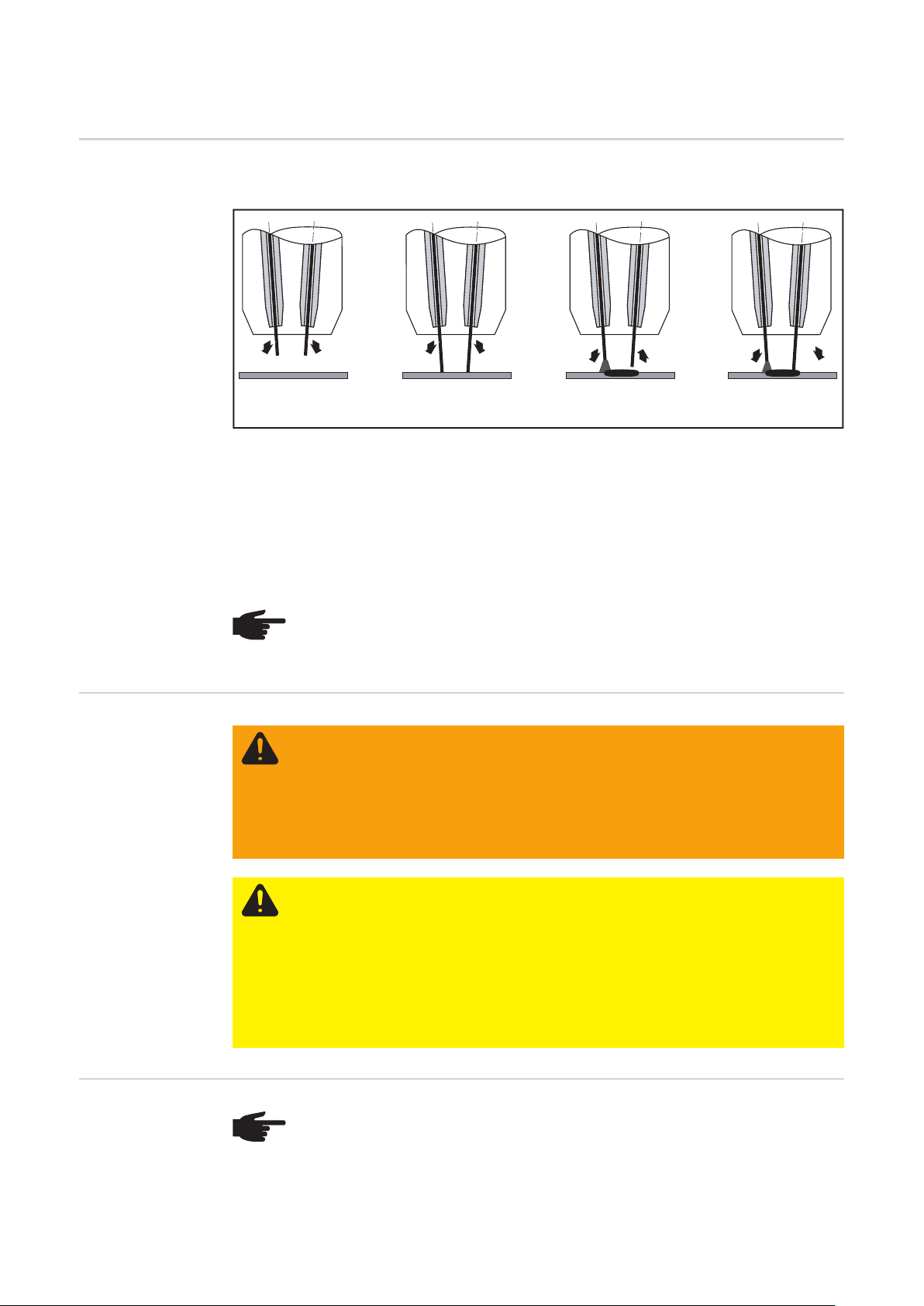

The welding start-up sequence for CMT Twin is as follows:

1. 2. 3. 4.

Welding start-up sequence

1. Both wire electrodes move towards the workpiece

2. Both wire electrodes touch the workpiece

3. The lead wire electrode commences the welding process, while the trail wire electrode

moves away from the workpiece and waits for the start signal from the lead wire electrode = welding start delay

4. Once the trail wire electrode receives the start signal, it then also starts the welding

process

NOTE! The welding start-up configured for CMT Twin is only available with characteristics version V2.9.4. Refer to the "Checking the characteristics version" section for instructions on how to check the characteristics version.

