Fromm P323 Operation Manual

OPERATION MANUAL / SPARE PARTS LIST

For Parts & Service 1-877-862-6699

BATTERY - POWERED

PLASTIC STRAPPING TOOL

MODEL P323

43.3132.01

43313201.en/MAS/© 08.05

CE Declaration of conformity

We declare that the machine P323

is in conformity with the following standard or

standardised documents:

98/37/EEC

FROMM Holding AG

Hinterbergstrasse 26

CH - 6330 Cham

12.08 2005

R.Fromm

Director

INDEX PAGE

For Parts & Service 1-877-862-6699

1 SAFETY INSTRUCTIONS 3

2 TECHNICAL DATA 4

3 ACCESSORIES 5

3.1 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Battery - chargers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Wearing plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

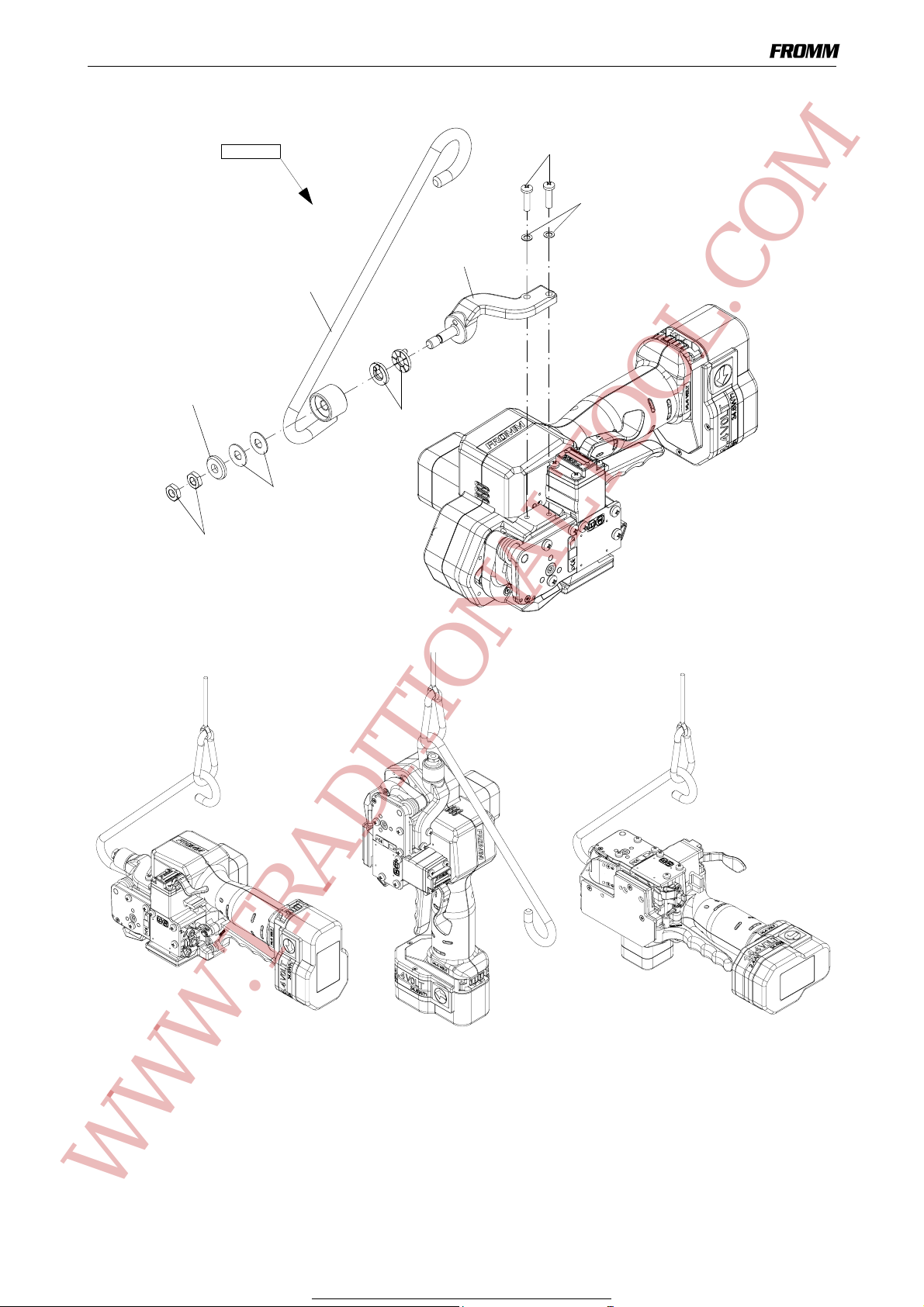

3.4 Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.5 Turning button kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 OPERATING ELEMENTS 8

5 OPERATION 8

5.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2.1 Preselecting of strap tension and tensioning speed . . . . . . . . . . . . . . . . . . . . . 9

5.2.2 Adjusting the welding time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3 Feeding the strap around the package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.4 Inserting the strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.5 Tensioning the strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.6 Sealing of the joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.7 Removing the tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.8 Seal - Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 CHART OF TYPES 12

7 ELECTRIC SCHEMATIC 12

8 EXCHANGE OF WEARING PARTS 13

8.1 Exchange of tensioning wheel and grippers . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.2 Exchange of cutter, welding stop gripper and welding gripper . . . . . . . . . . . . 14

8.3 Adjustment of the coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9 SERVICE 15

10 CLEANING 15

11 WARRANTY CONDITIONS AND LIABILITY 16

12 APPROPRIATE USE 16

13 SPARE PARTS LIST 43.3132.01 21

WWW.TRADITIONALTOOL.COM

2

1 SAFETY INSTRUCTIONS

For Parts & Service 1-877-862-6699

Read these instructions carefully. Failure to follow these instructions can result in severe personal injury.

Operation with battery

Environment protection:

• Do not dispose of used batteries in the household refuse,

water or by burning them.

FROMM distributors offer an environment friendly battery

disposal service.

Danger of shortcircuit:

• Do not store batteries together with metal objects.

