Page 1

/ Battery Charging Systems / Welding Technology / Solar Electronics

Autotrafo TT 2600 - 230/200 V

Autotrafo TT 2600/3000 - 480/440 V

Autotrafo TT 2600/3000 - 500/460 V

Autotrafo MW 2600 - 230/200 V

Autotrafo MW 2600/3000 - 480/440 V

Autotrafo MW 2600/3000 - 500/460 V

Autotrafo MW 2600 - 575 V

Fitting Instructions

Autotransformer

EN

42,0426,0036,EN 002-11042012

Page 2

Page 3

Contents

General ......................................................................................................................................................... 2

Concept .................................................................................................................................................... 2

Versions ................................................................................................................................................... 2

Controls and connections .............................................................................................................................. 4

Controls and connections „Version 1“ ...................................................................................................... 4

Controls and connections „Version 2“ ...................................................................................................... 4

Controls and connections „Version 3“ ...................................................................................................... 5

Setting the mains voltage .............................................................................................................................. 6

Safety ....................................................................................................................................................... 6

Converting the mains voltage for „Version 1“ ........................................................................................... 6

Converting the mains voltage for „Version 2“ ........................................................................................... 8

Putting the machine into service ................................................................................................................... 9

Safety ....................................................................................................................................................... 9

Preparing to install ................................................................................................................................... 9

Installing the components ...................................................................................................................... 10

Connecting the auto-transformer „Version 1“ .......................................................................................... 11

Connecting the auto-transformer „Versions 2 and 3“ ..............................................................................11

Care, maintenance and disposal ................................................................................................................. 12

General .................................................................................................................................................. 12

Every start-up ......................................................................................................................................... 12

Every 6 months ...................................................................................................................................... 12

Every 12 months .................................................................................................................................... 12

Disposal ................................................................................................................................................. 12

Troubleshooting........................................................................................................................................... 13

General .................................................................................................................................................. 13

Troubleshooting ..................................................................................................................................... 13

EN

Technical data ............................................................................................................................................. 15

Safety ..................................................................................................................................................... 15

Auto-transformer „Version 1“ (480/440 V, 500/460 V) ............................................................................ 15

Auto-transformer „Version 1“ (230/200 V) .............................................................................................. 16

Auto-transformer „Versions 2 and 3“ ...................................................................................................... 17

Spare parts list

Circuit diagrams

Fronius Worldwide

1

Page 4

General

Concept

Versions Version 1:

This range of digital machines is remarkably flexible and readily adaptable to a wide

range of applications. These welcome features are due firstly to the modular product

design and secondly to the scope that the system gives for troublefree system expansion. High-quality components, protective plastic frames and a powder-coated aluminium

housing ensure excellent reliability and durability.

The auto-transformers are especially designed to meet the requirements of this range of

digital machines.

They allow the machines to be used with available mains voltages.

