Fromm P380, P359 Operation Manual

P380 Pneumatic Powered Plastic

Strapping Tool

OPERATION MANUAL

Machine

Pneumatic Powered Plastic Strapping Tool

Model

P380

Date

April 2018

Issue

FPA001

CONTENTS

1. General Information 1

1.1 Note of Installation 1

1.2 Notice of Operation 1

2. Specification 2

2.1 Specification Table 2

2.2 Chart of Types 3

2.3 Tool Description 3

3. Operation Description 4

3.1 Installation 4

3.2 Suspension of Tool 4

3.3 Adjustments 5

3.4 Feeding the Strap Around the Package 5

3.5 Inserting the Upper Strap 6

3.6 Inserting the Lower Strap 6

3.7 Tensioning the Strap 6

3.8 Sealing the Straps 7

3.9 Removing the Tool 7

3.10 Seal – Control 8

3.11 Cleaning 8

3.12 Air Unit 8

4. Safety Notices 9

5. Safety Rules for Strapping Tools 10

5.1 Joints 10

5.2 Dispensing Strap 10

5.3 Strap Warnings 10

5.4 Strap Breakage Hazard 10

5.5 Cutting Tensioned Strap 10

5.6 Fall Hazard 10

6. Maintenance and Trouble Shooting 11

6.1 Suggested Maintenance 11

6.2 Warranty Periods 11

6.3 Fromm Service Solutions 11

6.4 Possible troubleshooting causes and remedies 12

7. Contact Fromm Packaging 14

P380 Pneumatic Strapping Tool Operation Manual | FPA001 | Apr 2018 | Page 1

1. GENERAL INFORMATION

Congratulations on the purchase of your Fromm Pneumatic Powered Plastic

Strapping Tool. We trust you will have many years of packaging efficiency.

Before proceeding with the operation or installation of your new tool please read

this manual thoroughly and gain a full understanding of the requirements, features

and operation of your new tool.

1.1 Note of Installation

To ensure your tool operates in a safe manner please review the following

requirements:

1. Tool power is pneumatic air, 6.0 bars / 87 psi.

2. Keep work area clean.

3. Tool can operate in temperatures between -10℃ and 45℃.

4. Please ensure you download and read our Install Guide before attempting it

yourself.

1.2 Notice of Operation

Before you start using the pneumatic tool, please review the following conditions:

1. Before operating, please read the operational manual carefully.

2. Ensure the switch is in the off position before connecting the air hose.

3. Avoid any damp object or water around the electric parts.

4. When a problem does occur, please check the troubleshooting section for more

information and advice.

P380 Pneumatic Strapping Tool Operation Manual | FPA001 | Apr 2018 | Page 2

2. SPECIFICATION

2.1 Specification table

Model

P380

Strap Width

13-19mm

Strap Thickness

0.4-1.35mm

Strap Tension

600-2000 Newtons

Tensioning Speed

120-260mm/s

Joint Strength

Approx. 75%

Tool Size with Suspension

Bracket

390mm(L)x135mm(W)x305mm(H)

