Page 1

User

Information

Australian edition - control panel

User Information

EN

42,0426,0003,EN 002-23092022

Page 2

Page 3

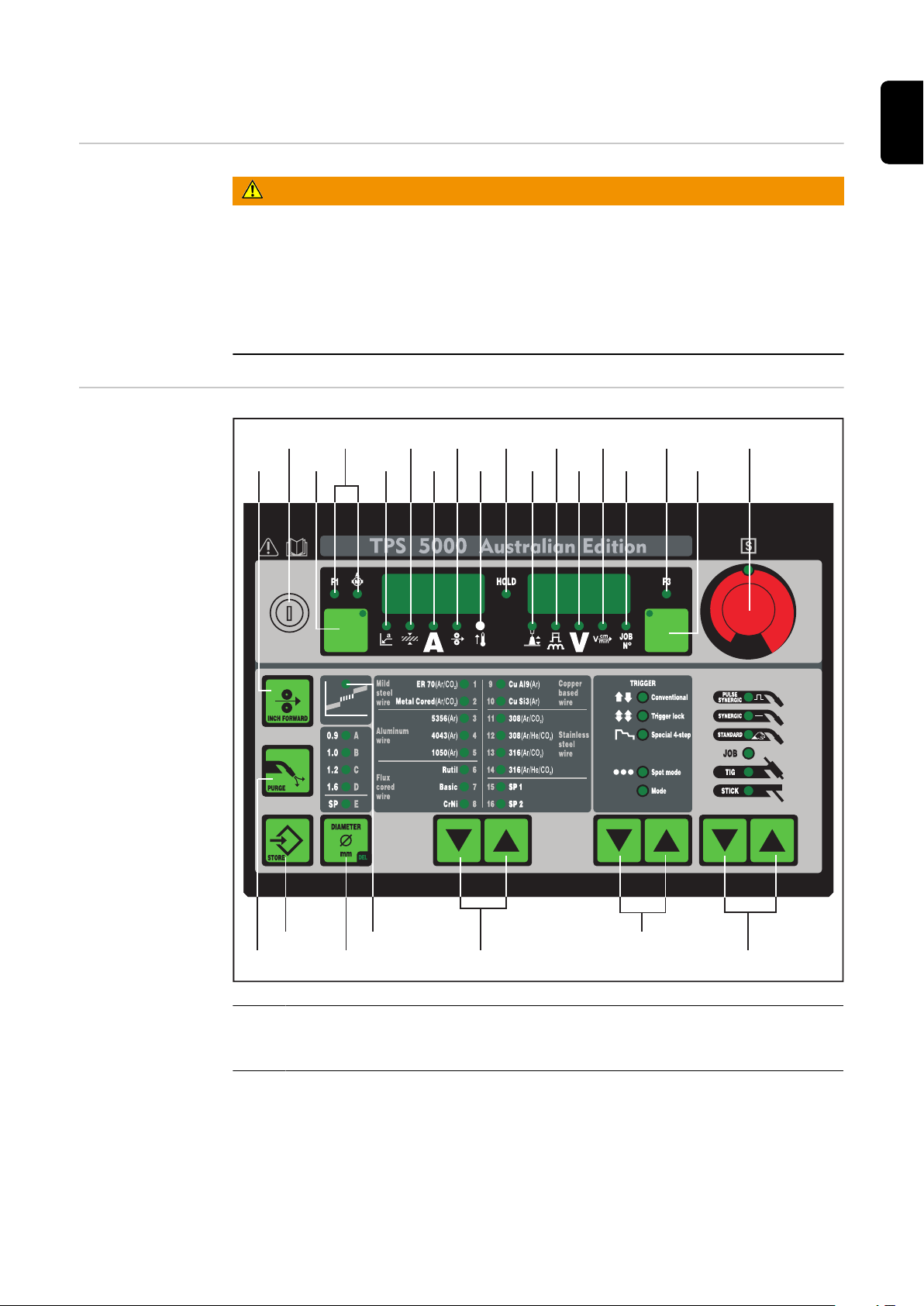

“Australian Edition” control panel

(1)

(24)

(23)

(19)

(18)

(16)

(15)

(14)

(13)

(12)(11)

(9) )3()8(

(2)

(19)

(22)

(21) (20)

(7)

(6)

(5)

(4)

(10)

(17)

EN

Safety

“Australian Edition” control

panel

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in serious personal injury and damage to property.