- Auto-transformer TT 2600/3000 - 480/440 V

- Auto-transformer TT 2600/3000 -500/460 V

- Auto-transformer MW 2600/3000 - 480/440 V

- Auto-transformer MW 2600/3000 -500/460 V

- Auto-transformer MW 2600 - 200, 230/400 V

- Auto-transformer TT 2600 - 200, 230/400V

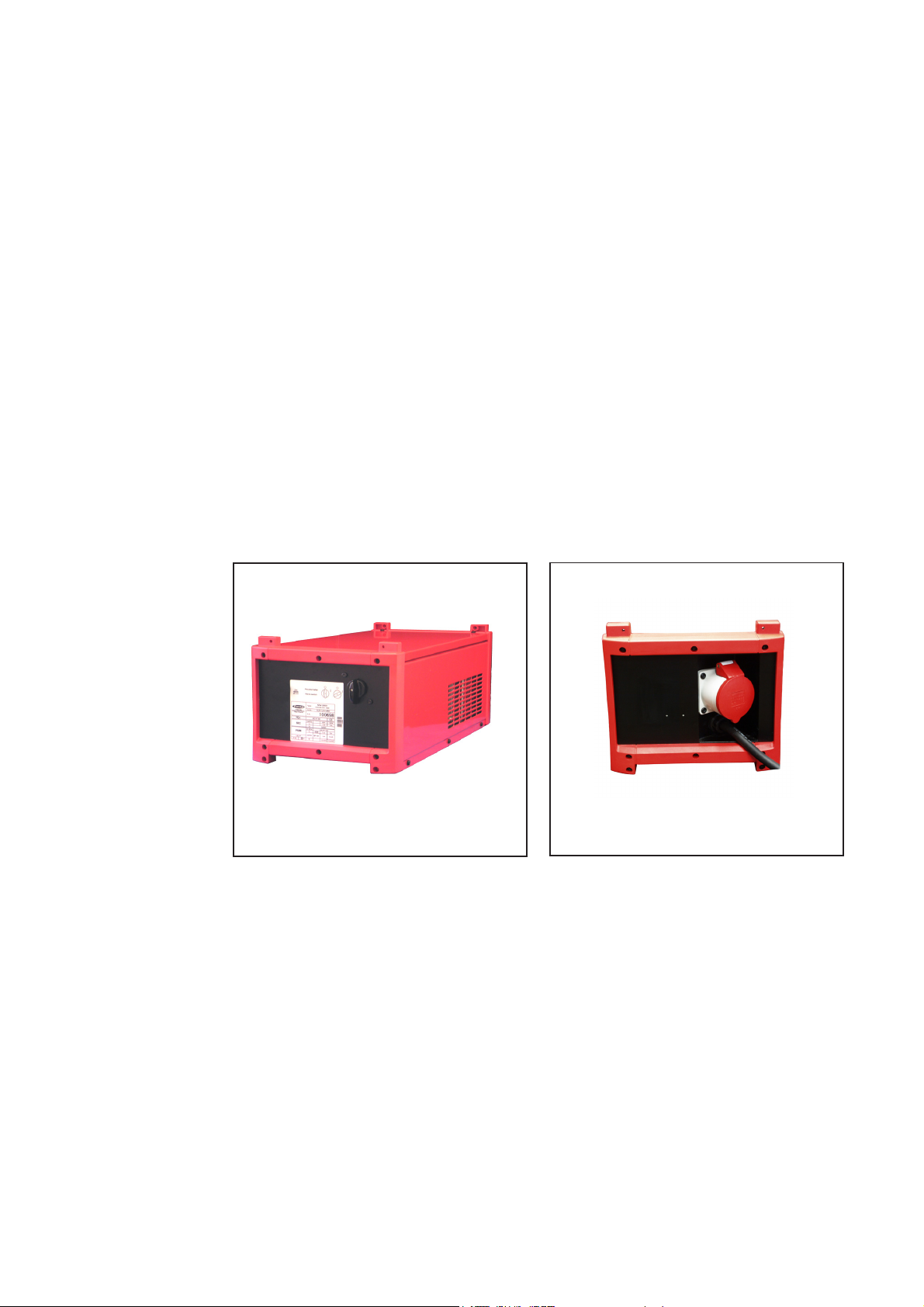

Fig. 1 Front view, „Version 1“

Fig. 2 Rear view, „Version 1“

2

Page 5

Versions

(continued)

Version 2:

- Auto-transformer MW 2600/3000 - 480/440 V

EN

Fig. 3 Front view, „Version 2“

Version 3:

- Auto-transformer MW 2600/3000 - 575 V

Fig. 5 Front view, „Version 3“

Fig. 4 Rear view, „Version 2“

Fig. 6 Rear view, „Version 3“

3

Page 6

Controls and connections

Controls and

connections

„Version 1“

(1)

(2)

(3)

Controls and

connections

„Version 2“

Fig. 1 Front view, auto-transformer TT 2600/3000

MW 2600/3000

Fig. 2 Rear view, auto-transformer TT 2600/3000

MW 2600/3000

(1) Main switch ... central switch for turning all system components of the welding

machine on and off

(2) Power source connection socket ... for supplying the power source with the

transformed voltage.

(3) Mains cable ... for supplying the auto-transformer with the mains voltage

(5)

(4)

(3)

(2)

Fig. 3 Front view. Auto-transformer MW2600

(1)

(6)

Fig. 4 Rear view. Auto-transformer MW2600

(1) Main switch ... central switch for turning all system components of the welding

machine on and off

(2) Socket fuse ...T10A 440V

(3) Power source connection cable „OUTPUT 50/60 Hz“ ... for supplying the power

source with the transformed voltage.

