/ Perfect Welding / Solar Energy / Perfect Charging

/ Perfect Welding / Solar Energy / Perfect Charging

PMC

CMT

PULSE MULTI CONTROL

COLD METAL TRANSFER

TOTALLY STABLE WELDING

/ 2

WELD LIGHT-GAGE SHEETS AT

MAXIMUM SPEED–WITH MINIMAL

HEAT INPUT AND VIRTUALLY

NO SPATTER

CMT (COLD METAL TRANSFER) has revolutionized welding

technology. Thanks to its PRECISE WIRE RETRACTION, the process

considerably increases the number of possible welding applications.

Wherever adhesive or solder was used before,

CMT welding can now be used instead.

The back and forth movement (reversing) of the welding wire–at up to 170 Hertz–produces an exceptionally stable

arc. This results in a 33% reduction in heat input and a welding speed almost twice as fast as the conventional dip

transfer arc.

What’s your

welding challenge?

Let's get connected.

THE ADVANTAGES OF CMT

/ 3

REDUCTION

IN REWORK

100%

HIGHER SPEED

STABLE

ARC

ICON

/ 99% less spatter*

/ 33% lower heat input reduces

distortion

/ Perfect ignition (SFI)

/ High speed but the same penetration

/ Fast joining of thin sheets

/ 100% CO2 welding

/ High-strength steels

/ Resistant to external inuences (change in stick out,

workpiece surface)*

GREEN

THINKING

ECONOMICAL AND SUSTAINABLE

RESOURCECONSERVING

This precisely controlled process

reduces spatter, and therefore rework,

which lets employees work more

eciently.

MATERIAL

SAVINGS

CMT considerably reduces the

consumption of wearing parts and the

number of component rejects, which

translates directly into greater savings

potential.

*/ Under laboratory conditions.

ENERGYSAVING

A stable, precisely controlled arc

improves weld quality. This shortens the

overall time necessary for welding tasks,

resulting in lower energy consumption

overall.