All the work and functions described in this document must only be carried

▶

out by technically trained and qualified personnel.

Read and understand this document in full.

▶

Read and understand all safety rules and user documentation for this device

▶

and all system components.

(1) Adjusting dial

for altering parameters. If the indicator on the adjusting dial is lit up,

then the selected parameter is one that can be altered.

3

Page 4

(2) Parameter selection button

for selecting the following parameters:

“a”-dimension

sheet thickness

welding current

F1 indicator

Wire-feed rate drive current-input indicator

If the indicators are lit up on the parameter selection button and on the

adjusting dial, then the indicated/selected parameter can be altered

with the adjusting dial.

(3) Parameter selection button

for selecting the following parameters:

arc length correction

droplet detachment /arc force dynamic correction

welding voltage

welding speed

o

Job N

F3 indicator

If the indicators are lit up on the parameter selection button and on the

adjusting dial, then the indicated/selected parameter can be altered

with the adjusting dial.

(4) Process button(s)

for selecting the welding process

MIG/MAG pulse synergic welding

MIG/MAG standard synergic welding

MIG/MAG standard manual welding

Job mode

TIG welding with touchdown ignition

Rod electrode (MMA) welding

(5) Mode button(s)

for selecting the operating mode

2-step mode (conventional)

4-step mode (trigger Lock)

Special 4-step mode (Aluminium welding start-up)

Spot welding mode

Operating Mode

(6) Material button(s)

for selecting the filler metal and shielding gas to be used. Parameters

SP1 and SP2 are reserved for additional materials.

4

Page 5

(7) Wire diameter button

for selecting the diameter of the wire to be used. Parameter SP is reserved for additional wire diameters.

(8) Welding current parameter

for selecting the welding amperage. Before the start of welding, the machine automatically displays a guideline value based on the programmed

parameters. During welding, the actual value is displayed.

(9) Welding voltage parameter

for selecting the welding voltage. Before the start of welding, the machine automatically displays a guideline value based on the programmed

parameters. During welding, the actual value is displayed.

Important! The power source has a pulsating open-circuit voltage.

Where the “Rod electrode (MMA) welding” process has been selected,

the display indicates an average welding-voltage value of 40 V before

the start of welding (open circuit).

For welding start-up and the main welding operation itself, however, a

welding voltage of max. 50 V (TPS 2700) or 70 V (TS/TPS 4000/5000)

is available. Optimum ignition properties are ensured.

(10) “a”-dimension parameter

for selecting the “a” dimension. The wirespeed and welding current /

voltage are calculated as a function of the pre-set welding speed.

EN

Important! Before you select the “a”-dimension, the welding-speed

parameter (17) must be set (recommended welding speed for manual

welding: ~35 cm/min or 13.78 ipm)

(11) Sheet thickness parameter

for selecting the sheet thickness in mm or in. This automatically sets all

the other parameters as well.

(12) Wirespeed parameter

for selecting the wirespeed in m/min or ipm. Other parameters that are

dependent on this are also automatically adjusted accordingly.

(13) Overtemperature indicator

lights up if the power source overheats (e.g. because the duty cycle has

been exceeded). For more information on this, see the “Troubleshooting” section.

(14) HOLD indicator

every time you finish a welding operation, the actual values for welding

current and voltage are stored, and the “Hold” indicator lights up.