Safety

Welding start-up

settings

WARNING! If the equipment is used or tasks are carried out incorrectly, serious

injury or damage may result. All the work described below must only be carried

out by trained and qualified personnel. Do not carry out any of the work described

below until you have fully read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

CAUTION! The power sources must be switched on for the following work. This

poses a risk of injury and material damage due to:

- welding current

- unintentional ignition of an arc

- emerging wire electrodes

Until all work is completed, ensure that:

- welding is not initiated by any power source

- the wire electrodes are not fed out

NOTE! When welding using two processes (one pulse wire electrode, one CMT

wire electrode), the welding process begins with the wire electrode performing the

pulse process.

36

NOTE! If both wire electrodes are to weld with the CMT process, then the following must be selected for each wire electrode in the "Filler metal/Select a shielding

gas" menu on the RCU 5000i:

- which wire electrode is the lead electrode (wire electrode 1)

- which wire electrode is the trail electrode (wire electrode 2)

EN

Start delay parameter correction

The "Start delay" parameter is corrected to

delay welding from the trail electrode until

the lead electrode has melted the material.

The trail electrode therefore welds in the

weld pool and not on the solid material, delivering an optimum start to the weld seam.

Setting range: 0 - 5 (0 - 2.5 seconds)

37

Pulse/CMT welding

Process description pulse/CMT

welding

Properties of lead wire electrode (pulse):

- deep fusion penetration

- high deposition rate

Properties of trail wire electrode (CMT):

- extremely good filling of the weld seam

- improved process stability

Symbol Explanation

Trail wire electrode (CMT)

Lead wire electrode (pulse)

Weld pool

Pulsed arc with droplet transfer

Start of arc burn phase

Droplet melting phase

Droplet detachment

Welding direction

38

NOTE! The pulse/CMT combination may be used in both welding directions.

CMT/CMT welding

EN

Process description CMT/CMT

welding

NOTE! Different characteristics are used for each wire electrode in this process

variant.

Properties of lead wire electrode (CMT):

- shorter arc than the trail wire electrode

- higher arc power than the trail wire electrode

- starts the welding process

Properties of trail wire electrode (CMT):

- arc tuned to the weld pool

Symbol Explanation

Trail wire electrode (CMT)

Lead wire electrode (CMT)

Weld pool

Droplet melting phase

Start of arc burn phase

Droplet detachment

Welding direction

NOTE! The CMT/CMT combination may be used in both welding directions.

39

Single-wire welding

Special features

and advantages

Material transfer

A signal is emitted from the robot control that triggers welding from one power source only

(single-wire welding). Depending on the position of the torch neck or the out-of-position

weld seam, single-wire welding can be performed from either the lead or trail power

source. The second power source is paused.

NOTE! If using FK 4000 R cooling units, both units must be switched to continuous operation in order to perform single-wire welding:

Parameter C-C (Cooling unit Control) = "On" on power source "1" and power

source "2".

NOTE! To ensure a full gas shield during single-wire welding, the solenoid valve

on the paused power source must be open.

In systems using Twin interfaces, the solenoid valve is actuated from the robot

control. For standard interfaces and fieldbus systems, the solenoid valve must be

actuated directly.

Pulse/standard

Symbol

Trail wire electrode

Lead wire electrode

Pulsed arc with droplet transfer

Standard arc

I

L

I

T

Welding current of lead power source

Welding current of trail power source

Welding direction

I (A)

I

L

t (s)

IT = 0

Pulse (single-wire, lead power source): Welding current/time curve and schematic representation of the

material transfer

I (A)

I

L

t (s)

IT = 0

Standard (single-wire, lead power source): Welding

current/time curve and schematic representation of

the material transfer

40

I (A)

I (A)

I

T

t (s)

IL = 0

Pulse (single-wire, trail power source): Welding current/time curve and schematic representation of the

material transfer

Symbol

Trail wire electrode

Lead wire electrode

Weld pool

Droplet melting phase

Start of arc burn phase

I

T

IL = 0

Standard (single-wire, trail power source): Welding

current/time curve and schematic representation of

the material transfer

CMT

EN

t (s)

Droplet detachment

I

L

I

T

Welding current of lead power source

Welding current of trail power source

Welding direction

I (A)

I

L

t (s)

IT = 0

CMT (single wire, lead power source): Welding current/time curve and schematic representation of the

material transfer

I (A)

