Page 1

Operating

Instructions

RI FB PRO/i TWIN Controller

RI MOD/i CC Ethernet/IP-2P TWIN FANUC

DE

EN-US

JA

Bedienungsanleitung

Operating instructions

操作手順

42,0410,2650 005-03022023

Page 2

Page 3

Inhaltsverzeichnis

Allgemeines 4

Sicherheit 4

Anschlüsse und Anzeigen 4

Eigenschaften der Datenübertragung 5

Konfigurationsparameter 6

Voraussetzungen für den Betrieb des Busmodules 6

IP-Adresse des Busmoduls einstellen 7

IP-Adresse des Busmoduls einstellen 7

Ein- und Ausgangssignale 9

Datentypen 9

Verfügbarkeit der Eingangssignale 9

Eingangssignale (vom Roboter zur Stromquelle) 9

Wertebereich Working mode 20

Wertebereich Processline selection 20

Wertebereich Operating mode TWIN System 20

Wertebereich Documentation mode 21

Wertebereich Process controlled correction 21

Wertebereich Command value selection 21

WertebereichPulse synchronization ratio 21

Verfügbarkeit der Ausgangssignale 22

Ausgangssignale (von der Stromquelle zum Roboter) 22

Zuordnung Sensorstatus 1-4 29

Wertebereich Safety status 29

TAG-Tabelle 29

DE

3

Page 4

Allgemeines

1234567

8

Sicherheit

WARNUNG!

Gefahr durch Fehlbedienung und fehlerhaft durchgeführte Arbeiten.

Schwere Personen- und Sachschäden können die Folge sein.

Alle in diesem Dokument beschriebenen Arbeiten und Funktionen dürfen

▶

nur von technisch geschultem Fachpersonal ausgeführt werden.

Dieses Dokument vollständig lesen und verstehen.

▶

Sämtliche Sicherheitsvorschriften und Benutzerdokumentationen dieses

▶

Gerätes und aller Systemkomponenten lesen und verstehen.

WARNUNG!

Gefahr durch elektrischen Strom.

Schwere Personen- und Sachschäden können die Folge sein.

Vor Beginn der Arbeiten alle beteiligten Geräte und Komponenten ausschal-

▶

ten und vom Stromnetz trennen.

Alle beteiligten Geräte und Komponenten gegen Wiedereinschalten sichern.

▶

WARNUNG!

Gefahr durch unplanmäßige Signalübertragung.

Schwere Personen- und Sachschäden können die Folge sein.

Über das Interface keine sicherheitsrelevanten Signale übertragen.

▶

Anschlüsse und

Anzeigen

1 TX+

2 TX-

3 RX+

6 RX-

4,5,7,8Normalerweise nicht ver-

wendet; um die Signalvollständigkeit sicherzustellen, sind diese Pins miteinander verbunden und enden

über einen Filterkreis am

Schutzleiter (PE).

Pin-Belegung RJ 45 ProfiNet Anschluss

4

Page 5

(1) LED MS - Modulstatus

Aus:

keine Versorgungsspannung

Leuchtet grün:

gesteuert durch einen Master

Blinkt grün (einmal):

Master nicht konfiguriert oder im

Ruhezustand

Leuchtet rot:

Hauptfehler (Ausnahmezustand,

schwerer Fehler, ...)

Blinkt rot:

behebbarer Fehler

(2) LED NS - Netzwerkstatus

Aus:

keine Versorgungsspannung oder

keine IP-Adresse

Leuchtet grün:

Online; eine oder mehrere Verbindungen hergestellt (CIP Kategorie 1

oder 3)

DE

Eigenschaften

der Datenübertragung

Blinkt grün:

Online; keine Verbindung hergestellt

Leuchtet rot:

doppelte IP-Adresse, schwerer Fehler

Blinkt rot:

Zeitüberlauf bei einer oder mehreren Verbindungen (CIP Kategorie 1

oder 3)

Übertragungstechnik

Ethernet

Medium

Bei der Auswahl der Kabel und Stecker ist die ODVA Empfehlung für die Planung und Installation vonEtherNet/IP Systemen zu beachten.

Seitens Hersteller wurden die EMV-Tests mit dem Kabel IE-C5ES8VG0030M40M40-F durchgeführt.

Übertragungs-Geschwindigkeit

10 Mbit/s or 100 Mbit/s

Busanschluss

RJ-45 Ethernet / M12

5

Page 6

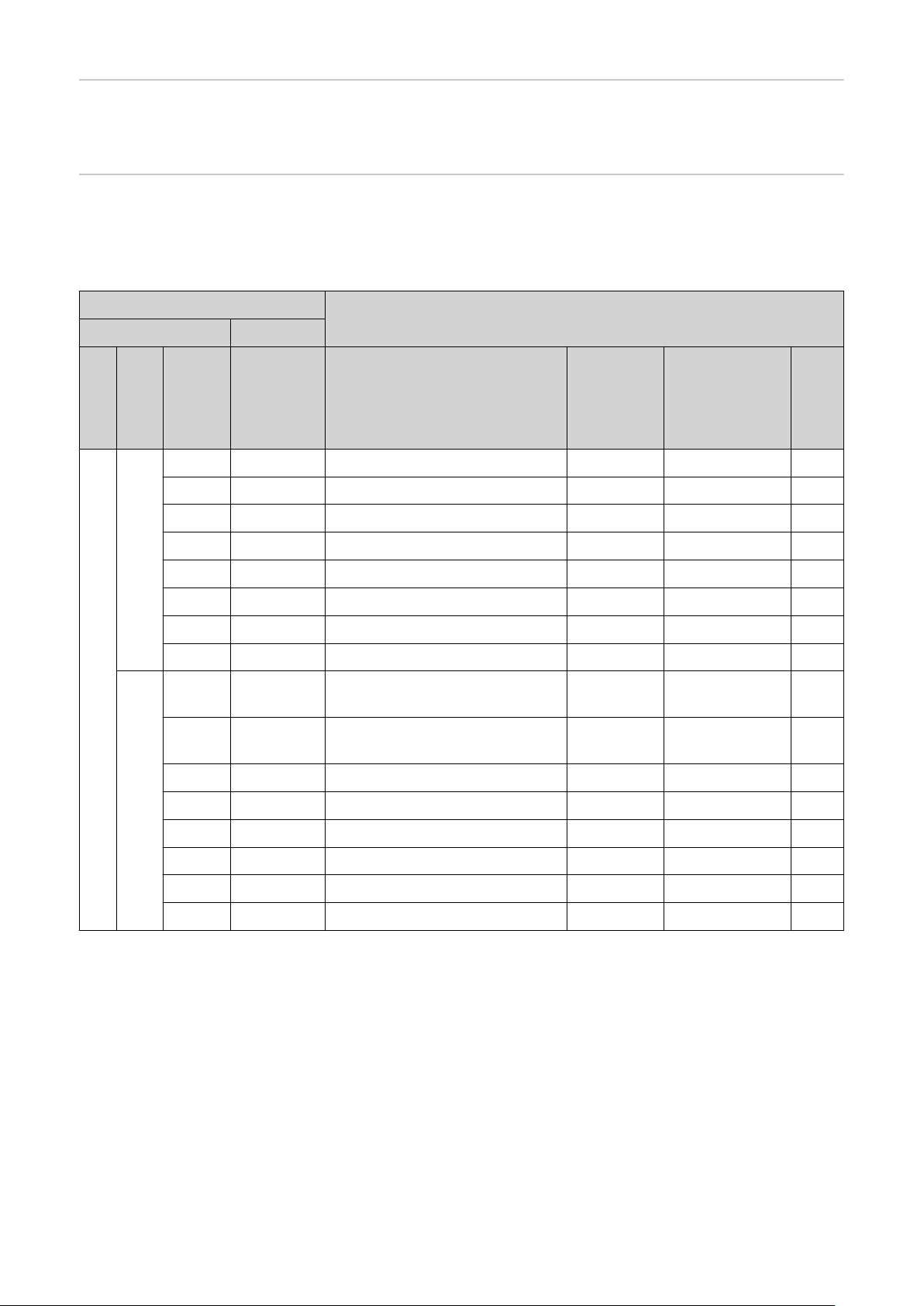

Konfigurationsparameter

Bei einigen Robotersteuerungen kann es erforderlich sein die hier beschriebenen

Konfigurationsparameter anzugeben, damit das Busmodul mit dem Roboter

kommunizieren kann.

Parameter Wert Beschreibung

Voraussetzungen für den Betrieb des Busmodules

Vendor ID 0534

Device Type 000C

Product Code 0390

hex

hex

hex

(1332

(12

dez

(912

) Fronius International GmbH

dez

) Communication adapter

) Fronius FB Pro TwinEthernet/IP-2-

dez

Port

Product Name Fronius-FB-Pro-Twin-EtherNetIP(TM)

Size

Image Type

Standard

Image

Con-

Instance

Type

Produ-

cing In-

stance

suming

Instance

Instance

Name

Input Da-

ta Stan-

dard

Output

Data

Standard

Instance

Description

Data from power

source to robot

Data from robot

to power source

Instance

Number

105 120

155 120

[Byt

e]

Folgende Voraussetzungen müssen erfüllt sein, damit das Busmodul verwendet

werden kann:

Die Option CFG/i RI FB PRO TWIN Fanuc 1.0 muss in beiden Stromquellen

1.

eingebaut sein

Die Option CFG/i RI FB PRO TWIN Fanuc 1.0 muss im SmartManager beider

2.

Stromquellen aktiviert sein:

SnartManager der Stromquelle

6

Page 7

IP-Adresse des Busmoduls einstellen

DE

IP-Adresse des

Busmoduls einstellen

Die IP-Adresse des Busmoduls kann

eingestellt werden:

mit dem DIP-Schalter im Interface

1.

im Bereich 192.168.0.xx

(xx = DIP-Schalterstellung = 1 bis

63)

Werksseitig sind alle Positio-

-

nen in Stellung OFF geschaltet. In diesem Fall muss die

Einstellung der IP-Adresse auf

der Website der Stromquelle

eingestellt werden

auf der Website der Stromquelle

2.

(wenn alle Positionen des DIPSchalters in Stellung OFF geschaltet sind)

Die IP-Adresse wird mit den Positionen 1 bis 6 des DIP-Schalters eingestellt. Die

Einstellung erfolgt im Binärformat. Das ergibt einen Einstellbereich von 1 bis 63

im Dezimalformat.

Beispiel für das Einstellen der IP-Adresse des Busmoduls mit dem DIPSchalter im Interface:

DIP-Schalter

8 7 6 5 4 3 2 1 IP-Adresse

- -

- -

- -

- -

- -

OFF OFF OFF OFF OFF ON

OFF OFF OFF OFF ON OFF

OFF OFF OFF OFF ON ON

ON ON ON ON ON OFF

ON ON ON ON ON ON

1

2

3

62

63

Anleitung für das Einstellen der IP-Adresse auf der Website der Stromquelle

(SmartManager):

IP-Adresse der verwendeten Stromquelle notieren:

Am Bedienpanel der Stromquelle „Voreinstellungen“ auswählen

1

Am Bedienpanel der Stromquelle „System“ auswählen

2

Am Bedienpanel der Stromquelle „Information“ auswählen

3

Angezeigte IP-Adresse notieren (Beispiel: 10.5.72.13)

4

Website der Stromquelle im Internetbrowser aufrufen:

Computer mit dem Netzwerk der Stromquelle verbinden

5

IP-Adresse der Stromquelle in die Suchleiste des Internetbrowsers eingeben

6

und bestätigen

Standard-Benutzernamen (admin) und Passwort (admin) eingeben

7

Website der Stromquelle wird angezeigt

-

IP-Adresse des Busmoduls einstellen:

Auf der Website der Stromquelle den Reiter „RI FB PRO/i TWIN“ auswählen

8

7

Page 8

Bei Punkt „Feldbus Konfiguration“ die gewünschte IP-Adresse für das Inter-

9

face eingeben

Beispielsweise: 192.168.0.12

„Konfiguration setzen“ auswählen

10

„Feldbus-Modul neu starten“ auswählen

11

die eingestellte IP-Adresse wird übernommen

-

8

Page 9

Ein- und Ausgangssignale

Datentypen Folgende Datentypen werden verwendet:

UINT16 (Unsigned Integer)

-

Ganzzahl im Bereich von 0 bis 65535

SINT16 (Signed Integer)

-

Ganzzahl im Bereich von -32768 bis 32767

Umrechnungsbeispiele:

für positiven Wert (SINT16)

-

z.B. gewünschter Drahtvorschub x Faktor

12.3 m/min x 100 = 1230

für negativen Wert (SINT16)

-

z.B. gewünschte Lichtbogen-Korrektur x Faktor

-6.4 x 10 = -64

= FFC0

dez

= 04CE

dez

hex

DE

hex

Verfügbarkeit

der Eingangssignale

Eingangssignale

(vom Roboter

zur Stromquelle)

Die nachfolgend angeführten Eingangssignale sind ab Firmware V1.8.0 des RI

MOD/i CC Ethernet/IP-2P TWIN FANUC verfügbar.

