OPERATION MANUAL / SPARE PARTS LIST

BATTERY - POWERED

PLASTIC STRAPPING TOOL

MODEL P329 M/HA

43.2533.01

CE Declaration of conformity

We declare that the machine P329

is in conformity with the following standard or

43253301.en/MAS/© 01.15

Original instructions

PAGE 1 OF 26 0118 I H -7184

standardised documents:

2006/42/EC,

2004/108/EC

Technical file at:

M.Rauch

FROMM System GmbH

Neulandstrasse 10

D-77855 Achern

06.03.2014

R.Fromm

Director

FROMM Holding AG

Hinterbergstrasse 26

CH - 6330 Cham

INDEX PAGE

1 GENERAL POWER TOOL SAFETY WARNINGS 3

2 SAFETY RULES FOR STRAPPING TOOLS 5

3 TECHNICAL DATA 6

4 ACCESSORIES 7

4.1 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Battery - chargers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.4 Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.5 Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.6 Turning button kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.7 Wearing plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 OPERATING ELEMENTS 9

6 OPERATION 10

6.1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2 Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3 Feeding the strap around the package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.4 Inserting the strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.5 Tensioning the strap,

Operation mode Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.6 Sealing the straps,

Operation mode Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.7 Tensioning and sealing the strap

Operation mode Semi-Automatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.8 Removing the tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.9 Seal - Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 CHART OF TYPES P329 M/HA 14

8 ELECTRIC SCHEMATIC ELS.1082 14

9 EXCHANGE OF WEARING PARTS 15

9.1 Exchange of tensioning wheel and grippers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.2 Exchange of cutter, welding stop gripper and welding gripper . . . . . . . . . . . . . . . . . . . . . . . . . 16

9.3 Adjustment of the coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10 CLEANING 17

11 SERVICE 17

12 TRANSPORT 18

13 DISPOSAL 18

14 WARRANTY CONDITIONS AND LIABILITY 18

15 APPROPRIATE USE 18

16 SPARE PARTS LIST 43.2533.01 23

PAGE 2 OF 26 0118 I H -7184

2

1 GENERAL POWER TOOL SAFETY WARNINGS

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated

(cordless) power tool.

1.1 Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to

lose control.

1.2 Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will

reduce the risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces the risk of electric shock.

1.3 Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating power tools may result in serious personal

injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment such as

dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will

reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before connecting to

power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your

finger on the switch or energising power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

PAGE 3 OF 26 0118 I H -7184

P329 M_HA mane.fm

3

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure

these are connected and properly used. Use of dust collection can reduce dust-related hazards.

1.4 Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The correct power

tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power tool before

making any adjustments, changing accessories, or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate the power tool. Power tools are dangerous in the

hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts

and any other condition that may affect the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the power tool

for operations different from those intended could result in a hazardous situation.

1.5 Battery tool use and care

a) Recharge only with the charger specified by the manufacturer. A charger that is suitable for one

type of battery pack may create a risk of fire when used with another battery pack.

b) Use power tools only with specifically designated battery packs. Use of any other battery packs

may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects, that can make a connection from one terminal

to another. Shorting the battery terminals together may cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or burns.

1.6 Service

a) Have your power tool serviced by a qualified repair person using only identical replacement

parts. This will ensure that the safety of the power tool is maintained.

PAGE 4 OF 26 0118 I H -7184

4

P329 M_HA mane.fm

2 SAFETY RULES FOR STRAPPING TOOLS

2.1 Joints

You are fully responsible to review the joints made by your tool. Become familiar with the seal

control and seal adjustment described in this operation manual.

Misformed joints may not secure the load and could cause serious injury. Never handle or ship any load

with improperly formed joints.

2.2 Dispensing strap

Only dispense strap from a dispenser specifically designed for strap.

Tuck strap end back into dispenser when not in use.

2.3 Strap warnings

Never use strap as a means of pulling or lifting loads. Failure to follow these warnings can result in

severe personal injury.

2.4 Strap breakage hazard

Improper operation of the tool, excessive tensioning, using strap not recommended for this tool or sharp

corners on the load can result in a sudden loss of strap tension or in strap breakage during tensioning,

which could result in the following:

A sudden loss of balance causing you to fall.

Both tool and strap flying violently towards your face.

Note as follows:

If the load corners are sharp, use edge protectors.

Place the strap correctly around a properly positioned load.

Positioning yourself in-line with the strap, during tensioning and sealing, can result in severe

personal injury from flying strap or tool. When tensioning or sealing, position yourself to one

side of the strap and keep all bystanders away.

Use the correct strap quality, strap width, strap gauge and strap tensile strength

recommended in this manual for your tool. Using strap not recommended for this tool can result in

strap breakage during tensioning.

2.5 Cutting tensioned strap

When cutting strapping, use the proper strapping cutter and keep other personnel and yourself

at a safe distance from the strap. Always stand to side of the strap, away from the direction the

loosened strap end will fly. Use only cutters designed for strap and never hammers, pliers, hacksaws,

axes, etc.

2.6 Environment protection

Do not dispose of used batteries in the household refuse, water or by burning them.

For disposal of the batteries the local laws and prescriptions must be observed.

PAGE 5 OF 26 0118 I H -7184

P329 M_HA mane.fm

5

3 TECHNICAL DATA

Description of the tool

The tool model P329 has been designed to strap packages with plastic strapping. The plastic strapping is fed

around the package manually or in combination with a strap feeder. The straps are inserted in the tool,

tensioned, sealed by friction welding and separated from the strap coil.

Tool size with battery

Length: 351 mm / 13.8"

Width: 134 mm / 5.3"

Height: 143 mm / 5.6"

Weight

with battery: 4.2 kg / 9.3 lbs

Noise information

The A-weighted equivalent continuous sound level at the work place of the machine operator is

typical 79 dB (A).

This value was determined according to EN ISO 11204.

Deviation K: 3 dB

Vibration information

The weighted effective value of the acceleration typically amounts to less than 2.5 m/s2.

This value was determined according to DIN EN 60745-1 (12.2003).

Deviation K: 0.5 m/s

2

Strap material

Strap qualities: PET (Polyester) and PP (Polypropylene) plain or embossed.

The plastic strap must be according to DIN EN 13394.

Use only plastic straps recommended by your sales shop (name and address

on the rear of the operation manual).

Strap dimensions: 16.0 - 19.0 mm / 5/8 - 3/4" x 0.65 - 1.35 mm / .026 - .053" (see chart of types).

Use only plastic straps with the correct strap dimensions for your tool.

Operation mode

Manual or Semi-Automatic mode

Strap tension

Tensioning force*: Adjustable from 500 - max. 4000 N / 112 - max. 900 lbs.

