Fromm P325.0001.01 Service Manual

5-1

SERVICE MANUAL

BATTERY - POWERED

PLASTIC STRAPPING TOOL

MODEL P325.0001.01

Manual for authorized dealers and service points

P325.0001.01.sen/MAS/© 12.08

5-2

INDEX PAGE

5.1 ACCESSORIES 5-3

5.1.1 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.2 Battery chargers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.3 Battery tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.4 Charger for car batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.5 Battery light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2 TECHNICAL DETAILS 5-4

5.2.1 Electric schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.2 Connecting plan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.3 Strap tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3 CONVERSION PARTS P325 5-5

5.4 PERIODIC MAINTENANCE AND CONTROL 5-6

5.4.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.4.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.4.3 Battery test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.4.4 Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.4.5 Glueing rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.4.6 Lubrication rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.4.7 Assembly informations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.4.8 Repair kit for electronic P32.2043 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.5 RECOMMENDED SPARE PARTS 5-15

5.6 ACCESSORY TOOLS 5-16

5.7 USE OF ACCESSORY TOOLS 5-17

5.8 ORDERING SPARE PARTS 5-21

5.8.1 Ordering manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.8.2 Ordering address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.8.3 Finding out of the tool type (item number),

the serial number and the version number:. . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.9 SERVICE ADDRESS 5-22

5.10 CHART OF TYPES 5-22

5-3

5.1 ACCESSORIES

5.1.1 Battery

Use only original Fromm batteries N5.4309 (NiCd) or N5.4316 (NiMH) for the P325 tool.

In case of a damaged battery housing, it can be ordered separately under item no. N5.4318.

5.1.2 Battery chargers

The battery charger must be ordered separately according to the table mentioned below.

Standard charger

Turbo charger

5.1.3 Battery tester

For testing the batteries order battery tester N7.5127.

5.1.4 Charger for car batteries

The charger N5.4407 must be ordered for connection to a car battery with 12 or 24V.

Can only charge NiCd-Batteries!

5.1.5 Battery light

For completely discharging of the battery the battery light N5.4313 can be used.

Item-No. Voltage / frequency Admitted for country

N5.4414 220 - 240V / 50 - 60Hz A, B, BG, BIH, BOL, BR, BY, CH, CL, CZ, D, DK, DZ, E, EAS, EST, ET, F,

FIN, GE, GR, H, HK, HR, I, IL, IND, IR, IRQ, IS, JOR, KSA, KWT, L, LAR, LT,

LV, MA, MC, MK, MOC, N, NL, P, PK, PE, PL, PRC, PY, RA, RCH, RI, RL,

RO, ROK, ROU, RP, RUS, S, SK, SLO, SYR, THA, TN, TR, UA, UAE, YU,

YV, (Z), (ZA), (ZW)

N5.4416 220 - 240V / 50 - 60Hz BRN, BRU, CY, EAK, EAT, GB, IRL, M, MAL, OM, SGP, Y

N5.4418 220 - 240V / 50 - 60Hz AUS, NZ

N5.4420 220V / 60Hz ROK

Item-No. Voltage / frequency Admitted for country

N5.4422 220 - 240V / 50 - 60Hz A, B, BG, BIH, BOL, BR, BY, CH, CL, CZ, D, DK, DZ, E, EAS, EST, ET, F,

FIN, GE, GR, H, HK, HR, I, IL, IND, IR, IRQ, IS, JOR, KSA, KWT, L, LAR, LT,

LV, MA, MC, MK, MOC, N, NL, P, PK, PE, PL, PRC, PY, RA, RCH, RI, RL,

RO, ROK, ROU, RP, RUS, S, SK, SLO, SYR, THA, TN, TR, UA, UAE, YU,

YV, (Z), (ZA), (ZW)

N5.4424 120V / 50-60Hz BR, C, CDN, CO, CR, DOM, EC, GCA, J, JA, KSA, LB, MEX, NIC, PA,

Puerto Rico, RC, RP, USA, YV

N5.4426 110V / 50 - 60Hz GB

N5.4428 220 - 240V / 50 - 60Hz BRN, BRU, CY, EAK, EAT, GB, IRL, M, MAL, OM, SGP, Y

N5.4430 220 - 240V / 50 - 60Hz AUS, NZ

5-4

5.2 TECHNICAL DETAILS

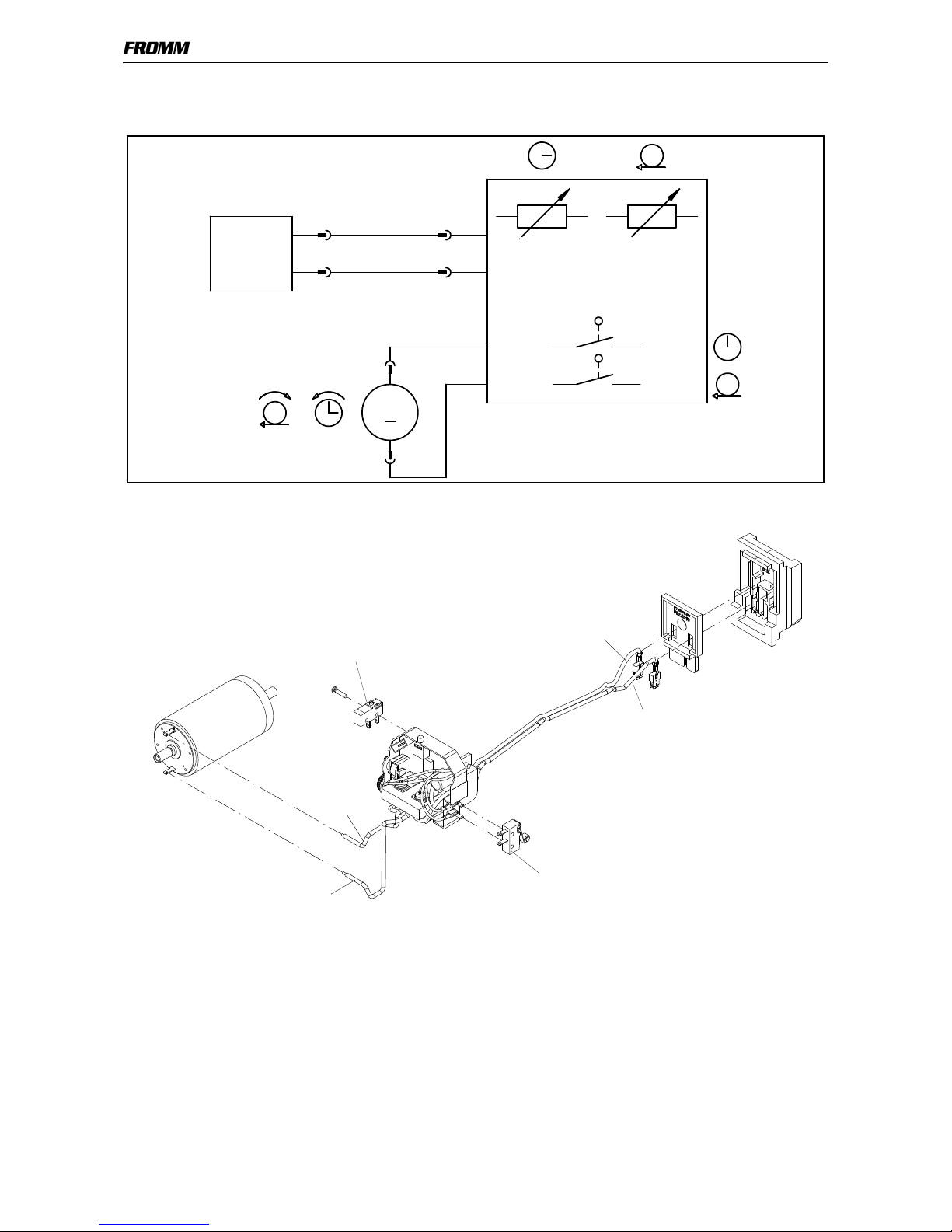

5.2.1 Electric schematic

5.2.2 Connecting plan

5.2.3 Strap tension

The tension force values mentioned in the P325 operation manual (600-3500N) are not achievable with each

strap. They depend on following factors:

• Hardness of the package,

the maximum tension force values are achievable with hard packages.

