Fromm P355.0001.01 Service Manual

SERVICE MANUAL

PNEUMATIC PLASTIC

STRAPPING TOOL

MODEL P355.0001.01

P355.0001.01se.en.fm/MAS/© 11.03

Manual for autorized dealers and service points

SERVICE MANUAL

PNEUMATIC PLASTIC

STRAPPING TOOL

MODEL P355.0001.01

1-2

INDEX PAGE

1.1 TECHNICAL DETAILS 1-3

1.1.1 Air supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.2 Pneumatic schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.1.3 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.1.4 Details of the pneumatic control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2 CONVERSION PARTS 1-7

1.2.1 Conversion parts: strap width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.2.2 Conversion parts: strap thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3 PERIODIC MAINTENANCE AND CONTROL 1-8

1.3.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.3.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.3.3 Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.3.4 Glueing rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.3.5 Lubrication rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.3.6 Assembly information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.4 RECOMMENDED SPARE PARTS 1-14

1.5 ACCESSORY TOOLS 1-15

1.5.1 Use of accessory tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.6 ORDERING SPARE PARTS 1-22

1.6.1 Ordering manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

1.6.2 Ordering address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

1.6.3 Finding out of the tool type (item number), the serial number

and the version number: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

1.7 SERVICE ADDRESS 1-23

TECHNICAL DETAILS

1-3

1.1 TECHNICAL DETAILS

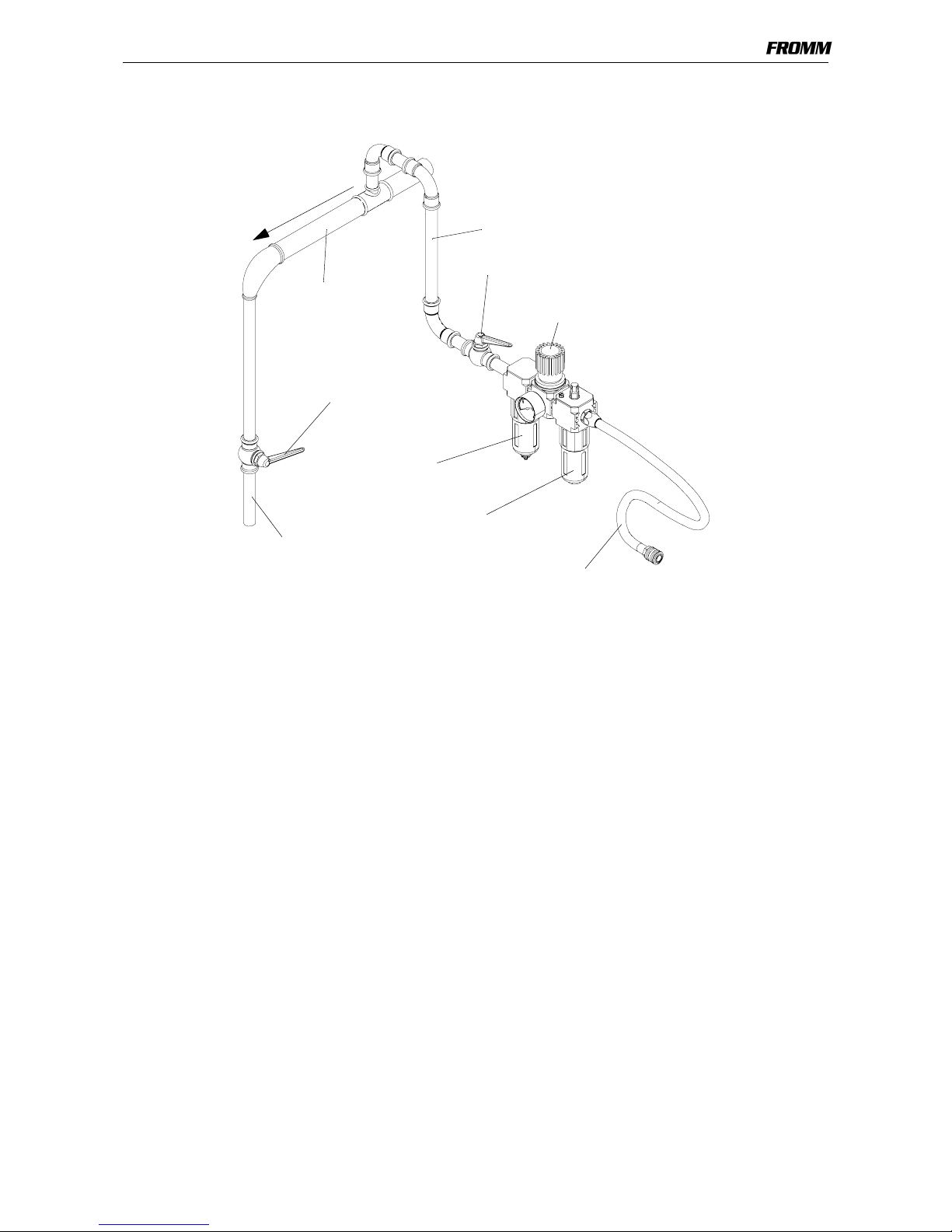

1.1.1 Air supply

Air pressure:

• The maximum air pressure allowed is 6.0 bars / 87 psi

Air unit:

•min. G3/8

• Air line in front of F.R.L.-unit min. 1/2"

• Main air line 2"

Maintenance:

• Checking the air-pressure daily

• Checking oil-level daily

• The water separator must be drained depending on developed water amount (unless automatic)

• The filter has to be cleaned regularly following the instructions of the manufacturer of the air- unit

• Check the function and proper adjustment of the lubricator daily (approximately 1-2 drops/min.)

Oil for the air-unit:

• Hl / CL ISO VG10

Shut off Valve

Drain of

Main air line

max. length 5m (16 ft.)

min. Ø-inside 9mm (3/8")

Lubricator

(app. 1-2 drops/min.)

Filter with

a

p

p

.

2

%

f

a

l

l

Shut off Valve

Pressure adjustment valve

with Manometer

water separator

coupling G1/4

2"

1/2"

