Page 1

/ Perfect Welding / Solar Energy / Perfect Charging

Translation of original

Operating Instructions

ArcRover 22

Operating Instructions

EN

Welding carriage

42,0426,0297,EN 19112019

Page 2

Page 3

Contents

About this document ........................................................................................................................................ 5

Function of this document .......................................................................................................................... 5

Explanation of safety information ............................................................................................................... 5

Copyright .................................................................................................................................................... 5

Qualied personnel .................................................................................................................................... 5

General ............................................................................................................................................................ 6

Principle......................................................................................................................................................6

Device concept ........................................................................................................................................... 6

Application area ......................................................................................................................................... 6

Proper use/intended purpose ..................................................................................................................... 6

Foreseeable misuse ................................................................................................................................... 7

Conversions or modications ..................................................................................................................... 7

Operating Instructions ................................................................................................................................ 7

Duty to provide instruction .......................................................................................................................... 7

Dangers from the rechargeable battery pack ............................................................................................. 8

Use of charger and rechargeable battery pack .......................................................................................... 9

Environmental conditions ........................................................................................................................... 9

Warning notices on the carriage ...............................................................................................................10

Scope of supply ........................................................................................................................................ 11

Carriage components .................................................................................................................................... 12

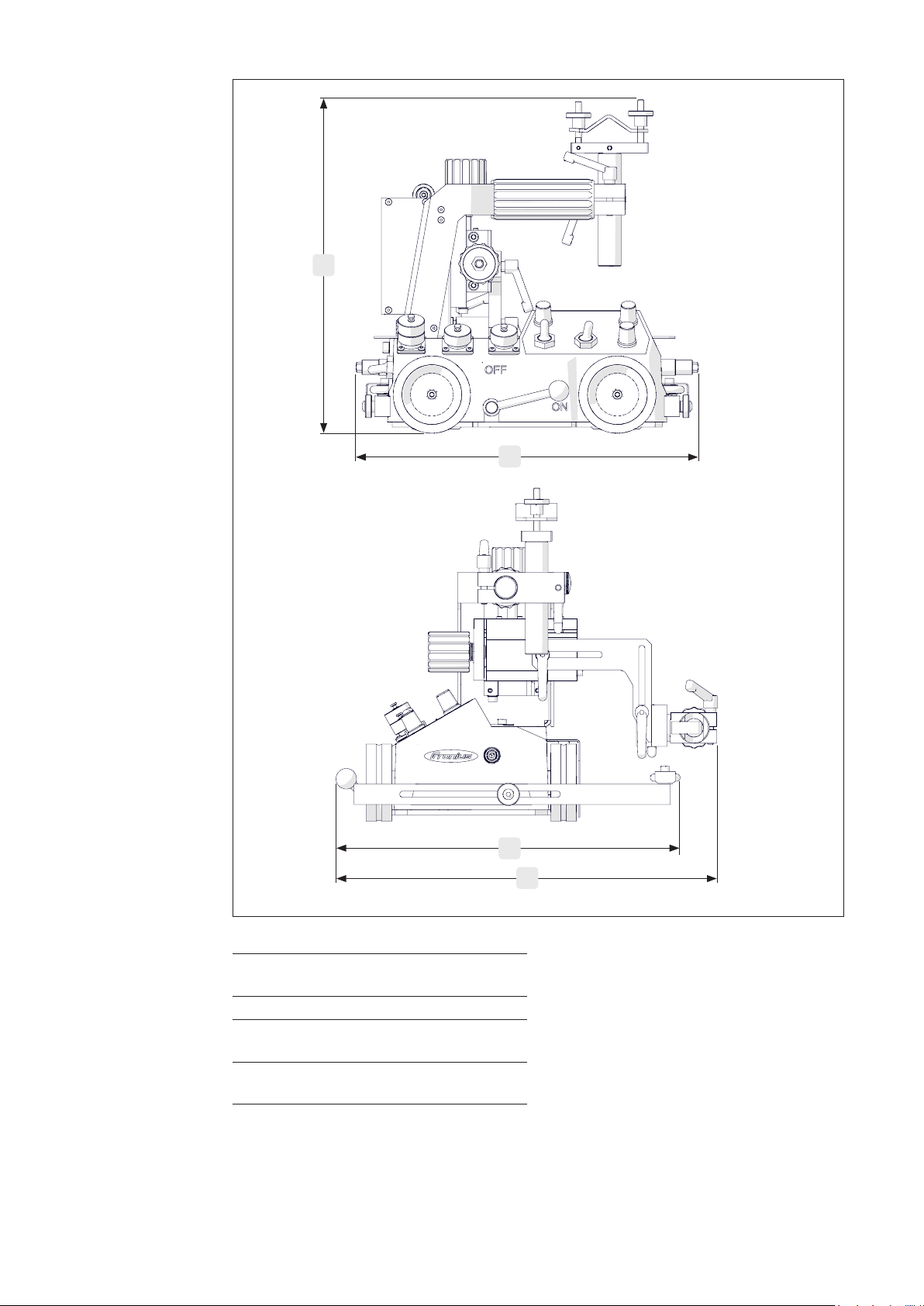

ArcRover 22 conguration with oscillation unit ........................................................................................ 12

ArcRover 22 conguration without oscillation unit ................................................................................... 13

Accessories and options ............................................................................................................................... 14

Accessories .............................................................................................................................................. 14

Options ..................................................................................................................................................... 16

Control and display elements, connections ................................................................................................... 17

Carriage....................................................................................................................................................17

Control panel ............................................................................................................................................ 19

Main menu................................................................................................................................................20

Charger and rechargeable battery pack ................................................................................................... 21

Menu navigation and parameter entry ........................................................................................................... 22

General.....................................................................................................................................................22

Turning/pressing the adjusting dial ...........................................................................................................22

Carriage parameters ..................................................................................................................................... 23

CAR menu ................................................................................................................................................ 23

OSC menu................................................................................................................................................24

Welding position and weld seam tracking .....................................................................................................26

Possible welding positions ....................................................................................................................... 26

Guidance of the carriage .......................................................................................................................... 27

Optional lateral guides ............................................................................................................................. 29

Additional torch holder ............................................................................................................................. 30

Preparing the carriage ................................................................................................................................... 31

Mounting and setting up the guide rails ................................................................................................... 31

Fitting the carriage brushes (option) ........................................................................................................ 32

Fitting the lateral guides (option) .............................................................................................................. 33

Fitting the second torch holder (option) .................................................................................................... 35

Charging the rechargeable battery pack .................................................................................................. 35

Inserting rechargeable battery pack into carriage .................................................................................... 37

Connecting the external power supply (option) ........................................................................................ 38

Setting up the carriage .................................................................................................................................. 39

Checking the workpiece surface and carriage ......................................................................................... 39

Placing the carriage ................................................................................................................................. 39

Attaching fall protection (only for vertical operation) ................................................................................ 40

Mounting and adjusting the welding torch ................................................................................................ 41

Disengaging the carriage ......................................................................................................................... 42

Page 4

Starting up the carriage ................................................................................................................................. 43

Checking the connections ........................................................................................................................ 43

Switching on the system components ...................................................................................................... 43

Setting the carriage parameters .................................................................................................................... 44

Parameter list ........................................................................................................................................... 44

Setting the carriage parameters ............................................................................................................... 45

Setting the oscillation parameters ............................................................................................................ 47

Saving a program ..................................................................................................................................... 49

Loading a program ................................................................................................................................... 50

