Fromm FS390 Series Original Manual

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

1

Semi-Automatic

WRAPPING MACHINE

FS390 Series

FS3.2780 V01

ORIGINAL MANUAL EN03

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc / ORIGINAL MANUAL © 04/18

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

2

INDEX

1

Preface

2

Technical files and Manufacturers

3

EC Declaration of Conformity

4

Identification plate

5

Machine data

6

General information

7

Machine dimensions

8

Safety instructions

9

Safety devices

10

Warnings

11

Technical data

12

Meaning of pictograms

13

Analysis of Residual risks

14

Main components

15

Handling and Transport

16

Installation Instructions

17

Assembly sequence and film feed / Cleaning the rubber rollers

18

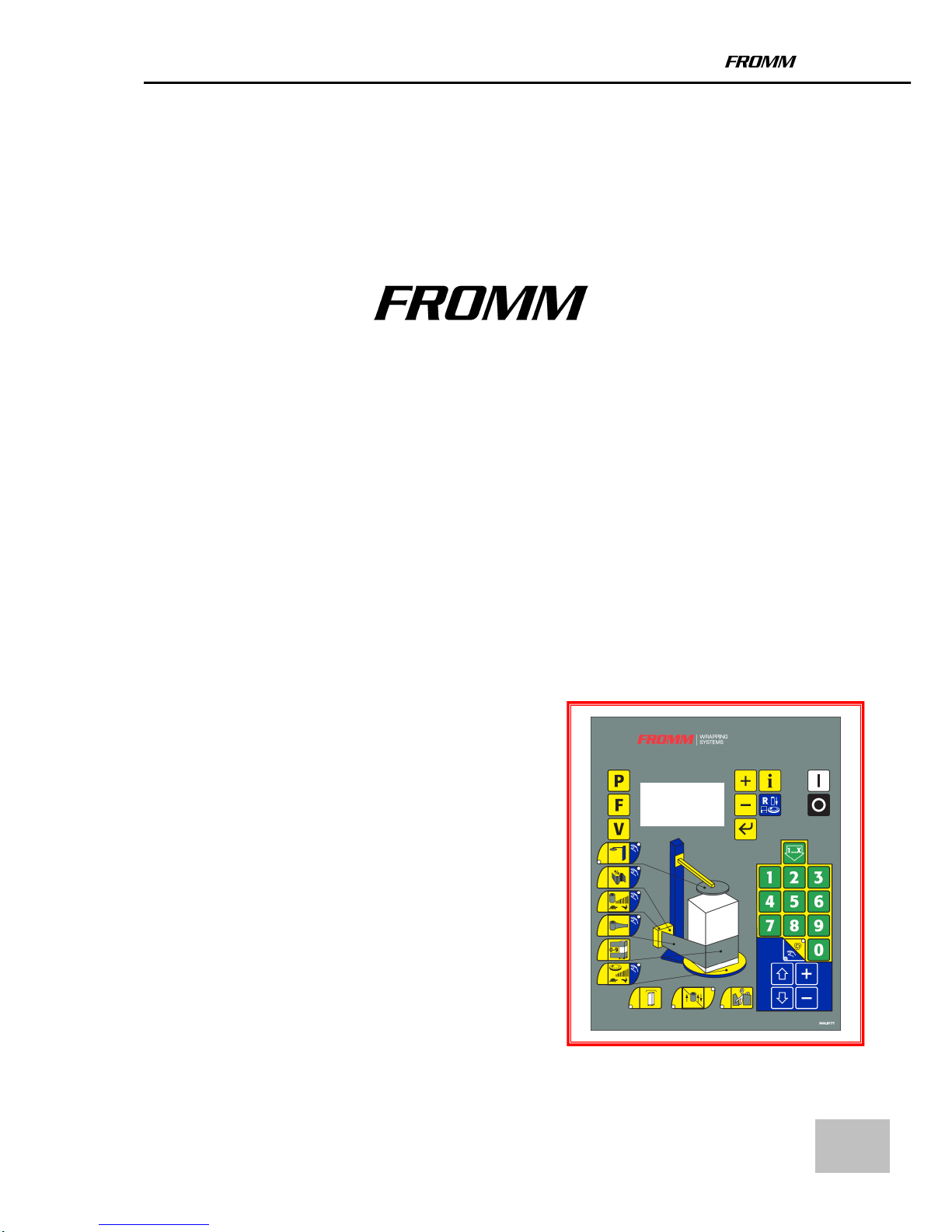

Control panel and general information

19

Basic operating instructions

20

Machine decommissioning

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

3

BE Opgelet!