4

Page 7

Controls and

connections

„Version 2“

(continued)

Controls and

connections

„Version 3“

(4) Mains cable „INPUT 50/60Hz“ ... for supplying the auto-transformer with the mains

voltage

(5) Socket outlet ... 230V/10 A

(6) Strain relief devices ... for connection cables of external devices

EN

(2)

Fig. 5 Front view, auto-transformer MW2600 575 V

(1)

(5)

(6)

Fig. 6 Rear view, auto-transformer MW2600 575 V

(3)

(4)

(1) Main switch ... central switch for turning all system components of the welding

machine on and off

(2) Fan fuse ...T400mA 440 V

(3) Power source connection cable „OUTPUT 50/60 Hz“ ... for supplying the power

source with the transformed voltage.

(4) Mains cable „INPUT 50/60Hz“ ... for supplying the auto-transformer with the mains

voltage

(5) Blanking cover

(6) Blanking cover

5

Page 8

7

7

7

7

7

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

Setting the mains voltage

Safety

Converting the

mains voltage for

„Version 1“

WARNING! Work performed incorrectly can cause serious injury and damage.

The following activities must only be carried out by Fronius-trained qualified

personnel! Take note of the safety rules in the power source operating instructions.

WARNING! An electric shock can be fatal. Before opening the unit, turn the main

switch to the „0“ position and pull out the mains plug or disconnect the power

supply.

1. Turn the main switch on the auto-transformer to the „0“ position

2. Pull out the mains plug or disconnect the power supply

3. Remove the auto-transformer cover

Example: Converting from 500 V to 460 V

23456789012345

23456789012345

Setting

460 V

23456789012345

Setting

23456789012345

23456789012345

500 V

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

Mains cable (50/60Hz)

„INPUT 50/60 Hz“

234567890123456

460V

L3=W

460V

L2=V

234567890123456

460V

500V

234567890123456

234567890123456

234567890123456

L1=U

L3=W

500V

L2=V

500V

L1=U

460 /

500V

460 /

500V

460 /

500V

PE

Fig. 7 Terminal strip TT 2600/3000 MW 2600/3000 - 500/460 V

6

Page 9

Converting the

7

7

7

7

7

7

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

7

7

7

7

7

mains voltage for

„Version 1“

(continued)

Example: Converting from 480 V (230 V) to 440 V (200 V)

23456789012345

23456789012345

Setting

440 V

(200 V)

440V

440V

L3=W

200V

440V

L2=V

L1=U

200VL2200VL3230VL1230VL2230VL3200 /

L1

Setting

23456789012345

23456789012345

480 V

23456789012345

23456789012345

23456789012345

(230 V)

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

23456789012345

234567890123456

234567890123456

234567890123456

480V

480V

234567890123456

234567890123456

234567890123456

L3=W

L2=V

234567890123456

234567890123456

234567890123456

234567890123456

234567890123456

480V

L1=U

Mains cable (50/60Hz)

„INPUT 50/60 Hz“

440 /

440 /

440 /

480V

480V

480V

200 /

200 /

230V

230V

230V

PE

PE

EN

Fig. 8 Terminal strip TT 2600/3000 MW 2600/3000 - 480/440 V (TT 2600 MW 2600 - 230/200 V)

4. Disconnect the phase conductors (L1, L2, L3) in the „Setting 500 or 480 V (230 V)“

section

NOTE! Operating the auto-transformer with phase conductors only partially

reconnected can cause serious damage. When converting the mains voltage,

always make sure that all phase conductors are reconnected.

5. Connect the phase conductors (L1, L2, L3) in the „Setting 460 or 440 V (200 V)“

section

6. Check that all cables are securely connected to the terminal strip

7. Attach the auto-transformer cover

8. Cross out the mains voltage in the space above the rating plate and enter the mains

voltage you have set in the empty box

CAUTION! Operating the equipment at an incorrect mains voltage can cause

serious damage. The entered value must correspond to the mains voltage actually set.