Welding mode ...............................................................................................................................................51

Retrieving parameter record (JOB) on the power source ........................................................................ 51

Loading the carriage program .................................................................................................................. 51

Performing a test run ................................................................................................................................ 52

Starting the welding process .................................................................................................................... 53

Correcting the Travel Speed .................................................................................................................... 53

Correcting the FMS oset ........................................................................................................................ 54

End of welding .......................................................................................................................................... 54

Troubleshooting ............................................................................................................................................. 55

General.....................................................................................................................................................55

Displayed error messages ....................................................................................................................... 55

Carriage....................................................................................................................................................56

Oscillation unit .......................................................................................................................................... 57

FMS 50/100 motor slide ........................................................................................................................... 57

Maintenance .................................................................................................................................................. 58

Personnel ................................................................................................................................................. 58

Maintenance record ................................................................................................................................. 58

Cleaning ................................................................................................................................................... 58

Maintenance intervals .............................................................................................................................. 58

Recommended lubricants ........................................................................................................................ 58

Horizontal welding torch adjustment unit ................................................................................................. 59

Vertical welding torch adjustment unit ...................................................................................................... 60

Carriage front ........................................................................................................................................... 61

Carriage back ........................................................................................................................................... 62

Charger .................................................................................................................................................... 63

Rechargeable battery pack ...................................................................................................................... 63

Disposal of components ........................................................................................................................... 64

Technical Data ............................................................................................................................................... 65

ArcRover 22 carriage ............................................................................................................................... 65

Oscillation unit FOU 30/ML6 .................................................................................................................... 66

FMS 100/ML15/SE/ACC (optional) .......................................................................................................... 66

FMS 50/ML15/SE/ACC (optional) ............................................................................................................ 66

ArcRover 22 dimensions .......................................................................................................................... 67

Environmental conditions ......................................................................................................................... 68

Spare parts .................................................................................................................................................... 69

Spare parts, wearing parts and auxiliary materials .................................................................................. 69

Ordering details ........................................................................................................................................ 69

ArcRover 22 carriage ............................................................................................................................... 70

„External power supply“ option ................................................................................................................. 72

FOU 30/ML6/radial oscillation unit ........................................................................................................... 73

Circuit Diagrams ............................................................................................................................................ 75

EU Declaration of Conformity ........................................................................................................................ 80

Page 5

About this document

Function of this

document

Explanation

of safety

information

These Operating Instructions explain how to commission and operate the carriage. Look

after the Operating Instructions carefully; they must always be to hand at the location

where the carriage is being used. They can be used as a reference should any operational or functional problems occur in the future.

DANGER!

Indicates an imminent danger. If not avoided, death or serious injury will result.

WARNING!

Indicates a possibly dangerous situation. If not avoided, death or serious injury may

result.

CAUTION!

Indicates a possibly harmful situation. If not avoided, minor or minor injury may result.

NOTE!

Indicates a risk of awed results and possible damage to the equipment.

IMPORTANT! Indicates usage tips and other particularly useful information. It is not a

signal word for a harmful or dangerous situation.

Copyright

Qualied

personnel

Special care is required if you see any of the symbols shown.

Copyright of these Operating Instructions remains with Fronius International GmbH. The

text and illustrations are all technically correct at the time of going to press. We reserve

the right to make changes. The content of the Operating Instructions shall not give rise to

any claims whatsoever on the part of the purchaser.

- These Operating Instructions are designed for trained personnel or persons with

practical welding experience. Personnel must be trained through veriable regular

instruction.

- Maintenance and repair of the carriage may likewise only be carried out by trained

technicians and in compliance with the specied maintenance activities and maintenance intervals.

- The manufacturer accepts no liability for damage caused by insucient knowledge of

how to use the device.

5

Page 6

General

Principle The ArcRover 22 carriage is a portable, battery-powered welding carriage with 4-wheel

drive. The carriage is used to execute mechanised butt and llet welds in horizontal or

vertical welding positions, with or without oscillation.

Device concept

The ArcRover 22 carriage has been

designed for exibility and to improve

productivity in the execution of longitudinal

weld seams. A spatter guard mounted on

the working side and powder coating of all

housing components enable use in harsh

operating conditions.

A large holding and carrying handle coupled with a robust yet lightweight design

allows quick and easy positioning on the

workpiece.

The carriage adheres to the workpiece

by means of a permanent magnet. This

guarantees the best possible traction even

in vertical use.

Adjustable guide rollers on the side of the

carriage ensure optimal tracking of the

ArcRover 22 carriage

The carriage can be equipped with a torch oscillation unit.

The carriage, together with the optional oscillation unit, is powered by the interchangeable rechargeable battery pack.

The control unit is integrated into the carriage. The control panel has an illuminated display allowing simple and user-friendly parameter setting for the carriage.

weld seam.

The universal torch holder allows use of

both manual and machine welding torches.

Application area The ArcRover 22 carriage can be used in all situations where a high degree of exibility

is required when executing longitudinal weld seams:

- Shipyards

- Bridge construction

- Workshops

- Production halls

- Building sites

Proper use/

intended purpose

The ArcRover 22 carriage must only be used for performing mechanised butt and llet

welds in horizontal or vertical welding positions. Any other use shall be deemed improper

and the manufacturer will assume no responsibility for any resulting damages.

The carriage can be used in the following welding processes:

- MIG / MAG process

Proper use also includes:

- Use of the charger and rechargeable battery pack included with the carriage

- Use of the permanent magnet with a minimum sheet thickness of 5 mm

6

Page 7

Proper use/intended purpose

(continued)

- Use of MIG/MAG welding torches with a holder diameter of up to 28 mm

- Use in welding position PA with the "stainless steel drive wheel" option

- Carrying out all maintenance work at the specied maintenance intervals

- Keeping a service book with the most important data (date, operator, activities carried

out)

- Using the spare parts stipulated by Fronius

- Following all the instructions contained in the Operating Instructions

- Using this document in conjunction with the operating

- instructions of the integrated system components (power source, wirefeeder, etc.)

Foreseeable

misuse

Conversions or

modications

Operating

Instructions

Any use other than for the intended purpose shall be deemed improper use. This includes:

- Operation on preheated components > 50 °C without stainless steel drive wheels

- Transporting people

- Use outside the permitted technical operating limits

- Use in hazardous areas

Any unauthorised conversions or modications made to the carriage by the user shall

invalidate all liability or warranty obligations on the part of the manufacturer!

The electromagnetic characteristics of the carriage can be adversely aected by additions or modications of any kind. No modications or additions should therefore be

undertaken without rst consulting the manufacturer and obtaining written approval.

The Operating Instructions help you to use the carriage safely and eciently, and must

therefore be to hand at all times:

- The Operating Instructions must always be kept near the carriage.

- Clearly mark the place where the instructions are kept.

- Ensure that all persons using the carriage know where the Operating Instructions are

located.

- The Operating Instructions will only be able to help you in the event of a problem if

they are at hand!

Duty to provide

instruction

IMPORTANT! The manufacturer shall not be liable for any damage that arises from fail-

ure to observe the Operating Instructions!

The operator must inform all people working with the carriage about the following before

starting work:

- Theoretical and practical aspects of operation

- Safety regulations

IMPORTANT! The duty to provide instruction applies in particular for people who only

work on the carriage occasionally.