Leest U in elk geval de gebruiksaanwijzing, vooraleer de machine wordt opgesteld, geïnstalleerd en in

gebruik genomen wordt. Daardoor zorgt U voor Uw eigen veiligheid en vermijdt U schade aan Uw

machine.

DE Achtung!

Lesen Sie unbedingt die Gebrauchsanweisung vor Aufstellung-Installation-Inbetriebnahme.

Dadurch schützen Sie sich und vermeiden Schäden an Ihrem Apparat.

DK OBS!

De bør absolut læse bruganvisningen, inden maskinen opstilles, installeres og tages i brug.

Derved beskytter De Dem selv og undgår skader på maskinen.

ES Atención!

Resulta imprescindible leer las Instrucciones de manejo antes de proceder al Emplazamiento/

Instalacion/Puesta en servicio del aparato, con objeto de protegerse a si mismo y evitar el deterioro de la

máquina debido a un manejo incorrecto.

FR Attention!

Lisez impérativement le mode d'emploi avant l'installation/la mise en service.

Vous vous protègerez ainsi et éviterez des détériorations sur votre appareil.

GB Important!

Read the operating instructions carefully before installation and before using this machine for the first

time.

You will avoid the risk of causing harm to yourself or to your machine in this way.

GR Πρо σоχ ή!

Πρί ν τ ην εγκ ατ άστ αση , σ ύν δεο η κ αί αρχ ικ ή λ ειτ ουρ για τη ς συ σκε υής δι αβ άστ ε

προ σεκ τικ ά τ ίς οδ ηγι ες χρ ήση ς.

‘Ετ σι προ στ ατε ύετ ε τ ον εαυ τό σα ς κ αι απ οφε ύγε τε πιθ αν ές β λά βες σ υσκ ευή .

IT Attenzione!

Leggere assolutamente le instruzione d'uso prima di procedere a posizionamento – installazione messa in funzione della macchina. In questo modo ci si protegge e si evitano danni all'apparecchio.

NO NB!

De må lese bruksanvisningen før oppstillning, installasjon og start av maskinen!

Gjør det for å unngå skade på Dem selv og maskinen.

NL Let op!

Lees beslist de gebruiksaanwijzing voor het plaatsen, installeren en in gebruik nemen van uw machine.

Dat is veiliger voor Uzelf en U voorkomt onnodige schade aan Uw machine.

PL Ważne!

Przed instalacją maszyny, bądź przed przystąpieniem do pracy z maszyną po raz pierwszy, należy

dokładnie przeczytać i zapoznać się z niniejszą instrukcją obsługi.

W ten sposób uniknie się ryzyka mogącego spowodować uraz ciała bądź uszkodzenie maszyny.

PT Atençāo!

Leia as instruçōes de utilizaçāo antes da montagem - instalaçāo e - primeira utilizaçāoā

Assim evita avarias no aparelho.

SE OBS!

Läs bruksanvisningen noga före uppställning, installation och använding. Ni förebygger därmed olycksrisker och undviker skador på maskinen.

FI Huomio!

Tutustukaa huolellisesti käyttöohjeeseen ennen laitteen asennusta jä käyttöönottoa.

Näin vältytte mahdollisilta vahingoilta käyttäes-sänne konetta.

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

4

MANDATORY

FROMM Wrapping Systems S.r.l.

Viale del Lavoro, 21

37013 Caprino Veronese (VR)

ITALY

Tel. +39 045 205 7300

Fax +39 045 205 7373

P.IVA IT 04146150232

www.fromm-stretch.com

info@fromm-stretch.com

MANIFACTURER

FROMM SLOVAKIA a.s.

Priemyselná 5885

SK-901 01 Malacky

(SLOVAK REPUBLIC)

VAT no. SK2022019109

DOCUMENTATION

For the spare parts, check the separately delivered spare-parts booklet.