9

Page 10

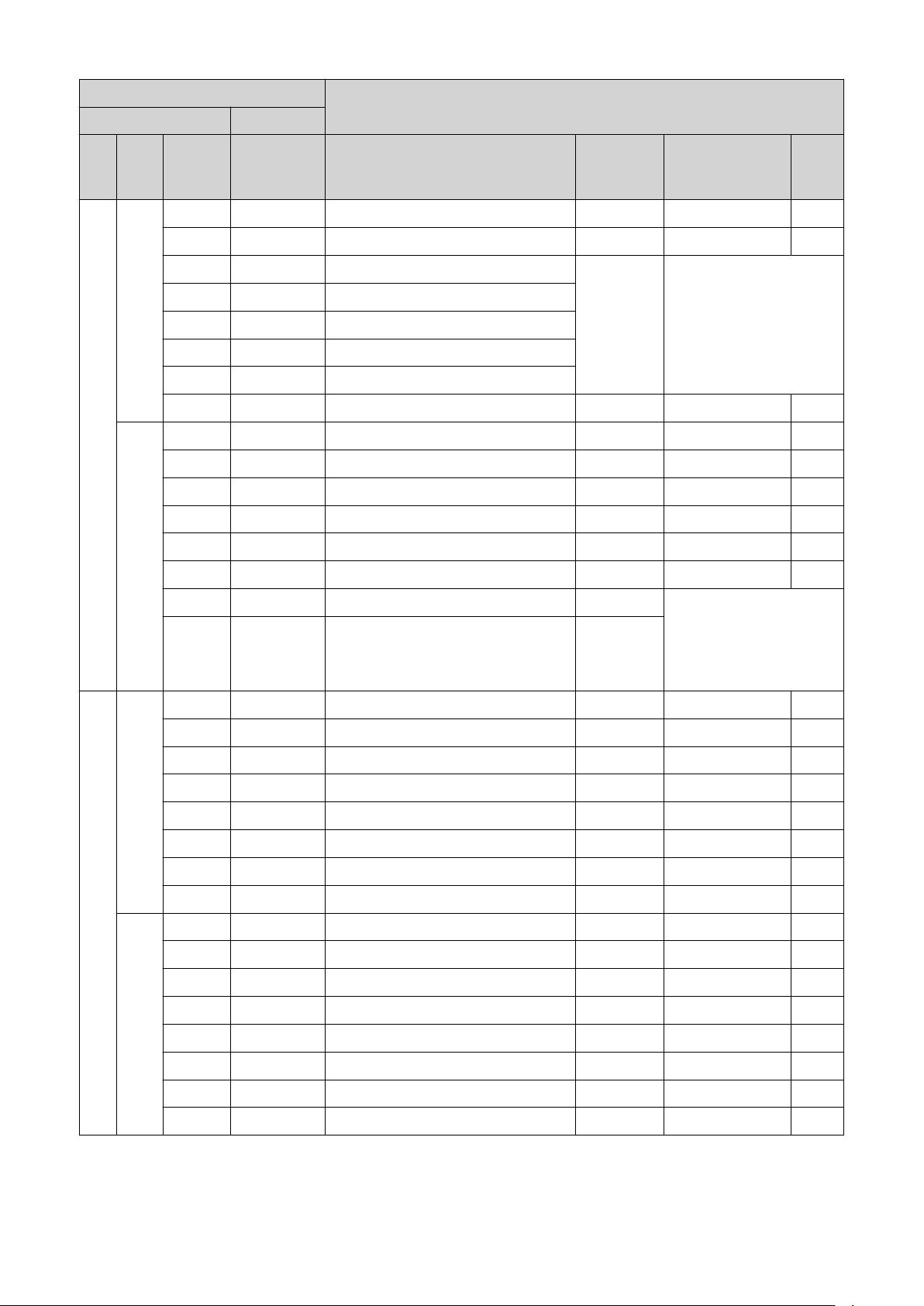

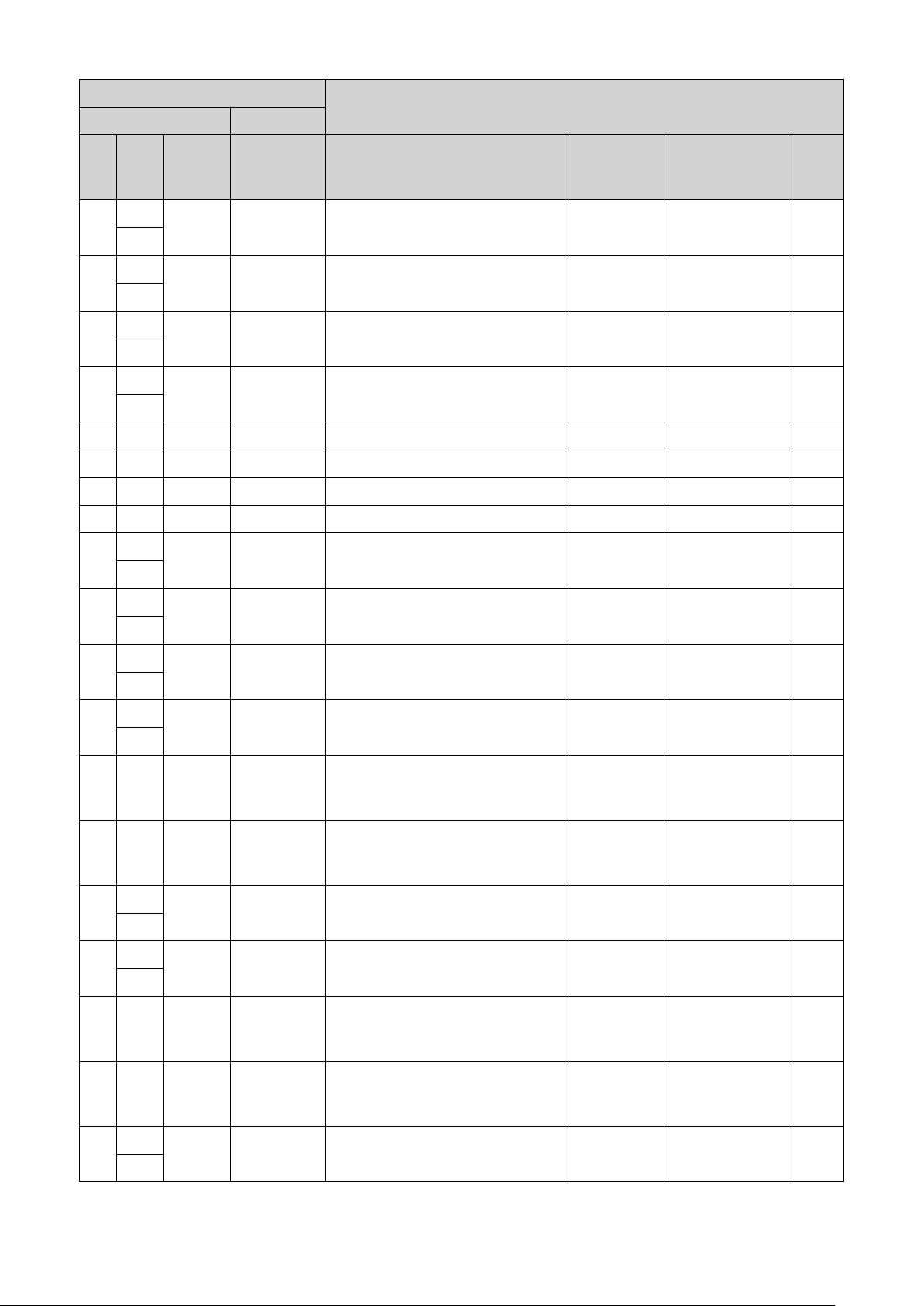

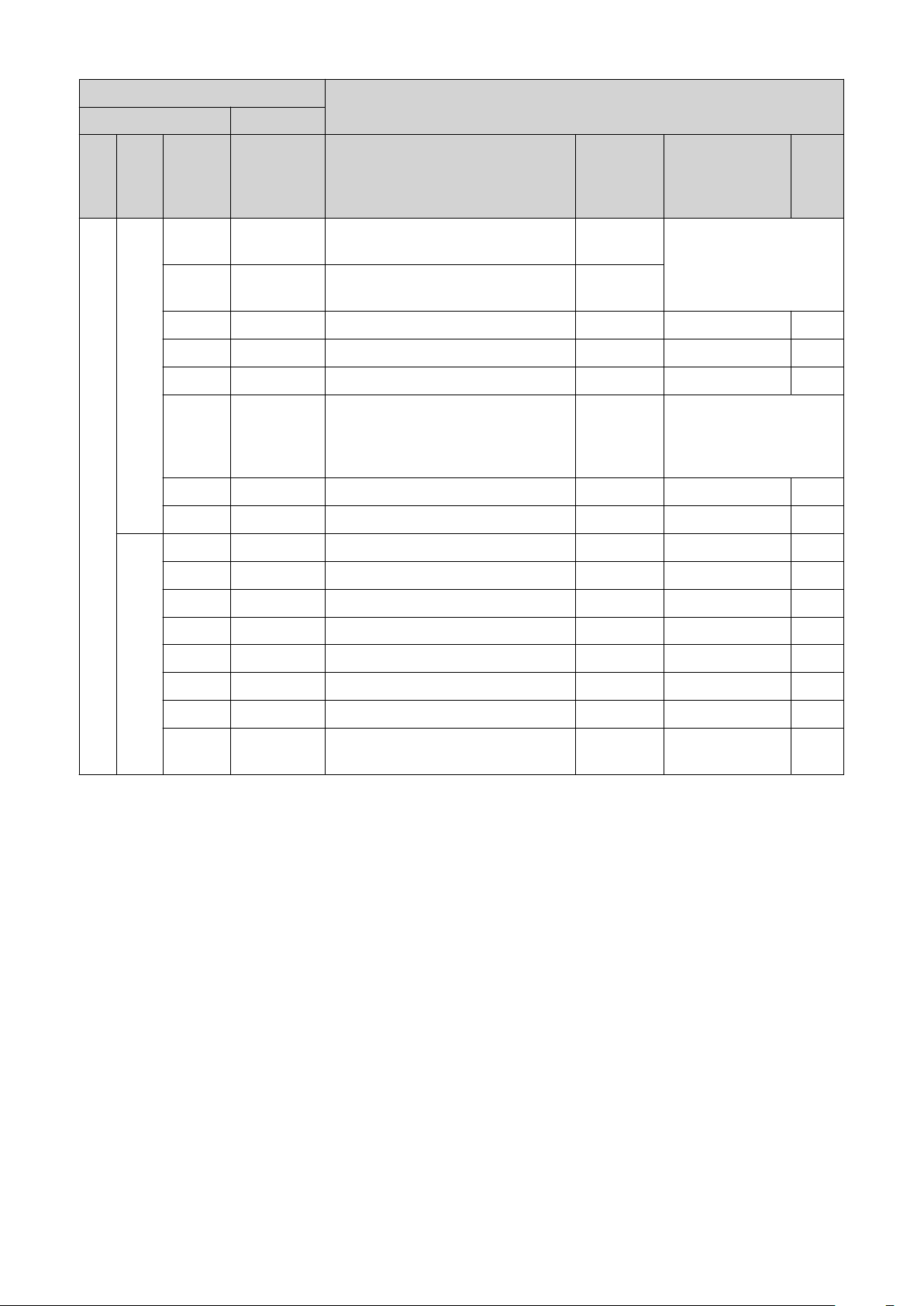

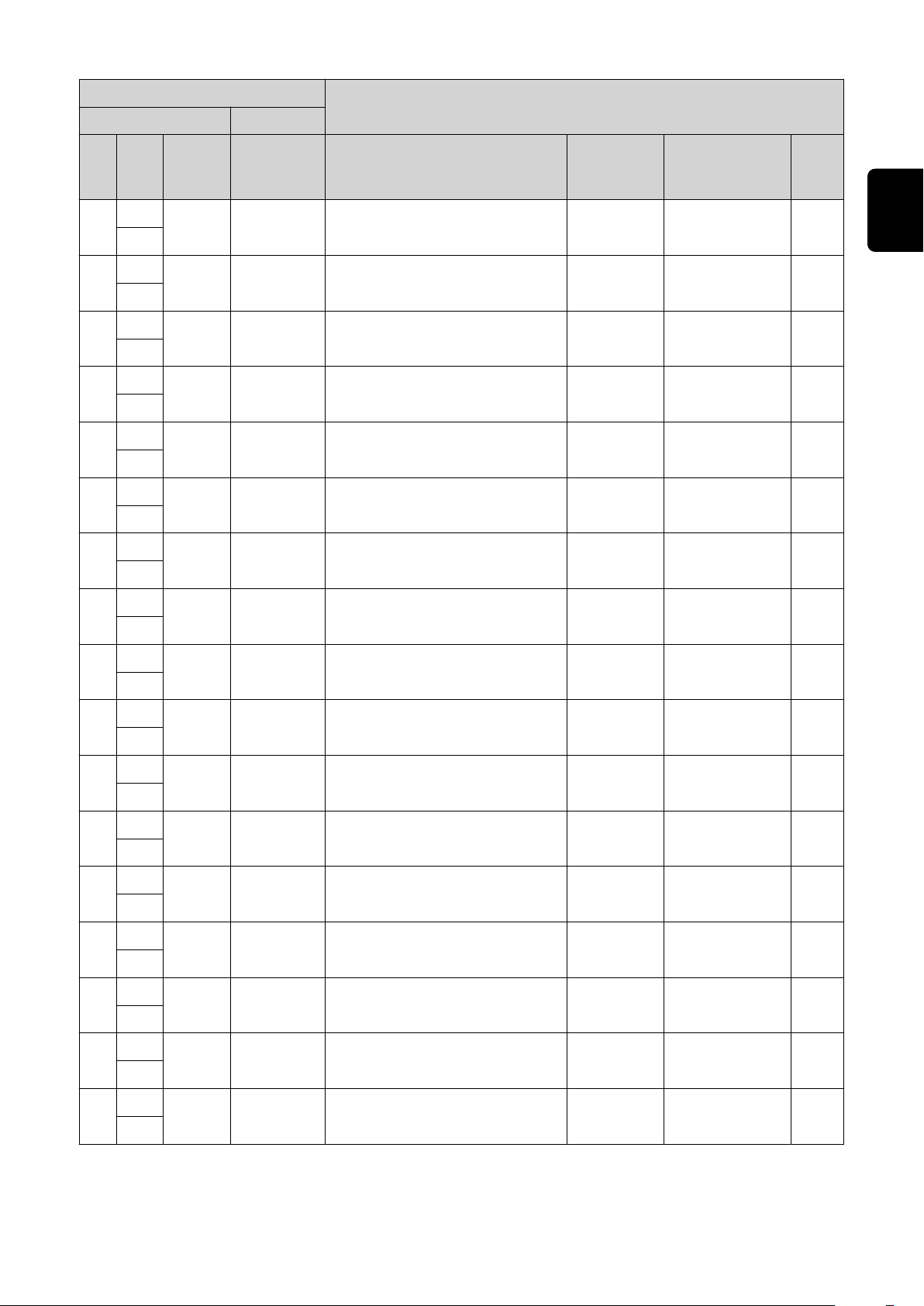

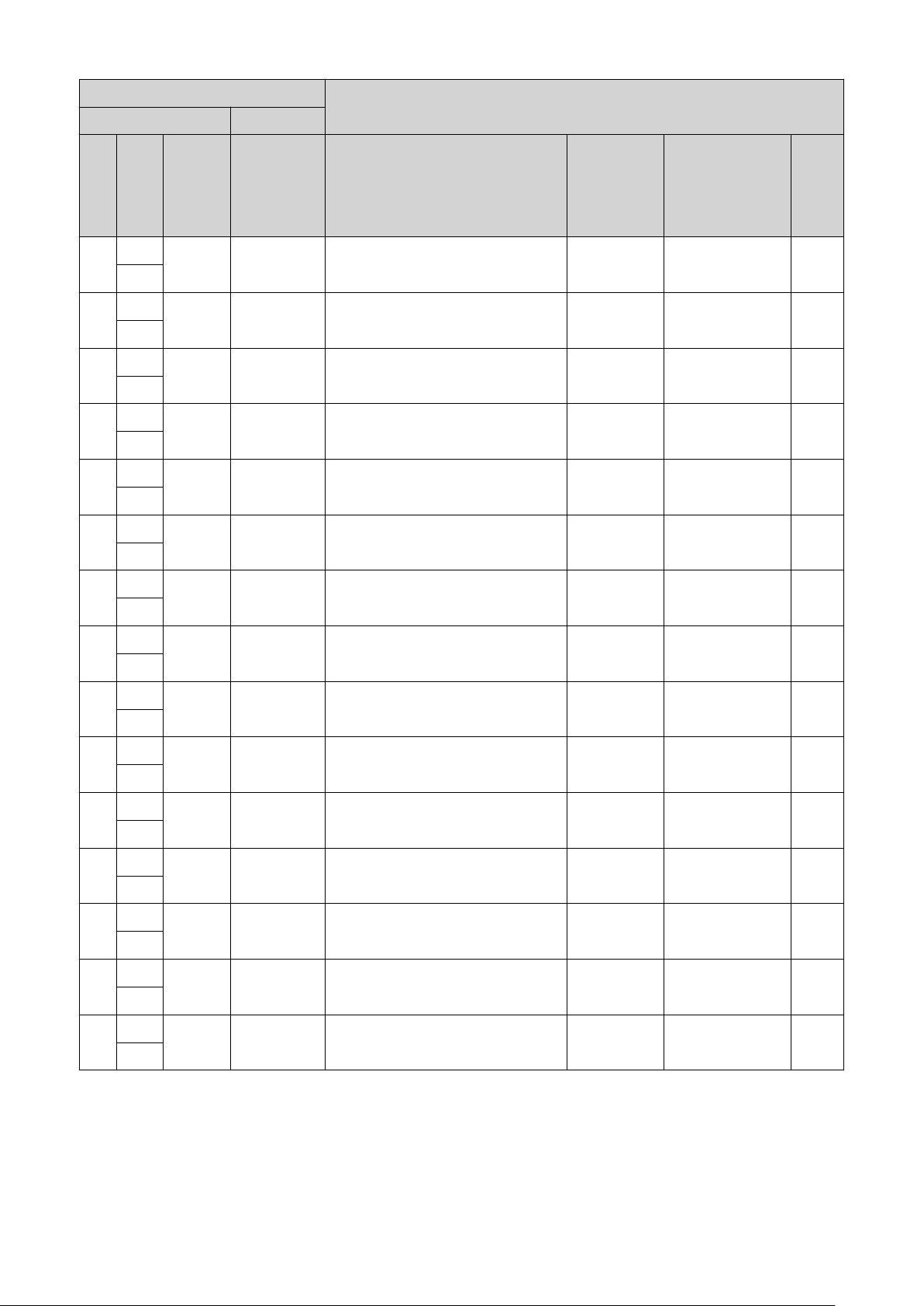

Adresse

relativ absolut

WORD

1

BYTE

1

2

BIT

1 1 Welding Start steigend

2 2 Robot ready High

3 3 Working mode Bit 0

4 4 Working mode Bit 1

5 5 Working mode Bit 2

6 6 Working mode Bit 3

7 7 Working mode Bit 4

8 8 —

1 9 Gas on steigend

2 10 Wire forward steigend

3 11 Wire backward steigend

4 12 Error quit steigend

5 13 Touch sensing High

6 14 Torch blow out steigend

BIT

Signal

Aktivität

/

Datentyp Bereich

Siehe nachfolgende

UINT5

(0 - 31)