7

Page 8

Dangers from

the rechargeable

battery pack

The substances contained in the battery used in this device can be harmful

to the environment and to human and animal health. If the device becomes

damaged, please observe the following points:

- Make sure that leaking uids cannot get into the soil or groundwater

- If pollution has already occurred, it must be removed in accordance with

relevant national regulations

The battery can catch re if overheated. Do not expose the device to heat

(e.g. a permanent heat source or re).

If the battery is damaged or subjected to improper use, dangerous vapours

may be given o which can irritate the airways.

Measures:

- Ensure an adequate supply of fresh air

- Seek medical attention in case of discomfort

With a faulty battery, liquid may leak out of the device.

- Avoid contact with the liquid

- Hand the device over to a Fronius Service Partner for repair

- Clean and check any parts that have come into contact with the liquid

Do not operate or store the device in a potentially explosive atmosphere.

Special regulations apply in rooms at risk of re or explosion:

- Observe relevant national and international regulations

To comply with European Directive 2006/66/EC on batteries and accumulators and its implementation in national law, batteries and rechargeable

batteries that have reached the end of their life must be collected separately

and returned to an approved recycling facility.

- Be sure to return any device that you no longer require to your dealer, or

nd out about the approved collection and recycling facilities in your area.

Ignoring this European Directive may be harmful to the environment and

your own health!

Devices with mechanically undamaged rechargeable batteries may be

returned to the relevant Fronius Service Partner for repair or battery replacement.

As soon as it becomes evident that the rechargeable battery has been mechanically damaged (e.g. electrolyte is escaping), dispose of the device at

your nearest recycling centre in accordance with national laws and guidelines.

If anything is unclear or you have any questions about disposal, contact your

Fronius Service Partner.

8

Page 9

Use of charger

and rechargeable

battery pack

- The charger and the rechargeable battery pack are designed for each other. Therefore

you should only ever use the supplied charger to charge the battery pack.

- Recharge the rechargeable battery pack after every discharge. Do not wait until the

rechargeable battery pack is completely discharged before recharging it.

- Objects must not be passed through the ventilation openings of the charger.

- Charging/discharging of the battery must be carried out according to the relevant

requirements for the environmental conditions (technical data).

- Should unusual temperatures, odours, discolorations or deformations occur during the

charging process, halt the process immediately.

- Disconnect the charger from the mains and rechargeable battery pack when not in

use.

- When handling the battery, check the packaging and/or the battery itself for obvious

signs of damage.

- Do not open, crush, dismantle or drop the rechargeable battery pack from a large

height.

- Do not short-circuit the rechargeable battery pack or expose it to high temperatures.

- Keep the rechargeable battery pack away from direct sunlight and other heat sources.

- Do not place the rechargeable battery pack or the charger on moist or wet surfaces.

- Do not operate the rechargeable battery pack and charger in environments where they

are exposed to dust, ammable gases, steam or solvents. Do not use in environments

with strong vibrations and magnetic elds.

Environmental

conditions

Operating, storing or transporting the system outside the specied area or environmental ranges is regarded as not complying with the intended purpose. The manufacturer

shall not be liable for any damage or loss resulting from this.

Ambient air temperature range:

- during operation: 0 °C to +40 °C (32 °F to 104 °F)

- during transport and storage: -10 °C to+45 °C (14 °F to 113 °F)

- Recommended temperature range during charging: +5 °C to +40 °C (41 °F to

104 °F)

Relative humidity:

- up to 65% +/- 20%

Environmental conditions:

- Surrounding air is free from dust and ammable vapours, solvents or gases.

- No strong vibrations and magnetic elds around the rechargeable battery pack.

- No direct sunlight on the rechargeable battery pack.

- No storing the rechargeable battery pack on moist or wet surfaces.

9

Page 10

Warning notices

on the carriage

A number of safety symbols can be seen on the rating plate axed to the carriage. The

rating plate and safety symbols must not be removed or painted over.

www.fronius.com

Froniusstraße 1

Pettenbach 4643

U weight

25,4 VDC 10,7 kg

ArcRover 22

Type:

Art.No.:

Ser.No.:

22 kg

ArcRover 22

8,045,642

XXXXXXXX

max. load

11 kg

Do not use the functions until you have fully read the Operating Instructions.

Do not dispose of used devices with domestic waste. Dispose of them according to safety rules.

WARNING!

Risk of burns from hot surfaces!

The protective plate for the wheels heats up during long periods of welding

operation. Touching the plate may cause burns.

- Do not touch the protective plate.

- Wear protective gloves and suitable safety goggles or a protective

helmet.

10

Page 11

Scope of supply

(1) (2) (3)

(4)

(5)

ArcRover 22 scope of supply

(1) Connecting cable to power source

(2) ArcRover 22 carriage

(3) Universal welding torch holder

(4) Hosepack holder

(5) Guide rails

(6) Allen keys: 2 / 2.5 / 3 / 4

(7) Rechargeable battery pack

25.4 V / 3.35 Ah

(8) Charger

(7)(8)

(6)

11

Page 12

Carriage components

ArcRover 22

conguration

with oscillation

unit

Handle

Rechargeable

battery pack

25.4 V / 3.35 Ah

Vertical welding

torch adjustment

unit

Hosepack holder

Oscillation unit

FOU 30/ ML6

Horizontal

welding torch

adjustment unit

On-board

control unit

Chassis with

4-wheel drive

Control lever for

permanent magnet

ArcRover 22 carriage with oscillation unit

Universal

welding torch

holder

Guide rails

with rollers

Lashing point for

securing the carriage

Limit switch

12

Page 13

ArcRover 22

conguration

without oscillation unit

Handle

Rechargeable

battery pack

25.4 V / 3.35 Ah

Vertical welding

torch adjustment

unit

Hosepack holder

Horizontal

welding torch

adjustment unit

On-board

control unit

Chassis with

4-wheel drive

Control lever for

permanent magnet

ArcRover 22 carriage without oscillation unit

Universal

welding torch

holder

Lashing point

for securing the

carriage

Guide rails

with rollers

Limit switch

13

Page 14

Accessories and options

Accessories

Article: Item number: Designation:

48,0005,2582 Stainless steel drive wheel

(for workpieces with particularly rough surfaces).

IMPORTANT! Use of the carriage with the "stainless steel drive wheel" accessory is

only permitted in the PA welding position. Please seek advice with Fronius service personnel if using pre-heated workpieces.

48,0005,2583 Brushes (2 pcs)

48,0005,2600 Rechargeable battery pack

25.4 V / 6.8 Ah

48,0005,2601 Charger

100-240 V 50/60 Hz /

29.4 V DC

48,0005,0165 External power supply

230V AC / 24V DC

38,0100,0433 Remote control cable 10 m

38,0100,0476 Extension cable 10 m

4,100,711 I-set external start signal

VR5000

(necessary for use with TransSteel;

installed in the wirefeeder)

14

Page 15

Accessories

(continued)

Article: Item number: Designation:

4,100,779,IK OPT/i WF external start

signal

(necessary in combination

with TPSi; installed in the WF

wirefeeder)

48,0005,2578 Tiltable lateral guide

48,0005,2577 Lateral guide for edge

(2)

(3)(1)

48,0005,2579 Magnetic lateral guide

(1) 48,0005,2580 Guide arm for rail 1850 mm

(2 pcs)

(2) 48,0005,1894 Flexible guide rail 1850 mm

(3) 48,0005,1895 Magnetic guide rail base

15

Page 16

Accessories

(continued)

Article: Item number: Designation:

48,0005,2581 Additional welding torch

holder (for 2nd torch)

Options

Article: Item number: Designation:

8,045,644 Oscillation unit

FOU 30/ML6/radial

8,045,599 Motor slide

FMS 100/ML15/SE/ACC

8,045,618 Motor slide

FMS 50/ML15/SE/ACC

16

38,0100,0459 Connection cable 0,8 m:

- FMS/ML15/SE/ACC

- FOU 30/ML6/radial

Page 17

Control and display elements, connections

Carriage

WARNING!