• Do not open batteries and store them only in dry and frostproof rooms. The maximum ambient temperature is 50°C.

Keep dry at all times.

• Never charge a damaged battery. Replace by a new one

immediately.

Eye injury hazard

Failure to wear safety glasses with side shields can result in

severe eye injury or blindness. Always wear safety glasses with

side shields which conform to ANSI Standard Z87.1.

Strap warnings

Never use strap as a means of pulling or lifting loads. Failure to

follow these warnings can result in severe personal injury.

Strap breakage hazard

Improper operation of the tool, excessive tensioning, using strap

not recommended for this tool or sharp corners on the load can

result in a sudden loss of strap tension or in strap breakage during

tensioning, which could result in the following:

• A sudden loss of balance causing you to fall.

• Both tool and strap flying violently towards your face.

Note as follows:

• If the load corners are sharp, use edge protectors.

• Place the strap correctly around a properly positioned

load.

• Positioning yourself in-line with the strap, during

tensioning and sealing, can result in severe personal

injury from flying strap or tool. When tensioning or sealing,

position yourself to one side of the strap and keep all

bystanders away.

• Use the correct strap quality, strap width, strap gauge and

strap tensile strength recommended in this manual for

your tool. Using strap not recommended for this tool can

result in strap breakage during tensioning.

Cutting tensioned strap

When cutting strapping, use the proper strapping cutter and keep

other personnel and yourself at a safe distance from the strap.

Always stand to side of the strap, away from the direction the

Operation

Tool must not be used by persons not properly trained in their use.

Before tensioning strap, read and understand the tool operating

instructions. Failure to follow the operating instructions or improper

load positioning could result in strap breakage.

Become familiar with your tool and keep fingers away from areas

that can pinch or cut.

Joints

You are fully responsible to review the joints made by your tool.

Become familiar with the seal control and seal adjustment

described in this operation manual. Misformed joints may not

secure the load and could cause serious injury. Never handle or

ship any load with improperly formed joints.

loosened strap end will fly. Use only cutters designed for strap and

never hammers, pliers, hacksaws, axes, etc.