Fig.9 Entering the mains voltage set - example

7

Page 10

Converting the

mains voltage for

„Version 2“

VOLTAGE CORRECTION DEVICE

480V 50/60Hz

CIRCUIT DIAGRAM

440/480V

INPUT 50/60 Hz

grey

U1

480V

grey

V1

480V

grey

W1

480V

440V

440V

440V

400V

OUTPUT 50/60 Hz

230V

230V~ 10A

KD 7000

PE

L1

L2

L3

L1

L2

L3

PE

0

PE

440V 50/60Hz

CIRCUIT DIAGRAM

grey

U1

grey

V1

grey

W1

KD 7000

Fig. 10 Connecting MW 2600 480/440 V

Fig. 11 Entering the mains voltage set

PE

L1

440/480V

L2

INPUT 50/60 Hz

L3

480V

480V

480V

440V

440V

440V

L1

L2

400V

L3

OUTPUT 50/60 Hz

PE

230V

0

230V~ 10A

PE

1. Turn the main switch on the autotransformer to the „0“ position

2. Pull out the mains plug or disconnect

the power supply

3. Remove the left side panel of the

auto-transformer

4. Disconnect the phase conductors

(U1, V1, W1) in the 480V section

NOTE! Operating the autotransformer with phase conductors only partially reconnected

can cause serious damage.

When converting the mains

voltage, always make sure that all

phase conductors are reconnected.

5. Connect the phase conductors (U1,

V1, W1) in the 440V section

6. Make sure all cables are securely

connected

7. Attach the left side panel of the autotransformer

8. Cross out the mains voltage in the

space above the rating plate and

enter the mains voltage you have set

in the empty box

CAUTION! Operating the equipment at an incorrect mains voltage can cause

serious damage. The entered value must correspond to the mains voltage actually set.

8

Page 11

Putting the machine into service

Safety

Preparing to

install

WARNING! Work performed incorrectly can cause serious injury and damage.

The following activities must only be carried out by Fronius-trained qualified

personnel! Take note of the safety rules in the power source operating instructions.

WARNING! An electric shock can be fatal. Only carry out work on the machine

when

- the mains switch is in the „0“ position,

- the machine is unplugged from the mains.

EN

Fig. 12 Dismantling the components

9

Page 12

Installing the

components

CAUTION! Beware of the danger of the trolley tipping over. Always place the

heavy auto-transformer at the bottom. This will reduce the danger of the trolley

tipping over as the centre of gravity is now lower.

Fig. 13 Installing the components

4 x

10

Page 13

Connecting the

auto-transformer

„Version 1“

WARNING! Operating the equipment incorrectly can cause serious injury and

damage. Read the following sections of the power source operating instructions

before starting the power source for the first time:

- Safety rules

- Putting the machine into service

- Putting the power source into operation

Connecting the

auto-transformer

„Versions 2 and

3“

The ventilation of the auto-transformer is a very important safety feature. When deciding

where to set up the system, ensure that cooling air can enter unhindered through the air

slots on the underside and escape through the slots in the sides.

1. If the auto-transformer mains cable needs to have a plug attached, fit a suitable

mains plug.

2. Switch the power source mains switch to the „0“ position

3. Turn the main switch on the auto-transformer to the „0“ position

4. Insert the mains plug of the auto-transformer and turn on the power supply.

5. Turn the main switch on the auto-transformer to the „I“ position

6. The auto-transformer is ready for use

Note: Operating the auto-transformer with phase conductors only partially

connected can cause serious damage. When connecting the connection cable,

always make sure that all phase conductors and the earth conductor are

connected.

WARNING! Operating the equipment incorrectly can cause serious injury and

damage. Read the following sections of the power source operating instructions

before starting the power source for the first time:

- Safety rules

- Putting the machine into service

- Putting the power source into operation

EN

The ventilation of the auto-transformer is a very important safety feature. When deciding

where to set up the system, ensure that cooling air can enter unhindered through the air

slots on the underside and escape through the slots in the sides.

1. If the auto-transformer mains cable „INPUT 50/60HZ“ needs to have a plug attached, fit a suitable mains plug.

2. Switch the power source mains switch to the „0“ position

3. Turn the main switch on the auto-transformer to the „0“ position

4. Connect the auto-transformer with power source to the terminals „OUTPUT 50/

60Hz“.

5. Insert the mains plug of the auto-transformer and turn on the power supply.

6. Turn the main switch on the auto-transformer to the „I“ position

7. The auto-transformer is ready for use

NOTE! Operating the auto-transformer with phase conductors only partially

connected can cause serious damage. When connecting the connection cable,

always make sure that all phase conductors and the earth conductor are

connected.

