Fromm FS15 Series Service Manual

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

FROMM

it is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

1

FROMM

SEMI – AUTOMATIC

Stretch Wrapping Machine

SERVICE MANUAL FS15x

V01/V02-V03-EN03_R03

SERVICE MANUAL FS150 / ORIGINAL MANUAL© 12/16

FROMM

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

2

INDEX

1

Foreword

2

Machine make - up

3

General

4

Safety instructions

5

Safety devices

6

Warnings

7

Identification Sticker

8

Technical Data

9

Dimensions / Layout

10

Explanation of pictograms

11

Main Components

12

Handeling & Transport

13

Installation

14

Assembly Sequence

15

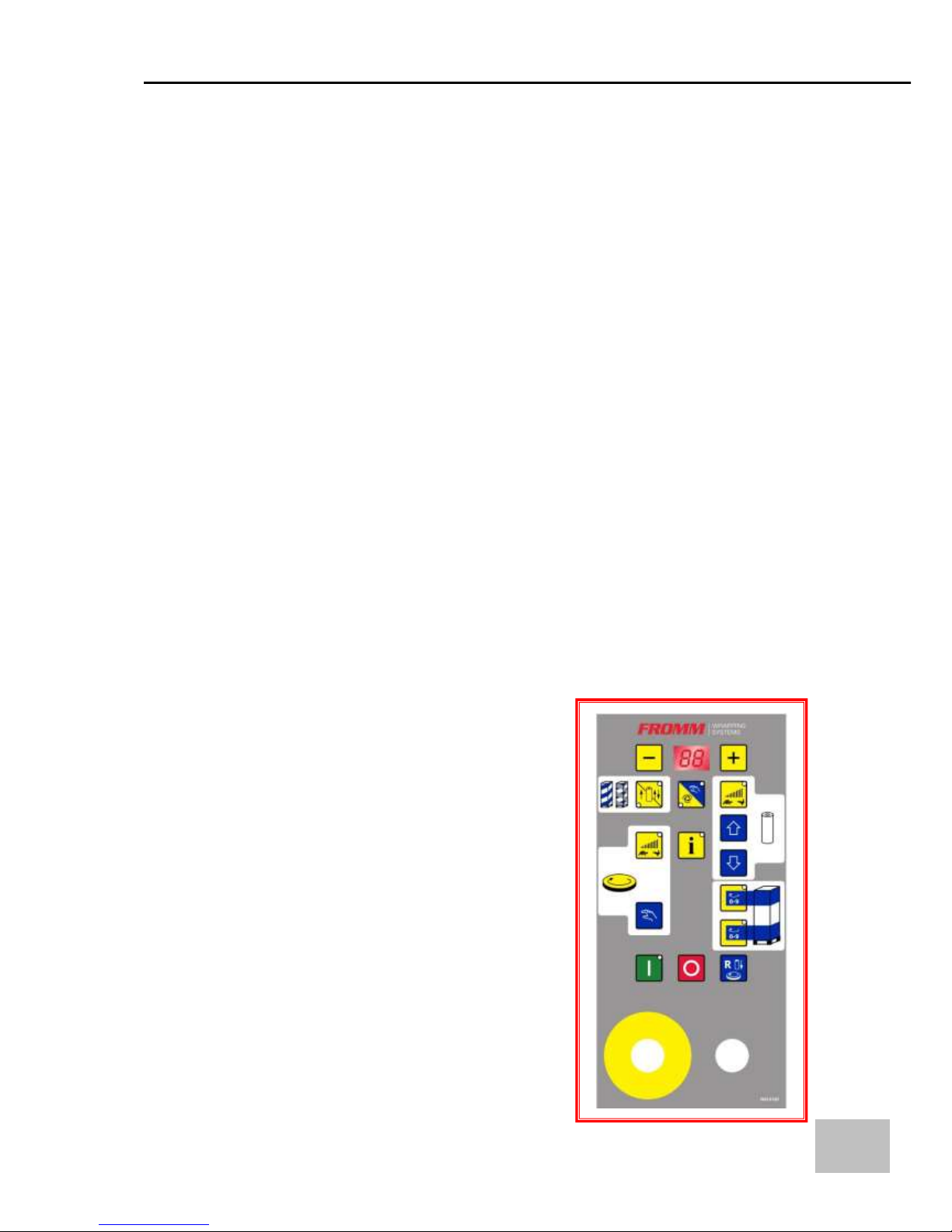

Control panel

16

Indications

17

Basic operating Instructions

18

Start wrapping Cycle

19

Wrapping Programs

20

Errors during operation

21

Possible errors during first installation

22

Alarms

23

Insering the film

24

Maintenance Instructions

25

Maintenance sheme & Lubrificants

26

Parameter settings

27

Mandatory & Manufacturer / Documentation

28

Warrantee conditions

29

Service logbook

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

FROMM

it is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

3

Dear Customer,

We would like to thank you for purchasing our machine. In this manual we would like to draw your attention

on the technical features and quality of the machine you have purchased.

Our machines are guaranteed to work at an maximum efficiency, only if original spare parts are used and

only if work and repair on the machines has been carried out by our own specialist staff. We advise you,

therefore, to entrust all maintenance work on the MANUFACTURER machine EXCLUSIVELY to our technical

assistance and spare parts service department. In fact, if any maintenance work on manufacturer machine

is carried out by non-authorized personnel, or if any NON-ORIGINAL spare- / replacement parts are used,

all the manufacturer guarantees, technical assistance and obligations will be nullified immediately.

We believe that you will understand the importance of the condition stated above.

From a technical point of view, it is our primary aim to protect our customers from negative experiences.

This INSTRUCTION MANUAL is your guide to the INSTALLATION/USE and MAINTENANCE

of the machine you have purchased. We advise you to follow all the instructions and suggestions in the

manual with great care, as the efficient operation and long life of the machine depends on its correct use