• Elongation and creep properties of the plastic strap,

the maximum tension force values are achievable by using plastic straps with a low elongation.

• Surface quality of the plastic strap,

the maximum tension force values are achievable with waxed and embossed straps.

• Strap width, strap thickness,

the maximum tension force values are achievable with thick and wide straps.

14,4VDC

+

M

+

-

black

red

red

white

N5.2359

N5.2322

black (-)

red (+)

red (+)

white (-)

5-5

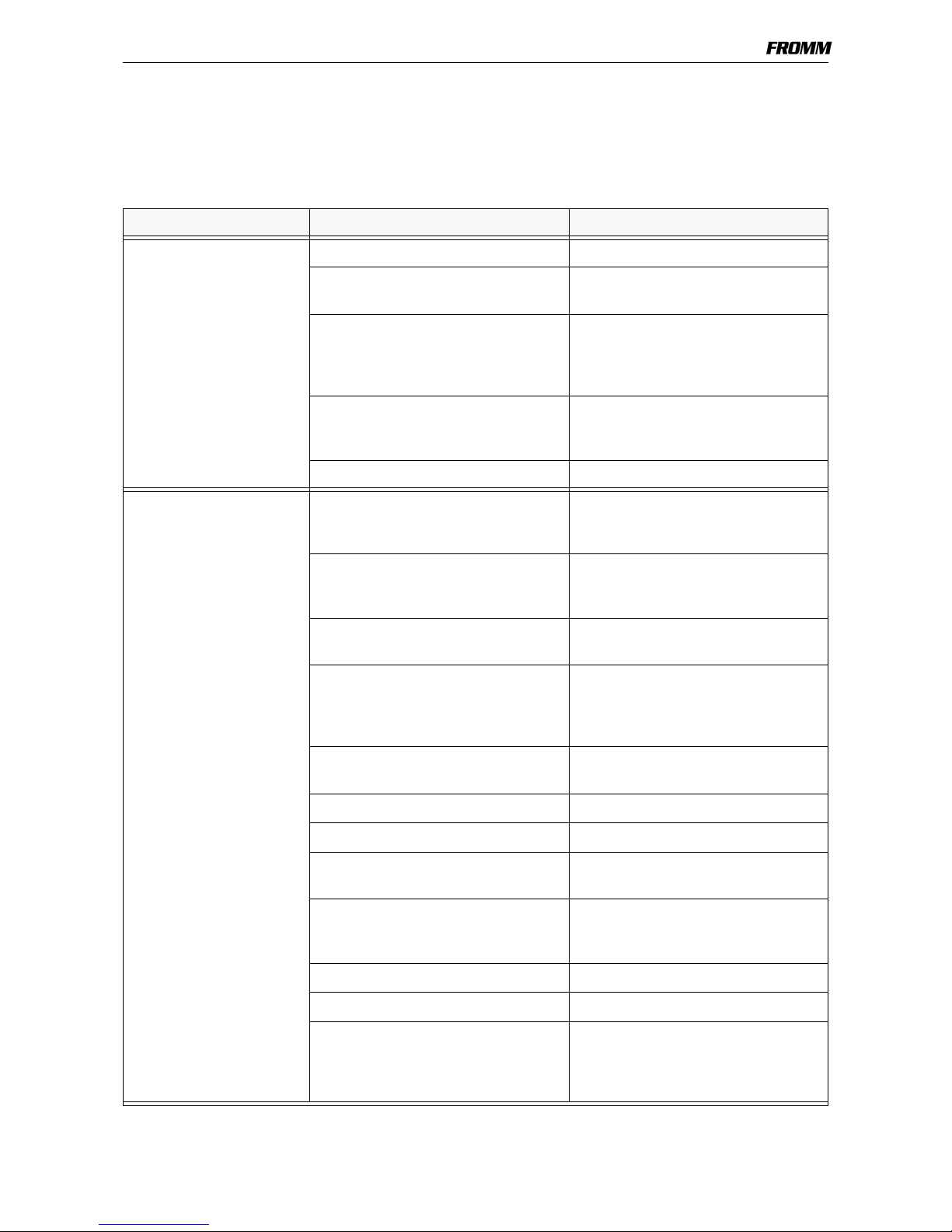

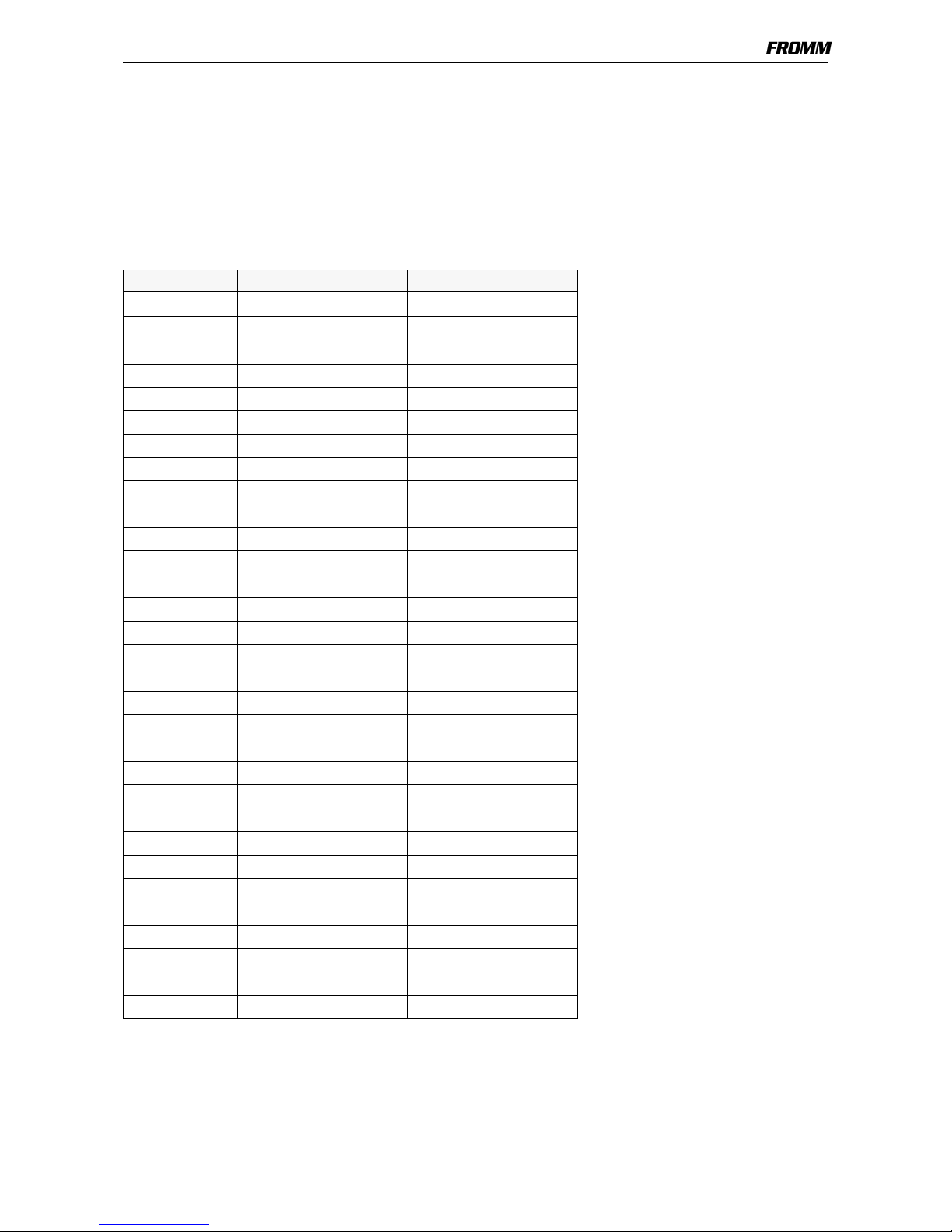

5.3 CONVERSION PARTS P325

By converting to an other tool type the following parts must be changed:

The conversion from tools with the strap thickness 1.06-1.35 and 0.65-1.05 to tools

with the strap thickness 0.40-0.64 is possible. However the number of required parts

and labour cost are making a conversion not economic anymore.