Tabelle Wertebe-

reich Working mode

auf Seite 20

Faktor

7 15 Processline selection Bit 0 High Siehe nachfolgende

Tabelle Wertebe-

8 16 Processline selection Bit 1 High

1 17 Welding Simulation High

2 18 —

3 19 —

4 20 —

3

5 21 —

6 22 Booster manual High

7 23 Wire brake on High

8 24 Torchbody Xchange High

2

1 25 —

2 26 Teach mode High

3 27 —

4 28 —

4

5 29 —

reich Processline

selection auf Seite

20

10

6 30 Wire sense start High

7 31 Wire sense break High

8 32 —

Page 11

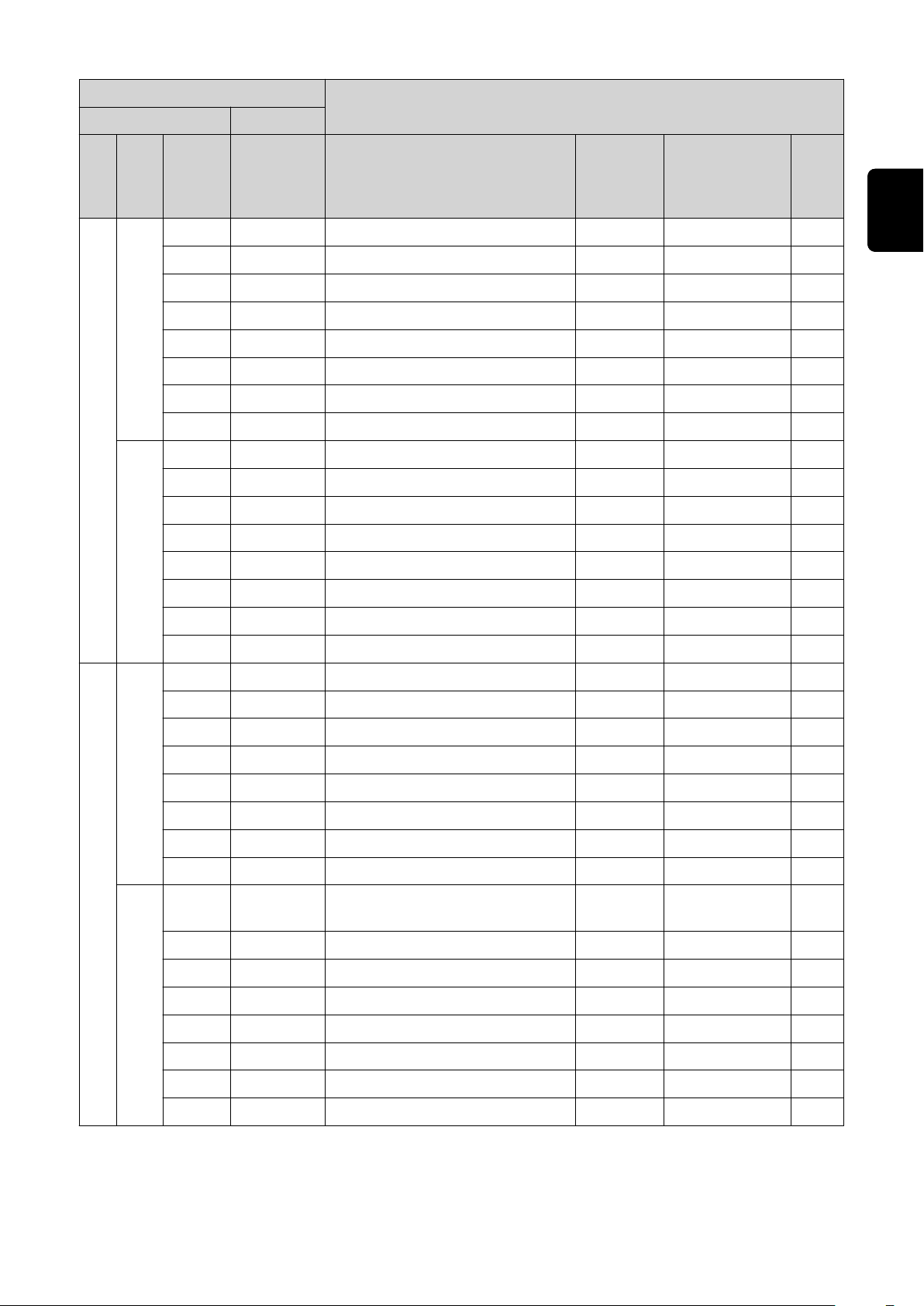

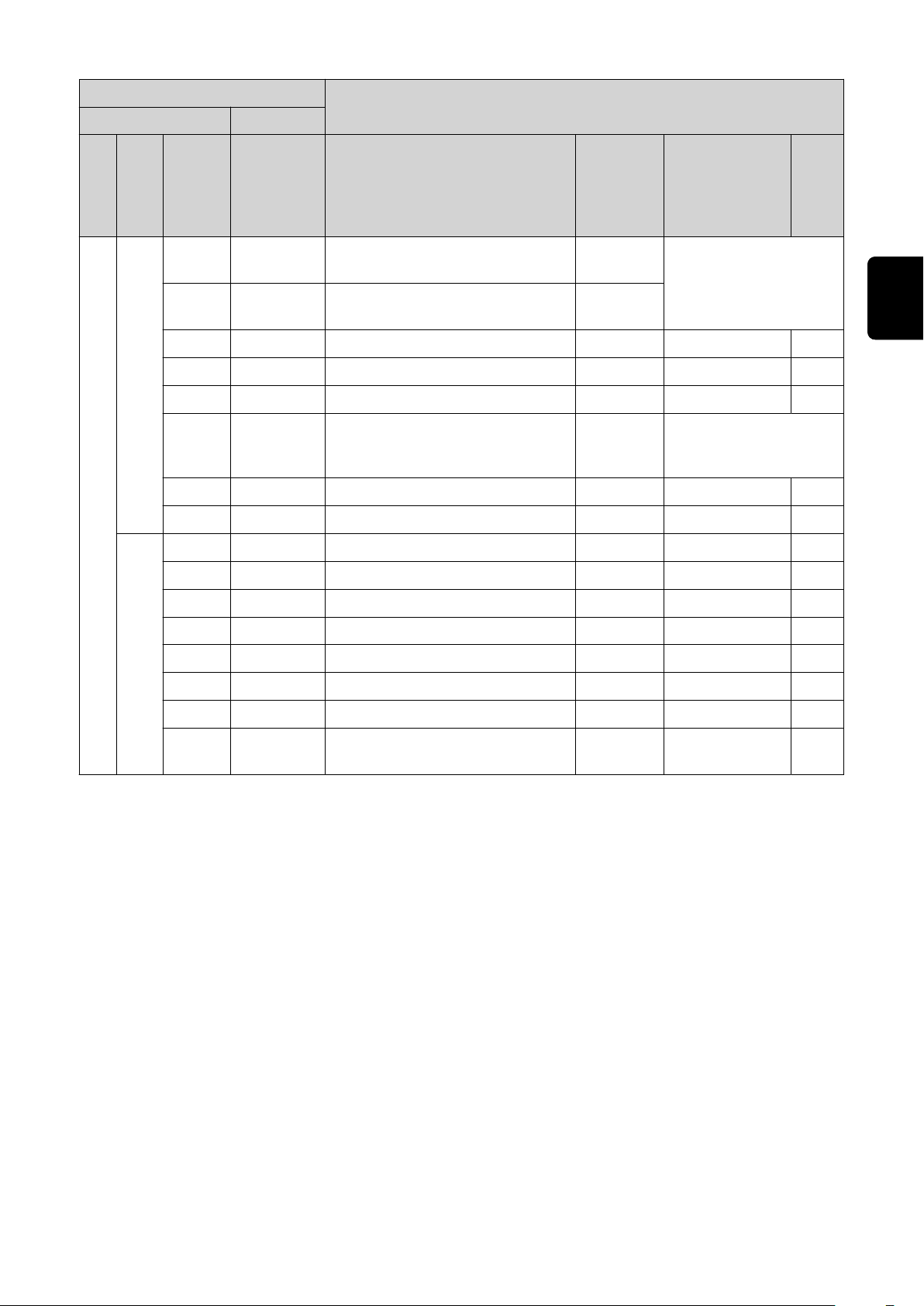

Adresse

relativ absolut

WORD

BYTE

5

3

BIT

1 33

2 34

3 35 —

4 36 —

5 37 —

6 38 Documentation mode High

7 39 —

8 40 —

1 41 —

BIT

Signal

Operating mode TWIN System

Bit 0

Operating mode TWIN System

Bit 1

Aktivität

/

Datentyp Bereich

High

High

Siehe nachfolgende

Tabelle Wertebe-

reich Operating mo-

de TWIN System auf

Seite 20

Siehe nachfolgende

Tabelle Wertebe-

reich Documentati-

on mode auf Seite

21

DE

Faktor

2 42 —

3 43 —

4 44 —

6

5 45 —

6 46 —

7 47 —

8 48

Disable Arclength stabilizer,

Power source 1 + 2

High

11

Page 12

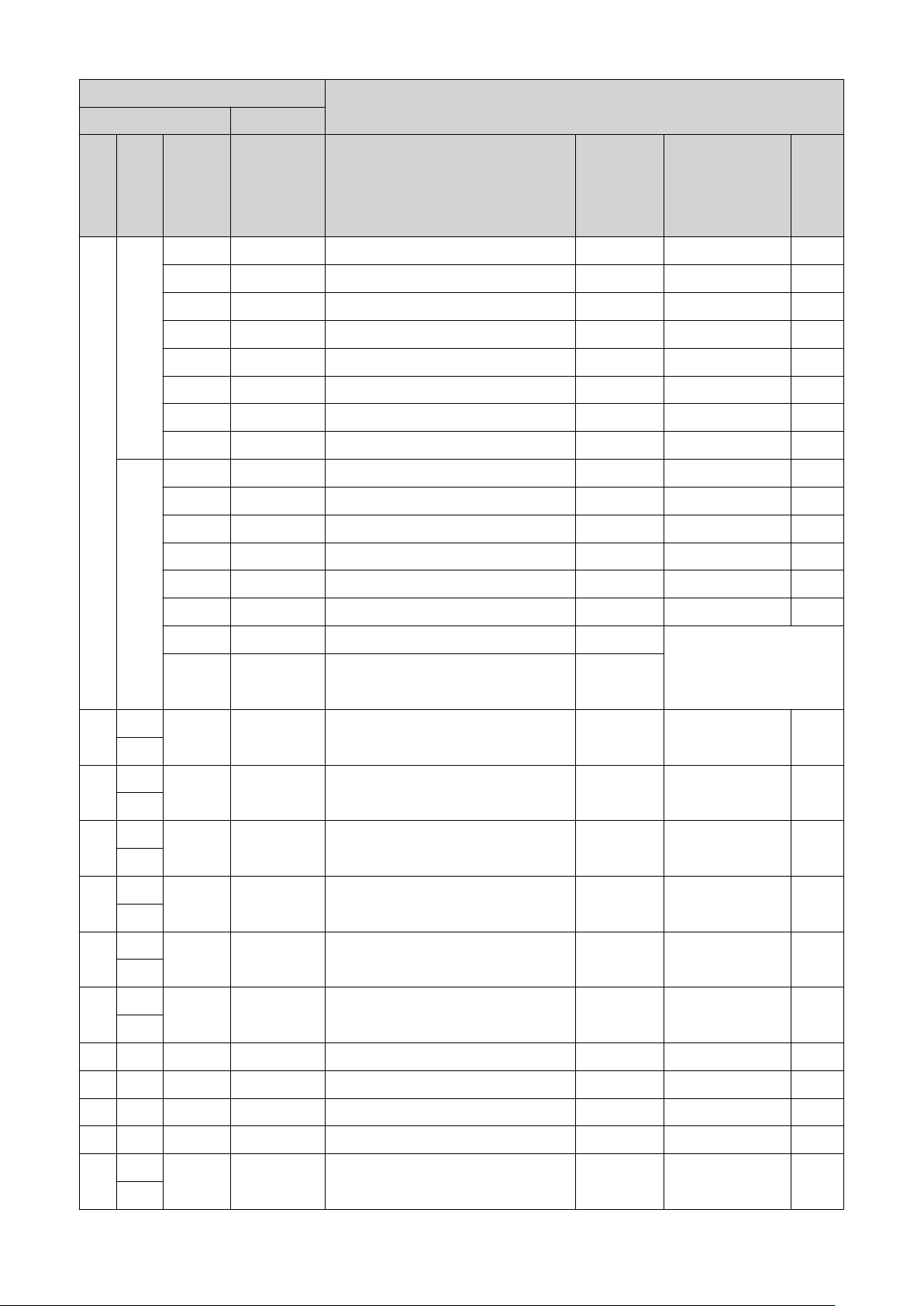

Adresse

relativ absolut

WORD

4

BYTE

7

8

BIT

1 49 —

2 50 —

3 51 —

4 52 —

5 53 —

6 54 —

7 55 —

8 56 —

1 57 ExtInput1 => OPT_Output 1 High

2 58 ExtInput2 => OPT_Output 2 High

3 59 ExtInput3 => OPT_Output 3 High

4 60 ExtInput4 => OPT_Output 4 High

5 61 ExtInput5 => OPT_Output 5 High

6 62 ExtInput6 => OPT_Output 6 High

BIT

Signal

Aktivität

/

Datentyp Bereich

Faktor

7 63 ExtInput7 => OPT_Output 7 High

8 64 ExtInput8 => OPT_Output 8 High

1 65 —

2 66 —

3 67 —

9

5

10

4 68 —

5 69 —

6 70 —

7 71 —

8 72 —

1 73

2 74 —

3 75 —

4 76 —

5 77 —

6 78 —

Contact tip short circuit detection on

High

12

7 79 —

8 80 —

Page 13

Adresse

relativ absolut

WORD

BYTE

11

6

12

BIT

1 81 —

2 82 —

3 83 —

4 84 —

5 85 —

6 86 —

7 87 —

8 88 —

1 89 —

2 90 —

3 91 —

4 92 —

5 93 —

BIT

Signal

Aktivität

/

Datentyp Bereich

DE

Faktor

6 94 —

7 95 —

8 96 —

13

7

14

15

8

16

17,

9

18

1-16 97-112

1-16 113-128

1-16 129-144

Welding characteristic- / Job

number, Power source 1

Welding characteristic- / Job

number, Power source 2

Beim Schweißverfahren

MIG/MAG Puls-Synergic,

MIG/MAG Standard-Synergic,

MIG/MAG Standard-Manuell,

MIG/MAG PMC,

MIG/MAG LSC,

CMT, ConstantWire:

Wire feed speed command value, Power source 1

Beim Job-Betrieb:

Power correction, Power

source 1

UINT16 0 bis 65535 1

UINT16 0 bis 65535 1

-327,68 bis

SINT16

SINT16

327,67

[m/min]

-20,00 bis

20,00

[%]

100

100

13

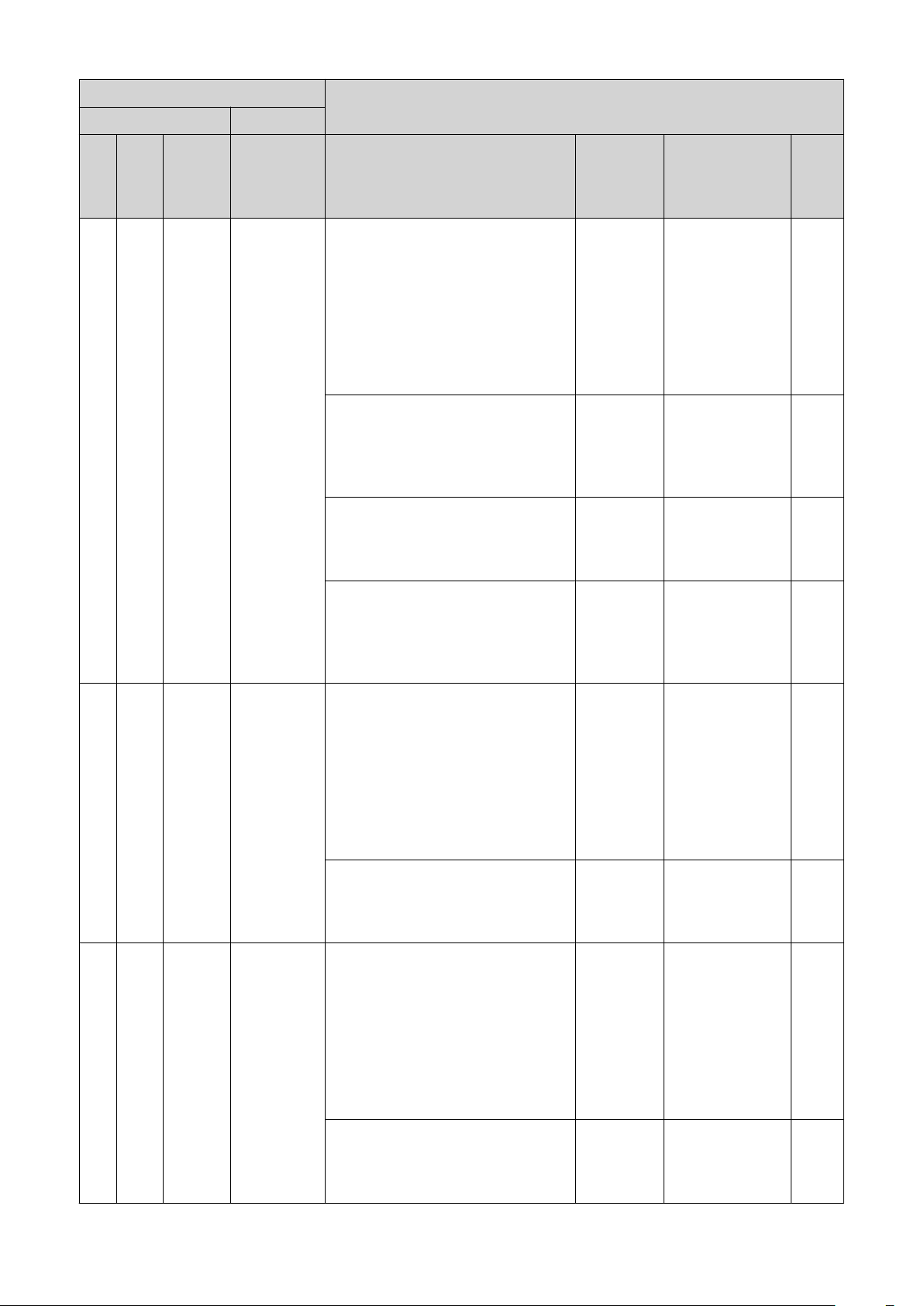

Page 14

Adresse

relativ absolut

10

WORD

19,

20

BYTE

BIT

1-16 145-160

BIT

Signal

Beim Schweißverfahren

MIG/MAG Puls-Synergic,

MIG/MAG Standard-Synergic,

MIG/MAG Standard-Manuell,

MIG/MAG PMC,

MIG/MAG LSC,

CMT, ConstantWire:

Wire feed speed command value, Power source 2

Beim Job-Betrieb:

Power correction, Power

source 2

Beim Schweißverfahren

MIG/MAG Puls-Synergic,

MIG/MAG Standard-Synergic,

MIG/MAG PMC,

MIG/MAG LSC,

CMT:

Aktivität

/

Datentyp Bereich

-327,68 bis

SINT16

SINT16

SINT16

327,67

[m/min]

-20,00 bis

20,00

[%]

-10,0 bis 10,0

[Schritte]

Faktor

100

100

10

11

21,

22

1-16 161-176

Arclength correction, Power

source 1

Beim Schweißverfahren

MIG/MAG Standard-Manuell:

Welding voltage, Power source

1

Beim Job-Betrieb:

Arclength correction, Power

source 1

Beim Schweißverfahren ConstantWire:

Hotwire current, Power source

1

UINT16

SINT16

UINT16

0,0 bis 6553,5

[V]

-10,0 bis 10,0

[Schritte]

0,0 bis 6553,5

[A]

10

10

10

14

Page 15

Adresse

relativ absolut

WORD

12

BYTE

23,

24

BIT

1-16 177-192

BIT

Signal

Beim Schweißverfahren

MIG/MAG Puls-Synergic,

MIG/MAG Standard-Synergic,

MIG/MAG PMC,

MIG/MAG LSC,

CMT:

Arclength correction, Power

source 2

Beim Schweißverfahren

MIG/MAG Standard-Manuell:

Welding voltage, Power source

2

Beim Job-Betrieb:

Arclength correction, Power

source 2

Aktivität

/

Datentyp Bereich

SINT16

UINT16

SINT16

-10,0 bis 10,0

[Schritte]

0,0 bis 6553,5

[V]

-10,0 bis 10,0

[Schritte]

DE

Faktor

10

10

10

13

14

25,

26

27,

28

1-16 193-208

1-16 208-223

Beim Schweißverfahren ConstantWire:

Hotwire current, Power source

2

Beim Schweißverfahren

MIG/MAG Puls-Synergic,

MIG/MAG Standard-Synergic,

MIG/MAG PMC,

MIG/MAG LSC,

CMT:

Pulse-/dynamic correction,

Power source 1

Beim Schweißverfahren

MIG/MAG Standard-Manuell:

Dynamic, Power source 1

Beim Schweißverfahren

MIG/MAG Puls-Synergic,

MIG/MAG Standard-Synergic,

MIG/MAG PMC,

MIG/MAG LSC,

CMT:

Pulse-/dynamic correction,

Power source 2

UINT16

SINT16

UINT16

SINT16

0,0 bis 6553,5

[A]

-10,0 bis 10,0

[Schritte]

0,0 bis 10,0

[Schritte]

-10,0 bis 10,0

[Schritte]

10

10

10

10

Beim Schweißverfahren

MIG/MAG Standard-Manuell:

Dynamic, Power source 2

UINT16

0,0 bis 10,0

[Schritte]

10

15

Page 16

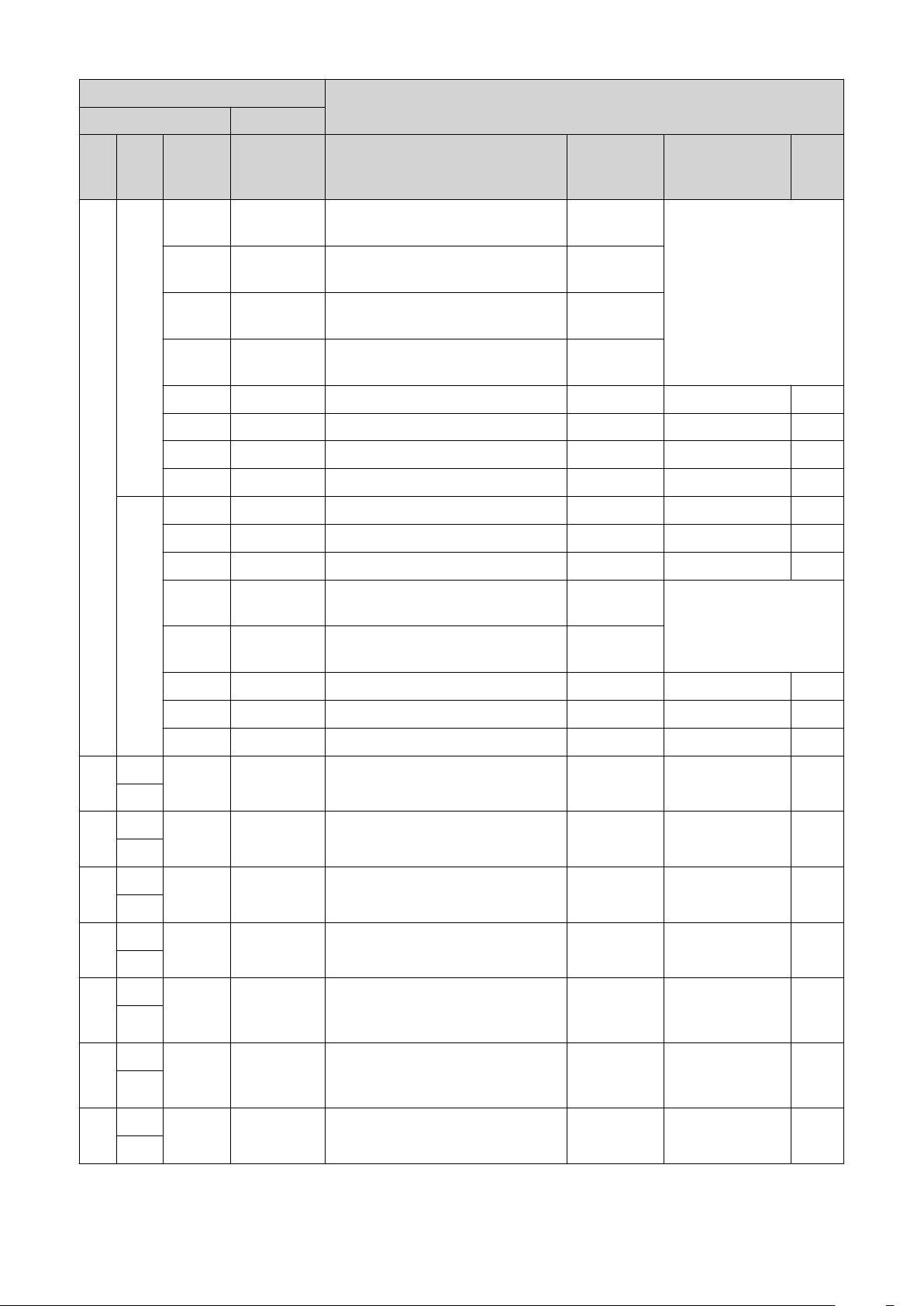

Adresse

relativ absolut

15

16

17

18

19

20

21

WORD

29

30

31

32

33

34

35

36

37

38

39

40

41

42

BYTE

BIT

1-16 225-240

1-16 241-256

1-16 257-272 Welding speed UINT16

1-16 273-288

1-16 289-304

1-16 305-320

1-16 321-336 Wire sense edge detection UINT16

BIT

Signal

Wire retract correction, Power

source 1

Wire retract correction, Power

source 2

Arclength stabilizer, Power

source 1

Arclength stabilizer, Power

source 2

Wire forward / wire backward

length

Aktivität

/

Datentyp Bereich

UINT16 0,0 bis 10,0 10

UINT16 0,0 bis 10,0 10

0,0 bis 6535,5

[cm/min]

UINT16 0,0 bis 5,0 10

UINT16 0,0 bis 5,0 10

OFF / 1 bis

UINT16

65355

[mm]

OFF / 0,5 bis

20,0

[mm]

Faktor

10

1

10

22

23

24

25

26

27

28

29

30

43

1-16 337-352 —

44

45

1-16 353-368 —

46

47

1-16 369-384 —

48

49

1-16 385-400 —

50

51

1-16 401-416 —

52

53

1-16 417-432 —

54

55

1-16 433-448 —

56

57

1-16 449-464 —

58

59

1-16 465-480 Seam number UINT16 0 bis 65535 1

60

16

Page 17

Adresse

relativ absolut

WORD

BYTE

61

31

BIT

1 481

2 482 —

3 483 —

4 484 —

5 485 Disable gas-settings High

6 486

7 487

8 488

1 489

2 490 —

BIT

Signal

Disable start-end-parameter

(Image)

Disable components setup

(TAG)

Disable language / units / standards (TAG)

Disable penetration stabilizer,

Power source 1 + 2

Enable arc break monitoring /

arc loss

Aktivität

/

Datentyp Bereich

High

High

High

High

High

DE

Faktor

62

3 491 —

4 492 —

5 493 —

6 494 —

7 495 —

8 496 —

17

Page 18

Adresse

relativ absolut

32

WORD

63

64

BYTE

BIT

1 497 —

2 498 —

3 499 —

4 500 —

5 501 —

6 502 —

7 503 —

8 504 —

1 505 —

2 506 —

3 507 —

4 508 —

5 509 —

6 510 —

BIT

Signal

Aktivität

/

Datentyp Bereich

Faktor

7 511

8 512 Command value selection Bit 1 High

65

33

66

67

34

68

69

35

70

71

36

72

73

37

74

75

38

76

39 77 1-8 609-616 TAG quantity UINT8 0 bis 5 1

1-16 513-528 TAG start address UINT16 1 bis 65535 1

1-16 529-544 TAG value 1

1-16 545-560 TAG value 2

1-16 561-576 TAG value 3

1-16 577-592 TAG value 4

1-16 593-608 TAG value 5

Command value selection Bit

0

High

Siehe nachfolgende

Tabelle Wertebe-

reich Command va-

lue selection auf Sei-

te 21

39 78 1 617 TAG command read steigend

39 78 2 618 TAG command write steigend

39 78 3-8 619-624 —

18

40

79

1-16 625-640 Gas preflow UINT16

80

0,0 bis 9,9

[s]

10

Page 19

Adresse

relativ absolut

WORD

BYTE

81

41

82

83

42

84

85

43

86

87

44

88

89

45

90

91

46

92

93

47

94

BIT

1-16 641-656 Gas postflow UINT16

1-16 657-672 Inching value UINT16

1-16 673-688 S2T - Starting current UINT16

1-16 689-704 S2T - Starting current time UINT16

1-16 705-720 S2T - Slope 1 UINT16

1-16 721-736 S2T - Slope 2 UINT16

1-16 737-752 S2T - End current UINT16

BIT

Signal

Aktivität

/

Datentyp Bereich

0,0 bis 9,9

[s]

-327,67 bis

327,67

[m/min]

0,0 bis 200

[%]

0,0 bis 9,9

[s]

0,0 bis 9,9

[s]

0,0 bis 9,9

[s]

0,0 bis 200

[%]

DE

Faktor

10

100

1

10

10

10

1

48

49

50

51

52

53

54

55

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

1-16 753-768 S2T - End current time UINT16

1-16 769-784 Start arclength correction SINT16 -10,0 bis 10,0 10

1-16 785-800 End arclength correction UINT16 -10,0 bis 10,0 10

1-16 801-816 Pulse synchronization ratio UINT16

1-16 817-832 Phase shift lead / trail UINT16

1-16 833-848 Ignition delay trail UINT16

1-16 849-864 —

1-16 865-880

Penetration stabilizer,

Power source 1

UINT16

0,0 bis 9,9

[s]

Siehe nachfolgende

Tabelle Wertebe-

reichPulse synchro-

nization ratio auf Sei-

te 21

0 bis 95

(255 = AUTO)

0,00 bis 2,00

(254 = OFF)

(255 = AUTO)

0,0 bis 10,0

[m/min]

10

1

100

10

56

57

111

112

113

114

1-16 881-896

1-16 897-912 —

Penetration stabilizer,

Power source 2

UINT16

0,0 bis 10,0

[m/min]

10

19

Page 20

Adresse

relativ absolut

WORD

BYTE

115

58

116

117

59

118

119

60

120

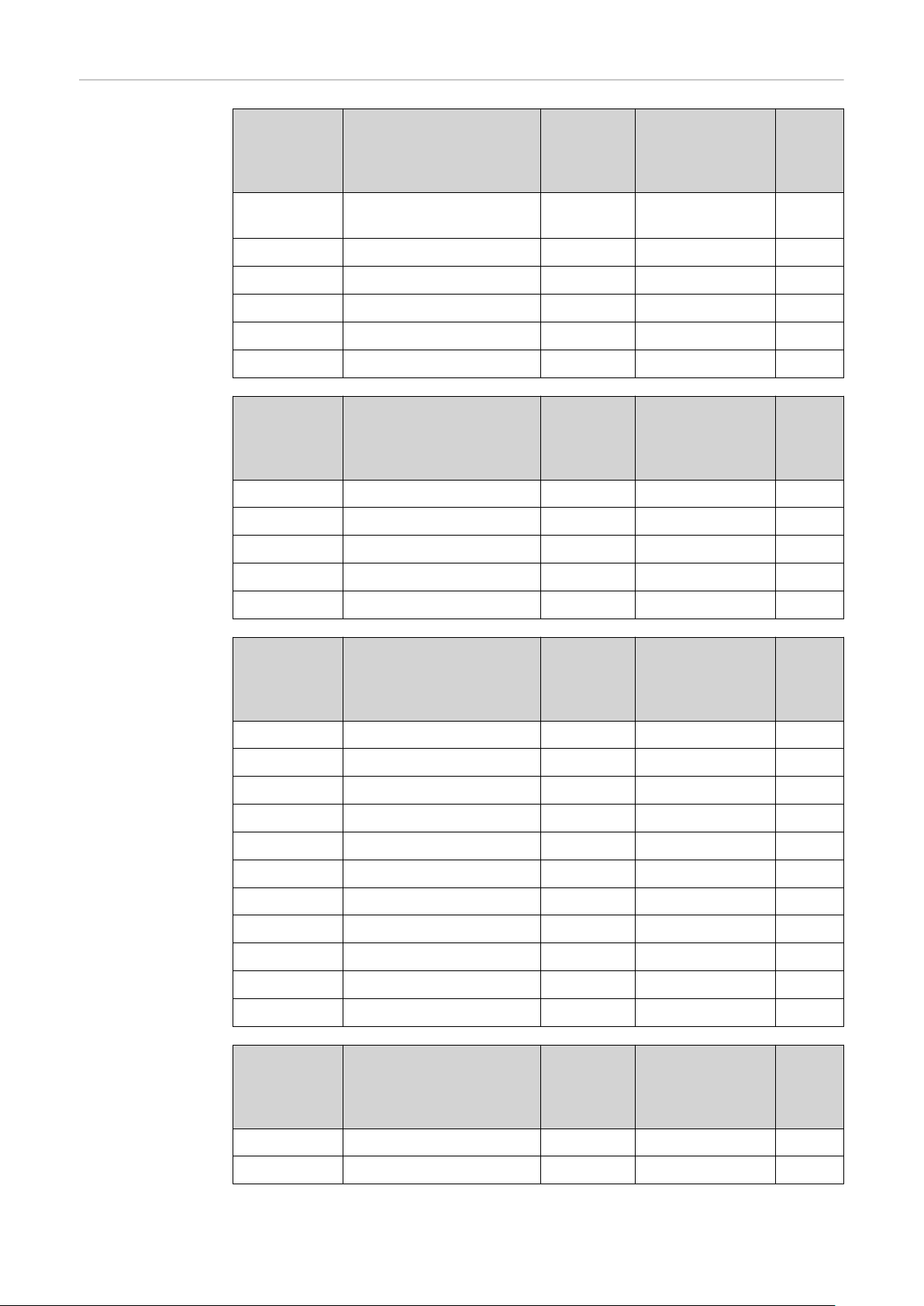

Wertebereich

Working mode

Aktivität

/

BIT

BIT

Signal

Datentyp Bereich

1-16 913-928 —

1-16 929-944 —

1-16 945-960 —

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Beschreibung

0 0 0 0 0 Parameteranwahl intern

0 0 0 0 1 Kennlinien Betrieb Sonder 2-Takt

0 0 0 1 0 Job-Betrieb

0 1 0 0 0 Kennlinien Betrieb 2-Takt

0 1 0 0 1 MIG/MAG Standard-Manuell 2-Takt

Faktor

Wertebereich

Processline

selection

Wertebereich

Operating mode

TWIN System

1 0 0 0 1 Kühlmittel-Pumpe stoppen

Wertebereich Betriebsart

Bit 1 Bit 0 Beschreibung

0 0 Prozesslinie 1 (default)

0 1 Prozesslinie 2

1 0 Prozesslinie 3

1 1 Reserviert

Wertebereich Prozesslinien-Auswahl

Bit 1 Bit 0 Funktion Stromquelle 1 Funktion Stromquelle 2

0 0 Single mode OFF

0 1 TWIN Lead TWIN Trail

1 0 TWIN Trail TWIN Lead

20

1 1 OFF Single mode

Wertebereich Betriebsart TWIN System

Page 21

Wertebereich

Documentation

mode

Wertebereich

Process controlled correction

Bit 0 Beschreibung

0 Nahtnummer von Stromquelle (intern)

1 Nahtnummer von Roboter (Word 29)

Wertebereich Dokumentationsmodus

Prozess

Signal

Aktivität /

PMC Arc length stabilizer SINT16

Wertebereich prozessabhängige Korrektur

Wertebereich

Datentyp

Einstellbereich

-327,8 bis +327,7

0,0 bis +5,0 Volt 10

Einheit

DE

Faktor

Wertebereich

Command value

selection

Wertebereich

Pulse synchronization ratio

Bit 1 Bit 0 Beschreibung

0 0 Wire feed speed command value

0 1 Welding current command value

Wertebereich Signal Command value selection

Wert Beschreibung

1 Auto

2 1/1

3 1/2

4 1/3

Wertebereich Pulse synchronization ratio

21

Page 22

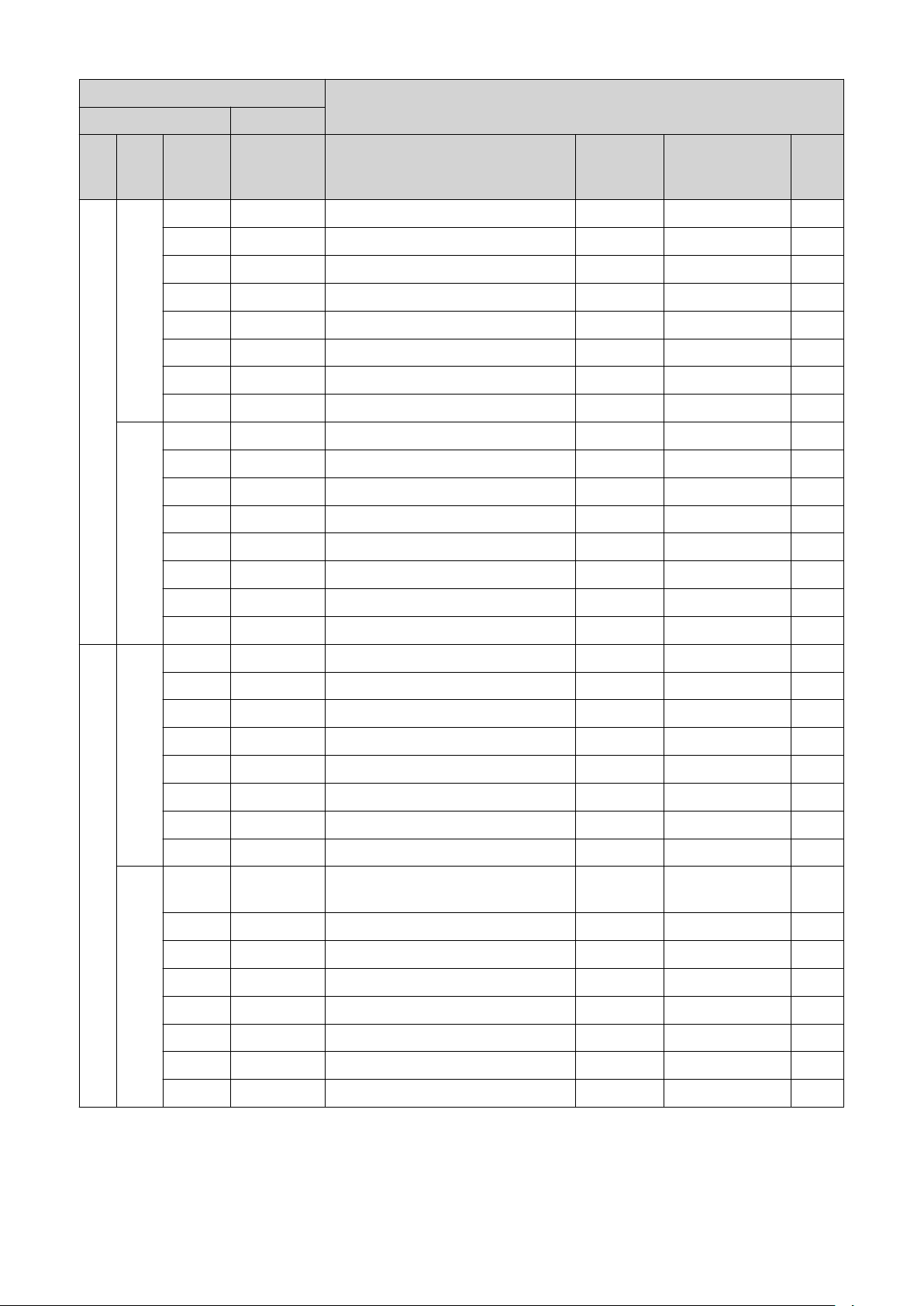

Verfügbarkeit

der Ausgangssignale

Ausgangssignale

(von der Stromquelle zum Roboter)

Adresse

relativ absolut

Die nachfolgend angeführten Ausgangssignale sind ab Firmware V1.8.0 des RI

MOD/i CC Ethernet/IP-2P TWIN FANUC verfügbar.