Operating the equipment incorrectly can cause serious injury and damage.

Do not use the functions described here until you have fully read and understood the

following documents:

- These Operating Instructions

- All operating instructions for the system components

(7)

(1)

(6)

ArcRover 22 carriage

No. Function

(1) Front limit switch

(2) Control panel

- For the complete operation of the carriage.

- For conguring carriage parameters and creating programs.

(3) Permanent magnet control lever ON/OFF

For switching the permanent magnet on and o during vertical operation.

(4) Connecting plug for FOU 30, FMSS 50/100, Service

- For connecting the cable to the optional oscillation unit FOU 30.

- For connecting the cable to the optional motor slide FMS 50 or FMS 100. Mo-

tor slide corrects the position of the welding torch.

- Connection for diagnostic and service purposes.

(5) Not used.

(6) Connecting plug for analogue power source control

For connecting the cable to the power source (analogue arc ignition).

(7) Rear limit switch

(3) (2)(4)(5)

17

Page 18

Carriage

(continued)

(11)

(8)

(9)

(10)

ArcRover 22 carriage

No. Function

(8) Compartment for rechargeable battery pack

(9) Connecting plug for rechargeable battery pack

- for plugging in the rechargeable battery pack (Li-Ion 25.4V / 3.35Ah)

- for connecting the connection cable of the control box during mains operation

(external power supply)

(10) Control unit ON/OFF toggle switch

For switching the carriage control unit on and o.

(11) Lock knob for locking the battery

18

Page 19

Control panel

000

(1)

ArcRover

(6)

TEST

22

Slot 0

CAR

OSC

000

O

O

I

(4)(5)

ArcRover 22 control panel

No. Function

(1) Display

For conguring parameters and creating programs using the menu adjusting dial

(6). The digital display is illuminated.

(2) FMS-Oset adjusting dial

- For correcting the welding torch position when a FMS 50 or FMS 100 motor

slide is installed.

- For returning to the main menu.

(3) Travel speed adjusting dial

Used to adjust the travel speed of the carriage. The currently set travel speed is

shown on the display.

Setting range: 5 - 200 cm/min

(4) Toggle switch Start LEFT/ 0/RIGHT

For starting and stopping the automatic program sequence in the relevant welding direction.

(5) Welding toggle switch I/0/TEST

For choosing whether to carry out the automatic program sequence with or without welding.

I ... Welding on preselection

0 ... Welding o preselection

TEST ... Arc immediately active (arc test)

(6) Adjusting dial menu

- For menu navigation and parameter entry.

- Pressing 2 seconds: for returning to the main menu.

(2)

(3)

19

Page 20

000

Main menu

(1)

Slot 0

(8)

(7)

No. Function

CAR

OSC

000

(4)(5)(6)

(4) Front limit switch active display

(5) Welding ON/OFF display

(6) Rear limit switch active display

(7) OSC menu

Opens the OSC menu for setting the parameters for the oscillation unit FOU 30.

(8) CAR menu

Opens the CAR menu for setting the carriage parameters.

(2)

(3)

No. Function

(1) Header

The following information is displayed:

- Currently loaded carriage program (program 0 - 9)

- Battery power level

- In the event of malfunction:

Error 1 - 11

(2) FMS-Oset active status display

A correction of the welding torch

position is currently being carried

out.

(3) Travel speed display

Displays the currently set travel

speed in cm/min.

20

Page 21

Charger and

rechargeable

battery pack

(1)

(2)

(3)

(5)

(4)

(7)(7)

(6)

Overview of charging set

No. Function

(1) Fuse holder with glass-tube fuse

(2) LED1

Steady red light ... Mains on.

(3) LED2

- Steady red light ... Charging process active

- Steady green light ... Battery nished charging

(4) Charging cable with plug

(5) Mains connection with integrated glass-tube fuse

(6) Mains cable

(7) Housing screws (Allen screws)

For guiding the rechargeable battery pack into the compartment.

(8) Connecting plug for charging lead

(8)

21

Page 22

Menu navigation and parameter entry

Slot 0

CAR

45%

45%

000

General General rules for entering parameters:

- Do not enter numbers; values must be entered using the relevant adjusting dial

- Changed parameters become active after the adjusting dial has been pressed, however they will not yet have been saved

Turning/pressing

the adjusting dial

Turn the adjusting dial to:

- Turning right highlights the next element (menu or parameter).

- Turning left highlights the previous element (menu or parameter).

To change values:

- Turning right increases the value to be set.

- Turning left decreases the value to be set.

Press the adjusting dial once:

OSC

Press the adjusting dial for 2 seconds,

Press the FMS-Oset adjusting dial once:

Slot 0

CAR

OSC

000

- Opens the highlighted menu (white frame)

- Activates parameter entry

- Deactivates parameter entry

- Return to main menu

22

Page 23

000

Carriage parameters

CAR menu

Slot 0

CAR

OSC

000

Parameter Function

Travel Speed

Denes the traversing speed of the carriage in cm/min.

Unit: cm/min

Setting range: 5 to 200 cm/min

40cm/min

Total Path

The total path for welding. Once this distance has been reached,

the program will stop automatically.

Unit: cm

Setting range: 0 to 9999 cm

Menu entry:

1. Turn menu adjusting dial and highlight the CAR

menu (white frame).

2. Press the menu adjusting dial once.

0cm

0cm

0cm

0.0s

Segment Width

Denes the length of the segments to be welded.

Unit: cm

Setting range: 0 to 99.9 cm

Segment Gap

Denes the length of the segments not to be welded.

Unit: cm

Setting range: 0 to 99.9 cm

Start Delay / Flying Start

Unit: s

- Setting range: 0 to +5 s ... Start Delay:

Denes the time between ignition of the arc and commencement of carriage movement.

- Setting range: 0 to -5 s ... Flying Start:

Denes the time between commencement of carriage movement and ignition of the arc.

23

Page 24

000

CAR menu

(continued)

Parameter Function

Back Filling

Denes for how long the torch should weld backwards at the end

of the weld.

Setting range: 0 to 5 s / ON / OFF

0.0s

End Crater Filling

Length of time that the carriage pauses at the end of the weld

seam to ll the end-crater. Value must be the same or higher

than the entered value on the power source (nal current duration).

Setting range: 0 to 5 s

0.0s

Change direction / Stop

- ON ... Once the limit switch has been reached, the carriage

reverses and runs to the other limit switch.

- OFF ... Once the limit switch has been reached, the carriage

stops

O

OSC menu

Slot 0

CAR

OSC

000

Parameter Function

50%

Menu entry:

1. Turn menu adjusting dial and highlight the OSC

menu (white frame).

2. Press the menu adjusting dial once.

Oscillation Speed

Traversing speed for oscillation in %.

Setting range: 5 to 100%

Oscillation Path

Denes the distance between left and right reversal points of the

oscillation motion.

Setting range: 5 to 100%

30%

24

Page 25

OSC menu

(continued)

Parameter Function

Dwell time Left

Oscillation dwell time in the left-hand limit position.