TECHNICAL DETAILS

1-4

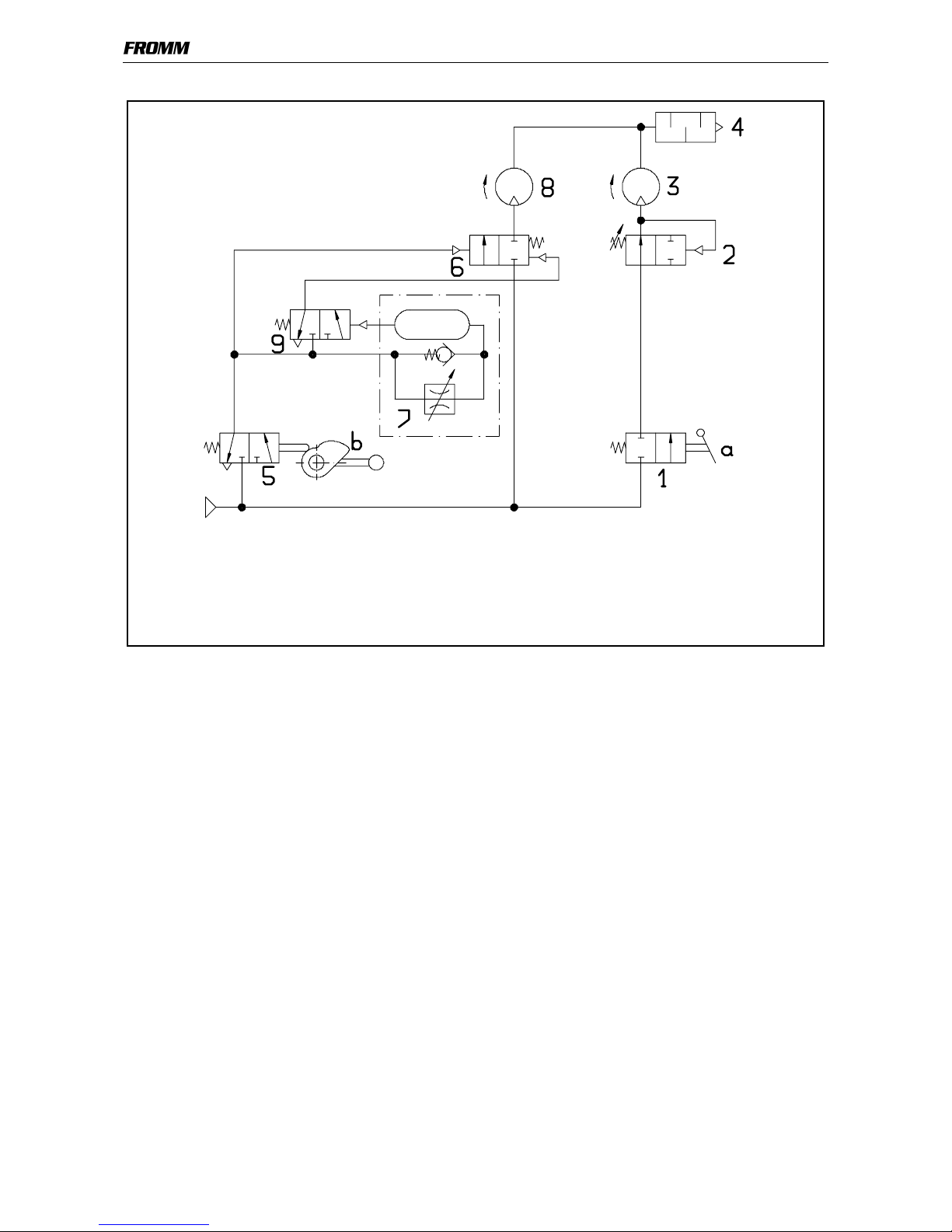

1.1.2 Pneumatic schematic

1.1.3 Functional description

A mechanical lock mechanism avoids simultaneous operation of tensioning and sealing lever.

• Pressing of the tensioning valve lever (a)

- The tensioning valve (1) is flowed through.

- The tension force control valve (2) is driven, the spring force is assisted and the valve is flown

through.

- The tensioning motor (3) starts.

- When reaching the preselected tension force the tension force control valve (2) is shut by the back

pressure of the tensioning motor.

- The motor stops.

- A return movement of the tension wheel is blocked by the needle free wheeling N3.4509.

- The tensioning valve lever (a) can be released.

• Activating the sealing valve lever (b)

- The welding valve (5) is flown through.

- The welding motor valve (6) is driven and releases the air flow to the welding motor (8).

- The welding motor (8) starts.

- At the same time the air is present at the turn off valve (9) and the welding time valve (7) is flown

through.

- When the preselected welding time (pressure) is reached the turn off valve (9) is driven.

- The turn off valve resets the welding motor valve (6) in combination with the spring pressure.

- The welding motor stops.

After the welding operation the welding lever (b) must be kept pressed in the welding position for 1-2 seconds in order to

let the welding seam cool down.

The outgoing air escapes in each case through the exhaust silencer (4).

Pos. Description Pos. Description Pos. Description

1 Tensioner valve 6 Welding motor valve a Valve lever for tensioning

2 Tension force control valve 7 Welding time valve b Valve lever for welding

3 Tensioning motor 8 Welding motor

4 Exhaust silencer 9 Turn off valve

5 Welding valve

P

TECHNICAL DETAILS

1-5

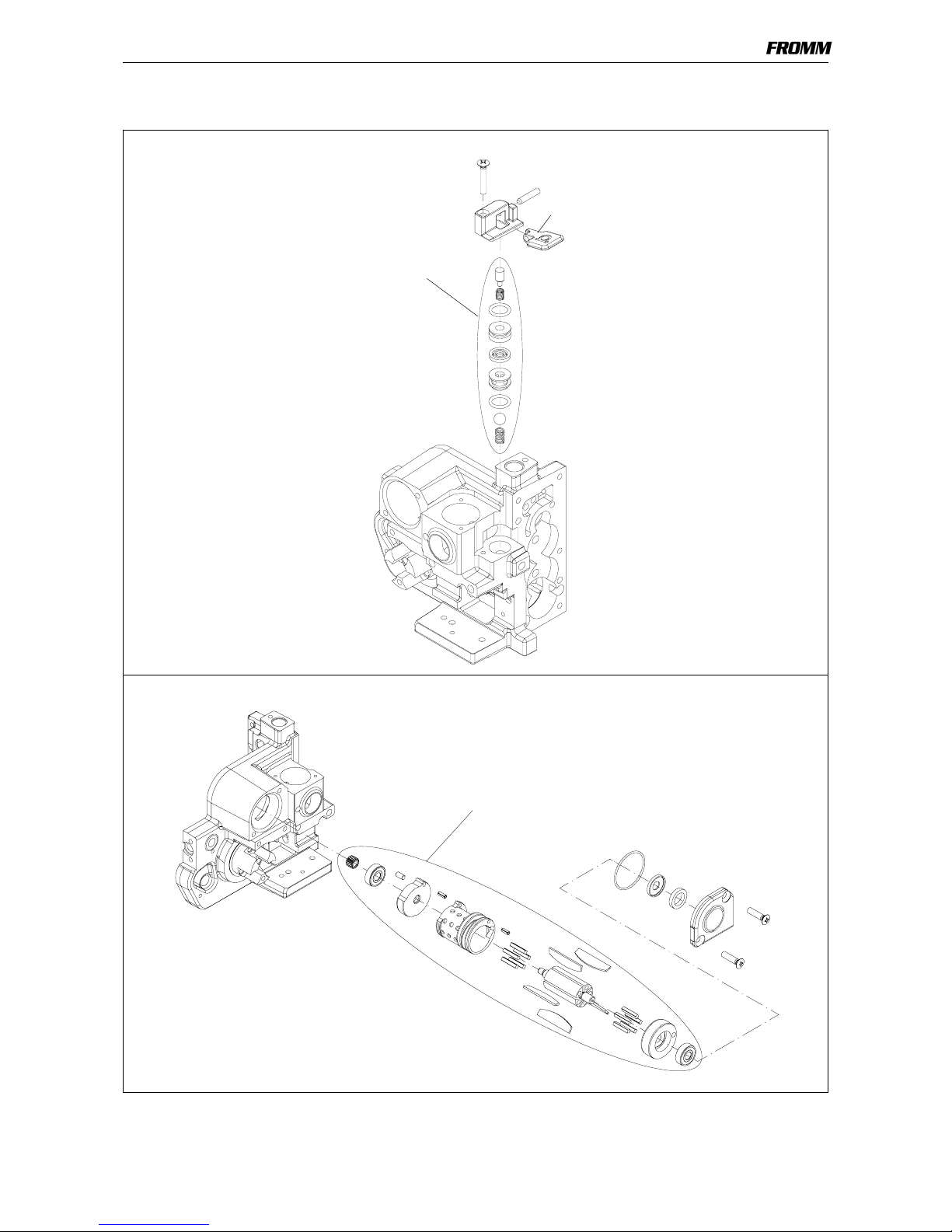

1.1.4 Details of the pneumatic control system

(Valve numbers correspond to the pneumatic schematic)

1 Tensioner valve

a Valve lever for tensioning

3

Tensioning motor

TECHNICAL DETAILS

1-6

5 Welding valve

2 Tension force control valve

4 Exhaust silencer

b Valve lever for welding

8 Welding motor

6 Welding motor valve

9 Turn off valve

7 Welding time valve

CONVERSION PARTS

1-7

1.2 CONVERSION PARTS

When changing strap thickness or strap width following parts must be exchanged.

