Fromm P328 M, P328, P328 HA, P328 A, P329 M/HA Service Manual

...

SERVICE MANUAL

BATTERY - POWERED

PLASTIC STRAPPING TOOL

MODEL

P328 M/HA / P328 A/A

P328.sen.fm/MAS/© 02.16

Manual for authorized dealers and service points

Purchase at Allstrap (866) 779-2673

1. SERVICE MANUAL P328 M/HA / P328 A/A

2. DRAWINGS P328 M/HA / P328 A/A

3. SPARE PARTS LISTS P328 M/HA / P328 A/A

Type i ndep e nden t spare parts

Type d epen dent spa re parts

4. MANUAL P328 M/HA

Techn ical Data

Chart of Types

Exchange of wearing parts

5. MANUAL P328 A/A

Techn ical Data

Chart of Types

Exchange of wearing parts

6. SERVICE MANUAL P329 M/HA / P329 A/A

7. DRAWINGS P329 M/HA / P329 A/A

8. SPARE PARTS LISTS P329 M/HA / P329 A/A

Type i ndep e nden t spare parts

Type d epen dent spa re parts

9. MANUAL P329 M/HA

Techn ical Data

Chart of Types

Exchange of wearing parts

10. MANUAL P329 A/A

Techn ical Data

Chart of Types

Exchange of wearing parts

11. NEWS

12. NOTES

1-2

INDEX PAGE

1.1 ACCESSORIES 1-3

1.1.1 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.2 Battery chargers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.3 Battery tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.4 Memory reader for circuit board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.5 Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.6 Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.2 TECHNICAL DETAILS 1-4

1.2.1 Strap tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

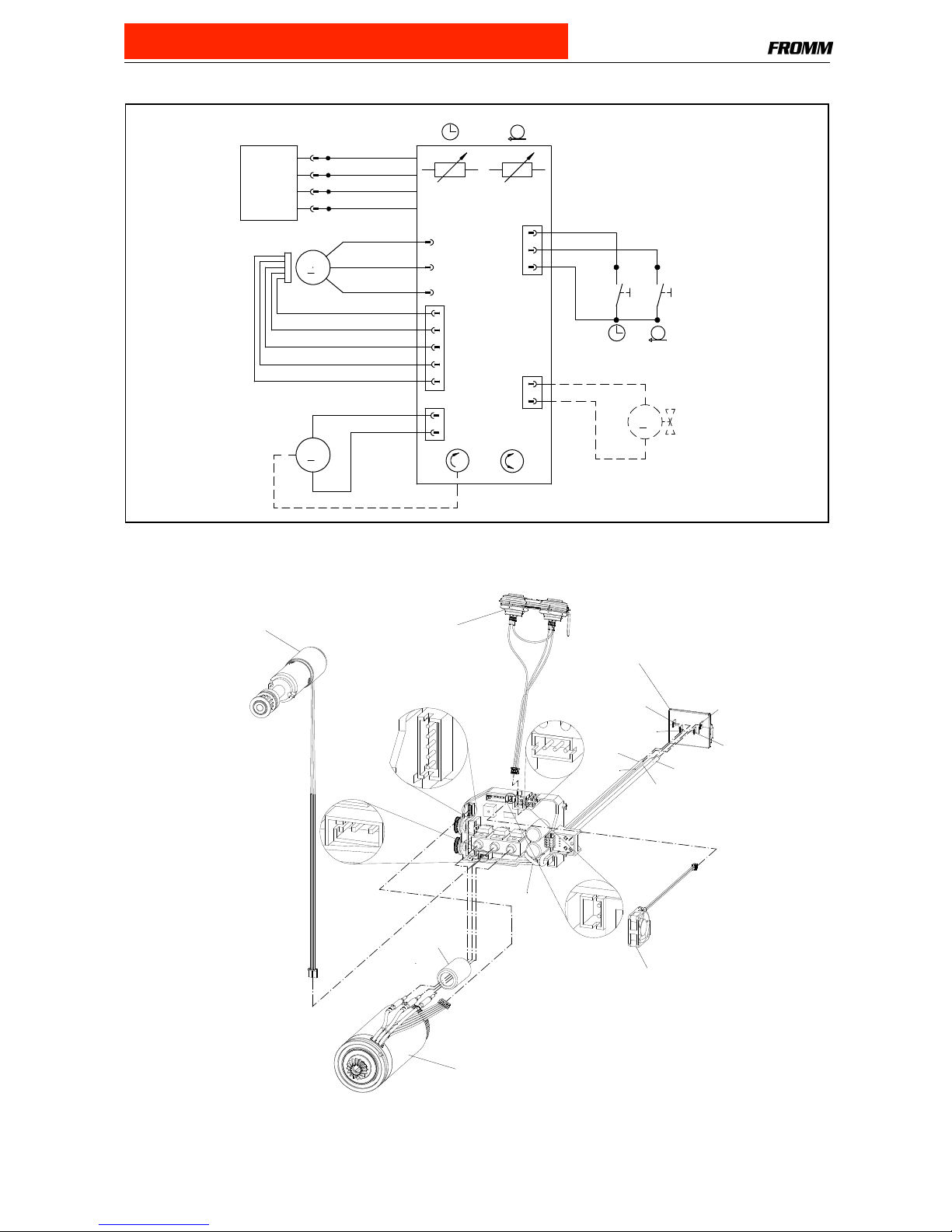

1.2.2 Electric schematic Semi Automatic ELS.1082 . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2.3 Connecting plan Semi Automatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