Setting range: 0.0 to 3 s

1,5s

Dwell time Middle

Oscillation dwell time in the middle position.

Setting range: 0.0 to 3 s

1.5s

Dwell time Right

Oscillation dwell time in the right-hand limit position.

Setting range: 0.0 to 3 s

1.5s

Triangle

Oscillation Mode

No oscillation

Trapezoidal oscillation

Triangular oscillation

Rectangular oscillation

25

Page 26

Welding position and weld seam tracking

Possible welding

positions

The 4-wheel drive and built-in permanent magnet ensure that the carriage adheres to the

workpiece and guarantee the best possible traction. The following welding positions are

possible:

SlopingHorizontal

NOTE!

From an angle of 45° upwards, the carriage must be secured by a load securing device

with a locking function to prevent it from falling.

Vertical

IMPORTANT! In vertical operation, the carriage must be secured by a load securing

device with a locking function to prevent it from falling. The load securing device must be

designed for the total weight of the carriage. The manufacturer accepts no liability for any

damage to persons or property resulting from vertical use of the carriage without a load

securing device.

NOTE!

When used on the “outside of a container”, the container must be turned in the opposite direction and at the same speed.

26

Outside of container with minimum diameter of

1500 mm

Page 27

Possible welding

positions

(continued)

NOTE!

When used on the “inside of a container”, the container must be turned in

the opposite direction and at the same

speed.

Inside of container with minimum diameter of 500 mm

Guidance of the

carriage

IMPORTANT! Use of the carriage in the "PE" overhead position is prohibited.

The adjustable guide wheels on the side of the carriage ensure proper tracking of the

weld seam. They can be positioned on either side of the carriage. For detailed information about the correct setting of the guide wheels, see the section "Preparing the carriage". The guide wheels can be set to the following positions:

Guidance on outside vertical surfaceGuidance on inside vertical surface

27

Page 28

Guidance of the

carriage

(continued)

Guidance on outside vertical surfaceGuidance on angle piece (vertical) or rail

Outside of container with minimum diameter of

5000 mm

Guidance on angle piece (horizontal) or rail

Inside of container with minimum diameter of

5000 mm

NOTE!

When guided on a horizontal angle

piece, the welding torch must only be

placed on the upper side.

28

Page 29

Optional lateral

guides

Tiltable lateral guide

Lateral guide for edge

Standard lateral guide / with magnet

Lateral guide with guide rail

- Guide arm for exible rail (2 pcs.) (1850 mm)

- Magnetic bases for guide rail

- Flexible guide rail (1850 mm)

IMPORTANT! 10 magnetic bases are required for each rail.

29

Page 30

Additional torch

holder

IMPORTANT! It is only possible to use two welding torches in a horizontal position.

30

Page 31

Preparing the carriage

Mounting and

setting up the

guide rails

1. Use the M6 knurled screw to attach the guide rails to the carriage.

2. Tighten knurled screws by hand rst. Make sure that the guide rails are sat correctly

in the appropriate recess on the carriage frame.

5 - 10 mm

(b)

(a)

(b)

(a)

Direction of travel

3. Undo the knurled screws (a).

4. Extend the guide wheels (b) to the desired length. To ensure that the carriage keeps

to the chosen direction, the extended guide wheels must be extended by 5 - 10 mm

(see diagram).

5. Tighten the knurled screws (a).

31

Page 32

Fitting the

carriage brushes

(option)

(a)

(a)

NOTE!

The brush may be tted to either the front or rear of the carriage.

1. Undo the M6 knurled screw (a).

2. Attach the brush brackets as shown.

3. Screw in the M6 knurled screw (a) and tighten by hand.

32

Page 33

Fitting the lateral

guides

(option)

All optional lateral guides for the ArcRover 22 carriage come with the M6 knurled screw

attached. The lateral guides are attached to the end faces of the carriage.

Tiltable lateral guide

Lateral guide for edge

Standard lateral guide with magnet

33

Page 34

Fitting the lateral

guides

(option)

(continued)

Lateral guide with guide rail

The exible lateral rail is secured using magnetic bases. Each rail (1850 mm) requires 10

magnetic bases to guarantee a secure hold.

The rail sections can be attached to the magnetic bases in the following ways:

- Placed end-on

- Overlapping

Attach the rails to the magnet block with the provided M5x16 xing screws.

M5x16

End-on join Overlapping join

When placed on a 5 mm thick magnetic surface, the magnetic bases have the following holding force:

- Up to a temperature of 100 °C (212 °F): 90 N

- From a temperature of 180 °C (356 °F): 54 N

34

Page 35

Fitting the second torch holder

(option)

The second torch holder is attached to the front of the carriage, in front of the control

panel.

1. Loosen and remove the Allen screws

(a, b).

(a)

(b)

2. Fit the torch holder (c).

3. Insert and tighten the Allen screws (a,

b).

(c)

Charging the

rechargeable

battery pack

(a)

(b)

IMPORTANT! Recharge the rechargeable

battery pack after every discharge. Do not

wait until the battery pack is completely

discharged before recharging it.

1. Connect the mains cable to the charger.

2. Insert the Schuko plug into a 230 V

socket.

LED1 lights up red (mains on).

35

LED1 LED2

Page 36

Charging the

rechargeable

battery pack

(continued)

3. Connect the charging plug from the

charger to the rechargeable battery

pack. The rechargeable battery pack

is charging.

LED2 lights up red (charging process

active).

LED1 LED2

IMPORTANT! The rechargeable battery pack is fully charged after a charging time of 2

hours.

LED2 lights up green (rechargeable battery pack fully charged).

LED1 LED2

4. Disconnect the Schuko plug.

5. Remove charging plug from the rechargeable battery pack.

36

Page 37

Inserting

rechargeable

battery pack into

carriage

(a)

(a)

IMPORTANT! Before inserting the rechargeable battery pack, check that

the connection contacts are not dirty or

shorted.

1. Insert the rechargeable battery pack

from above into the compartment.

The housing screws have to sit in the

appropriate recesses on the carriage

frame (a).

2. Keep turning the lock knob until the

fuse pin (b) locks.

(b)

37

Page 38

Connecting the

external power

supply (option)

With the „ArcRover 22 mains operation“ option, the carriage can be operated with an

external power supply instead of the battery pack.

External power supply

230V

Extension cable

max. 30 m

Remote control cable

10 m10 m10 m

IMPORTANT! When extending the remote control cable, observe the following points:

- use a maximum of 2 extension cables

- do not exceed total length of 30 m

- ensure that all union nuts are tightened at all connection points

38

Page 39

Setting up the carriage

Checking the

workpiece surface and carriage

Placing

the carriage

Before positioning the carriage, check the following:

- The surface of the workpiece must be clean (no sand, shavings, etc.)

- The base plate of the carriage must be free of objects which can be attracted by the

magnet

- The rubber elements of the drive wheels must be undamaged and free of swarf

- The guide wheels must be clean, undamaged and free of welding spatter

WARNING!

The activated permanent magnet poses a risk of injury.

There is a danger of injury to the ngers when positioning the carriage.

- Only hold the carriage by the handle and not by the base plate.

1. Place the carriage on the workpiece.

The side guide wheels must be in

contact with the workpiece.

2. If necessary, correct the position of the

guide wheels.

NOTE!

Detailed informations on „Setting up

the guide rails“ can be found in chapter

„Preparing the carriage“.

3. Set the permanent magnet control

lever to the "ON" position.