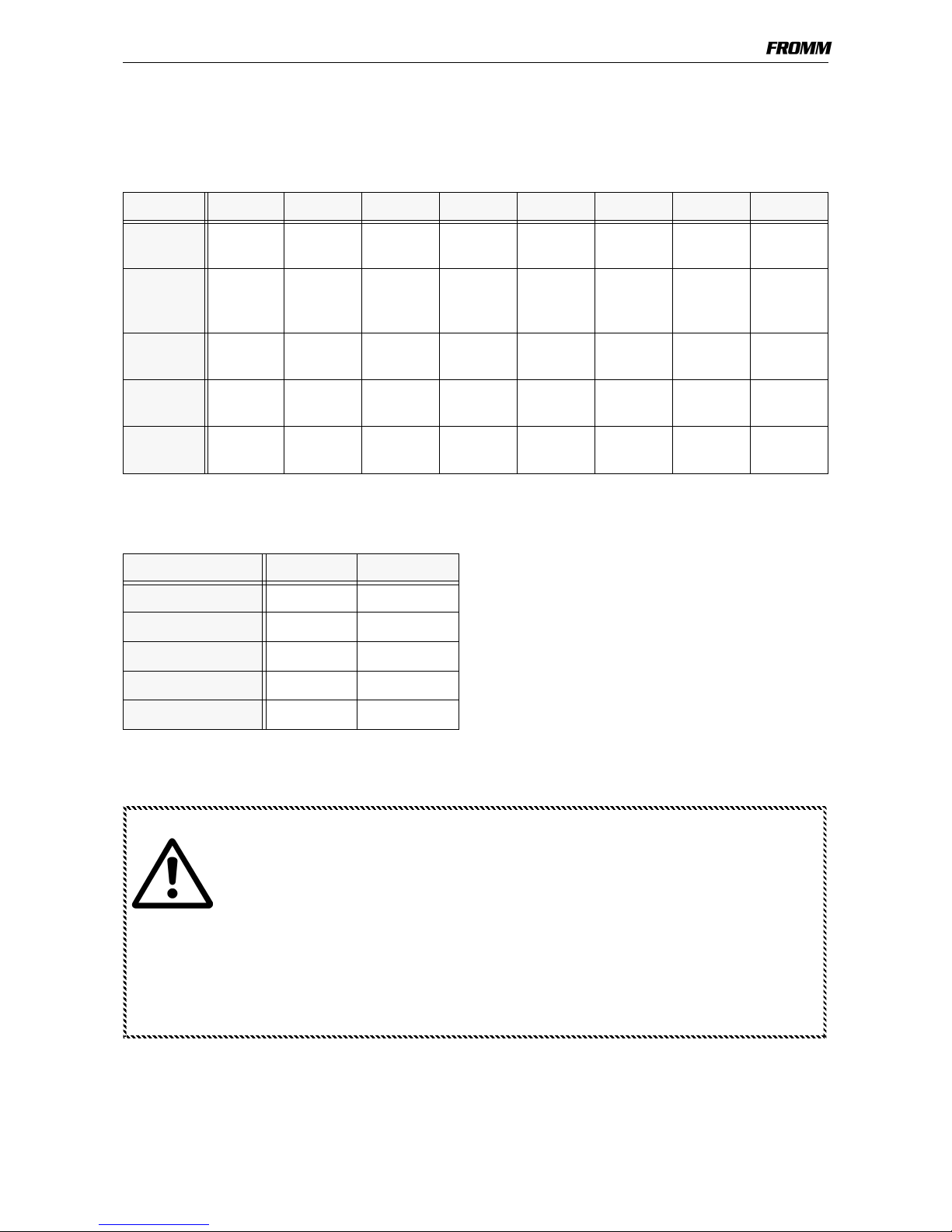

1.2.1 Conversion parts: strap width

1.2.2 Conversion parts: strap thickness

10mm 11.1mm 12mm 12.7mm 13mm 15mm 15.5mm 16mm

Guide

pin P30.1156 P30.1158 P30.1156 P30.1157 P30.1158 P30.1159 P30.1160 P30.1161

Guide

pin P30.1162 P30.1164 P30.1162 P30.1163 P30.1164 P30.1165 P30.1166 P30.1167

Guide

case P32.1205 P32.1205 P32.1206 P32.1206 P32.1206 P32.1206 P32.1206 P32.1206

Strap

stop P32.1230 P32.1231 P32.1232 P32.1233 P32.1234 P32.1235 P32.1236 P32.1237

Strap

guide P32.1239 P32.1240 P32.1241 P32.1242 P32.1243 P32.1244 P32.1245 P32.1246

0.4-0.64mm 0.65-1.05mm

Steel insert P32.1201 P32.1202

Tensioning wheel P32.1219 P32.1220

Gripper P32.1222 P32.1225

Gripper P32.1223 P32.1226

Gripper P32.1224 P32.1227

Attention!

When converting tools always change the item number on the ty pe label

Replace following parts:

Type label N41.9143

2 x hammer head bolts N2.4902

Enclose the suitable operation manual with the tool after each conversion

(see paragraph Ordering manuals)

PERIODIC MAINTENANCE AND CONTROL

1-8

1.3 PERIODIC MAINTENANCE AND CONTROL

Carry out 12- months cycles doing one shift work. Doing multiple shift work respectively more often.

1.3.1 Procedure

Before using check tool for following possible faults:

• Visual test of the tool for loose, lost or damaged parts

• Clean all dirty parts of the tool, especially strap abrasion in the tensioning or the welding unit by

using compressed air. (Never use any hard tools like a wire brush or a screw driver for cleaning)

• Condition of the tensioning wheel, the welding grippers and the tensioning grippers

Connect tool to the air supply and perform a test strapping.

Check the following:

• Tightness of the pneumatic system

• Strap guidance

• Strap feed and strap tensioning

• Tensioning force adjustment (see operation manual P355)

• Cutting of the upper strap

• Welding time adjustment (see operation manual P355)

• Welding pressure adjustment (see operation manual P355)

• Seal quality (see operation manual P355)

Proceed according to paragraph „Troubleshooting“ after a fault appears.

Attention!

Before maintenance always remove the tool from the compressed air supply.

For exchange of wearing parts see operation manual P355

Never use water or solvents for cleaning the tool’s surface.

PERIODIC MAINTENANCE AND CONTROL

1-9

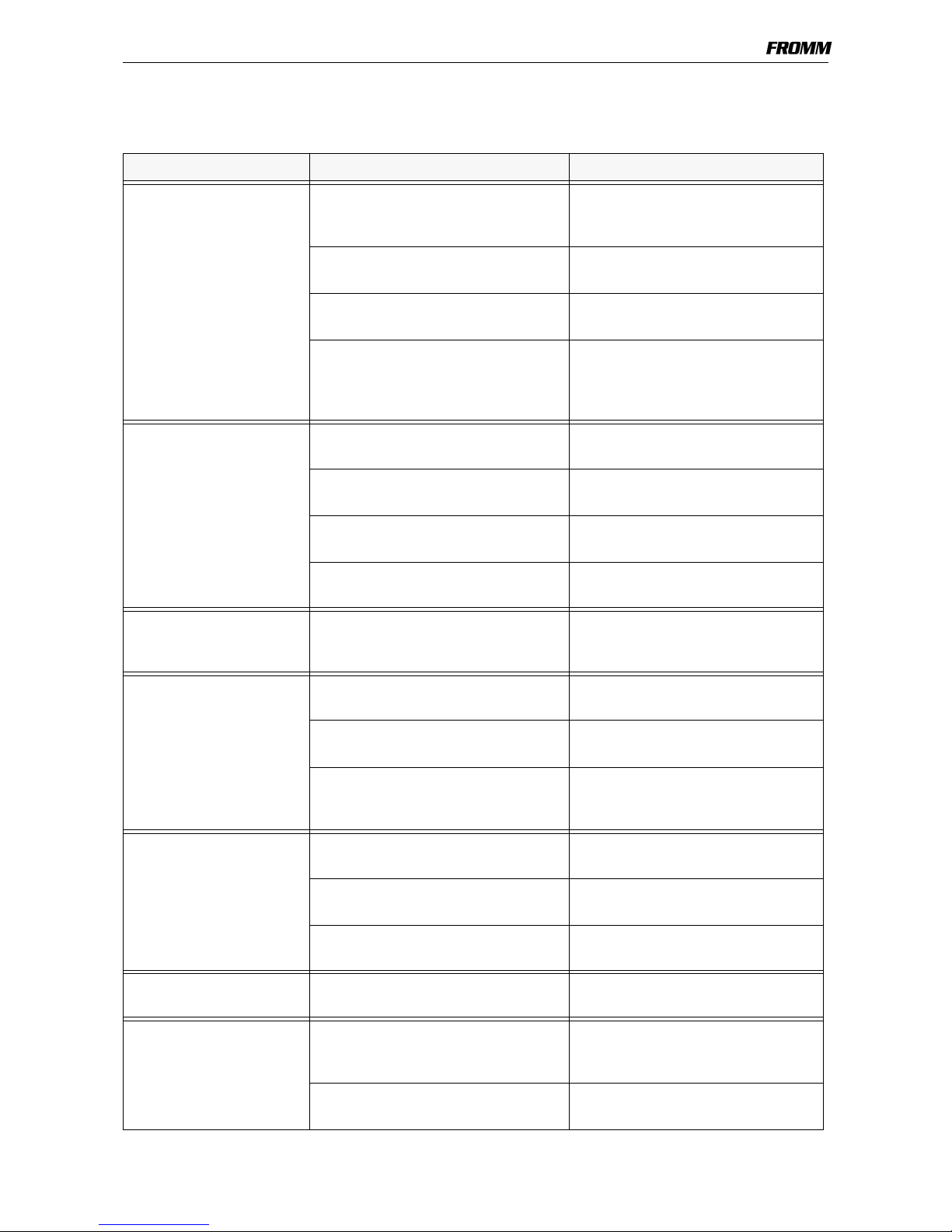

1.3.2 Troubleshooting

A sufficient compressed air supply and the use of the tool’ s specific strap should be guaranteed before

each tool repair.