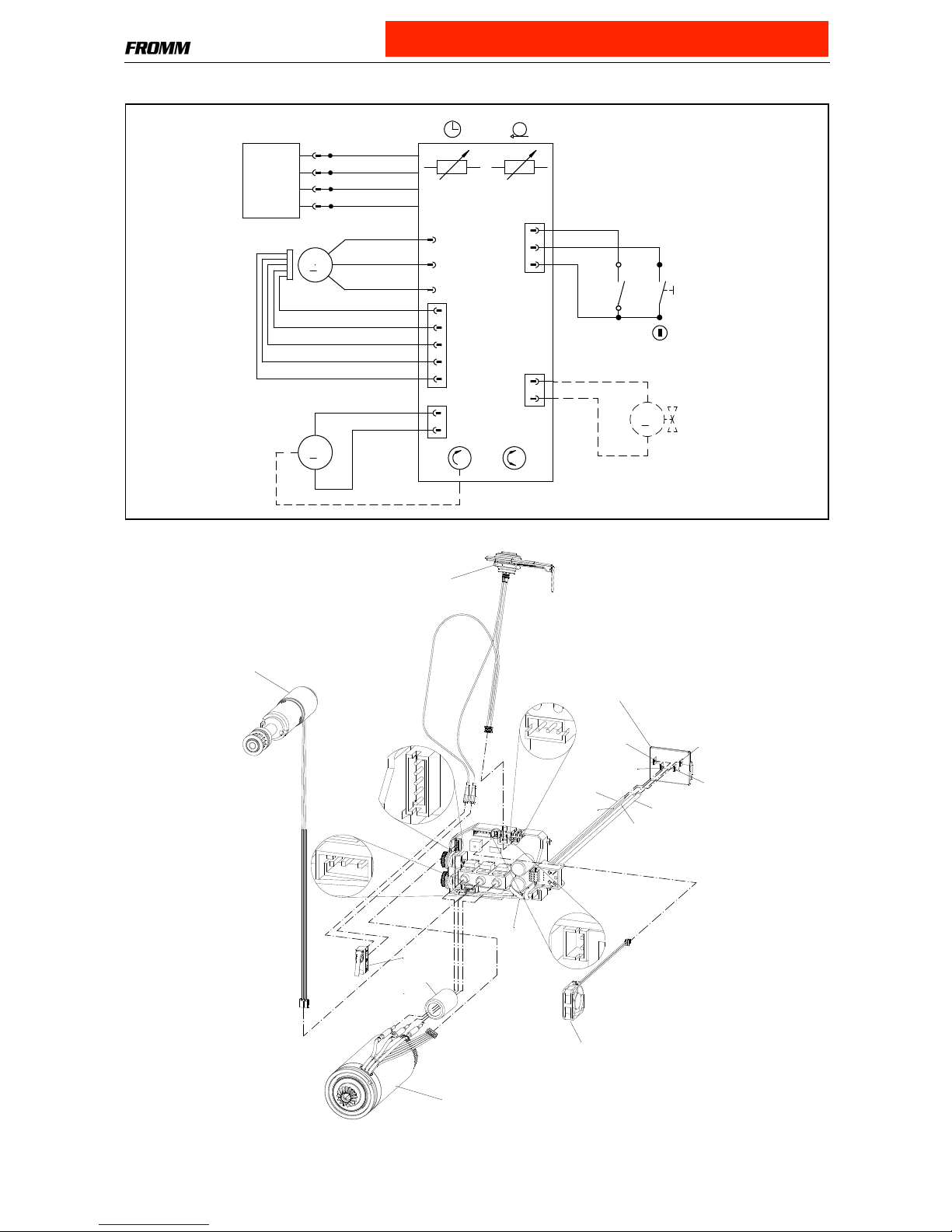

1.2.4 Electric schematic Automatic ELS.1083 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2.5 Connecting plan Automatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

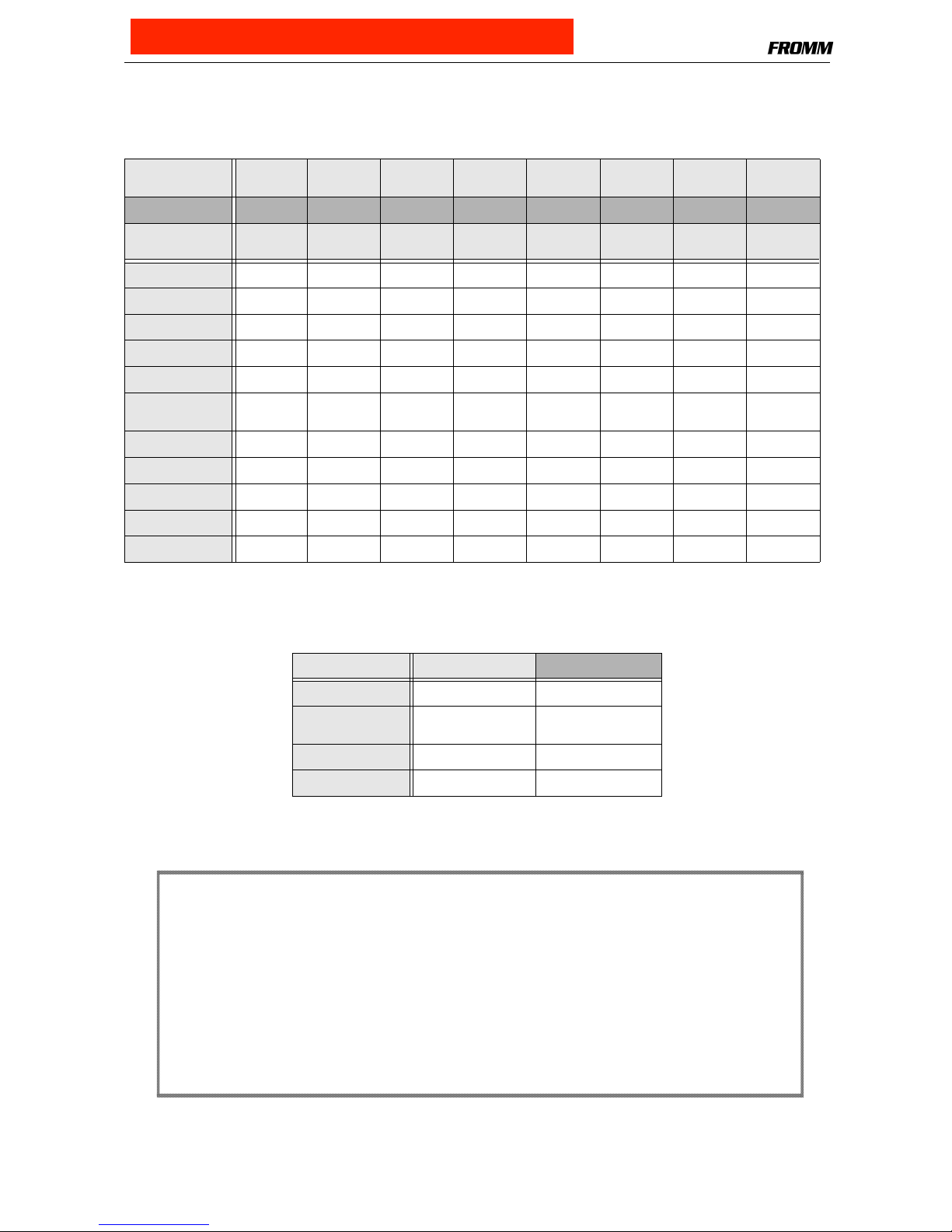

1.3 CONVERSION PARTS P328 1-7

1.4 PERIODIC MAINTENANCE AND CONTROL 1-8

1.4.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.4.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4.3 Battery test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.4.4 Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.4.5 Lubrication rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.4.6 Glueing rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.4.7 Assembly information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.5 RECOMMENDED SPARE PARTS 1-20

1.6 MAINTENANCE PLAN P328 1-21

1.7 ACCESSORY TOOLS 1-22

1.8 USE OF ACCESSORY TOOLS 1-23

1.9 ORDERING SPARE PARTS 1-29

1.9.1 Ordering manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

1.9.2 Ordering address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

1.9.3 Finding out of the tool type (item number), the serial number

and the version number: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

1.10 SERVICE ADDRESS 1-30

1.11 CHART OF TYPES 1-30

1.11.1 Chart of types P328 M / HA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

1.11.2 Chart of types P328 A / A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Purchase at Allstrap (866) 779-2673

1-3

1.1 ACCESSORIES

1.1.1 Battery

Use only original Fromm batteries N5.4349 (Li-Ion).

1.1.2 Battery chargers

The battery charger must be ordered separately according to the table mentioned below.

(..) = an adaptor N52.2102 is required.

1.1.3 Battery tester

Information to the Battery tester you will get by FROMM System GmbH.

(see 1.10 SERVICE ADDRESS)

1.1.4 Memory reader for circuit board

To r e ad th e m e mo ry in f or m at i on o f t h e t oo l s ci r cu it bo a rd th e r e ad e r N 7. 5 15 4 c an be or d er e d.