Tensioning speed*: approx. 49 - 79 mm/s / 1.9 - 3.1 inch/sec.

Seal

Type of seal: Friction weld sealing

Strength of seal*: approx. 75% of the tensile strength of the plastic strap.

* The value depends on the strap quality.

Working temperature

The ambient temperature should be between -10° and 45° C (14° and 113°F).

The best performance is achieved between 15° and 20°C (59° and 68°F).

PAGE 6 OF 26 0118 I H -7184

6

P329 M_HA mane.fm

4 ACCESSORIES

Use only parts and accessories mentioned in the operating instruction.

Using other parts or accessories can cause injuries to you and other persons.

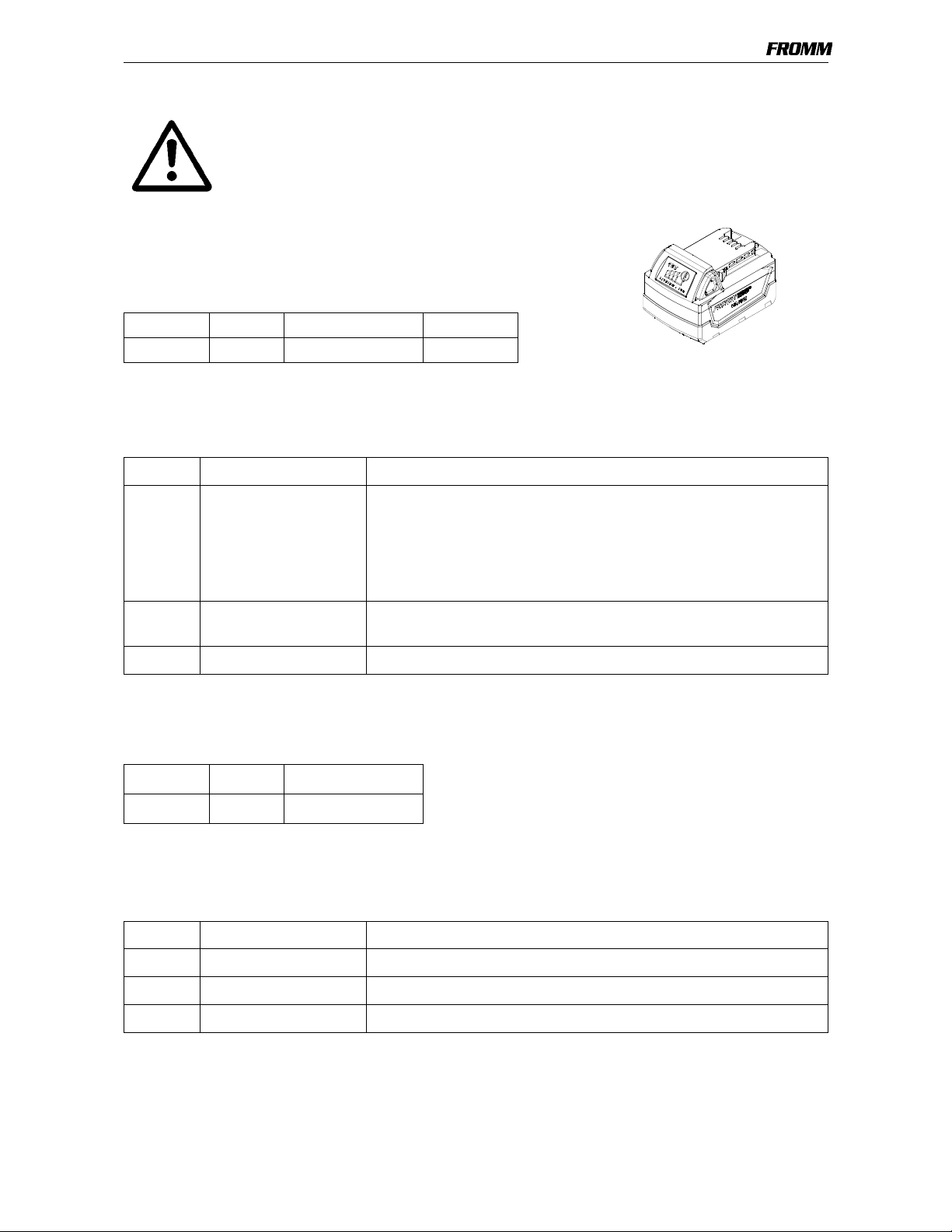

4.1 Battery

The battery is not automatically supplied with the tool. The battery has to

be ordered separately under the following item number.

Item-No. Battery Voltage Capacity

N5.4349 Li-Ion 18 VDC 4.0 Ah

4.2 Battery - chargers

The charger must be ordered separately according to below shown table.

Item-No. Voltage / frequency Admitted for country

N5.4443 220 - 240V / 50 - 60Hz A, B, BG, BIH, BOL, BR, BY, CH, CL, CZ, D, DK, DZ, E, EAS, EST,

ET, F, FIN, GE, GR, H, HK, HR, I, IL, IND, IR, IRQ, IS, JOR, KSA,

KWT, L, LAR, LT, LV, MA, MC, MK, MOC, N, NL, P, PK, PE, PL, PRC,

PY, RA, RCH, RI, RL, RO, ROK, ROU, RP, RUS, S, SK, SLO, SYR,

THA, TN, TR, UA, UAE, YU, YV, (BRN), (BRU), (CY), (EAK), (EAT),

(GB), (IRL), (M), (MAL), (OM), (SGP), (Y), (Z), (ZA), (ZW)

N5.4447 120V / 50 - 60Hz BR, C, CDN, CO, CR, DOM, EC, GCA, J, JA, KSA, LB, MEX, NIC,

PA, Puerto Rico, RC, RP, USA, YV

N5.4445 220 - 240V / 50 - 60Hz AUS, NZ

(..) = an adaptor N52.2102 is required.

Charging time

Item-No. Battery Charging time

N5.4349 Li-Ion approx. 80 min.

4.3 Power supply

With the optional power supply the strapping tool can be run directly at the mains.

The power supply must be ordered according to below table..

Item-No. Voltage / frequency Admitted for country

N5.1471 220 - 240V / 50 - 60Hz See 4.2 Battery - chargers

N5.1472 120V / 50 - 60Hz

N5.1473 220 - 240V / 50 - 60Hz

4.4 Fan

In order to avoid overheating of the motor we recommend at environmental temperatures above 40°C / 104°F

using the optional fan P32.0228.