43.0701

12.7 X

0.65-1.05

43.0711

13 X

0.65-1.05

43.0721

16 X

0.65-1.05

43.0722

16 X

1.06-1.35

43.0731

19 X

0.40-0.64

43.0732

19 X

0.65-1.05

43.0733

19 X

1.06-1.35

Spring bolt P32.1403 P32.1403 P32.1403 P32.1910

P32.1403 P32.1403 P32.1910

Tensioning body P35.0143 P35.0143 P35.0143 P35.0144

P35.0143 P35.0143 P35.0144

Gripper P32.1719 P32.1719 P32.1719 P35.3206

P32.1716 P32.1719 P35.3206

Gripper P32.1720 P32.1720 P32.1720 P35.3207

P32.1717 P32.1720 P35.3207

Gripper P32.1721 P32.1721 P32.1721 P35.3208

P32.1718 P32.1721 P35.3208

Holder P32.1229 P32.1229 P32.1229 P35.3209

P32.1229 P32.1229 P35.3209

Holder P32.1228 P32.1228 P32.1228 P35.3210

P32.1228 P32.1228 P35.3210

Strap guide P32.1242 P32.1243 P32.1246 P35.3212

P32.1724 P32.1724 P35.3213

Pressure spring N2.5237 N2.5237 N2.5237 N2.5282

N2.5237 N2.5237 N2.5282

Body P32.0160 P32.0160 P32.0160 P32.0160

P32.0164 P32.0160 P32.0160

Strap stop P32.1736 P32.1734 P32.1722 P32.1722

P32.1723 P32.1723 P32.1723

Tensioning wheel P35.3203 P35.3203 P35.3203 P35.3203

P35.3202 P35.3203 P35.3203

Guide pin P30.1156 P35.3226 P35.3216 P35.3216

P35.3218 P35.3218 P35.3218

Guide pin P30.1156 P35.3226 P35.3217 P35.3217

P35.3219 P35.3219 P35.3219

Cutter P32.1708 P35.3214 P35.3214 P35.3214

P35.3214 P35.3214 P35.3214

Guide case P32.1735 P35.3225 P35.3215 P35.3215

P35.3215 P35.3215 P35.3215

Seesaw lever P32.1248 P35.3220 P35.3220 P35.3220

P35.3220 P35.3220 P35.3220

Seesaw lever P32.1249 P35.3221 P35.3221 P35.3221

P35.3221 P35.3221 P35.3221

Thrust piece P32.1702 P35.3223 P35.3223 P35.3223

P35.3223 P35.3223 P35.3223

Attention!

When converting tools always change the item number on the type label

Replace following parts:

Type label N43.9143

2 x hammer head bolts N2.4902

Enclose the suitable operation manual with the tool after each

conversion

(see paragraph 5.8.1 Ordering manuals)

5-6

5.4 PERIODIC MAINTENANCE AND CONTROL

(Carry out 12- months cycles doing one shift work. Doing more shift work respectively more often.)

5.4.1 Procedure

Before using check tool for following possible faults:

• Visual test of the tool for loose, lost or damaged parts

• Clean all dirty parts of the tool, especially strap abrasion in the tensioning or the welding unit by

using compressed air. (Never use any hard tools like a wire brush or a screw driver for cleaning)

Carry out a test strapping and check following:

• Insertion of the strap

• Strap feed and strap tensioning

• Tensioning force adjustment (see operation manual P325)

• Cutting of the upper strap

• Welding time adjustment (see operation manual P325)

• Seal quality (see operation manual P325)

• Function of the LED - display

Proceed according to paragraph 5.4.2 after a fault appears.

Attention!

Remove battery from tool before each maintenance work.

For exchange of wearing parts see operation Manual P325.

Never use water or solvents for cleaning the tool’s surface.

5-7

5.4.2 Troubleshooting

Ensure before each tool repair that the battery is charged and

the tool’s specific strap is used

SYMPTOM CAUSE REMEDY

Tool doesn’t work at all Battery is empty or defective Charge or replace battery

Contact problems caused by a broken

battery housing N5.4318.

Replace battery housing

Contact problems caused by a

damaged cover P32.2010, insertation

part P32.2011 or damaged motor

housings P32.2040 and P32.2042

Replace cover insertation part or

motor housing

Contact problem of the internal wires Check contacts and fix them if

required, change defective parts or

solder on motor wires

Defective circuit board Replace circuit board

Tool doesn’t tension Tensioning wheel is dirty or worn Clean tensioning wheel or replace it,

don’t use any hard objects for this

(see operation manual P325)

P32.1051 is not meshing with

P32.2044, because spring N2.5822 is

defective or parts are dirty

Replace spring N2.5822,

clean dirty parts

Faulty tensioning wheel or tensioning

wheel is assembled reversed

Correct assembling

(see operation manual P325)

Grippers are dirty, worn or wrongly

assembled

Replace grippers, clean them or

assemble correct,

don’t use any hard objects for this

(see operation manual P325)