WORD

1

BYTE

1

2

BIT

1 1 Heartbeat Powersource High / Low 1 Hz

2 2 Power source ready High

3 3 Warning High

4 4 Process active High

5 5 Current flow High

6 6 Arc stable- / touch signal High

7 7 Main current signal High

8 8 Touch signal High

1 9 Collisionbox active Low

2 10

3 11 Wire stick workpiece High

4 12 —

BIT

Signal

Robot Motion Release, Power

source 1

Aktivität

/

Datentyp Bereich

0 = Kollision

oder Kabel-

bruch

High

Faktor

22

5 13 Short circuit contact tip High

6 14

7 15 —

8 16 Torch body gripped High

Parameter selection internally

High

Page 23

Adresse

relativ absolut

WORD

BYTE

3

2

4

BIT

1 17 Command value out of range High

2 18 Correction out of range High

3 19 —

4 20 Limitsignal, Power Source 1 High

5 21 —

6 22 Standby active High

7 23 Main supply status High

8 24 —

1 25

2 26

3 27

4 28

BIT

Signal

Sensor status 1, Power

Source 1

Sensor status 2, Power

Source 1

Sensor status 3, Power

Source 1

Sensor status 4, Power

Source 1

Aktivität

/

Datentyp Bereich

High

High

High

High

Siehe Tabelle Zuord-

nung Sensorstatus

1-4 auf Seite 29

DE

Faktor

5 29 —

6 30 —

7 31 —

8 32 —

1 33 —

2 34 —

3 35 —

4 36

5

5 37

6 38 —

7 39 Notification High

3

8 40 System not ready High

1 41 —

2 42 —

3 43 —

Safety status Bit 0, Power

Source 1

Safety status Bit 1, Power

Source 1

High

High

Siehe Tabelle Werte-

bereich Safety status

auf Seite 29

6

4 44 —

5 45 —

6 46 —

7 47 —

8 48 —

23

Page 24

Adresse

relativ absolut

WORD

4

BYTE

7

8

BIT

1 49 —

2 50 —

3 51 —

4 52 —

5 53 —

6 54 —

7 55 Gas nozzle touched High

8 56 —

1 57 ExtOutput1 <= OPT_Input1 High

2 58 ExtOutput2 <= OPT_Input2 High

3 59 ExtOutput3 <= OPT_Input3 High

4 60 ExtOutput4 <= OPT_Input4 High

5 61 ExtOutput5 <= OPT_Input5 High

6 62 ExtOutput6 <= OPT_Input6 High

BIT

Signal

Aktivität

/

Datentyp Bereich

Faktor

7 63 ExtOutput7 <= OPT_Input7 High

8 64 ExtOutput8 <= OPT_Input8 High

1 65 —

2 66

3 67 Limitsignal, Power source 2 High

9

5

10

4 68 —

5 69 —

6 70 —

7 71 —

8 72 —

1 73 —

2 74 —

3 75 —

4 76 —

5 77 —

6 78 —

Robot Motion Release, Power

source 2

High

24

7 79 —

8 80 —

Page 25

Adresse

relativ absolut

WORD

BYTE

11

6

BIT

1 81

2 82

3 83

4 84

5 85 —

6 86 —

7 87 —

8 88 —

1 89 —

2 90 —

3 91 —

BIT

Signal

Sensor status 1, Power

Source 2

Sensor status 2, Power

Source 2

Sensor status 3, Power

Source 2

Sensor status 4, Power

Source 2

Aktivität

/

Datentyp Bereich

High

High

High

High

Siehe Tabelle Zuord-

nung Sensorstatus

1-4 auf Seite 29

DE

Faktor

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

4 92

5 93

6 94 —

7 95 —

8 96 —

0-16 97-112

0-16 113-128

0-16 129-144

0-16 145-160

0-16 161-176

Safety status Bit 0, Power

Source 2

Safety status Bit 1, Power

Source 2

Real value welding voltage,

Power source 1

Real value welding voltage,

Power source 2

Real value welding current,

Power source 1

Real value welding current,

Power source 2

Real value wire feed speed,

Power source 1

High

High

UINT16

UINT16

UINT16

UINT16

SINT16

Siehe Tabelle Werte-

bereich Safety status

auf Seite 29

0,0 bis 655,35

[V]

0,0 bis 655,35

[V]

0,0 bis 6535,5

[A]

0,0 bis 6535,5

[A]

-327,68 bis

327,67

[m/min]

100

100

10

10

100

12

13

23

24

25

26

0-16 177-192

0-16 193-208

Real value wire feed speed,

Power source 2

Actual real value for seam

tracking

-327,68 bis

SINT16

UINT16 0 bis 6,5535

327,67

[m/min]

100

100

00

25

Page 26

Adresse

relativ absolut

14

15

16

17

18

19

20

WORD

27

28

29

30

31

32

33

34

35

36

37

38

39

40

BYTE

BIT

0-16 209-224 Error number, Power source 1 UINT16 0 bis 65535 1

0-16 225-240 Error number, Power source 2 UINT16 0 bis 65535 1

0-16 241-256

0-16 257-272

0-16 273-288

0-16 289-304

0-16 305-320

BIT

Signal

Motor current M1, Power

source 1

Motor current M1, Power

source 2

Motor current M2, Power

source 1

Motor current M2, Power

source 2

Motor current M3, Power

source 1

Aktivität

/

Datentyp Bereich

UINT16

UINT16

UINT16

UINT16

UINT16

0 bis 655,35

[A]

0 bis 655,35

[A]

0 bis 655,35

[A]

0 bis 655,35

[A]

0 bis 655,35

[A]

Faktor

100

100

100

100

100

21

22

23

24

25

26

27

28

29

41

42

43

44

45

46

47

48

49

50

51

52

53

54

58

56

57

58

0-16 321-336

0-16 337-352 Warning, Power source 1 UINT16 0 bis 65535 1

0-16 353-368 Warning, Power source 2 UINT16 0 bis 65535 1

0-16 369-384 Wire position, Power source 1 SINT16

0-16 385-400 Wire position, Power source 2 SINT16

0-16 401-416 —

0-16 417-432 —

0-16 433-448 —

0-16 449-464 —

Motor current M3, Power

source 2

UINT16

0 bis 655,35

[A]

-327,68 bis

327,67 [mm]

-327,68 bis

327,67 [mm]

100

100

100

26

30

59

0-16 465-480 —

60

Page 27

Adresse

relativ absolut

WORD

BYTE

61

31

62

BIT

1 481 —

2 482 —

3 483 —

4 484 —

5 485 —

6 486 —

7 487 —

8 488 —

1 489 —

2 490 —

3 491 —

4 492 —

5 493 —

BIT

Signal

Aktivität

/

Datentyp Bereich

DE

Faktor

32

6 494 —

7 495 —

8 496 —

1 497 —

2 498 —

3 499 —

4 500 —

63

5 501 —

6 502 —

7 503 —

8 504 —

1 505 —

2 506 —

3 507 —

4 508 —

64

5 509 —

6 510 —

33

34

7 511 —

8 512 —

65

1-16 513-528 TAG start address UINT16 1 bis 65535 1

66

67

1-16 529-544 TAG value 1

68

27

Page 28

Adresse

relativ absolut

WORD

BYTE

69

35

70

71

36

72

73

37

74

75

38

76

39 77 0-7 609-616 TAG quantity UINT8 1 bis 255

39 78 0 617 TAG command read steigend

39 78 1 618 TAG command write steigend

39 78 2-7 619-624 —

79

40

80

BIT

1-16 545-560 TAG value 2

1-16 561-576 TAG value 3

1-16 577-592 TAG value 4

1-16 593-608 TAG value 5

1-16 625-640 Cooler temperature UINT16

BIT

Signal

Aktivität

/

Datentyp Bereich

-100 bis 200

[°C]

Faktor

10

41

42

43

44

-

45

46

-

47

48

49

50

-

51

81

82

83

84

85

86

87

-

90

91

-

94

95

96

93

94

99

-

102

1-16 641-656 Cooler flow rate UINT16

1-16 657-672

1-16 673-688

1-32 689-720

1-32 721-752

1-16 753-768

1-16 769-784

1-32 785-816

Real energy value, Power

source 1

Power on value, Power source

1

Hour meter power on, Power

source 1

Hour meter arc on time,

Power source 1

Real energy value, Power

source 2

Power on value, Power source

2

Hour meter power on, Power

source 2

UINT16

UINT16

UINT32

UINT32

UINT16

UINT16

UINT32

-100 bis 100

[l/min]

0,0 bis 6535,5

[kJ]

0,0 bis 6535,5

[kW]

0 bis 100000

[h]

0 bis 100000

[h]

0,0 bis 6535,5

[kJ]

0,0 bis 6535,5

[kW]

0 bis 100000

[h]

10

10

10

10

10

10

10

10

28

52

53

54

103

-

-

1-32 817-848

106

107

108

1-16 849-864 —

Hour meter arc on time,

Power source 2

UINT32

0 bis 100000

[h]

10

Page 29

Adresse

relativ absolut

WORD

BYTE

109

55

110

111

56

112

113

57

114

115

58

116

117

59

118

119

60

120

BIT

1-16 865-880 —

1-16 881-896 —

1-16 897-912 —

1-16 913-928 —

1-16 929-944 —

1-16 945-960 —

BIT

Signal

Aktivität

/

Datentyp Bereich

DE

Faktor

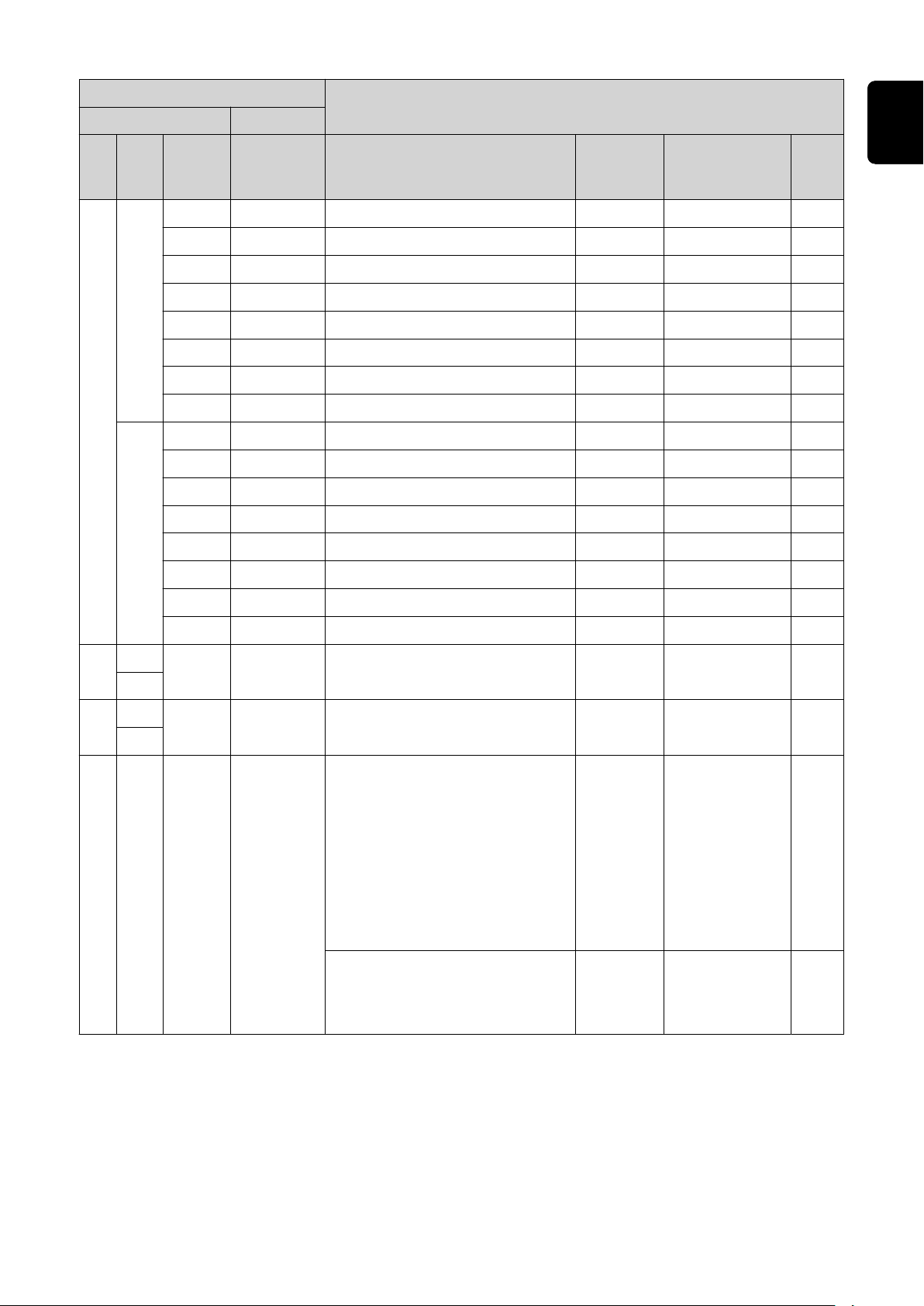

Zuordnung Sensorstatus 1-4

Wertebereich

Safety status

TAG-Tabelle

Signal Beschreibung

Sensor status 1 OPT/i WF R Drahtende (4,100,869)

Sensor status 2 OPT/i WF R Drahtfass (4,100,879)

Sensor status 3 OPT/i WF R Ringsensor (4,100,878)

Sensor status 4 Drahtpufferset CMT TPS/i (4,001,763)

Bit 1 Bit 0 Beschreibung

0 0 Reserve

0 1 Halt

1 0 Stopp

1 1 Nicht eingebaut / aktiv

Adresse TAG

Aktivität /

Datentyp

Bereich Faktor

BIT 481 Disable Start-end-pa-

rameter:

TAG 1 —

TAG 2 —

TAG 3 —

High

29

Page 30

Aktivität /

Adresse TAG

TAG 4 —

TAG 5 —

Datentyp

Bereich Faktor

Aktivität /

Adresse TAG

BIT 482

TAG 6 —

TAG 7 —

TAG 8 —

TAG 9 —

Adresse TAG

BIT 483

TAG 10 —

TAG 11 —

TAG 12 —

TAG 13 —

TAG 14 —

TAG 15 —

TAG 16 —

Datentyp

Aktivität /

Datentyp

Bereich Faktor

Bereich Faktor

TAG 17 —

TAG 18 —

TAG 19 —

Aktivität /

Adresse TAG

BIT 484

TAG 20 —

TAG 21 —

TAG 22 —

TAG 23 —

TAG 24 —

TAG 25 —

TAG 26 —

TAG 27 —

TAG 28 —

TAG 29 —

Datentyp

Bereich Faktor

30

Page 31

Aktivität /

Adresse TAG

BIT 485

TAG 30 —

TAG 31 —

TAG 32 —

TAG 33 —

TAG 34 —

TAG 35 —

TAG 36 —

TAG 37 —

TAG 38 —

TAG 39 —

Datentyp

Bereich Faktor

DE

Aktivität /

Adresse TAG

BIT 486 Disable Components

setup:

TAG 40 Cooling unit mode,

Power source 1

TAG 41 Delay time flow sensor,

Power source 1

TAG 42 Touch sensing sensitivi-

ty,

Power source 1 + 2

TAG 43 Ignition timeout,

Power source 1 + 2

TAG 44 —

TAG 45 —

TAG 46 —

TAG 47 —

TAG 48 —

TAG 49 —

Datentyp

High

UINT16 1 bis 4 1

UINT16

UINT16 0 bis 10 1

UINT16 5 bis 100 1

Bereich Faktor

5 bis 25 (in 5er

Schritten)

1

Aktivität /

Adresse TAG

BIT 487 Disable Units / Stan-

dards / Language:

TAG 50 Language,

Power source 1 + 2

TAG 51 Unit (metric / imperial),

Power source 1 + 2

TAG 52 Welding standard

(AWS / EU),

Power source 1 + 2

TAG 53 —

Datentyp

High

UINT16 1 bis 35 1

UINT16 1 bis 2 1

UINT16 1 bis 2 1

Bereich Faktor

31

Page 32

Aktivität /

Adresse TAG

TAG 54 —

TAG 55 —

TAG 56 —

TAG 57 —

TAG 58 —

TAG 59 —

Datentyp

Bereich Faktor

TAG 60 Arc break filter time /

Arc loss error time

TAG 61 Arc break monitoring

reaction

TAG 62 —

TAG 63 —

TAG 64 —

TAG 65 —

TAG 66 —

TAG 67 —

TAG 68 —

TAG 69 —

Adresse TAG

BIT 488

TAG 150 —

TAG 151 —

UINT16 0,00 bis 2,00 [s] 100

UINT16 1 bis 2 1

Aktivität /

Datentyp

Bereich Faktor

TAG 152 —

TAG 153 —

TAG 154 —

TAG 155 —

TAG 156 —

TAG 157 —

TAG 158 —

TAG 159 —

Adresse TAG

TAG 10001 Welding voltage, Power

source 1

TAG 10002 Welding current, Power

source 1

TAG 10003 Wire feed speed, Power

source 1

Aktivität /

Datentyp

UINT16

UINT16

SINT16

Bereich Faktor

0,00 bis 655,35

[V]

0,00 bis 6553,5

[A]

-327,68 bis

327,67 [m/min]

100

10

100

32

Page 33

Adresse TAG

TAG 10004 Real value power, Power

source 1

Aktivität /

Datentyp

UINT16

Bereich Faktor

0,00 bis 6553,5

[kJ]

DE

10

TAG 10005 Ignitiondistance, Power

source 1 + 2

TAG 10006 —

TAG 10007 —

TAG 10008 —

TAG 10009 Welding voltage, Power

source 2

TAG 10010 Welding current, Power

source 2

TAG 10011 Wire feed speed, Power

source 2

TAG 10012 Real value power, Power

source 2

TAG 10013 —

TAG 10014 —

TAG 10015 —

Schweißrelevante Werte

Adresse TAG

UINT16 0 bis 100 [mm] 10

UINT16

UINT16

SINT16

UINT16

Aktivität /

Datentyp

0,00 bis 655,35

[V]

0,00 bis 6553,5

[A]

-327,68 bis

327,67 [m/min]

0,00 bis 6553,5

[kJ]

Bereich Faktor

100

10

100

10

TAG 10100 Vd max. processline,

Power source 1

TAG 10101 Max. current WeldSys-

tem, Power source 1

TAG 10102 —

TAG 10103 Safety status, Power

source 1

TAG 10104 —

TAG 10105 —

TAG 10106 Vd max. processline,

Power source 2

TAG 10107 Max. current WeldSys-

tem, Power source 2

TAG 10108 —

TAG 10109 Safety status, Power

source 2

TAG 10110 —

TAG 10111 —

UINT16

SINT16

UINT16 1 bis 5 1

UINT16

SINT16

UINT16 1 bis 5 1

-0,0 bis 100,0

[m/min]

-5000 bis 5000

[A]

-0,0 bis 100,0

[m/min]

-5000 bis 5000

[A]

10

1

10

1

33

Page 34

Adresse TAG

Dokurelevante Werte

Daten-

typ / Ak-

tivität

Bereich Faktor

TAG 10200 Welding time, Power

source 1

TAG 10201 Selection time, Power

source 1

TAG 10202 —

TAG 10203 —

TAG 10204 —

TAG 10205 Welding time, Power

source 2

TAG 10206 Selection time, Power

source 2

TAG 10207 —

TAG 10208 —

TAG 10209 —

TAG 10210 —

Werteliste

Adresse TAG

UINT16 0 bis 65535 [s] 1

UINT16 0 bis 65535 [s] 1

UINT16 0 bis 65535 [s] 1

UINT16 0 bis 65535 [s] 1

Language

10 Norwegisch

11 Polnisch

12 Portugisisch

13 Slowakisch

14 Türkisch

15 Russisch

1 Englisch

2 Deutsch

3 Japanisch

4 Chinesisch

5 Spanisch

6 Französisch

7 Tschechisch

8 Ungarisch

9 Italienisch

34

16 Schwedisch

17 Estnisch

18 Finnisch

19 Litauisch

Page 35

Werteliste

20 Lettisch

21 Holländisch

22 Slowenisch

23 Rumänisch

24 Kroatisch

25 Ukrainisch

26 Koreanisch

27 Isländisch

28 Vietnamesisch

29 Thai

30 Indonesisch

31 Serbis

32 Hindi

33 Tamil

34 Dänisch

35 Bulgarisch

DE

Unit

0 Imperial, metrisch

1 —

2 —

Welding standard

0 —

1 AWS

2 CEN

Cooling unit mode

0 —

1 ECO

2 AUTO

3 ON

4 OFF

Safety status

0 —

1 Ungültig

2 Aktiv

3 Selbsttest

4 Halt

35

Page 36

5 Stop

Arc break watchdog reaction

0 —

1 IGNORE

2 ERROR

Werteliste

36

Page 37

Table of contents

General 38

Safety 38

Connections and Displays 38

Data Transfer Properties 39

Configuration parameters 39

Requirements for operating the bus module 40

Setting the Bus Module IP Address 41

Setting the Bus Module IP Address 41

Input and output signals 43

Data types 43

Availability of input signals 43

Input signals (from robot to power source) 43

Value Range for Working Mode 55

Value range Process line selection 55

Value range for Operating mode TWIN System 55

Value range for Documentation mode 56

Value range for Process controlled correction 56

Value range for Command value selection 56

Value rangePulse synchronization ratio 56

Availability of the output signals 57

Output signals (from power source to robot) 57

Assignment of Sensor Statuses 1–4 64

Value range Safety status 64

TAG Table 64

EN-US

37

Page 38

General

1234567

8

Safety

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in serious personal injury and damage to property.

All the work and functions described in this document must only be carried

▶

out by technically trained and qualified personnel.

Read and understand this document in full.

▶

Read and understand all safety rules and user documentation for this equip-

▶

ment and all system components.

WARNING!

Danger from electrical current.

This can result in serious personal injury and damage to property.

Before starting work, switch off all the devices and components involved and

▶

disconnect them from the grid.

Secure all devices and components involved so they cannot be switched back

▶

on.

WARNING!

Danger from unplanned signal transmission.

This can result in serious personal injury and damage to property.

Do not transfer safety signals via the interface.

▶

Connections and

Displays

1 TX+

2 TX-

3 RX+

6 RX-

4,5,7,8Not normally used; to ensu-

re signal completeness, these pins must be interconnected and, after passing

through a filter circuit, must

terminate at the ground

conductor (PE).

RJ45 connection

38

Page 39

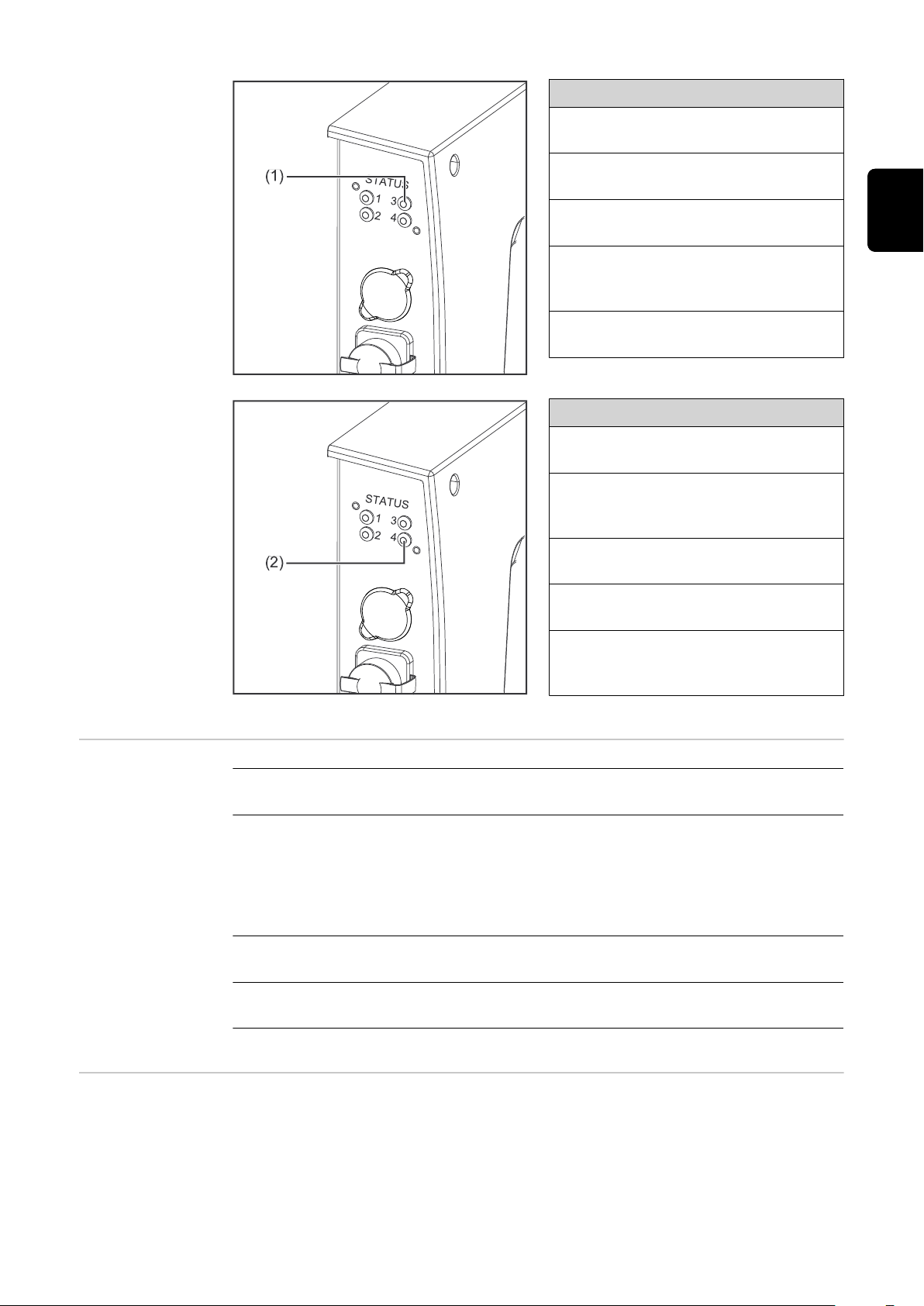

(1) LED MS - Module status

Off:

No supply voltage

Lights up green:

Controlled by a master

Flashes green (once):

Master not configured or master idle

Lights up red:

Major error (exception state, serious

fault, ...)

Flashes red:

Correctable error

(2) LED NS - Network status

Off:

No supply voltage or no IP address

Lights up green:

Online, one or more connections established (CIP category 1 or 3)

EN-US

Data Transfer

Properties

Flashes green:

Online, no connection established

Lights up red:

Double IP address, serious error

Flashes red:

Overrun of time for one or more

connections (CIP category 1 or 3)

Transfer technology

Ethernet

Medium

When selecting the cables and plugs, the ODVA recommendation for the planning and installation of EtherNet/IP systems must be observed.

The EMC tests were carried out by the manufacturer with the cable IEC5ES8VG0030M40M40-F.

Transmission speed

10 Mbit/s or 100 Mbit/s

Bus connection

RJ-45 Ethernet / M12

Configuration

parameters

In some robot control systems, it may be necessary to state the configuration parameters described here so that the bus module can communicate with the robot.

39

Page 40

Parameter Value Description

Requirements

for operating the

bus module

Vendor ID 0534

Device type 000C

Product code 0390

hex

hex

hex

(1332

(12

dec

(912

) Fronius International GmbH

dec

) Communication adapter

) Fronius FB Pro TwinEthernet/IP-2-

dec

Port

Product Name Fronius-FB-Pro-Twin-EtherNetIP(TM)

Size

Image Type

Standard

Image

Con-

Instance

Type

Produ-

cing In-

stance

suming

Instance

Instance

Name

Input Da-

ta Stan-

dard

Output

Data

Standard

Instance

Description

Data from power

source to robot

Data from robot

to power source

Instance

Number

105 120

155 120

[Byt

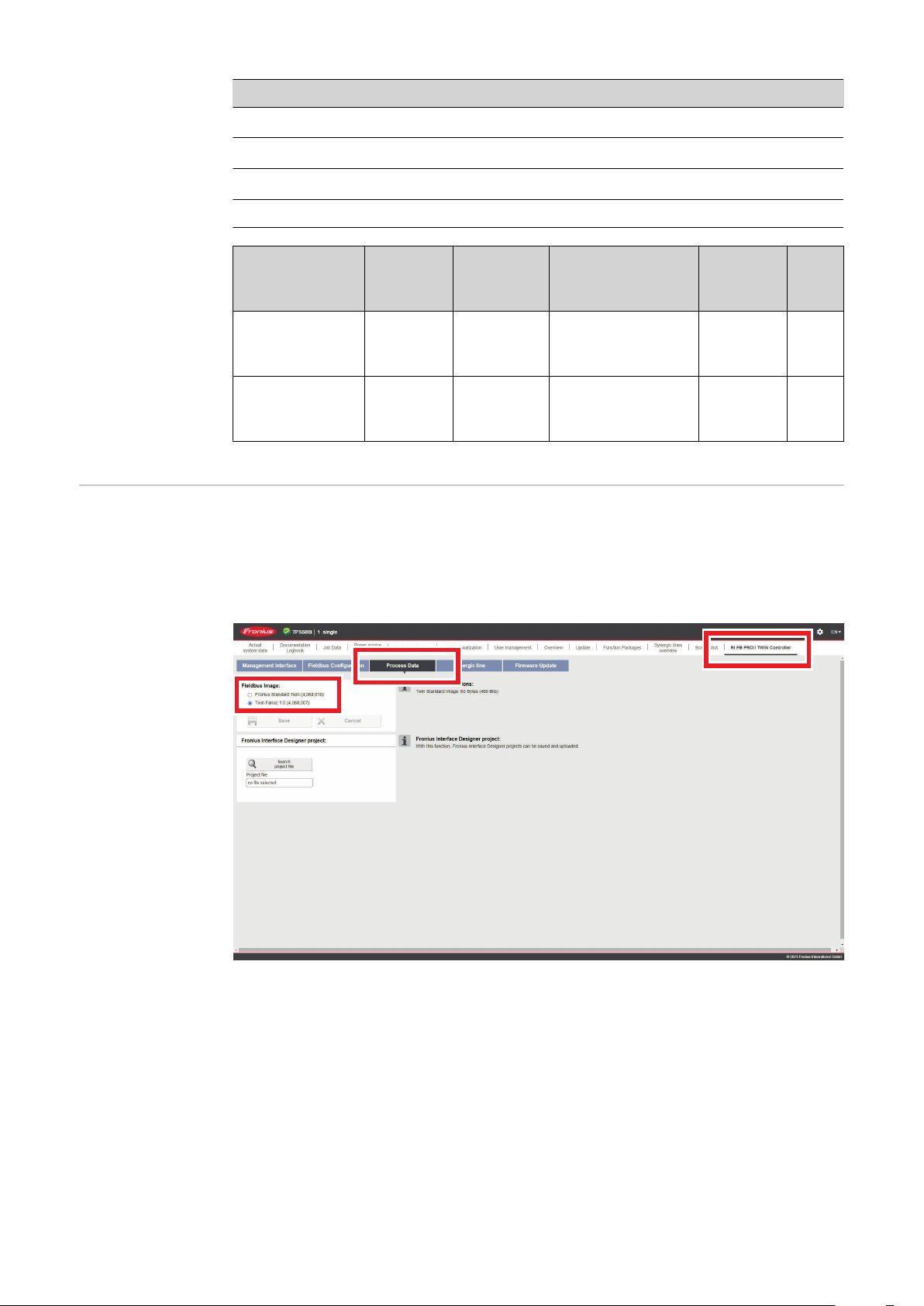

The following requirements must be met so that the bus module can be used:

The CFG/i RI FB PRO TWIN Fanuc 1.0 option must be installed in both

1.

power sources

The CFG/i RI FB PRO TWIN Fanuc 1.0 option must be activated in the

2.