PAGE 7 OF 26 0118 I H -7184

P329 M_HA mane.fm

7

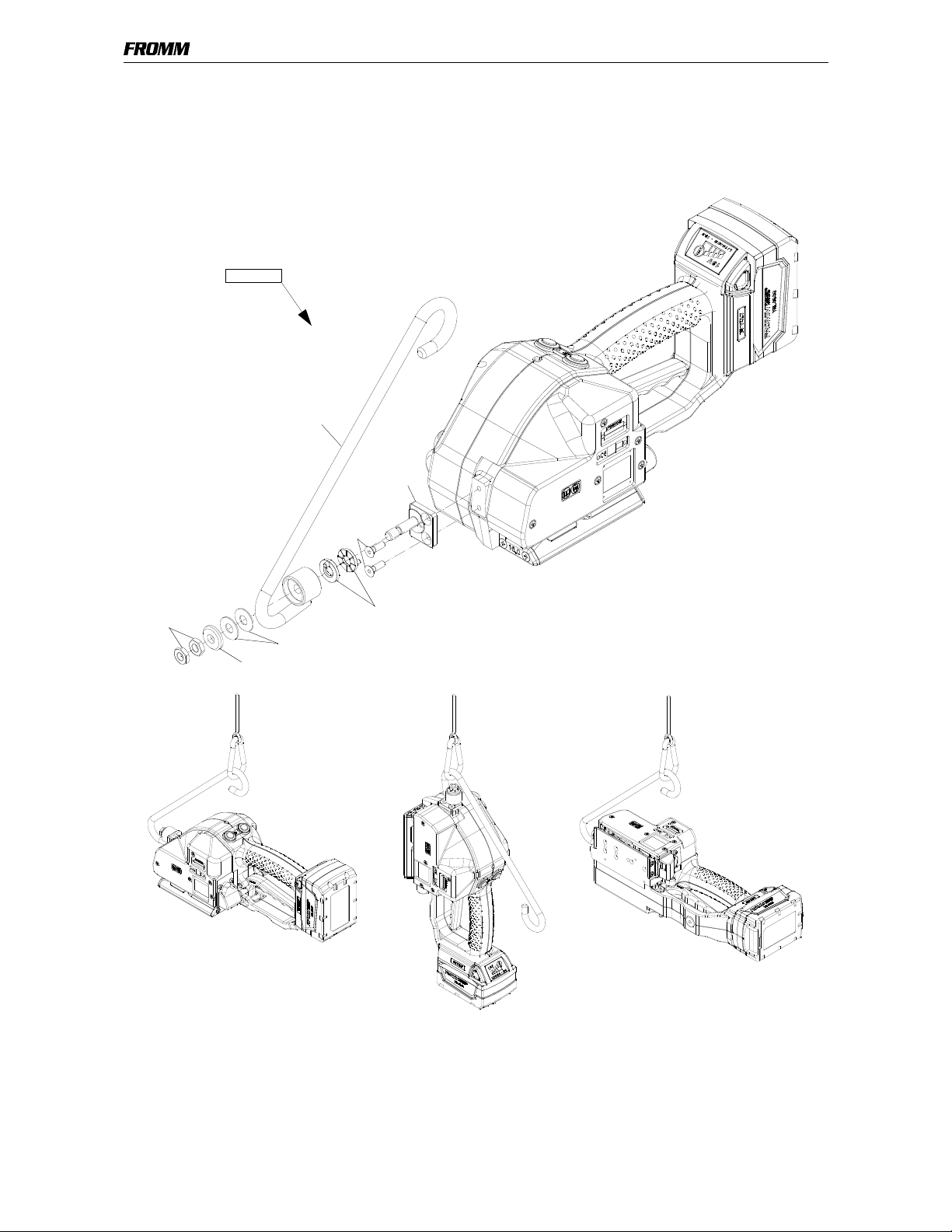

4.5 Suspension

N1.5105

When working stationary the P329 can be suspended at a spring loaded balancer by using a suspension

bracket. With the swivel mounted suspension bracket the package can be strapped in various working

positions.

The complete suspension bracket can be ordered under item number P32.0223.

P32.0223

P32.8302

P32.8301

N1.2163

N2.5623

P35.2073

P35.2069

Mobilux EP2

4.6 Turning button kit

For a remaining adjustment of tension force and welding time.

After exchanging of the turning buttons the adjustment can only be changed with the allen key (2mm) that

comes with the kit. The kit can be ordered under the item number P32.2061.

PAGE 8 OF 26 0118 I H -7184

8

P329 M_HA mane.fm

4.7 Wearing plate

As an option, the tool can be equipped with a wearing

plate to protect the base from excessive wear on

abrasive package surfaces.

The complete wearing plate can be ordered together

with the fastening screws under item number

P32.0226.

If the complete bottom side of the tool has to be

protected, the plate P32.0227 must be used.

5 OPERATING ELEMENTS

Tension button

Sealing button

Unlatching

LED

push button

P32.0226

P32.0227

LED - Indication at the tool

Green During tensioning the LED lights green.

Blue Welding is initiated.

(only in semi-automatic mode)

Green During welding the LED lights green.

P32.8305

N1.2163

P32.8306

N1.2163

Yellow Cooling time is running, the tool must not

be removed from the strap.

Blue

blinking

Green +

Acoustic

signal

Red Charge the battery.

Motor overheated,

Motor cool down time running.

If during this time a switch is operated, an

acoustic signal happens.

Cooling time is finished; the tool can be

removed from the strap.

Handle lever

Red

blinking

Without

indication

PAGE 9 OF 26 0118 I H -7184

P329 M_HA mane.fm

Malfunction: e.g. lowering motor blocked.

Remove battery

Clear malfunction

Insert battery

Power saving mode

9

6 OPERATION

6.1 Installation

Do not expose power tools to rain or wet conditions!

The batteries are supplied partially charged.

Before the first use, the battery must be completely charged.

See separate operating instruction of the battery charger.

Never charge a damaged battery. Replace by a new one immediately.

Do not open batteries and store them only in dry and frost-proof rooms.

Do not store the battery pack together with metal objects (short circuit risk).

The maximum ambient temperature is 50°C.

Keep dry at all times.

Inserting the battery

• Insert the battery from top to bottom into the tool

until both unlatching push buttons are engaged.

When inserting the battery the LED - indication

shortly lights green.

Removing the empty battery

If the red LED starts lighting while a tensioning or

welding procedure, the capacity of the battery is

exhausted. All electric functions of the tool are

blocked.

The battery must be recharged.

• Push the unlatching push buttons at both sides of the battery.

• Pull the battery out of the tool.

Displaying of the status of the battery charge

By pressing a button the status of the battery can be

shown in four steps.

If four lamps are lighting the battery is full.

If only one lamp is lighting shortly the battery has to be

charged.