SYMPTOM CAUSE REMEDY

Tool doesn’t tension,

Tensioning motor runs

The tensioning wheel is packed with

strap residue or is worn and mills on

the strap

Clean tensioning wheel with

compressed air or replace it

Wrong tensioning wheel or tensioning

wheel is assembled reversed

Correct assembling or use the correct

tensioning wheel.

Grippers are dirty, worn or wrongly

assembled

Replace grippers, clean them with

compressed air or assemble correctly

Gearing parts from the tensioning gear

are defective

Loose pinion P32.1123 on tensioning

motor

Check tensioning gear and replace

defect parts

Tensioning motor doesn’t

run

Tensioning motor defective Check component parts and replace

damaged ones

Tensioning gear defective Check component parts and replace

damaged ones

Pneumatic control system is defective Check component parts and replace

damaged ones

Needle free wheeling assembled

reversed

Assemble correctly

Tensioning wheel turns

back immediately after the

tensioning cycle

Defective needle free wheeling

N3.4509

Check and replace if necessary

Tool doesn’t weld,

welding motor runs

Welding gripper is dirty or worn Clean and check welding gripper and

replace damaged one

Welding stop gripper is dirty or worn Clean and check welding stop gripper

and replace damaged one

Pinion P32.1023 lose at the motor or

welding eccentric, resp. The journal at

the welding eccentric is broken off.

Check component parts and replace

damaged ones

Welding motor doesn’t run Welding motor defective Check component parts and replace

damaged ones

Welding mechanism defective Check component parts and replace

damaged ones

Pneumatic control system is defective Check component parts and replace

damaged ones

Gear noise Tensioning or welding gear is worn Check component parts and replace

damaged ones

Welding motor does not

stop

Turn off valve or welding motor valve

jam, resp. the welding time valve is

blocked.

Check and clean parts, exchange

damaged parts

Diameter of the air supply hose is too

small.

Install air supply hose with a minimum

inner diameter of 9mm (3/8")

PERIODIC MAINTENANCE AND CONTROL

1-10

1.3.3 Checklist

Carry out several test strappings and check the following items.

• Connect the tool to the compressed air supply and check if air escapes

• Insertion of the strap

• Strap guidance

• Strap feed and strap tension

• Tension force adjustment (see operation manual P355)

• Cutting of the upper strap

• Welding time adjustment (see operation manual P355)

• Seal quality (see operation manual P355)

• Type label

Tool badly cuts the strap or

doesn’t cut at all

Cutter is worn or damaged Replace cutter

Wrong adjustment of the coupler

P32.1250

Check adjustment and readjust if

necessary

(see operation manual P355)

Welding gripper is worn Replace welding gripper

Welding time too short Change adjustment

(see operation manual P355)

Defective pressure spring N2.5237 Replace pressure spring

Welding time not

adjustable

Welding time valve dirty or damaged Clean and check component parts

and replace damaged ones

Tensioning force not

adjustable

Tension force control valve dirty or

damaged

Clean and check component parts

and replace damaged ones

SYMPTOM CAUSE REMEDY

PERIODIC MAINTENANCE AND CONTROL

1-11

1.3.4 Glueing rules

Following parts have to be glued with LOCTITE 603:

Additional the screws N1.2112 have to be glued in the

planetary gear stage P32.0118 using LOCTITE 222.

Don’t clamp the planet shaft directly on the teeth when

loosening or tightening the screws N1.2112.

1.3.5 Lubrication rules

All bearing parts of the welding unit have to be cleaned and

lubricated with Klueber Isoflex Alltime SL2 grease during each

maintenance.

Lubrication interval:

At each maintenance or after 12 months at the latest.

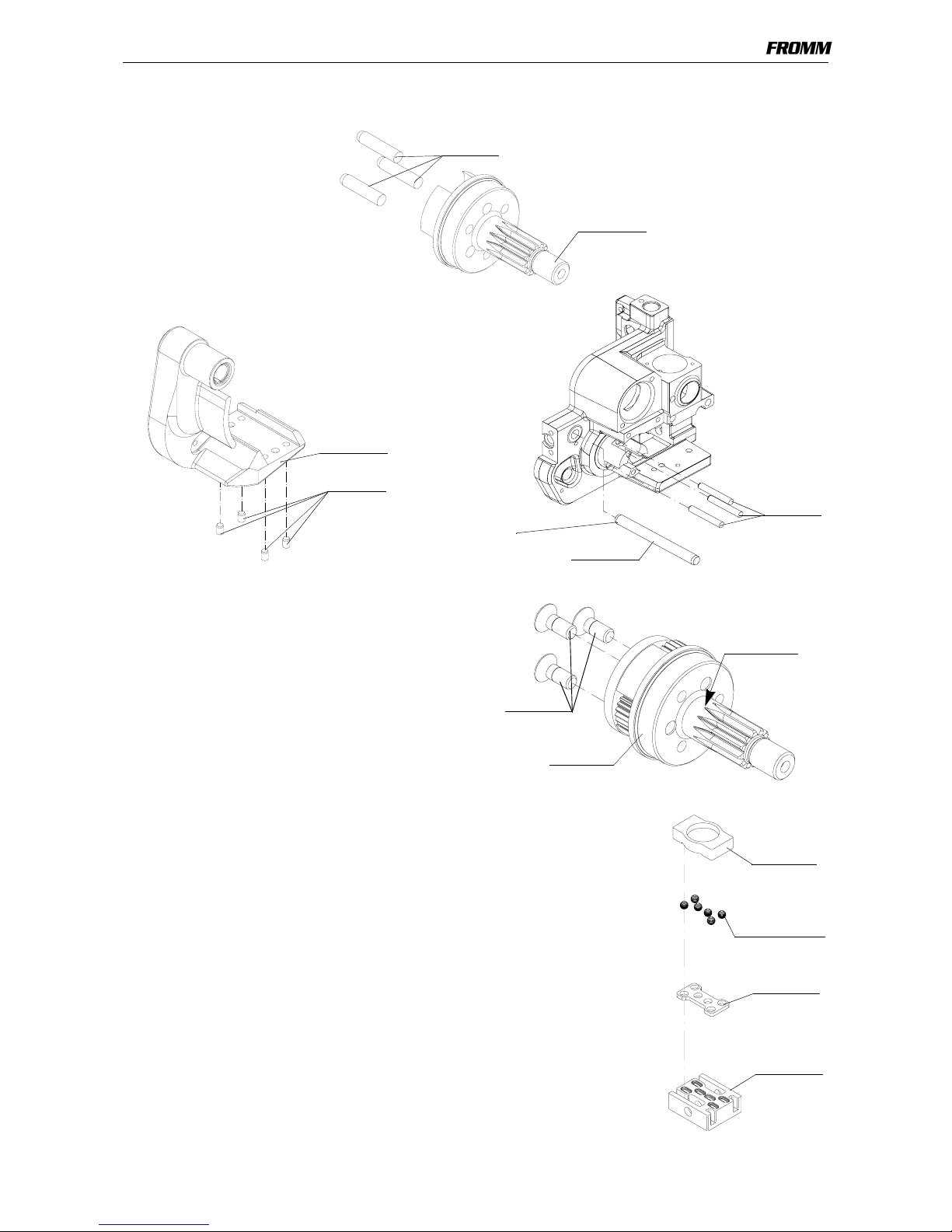

Planet shaft P32.1044

with the parallel pins N2.2145.