Gearing parts from the tensioning gear

are defective

Check tensioning gear and replace

defective parts

Defective motor P32.2065 Replace motor

Defective circuit board Replace circuit board

Micro switch N5.2359 for tensioning

is defective

Replace micro switch

Contact problem of the internal wires Check contacts and fix them if

required, change defective parts or

solder on motor wires

Defective gear bearings Replace bearings

Defective tensioning body Replace tensioning body

Needle free wheeling in gear wheel

P32.0156 or in conical gear wheel

P32.0151 assembled reversed

or defective

Assemble the needle free wheeling

correct or replace it

5-8

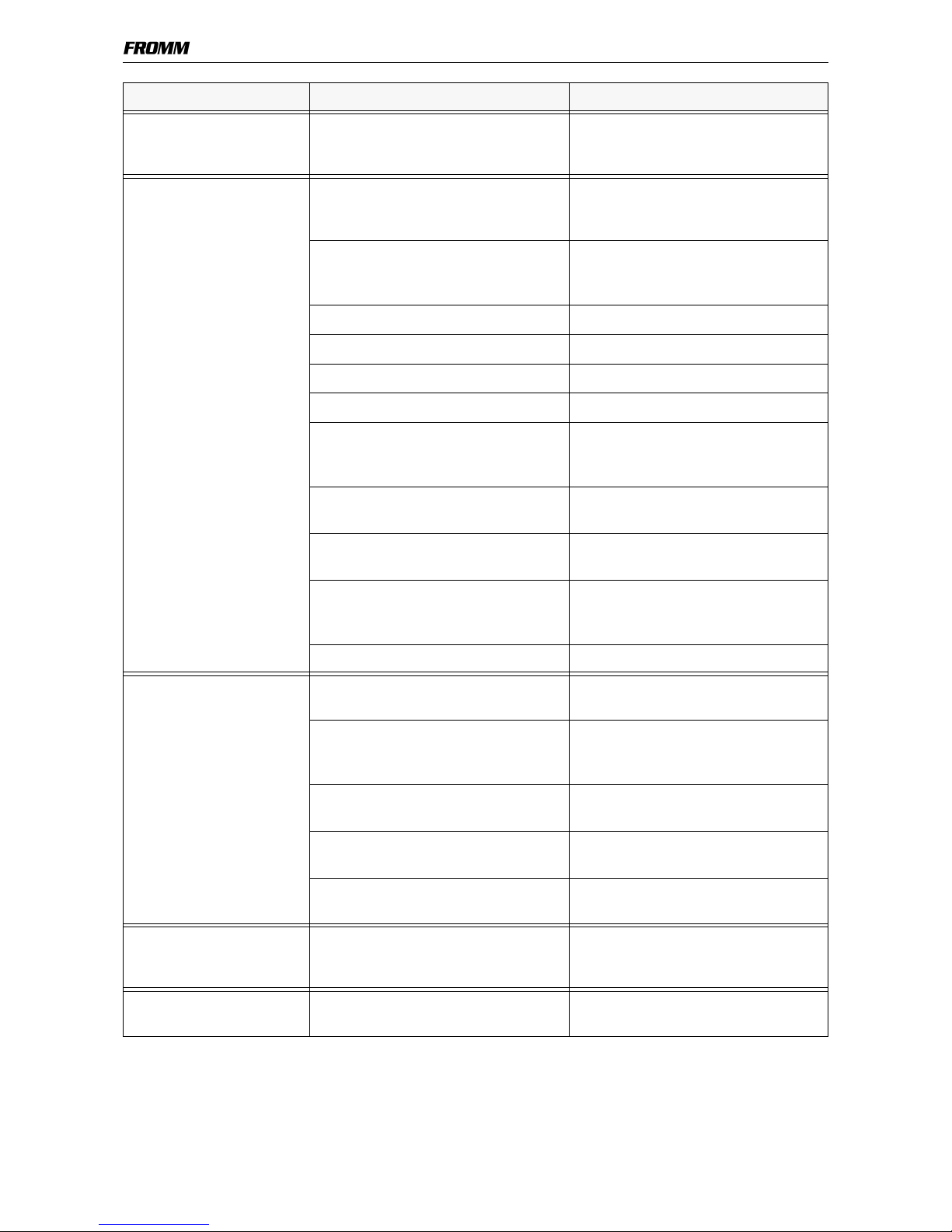

Tensioning wheel turns

back immediately after the

tensioning cycle

Defective needle free wheeling

N3.4509 in P32.0156

Check parts and replace if necessary

Tool doesn’t weld Welding gripper P32.1511 is dirty or

worn

Replace or clean welding gripper, don’t

use any hard objects for this

(see operation manual P325)

Welding stop gripper is dirty or worn Replace or clean welding stop gripper,

don’t use any hard objects for this

(see operation manual P325)

Damaged housing parts Replace housing parts

Defective circuit board Replace circuit board

Defective motor P32.2065 Replace motor

Pressure spring N2.5294 defective Replace pressure spring

Needle free wheeling N3.4509 in

P32.0150 defective or assembled

reversed

Assemble the needle free wheeling

correct or replace it

Gearing parts of the welding gear are

defective

Check welding gear and replace

defective parts

Micro switch N5.2322 for welding

is defective

Replace micro switch

Contact problem of the internal wires Check contacts and fix them if

required, change defective parts or

solder on motor wires

Defective gear bearing Replace bearing

Tool badly cuts the strap or

doesn’t cut at all

Cutter is worn or damaged Replace cutter

(see operation manual P325)

Wrong adjustment of the coupler Check adjustment and readjust if

necessary

(see operation manual P325)

Welding gripper is worn Replace welding gripper

(see operation manual P325)

Welding time too short Change adjustment

(see operation manual P325)

Defective pressure spring

N2.5237/N2.5282

Replace pressure spring

Tool switches off after a few

strappings

(Displaying empty battery)

Battery defective or empty Check the battery and change

defective batteries

Gear noise Tensioning or welding gear is worn Check component parts and replace

defective ones

SYMPTOM CAUSE REMEDY

5-9

5.4.3 Battery test

The battery should be checked while each maintenance by using the battery tester N7.5127.

The use is described in the instruction manual of the battery tester.

• NiCd-Batteries 14,4V / (2,4Ah) must be replaced at a capacity less than 70% (1,7 Ah).

• NiMH-Batteries 14,4V / (3Ah) must be replaced at a capacity less than 70% (2,1Ah).

5.4.4 Checklist

Carry out some test strappings and check following tool components.

• Inserting of the strap

• Insert battery in the tool and check function of the LED-display (see operation manual P325)

• Strap feed and strap tension

• Tension force adjustment (see operation manual P325)

• Cutting of the upper strap

• Welding time adjustment (see operation manual P325)

• Seal quality (see operation manual P325)

• Function of the LED-display (see operation manual P325)