I

T

t (s)

IL = 0

CMT (single-wire, trail power source): Welding current/time curve and schematic representation of the

material transfer

41

Applying the 'HD' ('Heavy Duty') configuration

Available characteristics

Description of

characteristics

Characteristic

number

1474 Pulse G3Si1 1.2 M21 Ar+18% CO

1476 CMT G3Si1 1.2 M21 Ar+18% CO

1477 CMT G3Si1 1.2 C1 100% CO2 Lead

1478 CMT G3Si1 1.2 C1 100% CO2 Trail

Characteristic number

Welding process

1474 PulseFillet weld

1476 CMT Fillet weld

1477 CMT Fillet weld

1478 CMT Fillet weld

Welding process

thick-gauge sheet

thick-gauge sheet

light-gauge sheet/thick-gauge

sheet

light-gauge sheet/thick-gauge

sheet

Material Wire di-

Weld seam profile

Shielding gas

ameter

Characteristic

High frequency pulsed arc; short

arc length; optimised for fillet

welds

CMT arc length with greater arc

proportion; optimised for better

weld seam formation on thickgauge sheets

Lead CMT characteristic; starts

welding first; higher arc power; for

welding with 100% CO2, optimised for fillet welds

Trail CMT characteristic; arc burn

time modified for improved weld

seam formation when welding

with 100% CO

2

2

2

Combination

of characteristics

1474

Lead

with

1476

Trail

1477

Lead

with

1478

Trail

Configuring the

system

42

WARNING! If the equipment is used or tasks are carried out incorrectly, serious

injury or damage may result. All the work described below must only be carried

out by trained and qualified personnel. Do not carry out any of the work described

below until you have fully read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

Ensure that the wearing parts from the "HD" original equipment kit have been fitted

1

CAUTION! The power sources must be switched on for the following work. This

poses a risk of injury and material damage due to:

- welding current

- unintentional ignition of an arc

- emerging wire electrodes

Until all work is completed, ensure that:

- welding is not initiated by any power source

- the wire electrodes are not fed out

NOTE! The work described below is performed on both power sources using the

RCU 5000i.

Use the adjusting dial to select "MIG/

2

MAG synergic welding" from the RCU

5000i menu

Press the OK button

3

EN

- The last "Data" screen called up appears

43

In the relevant "Data" screen, press F4

4

"Filler metal"

- The 1st screen in the wizard appe-

ars ("Select a filler metal")

Depending on the application, apply

5

the settings for both power sources on

both RCU 5000i devices

NOTE! If both wire electrodes are to weld using the CMT process, then the following must be selected for each wire electrode (each power source) on the RCU

5000i:

- which wire electrode is the lead electrode

- which wire electrode is the trail electrode

Refer to the "Welding start-up" section for further details.

Stick out

Lead

Trail

9,5 mm

(0.37 in.)

Stick out and distance of the wire electrodes

=

1

17 mm (0.67 in.)

Stickout s

44

Use 'Speed' configuration

EN

Available characteristics

Description of

characteristics

Characteristic

number

1470 Pulse G3Si1 1.0 M21 Ar+18% CO

1471 CMT G3Si1 1.0 M21 Ar+18% CO

1472 Pulse G3Si1 1.2 M21 Ar+18% CO

1473 CMT G3Si1 1.2 M21 Ar+18% CO

1479 CMT G3Si1 1.2 M21 Ar+18% CO

Welding process

Material Wire di-

ameter

Shielding gas

2

2

2

2

2

1500 CMT G3Si1 1.2 C1 100% CO2 Lead

1501 CMT G3Si1 1.2 C1 100% CO2 Trail

1510 Pulse AlMg5 1.2 I1 100% Argon

1511 CMT AlMg5 1.2 I1 100% Argon

1522 Pulse AlMg5 1.6 I1 100% Argon

1523 CMT AlMg5 1.6 I1 100% Argon

Characteristic number

Welding process

1470 PulseLap joint, fillet weld

light-gauge sheet

1471 CMT Lap joint, fillet weld

light-gauge sheet

1472 PulseLap joint, fillet weld

light-gauge sheet

1473 CMT Lap joint

light-gauge sheet

1479 CMT Fillet weld

light-gauge sheet

1500 CMT Lap joint

light-gauge sheet

1501 CMT Lap joint

light-gauge sheet

Weld seam profile

Characteristic

High frequency pulsed arc; arc

length kept short; optimised for

high welding speeds

CMT arc length extremely short;