Weight

6.8kg

Sound level

78dB

Air Pressure

6.0 bars / 87 psi

Joining Thread

G 1/4

Air Flow of Air Unit

Min. 520 NI/min with a maximum pressure drop of

0.5 bar / 7.25 psi

Air Consumption

Tensioning: Approx. 6.5 NI uncompressed air /sec

Sealing: Approx. 10.9 NI uncompressed air /sec

Oil for Air Unit

HL / CL ISO VG 10

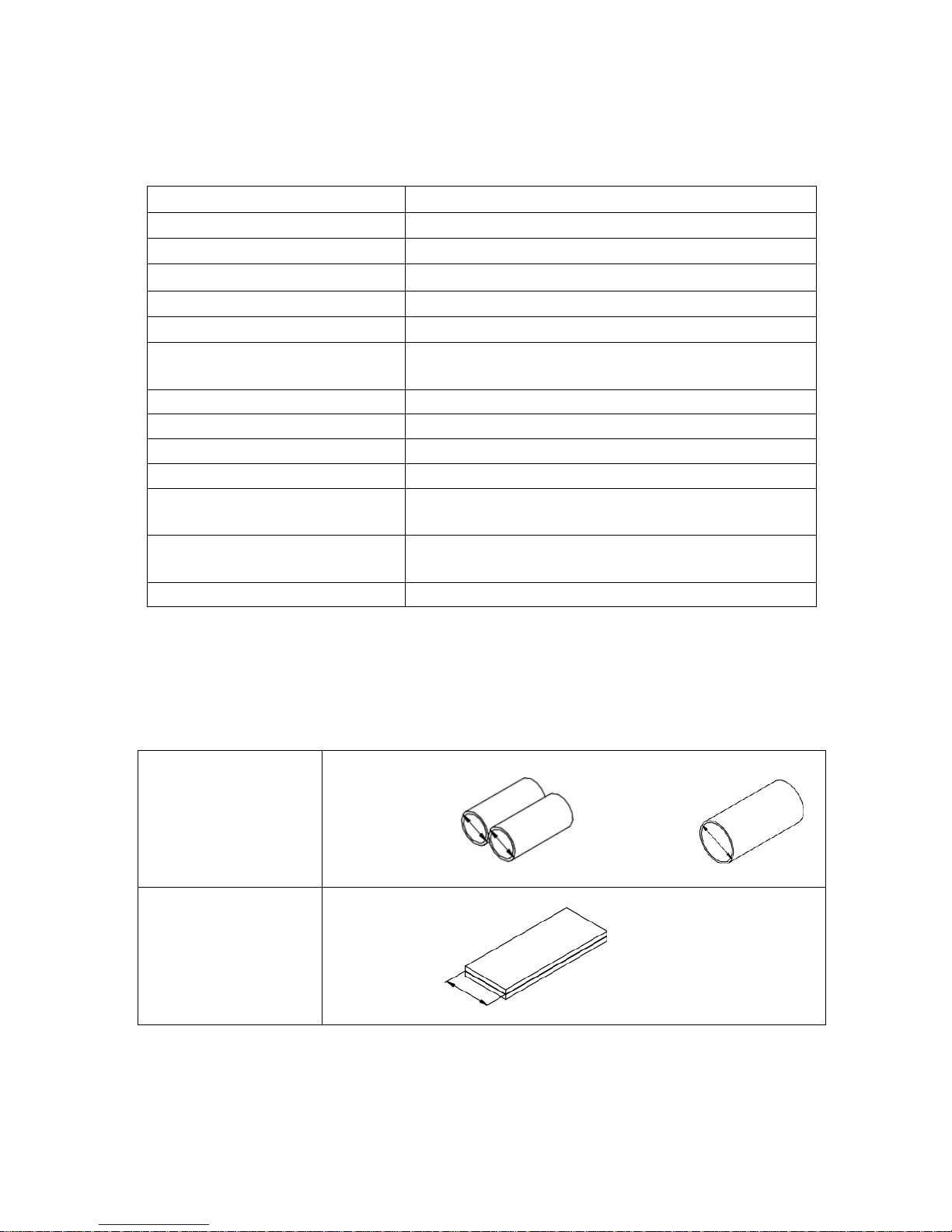

Accessories:

Protection Plate

Package Dimensions

Diameter of round /

circular goods

Min 2 x Ø70mm Min Ø240mm

Width

Min 80mm

P380 Pneumatic Strapping Tool Operation Manual | FPA001 | Apr 2018 | Page 3

2.2 Chart of Types

Item No.