Or download directly from our website:

http://www.fromm-stretch.com

Or contact your Fromm Distributor.

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

5

EC Declaration of Conformity

(EC machinery directive 2006/42/EC - Annex IIA)

The Supplier (manufacturer): FROMM SLOVAKIA a.s.

Priemyselná 5885

SK-901 01 Malacky

(SLOVAK REPUBLIC)

Agent: FROMM Wrapping Systems S.r.l.

Via del Lavoro 21

IT-37013 Caprino V.se (VR)

(ITALY)

Declares, under its responsibility, that the product:

Model: FS390

Machine type:

Serial no.:

Description: Semi-automatic wrapping machine using stretch film

has been manufactured in compliance with the following directives:

2006/42/EC (Directive)

2004/108/EC (Electromagnetic compatibility)

2006/95/EC (Low voltage)

and in compliance with the following harmonised and national standards as well as other standard

documents:

UNI EN 12100:2010

ISO 13849-1:2008 + AC:2009

IEC EN 60204-1:2006

UNI EN 415-6-2013

UNI EN415-10:2014

01/01/2018

Name: Mr. Reinhard Fromm

Function: Legal Representative

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

6

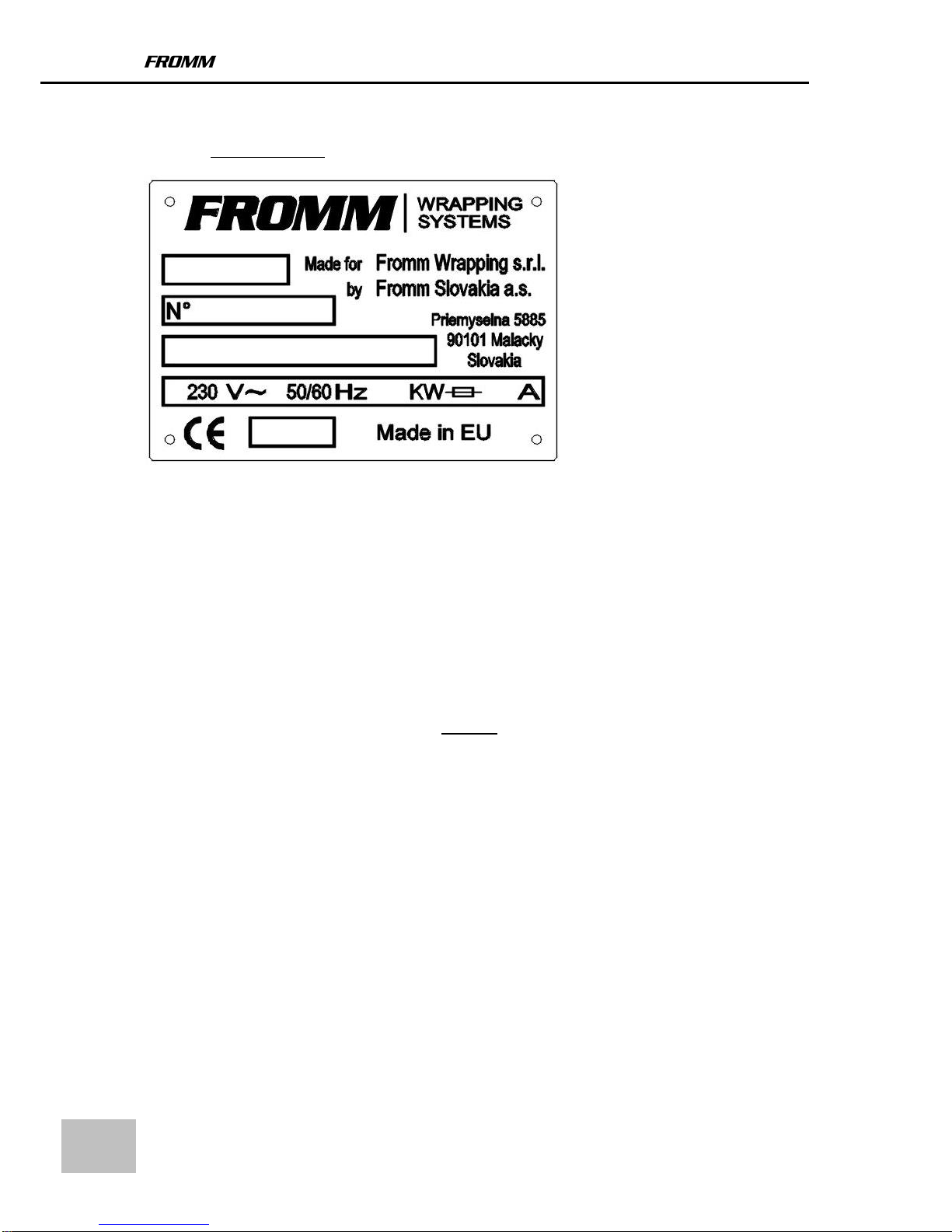

IDENTIFICATION PLATE

The serial identification plate with the following information is affixed to the back of the column.

Name of manufacturer : FROMM Slovakia a.s.

Type : Machine Type.

Serial number : Manufacturer’s production number

Voltage : Power supply voltage.

Power : Power consumption

Fuse : 10 Amp

Year of manufacture : year in which the machine was built by the manufacturer

Furthermore, the identification plate shows the CE mark:

CE mark

The machine meets the applicable requirements as provided for in the EC machinery directives:

2006/42/EC (Directive)

2004/108/EC (Electromagnetic compatibility)

2006/95/EC (Low voltage)

It is strictly forbidden to remove the identification plate or to replace it with one that is similar or of a

different type.

If the identification plate should become damaged for any reason, immediately contact the

MANUFACTURER.

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

7

MACHINE DATA

Machine item

Serial number

Manufactured by

Distributed by Date

UNITS:

OPERATING PANEL

TURNTABLE

COLUMN

CARRIAGE

PRESS

VARIOUS

OPTIONS

34.1