Push here

PAGE 10 OF 26 0118 I H -7184

10

P329 M_HA mane.fm

6.2 Adjustments

6.2.1 Preselecting of strap tension and tensioning speed

Do not adjust the tensioning force too high.

If the tensioning force is higher than the tensioning strength of the strap,

the strap will tear while the tensioning.

Tensioning force and tensioning speed can be preselected

with the upper adjusting knob.

Turning clockwise increases;

turning counter clockwise decreases the tensioning force

and the tensioning speed resp..

The tensioning force on the minimum setting is 500 N

(112 lbs) and it is increased on the maximum setting to

4000 N (900 lbs).

The tensioning speed on the minimum setting is 49 mm/s

(1.9 inch/sec), it is increasing linear up to 79 mm/s

(3.1 inch/sec) on the maximum setting.

6.2.2 Adjusting the welding time

Depending on the size and quality of the strap, different

welding times are required.

The welding time can be adjusted at the lower adjusting

knob.

Turning clockwise increases,

turning counter clockwise decreases the welding time.

Adjusting knob tensioning force /

tensioning speed

Adjusting knob

welding time

The adjustment knobs can be

easily turned with a coin.

6.2.3 Choose operation mode

There are 2 operation modes possible.

1. Manual

In this operation mode is the tensioning as well as the welding of the strap started by the operator.

2. Semi-Automatic

In this operation mode the welding of the strap is automatically started as soon as the preselected tension has

been reached.

The choice of the operation mode can be made with the adjustment screw for operation mode.

Operation mode Manual Operation mode Semi-Automatic

Turn adjustment screw with a screw driver in the desired position.

Confirm the choice of the operation mode by pressing the tension button shortly.

PAGE 11 OF 26 0118 I H -7184

P329 M_HA mane.fm

11

6.3 Feeding the strap around the

package

• The strapping is fed around the package as

illustrated.

Warning! The plastic strap which will be welded

must be free from oil, grease and other dirt.

Dirty plastic straps can't be welded correct!

6.4 Inserting the strap

• Pull up the handle lever firmly with your right hand.

• Insert the two straps well aligned on each other

into the strap guide using your left hand.

The lower strap end must slightly protrude the end

of the base plate.

• Release the handle lever.

6.5 Tensioning the strap,

Operation mode Manual

• Press down the tension button and then release it

again after the desired strap tension has been

reached.

The tensioning operation can be interrupted and

restarted at any time.

During tensioning the LED lights green.

After automatic cut off of the tensioning force it

can be tensioned again not before 8 seconds.

6.6 Sealing the straps,

Operation mode Manual

• Press and release immediately the sealing button.

The plastic strap is welded and cut off from the rest of

the strap.

During the welding the LED lights green.

After elapsing of the adjusted welding time (see 6.2.2)

the cooling time begins (LED lights yellow).

During that time the tool must not be removed from

the strap.

PAGE 12 O F 26 0118 I H -718 4

12

P329 M_HA mane.fm

6.7 Tensioning and sealing the strap

Operation mode Semi-Automatic

• Push tension button until the adjusted tension

force is reached.

During tensioning the LED lights green.

The tensioning operation can be interrupted and

restarted at any time.

After reaching the adjusted strap tension the sealing

cycle is initiated automatically (LED lights blue).

Welding gripper is lowered,

the welding starts (LED lights green).

• Release the tension button after the sealing process has been started.

The plastic strap is welded and cut off from the rest of the strap.

After elapsing of the adjusted welding time (see 6.2.2) the cooling time begins (LED lights yellow).

The tool must not be removed from the strap as long as the cooling time is not

finished. Disregard of this regulation is causing insufficient seal efficiencies, which

can cause severe injuries.

6.8 Removing the tool

After the cooling time is elapsed an acoustic signal

happens and the LED lights green again. The sealing

process is finished.

• Pull up the handle lever,

• pull the tool right and off the strapping.

6.9 Seal - Control

A regular control of the seal is necessary. The seal can be examined visually.

Make a seal, peel it apart and examine it as follows:

Correct seal

The seal must be completely welded over the whole width of the strap

on a length of ca. 19 mm. Minor quantities of fused plastic may

overflow on sides.

Welding time too short

The plastic strap is not welded over the whole width of the strap. The

seal efficiency is insufficient.

Warning! Straps with insufficient seal strength must be removed from

the package! Adjust the welding time (see 6.2.2).

Welding time too long

If the welding time is too long the straps are overheated. The fused

plastic overflows on both sides of the straps. The seal efficiency is

affected.

Warning! Straps with insufficient seal strength must be removed from

the package! Adjust the welding time (see 6.2.2).

PAGE 13 O F 26 0118 I H -718 4

P329 M_HA mane.fm

13

7 CHART OF TYPES P329 M/HA

Item No. Model Strap width Strap thickness

43.2522 P329/16/0.65-1.05 16 mm / 5/8" 0.65-1.05 mm / .026 - .041"

43.2532 P329/19/0.65-1.05 19 mm / 3/4" 0.65-1.05 mm / .026 - .041"

43.2533 P329/19/1.06-1.35 19 mm / 3/4" 1.06-1.35 mm / .042 - .053"

8 ELECTRIC SCHEMATIC ELS.1082

18VDC

DC

DP

+

2

yellow

violett

brown

Hall3

Hall2

Hall1

GND

+5V

(+)

(-)

blackblack

black

red

red

5

4

3

2

1

2

1black

-

W

M2

V

U

red

M1

HA

1

3

2

1

UB

M3

1

optional Fan

2

(-)

1

(+)

2

blue

red

M

Manual / 1/2 Auto

PAGE 14 OF 26 0118 I H -718 4

14

P329 M_HA mane.fm

9 EXCHANGE OF WEARING PARTS

Remove always the battery from the tool before starting maintenance works.

9.1 Exchange of tensioning wheel and grippers

Disassembling

• Unscrew cover P32.0221 and remove it;

• Unscrew end cover P32.0222 and remove it;

• Raise tension wheel P35.3203 by lifting the handle lever P32.8142;

• Remove the tensioning wheel together with the bearing N3.1172 from the tool;

• Unscrew the holder P32.8108 and remove it from the body;

• Remove the grippers (P32.8109, P32.8110, P32.8111) from the body.

N1.6504

N1.1305

P32.8111

P32.8110

P32.8109

Molykote BR2 plus

Loctite 222

Assembling in opposite order.

P32.8108

P32.8142

N1.6504

P35.3203

N3.1172

P32.0222

P32.0221

N1.6504

N1.1168

N1.6504

N1.1973

N1.1928

N1.6504

N1.1934

N1.1943

Assembly advise

• Lubricate the internal toothing of the tensioning wheel with Molykote BR2 plus.