• Correct type label

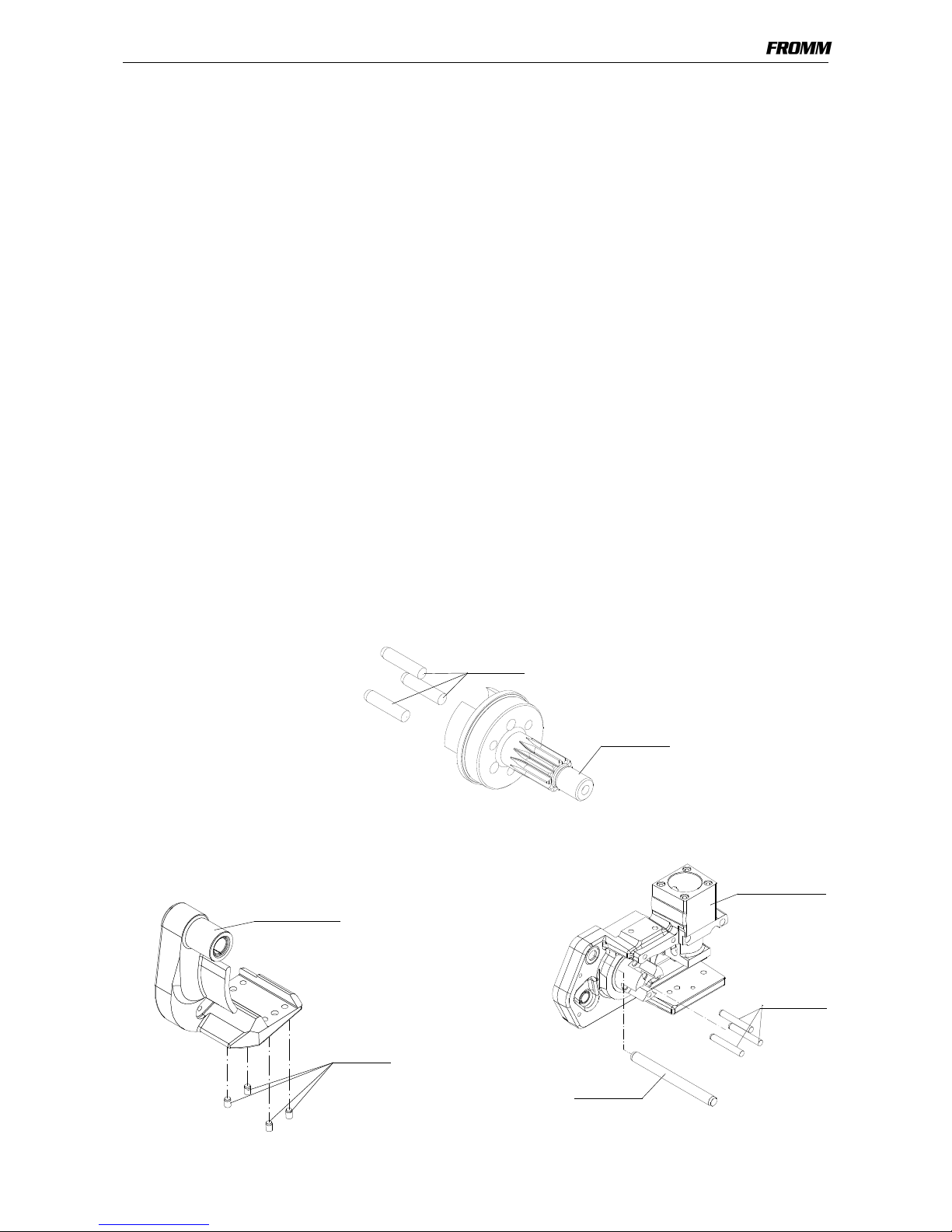

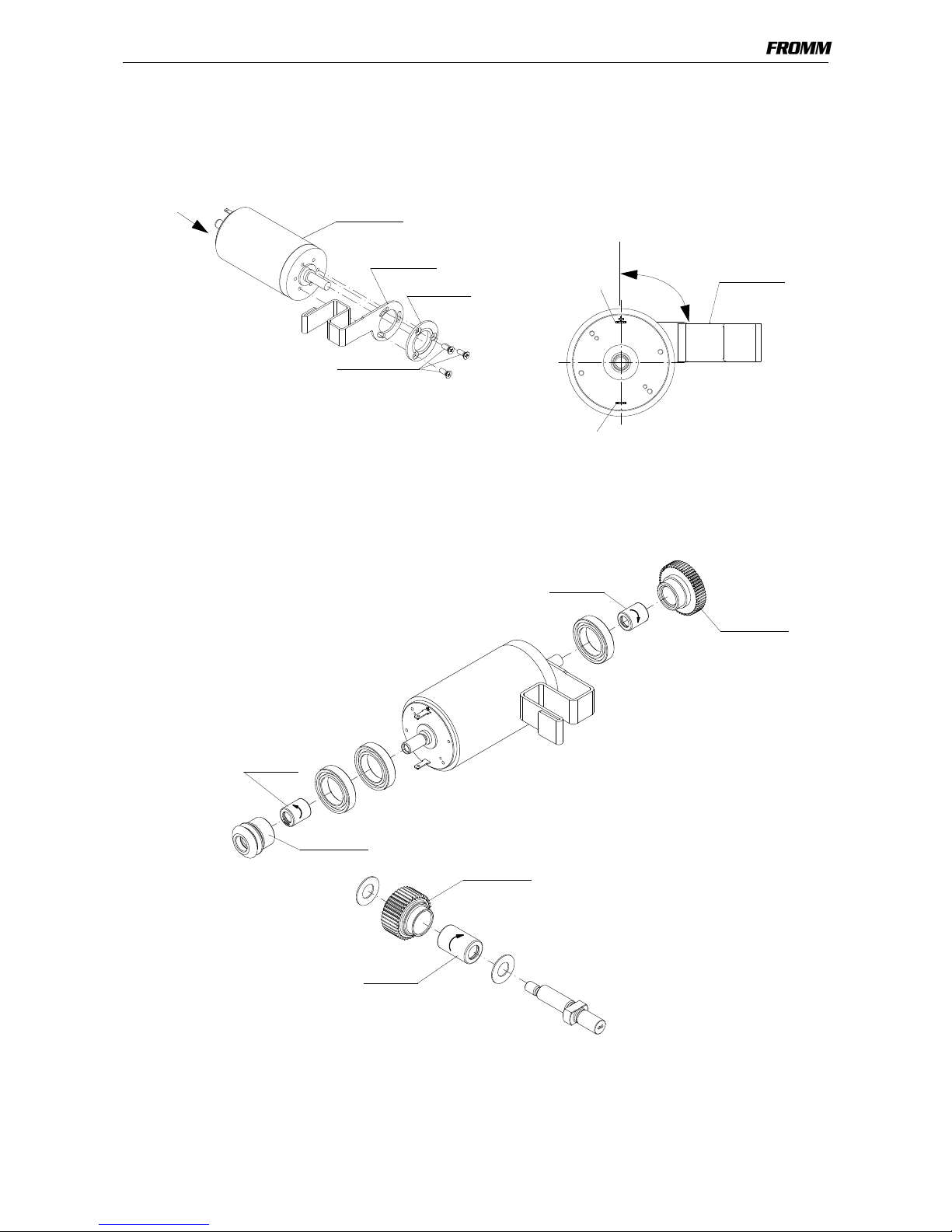

5.4.5 Glueing rules

Following parts have to be glued with LOCTITE 603:

Planet shaft P35.3103

with the parallel pins N2.2145.

Tensioning body P35.3204/05

with the parallel pins N2.2189

Body P32.2003/45 with

swivel shaft P32.2037

and parallel pins N21.2101

N2.2145

P35.3103

N2.2189

P35.3204/05

N21.2101

P32.2037

P32.2003/45

5-10

Additional the screws N1.2112 have to be glued with the

idler step P35.0130 using LOCTITE 222.

Don’t clamp the planet shaft on the pinion while loosening or

tightening the screws N1.2112.

5.4.6 Lubrication rules

All gear parts have to be lubricated with MOLYKOTE BR 2 PLUS grease.

Lubrication interval: While each maintenance or after 12 months at the latest.

All bearing parts of the welding unit have to be cleaned and

lubricated with Klüber Isoflex Alltime SL2 grease while

each maintenance.

Lubrication interval: While each maintenance or after 12

months at the latest.

All other parts have to be greased due to the explosion drawing.