39

Page 40

Attaching fall

protection

(only for vertical

operation)

IMPORTANT! In vertical operation, the carriage must be secured by a load securing

device with a locking function to prevent it from falling. The load securing device must be

designed for the total weight of the carriage. The manufacturer accepts no liability for any

damage to persons or property resulting from vertical use of the carriage without a load

securing device.

1. Attach the snap hook of the load

securing device to the lashing point for

securing the carriage

NOTE!

Do not stand beneath a suspended

carriage.

2. Make sure the cable is kept perma-

nently taut

40

Page 41

Mounting and

adjusting the

welding torch

(b)

1. Turn the adjusting dial (a) to the left

and release the torch holder.

2. Insert the welding torch (b).

3. Turn the adjusting dial (a) to the right

and x the welding torch in position.

(a)

4. Set the welding torch inclination:

- Loosen the clamping lever (c)

- Twist the torch holder (d) and set

the required inclination

- Tighten the clamping lever (c)

5. Release all other necessary clamping

(c)

levers and position the welding torch.

(f)

(e)

(d)

6. Turn the adjusting dial on the relevant

mechanical adjustment unit (e, f) until

the correct welding torch position is

reached.

41

Page 42

Disengaging the

carriage

To attain correct wirefeed, observe the following when laying the hose pack:

- Do not allow the hosepack to become

kinked

- Always lay the hosepack as straight as

possible

Handling the hosepack

1. Undo the knurled screws (a) on the

(b)

clamp.

2. Insert the hosepack (b) as illustrated.

IMPORTANT! Make sure the hosepack

does not become kinked - this can lead

to wirefeed problems.

3. Tighten the knurled screws (a).

(a)

NOTE!

Observe the maximum tensile load on the hosepack holder (see the “Technical data”

section). This value must not be exceeded.

► If necessary, suspend the hosepack. The hosepack must not come into contact

with the oor. Use balancers and hosepack holders (e.g. universal hosepack hold-

er).

42

Page 43

Starting up the carriage

000

Checking the

connections

Switching on the

system components

The following activities and work steps apply to the fully installed system. Before startup, check all the connections between, and connection sockets of, the following system

components:

- Carriage

- Rechargeable battery pack or control box (external power supply)

- Oscillation unit or motor slide (if used)

- Power source

- Cooling unit

- Gas cylinder

- Wirefeeder

- Welding torch with hosepack

Precise information on the assembly and connection of the system components can be

found in the relevant operating instructions for the system component.

WARNING!

Danger of injury from premature arc ignition.

The arc may be ignited accidentally. This can cause serious eye injuries.

- Before switching on the system components, make sure that the

“Start LEFT/0/RIGHT” toggle switch on the carriage control panel is set to the “0”

position.

IMPORTANT! There are no xed rules for the sequence in which the system compo-

nents are switched on. They can be switched on in any order.

Switch on the main switch on the following system components:

- Control box (mains operation via external power supply instead of battery)

- Carriage control unit

- Power source

The start screen appears and the main menu is opened:

Slot 0

CAR

OSC

000

43

Page 44

Setting the carriage parameters

Parameter list

Carriage parameter

No. Parameter name Setting range: Unit:

(1) Travel Speed 5 - 200 cm / min

(2) Total Path 0 - 9999 cm

(3) Segment Width 0 - 99.9 cm

(4) Segment Gap 0 - 99.9 cm

(5) Start Delay 0 - (+5) s

Flying Start 0 - (-5) s

(6) Back Filling 0 - 5 / ON / OFF s

(7) End Crater Filling 0 - 5 s

(8) Change direction / Stop ON / OFF -

Oscillation parameters

No. Parameter name Setting range: Unit:

(1) Oscillation Speed 5 - 100 %

(2) Oscillation Path 5 - 100 %

(3) Dwell time Left 0.0 - 3 s

(4) Dwell time Middle 0.0 - 3 s

(5) Dwell time Right 0.0 - 3 s

(6) Oscillation Mode Without,

Trapezoidal,

Triangular,

Rectangular;

-

Continuous and

path welding

Continuous welding:

For this application, the total path must be set to "0". This means that the welding path

variable is ignored.

Welding is stopped when:

- The front or back limit switch has been reached; or

- The "Start LEFT/0/RIGHT" toggle switch is actuated on the control panel.

Path welding:

The total path must be set for this application. The welding path variable will be checked

and only the dened distance will be welded. The total welding path can be divided into

segments (Segment Width, Segment Gap). The end of welding always occurs after the

set total welding path has run.

44

Page 45

000

Setting the

carriage

parameters

Press

Slot 0

CAR

1. Press the adjusting dial once; the

menu selection is activated.

Press

Press

OSC

Slot 0

CAR

OSC

Slot 0

CAR

OSC

000

2. Press the menu adjusting dial once;

the highlighted CAR menu opens.

IMPORTANT! The most recently used

parameter will always be displayed

when the menu is opened. Turn the

menu adjusting dial left to display the

rst parameter (Travel Speed).

40cm/min

3. Press the menu adjusting dial once.

The adjustment value (40 cm/min) is

highlighted white and can be changed.

Turn

Press

Slot 0

CAR

OSC

Slot 0

CAR

OSC

40cm/min

4. Turn the menu adjusting dial and set

the desired value (e.g. 25 cm/min).

25cm/min

5. Press the menu adjusting dial once;

value takes eect and the input is

deactivated.

25cm/min

45

Page 46

Setting the

025

carriage

parameters

(continued)

6. Turn the menu adjusting dial to select and set the next parameter (Total Path).

7. Repeat this process on all further carriage parameters.

Slot 0

Slot 0

CAR

OSC

CAR

OSC

0cm

Total Path Segment Width

Slot 0

CAR

OSC

Slot 0

CAR

OSC

0.0s

Start Delay / Flying Start

Slot 0

CAR

Segment Gap

Slot 0

CAR

0cm

0cm

Slot 0

CAR

OSC

OSC

End Crater Filling

025

0.0s

OSC

0.0s

Back Filling

Slot 0

CAR

OSC

O

Change direction / Stop

8. Press the FMS-Oset adjusting dial

once to return to the main menu.

Press

46

Page 47

Setting the

025

025

oscillation

parameters

Press

Slot 0

CAR

1. Press the adjusting dial once; the

menu selection is activated.

Turn

Press

OSC

Slot 0

CAR

OSC

Slot 0

CAR

OSC

025

2. Turn adjusting dial menu and highlight

the OSC menu item.

025

3. Press the menu adjusting dial once;

the highlighted OSC menu opens.

IMPORTANT! The most recently used

parameter will always be displayed

when the menu is opened. Turn the

menu adjusting dial left to display the

rst parameter (Oscillation Speed).

50%

Press

Turn

Slot 0

CAR

OSC

Slot 0

CAR

OSC

4. Press the menu adjusting dial once.

The adjustment value (50%) is highlighted in white and can be changed.

50%

5. Turn the menu adjusting dial and set

the desired value (e.g. 60%).

60%

47

Page 48

Setting the

025

oscillation

parameters

(continued)

6. Press the menu adjusting dial once;

value takes eect and the input is

deactivated.

Press

Slot 0

CAR

OSC

60%

7. Turn the menu adjusting dial to select and set the next parameter (Oscillation Path).

8. Repeat this process on all further oscillation parameters.

Slot 0

CAR

OSC

Oscillation Path

Slot 0

CAR

OSC

Dwell time Middle

Slot 0

30%

1.5s

Slot 0

CAR

OSC

1,5s

Dwell time Left

Slot 0

CAR

OSC

1.5s

Dwell time Right

Slot 0

CAR

OSC

CAR

OSC

Triangle

Oscillation Mode

9. Press the FMS-Oset adjusting dial

once to return to the main menu.