• Observe the position of the tensioning wheel. The direction of rotation of the tensioning wheel is marked at

the front of the tensioning wheel (see drawing).

• Observe the position of the grippers (see drawing).

• Safe the screws N1.1305 with Loctite 222.

PAGE 15 OF 26 0118 I H -7184

P329 M_HA mane.fm

15

9.2 Exchange of cutter, welding stop gripper and welding gripper

Disassembling

• Unscrew cover P32.0221 and remove it;

• Unscrew end cover P32.0222 and remove it;

• Raise tensioning wheel P35.3203 by lifting the handle lever P32.8142;

• Pull off tensioning wheel together with bearing N3.1172 from the body.

• Remove cover P32.8195;

• Don’t loosen screw N1.1553 at the coupler P35.0146.

• Disassemble the security ring N2.1121 from the coupler, remove the coupler;

• Pull out the centering sleeve P32.1710 from the guide case P35.3215, disassemble the guide case;

• Pull out the pressure spring N2.5237 with a screw driver from the cutter P35.3214;

• Remove the cutter from the driving pin P32.1032;

• Disassemble strap guide plate P32.8118;

• Disassemble the screws N1.1305, lift slightly the welding stop gripper P32.8107 and the steel insert P32.8106

and remove them from the tool;

• Push the steel insert without welding stop gripper under the welding gripper P32.1511 until it touches the parallel

pin N2.2110;

• Turn welding gripper down, in case the welding gripper does not sit on the steel insert, put a piece of plastic

strap underneath the steel insert;

• Disassemble the safety ring N2.1121 from the bolt P32.1028, remove the bolt from the welding gripper;

• Turn welding gripper up;

• Remove the thrust piece P32.1029 from the tool;

• Pull out the steel insert with care to right under the welding gripper;

• Lift the rocker P32.1024 behind the welding gripper with a screw driver, remove the welding gripper together with

the ball cage P32.1027 and the balls N3.1702 from the tool.

P32.0221

P32.0222

P35.3203

P32.1029

P32.1027

6 x N3.1702

N2.1121

P32.1511

P32.8107

P32.8106

P32.8118

N1.6504

N1.1911

P32.1028

N1.6504

N1.1305

Mobilux EP2

Molykote BR2 plus

Loctite 222

Klüber Isoflex Alltime SL2

Klüber Isoflex NBU 15

P32.1032

P35.3214

N2.5237

P35.3215

P35.0146

N2.1121

P32.1710

N1.1553

P32.8195

N1.1910

N1.6504

Insert part P32.8198 only for strap thickness 0.65-1.05mm

Assembling in opposite order.

PAGE 16 O F 26 0118 I H -718 4

16

P329 M_HA mane.fm

Assembly advise

Coupler

• During assembling move the strap guide plate P32.8118 downwards against the holding gripper.

• Pay attention to the fitting position of the cutter (see drawing).

• Safe the screws N1.1305 with Loctite 222.

• Lubricate the rocker and the bolt P32.1028 in the area of the welding gripper with Klüber Isoflex NBU 15.

• Lubricate the balls, ball cage and the running surface of the balls on the welding gripper with Klüber Isoflex

Alltime SL2.

• Lubricate the cutter and the driver with Mobilux EP2.

9.3 Adjustment of the coupler

The coupler is adjusted in our works.

In case of replacing the seesaw lever, the coupler or the lever body, the coupler has to be readjusted.

Procedure as follows:

The battery is removed from the tool.

The coupler is fitted into the tool.

• Loosen screw N1.1553.

• Displace thrust piece, so that it touches the two

seesaw levers without moving them.

• Re-tighten screw N1.1553.

Control:

The thrust piece must touch the seesaw levers (X1).

Both guide pins must sit on the welding stop

gripper (X2).

X2

Thrust piece

N1.1553

X1

Seesaw lever

Guide pin

Welding stop

gripper

10 CLEANING

Clean strap gripping parts from strap abrasion

regularly using compressed air.

Thus also the cover can be removed and with a

suitable air gun air been blown on the welding

elements.

Do not use any mechanical tool for cleaning.

When cleaning the surface of the tool do not use water

or aggressive solvents!

11 SERVICE

Servicing and repair work must only be carried out by authorized service centres.

If the tool breaks down or does no longer operate do not disassemble it. Send it fully assembled to the local

service centre (see name and address on the rear page of this manual). Use original packing.

In order to prevent damages to the motor shaft the two needle free wheeling N3.4509/N3.4520 have to

be replaced after maximum 80 000 strapping cycles.

The battery powered plastic strapping tool P329 is a high performance tool. We strongly recommend you to

have it serviced by an authorized service shop after 12 months at the latest if used one shift per day. If used

two or more shifts per day the tool has to be serviced after a shorter period of time.

PAGE 17 OF 26 0118 I H -7184

P329 M_HA mane.fm

17

12 TRANSPORT

Lithium-ion batteries are subject to the Dangerous Goods Legislation requirements. The user can transport

the batteries by road without further requirements.

When being transported by third parties (e.g.: air transport or forwarding agency), special requirements on

packaging and labelling must be observed.

For preparation of the item being shipped, consulting an expert for hazardous material is required.

Dispatch batteries only when the housing is undamaged.

Tape or mask off open contacts and pack up the battery in such a manner that it cannot move around in the

packaging.

Please also observe possibly more detailed national regulations.

13 DISPOSAL

The machine, rechargeable batteries, accessories and packaging

should be sorted for environmental- friendly recycling.

Do not dispose of power tools and batteries/rechargeable batteries into

household waste!

Only for EC countries:

According to the European Guideline 2002/96/EC, power tools that are

no longer usable, and according to the European Guideline 2006/66/EC,

defective or used battery packs/batteries, must be collected separately

and disposed of in an environmentally correct manner.

14 WARRANTY CONDITIONS AND LIABILITY

FROMM Holding AG warrants all its strapping tools and machine heads during a period of 24 months from the

date of installation at the end-user's sight by the distributor, however, not later than 30 months from the date of

shipment to the distributor of FROMM Holding AG.

The warranty includes all deficiencies clearly resulting from poor manufacturing or faulty materials. Damage

claims as a result of production shutdowns and claims for damage to persons and to property resulting from

warranty deficiencies cannot be asserted by the customer.

The warranty excludes:

• wearing parts (tensioning wheels, cutters, punches, dies, notching knifes, grippers, batteries and

motors),

• deficiencies resulting from improper installing, incorrect handling and maintaining the tool,

• deficiencies resulting from using the tool without or with defective security- and safety devices,

• disregard of directions in the operation manual,

• arbitrary modifications of the tool,

• deficient control of wearing parts,

• deficient repair works of the tool,

• use of consumable products not recommended by FROMM Holding AG.