Tensioning body P32.1254

with the parallel pins N2.2189

Body P35.2002 with

swivel shaft P35.2004

and parallel pins N2.2188

P35.2004

N2.2188

Press in measure see

P32.1044

N2.2145

P32.1254

N2.2189

„Assembly information“

Clamp here

P32.0118

N1.2112

Bearing

welding unit

P32.1029

N3.1702 (6X)

P32.1027

P32.1053

PERIODIC MAINTENANCE AND CONTROL

1-12

All movable gear parts have to be lubricated with MOLYKOTE BR 2 PLUS grease.

Lubrication interval: At each maintenance or after 12 months at the latest.

All other parts have to be greased according to the explosion drawing.

Lubrication interval: At each maintenance or after 12 months at the latest.

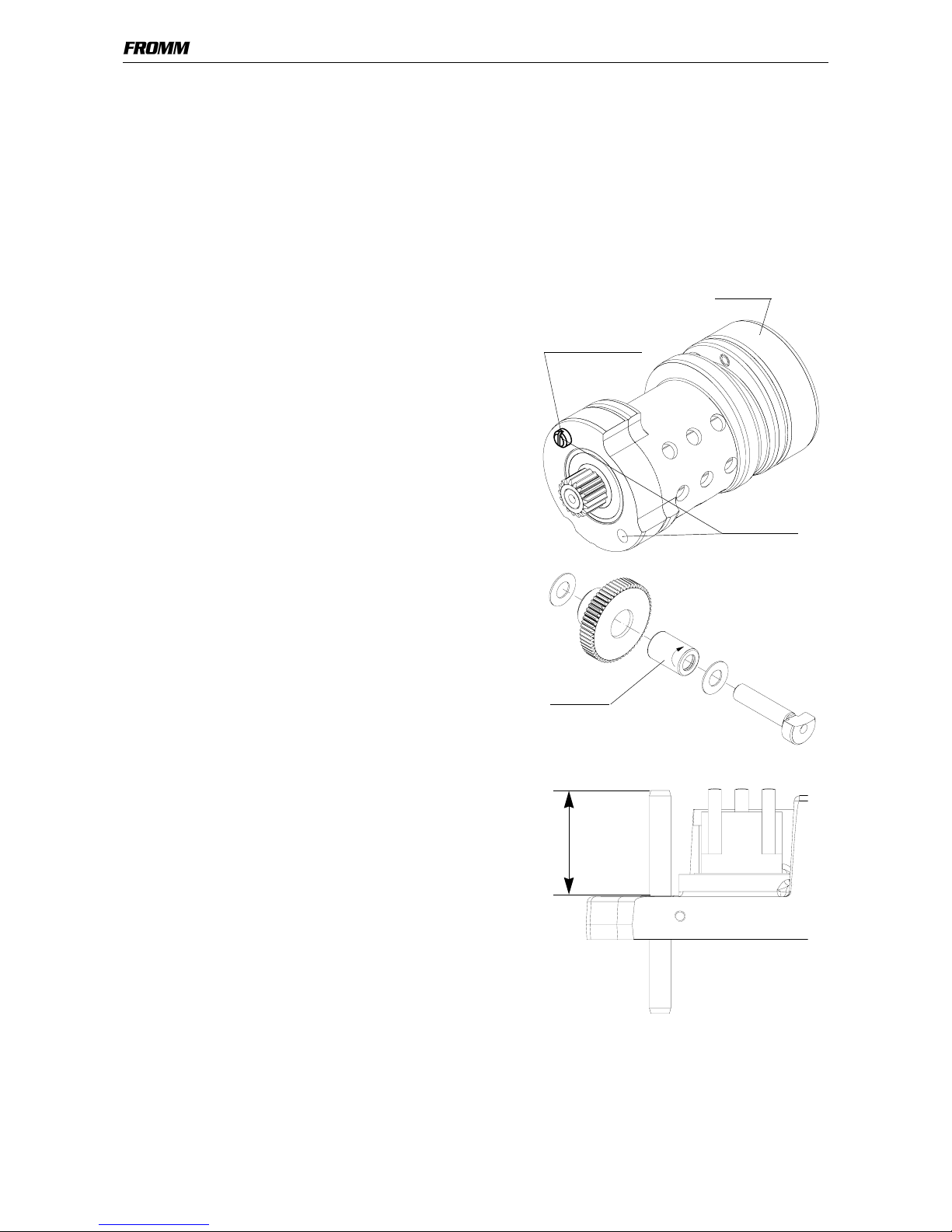

1.3.6 Assembly information

Air motors

Installation:

When installing the air motors pay attention to the correct

position of the position screw.

(see picture)

Removing welding motor:

- Remove positioning screw and screw in two screws

M4 (e.g. N1.1936) in the two existing thread holes.

- Pull out welding motor.

Needle free wheeling:

Pay attention to the assembling direction of the needle

free wheeling N3.4509.

The sense of rotation is stamped in the front of the free

wheeling.

Swivel shaft:

When pressing in the swivel shaft P35.2004 the

dimension 39.2 mm must be observed (see drawing)