/ 4

CMT

WELDING

PROCESS

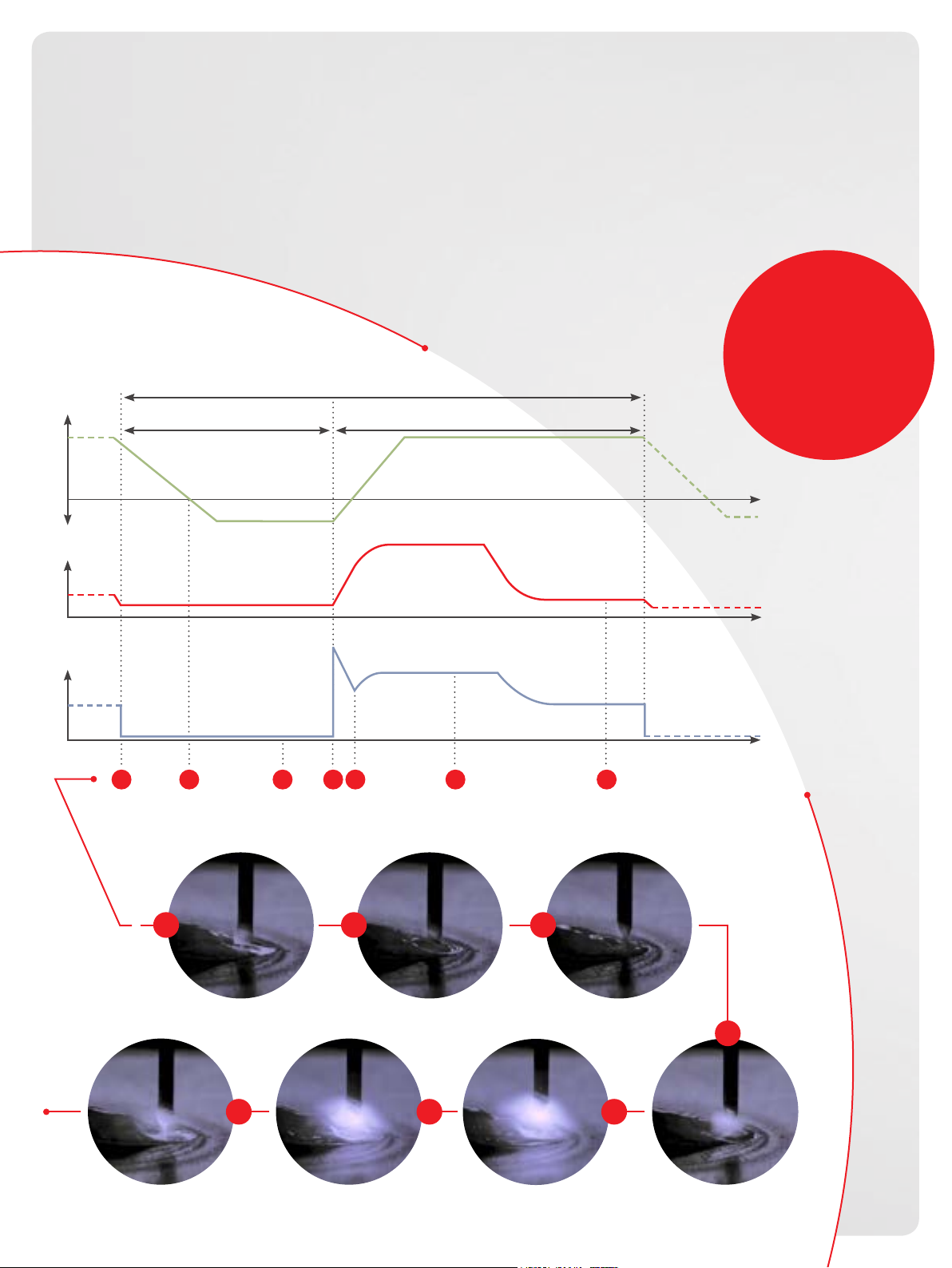

THE CMT PROCESS IS

BASED ON THE MOST

ADVANCED TYPE OF

DROPLET DETACHMENT.

MADE POSSIBLE

BYREVERSIBLE WIRE

ELECTRODE MOTION.

In a conventional dip transfer arc process,

the wire is advanced continuously towards

the workpiece. If a short circuit occurs, the

current is increased, which breaks the

short circuit so the arc can ignite again.

However, in the event of a short circuit

while using the CMT process, the reverse

motion of the wire electrode produces a

more controlled droplet detachment and

reignition. This reversing wire motion takes

place in a frequency range of 50 to 170 Hz,

depending on the filler metal, shielding

gas and electrode diameter.

IDEAL

FOR ALL

POSITIONS

/ 5

Dip transfer arc

Pulsed arc

High performance arc

Spray arcCMT arc Intermediate arc

APPLICATIONS

/ Joint welding (CrNi applications, food industry)

/ Overlay welding

/ Rapid prototyping & additive manufacturing

/ Brazing, specifically with high demands for

speed and process stability

/ 100% CO

/ Root passes

/ Thin and medium sheet range

/ Special joints, e.g., copper, steel aluminum,

titanium

welding on steel

2

/ 6

THE

SPECIAL FEATURES

OF CMT

v4 [m/min]

Short circuit phase Arc phase

CMT cycle time

With its revolutionary reversible wire

motion, CMT oers a wide range of

advantages, enabling cost-eective and

sustainable welding that reduces re-

work and minimizes welding defects.

THE ESSENCE

OF CMT

/ FAST

/ VIRTUALLY

SPATTER-FREE

/ COLD

t [s]

I [A]

U [V]

/1

t [s]

t [s]

41 2 6 73 5

1

2 3

/ *In comparison with TPS pulsed arc. **In comparison with standard dip transfer arc

4

567

Loading...

Loading...