Fall hazard

Keep your working area tidy. Untidiness of your working area may

cause a risk of injury. Maintaining improper footing and/or balance

when operating the tool can cause you to fall. Before tensioning

and especially in elevated areas, always establish good balance.

Both feet should be securely placed on a flat, solid surface,

especially when working in elevated areas. Do not use the tool

when you are in an awkward position.

Pay attention to the rules and regulations for preventions of

accident which are valid for the work place.

Tool hazards

Dispensing strap

Only dispense strap from a dispenser specifically designed for

strap.

Tuck strap end back into dispenser when not in use.

A well maintained tool is a safe tool!

Check tool regularly for broken or worn parts. Do not operate a

tool with broken or worn parts.

Never modify any tool. Modification can result in severe bodily

injury.

WWW.TRADITIONALTOOL.COM

P323mane.fm

3

2 TECHNICAL DATA

For Parts & Service 1-877-862-6699

Description of the tool

The tool model P323 has been designed to strap packages with plastic strapping. The plastic strapping is fed

around the package manually or in combination with a strap feeder. The straps are inserted in the tool,

automatically tensioned, sealed by friction welding and separated.

Tool size with battery

Length: 335 mm / 13.2"

Width: 165 mm / 6.5"

Height: 135 mm / 5.3"

Weight: 4.5 kg / 9.9 lbs

Sound information

The A-weighted equivalent continuous sound level at the work place of the machine operator is

typical 82 dB (A).

This value was determined according to DIN 45 635 T3 (11.85).

Vibration information

The weighted effective value of the acceleration typically amounts to less than 2,5m/s2.

This value was determined according to DIN EN 28 662 T1 (01.93).

Strap material

Strap qualities: PET (Polyester) and PP (Polypropylene) plain or embossed.

Use only plastic straps recommended by your sales shop (name and address

on the rear of the operation manual).

Strap dimensions: 12.7 - 19.0 mm x 0.4 - 1.35 mm (see chart of types).

Use only plastic straps with the correct strap dimensions for your tool.

Strap tension

Tensioning force: Adjustable from 650 - max. 3000 N / 146.25 - max. 675 lbs.

The maximum value depends on the strap quality.

Tensioning speed: approx. 152 - 225 mm/s / 6 - 8.9 inch/sec.

Joint strength: approx. 75% of the tensile strength of the plastic strap

(depending on the strap quality).

Working temperature

The ambient temperature should be between 5° and 45° C (41° and 113°F).

The best performance is achieved between 15° and 20°C (59° and 68°F).

WWW.TRADITIONALTOOL.COM

4

P323mane.fm

3 ACCESSORIES

For Parts & Service 1-877-862-6699

Use only parts and accessories mentioned in the operating instruction. Using other

parts or accessories can cause injuries to you and other persons.

3.1 Battery

Since the tool can be operated with NiCd or NiMH batteries, the battery is not

automatically supplied with the tool. The battery has to be ordered separately under

the following item numbers.

Item-No. Battery Voltage Capacity

N5.4309 NiCd 14,4 VDC 2,4Ah

N5.4316 NiMH 14,4 VDC 2,7Ah

3.2 Battery - chargers

The charge must be ordered separately according to below shown table.

Standard charger

Item-No. Voltage / frequency Admitted for country

N5.4414 220 - 240V / 50 - 60Hz A, B, BG, BIH, BOL, BR, BY, CH, CL, CZ, D, DK, DZ, E, EAS, EST, ET, F,

FIN, GE, GR, H, HK, HR, I, IL, IND, IR, IRQ, IS, JOR, KSA, KWT, L, LAR, LT,

LV, MA, MC, MK, MOC, N, NL, P, PK, PE, PL, PRC, PY, RA, RCH, RI, RL,

RO, ROK, ROU, RP, RUS, S, SK, SLO, SYR, THA, TN, TR, UA, UAE, YU,

YV, (Z), (ZA), (ZW)