and on the methodical application of the maintenance regulations described later on.

We point out that, if any difficulties arise, our INTERNATIONAL CUSTOMER ASSISTANCE SERVICE is entirely

at your service for explanations or call-outs. If needed you can reach us by sending an English E-mail to:

service@fromm-stretch.com. Your question will be answered directly by us, or forwarded to one of our service

hubs in the area for which the service request has been done. Obviously you can also take a direct contact

with the supplier of your machine.

The MANUFACTURER, declines all responsibility for any incorrect usage of the machine or inadequate

maintenance work. The INSTRUCTIONS MANUAL is to be considered as an integral part of the product.

Keep and look after this Manual throughout the whole lifecycle of the machine. The MANUFACTURER

reserves the right to make modifications for the improvement of his machines, without giving prior notice.

Make sure that any amendments are added to the manual. Hand this Manual on to any other users or

subsequent owners of the machine. When using the manual, take care not to damage its contents, either

wholly or partial. On no account parts of this manual should be removed, torn out or rewritten. Keep the

manual in places which are protected from dampness and heat. Look at the cover of the manual to identify

the model dealt with now in your possession. Look at the INDEX to find the CHAPTER or SECTION

containing all the notes on a specific subject.

The intention of all the INSTRUCTIONS AND/OR NOTES ON THE PRODUCT is to point out the safety

precautions, correct procedures and operational instructions required for the efficient operation of the

machine. The SPAREPARTSLIST supplied with the delivery is an integral part of the manual, it contains

technical information on the acquired components mounted on the machine.

Each page is marked with the Document code (On the inner side the top left and right side)

We wish you all the best results with our machine and we remain at your service.

We take this occasion to send you our best regards.

Fromm Stretch Wrapping Division

ITALY

Copyright

This manual contains confidential industrial information belonging to MANUFACTURER.

All rights are reserved and may be protected by copyright or other ownership laws and treaties.

No part of this manual may be reproduced in any form or by any means without explicit permission from

MANUFACTURER.

FROMM

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

4

BE Opgelet!