Lubrication interval: While each maintenance

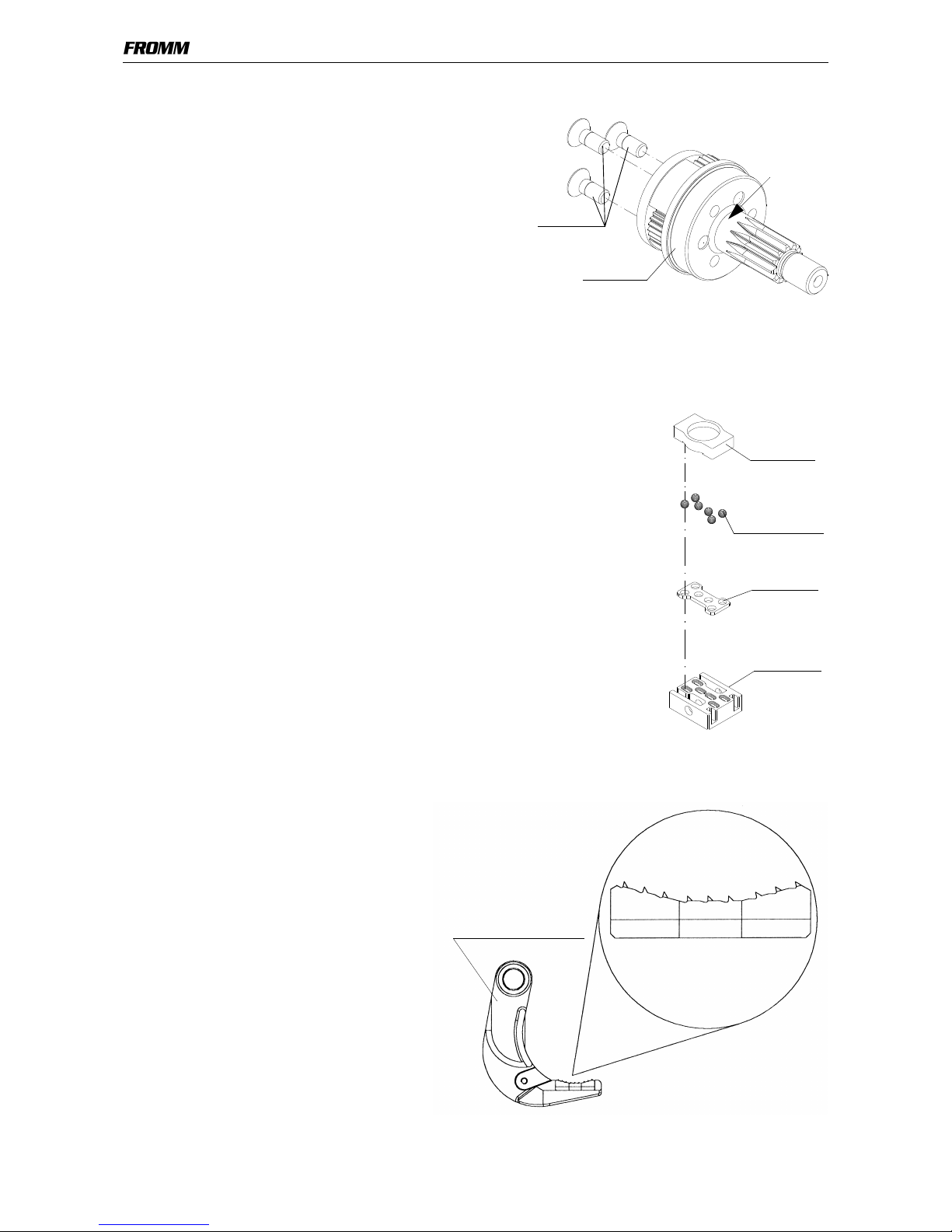

5.4.7 Assembly informations

Pay attention to the direction of the teeths

while assembling the grippers into the

tensioning body P35.3204/P35.3205.

(look at the picture)

P35.0130

N1.2112

Clamp

here

P32.1029

N3.1702 (6X)

P32.1027

P32.1511

Bearing

welding unit

P35.3204/P35.3205

Grippers

5-11

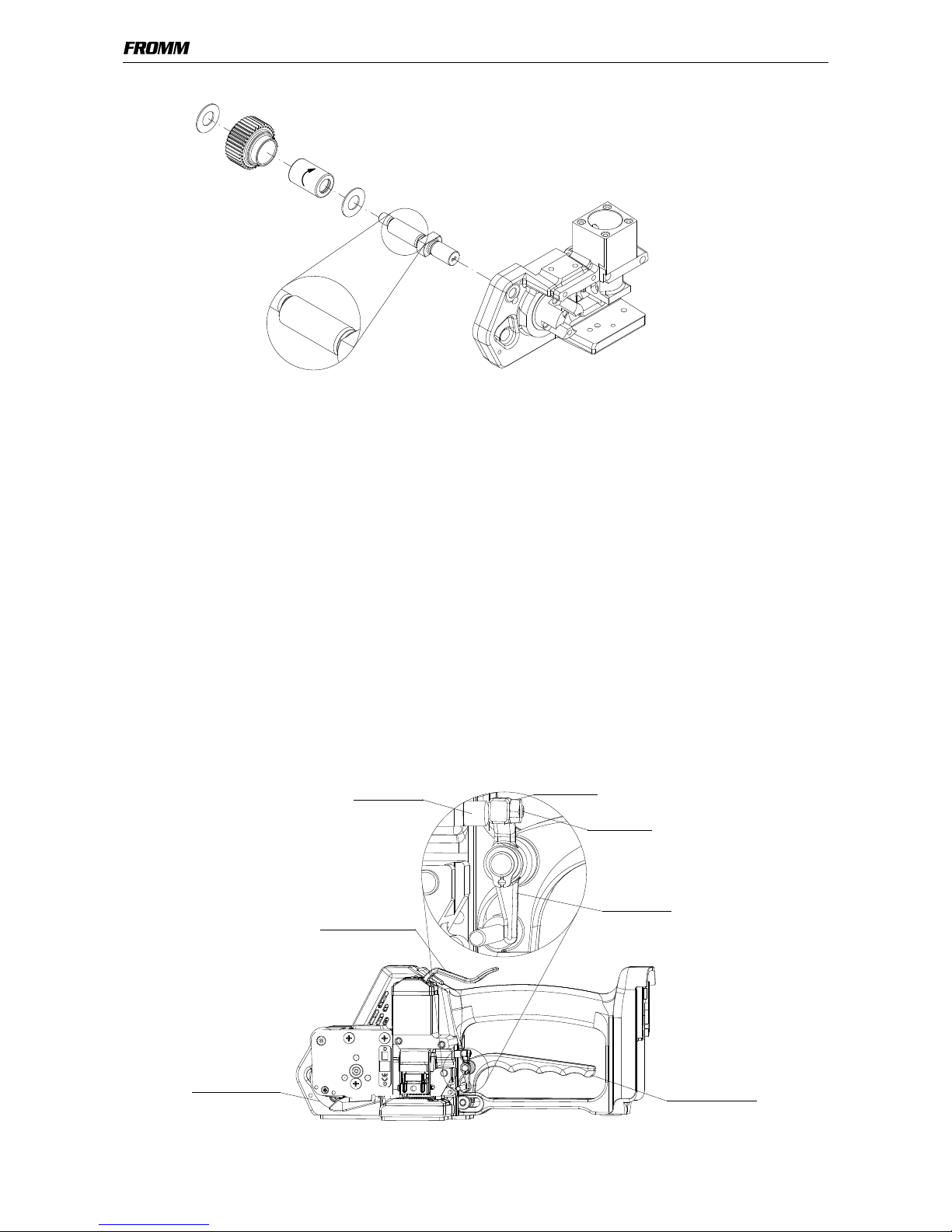

Like imaged the connections of the motor P32.2065 must be adjusted 90° to the sheet P32.2064.

The mounting of the sheet happens by fixation of the disk P32.2063 with the screws N1.2216.

To adjust the sheet the motor could be placed into the housing.

Pay attention to the mounting position of the needle free wheelings N3.4509 and N3.4520.

The rolling direction is stamped in at the front side of the free wheelings.

P32.2065

P32.2064

P32.2063

N1.2216

90°

P32.2064

(+)

(-)