11

Page 14

Care, maintenance and disposal

General Under normal operating conditions the auto-transformer requires only a minimum of care

and maintenance. However, it is essential that certain important points are observed to

ensure the welding machine remains serviceable for many years to come.

WARNING! An electric shock can be fatal. Before opening the machine, turn off

the machine, disconnect the mains supply and attach a clearly legible and

comprehensible warning sign to prevent anyone switching it on again. Discharge electrolytic capacitors where necessary. The housing screws provide an

adequate PE conductor connection for earthing the housing. The screws must

never be replaced with different screws unless a reliable PE conductor connection is set up.

Every start-up

Every 6 months

Every 12 months

Disposal

- Check the mains plug and mains cable for damage

- Check that there is a gap of 0.5 m (1.6 ft.) all around the machine to ensure that

cooling air can flow and escape unhindered.

NOTE! Air inlets and outlets must never be covered, not even partially.

- Dismantle machine side panels and clean machine inside with dry reduced compressed air

NOTE! Risk of damage to electronic components. Do not bring the air nozzle

too close to the electronic components.

- If a lot of dust has accumulated, clean the cooling air ducts.

Carry out a safety inspection

(see the „Safety rules“ chapter in the power source operating instructions)

Dispose of in accordance with the applicable national and local regulations.

12

Page 15

Troubleshooting

General

Troubleshooting

WARNING! An electric shock can be fatal. Before opening the auto-transformer,

turn the mains switch to the „0“ position, pull out the mains plug and attach a

clearly legible and comprehensible warning sign to prevent anyone switching it on

again. The housing screws provide an adequate PE conductor connection for

earthing the housing. The screws must never be replaced with different screw

fastenings unless a reliable PE conductor connection is set up.

Power source does not function

Mains switch is on, but indicators are not lit up

Cause: There is a break in the mains lead; the mains plug is not plugged in

Remedy: Check mains lead, check mains voltage if necessary

Cause: Mains fuse is faulty

Remedy: Replace mains fuse

Cause: Mains outlet socket or plug is faulty

Remedy: Replace faulty components

Cause: Mains switch is faulty

Remedy: Replace the mains switch

EN

Cause: Phase conductors (L1, L2, L3) connected incorrectly

Remedy: Connect phase conductors as described

Mains fuse or automatic circuit breaker has tripped

Cause: Mains fuse underrated

Remedy: Rate mains lead fuse according to rating plate

Cause: Short circuit on the transformer windings

Remedy: Replace the auto-transformer

Output voltage too low on „Version 1“

Auto-transformer TT 2600/3000 MW 2600/3000 - 480/440V - 500/460 V

Cause: Incorrect mains voltage

Remedy: Check the mains voltage

Cause: Mains leads connected incorrectly

Remedy: Correct the mains connection

Cause: Mains voltage is 460 V or 440 V: Phase conductors (L1, L2, L3) connected

in the „500 V“ or „480 V“ sesction

Remedy: Connect phase conductors (L1, L2, L3) in the „460 V“ or „440 V“ section

Output voltage too high on „Version 1“

Auto-transformer TT 2600/3000 MW 2600/3000 - 480/440V - 500/460 V

Cause: Mains voltage is 500 V or 480 V: Phase conductors (L1, L2, L3) connected

in the „460 V“ or „440 V“ sesction

Remedy: Connect phase conductors (L1, L2, L3) in the „500 V“ or „480 V“ section

13

Page 16

Fault / Cause /

Remedy

(continued)

Output voltage too low on „Version 2“

Auto-transformer MW 2600 480/440V

Cause: Incorrect mains voltage

Remedy: Check the mains voltage

Cause: Mains leads connected incorrectly

Remedy: Correct the mains connection

Cause: Mains voltage is 440 V: Phase conductors (U1, V1, W1) connected in the

„480V“ section

Remedy: Connect phase conductors (U1, V1, W1) in the „440V“ section

Output voltage too high on „Version 2“

Auto-transformer MW 2600 480/440V

Cause: Mains voltage is 480 V: Phase conductors (U1, V1, W1) connected in the

„440V“ section

Remedy: Connect phase conductors (U1, V1, W1) in the „480V“ section

Surface of auto-transformer housing feels hot

Cause: Permitted duty cycle exceeded

Remedy: Move power source mains switch to „0“ position, allow auto-transformer to

cool

Important! The auto-transformer must remain switched on to allow the fan

to operate

Cause: The connected welding machine is drawing too much current

Remedy: Check the current consumption of the connected welding machine

Cause: Faulty fan fuse (only on MW 2600 - 575 V „Version 3“)