With this the following data could be read:

• software version

•date of software

• strapping cycles

• calibration current

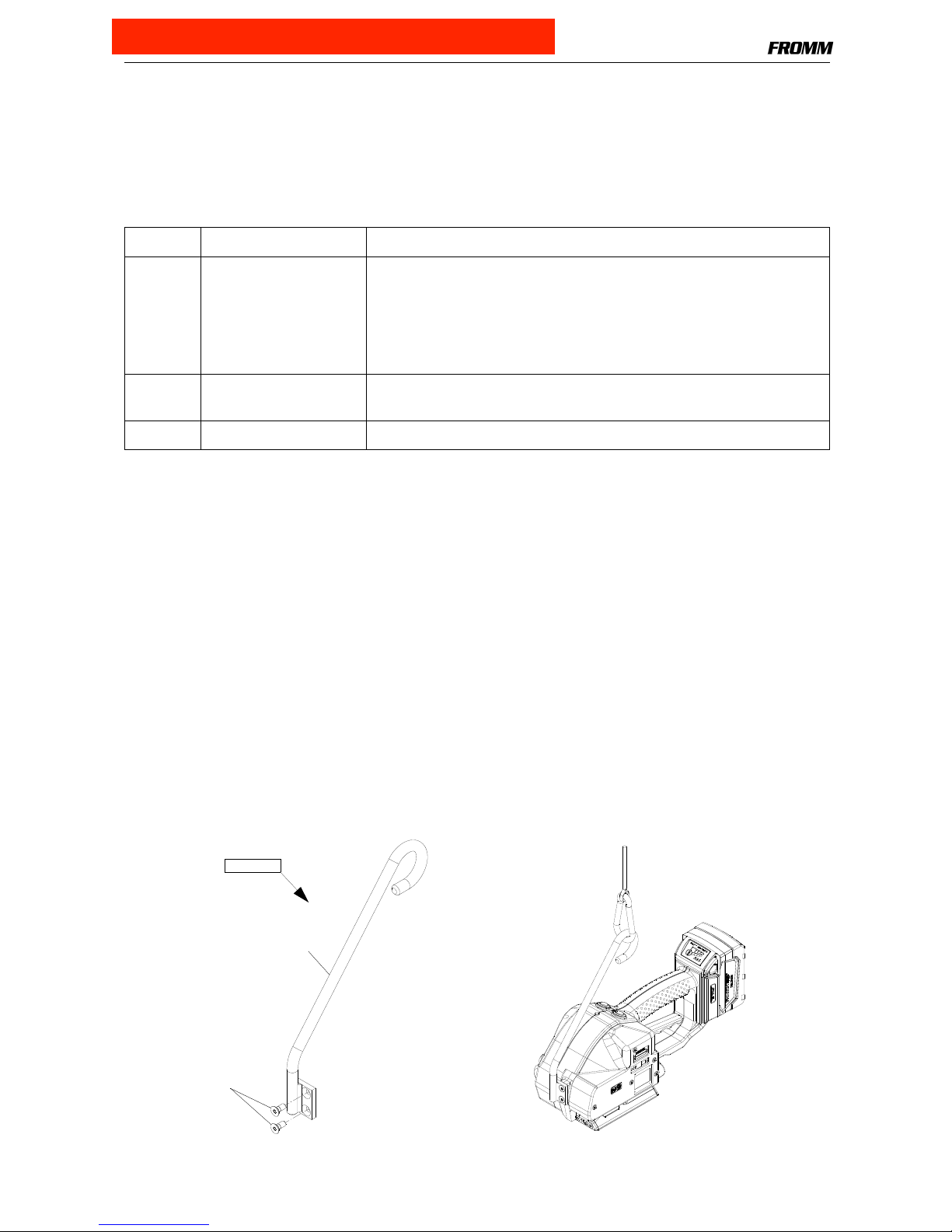

1.1.5 Suspension

When working stationary the strapping tool can be suspended at a spring loaded balancer by using a

suspension bracket.

For working in normal position a stiff suspension bracket with screws and washers can be ordered under item

number P32.0231.

Item-No. Voltage / frequency Admitted for country

N5.4443 220 - 240V / 50 - 60Hz A, B, BG, BIH, BOL, BR, BY, CH, CL, CZ, D, DK, DZ, E, EAS, EST,

ET, F, FIN, GE, GR, H, HK, HR, I, IL, IND, IR, IRQ, IS, JOR, KSA,

KWT, L, LAR, LT, LV, MA, MC, MK, MOC, N, NL, P, PK, PE, PL, PRC,

PY, RA, RCH, RI, RL, RO, ROK, ROU, RP, RUS, S, SK, SLO, SYR,

THA, TN, TR, UA, (UAE), YU, YV, (BRN), (BRU), (CY), (EAK), (EAT),

(GB), (IRL), (M), (MAL), (OM), (SGP), (Y), (Z), (ZA), (ZW)