arc burn phase adjusted to prevent notches

High frequency pulsed arc; arc

length kept short

CMT arc length extremely short;

arc burn phase adjusted to prevent notches

Longer CMT arc to achieve a wider seam formation for fillet welds

Lead CMT characteristic; starts

welding first; higher arc power; for

welding with 100% CO

2

Trail CMT characteristic; extremely short CMT arc length; arc burn

phase adjusted to prevent notches; welding with 100% CO

2

Combination

of characteristics

1470

Lead

with

1471

Trail

1472

Lead

with

1473

Trail

or

1479

Trail

1500

Lead

with

1501

Trail

45

Characteristic number

Welding process

1510 PulseLap joint, fillet weld

light-gauge sheet

1511 CMT Lap joint, fillet weld

light-gauge sheet

1522 PulseFillet weld High frequency pulsed arc; arc

1523 CMT Fillet weld CMT arc; higher current in the

Weld seam profile

Characteristic

High frequency pulsed arc; arc

length kept short; optimised for

high welding speeds and aluminium

CMT arc; higher current in the

arc-on phase; optimised for aluminium

length kept short; optimised for

high welding speeds and aluminium, wire diameter 1.6 mm

arc-on phase; optimised for aluminium, wire diameter 1.6 mm

Combination

of characteristics

1510

Lead

with

1511

Trail

1522

Lead

with

1523

Trail

Configuring the

system

WARNING! If the equipment is used or tasks are carried out incorrectly, serious

injury or damage may result. All the work described below must only be carried

out by trained and qualified personnel. Do not carry out any of the work described

below until you have fully read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

Ensure that the wearing parts from the "Speed" original equipment kit have been fitted

1

CAUTION! The power sources must be switched on for the following work. This

poses a risk of injury and material damage due to:

- welding current

- unintentional ignition of an arc

- emerging wire electrodes

Until all work is completed, ensure that:

- welding is not initiated by any power source

- the wire electrodes are not fed out

NOTE! The work described below is performed on both power sources using the

RCU 5000i.

46

Use the adjusting dial to select "MIG/

2

MAG synergic welding" from the RCU

5000i menu

Press the OK button

3

- The last "Data" screen called up appears

EN

In the relevant "Data" screen, press F4

4

"Filler metal"

- The 1st screen in the wizard appe-

ars ("Select a filler metal")

Depending on the application, apply

5

the settings for both power sources on

both RCU 5000i devices

NOTE! If both wire electrodes are to weld using the CMT process, then the following must be selected for each wire electrode (each power source) on the RCU

5000i:

- which wire electrode is the lead electrode

- which wire electrode is the trail electrode

Refer to the "Welding start-up" section for further details.