N5.4416 220 - 240V / 50 - 60Hz BRN, BRU, CY, EAK, EAT, GB, IRL, M, MAL, OM, SGP, Y

N5.4418 220 - 240V / 50 - 60Hz AUS, NZ

N5.4420 220V / 60Hz ROK

Turbo charger

Item-No. Voltage / frequency Admitted for country

N5.4422 220 - 240V / 50 - 60Hz A, B, BG, BIH, BOL, BR, BY, CH, CL, CZ, D, DK, DZ, E, EAS, EST, ET, F,

FIN, GE, GR, H, HK, HR, I, IL, IND, IR, IRQ, IS, JOR, KSA, KWT, L, LAR, LT,

LV, MA, MC, MK, MOC, N, NL, P, PK, PE, PL, PRC, PY, RA, RCH, RI, RL,

RO, ROK, ROU, RP, RUS, S, SK, SLO, SYR, THA, TN, TR, UA, UAE, YU,

YV, (Z), (ZA), (ZW)

N5.4424 120V / 60Hz BR, C, CDN, CO, CR, DOM, EC, GCA, J, JA, KSA, LB, MEX, NIC, PA,

Puerto Rico, RC, RP, USA, YV

N5.4426 110V / 50 - 60Hz GB

N5.4428 220 - 240V / 50 - 60Hz BRN, BRU, CY, EAK, EAT, GB, IRL, M, MAL, OM, SGP, Y

N5.4430 220 - 240V / 50 - 60Hz AUS, NZ

Charging times

NiCd-Battery 14,4 VDC, 2,4Ah approx. 80 min. approx. 20 min.

NiMH-Battery 14,4 VDC, 2,7Ah approx. 85 min. approx. 25 min.