N5.4447 120V / 50 - 60Hz BR, C, CDN, CO, CR, DOM, EC, GCA, J, JA, KSA, LB, MEX, NIC,

PA, Puerto Rico, RC, RP, USA, YV

N5.4445 220 - 240V / 50 - 60Hz AUS, NZ

P32.0231

P32.8313

N1.2163

Purchase at Allstrap (866) 779-2673

1-4

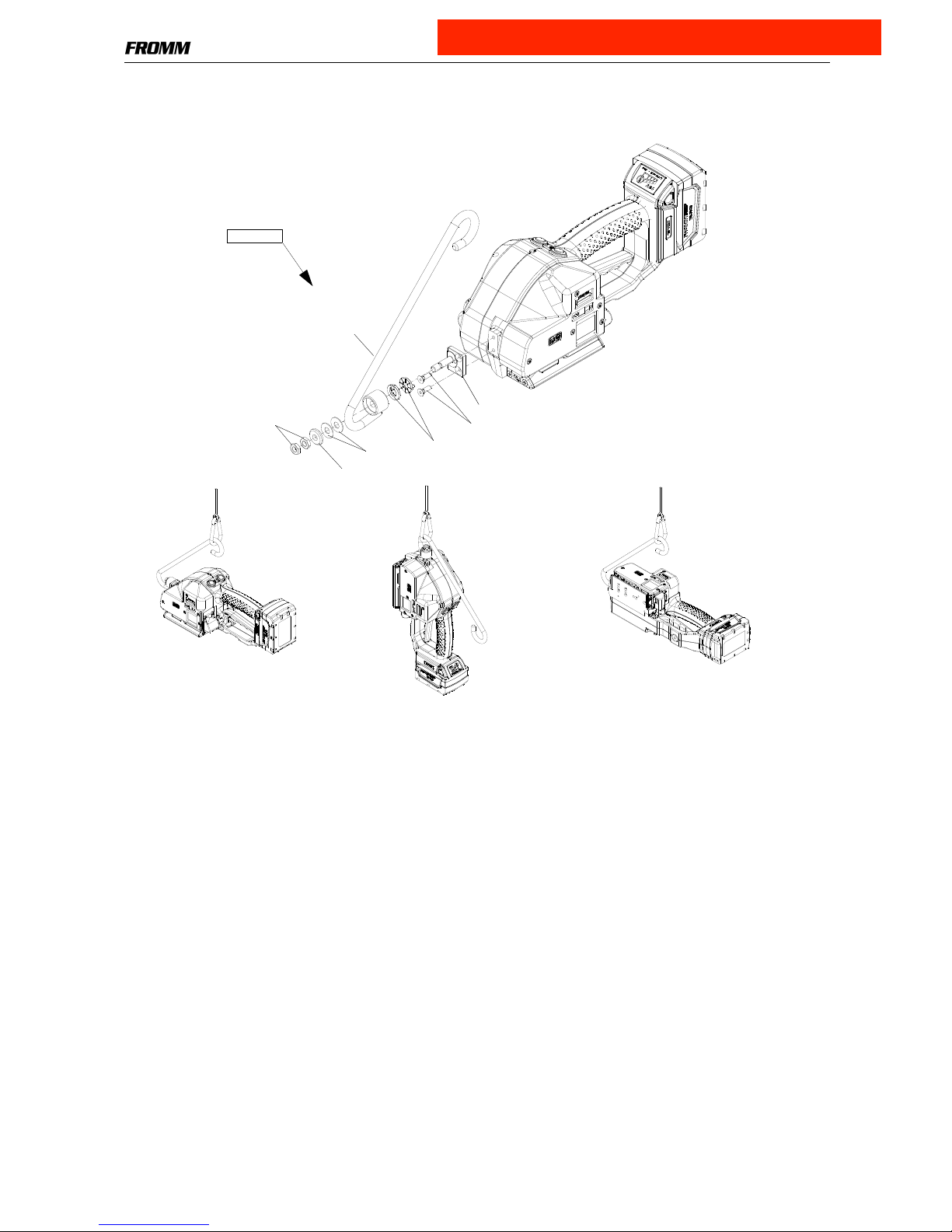

For working in alternating positions a turnable suspension bracket with screws and washers can be ordered

under item number P32.0223.

1.1.6 Fan

In order to avoid overheating of the motor we recommend at environmental temperatures above 40°C / 104°F

using the optional fan P32.0228.

(see 1.4.7 Assembly information)

1.2 TECHNICAL DETAILS

1.2.1 Strap tension

The tension force values mentioned in the operation manual (250-2600N) are not achievable with each strap.

They depend on following factors:

•Hardness of the package,

the maximum tension force values are achievable with hard packages.

•Elongation and creep properties of the plastic strap,

the maximum tension force values are achievable by using plastic straps with a low elongation.

•Surface quality of the plastic strap,

the maximum tension force values are achievable with waxed and embossed straps.

•Strap width, strap thickness,

the maximum tension force values are achievable with thick and wide straps.

P32.0223

N1.5105

N2.5623

P35.2073

P32.8302

P35.2069

N1.2163

Mobilux EP2

P32.8301

Purchase at Allstrap (866) 779-2673

1-5

1.2.2 Electric schematic Semi Automatic ELS.1082

1.2.3 Connecting plan Semi Automatic

18VDC

red

-

+

red

2

1

UB

M3

2

1

3

red

blue

1

2

(-)

(+)

M2

U

V

W

yellow

violett

brown

Hall3

Hall2

Hall1

GND

+5V

5

4

3

2

1

M1

2

1black

red

(+)

(-)

optional Fan

blackblack

black

DC

DP

2

1

HA

M

Manual / 1/2 Auto

P32.8150

N51.1127

P32.0213

P32.0228 (optional)

P33.2155

N51.2194

red

red

black

blue

red

blue

black

red

P32.8148

Purchase at Allstrap (866) 779-2673

1-6

1.2.4 Electric schematic Automatic ELS.1083

1.2.5 Connecting plan Automatic

18VDC

red

-

+

red

2

1

UB

M3

2

1

3

red

blue

1

2

(-)

(+)

M2

U

V

W

yellow

violett

brown

Hall3

Hall2

Hall1

GND

+5V

5

4

3

2

1

M1

2

1black

red

(+)

(-)

A

A

Auto / Auto

1(C)

4(N0)

optional Fan

blackblack

black

DC

DP

P32.8154

N51.1127

P32.0213

P32.0228 (optional)

P33.2155

N51.2194

red

red

black

blue

red

blue

black

red

P32.8151

N5.2382

Purchase at Allstrap (866) 779-2673

1-7

1.3 CONVERSION PARTS P328

Conversion parts for changing of strap width and strap thickness

Conversion parts from Semi automatic to Automatic

Semi

automatic

43.2422 43.2423 43.2424 43.2432 43.2453 43.2454 43.2461 43.2462

Automatic

43.2622 43.2623 43.2624 43.2632 43.2653 43.2654 43.2661 43.2662

12 x

0.65-1.05

12.7 x

0.4-0.64

12.7 x

0.65-1.05

13 x

0.65-1.05

15.5 x

0.4-0.64

15.5 x

0.65-1.05

16 x

0.4-0.64

16 x

0.65-1.05

Guide pin

P32.8182 P32.8183 P32.8183 P32.8185 P32.8186 P32.8186 P35.3216 P35.3216

Guide pin

P32.8181 P32.8191 P32.8191 P32.8193 P32.8194 P32.8194 P35.3217 P35.3217

Guide case

P32.8179 P32.8179 P32.8179 P32.8179 P35.3215 P35.3215 P35.3215 P35.3215

Strap stop

P32.8162 P32.8163 P32.8163 P32.8164 P32.8166 P32.8166 P32.8167 P32.8167

Strap guide

P32.8172 P32.8173 P32.8173 P32.8174 P32.8176 P32.8176 P32.8177 P32.8177

Ten si oni ng

wheel

P35.3203 P35.3202 P35.3203 P35.3203 P35.3202 P35.3203 P35.3202 P35.3203

Gripper

P32.8109 P32.8112 P32.8109 P32.8109 P32.8112 P32.8109 P32.8112 P32.8109

Gripper

P32.8110 P32.8113 P32.8110 P32.8110 P32.8113 P32.8110 P32.8113 P32.8110

Gripper

P32.8111 P32.8114 P32.8111 P32.8111 P32.8114 P32.8111 P32.8114 P32.8111

Cutter

P35.3214 P32.8197 P35.3214 P35.3214 P35.3214 P35.3214 P35.3214 P35.3214

Insertation part

-- P32.8198 -- -- P32.8198 -- P32.8198 --

Semi automatic Automatic

Circuit board

P32.8148 P32.8151

Tou ch con tac t-

switch

P32.8150 P32.8154

Pusher

-- P32.8133

Adhesive label

N44.9160 N44.9170

Attention!

When converting tools always change the item number on the type label.

Replace following parts:

Type label N44.9122

2 x hammer head bolts N2.4902

Enclose the suitable operation manual with the tool after each conversion

(see paragraph 1.9.1 Ordering manuals).

Purchase at Allstrap (866) 779-2673

1-8

1.4 PERIODIC MAINTENANCE AND CONTROL

(Carry out 12- months cycles doing one shift work. Doing more shift work respectively more often.)

To a v o i d d a m ages o n t h e mo t o r sha ft the t wo n e edle free wheelings N3.4509 and N3.4520 have to be

replaced after 80 000 strapping cycles.

1.4.1 Procedure

Before using check tool for following possible faults:

•Visual test of the tool for loose, lost or damaged parts

•Clean all dirty parts of the tool, especially strap abrasion in the tensioning or the welding unit by

using compressed air. (Never use any hard tools like a wire brush or a screw driver for cleaning)

Carry out a test strapping and check following:

•Insertion of the strap

•Strap feed and strap tensioning

•Tensioning force adjustment (see operation manual P328)

•Cutting of the upper strap

•Welding time adjustment (see operation manual P328)

• Seal quality (see operation manual P328)

•Function of the LED - display

Proceed according to paragraph 1.4.2 after a fault appears.

For exchange of wearing parts see operation manual P328.

