Fromm P404, P403 Operation Manual & Spare Parts List

OPERATION MANUAL / SPARE PARTS LIST

MANUAL PLASTIC STRAPPING TOOL

MODEL P404

43.0404.02

43040402.en/MAS/© 12.05

2

1 SAFETY INSTRUCTIONS

Read these instructions carefully. Failure to follow these instructions can result in severe personal injury.

Eye injury hazard

Failure to wear safety glasses with side shields can result in severe eye injury or blindness.

Always wear safety glasses with side shields which conform to ANSI Standard Z87.1.

Operation

Tool must not be used by persons not properly trained in their use. Before tensioning strap, read and

understand the tool operating instructions. Failure to follow the operating instructions or improperload

positioning could result in strap breakage.

Become familiar with your tool and keep fingers away from areas that can pinch or cut.

Cutting tensioned strap

When cutting strappi ng, use the proper strapping cutter an d keep other personnel and yourself at a safe

distance from the strap. Always stand to side of the s tr ap, awa y from the dir e ction th e loosened strap end will

fly. Use only cutters designed for strap and never hammers, pliers, hacksaws, axes, etc.

INDEX PAGE

1 SAFETY INSTRUCTIONS 2

2 TECHNICAL DATA 3

3 OPERATION ELEMENTS 4

4 ADJUSTMENT OF THE STRAP THICKNESS 5

5OPERATION 5

6 SPARE PARTS LIST 43.0404.02 10

7 EXCHANGE OF WEARING PARTS 12

7.1 Exchange of the cutter . . . . . . . . . . . . . . . . . . . . 12

7.2 Exchange of gripper and gripping jaw . . . . . . . . 13

8 WARRANTY CONDITIONS AND LIABILITY 14

9 APPROPRIATE USE 14

3

Joints

You are fully responsible to review the joints made by your tool. Become familiar with the seal control and seal

adjustment described in this operation manual.

Misformed joints may n ot sec ure t he loa d and c ould cause serio us in jury. Never handle or ship any l oad wi th

improperly formed joints.

Dispensing strap

Only dispense strap from a dispenser specifically designed for strap.

Tuck strap end back into dispenser when not in use.

Strap warnings

Never use str ap as a means of pulling or l ifting loads. Failu re to follow th ese warnings c an result in severe

personal injury.

Strap breakage hazard

Improper operation of the tool, excessive tensioning, using strap not recommended for this tool or sharp

corners on the load ca n r es ul t i n a su dde n l os s o f st rap tens io n o r in str ap breakage during tension in g, which

could result in the following:

• A sudden loss of balance causing you to fall.

• Both tool and strap flying violently towards your face.

Note as follows:

• If the load corners are sharp, use edge protectors.

• Place the strap correctly around a properly positioned load.

• Positioning yourself in-line with the strap, during tensioning and sealing, can result in severe personal

injury from flying strap or tool. When tensioning or sealing, position yourself to one side of the strap and

keep all bystanders away.

• Use the correct strap quality, strap width, strap gauge and strap tensile strength recommended in this

manual for your tool. Using strap not recommended for this tool can result in strap breakage during

tensioning.

Fall hazard

Maintaining improper fo oting a nd/or b alance whe n oper ating the tool ca n cause y ou to fal l. Before tensio ning

and especially i n elevated a reas, always es tablish good balan ce. Both feet s hould be secur ely placed on a

flat, solid surface, especially when working in elevated areas. Do not use the tool when you are in an awkward

position.

Tool hazards

A well maintained tool is a safe tool!

Check tool regularly for broken or worn parts. Do not operate a tool with broken or worn parts.

Never modify any tool. Modification can result in severe bodily injury.

2 TECHNICAL DATA

Dimensions

Length: 376 mm / 14.8"

Width: 128 mm / 5"

Height: 244 mm / 9.6"

Weight

Tool : 3.8 Kg / 8.4 lbs

Strap Dimensions

Widths: 15 - 16 mm / 0.59 - 0.63"

Thicknesses: 0.5 - 0.9 mm / 0.020 - 0.035"

4

Strap Qualities

Polypropylene, plain or embossed

Polyester, plain or embossed

Seals

P404 / 16 MM Item No.: 41.5082

Joint strength

Depending on the stra p quality the joint stren gth varies between 40 t o 80 % of the breaking st rength of the

strap.

Using low gauge s traps, the jo int strengt h is relative ly high wh ereas high g auge straps tend to have a lower

joint strength.

Tension force

The tension force is calculated by the applied manual force multiplied by 10.