X

view X

N3.4509

P32.2036

P32.2018

N3.4520

N3.4509

P32.2015

5-12

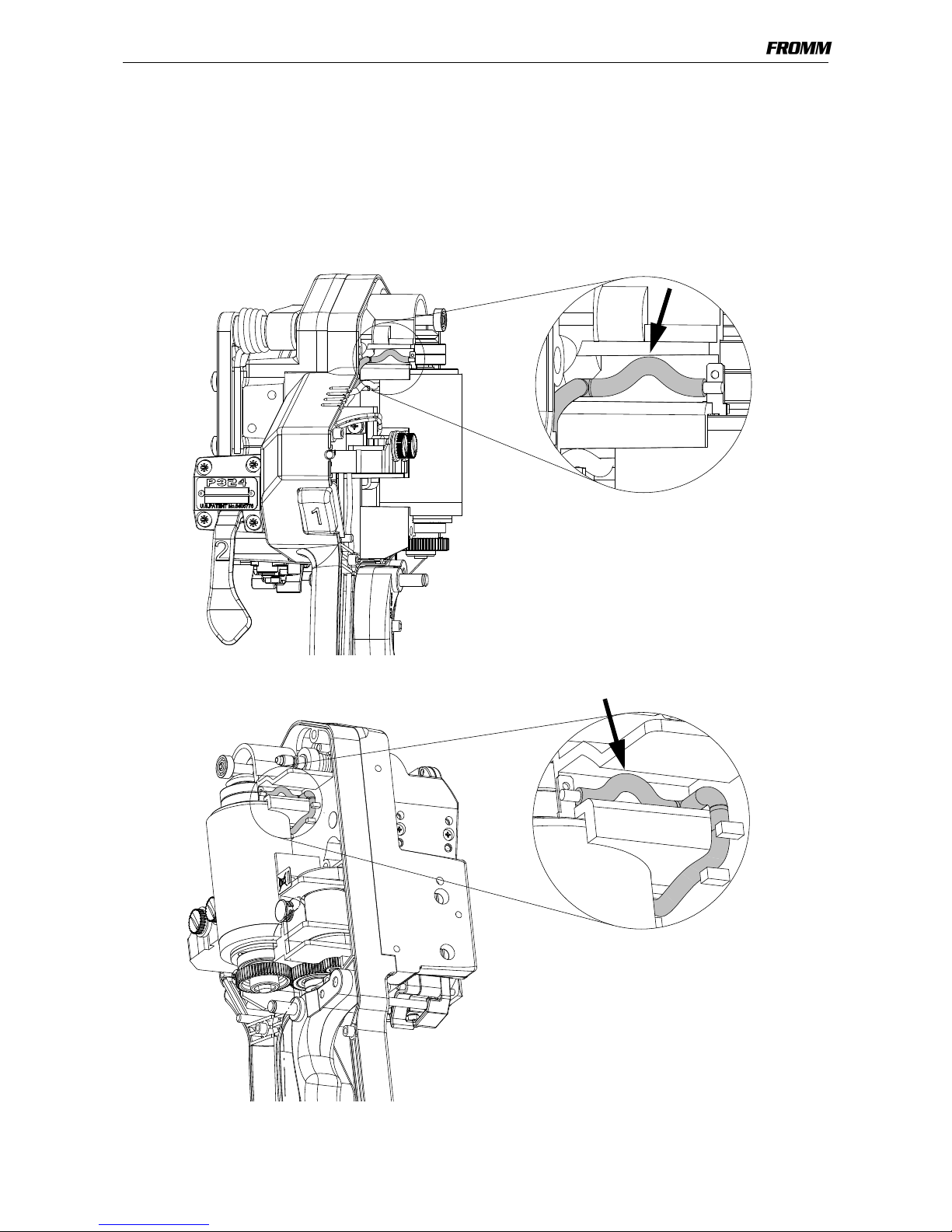

Pay attention to the mounting position of the eccentric (P32.2034).

Adjustment of the lever P32.1414

If the handle lever after welding and cooling of the strap can be pulled up difficult or not at all, the adjustment

of the lever P32.1414 must be checked.

It can be done as follows:

- Loose lock nut N1.5120

- Screw in the socket set screw N1.3150, until it touches the coupler P32.1410

- Tighten lock nut N1.5120

Test without battery and strap:

- Press welding lever down until it locks

- Pull handle lever up

The welding lever must move up before the tension body swings forward.

Swings the tension body forward first, the strap blocks the welding jaw and the handle lever can be pulled up

difficult or not at all.

Afterwards do a test strapping and readjust if necessary.

(P325) Eccentric down

Welding lever

Tension body

P32.1410

N1.3150

N1.5120

P32.1414

Handle lever

5-13

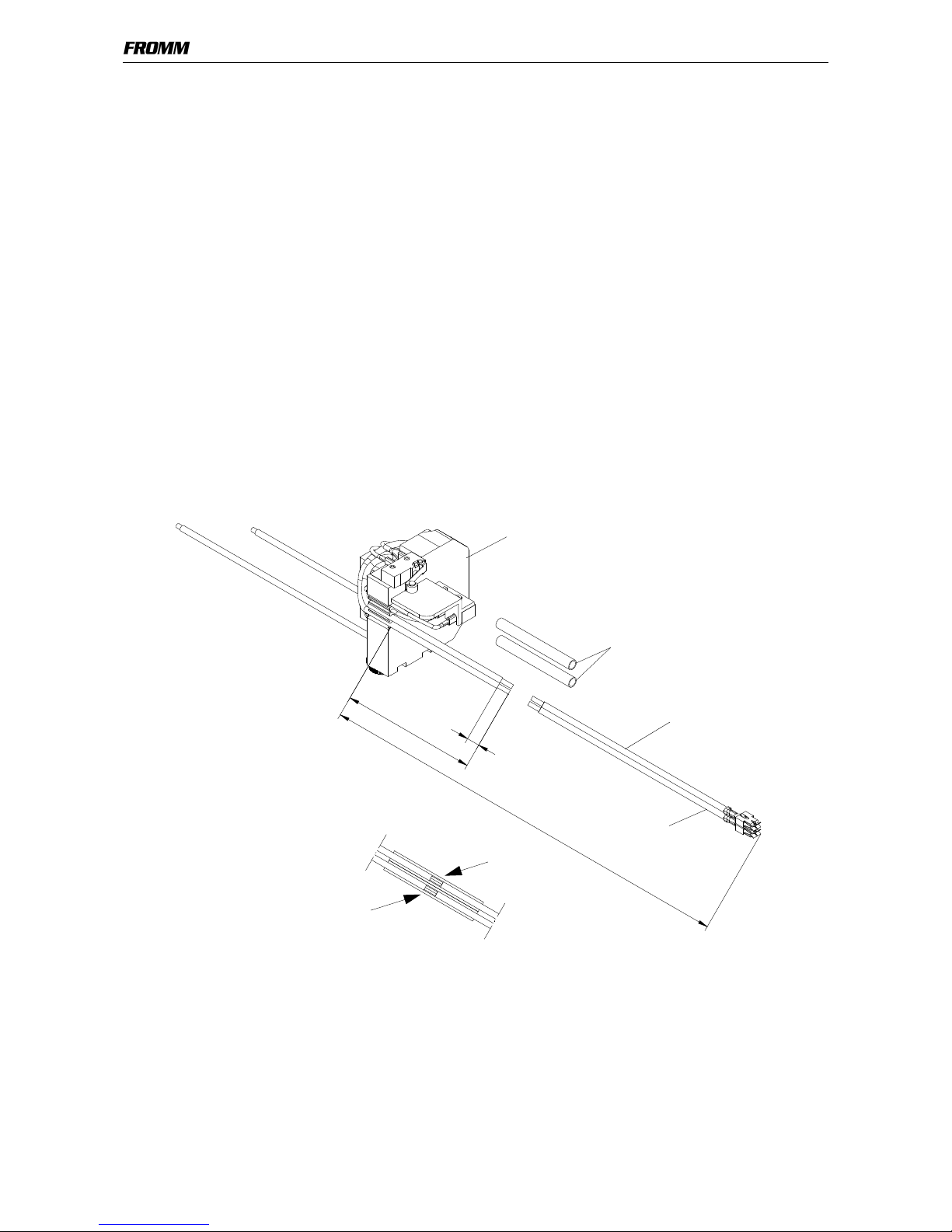

Connection of the electronic to the motor

In order to prevent a cracking of the terminals on the motor, the connection cables of the electronic are laid

with a light bend before soldered to the motor.

This method is used for all battery powered plastic strapping tools.

5-14

5.4.8 Repair kit for electronic P32.2043

The repair kit can be ordered with the article number P32.2075.

With the repair kit defective plugs on the connection cables of the electronic can be changed.

Procedure:

• Cut the cables to a length of 126 mm (see drawing).