Leest U in elk geval de gebruiksaanwijzing, vooraleer de machine wordt opgesteld, geïnstalleerd en in

gebruik genomen wordt. Daardoor zorgt U voor Uw eigen veiligheid en vermijdt U schade aan Uw

machine.

DE Achtung!

Lesen Sie unbedingt die Gebrauchsanweisung vor Aufstellung-Installation-Inbetriebnahme.

Dadurch schützen Sie sich und vermeiden Schäden an Ihrem Apparat.

DK OBS!

De bør absolut læse bruganvisningen, inden maskinen opstilles, installeres og tages i brug.

Derved beskytter De Dem selv og undgår skader på maskinen.

ES Atención!

Resulta imprescindible leer las Instrucciones de manejo antes de proceder al Emplazamiento/

Instalacion/Puesta en servicio del aparato, con objeto de protegerse a si mismo y evitar el deterioro de la

máquina debido a un manejo incorrecto.

FR Attention!

Lisez impérativement le mode d'emploi avant l'installation/la mise en service.

Vous vous protègerez ainsi et éviterez des détériorations sur votre appareil.

GB Important!

Read the operating instructions carefully before installation and before using this machine for the first

time.

You will avoid the risk of causing harm to yourself or to your machine in this way.

GR Πρоσо χή!

Πρί ν τ ην ε γκατ άστ αση , σύ νδε οη κ αί αρχ ικ ή λ ειτο υργ ια τ ης συ σκ ευή ς δ ιαβά στε

προ σεκ τικά τίς οδ ηγι ες χ ρήσ ης.

‘Ετ σι προσ τατ εύετ ε τ ον ε αυτ ό σα ς κ αι α ποφ εύγ ετε πιθ ανές βλά βες συσ κευ ή.

IT Attenzione!

Leggere assolutamente le istruzione d'uso prima di procedere alla posizionatura, installazione, messa in

funzione della macchina. Questo per proteggere la incolumità dell’operatore e danni all'apparecchio.

NO NB!

De må lese bruksanvisningen før oppstillning, installasjon og start av maskinen!

Gjør det for å unngå skade på Dem selv og maskinen.

NL Let op!

Lees beslist de gebruiksaanwijzing voor het plaatsen, installeren en in gebruik nemen van uw machine.

Dat is veiliger voor Uzelf en U voorkomt onnodige schade aan Uw machine.

PL Ważne!

Przed instalacją maszyny, bądź przed przystąpieniem do pracy z maszyną po raz pierwszy, należy

dokładnie przeczytać i zapoznać się z niniejszą instrukcją obsługi.

W ten sposób uniknie się ryzyka mogącego spowodować uraz ciała bądź uszkodzenie maszyny.

PT Atençāo!

Leia as instruçōes de utilizaçāo antes da montagem - instalaçāo e - primeira utilizaçāoā

Assim evita avarias no aparelho.

SE OBS!

Läs bruksanvisningen noga före uppställning, installation och använding. Ni förebygger därmed olycksrisker och undviker skador på maskinen.

FI Huomio!

Tutustukaa huolellisesti käyttöohjeeseen ennen laitteen asennusta jä käyttöönottoa.

Näin vältytte mahdollisilta vahingoilta käyttäes-sänne konetta.

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

FROMM

it is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

5

MACHINE MAKE - UP

Article number

Serial number

Manufactured by

Delivered by Delivery date

GROUPS

OPERATING PANEL

16.8411

OP1 /Quadro1 FS110

16.8412

OP2 /Quadro2 FS130

16.8413

OP2 - AWP / Operating panel 2 - AWP

TURNTABLE

16.8421

Turntable diameter Ø1500mm / 1.200kg*

16.8422

Turntable diameter Ø1650mm / 1.350kg*

16.8423

Turntable diameter Ø1650mm / 2.000kg*

16.8424

Turntable diameter Ø1500mm / 1.250kg*, HS right side

16.8425

Turntable diameter Ø1500mm / 1.250kg*, HS left side

*NOTE!! KG refers to maximal loading capacity on the turntable

MAST

16.8431

Mast 2.100mm / 2.000mm + 100mm (Overlap)

16.8432

Mast 2.500mm / 2.400mm + 100mm (Overlap)

32.4

3 . .