Remedy: Replace fuse

Cause: Fan faulty

Remedy: Check fan connections, replace fan

Cause: Unsuitable installation location

Remedy: Change installation location (ensure air can move freely through openings

in housing)

Cause: Ambient temperature too high

Remedy: Reduce ambient temperature or change installation location

Cause: Housing interior dirty

Remedy: Open auto-transformer and clean with dry compressed air

No voltage at the socket outlet („Version 2“ only)

Cause: Socket fuse faulty

Remedy: Replace fuse

14

Page 17

Technical data

Safety

Auto-transformer

„Version 1“ (480/

440 V, 500/460 V)

NOTE! Incorrectly rated mains plugs, mains leads or fuses can lead to serious

damage. If the power source is designed for a special voltage, the technical

data on the rating plate apply. The mains plug, mains lead and their fuse protection must be rated accordingly.

Auto-transformer 480/440 V

Auto-transformer 500/460 V

Mains voltage 1 3x480 V 3x500 V

Mains voltage 2 3x440 V 3x460 V

Mains voltage tolerance +/- 10 % +/- 10 %

Mains frequency 50/60 Hz 50/60 Hz

Output voltage 3x400 V 3x400 V

Mains fuse protection (slow-blow) 16 A 16 A

Maximum apparent power 12.1 kVA 12.1 kVA

Effective apparent power 10.4 kVA 10.4 kVA

Cos phi 0.9 0.9

Maximum primary current for

Mains voltage 1 14.5 A 14 A

Mains voltage 2 15.5 A 14 A

Effective primary current for

Mains voltage 1 12.5 A 12 A

Mains voltage 2 13.5 A 13 A

Secondary current for

10 min / 40 °C 65 % d.c. 17 A 17 A

10 min / 40 °C 100 % d.c. 14 A 14 A

Protection IP 23 IP 23

Type of cooling F F

Insulation class F F

Auto-transformer dimensions l/w/h

TT 2600/3000 630/240/250 mm 630/240/250 mm

24.80/9.45/9.84 in. 24.80/9.45/9.84 in.

Dimensions l/w/h

Auto-transformer MW 2600/3000 630/290/250 mm 630/290/250 mm

24.80/11.42/9.84 in. 24.80/11.42/9.84 in.

Weight 39.5 kg 39.5 kg

87.1 lb. 87.1 lb.

Marks of conformity CE, CSA CE, CSA

EN

15

Page 18

Auto-transformer

„Version 1“ (230/

200 V)

Auto-transformer 230/200 V

Mains voltage 1 3x230 V

Mains voltage 2 3x200 V

Mains voltage tolerance +/- 10 %

Mains frequency 50/60 Hz

Output voltage 3x400 V

Mains fuse protection (slow-blow) 35 A

Maximum apparent power 11.8 kVA

Effective apparent power 9.7 kVA

Cos phi 0.9

Maximum primary current for

Mains voltage 1 34 A

Mains voltage 2 30 A

Effective primary current for

Mains voltage 1 28 A

Mains voltage 2 25 A

Secondary current for

10 min / 40 °C 65 % d.c. 17 A

10 min / 40 °C 100 % d.c. 14 A

Protection IP 23

Type of cooling F

Insulation class F

Auto-transformer dimensions l/w/hTT 2600/3000 630/240/250 mm

24.80/9.45/9.84 in.

Dimensions l/w/hAuto-transformer MW 2600/3000 630/290/250 mm

24.80/11.42/9.84 in.

Weight 45 kg

99.20 lb.