Attention!

Remove battery from tool before each maintenance work.

Never use water or solvents for cleaning the tool’s surface.

Purchase at Allstrap (866) 779-2673

1-9

1.4.2 Troubleshooting

Ensure before each tool repair that the battery is charged and

the tool’s specific strap is used

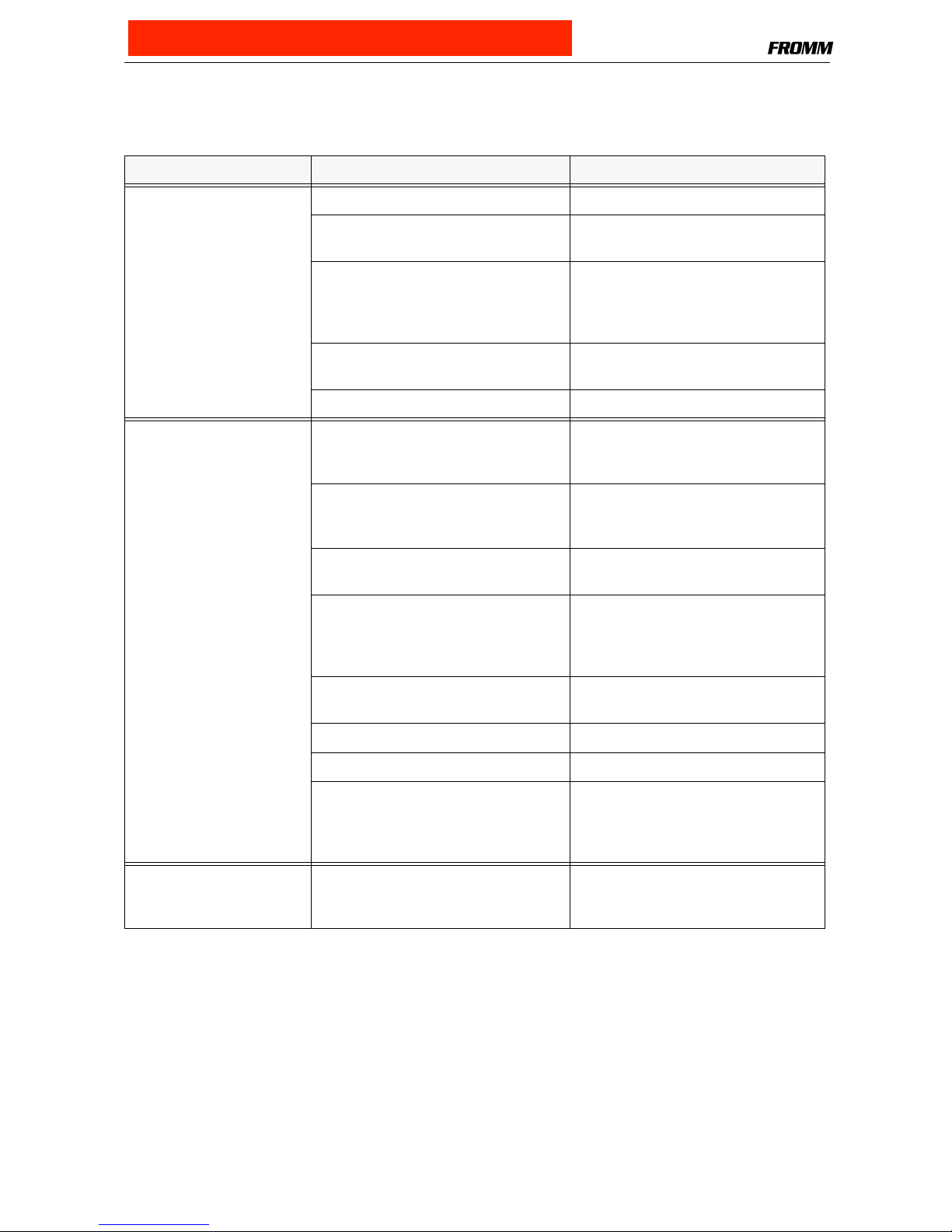

SYMPTOM CAUSE REMEDY

To ol d oe sn ’t w or k at a ll B at t er y is e mpty or defective Charge or replace battery

Contact problems caused by a broken

battery housing

Replace battery

Contact problems caused by a

damaged insertation part N51.2194 or

damaged motor housings P32.8103

and P32.8105/96

Replace insertation part or

motor housing

Contact problem of the internal wires Check contacts and fix them if

required or change defective parts

Defective circuit board Replace circuit board

To ol do e sn ’ t t en si o n Te ns i on i ng wh e el is d i rt y o r w o rn C l ea n t e ns i on i ng wh e el or r e pl a ce it ,

don’t use any hard objects for this

(see operation manual P328)

P32.8128 is not meshing with

P32.8130 because spring N2.5296 is

defective or parts are dirty

Replace spring N2.5296,

clean dirty parts

Faulty tensioning wheel or tensioning

wheel is assembled reversed

Correct assembling

(see operation manual P328)

Grippers are dirty, worn or wrongly

assembled

Replace grippers, clean them or

assemble correct,

don’t use any hard objects for this

(see operation manual P328)