Position screw

Thread M4

Air motor

N3.4509

39.2 mm

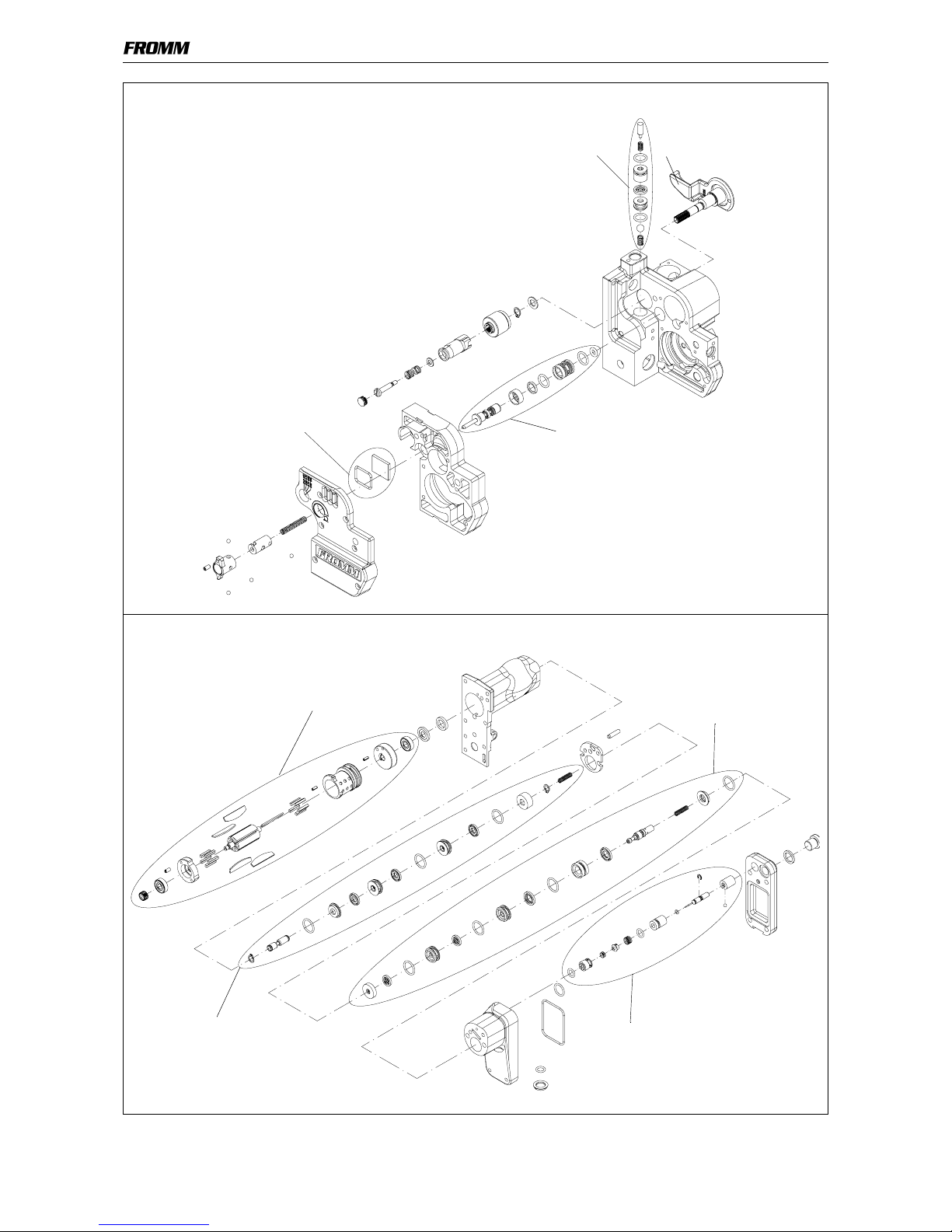

PERIODIC MAINTENANCE AND CONTROL

1-13

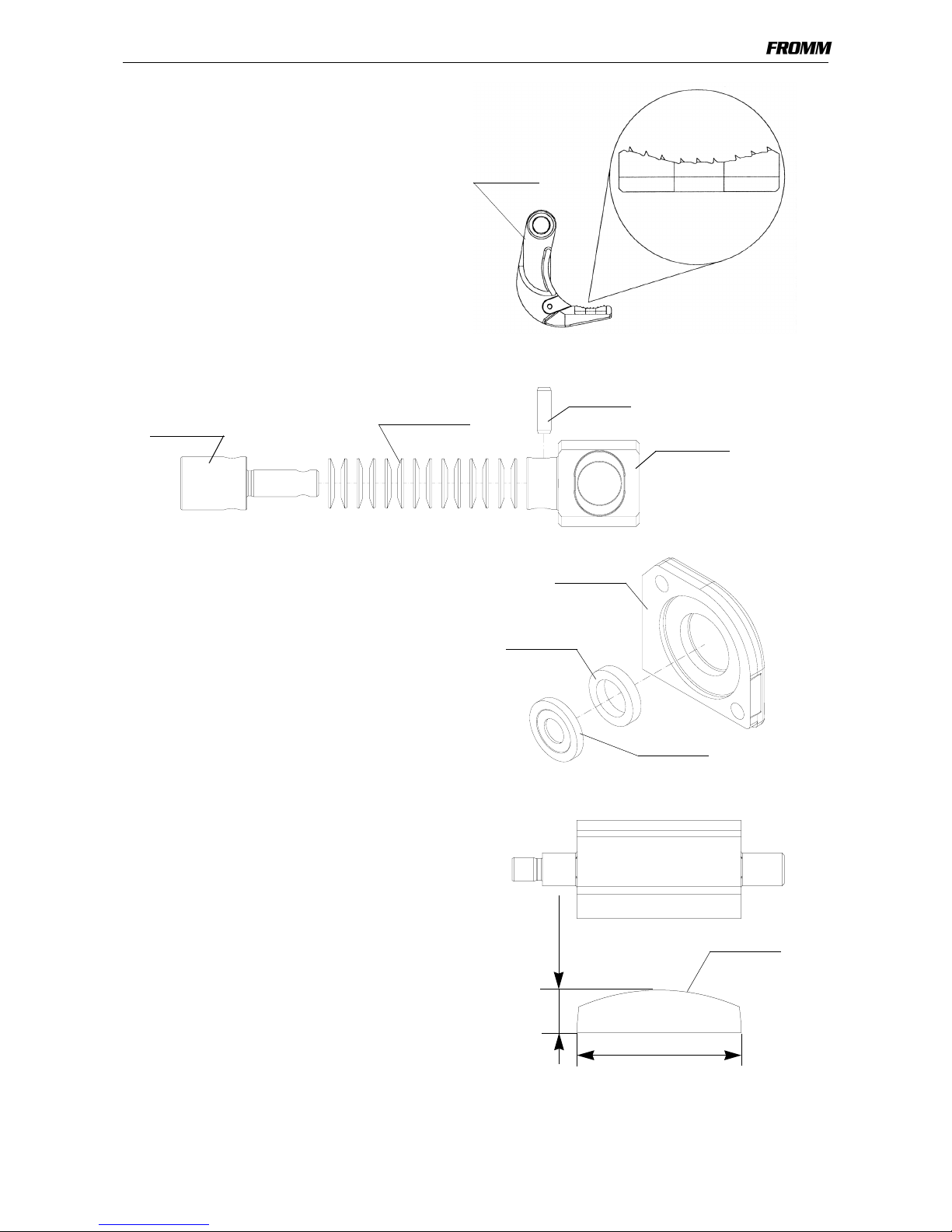

Grippers:

When installing the grippers into the tensioning

body P32.1254 pay attention to the direction of

the teeth.(see picture)

Cup springs:

Assemble the cup springs N2.5621 as shown in the picture.

Motor cover:

When assembling the motor cover P35.2028, pay

attention to the assembling direction of the spring

P35.2026 and the thrust piece P35.2027. (See drawing)

Attach parts with grease (ESSO BEACON 2) !

The same assembling position is valid for the

welding motor too!

Vane:

If the minimum diameters (see drawing) are not

reached anymore, the vanes P35.2024 must be

exchanged.

P32.1254

Grippers

N2.5621(14X)

N2.2443

P32.1031

P32.1030

P35.2028

P35.2026

P35.2027

min. 8.2 mm

min. 37.2 mm

P35.2024

RECOMMENDED SPARE PARTS

1-14

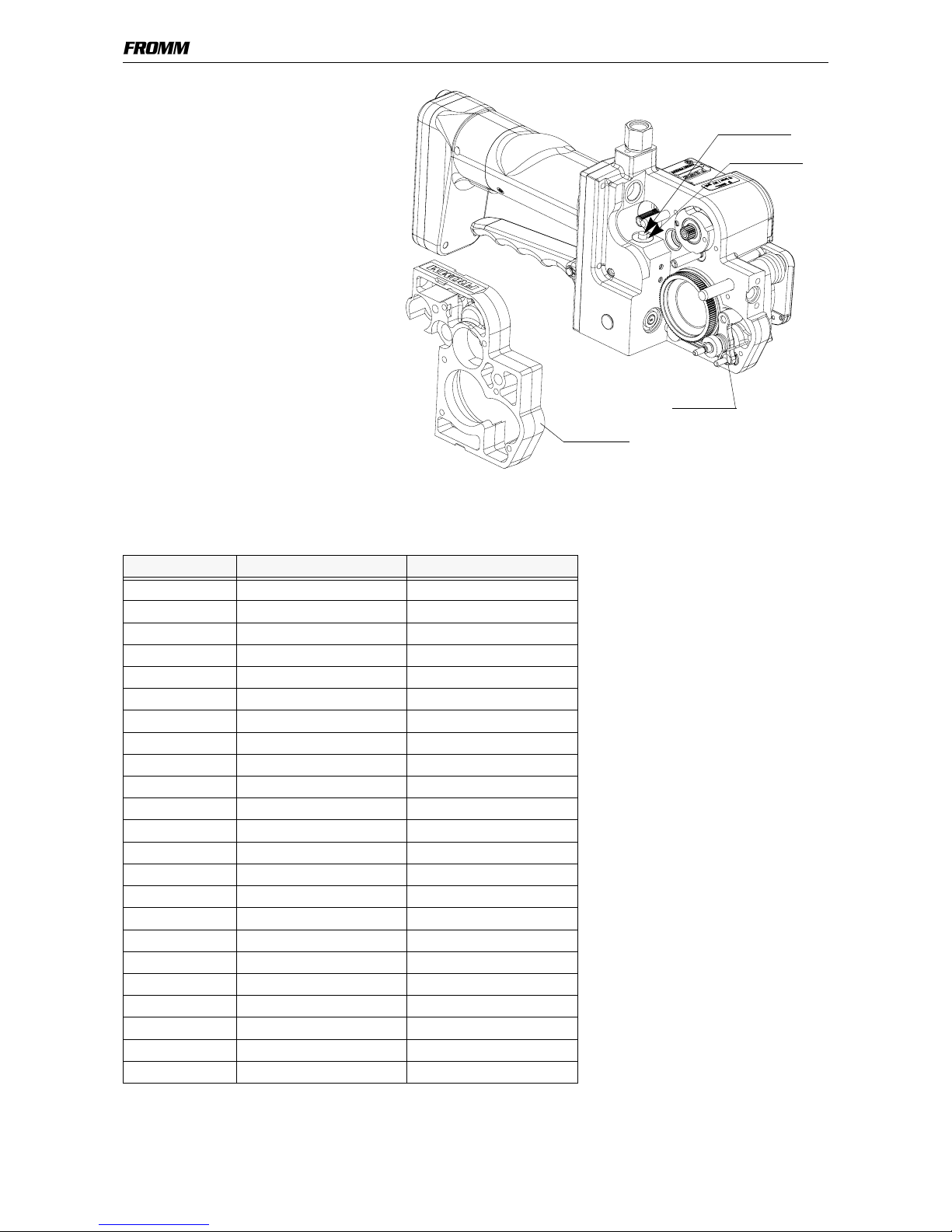

Gear body:

When assembling or disassembling the

gear body (P35.2034) the touch bolt

(P35.2007) and the guide (P35.2006) of

the welding valve must be pressed down.