WWW.TRADITIONALTOOL.COM

P323mane.fm

Standard charger Turbo charger

5

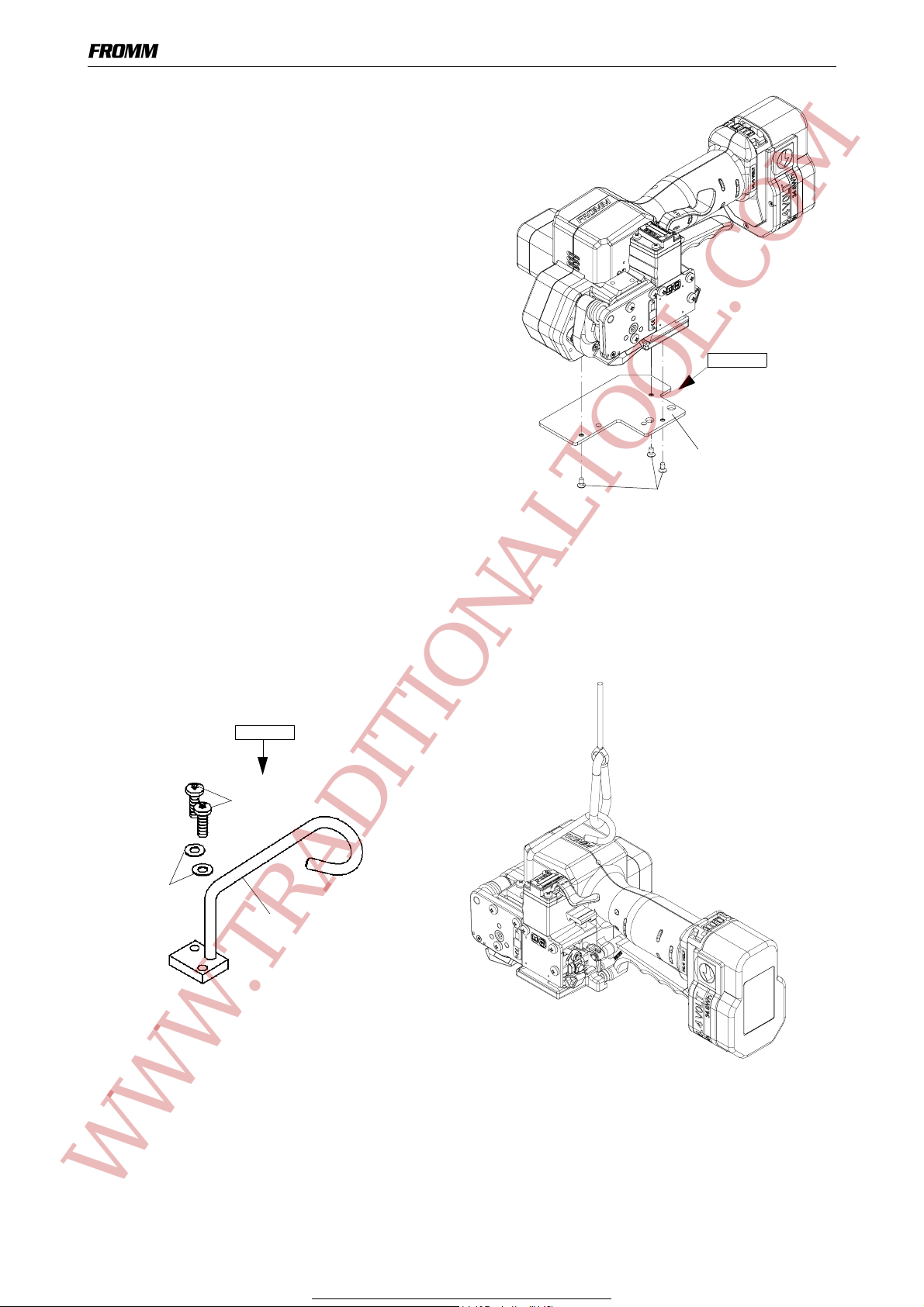

3.3 Wearing plate

For Parts & Service 1-877-862-6699

As an option, tool can be equipped with a wearing plate to

protect base from excessive wear on abrasive package

surfaces (like bricks, concrete blocks etc.).

The complete wearing plate can be ordered together with

the fastening screws under item number P32.0127.

P32.0127

P32.1801

N1.2221

3.4 Suspension

When working stationary the P323 can be suspended at a spring loaded balancer by using a suspension

bracket.

For working in normal position a stiff suspension bracket with screws and washers can be ordered under item

number P32.0112.

P32.0112

N1.1912

N1.6503

P32.1303

WWW.TRADITIONALTOOL.COM

6

P323mane.fm

For working in alternating positions a turn able suspension bracket with screws and washers can be ordered

For Parts & Service 1-877-862-6699

under item number P32.0137.

P32.0137

P35.2073 ➂

N1.5105

N1.1904

N1.6503

➂ P32.1307

P32.1310

P35.2069 ➂

N2.5623 ➂

➂ ESSO Beacon 2

3.5 Turning button kit

For a remaining adjustment of tension force and welding time.

After exchanging of the turning buttons the adjustment can only be changed with the allen key (2mm) that

comes with the kit. The kit can be ordered under the item number P32.1129.