Gearing parts from the tensioning gear

are defective

Check tensioning gear and replace

defective parts

Defective circuit board Replace circuit board

Defective gear bearings Replace bearings

Needle free wheeling N3.4509 in gear

wheel P32.8139 or N3.4520 in conical

gear wheel P32.8138 assembled

reversed or defective

Assemble the needle free wheeling

correct or replace it

Te ns i on i ng wh e el tu rn s

back immediately after the

tensioning cycle

Defective needle free wheeling

N3.4509 in P32.8134

Check parts and replace if necessary

Purchase at Allstrap (866) 779-2673

1-10

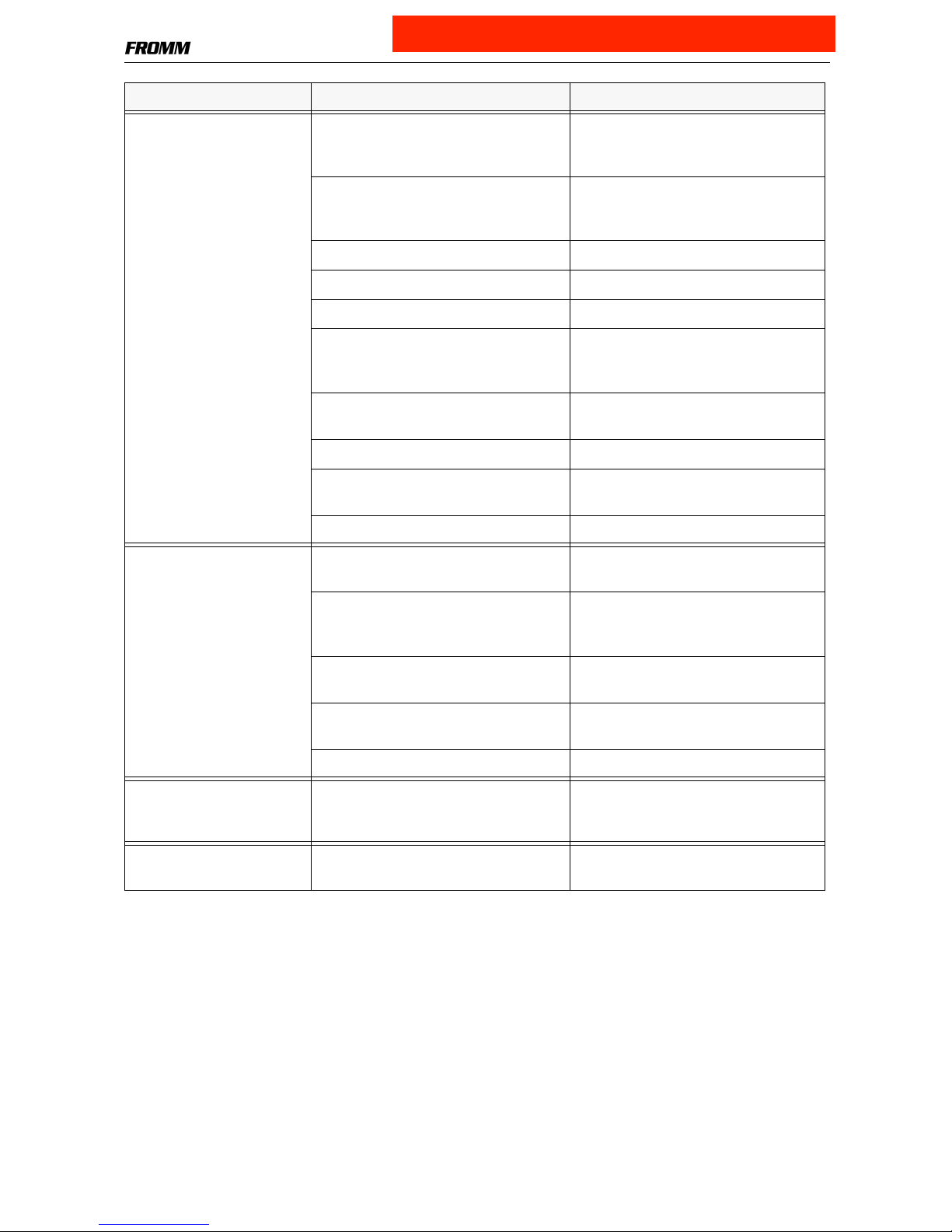

To ol do e sn ’ t w el d We l di n g g ri p pe r P 32 . 15 11 is di r ty or

worn

Replace or clean welding gripper,

don’t use any hard objects for this

(see operation manual P328)

Welding stop gripper P32.8107 is dirty

or worn

Replace or clean welding stop gripper,

don’t use any hard objects for this

(see operation manual P328)

Damaged housing parts Replace housing parts

Defective circuit board Replace circuit board

Pressure spring N21.5138 defective Replace pressure spring

Needle free wheeling N3.4509 in

P32.8139 defective or assembled

reversed

Assemble the needle free wheeling

correct or replace it

Gearing parts of the welding gear are

defective

Check welding gear and replace

defective parts

Gear motor N51.1127 defective Replace Gear motor

To ot he d be lt N 4. 3 23 6 or To ot he d be lt

pulley P32.8122 is worn

Replace Toothed belt or

To ot h ed be l t p ul le y

Defective gear bearing Replace bearing

Tool badly cuts the strap or

doesn’t cut at all

Cutter is worn or damaged Replace cutter

(see operation manual P328)

Wrong adjustment of the coupler

P35.0146

Check adjustment and readjust if

necessary

(see operation manual P328)

Welding gripper P32.1511 is worn Replace welding gripper

(see operation manual P328)

Welding time too short Change adjustment

(see operation manual P328)

Defective pressure spring N2.5237 Replace pressure spring

Tool switches off after a few

strappings

(Displaying empty battery)

Battery defective or empty Check the battery and change

defective batteries

Gear noise Tensioning or welding gear is worn Check component parts and replace

defective ones

SYMPTOM CAUSE REMEDY

Purchase at Allstrap (866) 779-2673

1-11

1.4.3 Battery test

The battery should be checked while each maintenance with a battery tester.

Information to the Battery tester you will get by FROMM System GmbH.

(see 1.10 SERVICE ADDRESS)

•Li-Ion-Batteries 18V / (4,0Ah) must be replaced at a capacity less than approx. 60% (2,4 Ah)

1.4.4 Checklist

Carry out some test strappings and check following tool components.

•Inserting of the strap

•Insert battery in the tool and check function of the LED-display (see operation manual P328)

•Strap feed and strap tension

• Tension force adjustment (see operation manual P328)

•Cutting of the upper strap

•Welding time adjustment (see operation manual P328)

• Seal quality (see operation manual P328)

•Function of the LED-display (see operation manual P328)

•Correct type label

1.4.5 Lubrication rules

All gear parts have to be lubricated with MOLYKOTE BR2 PLUS grease.

All other parts have to be lubricated according to the explosion drawing.

Lubrication interval: While each maintenance or after 12 months at the latest.

Particular note:

All bearing parts of the welding unit have to be cleaned and lubricated as follows:

P32.1511

Mobilux EP2

Klüber Isoflex Alltime SL2

Klüber Isoflex NBU 15

P32.1029

N3.1702 (6X)

P32.1027

P32.1028

P32.1035

grease here

P32.1024

P32.1035

Purchase at Allstrap (866) 779-2673

1-12

Eccentric shaft P32.8121, Spring slide P32.8116, Spring bolt P32.8117 and the Pressure spring N21.5138

have to be greased as follows:

Lubrication interval: While each maintenance or after 12 months at the latest.