Press

025

48

Page 49

Saving a

O

TEST

I

ArcRover 22

Memory 0

CAR

OSC

ACC

000000

025

program

O

Press

for 4

seconds

Press

1. Turn welding toggle switch I/0/TEST to "0" position.

2. Press the menu adjusting dial for 4

seconds, the LOADING/SAVING menu

will open.

CAR

OSC

Slot 0

IMPORTANT! The most recently used

menu (LOADING or SAVING) will

always be displayed when the menu

is opened. Turn the menu adjustment

dial to the left until the SAVING menu

(disk symbol) is displayed.

3. Press the menu adjusting dial once.

The set value (Slot 0) is highlighted

white and can be changed.

CAR

OSC

Turn

Press

CAR

OSC

CAR

OSC

Slot 0

4. Turn the menu adjusting dial and set

the desired program location (e.g. Slot

3).

IMPORTANT! Program 0 is a factory-set, read-only default program. All

carriage parameters and oscillation

parameters are contained in this program.

Slot 3

5. Press the menu adjusting dial once;

program is saved and the input is

deactivated.

Slot 3

Slot 0

CAR

OSC

6. Press the FMS-Oset adjusting dial

once to return to the main menu.

Press

025

49

Page 50

Loading a

O

TEST

I

ArcRover 22

Memory 0

CAR

OSC

ACC

000000

000

program

O

Press

for 4

seconds

Press

1. Turn welding toggle switch I/0/TEST to "0" position.

2. Press the menu adjusting dial for 4

seconds, the LOADING/SAVING menu

will open.

CAR

OSC

Slot 0

IMPORTANT! The most recently used

menu (LOADING or SAVING) will

always be displayed when the menu

is opened. Turn the menu adjustment

dial to the right until the LOADING

menu (folder symbol) is displayed.

3. Press the menu adjusting dial once.

The set value (Slot 0) is highlighted

white and can be changed.

CAR

OSC

Turn

Press

CAR

OSC

CAR

OSC

Slot 0

4. Turn the menu adjusting dial and set

the desired program location (e.g. Slot

3).

IMPORTANT! Program 0 is a factory-set, read-only default program. All

carriage parameters and oscillation

parameters are contained in this program.

Slot 3

5. Press the adjusting dial once; program

is loaded and the input is deactivated.

Slot 3

Slot 3

CAR

OSC

6. Press the FMS-Oset adjusting dial

once to return to the main menu.

The loaded program is displayed in

the header.

Press

000

50

Page 51

Welding mode

O

TEST

I

ArcRover 22

Memory 0

CAR

OSC

ACC

000000

Retrieving parameter record (JOB)

on the power

source

Loading the

carriage program

► Load the relevant job on the control panel for the power source. More detailed

information on "Job Mode" can be found in the operating instructions for the power

source.

When an analogue power source is being used, the requisite welding parameters must

be set manually on the power source.

1. Turn welding toggle switch I/0/TEST to "0".

O

2. Press the menu adjusting dial for 4

seconds, the LOADING/SAVING menu

will open.

Press

for 4

seconds

CAR

OSC

Slot 0

IMPORTANT! The most recently used

menu (LOADING or SAVING) will

always be displayed when the menu

is opened. Turn the menu adjustment

dial to the right until the LOADING

menu (folder symbol) is displayed.

Press

Turn

CAR

OSC

CAR

OSC

3. Press the menu adjusting dial once.

The set value (Slot 0) is highlighted

white and can be changed.

Slot 0

4. Turn the menu adjusting dial and set

the desired program location (e.g. Slot

3).

IMPORTANT! Program 0 is a factory-set, read-only default program. All

carriage parameters and oscillation

parameters are contained in this program.

Slot 3

51

Page 52

Loading the

O

TEST

I

ArcRover 22

Memory 0

CAR

OSC

ACC

000000

Memory 0

CAR

OSC

ACC

000000

000

carriage program

(continued)

Press

5. Press the adjusting dial once;

program is loaded and the input is

deactivated.

CAR

OSC

Slot 3

Performing a

test run

Slot 3

CAR

Press

6. Press the FMS-Oset adjusting dial

once to return to the main menu.

The loaded program is displayed in

the header.

OSC

000

Carry out a test run to check that all system components work together correctly. This

is performed without an arc and allows the movements during the processes to be

checked.

NOTE!

Before commencing work in vertical operation, ensure that the switch lever for the

permanent magnet is turned to “ON”.

1. Turn welding toggle switch I/0/TEST to "0".

O

O

2. Set the "Start LEFT/0/RIGHT" toggle switch to the desired direction the test run starts. To stop the process early, turn the switch to the "0"

position.

IMPORTANT! Never leave the carriage unattended, especially when it

is moving automatically.

3. Carry out a visual inspection during the test run.

4. Make any necessary corrections (welding torch position, carriage

direction of travel, speed, oscillation motion, etc.)

52

Page 53

Starting the

O

TEST

I

ArcRover 22

Memory 0

CAR

OSC

ACC

000000

Memory 0

CAR

OSC

ACC

000000

035

045

045

welding process

1. Turn welding toggle switch I/0/TEST to "I".

O

Correcting the

Travel Speed

O

Slot 5

CAR

OSC

Slot 5

CAR

2. Set the "Start LEFT/0/RIGHT" toggle switch to the desired direction the welding process starts. To stop the process early, turn the switch

to the "0" position.

IMPORTANT! Never leave the device unattended, especially when it

is moving automatically.

1. Press speed adjusting dial once;

speed is highlighted (white frame).

Press

035

2. Turn the adjusting dial and set the

desired speed (e.g. 45 cm/min).

Turn

OSC

Slot 5

CAR

OSC

045

3. Press the adjusting dial once; value

takes eect and the input is deactivated.

Press

045

53

Page 54

Correcting the

000

000

000

FMS oset

Slot 5

CAR

OSC

1. Press the FMS oset adjusting dial

once; the FMS oset status indicator

is highlighted (white frame).

Press

000

End of welding

Slot 5

CAR

Turn

OSC

2. Turn the adjusting dial and apply the

desired oset correction.

000

Slot 5

CAR

Press

OSC

3. Press the adjusting dial once; value

takes eect and the input is deactivated.

000

Welding stops after the following events:

- After the Total Path has run,

- When the front or back limit switch has started up,

- When the "Start LEFT/0/RIGHT toggle switch is activated on the control panel;

54

Page 55

Troubleshooting

General

Displayed error

messages

In the event of faults, note that the functioning of the entire system depends on many

additional components (power source, wirefeeder, etc.) that are also potential sources of

problems.

If an error message that is not described here appears on the display, then the fault can

only be xed by After-Sales Service. Make a note of the error message shown and of the

serial number of the carriage, and contact the After-Sales Service team with a detailed

description of the error.

Display Cause Remedy

BAT

ow Bat.

Error 1

Error 1

Error 2

Error 2

Error 3

Error 3

Error 4 --- ---

- Battery warning - the re-

chargeable battery pack is

nearly at.

- CAN communication systems

initialisation error.

- Communication error between the controller and

carriage motor controller.

- Communication error between the controller and oscillation unit motor controller.

► Charge up the rechargeable

battery pack with the charger.

► Contact Fronius service tech-

nicians.