We reserve the right to modify the product at any time in order to improve its quality.

15 APPROPRIATE USE

The tool model P329 has been designed to strap packages with plastic strapping exclusively.

For the use in hazardous areas the tool is not suitable.

The warranty / liability excludes:

• non appropriate use of the tool,

• disregard of directions in the operation manual,

• disregard of control- and maintenance instructions.

PAGE 18 O F 26 0118 I H -718 4

18

P329 M_HA mane.fm

6

P32.8169

1 Mobil ux EP2

2 Molyko te BR 2 plus

3 Loctite 603

4 Loctite 222

5 Klüber Isoflex Alltime SL2

6 Klüber Isoflex NBU 15

8 Orientation

9 NyoGel 760G

N1.1928

N44.9148

N1.1973

N2.4902

N4.9159

N2.4902

N1.1943

N1.1934

N1.1196

P32.0219

5

P32.8159

P32.0221

P32.8118

P32.8158

N1.6504

N1.1911

234

N3.1185

N41.9127

N1.6504

2P35.3201

2N3.2107

N3.1172

3N21.2145

P32.0207

2P35.3203

N3.1172

1P32.8178

P32.8108

N2.2119

N1.6504

N3.3150

P32.0222

P32.8111

P32.8110

P32.8109

4N1.1305

N2.2147

N2.2124

N1.6504

C

N1.2222

7 1 Nm

D

P32.0218

A1

B

PAGE 19 O F 26 0118 I H -718 4

43253301.z

19

8 9 10 11 12

P32.1251

1 P32.8121

N1.1553

N1.6504

P35.3223

N2.1121

P35.0146

P32.1710

P32.0219

1 Mobilux EP2

N2.5178

2 Molyko te BR 2 plus

3 Loctite 603

4 Loctite 222

5 Klüber Isoflex Alltime SL2

6 Klüber Isoflex NBU 15

7 1 Nm

8 Orientation

9 NyoGel 760G

P35.3215

P35.3220

N1.1910

N1.6504

N2.5237

1 P35.3214

5 P32.1029

P32.8107

N2.2193

5 N3.1702(6x)

5 P32.1027

P35.3219

P35.3221

N2.1121

1P32.1035

P32.1032

P35.3218

6P32.1028

5P32.1511

1P32.1035

N2.1121

1P32.8116

N31.3115

N2.2443

1 N21.5138

P32.0203

A7

1 P32.8117

B

N2.1118

P32.8122

N1.6331

P32.8195

N2.2187

P32.8106

4 N1.1305

N1.6504

1 N2.5157

P32.8157

P32.0218

N2.3364

C

N2.2110

N21.2140

P32.8120

D

PAGE 20 OF 26 0118 I H -7184

20

43253301.z

A 13

14 15 16 17 18

4 N1.2188

P32.0218

P33.0204

1 Mobilux EP2

2 Molyko te BR 2 plus

3 Loctite 603

4 Loctite 222

5 Klüber Isoflex Alltime SL2

6 Klüber Isoflex NBU 15

7 1 Nm

8 Orientation

N2.2190

9 NyoGel 760G

3 P32.8137

N3.3172

6P32.1024

N3.2347

N3.2347

P32.0144

N21.2144

P32.2012

N3.1134

N2.2126

1 N21.5139

N3.1178

2 N1.6331

3 N3.1159

2 P32.2016

2 N1.6331

P32.0207

P32.8131

2N2.5296

N2.2180

P32.0209

2P32.8130

2N2.2142

P32.0206

2N1.6386

8N3.4509

2P32.8134

2P32.8129

N31.1169

N3.1185

P32.8132

P32.1022

N3.1134

2 P 32.8115

P32.0202

P31.1124

P32.0204

2 P32.8126

N2.1610

N31.1120

2 P32.8127

N1.2189

3 N2.2145

1 P32.8125

1 N21.5219

P32.0208

B

P32.0205

C

PAGE 21 OF 26 0118 I H -7184

43253301.z

2 N3.2105

2 P35.3104

2 P32.8128

P32.0219

D

21

A 19

20 21 22 23 24

(N43.91 92)

9 N51.2194

2P32.8153

P32.0219

7 N1.1966

2N1.6305

P32.81 36

N3.2362

N2.1118

P32.0214

1 Mobilux EP2

1N61.6220

2 Molyko te BR 2 plus

3 Loctite 603

4 Loctite 222

5 Klüber Isoflex Alltime SL2

6 Klüber Isoflex NBU 15

7 1 Nm

8 Orientation

9 NyoGel 760G

2P32.8139

P32.0211

2 P32.8138

8 N3.4520

N31.1151

P32.0213

N31.1163

P32.02 12

(N44.91 04)

N1.7211

N4.3236

2P32.0159

P32.0229

N31.1118

P33.21 55

N31.1120

8N3.4509

1 N6.6224

P32.819 9

(P32.2 009)

(P30.12 10)

(P33.2 115)

P32.81 03

(N43.91 92)

P32.8140

P32.8150

(N51.54 77)

N1.7222

P33.21 45

P32.8141

P32.8142

N51.1127

1N6.6232

B

N1.7207

N43.9164

P32.81 05

N21.5124

N1.7211

C

N5.2702

N1.6504

N2.1606

N1.7211

P32.1215

N1.6504

7N1.1972

7 N1.1927

7 N1.1934

(N44.91 60)