1 1 .

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

8

GENERAL INFORMATION

This manual only covers the semi-automatic wrapping machine for pallets, shown on page one, as

supplied by FROMM WRAPPING SYSTEMS.

THAT DESCRIBED IN THIS MANUAL IS VALID IF APPLIED!

This machine with turntable can be installed on the floor. As an optional, it can be equipped with a

frame for floor positioning.

Lay the film prior to application on the goods (stretching), reduces packaging costs and has a better

impact on the environment (option available depending on the model).

Refer to the technical data chapter that describes installation in detail and to the chapter on overall

dimensions of the system.

Carefully read at least the HANDLING AND TRANSPORT and INSTALLATION chapters.

For safety reasons, we recommend you read the entire instruction manual before

commissioning/installation of the machine, repairs and maintenance operations.

Pay careful attention to the SAFETY INSTRUCTIONS and WARNINGS chapters that illustrate the

intended uses and the dangerous situations that could not be avoided during designing and

manufacturing of the wrapping machine.

It is strictly forbidden to tamper with the machine. It is forbidden to feed the machine with non-

intended, corrosive or flammable products as the machine is not protected against explosions.

The warranty period is ensured if the following are respected: use for which the machine has been

designed, manufactured and equipped with protection devices, the recommendations, information

(including general issues), details and technical limits for health and safety provided by the

Manufacturer to the User with the user instructions.

We do not accept warranty claims if original spare parts have not been used.

If the machine is used beyond the operating limits and if the manufacturer’s features are in some way

altered, this is considered as improper use. In this case, the MANUFACTURER is not liable for

injuries/damage to people/things caused by failure to follow these guidelines.

For the above-mentioned points, we recommend that customers always contact the Assistance

Service.

ASSISTANCE SERVICE For any problems, contact:

SPARE PARTS The spare parts can be ordered from:

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

9

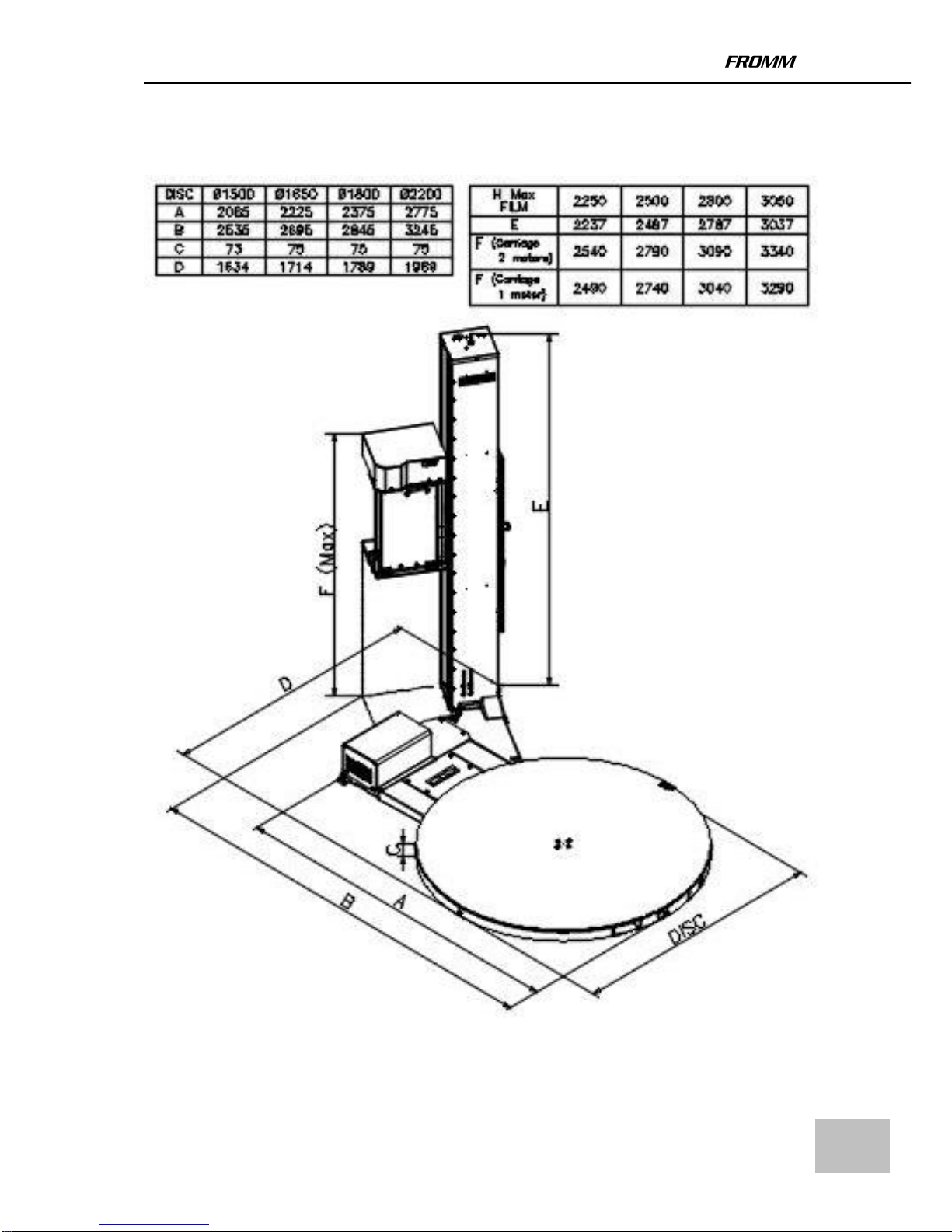

DIMENSIONS / DIAGRAM

Refer to the following diagram for the dimensions:

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

10

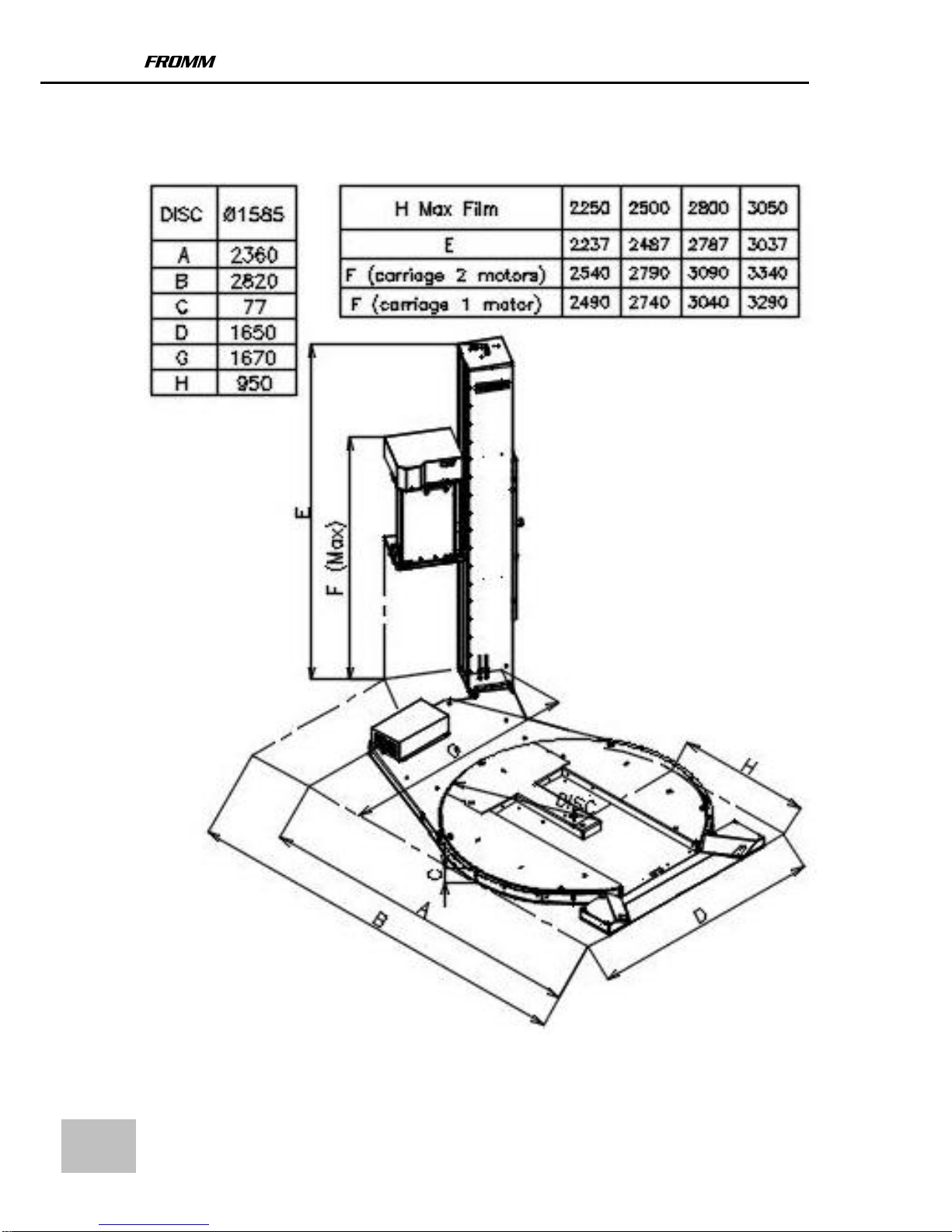

DIMENSIONS / DIAGRAM

Refer to the following diagram of the open turntable for the dimensions.

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

11

SAFETY INSTRUCTIONS

The following conditions must always be met unless otherwise indicated in other instructions

in this manual.

This wrapping machine has been supplied by FROMM WRAPPING SYSTEMS and can be used only

to wrap pallets that meet the requirements indicated in the description of the machine in the

TECHNICAL DATA chapter.

Any other uses of the machine, other than those described, can constitute a damage risk for the

machine and/or danger to the safety of the operator and anyone else near the machine.

Carefully read this manual before using the machine and understand the residual risks that cannot

be excluded during development of this machine.

The machine can be used only by suitably trained personnel.

The electrical interventions on the machine must be carried out only by suitably trained electricians.

During installation of the machine, as a precaution, always check that the controls and the safety

systems are mounted correctly and operate efficiently. If any malfunctions are detected, immediately

stop the production cycle and request the intervention of an authorised technical assistance service.

Check the nameplates. If they are extremely damaged, replace them with the utmost urgency and

directly and only contact the authorised technical assistance service or the Manufacturer.

During adjustment and maintenance operations, all requirements described in the MAINTENANCE

INSTRUCTIONS chapter must be met.

The manufacturer will commission the machine only when connection to the electrical network meets

the standards applicable in the country of delivery.

The supplier will provide training for the assigned personnel, otherwise training must be duly

performed by the installation company.