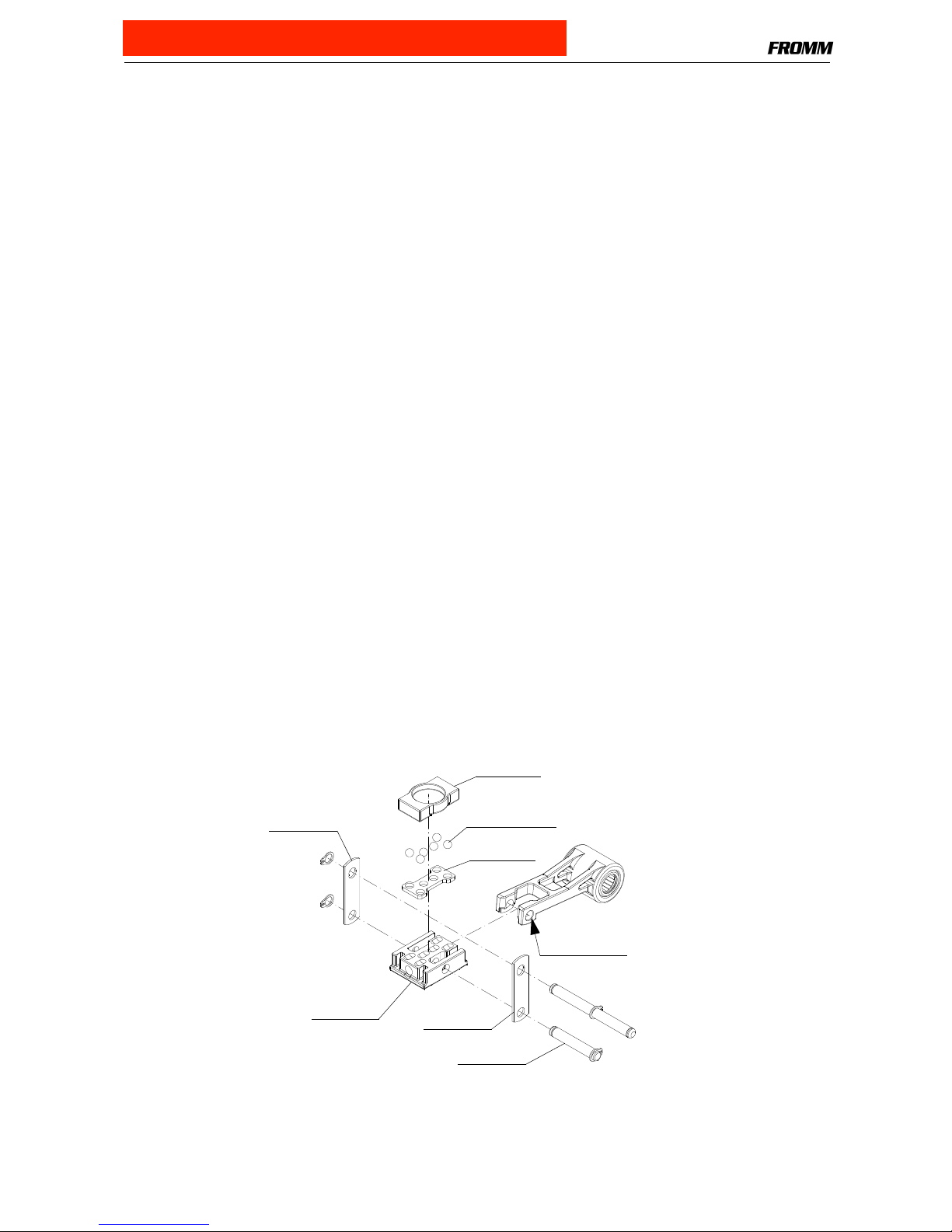

1.4.6 Glueing rules

P32.8121

P32.8116

P32.8117

Mobilux EP2

N21.5138

N21.2145

N2.2145

P32.8128

N1.2188

P32.0205

P32.8131

P32.2016

N3.1159

The Bearing N3.1159 has to be glued into

the gear wheel P32.2016 with LOCTITE 603.

The parallel pins N21.2145 have to be glued into the

gear body P32.8131 using LOCTITE 603.

Gear wheel P32.8128 and

parallel pins N2.2145

have to be glued with

LOCTITE 603

The screws N1.2188 have to be glued

additionally in the wheel P32.0205 using

LOCTITE 222.

Don‘t damage the teeth when loosening or

tightening the screws.

Purchase at Allstrap (866) 779-2673

1-13

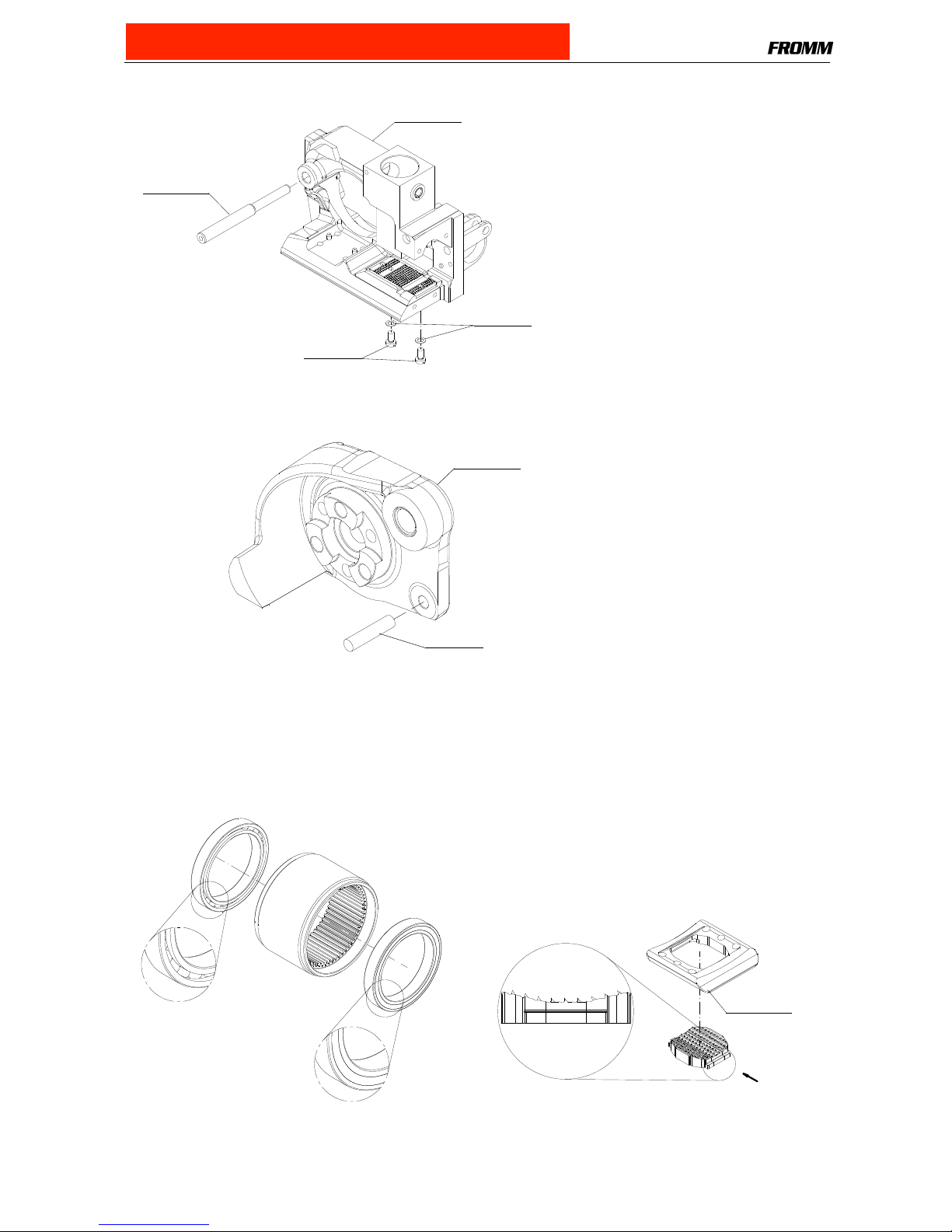

1.4.7 Assembly information

P32.8137

N1.1305

N1.6504

P32.8101

The bolt P32.8137 has to be glued into the

body P32.8101 using Loctite 603.

The screws N1.1305 have to be glued

with Loctite 222.

P32.8159

N2.2119

The parallel pin N2.2119 has to be

glued into the end cover P32.8159

with Loctite 603.

P32.8108

Grippers

One sided sealed bearings N3.1172 in the tensioning wheel.

The sealed side has to face to the outside. (see drawing)

When installing the grippers into the holder P32.8108

pay attention to the direction of the teeth (see drawing).