WWW.TRADITIONALTOOL.COM

P323mane.fm

7

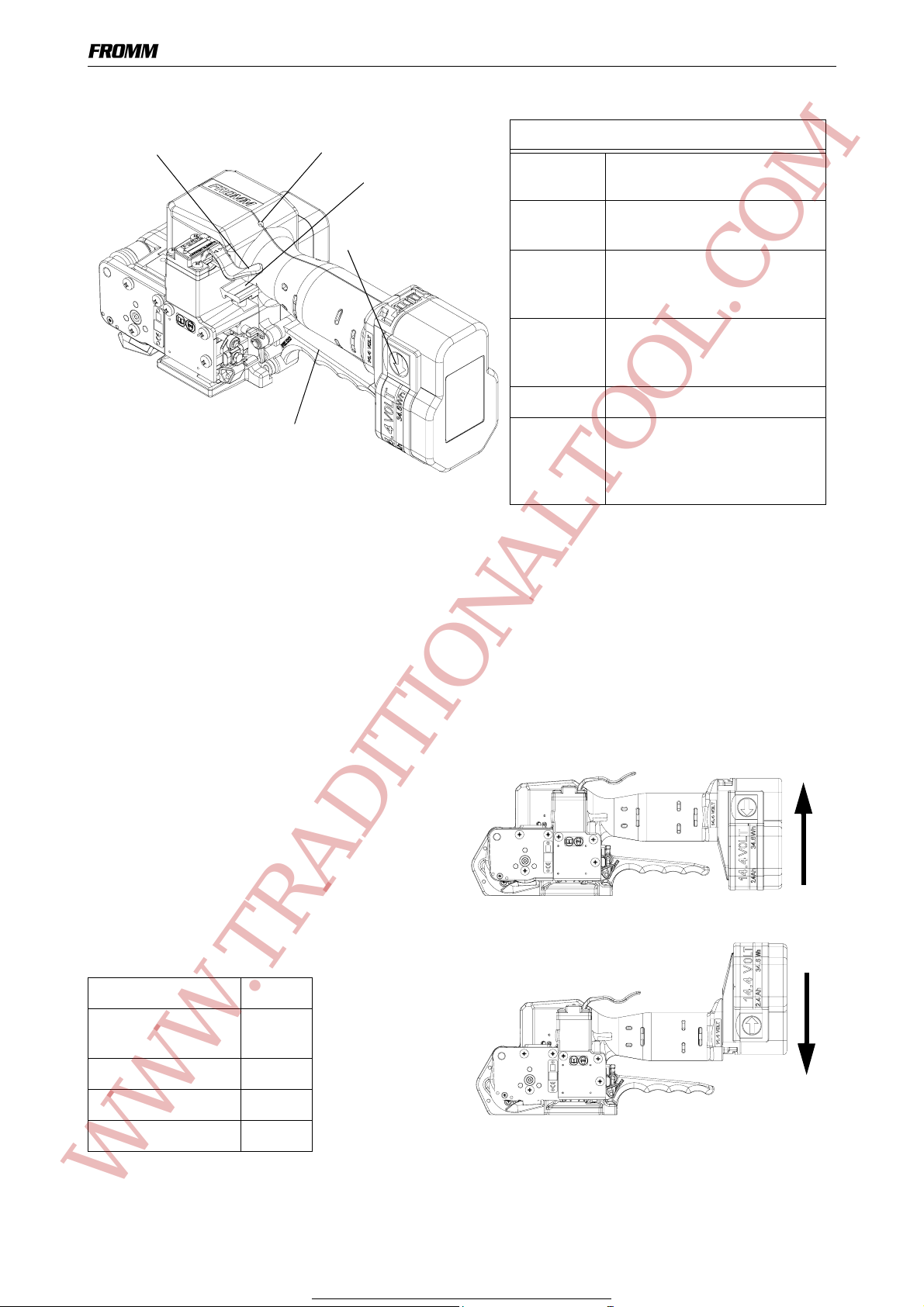

4 OPERATING ELEMENTS

For Parts & Service 1-877-862-6699

Lever

Handle lever

5 OPERATION

LED

Switch rocker

Unlatching

push button

LED - Indication

Green During tensioning the LED

lights green.

Green During welding the LED lights

green.

Yellow Cooling time is running, the

tool must not be removed from

the strap.

Green Cooling time is finished, the

tool can be removed from the

strap.

Red Charge the battery.

Red blinking The control board is

overheated,

the tool has to cool down,

the switches are locked.

5.1 Installation

Do not expose the tool to rain!

For safety reasons the battery is delivered uncharged.

Charge the battery before working. See separate operating instruction of the battery charger.

Inserting the battery

Insert the battery from bottom to top into the tool

both unlatching push buttons latch.

Depending on the application, the battery can also

be inserted from top to bottom in order achieve a

better handling.

When inserting the battery the status of the charge

is displayed shortly.

Displaying of the status of the battery charge by LED

Green blinking full

Green yellow

blinking

3/4 full

Yellow blinking 1/2 full

Yellow - red blinking 1/4 full

Red blinking empty

WWW.TRADITIONALTOOL.COM

8

P323mane.fm

Loading...

Loading...