The machines are designed and manufactured in compliance with the safety laws in force,

therefore, if the machine is used correctly, no fire risks are foreseen.

To prevent any fire risk, the equipment within the machine’s user company is sufficient to deal with

any problems caused by the material used for the process.

In the event of fire, we recommend you use extinguishers containing CO2 to avoid damaging the

equipment and the electrical system.

In the event of flooding, it is essential to disconnect the electrical power supply before entering the

room where the machine is installed.

In the event of flooding, contact the MANUFACTURER’S customers technical assistance service.

We recommend you avoid wearing unsuitable clothing (with buttons, flaps) or accessories

(bracelets, watches, rings, etc.) during use of the machine.

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

12

SAFETY INSTRUCTIONS

MACHINE USES NOT ALLOWED

The following conditions must always be met unless otherwise indicated in other instructions

in this manual.

The machine is not equipped with components that have special disposal problems.

Do not stand near the turntable when the machine is in operation. (Use the emergency stop button to

immediately stop the machine.)

Do not touch the pallet when the machine is in operation. (Use the emergency stop button to

immediately stop the machine.)

Do not put your hand or fingers between the column and the carriage when the machine is in

operation. (Use the emergency stop button to immediately stop the machine.)

Do not put your hand or fingers in the column. (Use the emergency stop button to immediately stop

the machine.)

Do not put your hand or fingers near the wheels that move the carriage. (Use the emergency stop

button to immediately stop the machine.)

Do not put your hand or fingers in the electrical panel. (Use the emergency stop button to

immediately stop the machine.)

Do not cross the space between the column and the turntable. (Use the emergency stop button to

immediately stop the machine.)

Do not put your fingers in the space between the turntable and the disk. (Use the emergency stop

button to immediately stop the machine.)

People must not climb on the transport vehicles, unless otherwise indicated.

People must not be above the transport vehicles.

Do not put tools or components on the machine.

The safety devices must not be bypassed or turned off.