• Strip wire ends 6mm,

• tin plate wire ends,

• push insulating hose N5.3420 above the cables.

• Overlap the cables and solder them together,

• push the insulating hoses over the solder joint X.

The cable length after soldering must be between 240 and 248mm (see drawing).

red

white

black

red

6

1

2

6

2

4

0

+

8

P32.2043

N5.3420

P32.2071

P32.2073

X

X

5-15

5.5 RECOMMENDED SPARE PARTS

Following spare parts are recommended for stock keeping:

Besides schould be stocked the wearing parts of the different Types.

Stock only parts from tools that are in sale.

Item-No. Description Pieces per tool

N1.1305 Screw 2

N1.1904 Screw 4

N1.1909 Flat head screw 2

N1.1925 Screw 1

N1.1927 Flat head screw 1

N1.1929 Screw 1

N1.1934 Flat head screw 4

N1.6503 Safety washer 5

N1.6504 Safety washer 13

N1.6505 Safety washer 3

N1.7206 PT-screw 1

N1.7211 PT-screw 7

N2.1118 Security ring 1

N2.1121 Security ring 5

N2.1606 Spring ring 1

N2.1805 Tensioning ring 1

N3.1702 Ball 6

N3.4509 Free wheeling 2

N3.4520 Free wheeling 1

N5.2322 Micro switch 1

N5.2359 Micro switch 1

N5.4318 Housing 1

P32.0160/64 Body 1

P32.2010 Cover 1

P32.2011 Insertation part 1

P32.2028 Lever 1

P32.2040 Motor housing 1

P32.2042 Motor housing 1

P32.2043 Circuit board 1

P32.2065 Electric motor 1

P35.3211 End cover 1

5-16

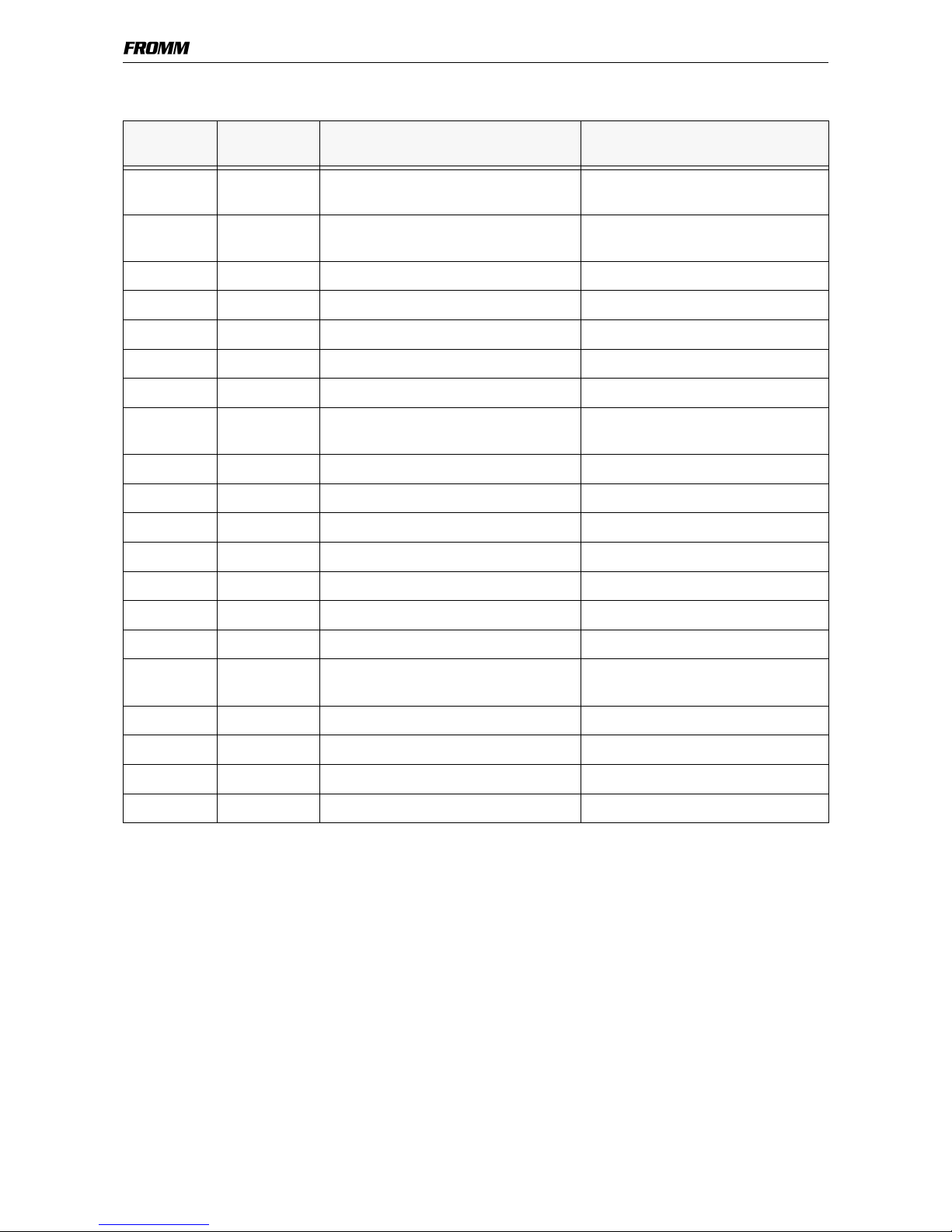

5.6 ACCESSORY TOOLS

* a) These tools are also included in the P320 tool set.

b) These tools are also included in the P321 tool set.

c) These tools are also included in the P322 tool set.

d) These tools are also included in the P323 tool set.

e) These tools are also included in the P355 tool set.

f) These tools are also included in the P356 tool set.

g) These tools are also included in the P324 tool set.

Item

number

Description Application

N71.3235 *a,b,c,d,e,f,g Press in and press out arbor N3.4509/P32.2036;

N3.4509/P32.2015

N71.3237 *a,b,c,d,e,f,g Press in and press out arbor N3.1159/P32.2016;

N3.2356/P35.3211

N71.3239 *a,b,c,d,e,f,g Press in arbor N3.2347/P32.1510

N71.3240 *a,b,c,d,e,f,g Press out arbor N3.2347/P32.1510

N71.3241 *a,b,c,d,e,f,g Press in and press out pressure pad N3.2347/P32.1510

N71.3243 *a,b,c,d,e,f,g Press in arbor N3.1134, P32.1023/P32.1022

N71.3244 *a,b,c,d,e,f,g Press out arbor N3.1134, P32.1023/P32.1022

N71.3245 *a,b,c,d,e,f,g Pressure pad N3.1134, P32.1023/P32.1022;

N3.2356/P35.3211

N71.3247 *a,d,e,f,g Press in and press out pressure pad N3.1157/P35.3103

N71.3248 *a,b,c,d,e,f,g Press in arbor N3.3150/P35.3204/05

N71.3250 *a,c,e,f,g Press in and press out arbor N3.3172/P32.2003/45

N71.3264 *b,d,f Press in and press out arbor N3.1157/P35.3103

N71.3266 *b,d,f Press out arbor N3.2356/P35.3211

N71.3267 *b,d,f Press out arbor N3.3150/P35.3204/05

N71.3268 *b,d,f Press out pressure pad N3.3150/P35.3204/05

N71.3282 g Press in and press out pressure pad N3.4509/P32.2015; N3.4520/

P32.2018; N3.4509/P32.2036

N71.3283 g Press in and press out pressure pad N3.1159/P32.2016

N71.3284 g Press out arbor N3.4520/P32.2018

N71.3285 g Press out pressure pad N3.1137/P32.2015

N71.3286 g Press out arbor N3.1137/P32.2015

Loading...

Loading...