Marks of conformity CE

16

Page 19

Auto-transformer

„Versions 2 and

3“

Auto-transformer 480/440 V

Auto-transformer 575 V

Mains voltage 1 3x480 V 3x575 V

Mains voltage 2 3x440 V -

Mains voltage tolerance +/- 10 % +/- 10 %

Mains frequency 50/60 Hz 50/60 Hz

Output voltage 3x400 V 3x400 V

Mains fuse protection (slow-blow) 16 A 16 A

Fan fuse (slow-blow) 0.4 A

230 V fuse (slow-blow) 10 A -

Maximum apparent power 12.1 kVA 12.1 kVA

Effective apparent power 10.4 kVA 10.4 kVA

Cos phi 0.9 0.9

Maximum primary current for

Mains voltage 1 14.5 A 12 A

Mains voltage 2 15.5 A

Effective primary current for

Mains voltage 1 12.5 A 10.4 A

Mains voltage 2 13.5 A

Secondary current for

10 min / 40 °C 65 % d.c. 17 A 17 A

10 min / 40 °C 100 % d.c. 14 A 14 A

Protection IP 23 IP 23

Type of cooling F F

Insulation class F F

Dimensions l/w/h 630/290/250 mm 630/290/250 mm

24.80/11.42/9.84 in. 24.80/11.42/9.84 in.

Weight 39 kg 39.5 kg

86 lb. 87.1 lb.

Marks of conformity CE, CSA CE, CSA

EN

17

Page 20

18

Page 21

Ersatzteilliste

DEENFRITESPT-BRNLNOCSRUSKSVTR

Schaltplan

Spare Parts List

Circuit Diagram

Liste de pièces de rechange

Schéma de connexions

Lista parti di ricambio

Schema

Lista de repuestos

Esquema de cableado

Lista de peças sobresselentes

Esquema de conexões

Onderdelenlijst

Bedradingsschema

Reservdelsliste

Koblingsplan

Seznam náhradních dílù

Schéma zapojení

Список запасных частей

Электрическая схема

Zoznam náhradných dielov

Schéma zapojenia

Reservdelslistan

Kopplingsschema

ud_fr_st_tb_00149 012012

Parça Listesi

Baðlantý þemasý

Czyszczenie palnika

PL

Schemat po³¹czeñ

Page 22

Auto Transformer MW 2600 480;440V/400V 4,001,568,800

Auto Transformer MW 2600 3x575V/400V 4,001,631,800

AM2,0200,8927

AM2,0200,8827

AM2,0200,8823

33,0030,0094 - 3x480;440V

33,0030,0096 - 3x575V/400V

41,0007,0169

41,0007,0158

41,0007,0166 - 10A/500V

41,0007,0179 - 0,4A/440V

41,0007,0159

41,0009,0197 - 10²

41,0009,0198 - 10²

41,0009,0217 - 0,2-4²

41,0009,0216 - 0,2-4²

43,0006,0042

43,0004,2567

43,0004,2323

42,0201,0256

42,0300,1815 - PG16

42,0300,0648 - PG13,5

43,0003,0316

43,0003,0315

22,0405,0163

BE2,0201,1678

22,0405,0163

43,0002,0257

42,0406,0137

Auto - Transformer MW 2600

Ersatzteilliste / Spare parts list / Listes de pièces de rechange / Lista de repuestos / Lista de pecas sobresselentes / Lista dei Ricambi

el_fr_st_so_00878 012004

1/1

Page 23

Auto Transformer 3x480; 440/400V TT 2600 4,001,614

Auto Transformer 3x500; 460/400V TT 2600 4,001,615

AM2,0200,9036

AM2,0200,8827

AM2,0200,8823

33,0030,0047

43,0006,0042

43,0004,0507

43,0003,0317

42,0300,1511

22,0405,0166

41,0009,0066

BE4,0450,1018

22,0405,0166

43,0002,0257

42,0406,0137

Auto - Transformer TT2600

Ersatzteilliste / Spare parts list / Listes de pièces de rechange / Lista de repuestos / Lista de pecas sobresselentes / Lista dei Ricambi

1/1

el_fr_st_so_01103 012005

Page 24

TT 2600/3000- MW 2600/3000 - 440/480 V („Ausführung 1“)

Page 25

TT 2600/3000- MW 2600/3000 - 460/500 V („Ausführung 1“)

Page 26

MW 2600 / TT 2600 - 230/200 V („Ausführung 1“)

Page 27

MW 2600 - 440/480 V („Ausführung 2“)

Page 28

FRONIUS INTERNATIONAL GMBH

Froniusplatz 1, A-4600 Wels, Austria

Tel: +43 (0)7242 241-0, Fax: +43 (0)7242 241-3940

E-Mail: sales@fronius.com

www.fronius.com

Under http://www.fronius.com/addresses you will find all addresses

www.fronius.com/addresses

of our Sales & service partners and Locations.

ud_fr_st_so_00082 012011

Loading...

Loading...