The spring N2.5822 must be slightly lifted

up. (see drawing)

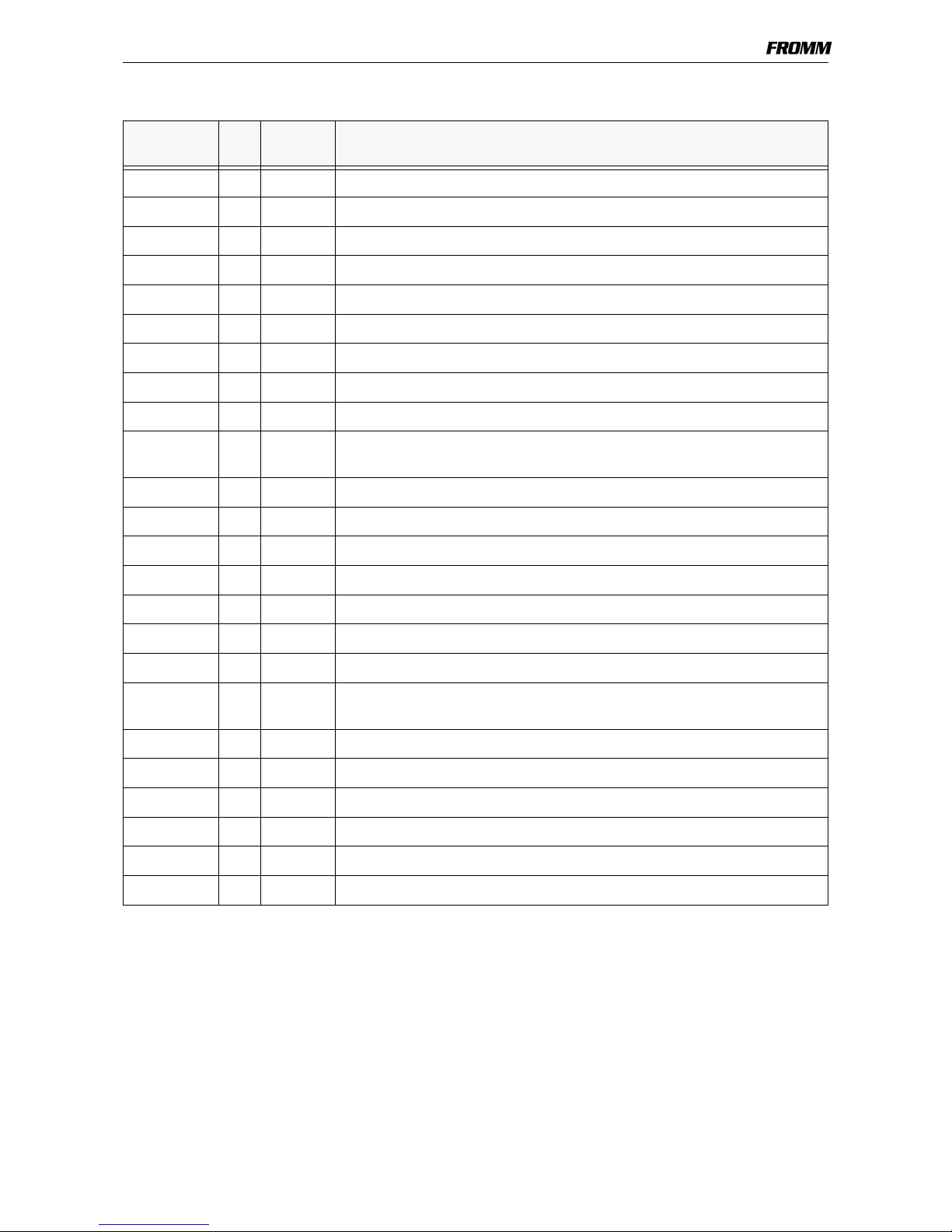

1.4 RECOMMENDED SPARE PARTS

Following spare parts are recommended for stock keeping:

Besides should be stocked the wearing parts of the different Types.

Stock only parts from tools that are in sale.