Thus the tension force is 200 N x 10= 2‘000 N if the applied manual force is 200 N at the tension lever.

When applying tension, the tension force must not exceed the breaking strength of the seal joint.

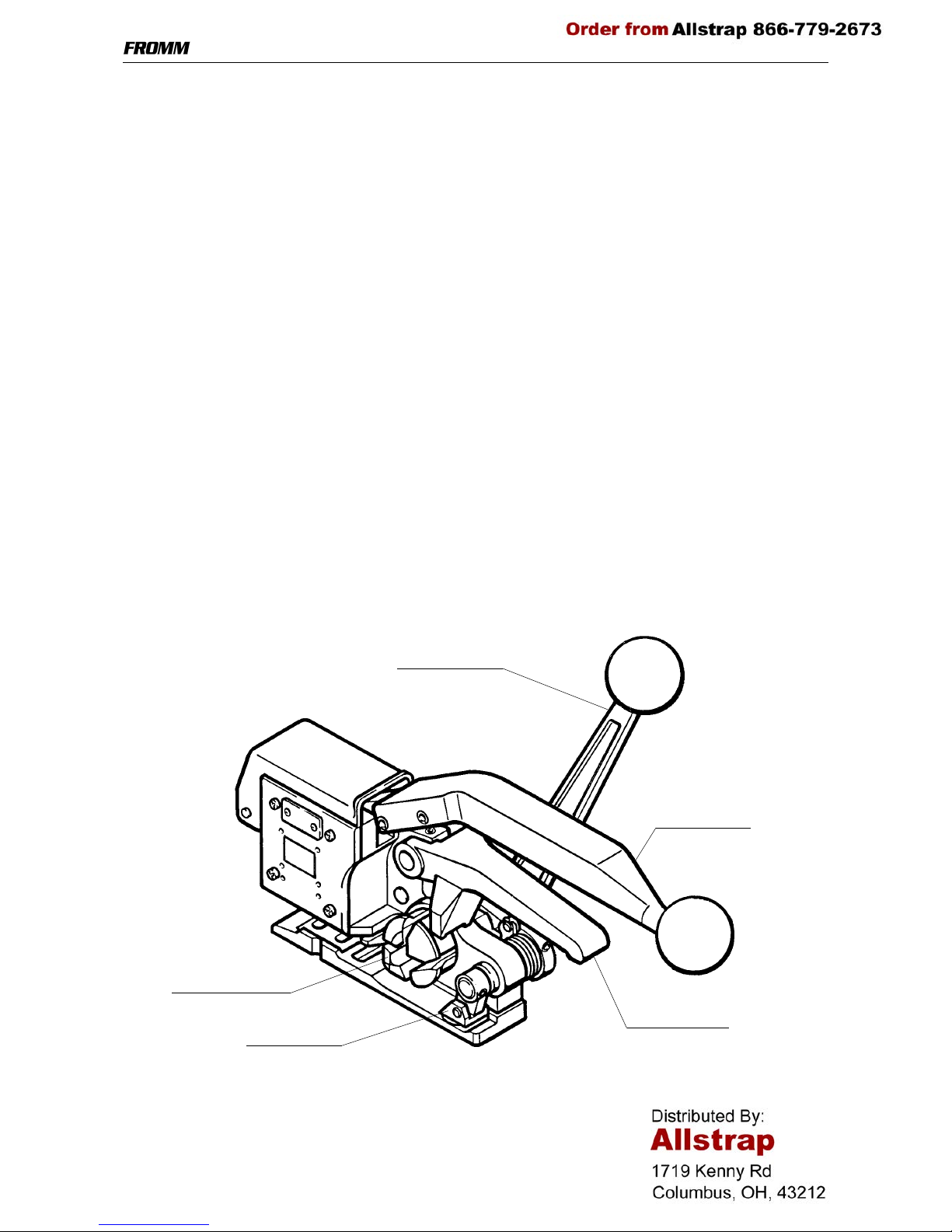

3 OPERATION ELEMENTS

Tension handle

Sealing lever

Lifting handle

Tensioning drum

Gripping jaw

5

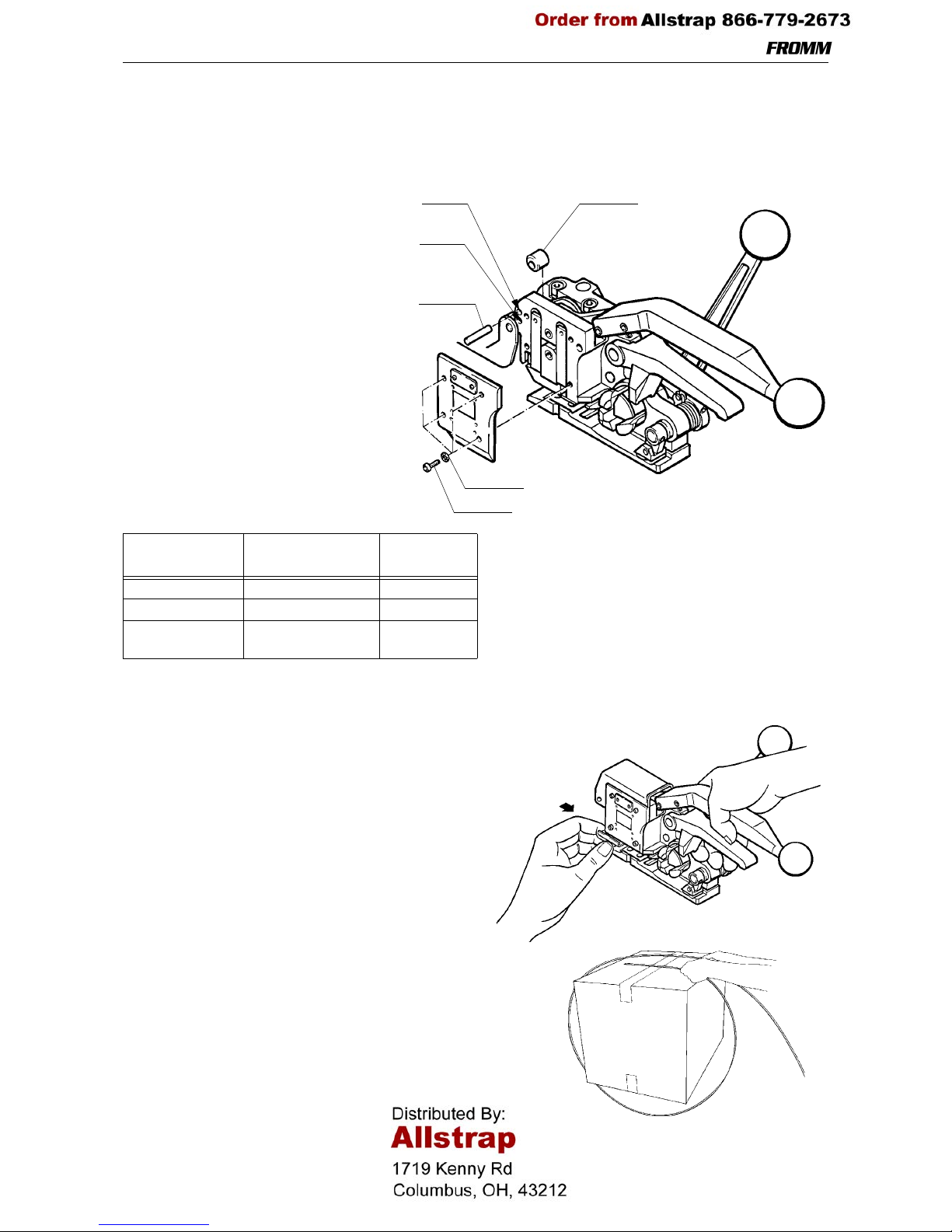

ATTENTION! Before starting using the tool it has to be adjusted

to the strap thickness used!

4 ADJUSTMENT OF THE STRAP THICKNESS

In order to achieve the highest possible

seal efficiency the tool must be adjusted t o

the respective stra p thickness through th e

use of the parallel pin N2.2185 and the

stop P40.2511. Please proceed as follows:

- remove the side plate

- bring the parallel pin N2.2185 and if

necessary the stop P40.2511 into

the correct position of the strap

thickness used

- reattach the side plate

- in order to avoid the strap slipping

between gripper and gripping jaw

the shims underneath the gripping

jaw have to be assembled according

to below table.

* See 7.2 changing of gripper and gripping jaw.

5 OPERATION

Introducing the seal

The seal is introduced i nto the tool from the rear side

until it hits the strap stop. Use the left hand.

Feeding the strapping around the pack age

The plastic strapping is fed around the package as

shown in the illustration.

Strap

thickness

Stop Shim*

0.50 - 0.59 mm N2.2185 in Pos. 1 2 x P40.2052

0.60 - 0.74 mm N2.2185 in Pos. 2 1 x P40.2052

0.75 - 0.90 mm N2.2185 and

P40.2511 in Pos. 2

0

N2.2185

Pos. 1

Pos. 2

P40.2511

N1.6504

N1.1910

Loading...

Loading...