Purchase at Allstrap (866) 779-2673

1-14

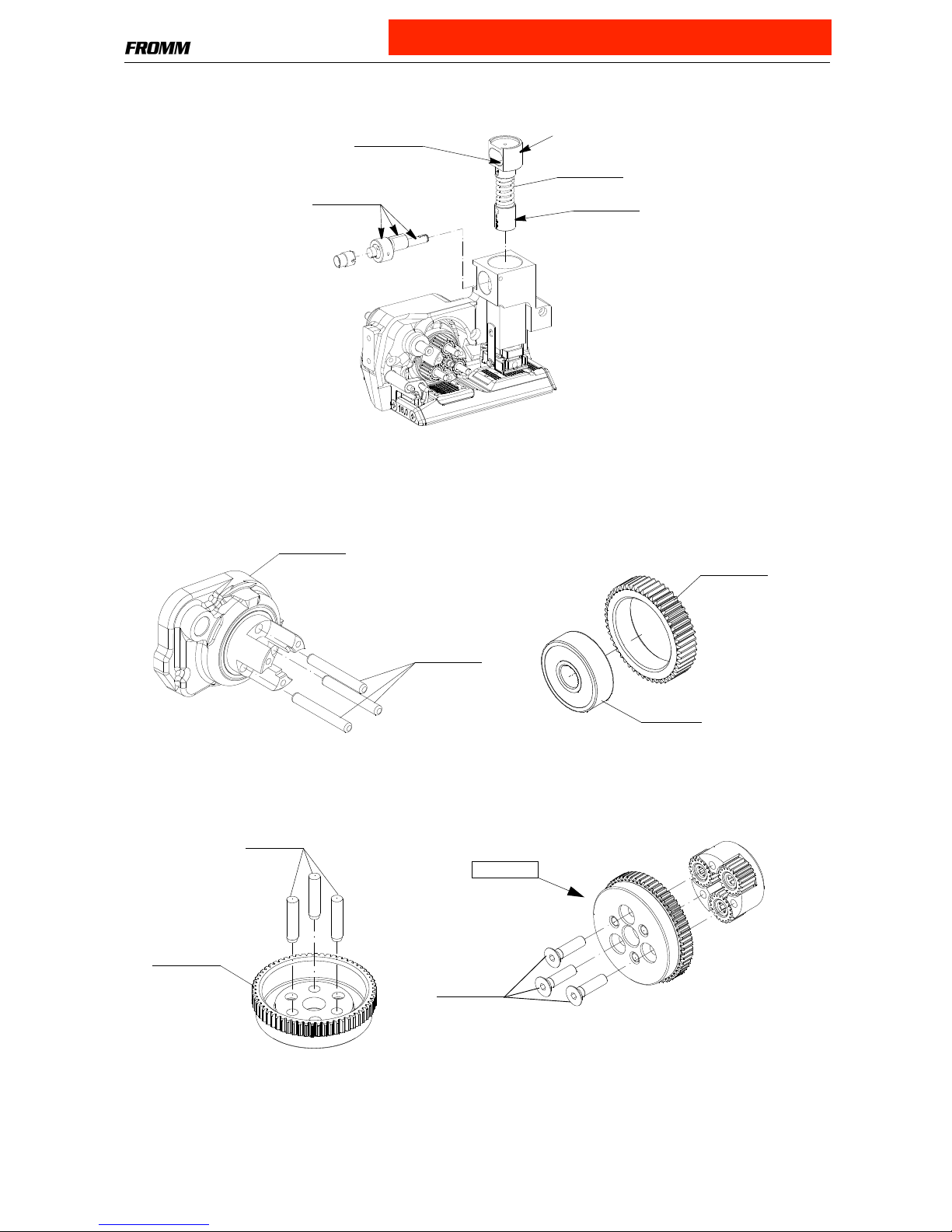

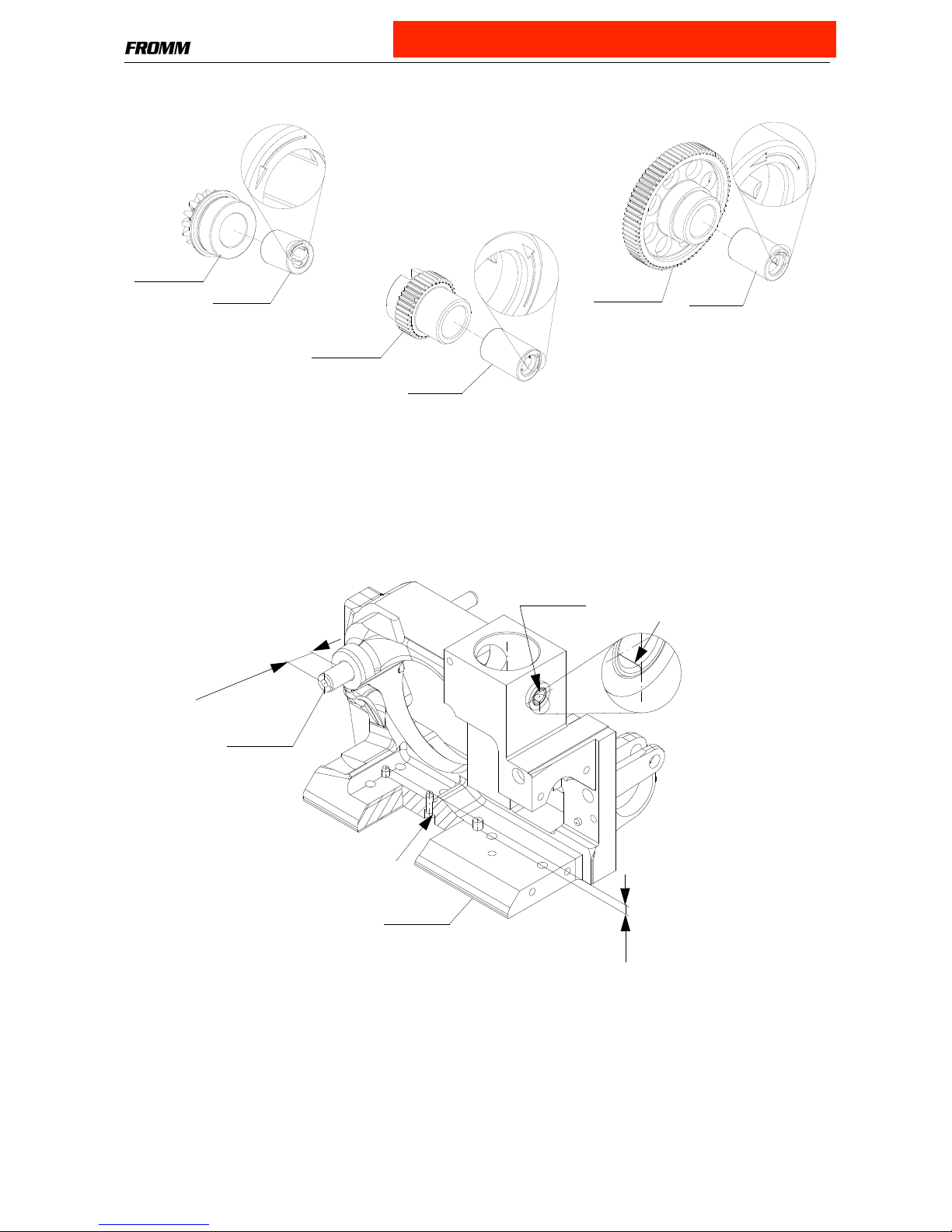

Pay attention to the mounting position of the needle free wheelings N3.4509 and N3.4520.

The rolling direction is stamped in at the front side of the free wheelings.

Position of the joint from slide bearings

Pay attention to the position of the joint from the slide bearing N31.3115 (see drawing).

N3.4509

P32.8134

P32.8138

N3.4509

N3.4520

P32.8139

1

2

,

5

5

+

-

0

,

2

N31.3115

press in pins flush

(4,4)

P32.8101

P32.8137

position joint

Purchase at Allstrap (866) 779-2673

Loading...

Loading...