Model

Strap

Width

Strap

Thickness

49.3801

P380/13/0.40-0.64

13.0 mm

0.40 - 0.64 mm

49.3802

P380/13/0.64-1.05

13.0 mm

0.65 - 1.05 mm

49.3811

P380/15/0.40-0.64

15.0 mm

0.40 - 0.64 mm

49.3812

P380/15/0.65-1.05

15.0 mm

0.65 - 1.05 mm

49.3821

P380/16/0.40-0.64

16.0 mm

0.40 - 0.64 mm

49.3822

P380/16/0.65-1.05

16.0 mm

0.65 - 1.05 mm

49.3831

P380/19/0.40-0.64

19.0 mm

0.40 - 0.64 mm

49.3832

P380/19/0.65-1.05

19.0 mm

0.65 - 1.05 mm

49.3833

P380/19/1.06-1.35

19.0 mm

1.06 - 1.35 mm

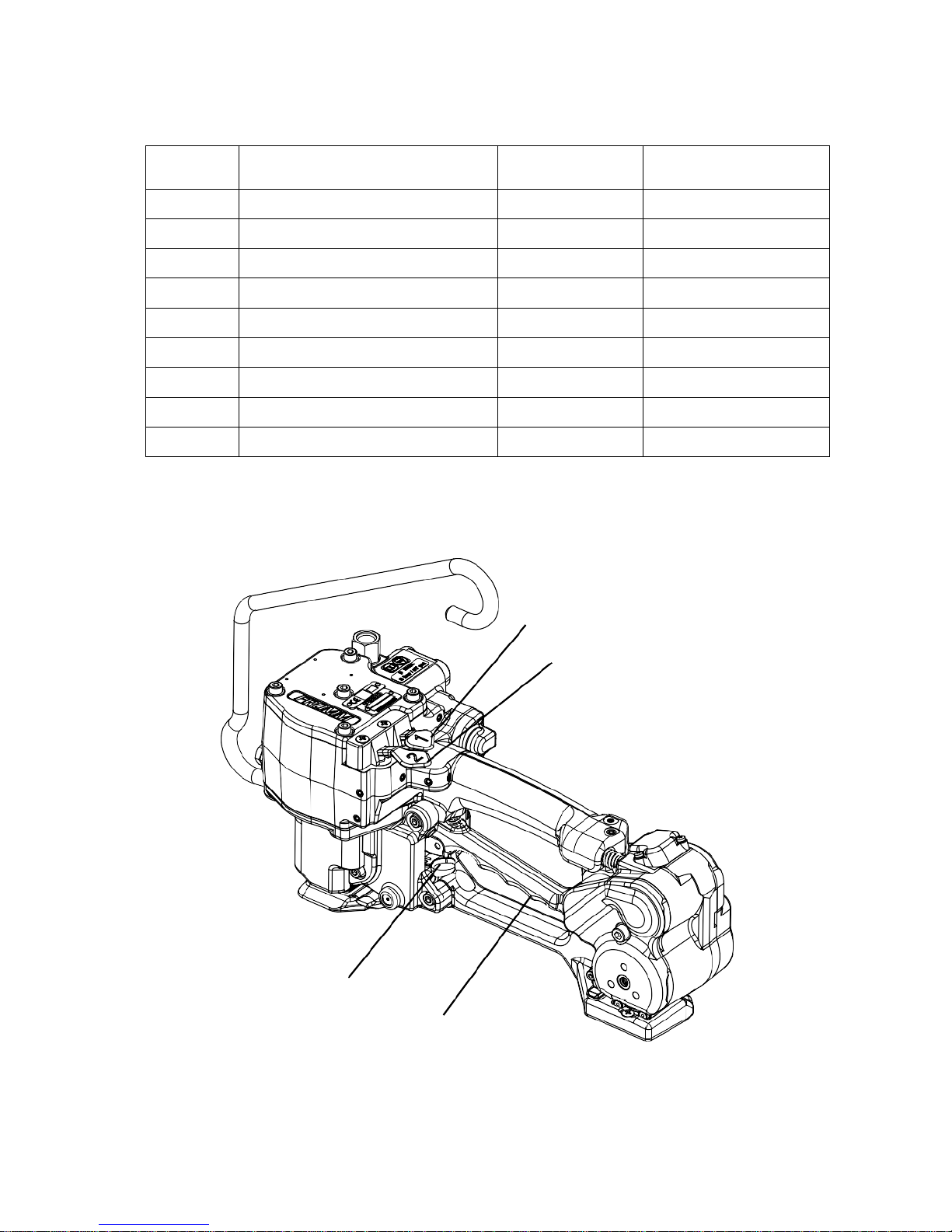

2.3 Tool Description

Tensioner valve lever

Sealer valve lever

Handle lever

Seesaw lever

Loading...

Loading...