(15) Arc length correction parameter

for correcting the arc length

- shorter arc length

0 neutral arc length

+ longer arc length

5

Page 6

(16) Droplet detachment, arc-force correction and arc-force parameter

has a different function assigned to it, depending on the process being

used.

MIG/MAG standard-synergic welding ... for influencing the short-circuiting dynamic at the instant of droplet transfer

- harder and more stable arc

0 neutral arc

+ soft and low-spatter arc

MIG/MAG pulse-synergic welding ... continuous correction facility for

the droplet-detachment force

- lower droplet-detachment force

0 neutral droplet-detachment force

+ increased droplet-detachment force

MIG/MAG standard manual welding ... for influencing the short-circuiting dynamic at the instant of droplet transfer

0 harder and more stable arc

10 soft, low-spatter arc

Rod electrode (MMA) welding ... for influencing the short-circuiting amperage at the instant of droplet transfer

0 soft, low-spatter arc

100 harder, more stable arc

(17) Welding-speed parameter

for selecting the welding speed. The wirespeed and welding current &

voltage are calculated as a function of the “a”-dimension parameter

(10).

(18) JOB n° parameter

for retrieving parameter records / job numbers that were previously

saved with the “Store” button

(19) Indicators F1 / wirefeed-drive current input / F3

for displaying defined parameters

(20) Intermediate arc indicator

between the dip-transfer arc and the spray arc, a spatter-prone “intermediate arc” occurs. To alert you to this critical area - and help you

avoid it - the intermediate arc indicator lights up.

(21) Store button

for accessing the Set-up menu or (in Job Mode) for storing parameter

settings.

Important! If you press the Store button (21) and the “Material” button

(6) at the same time, the display gives you a read-out of the software

version.

If you then press the “Material” button (6) on its own, the version number of the welding databank appears on the display (e.g.: “0 | 029” =

M0029).

If you then press the “Material” button (6) a second time, the number of

the wirefeeder (A, or B in the case of twin-head mounts) and the software version n° of the wirefeeder appear on the display (e.g.: A 1.5 |

0.23).

To exit, press the Store button (21).

6

Page 7

(22) Gas test button

for setting the required gas-flow rate on the pressure regulator. After

you press this button, gas will flow out for 30 s. Press the button again

to stop the gas test-flow before the end of this period.

If you press the Store button (21) and the gas-test button (22) at the

same time, the display gives you a read-out of the pre-set gas pre-flow

time (e.g. “GPr | 0.1 s”).

- You can alter the gas pre-flow time with the adjusting dial (1)

If you now press the “Process” button (4), the display gives you a readout of the pre-set gas post-flow time (e.g. “GPo | 0.5 s”)

- You can alter the gas post-flow time with the adjusting dial (1)

To exit, press the Store button (21).

(23) "Feeder inching" button

for feeding the welding wire into the torch hosepack with no accompanying flow of gas or current

For information on the various wire-inching sequences that are possible

when the welder presses and holds the “"Feeder inching" button”, see

the section headed “The Set-up Menu“, sub-section “’Process’ parameters”, parameter “Fdi“.

EN

Important! If you press the Store button (21) and the "Feeder inching"

button (23) at the same time, the display gives you a read-out of the

pre-set feeder-inching speed (e.g. “Fdi | 10 m/min” or 393.70 ipm).

- You can alter the feeder-inching speed with the adjusting dial (1)

To exit, press the Store button (21).

(24) Keylock switch (Option)

When the key is in the horizontal position, the following functions are

disabled:

Selecting the welding process with the “Process” button(s) (4)

-

Selecting the operating mode with the “Mode” button(s) (5)

-

Selecting the filler metal with the “Material” button(s) (6)

-

Accessing the set-up menu with the “Store” button (21)

-

Accessing the job-correction menu (see the section headed “Job

-

mode”)

Important! In this case, the functions available on the control panel of the system components are then restricted in the same way

as those of the control panel on the power source.

7

Page 8

Loading...

Loading...