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

13

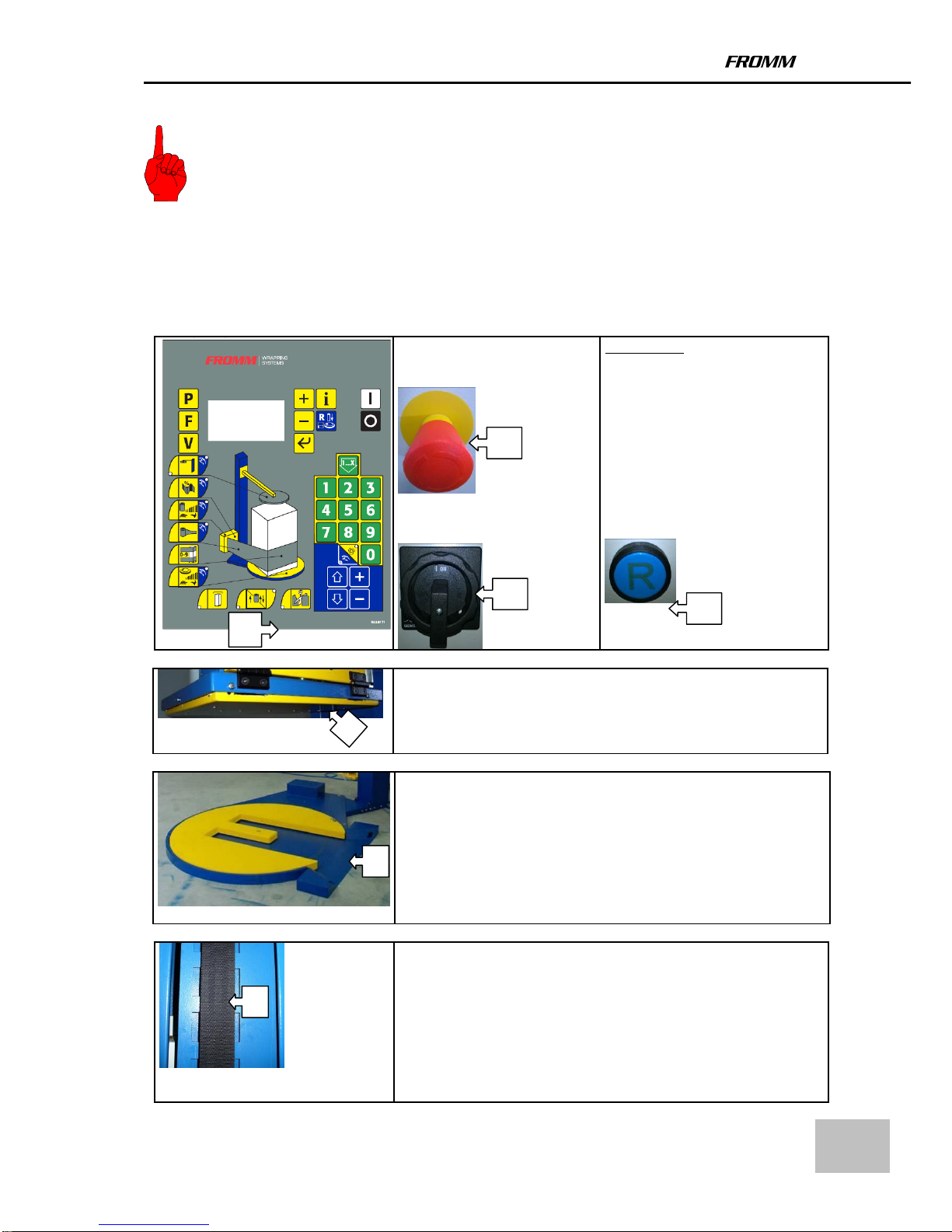

SAFETY DEVICES

We would like to again highlight how all safety devices have been installed for operator safety,

etc. and must not be manipulated or excluded from the operations.

Refer to the drawings below and to the notes applied.

Observe the control panel

A = Acoustic signal

B = Emergency stop button

C = Main

switch

Main switch:

The power (1x230V) is supplied

by turning on the main switch.

The voltage for the various control

parts (24Vdc) is also supplied by

turning on the machine.

D= Anti-crushing device

E = Parachute system

R= Reset Button

D = Anti-crushing device

This mobile anti-crushing device works with the aid of 4

mechanical sensors.

Each time a foreign body touches the underside of the carriage,

the latter reverses direction and simultaneously sends a signal to

the turntable to stop in phase.

D = Anti-crushing device

This safety device works with the aid of a photocell and a reflector.

Each time a foreign body gets between the photocell and the

reflector, a signal is sent to the turntable to immediately stop.

E = Parachute system

This mechanical safety device, parachute system, functions

whenever the belt is not tensioned, in other words it stops the

carriage from falling.

D

B

C D E

R

FS3.2780-Manual-34.111XXXXXXXXX.V01-EN03.doc

For further updates, see our website www.fromm-stretch.com and Login!

It is forbidden to duplicate this manual or parts thereof or any other form without the author’s authorisation © 2018

14

WARNINGS

The machine’s average noise level is less than 80 dB. Depending on the film applied, during the

pallet wrapping phase a maximum noise level of 80 dB may be recorded. We recommend using

noise protection safety devices.

We would like to remind you that the film (roll) can contain an electrostatic charge.

Pay close attention to the electrical installation. Only suitably trained personnel can perform these

interventions only after having taken all necessary safety measures described in the SAFETY

INSTRUCTIONS chapter.

It is necessary to consider all European safety requirements and standards should the machine

require adjusting; the safety measures and protective covers should also be adjusted.

Touching the electrical system constitutes a danger to personnel safety.

The people who modify or adjust the machine (functions, operation, principles) are entirely

responsible for these modifications or adjustments.

Take all necessary safety measures when intervening on the machine, especially during

maintenance operations and resolution of faults.

Ensure that the main switch is off (0) and padlocked (if possible) or that the power cable is

disconnected to prevent other personnel from using the machine during the interventions.

Furthermore, all safety measures and standards in force must be taken and complied with during

these activities.

Handling or approaching the machine can create dangerous situations if the machine is in operation.

These actions are forbidden!

Comply with all recommendations and laws relating to working conditions and safety in the

workplace.

There is an acoustic signal device installed in the control cabinet that activates briefly, as a warning,

before the machine is operated.

Loading...

Loading...