SmartManager of both power sources:

e]

40

SnartManager of power source

Page 41

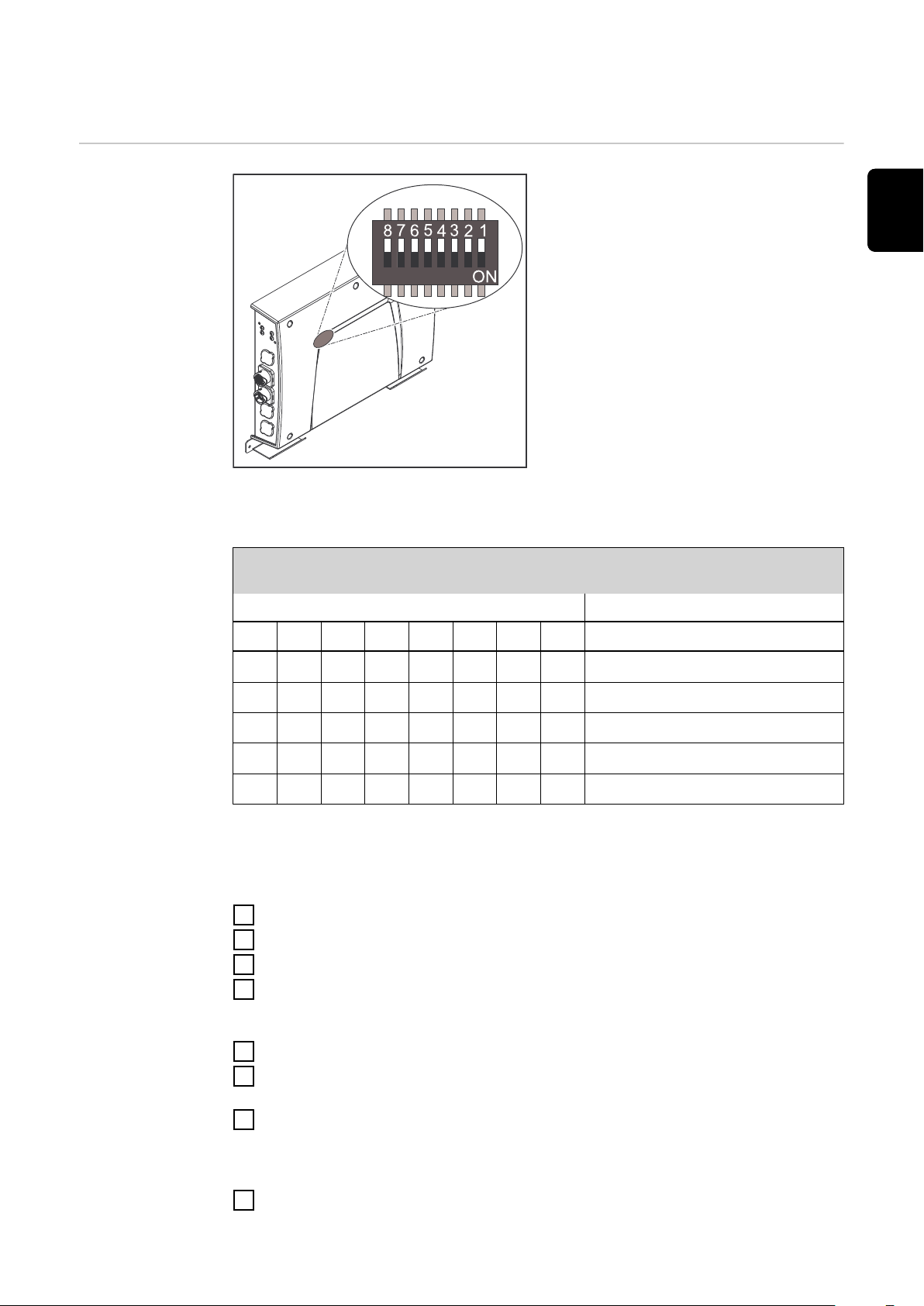

Setting the Bus Module IP Address

Setting the Bus

Module IP Address

You can set the bus module IP address

as follows:

Using the DIP switch in the inter-

1.

face within the range defined by

192.168.0.xx

(xx = DIP switch setting = 1 to 63)

All positions are set to the

-

OFF position at the factory. In

this case, the IP address must

be set on the website of the

power source

On the website of the power

2.

source (if all positions of the DIP

switch are set to the OFF position)

The IP address is set using DIP switch positions 1 to 6. The setting is in binary

format. This results in a configuration range of 1 to 63 in decimal format.

Example for setting the IP address of the bus module using the DIP switch in

the interface:

DIP-Switch

EN-US

8 7 6 5 4 3 2 1 IP Adress

- -

- -

- -

- -

- -

OFF OFF OFF OFF OFF ON

OFF OFF OFF OFF ON OFF

OFF OFF OFF OFF ON ON

ON ON ON ON ON OFF

ON ON ON ON ON ON

1

2

3

62

63

Instructions for setting the IP address on the website of the power source

(SmartManager):

Note down the IP address of the power source used:

On the power source control panel, select "Defaults"

1

On the power source control panel, select "System"

2

On the power source control panel, select "Information"

3

Note down the displayed IP address (example: 10.5.72.13)

4

Access the website of the power source in the internet browser:

Connect the computer to the network of the power source

5

Enter the IP address of the power source in the search bar of the Internet

6

browser and confirm

Enter the standard user name (admin) and password (admin)

7

The website of the power source is displayed

-

Set the bus module IP address:

On the power source website, select the "RI FB PRO/i TWIN" tab

8

41

Page 42

Enter the desired IP address for the interface under "Module configuration".

9

For example: 192.168.0.12

Select "Set configuration"

10

Select "Restart module"

11

The set IP address is applied

-

42

Page 43

Input and output signals

Data types The following data types are used:

UINT16 (Unsigned Integer)

-

Whole number in the range from 0 to 65535

SINT16 (Signed Integer)

-

Whole number in the range from -32768 to 32767

Conversion examples:

for a positive value (SINT16)

-

e.g. desired wire speed x factor

12.3 m/min x 100 = 1230

for a negative value (SINT16)

-

e.g. arc correction x factor

-6.4 x 10 = -64

= FFC0

dec

= 04CE

dec

hex

EN-US

hex

Availability of input signals

Input signals

(from robot to

power source)

The input signals listed below are available from firmware V1.8.0 of the RI MOD/i

CC Ethernet/IP-2P TWIN FANUC.

43

Page 44

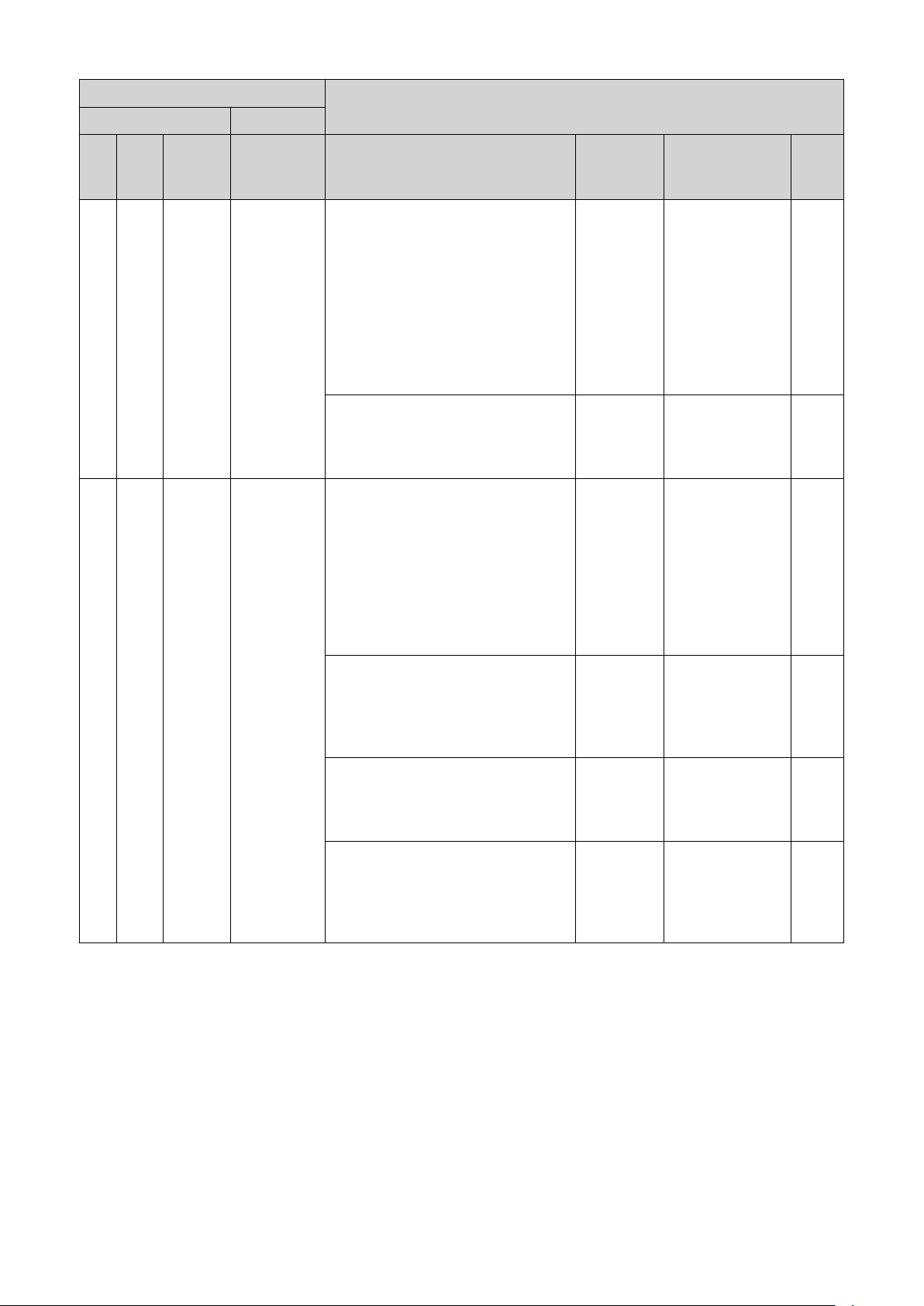

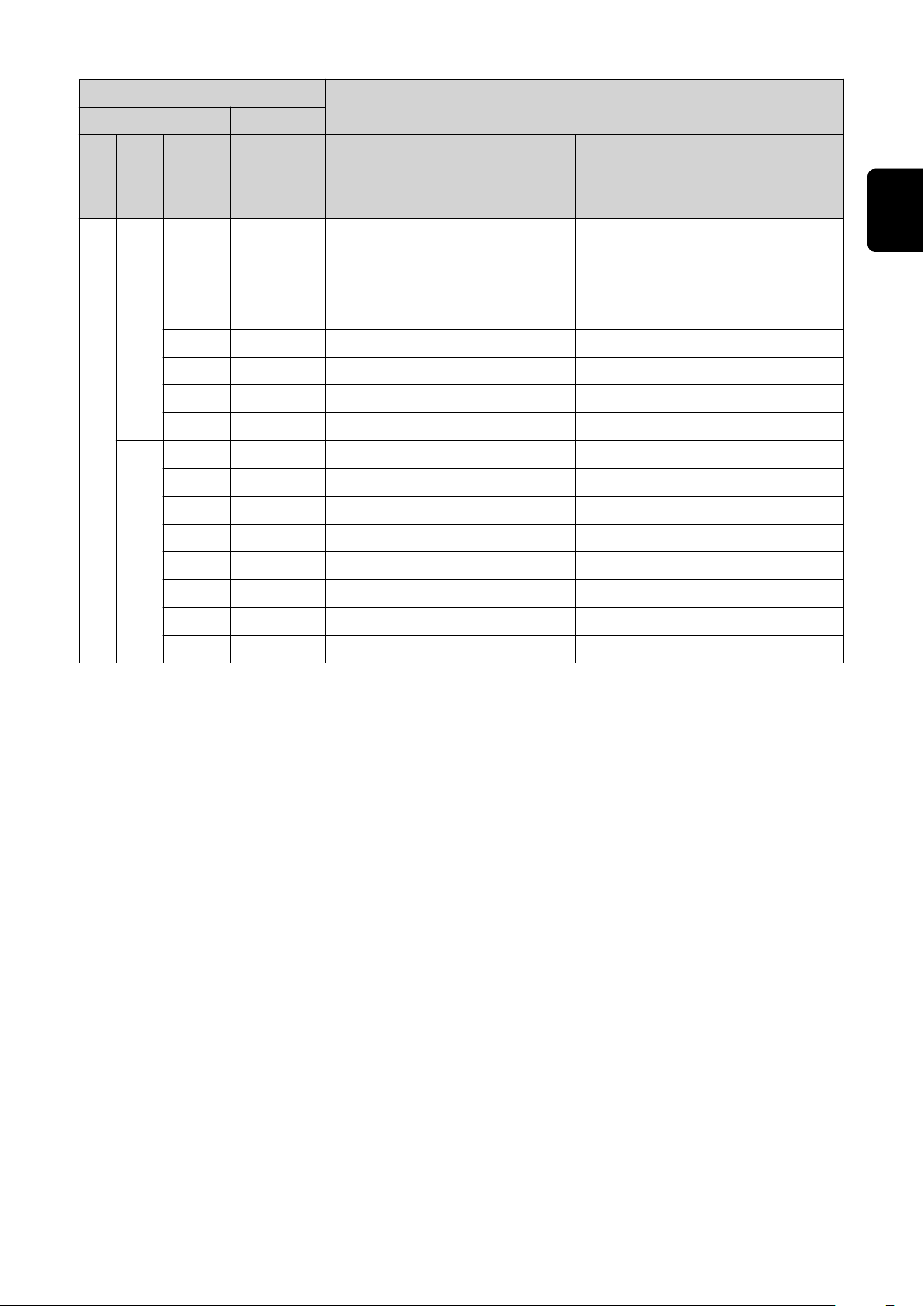

Address

Relative Absolute

WORD

BYTE

BIT

1 1 Welding Start

2 2 Robot ready High

3 3 Working mode Bit 0

BIT

Signal

Activity

/

data ty-

pe Range

Increa-

sing

Factor

1

1

2

4 4 Working mode Bit 1

5 5 Working mode Bit 2

6 6 Working mode Bit 3

7 7 Working mode Bit 4

8 8 —

1 9 Gas on

2 10 Wire forward

3 11 Wire backward

4 12 Error quit

5 13 Touch sensing High

6 14 Torch blow out

7 15 Processline selection Bit 0 High See following table

8 16 Processline selection Bit 1 High

UINT5

(0 - 31)

Increa-

sing

Increa-

sing

Increa-

sing

Increa-

sing

Increa-

sing

See following table

Value Range for

Working Mode on pa-

ge 55

Value range Process

line selection on pa-

ge 55

44

Page 45

Address

Relative Absolute

WORD

BYTE

BIT

1 17 Welding Simulation High

2 18 —

3 19 —

BIT

Signal

Activity

/

data ty-

pe Range

Factor

EN-US

3

2

4

4 20 —

5 21 —

6 22 Booster manual High

7 23 Wire brake on High

8 24 Torchbody Xchange High

1 25 —

2 26 Teach mode High

3 27 —

4 28 —

5 29 —

6 30 Wire sense start High

7 31 Wire sense break High

8 32 —

45

Page 46

Address

Relative Absolute

WORD

BYTE

5

BIT

1 33

2 34

3 35 —

4 36 —

5 37 —

6 38 Documentation mode High

BIT

Signal

Operating mode TWIN System

Bit 0

Operating mode TWIN System

Bit 1

Activity

/

data ty-

pe Range

High

High

See following table

Value range for Ope-

rating mode TWIN

System on page 55

See following table

Value range for Do-

cumentation mode

Factor

on page 56

3

6

7 39 —

8 40 —

1 41 —

2 42 —

3 43 —

4 44 —

5 45 —

6 46 —

7 47 —

8 48

Disable Arclength stabilizer,

Power source 1 + 2

High

46

Page 47

Address

Relative Absolute

WORD

BYTE

BIT

1 49 —

2 50 —

3 51 —

BIT

Signal

Activity

/

data ty-

pe Range

Factor

EN-US

7

4

8

9

4 52 —

5 53 —

6 54 —

7 55 —

8 56 —

1 57 ExtInput1 => OPT_Output 1 High

2 58 ExtInput2 => OPT_Output 2 High

3 59 ExtInput3 => OPT_Output 3 High

4 60 ExtInput4 => OPT_Output 4 High

5 61 ExtInput5 => OPT_Output 5 High

6 62 ExtInput6 => OPT_Output 6 High

7 63 ExtInput7 => OPT_Output 7 High

8 64 ExtInput8 => OPT_Output 8 High

1 65 —

2 66 —

3 67 —

4 68 —

5 69 —

6 70 —

7 71 —

8 72 —

5

10

1 73

2 74 —

3 75 —

4 76 —

5 77 —

6 78 —

7 79 —

8 80 —

Contact tip short circuit detection on

High

47

Page 48

Address

Relative Absolute

WORD

BYTE

BIT

1 81 —

2 82 —

3 83 —

BIT

Signal

Activity

/

data ty-

pe Range

Factor

11

6

12

13

7

14

15

8

16

4 84 —

5 85 —

6 86 —

7 87 —

8 88 —

1 89 —

2 90 —

3 91 —

4 92 —

5 93 —

6 94 —

7 95 —

8 96 —

1-16 97-112

1-16 113-128

Welding characteristic- / Job

number, Power source 1

Welding characteristic- / Job

number, Power source 2

UINT16 0 to 65535 1

UINT16 0 to 65535 1

For the welding processes

MIG/MAG pulse synergic,

MIG/MAG standard synergic,

MIG/MAG standard manual,

MIG/MAG PMC,

MIG/MAG LSC,

17,

9

18

1-16 129-144

CMT, ConstantWire:

Wire feed speed command value, Power source 1

For job mode:

Power correction, Power

source 1

SINT16

SINT16

-327.68 to

327.67

[m/min]

-20.00 to

20.00

[%]

100

100

48

Page 49

Address

Relative Absolute

WORD

10

BYTE

19,

20

BIT

1-16 145-160

BIT

Signal

For the welding processes

MIG/MAG pulse synergic,

MIG/MAG standard synergic,

MIG/MAG standard manual,

MIG/MAG PMC,

MIG/MAG LSC,

CMT, ConstantWire:

Wire feed speed command value, Power source 2

Activity

/

data ty-

pe Range

-327.68 to

SINT16

[m/min]

327.67

Factor

EN-US

100

11

21,

22

1-16 161-176

For job mode:

Power correction, Power

source 2

For the welding processes

MIG/MAG pulse synergic,

MIG/MAG standard synergic,

MIG/MAG PMC,

MIG/MAG LSC,

CMT:

Arclength correction, Power

source 1

For the welding process

MIG/MAG standard manual:

Welding voltage, Power source

1

For job mode:

Arclength correction, Power

source 1

For the welding process ConstantWire:

Hotwire current, Power source

1

SINT16

SINT16

UINT16

SINT16

UINT16

-20.00 to

20.00

[%]

-10.0 to 10.0

[steps]

0.0 to 6553.5

[V]

-10.0 to 10.0

[steps]

0.0 to 6553.5

[A]

100

10

10

10

10

49

Page 50

Address

Relative Absolute

WORD

12

BYTE

23,

24

BIT

1-16 177-192

BIT

Signal

For the welding processes

MIG/MAG pulse synergic,

MIG/MAG standard synergic,

MIG/MAG PMC,

MIG/MAG LSC,

CMT:

Arclength correction, Power

source 2

For the welding process

MIG/MAG standard manual:

Welding voltage, Power source

2

For job mode:

Arclength correction, Power

source 2

Activity

/

data ty-

pe Range

SINT16

UINT16

SINT16

-10.0 to 10.0

0.0 to 6553.5

-10.0 to 10.0

[steps]

[V]

[steps]

Factor

10

10

10

13

14

25,

26

27,

28

1-16 193-208

1-16 208-223

For the welding process ConstantWire:

Hotwire current, Power source

2

For the welding processes

MIG/MAG pulse synergic,

MIG/MAG standard synergic,

MIG/MAG PMC,

MIG/MAG LSC,

CMT:

Pulse-/dynamic correction,

Power source 1

For the welding process

MIG/MAG standard manual:

Dynamic, Power source 1

For the welding processes

MIG/MAG pulse synergic,

MIG/MAG standard synergic,

MIG/MAG PMC,

MIG/MAG LSC,

CMT:

Pulse-/dynamic correction,

Power source 2

UINT16

SINT16

UINT16

SINT16

0.0 to 6553.5

[A]

-10.0 to 10.0

[steps]

0.0 to 10.0

[steps]

-10.0 to 10.0

[steps]

10

10

10

10

50

For the welding process

MIG/MAG standard manual:

Dynamic, Power source 2

UINT16

0.0 to 10.0

[steps]

10

Page 51

Address

Relative Absolute

WORD

BYTE

29

15

30

BIT

1-16 225-240

BIT

Signal

Wire retract correction, Power

source 1

Activity

/

data ty-

pe Range

UINT16 0.0 to 10.0 10

Factor

EN-US

16

17

18

19

20

21

22

23

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

1-16 241-256

1-16 257-272 Welding speed UINT16

1-16 273-288

1-16 289-304

1-16 305-320

1-16 321-336 Wire sense edge detection UINT16

1-16 337-352 —

1-16 353-368 —

Wire retract correction, Power

source 2

Arclength stabilizer, Power

source 1

Arclength stabilizer, Power

source 2

Wire forward / wire backward

length

UINT16 0.0 to 10.0 10

0.0 to 6535.5

[cm/min]

UINT16 0.0 to 5.0 10

UINT16 0.0 to 5.0 10

OFF / 1 to

UINT16

65355

[mm]

OFF / 0.5 to

20.0

[mm]

10

1

10

24

25

26

27

28

29

30

47

1-16 369-384 —

48

49

1-16 385-400 —

50

51

1-16 401-416 —

52

53

1-16 417-432 —

54

55

1-16 433-448 —

56

57

1-16 449-464 —

58

59

1-16 465-480 Seam number UINT16 0 to 65535 1

60

51

Page 52

Address

Relative Absolute

WORD

BYTE

BIT

1 481

2 482 —

3 483 —

4 484 —

BIT

Signal

Disable start-end-parameter

(Image)

Activity

/

data ty-

pe Range

High

Factor

31

61

62

5 485 Disable gas-settings High

6 486

7 487

8 488

1 489

2 490 —

3 491 —

4 492 —

5 493 —

6 494 —

7 495 —

8 496 —

Disable components setup

(TAG)

Disable language / units / standards (TAG)

Disable penetration stabilizer,

Power source 1 + 2

Enable arc break monitoring /

arc loss

High

High

High

High

52

Page 53

Address

Relative Absolute

WORD

BYTE

BIT

1 497 —

2 498 —

3 499 —

BIT

Signal

Activity

/

data ty-

pe Range

Factor

EN-US

32

33

34

63

64

65

66

67

68

4 500 —

5 501 —

6 502 —

7 503 —

8 504 —

1 505 —

2 506 —

3 507 —

4 508 —

5 509 —

6 510 —

7 511

8 512 Command value selection Bit 1 High

1-16 513-528 TAG start address UINT16 1 to 65535 1

1-16 529-544 TAG value 1

Command value selection Bit

0

High

See following table

Value range for Com-

mand value selection

on page 56

69

35

70

71

36

72

73

37

74

75

38

76

39 77 1-8 609-616 TAG quantity UINT8 0 to 5 1

39 78 1 617 TAG command read

39 78 2 618 TAG command write

39 78 3-8 619-624 —

1-16 545-560 TAG value 2

1-16 561-576 TAG value 3

1-16 577-592 TAG value 4

1-16 593-608 TAG value 5

Increa-

sing

Increa-

sing

53

Page 54

Address

Relative Absolute

WORD

BYTE

79

40

80

BIT

1-16 625-640 Gas preflow UINT16

BIT

Signal

Activity

/

data ty-

pe Range

0.0 to 9.9

[s]

Factor

10

41

42

43

44

45

46

47

48

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

1-16 641-656 Gas postflow UINT16

1-16 657-672 Inching value UINT16

1-16 673-688 S2T - Starting current UINT16

1-16 689-704 S2T - Starting current time UINT16

1-16 705-720 S2T - Slope 1 UINT16

1-16 721-736 S2T - Slope 2 UINT16

1-16 737-752 S2T - End current UINT16

1-16 753-768 S2T - End current time UINT16

0.0 to 9.9

[s]

-327.67 to

327.67

[m/min]

0.0 to 200

[%]

0.0 to 9.9

[s]

0.0 to 9.9

[s]

0.0 to 9.9

[s]

0.0 to 200

[%]

0.0 to 9.9

[s]

10

100

1

10

10

10

1

10

49

50

51

52

53

54

55

56

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

1-16 769-784 Start arclength correction SINT16 -10.0 to 10.0 10

1-16 785-800 End arclength correction UINT16 -10.0 to 10.0 10

See following table

1-16 801-816 Pulse synchronization ratio UINT16

1-16 817-832 Phase shift lead / trail UINT16

1-16 833-848 Ignition delay trail UINT16

1-16 849-864 —

1-16 865-880

1-16 881-896

Penetration stabilizer,

Power source 1

Penetration stabilizer,

Power source 2

UINT16

UINT16

Value rangePulse

synchronization ratio

on page 56

0 to 95

(255 = AUTO)

0.00 to 2.00

(254 = OFF)

(255 = OFF)

0.0 to 10.0

[m/min]

0.0 to 10.0

[m/min]

1

100

10

10

54

Page 55

Address

Relative Absolute

WORD

BYTE

BIT

113

57

1-16 897-912 —

114

115

58

1-16 913-928 —

116

117

59

1-16 929-944 —

118

119

60

1-16 945-960 —

120

BIT

Signal

Activity

/

data ty-

pe Range

Factor

EN-US

Value Range for

Working Mode

Value range Process line selection

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Description

0 0 0 0 0 Internal parameter selection

0 0 0 0 1 Special 2-step mode characteristics

0 0 0 1 0 Job mode

0 1 0 0 0 2-step mode characteristics

0 1 0 0 1 2-step MIG/MAG standard manual

1 0 0 0 1 Stop coolant pump

Value range for operating mode

Bit 1 Bit 0 Description

0 0 Process line 1 (default)

0 1 Process line 2

1 0 Process line 3

1 1 Reserved

Value range for process line selection

Value range for

Operating mode

TWIN System

Bit 1 Bit 0 Function power source 1 Function power source 2

0 0 Single mode OFF

0 1 TWIN Lead TWIN Trail

1 0 TWIN Trail TWIN Lead

1 1 OFF Single mode

Value range for TWIN System Mode

55

Page 56

Value range for

Documentation

mode

Value range for

Process controlled correction

Bit 0 Description

0 Seam number of power source (internal)

1 Seam number of robot (Word 29)

Value range for documentation mode

Process

Signal

Activity /

data type

PMC Arc length stabilizer SINT16

Value range for process-dependent correction

Value range

configuration

range

Unit

-327.8 to +327.7

0.0 to +5.0 Volts 10

Factor

Value range for

Command value

selection

Value range

Pulse synchronization ratio

Bit 1 Bit 0 Description

0 0 Wire feed speed command value

0 1 Welding current command value

Value range Signal Command value selection

Value Description

1 Auto

2 1/1

3 1/2

4 1/3

Value range Pulse synchronization ratio

56

Page 57

Availability of

the output signals

The output signals listed below are available from firmware V1.8.0 of the RI

MOD/i CC Ethernet/IP-2P TWIN FANUC.

Output signals

(from power

source to robot)

Address

Relative Absolute

WORD

BYTE

1

1

BIT

1 1 Heartbeat Powersource High/low 1 Hz

2 2 Power source ready High

3 3 Warning High

4 4 Process active High

5 5 Current flow High

6 6 Arc stable- / touch signal High

7 7 Main current signal High

8 8 Touch signal High

1 9 Collisionbox active Low

BIT

Signal

Activity

/

data type Range

0 = collision or

cable break

EN-US

Factor

2 10

3 11 Wire stick workpiece High

2

4 12 —

5 13 Short circuit contact tip High

6 14

7 15 —

8 16 Torch body gripped High

Robot Motion Release, Power

source 1

Parameter selection internally

High

High

57

Page 58

Address

Relative Absolute

WORD

2

BYTE

3

4

BIT

1 17 Command value out of range High

2 18 Correction out of range High

3 19 —

4 20 Limitsignal, Power Source 1 High

5 21 —

6 22 Standby active High

7 23 Main supply status High

8 24 —

1 25

2 26

3 27

4 28

BIT

Signal

Sensor status 1, Power

Source 1

Sensor status 2, Power

Source 1

Sensor status 3, Power

Source 1

Sensor status 4, Power

Source 1

Activity

/

data type Range

High

High

High

High

See table Assign-

ment of Sensor Sta-

tuses 1–4 on page

64

Factor

5 29 —

6 30 —

7 31 —

8 32 —

1 33 —

2 34 —

3 35 —

4 36

5

5 37

6 38 —

7 39 Notification High

3

8 40 System not ready High

1 41 —

2 42 —

3 43 —

Safety status Bit 0, Power

Source 1

Safety status Bit 1, Power

Source 1

High

High

See table Value ran-

ge Safety status on

page 64

58

6

4 44 —

5 45 —

6 46 —

7 47 —

8 48 —

Page 59

Address

Relative Absolute

WORD

4

BYTE

7

8

BIT

1 49 —

2 50 —

3 51 —

4 52 —

5 53 —

6 54 —

7 55 Gas nozzle touched High

8 56 —

1 57 ExtOutput1 <= OPT_Input1 High

2 58 ExtOutput2 <= OPT_Input2 High

3 59 ExtOutput3 <= OPT_Input3 High

4 60 ExtOutput4 <= OPT_Input4 High

5 61 ExtOutput5 <= OPT_Input5 High

6 62 ExtOutput6 <= OPT_Input6 High

BIT

Signal

Activity

/

data type Range

Factor

EN-US

7 63 ExtOutput7 <= OPT_Input7 High

8 64 ExtOutput8 <= OPT_Input8 High

1 65 —

2 66

3 67 Limitsignal, Power source 2 High

9

5

10

4 68 —

5 69 —

6 70 —

7 71 —

8 72 —

1 73 —

2 74 —

3 75 —

4 76 —

5 77 —

6 78 —

Robot Motion Release, Power

source 2

High

7 79 —

8 80 —

59

Page 60

Address

Relative Absolute

WORD

6

11

12

BYTE

BIT

1 81

2 82

3 83

4 84

5 85 —

6 86 —

7 87 —

8 88 —

1 89 —

2 90 —

3 91 —

4 92

5 93

BIT

Signal

Sensor status 1, Power

Source 2

Sensor status 2, Power

Source 2

Sensor status 3, Power

Source 2

Sensor status 4, Power

Source 2

Safety status Bit 0, Power

Source 2

Safety status Bit 1, Power

Source 2

Activity

/

data type Range

High

High

High

High

High

High

See table Assign-

ment of Sensor Sta-

tuses 1–4 on page

See table Value ran-

ge Safety status on

page 64

64

Factor

7

8

9

10

11

12

13

13

14

15

16

17

18

19

20

21

22

23

24

25

26

6 94 —

7 95 —

8 96 —

0-16 97-112

0-16 113-128

0-16 129-144

0-16 145-160

0-16 161-176

0-16 177-192

0-16 193-208

Real value welding voltage,

Power source 1

Real value welding voltage,

Power source 2

Real value welding current,

Power source 1

Real value welding current,

Power source 2

Real value wire feed speed,

Power source 1

Real value wire feed speed,

Power source 2

Actual real value for seam

tracking

UINT16

UINT16

UINT16

UINT16

SINT16

SINT16

UINT16 0 to 6,5535

0.0 to 655.35

[V]

0.0 to 655.35

[V]

0.0 to 6535.5

[A]

0.0 to 6535.5

[A]

-327.68 to

327.67

[m/min]

-327.68 to

327.67

[m/min]

100

100

10

10

100

100

100

00

60

Page 61

Address

Relative Absolute

14

15

16

17

18

19

20

WORD

27

28

29

30

31

32

33

34

35

36

37

38

39

40

BYTE

BIT

0-16 209-224 Error number, Power source 1 UINT16 0 to 65535 1

0-16 225-240 Error number, Power source 2 UINT16 0 to 65535 1

0-16 241-256

0-16 257-272

0-16 273-288

0-16 289-304

0-16 305-320

BIT

Signal

Motor current M1, Power

source 1

Motor current M1, Power

source 2

Motor current M2, Power

source 1

Motor current M2, Power

source 2

Motor current M3, Power

source 1

Activity

/

data type Range

UINT16

UINT16

UINT16

UINT16

UINT16

0 to 655.35

[A]

0 to 655.35

[A]

0 to 655.35

[A]

0 to 655.35

[A]

0 to 655.35

[A]

Factor

EN-US

100

100

100

100

100

21

22

23

24

25

26

27

28

29

41

42

43

44

45

46

47

48

49

50

51

52

53

54

58

56

57

58

0-16 321-336

0-16 337-352 Warning, Power source 1 UINT16 0 to 65535 1

0-16 353-368 Warning, Power source 2 UINT16 0 to 65535 1

0-16 369-384 Wire position, Power source 1 SINT16

0-16 385-400 Wire position, Power source 2 SINT16

0-16 401-416 —

0-16 417-432 —

0-16 433-448 —

0-16 449-464 —

Motor current M3, Power

source 2

UINT16

0 to 655.35

[A]

-327.68 to

327.67 [mm]

-327.68 to

327.67 [mm]

100

100

100

30

59

0-16 465-480 —

60

61

Page 62

Address

Relative Absolute

31

WORD

61

62

BYTE

BIT

1 481 —

2 482 —

3 483 —

4 484 —

5 485 —

6 486 —

7 487 —

8 488 —

1 489 —

2 490 —

3 491 —

4 492 —

5 493 —

6 494 —

BIT

Signal

Activity

/

data type Range

Factor

32

7 495 —

8 496 —

1 497 —

2 498 —

3 499 —

4 500 —

63

5 501 —

6 502 —

7 503 —

8 504 —

1 505 —

2 506 —

3 507 —

4 508 —

64

5 509 —

6 510 —

7 511 —

62

33

34

8 512 —

65

1-16 513-528 TAG start address UINT16 1 to 65535 1

66

67

1-16 529-544 TAG value 1

68

Page 63

Address

Relative Absolute

WORD

BYTE

69

35

70

71

36

72

73

37

74

75

38

76

39 77 0-7 609-616 TAG quantity UINT8 1 to 255

39 78 0 617 TAG command read Increasing

39 78 1 618 TAG command write Increasing

39 78 2-7 619-624 —

79

40

80

BIT

1-16 545-560 TAG value 2

1-16 561-576 TAG value 3

1-16 577-592 TAG value 4

1-16 593-608 TAG value 5

1-16 625-640 Cooler temperature UINT16

BIT

Signal

Activity

/

data type Range

-100 to 200

[°C]

Factor

EN-US

10

41

42

43

44

-

45

46

-

47

48

49

50

-

51

81

82

83

84

85

86

87

-

90

91

-

94

95

96

93

94

99

-

102

1-16 641-656 Cooler flow rate UINT16

1-16 657-672

1-16 673-688

1-32 689-720

1-32 721-752

1-16 753-768

1-16 769-784

1-32 785-816

Real energy value, Power

source 1

Power on value, Power source

1

Hour meter power on, Power

source 1

Hour meter arc on time,

Power source 1

Real energy value, Power

source 2

Power on value, Power source

2

Hour meter power on, Power

source 2

UINT16

UINT16

UINT32

UINT32

UINT16

UINT16

UINT32

-100 to 100

[l/min]

0.0 to 6535.5

[kJ]

0.0 to 6535.5

[kW]

0 to 100000

[h]

0 to 100000

[h]

0.0 to 6535.5

[kJ]

0.0 to 6535.5

[kW]

0 to 100000

[h]

10

10

10

10

10

10

10

10

52

53

54

103

-

–

1-32 817-848

106

107

108

1-16 849-864 —

Hour meter arc on time,

Power source 2

UINT32

0 to 100000

[h]

10

63

Page 64

Address

Relative Absolute

55

56

57

58

59

60

WORD

109

110

114

115

116

118

119

120

111

112

113

117

BYTE

BIT

1-16 865-880 —

1-16 881-896 —

1-16 897-912 —

1-16 913-928 —

1-16 929-944 —

1-16 945-960 —

BIT

Signal

Activity

/

data type Range

Factor

Assignment of

Sensor Statuses

1–4

Value range

Safety status

TAG Table

Signal Description

Sensor status 1 OPT/i WF R wire end (4,100,869)

Sensor status 2 OPT/i WF R wire drum (4,100,879)

Sensor status 3 OPT/i WF R ring sensor (4,100,878)

Sensor status 4 Wire buffer set CMT TPS/i (4,001,763)

Bit 1 Bit 0 Description

0 0 Reserve

0 1 Hold

1 0 Stop

1 1 Not installed / active

Address TAG

Activity /

data type

Range Factor

64

BIT 481 Disable Start-end-pa-

rameter:

TAG 1 —

TAG 2 —

TAG 3 —

High

Page 65

Activity /

Address TAG

TAG 4 —

TAG 5 —

data type