47

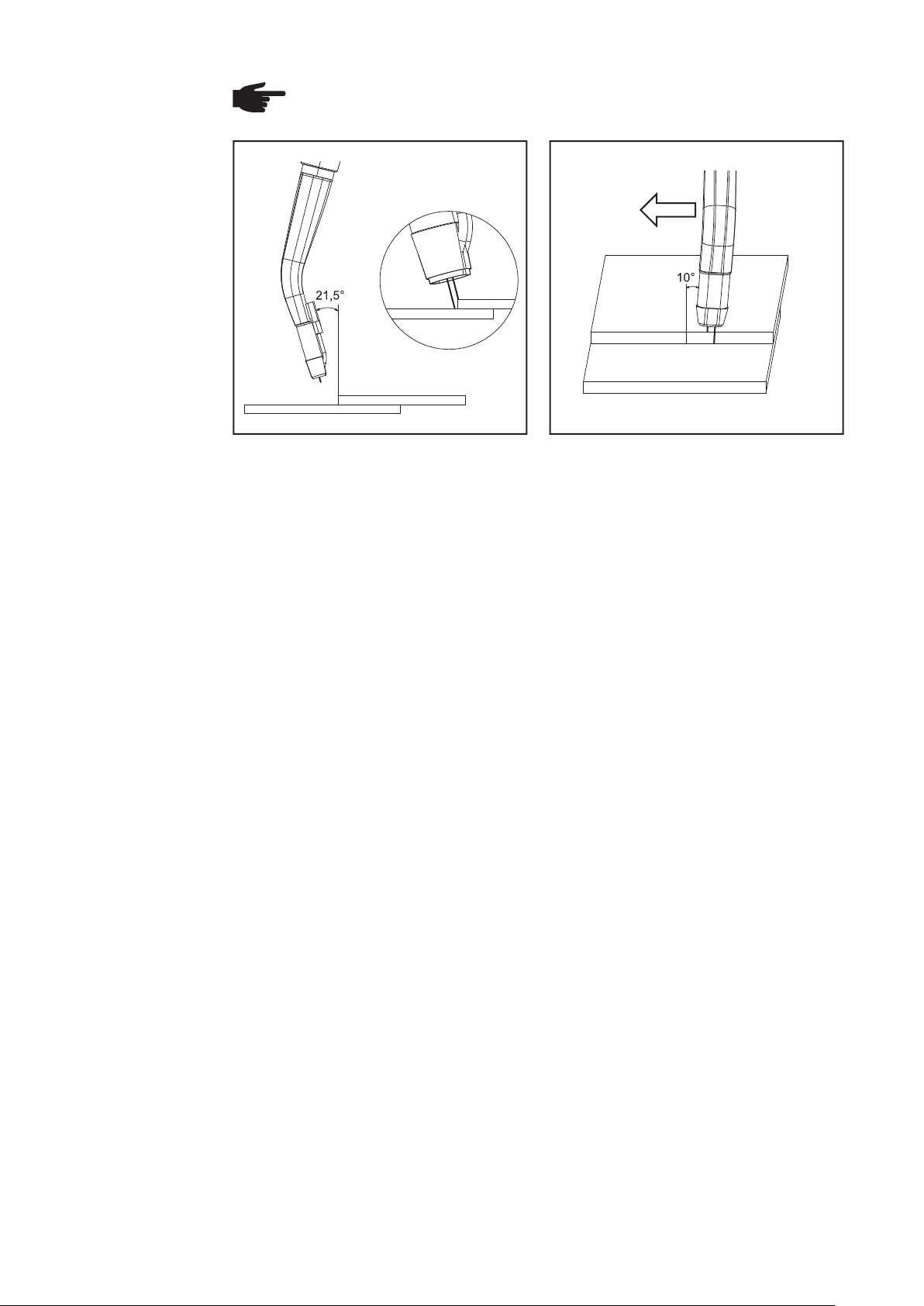

Stick out

Lead

Trail

10 mm

(0.39 in.)

Stick out and distance of the wire electrodes

=

1

15 mm (0.59 in.)

Stickout s

48

Use 'Root' configuration

EN

Available characteristics

Description of

characteristics

Characteristic number

1524 Pulse G3Si1 1.2 M21 Ar+18% CO

1525 CMT G3Si1 1.2 M21 Ar+18% CO2 Lead

1526 CMT G3Si1 1.2 M21 Ar+18% CO2 Trail

Characteristic number

1524 PulseRoot pass Pulsed arc; optimised for root

1525 CMT Root pass Lead CMT characteristic; CMT

1526 CMT Root pass Trail CMT characteristic; CMT arc

Welding process

Welding process

Material Wire di-

ameter

Weld seam profile

pass

arc with greater arc proportion

with less arc pressure on the weld

pool

Shielding gas

2

Characteristic

Combination

of characteristics

1524

Lead

with

1525

Trail or

1526

Trail

1525

Lead

with

1526

Trail

Configuring the

system

WARNING! If the equipment is used or tasks are carried out incorrectly, serious

injury or damage may result. All the work described below must only be carried

out by trained and qualified personnel. Do not carry out any of the work described

below until you have fully read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

Ensure that the wearing parts from the "HD" original equipment kit have been fitted

1

CAUTION! The power sources must be switched on for the following work. This

poses a risk of injury and material damage due to:

- welding current

- unintentional ignition of an arc

- emerging wire electrodes

Until all work is completed, ensure that:

- welding is not initiated by any power source

- the wire electrodes are not fed out

49

NOTE! The work described below is performed on both power sources using the

RCU 5000i.

Use the adjusting dial to select "MIG/

2

MAG synergic welding" from the RCU

5000i menu

Press the OK button

3

- The last "Data" screen called up appears

In the relevant "Data" screen, press F4

4

"Filler metal"

- The 1st screen in the wizard appe-

ars ("Select a filler metal")

Depending on the application, apply

5

the settings for both power sources on

both RCU 5000i devices

NOTE! If both wire electrodes are to weld using the CMT process, then the following must be selected for each wire electrode (each power source) on the RCU

5000i:

- which wire electrode is the lead electrode

- which wire electrode is the trail electrode

Refer to the "Welding start-up" section for further details.