D

PAGE 22 OF 26 0118 I H -7184

22

43253301.z

16 SPARE PARTS LIST 43.2533.01

43.2533.01 P329/19/1.06-1.35 P329.0001.01 13.05.14

Item-No. in group Pcs. Description Dimension Field

N1.1196 3 SCREW M4 X 16 D6

N1.1305 6 SCREW M4 X 7.8 C2+

N1.1553 P35.0146 1 HEXAGON SCREW M4 X 8 B12

N1.1910 2 FLAT HEAD SCREW M4 X 12 B10

N1.1911 2 FLAT HEAD SCREW M4 X 8 A3

N1.1927 P32.0219 1 FLAT HEAD SCREW M4 X 60 D19

N1.1928 1 FLAT HEAD SCREW M4 X 16 B6

N1.1934 1 FLAT HEAD SCREW M4 X 50 B6

N1.1934 P32.0219 2 FLAT HEAD SCREW M4 X 50 D19

N1.1943 2 FLAT HEAD SCREW M4 X 40 B6

N1.1966 P32.0219 1 SCREW M4 X 70 C19

N1.1972 P32.0219 1 SCREW M4 X 80 D19

N1.1973 1 FLAT HEAD SCREW M4 X 10 A6

N1.2188 P32.0205 3 COUNTERSUNK SCREW M4 X 16 D13

N1.2189 P32.0208 3 COUNTERSUNK SCREW M4 X 20 D14

N1.2222 2 COUNTERSUNK SCREW M4 X 10 C1

N1.6305 P32.0219 1 SPACER WASHER 6 X 18 X 0.5 B24

N1.6331 P32.0219 3 SPACER WASHER 6 X 12 X 0.5 C18+

N1.6386 P32.0219 1 SPACER WASHER 9 X 15 X 0.50 D17

N1.6504 18 SAFETY WASHER M4 B4+

N1.6504 P32.0219 5 SAFETY WASHER M4 D20+

N1.6504 P35.0146 1 SAFETY WASHER M4 B12

N1.7207 P32.0219 1 PT-SCREW 3 X 40 C20

N1.7211 P32.0219 8 PT-SCREW 3 X 20 C19+

N1.7222 P32.0219 1 PT-SCREW 2.2 X 5 B21

N2.1118 P32.0219 2 SECURITY RING 6 B9+

N2.1121 1 SECURITY RING 5 B12

N2.1121 P32.0219 4 SECURITY RING 5 C11+

N2.1606 P32.0219 1 SPRING RING SW6 C19

N2.1610 P32.0208 1 SPRING RING SB44 C14

N2.2110 P32.0218 1 PARALLEL PIN 4 m6 X 10 D8

N2.2119 P32.0222 1 PARALLEL PIN 4 m6 X 18 D4

N2.2124 1 PARALLEL PIN 4 m6 X 40 C2

N2.2126 P32.0207 1 PARALLEL PIN 5 m6 X 26 B15

N2.2142 P32.0206 1 PARALLEL PIN 4 m6 X 28 C16

N2.2145 P32.0205 3 PARALLEL PIN 4 h6 X 18 C14

N2.2147 P32.0218 2 PARALLEL PIN 3 m6 X 10 C2

N2.2180 P32.0208 1 PARALLEL PIN 4 m6 X 16 C16

N2.2187 P32.0218 1 PARALLEL PIN 3 m6 X 6 C9

N2.2190 P32.0219 1 PARALLEL PIN 6 h6 X 18 C18

N2.2193 1 PARALLEL PIN 3 m6 X 32 C12

N2.2443 P32.0203 1 DOWEL PIN 4 X 15 A8

N2.3364 P32.0219 1 FEATHER KEY 2 X 2 X 6 C7

N2.4902 2 HAMMER HEAD BOLT 1.85 X 4.76 A6

N2.4902 P32.0221 2 HAMMER HEAD BOLT 1.85 X 4.76 A6

N2.5157 P32.0219 2 PRESSURE SPRING 0.6 X 4.8 X 20/15.5 B8

N2.5178 2 PRESSURE SPRING 0.32X2.82X20.5/20.5 C12

N2.5237 1 PRESSURE SPRING 0.8 X 4.8 X 25/18.5 C11

N2.5296 P32.0208 1 PRESSURE SPRING 0.5 X 4 X 24/16.5 C16

N21.2140 P32.0219 1 PARALLEL PIN 2 m6 X 16 D7

N21.2144 P32.0219 1 PARALLEL PIN 3 h6 X 30 B16

PAGE 23 OF 26 0118 I H -7184

[ ] = Group * = Wearing parts

43253301.een.fm

23

43.2533.01 P329/19/1.06-1.35 P329.0001.01 13.05.14

Item-No. in group Pcs. Description Dimension Field

N21.2145 P32.0207 3 PARALLEL PIN 5 h6 X 37.3 B3

N21.5124 P32.0219 1 PRESSURE SPRING 0.9 X 10 X 15/5.5 B19

N21.5138 P32.0203 1 PRESSURE SPRING 2.5 X 14.2 X 33.5/7.5 A8

N21.5139 P32.0219 1 PRESSURE SPRING 1.25 X 9.8 X 45/14.5 B15

N21.5219 P32.0219 1 PRESSURE SPRING 0.43 X 3.6 X 32.9/27.5 B13

N3.1134 P32.0202 1 BALL BEARING 7 X 22 X7 A15

N3.1134 P32.0219 1 BALL BEARING 7 X 22 X7 B16

N3.1159 P33.0204 1 BALL BEARING 6 X 19 X 6 B17

N3.1172 2 BALL BEARING 30 X 42 X 7 B3+

N3.1178 P32.0204 1 BALL BEARING 35 X 44 X 5 B15

N3.1185 1 BALL BEARING 5 X 16 X 5 C5

N3.1185 P32.0208 1 BALL BEARING 5 X 16 X 5 D16

N3.1702 P32.0219 6 BALL 4 MM C10

N3.2105 P32.0205 3 NEEDLE CAGE K 4 X 7 X 7 TN C14

N3.2107 3 NEEDLE CAGE K 5 X 9 X 13 TN B4

N3.2347 P32.0144 2 NEEDLE BUSH 10 X 14 X 12 A15+

N3.2362 P32.0214 1 NEEDLE BUSH 6 X 10 X 8 B24

N3.3150 P32.0222 1 SLIDE-BEARING 8 X 10 X 12 D5

N3.3172 P32.0207 1 SLIDE-BEARING 8 X 10 X 10 B17

N3.4509 P32.0209 1 NEEDLE FREE WHEELING 6 X 10 X 15 D17

N3.4509 P32.0212 1 NEEDLE FREE WHEELING 6 X 10 X 15 D21

N3.4520 P32.0211 1 FREE-WHEELING 6 X 10 X 12 D22

N31.1118 P32.0219 2 BALL BEARING 10 X 19 X 5 B22

N31.1120 P32.0205 1 BALL BEARING 4 X 11 X 4 C14

N31.1120 P32.0219 1 BALL BEARING 4 X 11 X 4 C22

N31.1151 P32.0219 1 BALL BEARING 17 X 30 X 7 D22

N31.1163 P32.0212 1 BALL BEARING 15 X 24 X 5 D21

N31.1169 P32.0205 1 BALL BEARING 40 X 50 X 6 D16

N31.3115 P32.0218 1 SLIDE-BEARING 6 X 8 X 6 B9

N4.3236 P32.0219 1 TOOTHED BELT 9 MM A23

N4.9159 P32.0221 1 LABEL <<CE>> A6