► Eliminate short circuit between

cables or communication

ports.

► Check plug connection.

If necessary, tighten union nut.

► Check communication cable

for signs of damage. Replace

if necessary.

Error 5

Error 5

Error 6 --- ---

Error 7

Error 7

Error 8

Error 8

Error 9 --- ---

Error 10 --- ---

- Save/load error. Possible

damage of the mobile controller memory.

- Carriage motor controller

internal error.

- Oscillation unit motor controller internal error.

- FOU 30 oscillation unit was

disconnected from the carriage when the carriage control

unit was switched on.

► Contact Fronius service tech-

nicians.

► Contact Fronius service tech-

nicians.

► Contact Fronius service tech-

nicians.

► Switch carriage control unit o

and on.

Connect or disconnect the

FOU 30 oscillation unit only

when carriage control unit is

switched o.

55

Page 56

Displayed error

messages

(continued)

Error 11

Error 11

Error 12

Error 12

- Communication error between the controller and

FMS-motor controller.

- FMS 50/100 motor slide was

disconnected from the carriage when the carriage control

unit was switched on.

- FMS-motor controller internal

error.

► Check plug connection.

If necessary, tighten connecting plug.

► Check communication cable

for signs of damage. Replace

if necessary.

► Connect or disconnect the

FMS 50/100 motor slide only

when carriage control unit is

switched o.

► Contact Fronius service tech-

nicians.

Carriage

Error Cause Remedy

Drive wheels slip

- Wheels contaminated. ► Clean wheels.

during travel

- Carriage overloaded -

hosepack pulls the car-

► Relieve load on the car-

riage. Hang hosepack.

riage up.

- Insucient magnetic

force.

► Sheet too thin - must be at

least 5 mm thick - change

welding conditions.

- Magnetic force too low.

Carriage raised from the

► Reduce clearance

(s < 6 mm).

ground by an obstacle or

unevenness.

- Insucient magnetic force

- switch lever is in ON

position.

- Magnet is overheated and

not eective - working

temperature over 150 °C.

► Remove the base plate

and check the operation of

the mechanism.

► Change magnet.

► Change welding condi-

tions (reduce working

temperature).

Play at the welding

torch

- Play at the adjustment

units.

► Eliminate play: tighten

pressure screws with allen

key.

- Play at the guide rails. ► Tighten knurled screws.

Display does not

light up

- Rechargeable battery

pack discharged.

- Electronic module - no

power.

► Charge rechargeable bat-

tery pack with charger.

► Check the connections

between the compartment

and the electronic module.

Display lit but

- Electronic module damaged.

- Travel Speed is set to "0". ► Set Travel Speed.

► Change the electronic

module.

carriage does not

work

- Drive system faulty. ► Remove the cover and

check the operation of the

drive system.

56

Page 57

Carriage

(continued)

Error Cause Remedy

Power source does

not start

- "Welding I/0/TEST" toggle

switch is in the "0" posi-

► Turn toggle switch to the

"I" position.

tion.

- Connecting cable between

carriage and power source

► Check connecting cable.

Replace if necessary.

is damaged.

Oscillation unit

Error Cause Remedy

Oscillation does not

work

- Oscillation form set to

"without oscillation".

► Adjust Oscillation Mode

(trapezoidal, triangular,

rectangular)

- Oscillation parameters

incorrectly set.

► Adjust the oscillation

parameters.

- Loose plug connection. ► Check plug connection.

Tighten union nut if necessary.

- Connecting cable to

the carriage control unit

► Check connecting cable.

Replace if necessary.

damaged.

- Oscillation arm blocked. ► Check that the oscillation

arm, linkage and torch

holder are moving freely.

- Device not recognized:

FOU 30 oscillation unit

was connected to the

carriage when the carriage control unit was

switched on.

► Switch carriage control

unit o and on.

Connect or disconnect

the FOU 30 oscillation

unit only when carriage

control unit is switched

o.

Oscillation unit is not

oscillating,

motor audible

- Gearing damaged. ► Contact Fronius Service

Partner (replace gear-

ing).

FMS 50/100

motor slide

Error Cause Remedy

Motor slide does not

work

- Device not recognized:

FMS 50/100 motor

slide was connected to

the carriage when the

carriage control unit

was switched on.

► Switch carriage control

unit o and on.

Connect or disconnect

the FMS 50/100 motor

slide only when carriage

control unit is switched

o.

57

Page 58

Maintenance

Personnel

Maintenance

record

Cleaning

WARNING!

Risk of injury and damage from incorrectly performed maintenance work.

It is essential to adhere to the maintenance intervals and maintenance procedures.

The manufacturer accepts no liability for any damage caused by inadequate or poorly

performed maintenance.

- All maintenance work on the carriage must only be carried out by trained

technicians.

The operator of the carriage is responsible for correctly keeping a service book with the

following information as a minimum:

- Date

- Operator

- Maintenance work carried out

- Use a clean, dry cloth to clean the components. Only use a dierent cleaning agent if

this is indicated in the maintenance procedure for a specic component.

- Remove the rechargeable battery pack before carrying out any maintenance operations.

Maintenance

intervals

Recommended

lubricants

D Daily

W Weekly

M Monthly

1/4 Y Quarterly

1/2 Y Half-yearly

Y Annually

IMPORTANT! Lubricants with solid lubricant additives (e.g. MoS2, graphite and PTFE)

are not suitable for the guide systems.

Lubricant DIN DIN number Comment

Grease KP 2-K 51502/51825 Lithium soap grease

Lubricating oil CLP32-100 51517 Part 3 ISO VG 32-100

58

Page 59

Horizontal

welding torch

adjustment unit

A

A

B

A

Item Component Measure Interval

Linear guides ► Clean

A

1/2 Y

► Check oil lm

► Eliminate play: tighten pres-

sure screws with Allen key

Threaded spindle ► Check

B

► Clean, regrease

M

1/4 Y

59

Page 60

Vertical

welding torch

adjustment unit

B

A A

Item Component Measure Interval

Linear guides ► Clean

A

1/2 Y

► Check oil lm

► Eliminate play: tighten pres-

sure screws with Allen key

Threaded spindle ► Check

B

► Clean, regrease

M

1/4 Y

A

60

Page 61

Carriage front

K

K

E

FK K

Item Component Measure Interval

Rollers and rails ► Clean

E

1/4 Y

► Position check

Safety measures:

F

- Limit switch

Wheels, underbody,

K

► Clean

► Function test

► Clean D

D

guide rails

61

Page 62

Carriage back

K

E

F KK

Item Component Measure Interval

Rollers and rails ► Clean

E

1/4 Y

► Position check

Safety measures:

F

- Limit switch

Wheels, underbody,

K

► Clean

► Function test

► Clean D

D

guide rails

K

62

Page 63

Charger

These devices are largely maintenance-free. To ensure problem-free operation, observe

the following instructions:

L

II

Item Component Measure Interval

Ventilation openings

I

(air inlet, air outlet)

► Keep clean to ensure that

cooling air is able to circu-

M

late. Danger of short circuiting! Make sure that no metal

objects, such as metal chips,

penetrate the interior of the

device through the ventilation

openings.

Aluminium housing ► Place in a well-ventilated and

L

-

dry area.

► The aluminium hosing func-

tions as a heat sink - do not

cover.

Rechargeable

battery pack

J

Item Component Measure Interval

Connection contacts ► Visual inspection before plug-

J

W

ging in

► Protect against contamina-

tion