50

Standard welding parameter values for fillet welds

EN

Standard welding

parameter values

for fillet welds

NOTE! The following specifications are standard values determined under labo-

ratory conditions.

Filler metal and welding position:

Shielding gas: M21 Ar+18% CO2, 2 x 12 l/min

Wire electrode: G3Si1, 1.2 mm

Welding position: PB

Sheet thickness (mm)

a dimension (mm)

Wire electrode /

welding process

Lead /

Pulse

3 2.8

Trail /

CMT

Wire feed speed

(m/min)

Current

(A)

Voltage

(V)

Characteristics

used

16 420 28.0 1472*

10 275 19.0 1479*

Welding speed

3 2.7 13.3

(m/min)

Energy input

(kJ/cm)

Deposition rate

(kg/h)

Micrograph

43

6 3.5

84

10 5

12 6

Lead /

Pulse

Trail /

CMT

Lead /

Pulse

Trail /

CMT

Lead /

Pulse

Trail /

CMT

Lead /

Pulse

Trail /

CMT

Lead /

Pulse

Trail /

CMT

16 420 28.0 1472*

2.5 3.2 13.3

10 275 19.0 1479*

15.5 410 28.0 1474**

1.8 4.3 13

10 280 19.0 1476**

15.5 415 27.5 1474**

1.5 5 12.5

9 225 19.0 1476**

15 380 27.0 1474**

1 6.9 12.3

9 220 18.5 1476**

15 390 28.0 1472***

0.6 6.9 11.7

8 215 17.0 1479***

* 'Speed' configuration used

51

** 'HD' configuration used

*** 'HD' configuration wearing parts, characteristics from 'Speed' configuration used -

the characteristics from the Speed configuration were used to prevent an undesired "run-off" of the weld pool

Alignment of

welding torch relative to the workpiece

(1)

45°

(2)

Side view of welding torch/workpiece

- Welding torch (1) at a 45° angle to the

workpiece (2)

- Welding torch (1) at a 5° angle to the

welding direction

- both wire electrodes parallel to the welding direction

52

Standard welding parameter values for lap joints

EN

Standard welding

parameter values

for lap joints

NOTE! The following specifications are standard values determined under labo-

ratory conditions.

Filler metal and welding position:

Shielding gas: M21 Ar+18% CO2, 2 x 12 l/min

Wire electrode: G3Si1, 1.2 mm

Welding position: PB

Sheet thickness (mm)

Wire electrode

Lead 15 370 28.0 1472*

2

Trail 6 210 14.0 1473*

Wire feed speed

(m/min)

Current

(A)

Voltage

(V)

Characteristics

used

Welding speed

(m/min)

3.6 3.7 11.2

Energy input

(kJ/cm)

Deposition rate

(kg/h)

Micrograph

Alignment of

welding torch relative to the workpiece

Lead 15.5 390 28.5 1472*

3

Trail 6.5 225 15.0 1473*

* 'Speed' configuration used

(1)

35°

(2)

3 4 11.7

- Welding torch (1) at a 35° angle to the

workpiece (2)

- Welding torch (1) at a 5° angle to the

welding direction

- both wire electrodes parallel to the welding direction

Side view of welding torch/workpiece

53

NOTE! If notches appear in the weld seam on the top sheet, adopting the welding

torch alignment shown below can prevent these notches from occurring.

54

Prerequisities for welding

EN

Safety

Prerequisities for

welding

WARNING! Incorrect operation or shoddy workmanship can cause serious injury

or damage. All the work described below must only be carried out by trained and

qualified personnel. Do not carry out any of the work described below until you

have fully read and understood the following documents:

- these operating instructions

- all the operating instructions for the system components, especially the safety rules

Prerequisities for CMT Twin welding:

- wearing parts fitted to the torch neck

- all system components fitted and installed properly

- compatibility of power sources and remote control systems confirmed

- characteristics version checked

- L/R alignment - welding circuit inductivity and welding circuit resistance aligned

- welding system connected to robot control

- welding system configured in line with the application

55

FRONIUS INTERNATIONAL GMBH

Froniusplatz 1, A-4600 Wels, Austria

Tel: +43 (0)7242 241-0, Fax: +43 (0)7242 241-3940

E-Mail: sales@fronius.com

www.fronius.com

www.fronius.com/addresses

Under http://www.fronius.com/addresses you will find all addresses

of our Sales & service partners and Locations

Loading...

Loading...