Item-No. Description Pieces per tool

N1.1305 Screw 2

N1.1813 Screw 6

N1.1820 Screw 1

N1.1904 Screw 5

N1.1909 Flat head screw 2

N1.1915 Screw 2

N1.1929 Screw 1

N1.1932 Flat head screw 2

N1.1935 Flat head screw 4

N1.1936 Flat head screw 2

N1.6205 Spring lock washer 2

N1.6503 Safety washer 6

N1.6504 Safety washer 9

N1.6505 Safety washer 4

N2.1107 Security ring 1

N2.1118 Security ring 1

N2.1121 Security ring 5

N3.1174 Ball bearing 2

N3.1702 Ball 6

N3.1703 Ball 1

N5.2702 Cover 2

P32.1034 Lever 1

P32.0110 End cover 1

P35.2007

P35.2034

N2.5822

P35.2006

ACCESSORY TOOLS

1-15

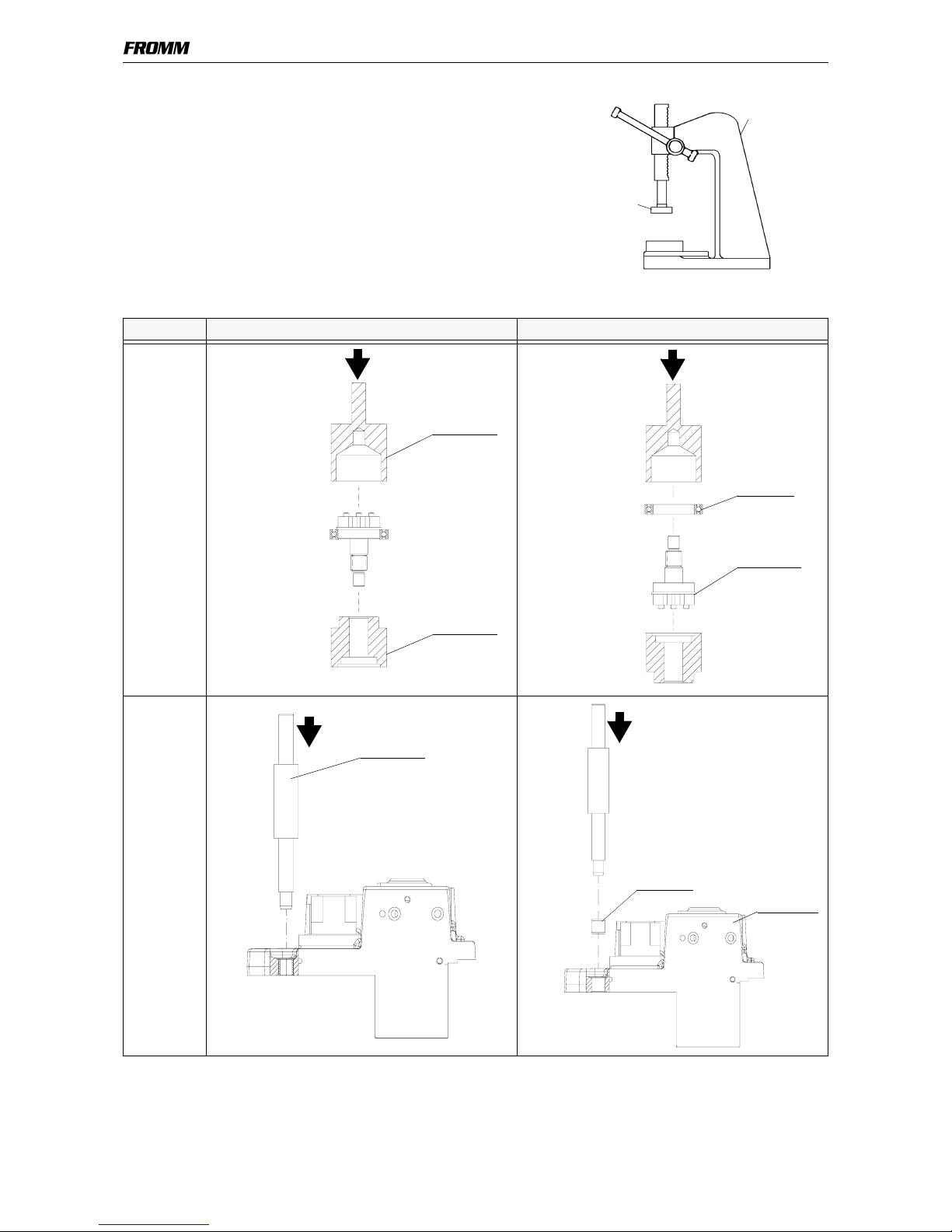

1.5 ACCESSORY TOOLS

*These tools are also included in the P320 tool set.

**These tools are also included in the P300 tool set.

Item

number

Field Use

N7.3219 ** F10 Press in and press out pressure pad for N3.3173/P35.2002

N71.3235 * F5 Press in and press out arbor for N3.4509/P35.2036

N71.3237 * F3 Press in and press out arbor for N3.1159/P32.1037

N71.3238 * F3 Press in and press out pressure pad for N3.1159/P32.1037

N71.3239 * F7 Press in arbor for N3.2347/P32.1024

N71.3240 * F7 Press out arbor for N3.2347/P32.1024

N71.3241 * F7 Press in and press out pressure pad for N3.2347/P32.1024

N71.3242 * F8 Press in and press out arbor for N3.2346/P32.1238

N71.3243 * F6 Press in arbor for N3.1134, P32.1023/P32.1022

N71.3244 * F6, F9 Press out arbor for N3.1134, P32.1023/P32.1022; P35.0123/P32.1123;

P35.0124/P32.1023

N71.3245 * F6, F8 Pressure pad for N3.1134, P32.1023/P32.1022; N3.2346/P32.1238

N71.3246 * F1 Press in and press out arbor for N3.1157/P32.1044

N71.3247 * F1 Press in and press out pressure pad for N3.1157/P32.1044

N71.3248 * F4 Press in arbor for N3.3172/P32.1254

N71.3249 * F4 Press out pressure pad for N3.3172/P32.1254

N71.3250 * F2, F4 Press in and press out arbor for N3.3172/P35.2002; N3.3172/P32.1254

N71.3253 * F10 Press in and press out arbor for N3.3173/P35.2002

N71.3254 * F10, F9 Press out arbor for N3.3173/P35.2002; Press on arbor for P32.1123/

P35.0123 and P32.1023/P35.0124

N71.3273 F5 Press in and press out pressure pad for N3.4509/P35.2036

N71.3274 F12 Hook for exhaust ring P35.2005/P35.2002

N71.3275 F9 Press on pressure pad for P32.1123/P35.0123, P32.1023/P35.0124

N71.3276 F11 Pressure pad for P35.2021/P35.2023, N3.1174

N71.3277 F11 Thrust piece for P35.2021/P35.2023, N3.1174

N71.3280 F9 Press out pressure pad for P32.1123/P35.0123, P32.1023/P35.0124

ACCESSORY TOOLS

1-16

1.5.1 Use of accessory tools

Accessory tools should only be used with the suitable arbor press

N7.5108 in order to avoid a tilt of the pressed in parts.

Additional a retainer (N7.3215) is necessary.

Part Disassembly Assembly

N3.1157/

P32.1044

F1

N3.3172/

P35.2002

F2

N7.5108

N7.3215

N71.3246

N71.3247

N3.1157

P32.1044

N71.3250

N3.3172

P35.2002

ACCESSORY TOOLS

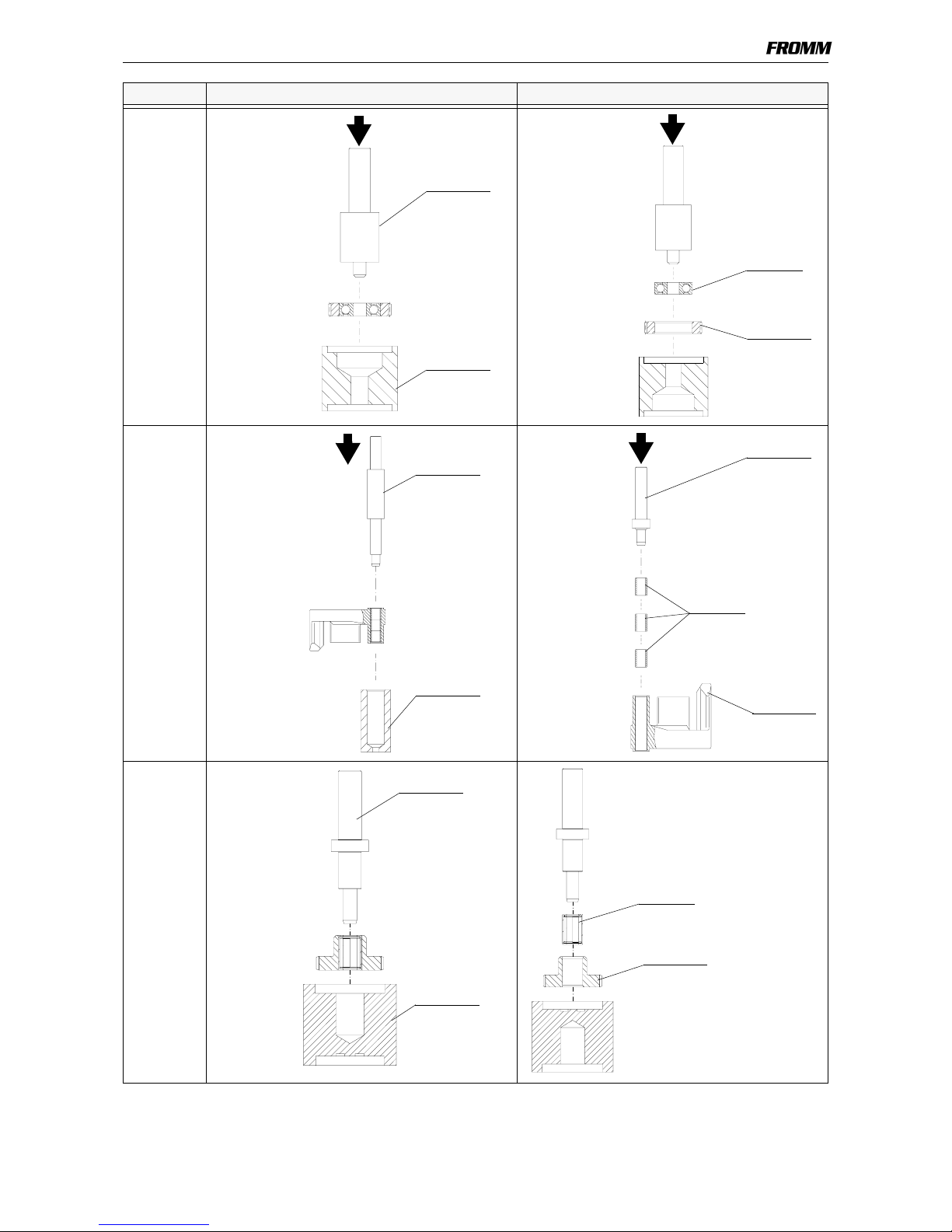

1-17

N3.1159/

P32.1037

F3

N3.3172/

P32.1254

F4

N3.4509/

P35.2036

F5

Part Disassembly Assembly

N71.3237

N71.3238

N3.1159

P32.1037

N71.3250

N71.3249

N71.3248

N3.3172

P32.1254

A

A

N71.3235

N71.3273

N3.4509*

P35.2036

*Assembling position

see „Assembly information“

Loading...

Loading...