N41.9127 P32.0221 1 ADHESIVE LABEL 20 X 10 X 0.1 B5

N43.9164 P32.8105 1 ADHESIVE LABEL WEEE C19

N43.9192 P32.8103 1 ADHESIVE LABEL 18 Volt A22

N43.9192 P32.8105 1 ADHESIVE LABEL 18 Volt B19

N44.9104 P32.8105 1 ADHESIVE LABEL <<FROMM>> D21

N44.9148 1 TYPE PLATE <<P329>> A6

N44.9160 P32.8105 1 ADHESIVE LABEL D19

N5.2702 1 COVER C20

N51.1127 P32.0219 1 GEAR MOTOR A21

N51.2194 P32.0229 1 INSERTATION PART A19

N51.5477 P32.8103 1 SPRING PIN A22

N6.6224 P32.0219 2 O-RING 24 X 2 C21

N6.6232 P32.0219 1 O-RING 8 X 2 A20

N61.6220 P32.0219 2 O-RING 29.5 X 3 D23

P30.1210 P32.8199 1 HOLDING-DOWN CLAMP C20

P31.1124 P32.0218 1 TUBE B14

[P32.0144] P32.0219 1 ROCKER B15

P32.0159 P32.0219 1 PINION C22

[P32.0202] P32.0219 1 WELDING EXCENTRIC A14

[P32.0203] P32.0219 1 SPRING BOLT A7

[P32.0204] P32.0208 1 GEAR WHEEL B14

[P32.0205] P32.0208 1 IDLER STEP C13

PAGE 24 OF 26 0118 I H -7184

[ ] = Group * = Wearing parts

24

43253301.een.fm

43.2533.01 P329/19/1.06-1.35 P329.0001.01 13.05.14

Item-No. in group Pcs. Description Dimension Field

[P32.0206] P32.0208 1 LEVER C16

[P32.0207] P32.0208 1 GEAR BODY C17+

[P32.0208] P32.0219 1 GEAR B13

[P32.0209] P32.0219 1 GEAR WHEEL C17

[P32.0211] P32.0219 1 CONICAL GEAR WHEEL D23

[P32.0212] P32.0219 1 GEAR WHEEL D21

*

P32.0213

P32.0219 1 MOTOR D21

[P32.0214] P32.0219 1 GEAR WHEEL B23

[P32.0218] P32.0219 1 BODY A1+

[P32.0219] 1 BASE MODEL D6+

[P32.0221] 1 COVER A4

[P32.0222] 1 END COVER D4

[P32.0229] P32.0219 1 CIRCUIT BOARD B21

P32.1022 P32.0202 1 WELDING EXCENTRIC A15

P32.1024 P32.0144 1 ROCKER A16

P32.1027 P32.0219 1 BALL CAGE C10

P32.1028 P32.0219 1 BOLT D11

P32.1029 P32.0219 1 THRUST PIECE C10

P32.1032 P32.0219 1 DRIVING PIN D11

P32.1035 P32.0219 2 DRIVER C11+

P32.1215 P32.0219 1 HANDLE SHAFT C19

P32.1251 P35.0146 1 PUSHER B12

*

P32.1511

P32.0219 1 WELDING GRIPPER D11

P32.1710 1 CENTERING SLEEVE C12

P32.2009 P32.8199 2 TURNING BUTTON C20

P32.2012 P32.0219 1 GUIDE B16

P32.2016 P33.0204 1 GEAR WHEEL C17

[P32.8103] P32.0219 1 MOTOR HOUSING A22

[P32.8105] P32.0219 1 MOTOR HOUSING B19

P32.8106 1 STEEL INSERT D9

P32.8107

*

1 WELDING STOP GRIPPER C10

P32.8108 1 HOLDER C3

P32.8109

P32.8110

P32.8111

*

*

*

1 GRIPPER D3

1 GRIPPER D3

1 GRIPPER D3

P32.8115 P32.0202 1 PINION A14

P32.8116 P32.0203 1 SPRING SLIDE A9

P32.8117 P32.0203 1 SPRING BOLT B8

P32.8118 1 STRAP GUIDE PLATE A3

P32.8120 P32.0219 1 MAGNET D7

P32.8121 P32.0219 1 ECCENTRIC SHAFT C7

P32.8122 P32.0219 1 TOOTHED BELT PULLEY B9

P32.8125 P32.0219 1 PUSHER B14

P32.8126 P32.0204 1 GEAR WHEEL C15

P32.8127 P32.0205 1 PLANET SHAFT C14

P32.8128 P32.0205 1 GEAR WHEEL C13

P32.8129 P32.0208 1 GEAR WHEEL D16

P32.8130 P32.0206 1 LEVER C16

P32.8131 P32.0207 1 GEAR BODY C17

P32.8132 P32.0208 1 GEARING COVER D15

P32.8134 P32.0209 1 GEAR WHEEL D17

P32.8136 P32.0219 1 HOUSING B24

P32.8137 P32.0218 1 SWIVEL SHAFT A18

PAGE 25 OF 26 0118 I H -7184

[ ] = Group * = Wearing parts

43253301.een.fm

25

43.2533.01 P329/19/1.06-1.35 P329.0001.01 13.05.14

Item-No. in group Pcs. Description Dimension Field

P32.8138 P32.0211 1 CONICAL GEAR WHEEL D22

P32.8139 P32.0212 1 GEAR WHEEL D21

P32.8140 P32.0219 1 RETAINER A22

P32.8141 P32.0219 1 COVERING B21

P32.8142 P32.0219 1 HANDLE LEVER B21

P32.8150 P32.0219 1 TOUCH CONTACT-SWITCH A21

P32.8153 P32.0214 1 GEAR WHEEL B24

P32.8157 P32.0218 1 BODY C7

P32.8158 P32.0221 1 COVER A4

P32.8159 P32.0222 1 END COVER C5

P32.8169 1 STRAP STOP B1

P32.8178 1 STRAP GUIDE D4

P32.8195 1 COVER C9

[P32.8199] P32.0229 1 CIRCUIT BOARD B20

[P33.0204] P32.0219 1 GEAR WHEEL B18

P33.2115 P32.8199 1 TURNING BUTTON C20

P33.2145 P32.0219 1 DISK B21

P33.2155 P32.0219 1 DOWEL C22

[P35.0146] 1 PUSHER C12

P35.3104 P32.0205 3 IDLER GEAR C13

P35.3201 3 IDLER GEAR B4

P35.3203

P35.3214

P35.3215 1 GUIDE CASE B11

P35.3218 1 GUIDE PIN D12

P35.3219 1 GUIDE PIN D12

P35.3220 1 SEESAW LEVER B11

P35.3221 1 SEESAW LEVER C12

P35.3223 P35.0146 1 THRUST PIECE B12

*

*

1 TENSIONING WHEEL C4

1 CUTTER C11

PAGE 26 OF 26 0118 I H -7184

[ ] = Group * = Wearing parts

26

43253301.een.fm

Loading...

Loading...