FROMM

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

6

CARRIAGE

16.8440

Carriage 0 / Mechanical film-core tension

16.8441

Carriage 1 / Mechanical film-core tension

16.8442

Carriage 2 / Mechanical break-roll tension

16.8443

Carriage 3 / Mechanical break-rollers pre-stretch

16.8444

Carriage 4 / Magnetic tension

VARIATION

16.8451

Gearbox fixed position

OPTIONS

16.8280

Ramp turntable Ø1.500mm, length 1.449mm, width 990mm, 1.350kg*

16.8465

Ramp turntable Ø1.650mm, length 1.449mm, width 990mm, 1.350kg*

16.8211

Ramp turntable Ø1.650mm, length 1.550mm, width 1.000mm, 1.500kg*

16.8462

Pit-option for table 1.500mm – FS1xx series

16.8463

Pit-option for table 1.650mm – FS1xx series

N5.2638

Photocell for black film

N5.2651

Photocell for black products

*NOTE!!

Ramps KG refers to maximal loading capacity on the ramp

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

FROMM

it is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

7

GENERAL

The FS1 “CENTO” machine is an semi-automatic pallet wrapping machine.

The operator has to place the pallet on top of the turntable and connect the film on the pallet.

The tension or stretch can be adjusted on the operating panel or carriage.

Depending on the functionality of the machine, the operator can start the wrapping process or initially

he has to setup the wrapping cycle, speed of turntable and carriage.

The process will be activated by pressing the start button. After completing the cycle, the machine will

stop in his original start position, the film can be disconnected and the operator can take away the

pallet from the turntable.

This manual is only intended for a semi-automatic pallet stretch wrapping machine, mentioned at

page one, as delivered by FROMM Stretch Wrapping Division.

FOR EVERYTHING IN THIS MANUAL IS VALID, IF APPLIED!

THE ORIGINAL, SIGNED FACTORY MANUAL HAS TO REMAIN CLOSE TO THE MACHINE,

TOGETHER WITH THE MACHINE ELECTRICAL PLAN AND INVERTER MANUALS.

A special bracket FS3.0250 can be purchase to keep this documentation together.

This so-called turntable machine can be build into the floor.

A support frame for building the machine in the floor can be supplied as an option.

Pre- stretching (Stretching out) the film prior to application on the goods reduces the costs of

packaging and is easier on the environment. (Available pre stretch depends on the model)

Refer to chapter for the technical data, which describes the installation in detail and for the

complete size of the installation.

Read carefully at least the chapters HANDELING AND TRANSPORT and INSTALLATION.

For safety reasons the entire instruction manual should be read before setting in operation the

machine/installation, solving failures and executing maintenance.

We particularly draw your attention to the chapters SAFETY INSTRUCTIONS and WARNINGS

which point out the intended use and unsafe situations that could not be prevented in the design and

manufacture of the wrapping machine.

It is strictly prohibited to tamper with the machine It is prohibited to feed the machine with unforeseen,

corrosive or inflammable products since the machine is not the explosion-proof type.

The duration of guarantee is provided the following are observed: the use for which the machine was

designed, built and protected, in addition to recommendations, information - including matters of

general knowledge - details plus the safety and health technical limits notified to by the Manufacturer

to the User by virtue of the operating use.

We cannot accept any claim for warranty if non-original spare parts are utilized.

If the machine is used beyond its operating limits and if the manufacturer's features are altered in any

way, such use is considered improper. In this case MANUFACTURER is relieved of any liability for

injury/damage caused to people/property due to failure to comply with these guidelines.

For all the aforementioned reasons, we recommend that our customers always notify the Service

Department.

FROMM

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

8

SAFETY INSTRUCTIONS

ATTENTION!

The following conditions have always to be satisfied, unless otherwise indicated in other

instructions in this manual.

This wrapping machine has been delivered by FROMM Stretch Wrapping Division and may only be

applied for wrapping of pallets / products which meet the requirements as mentioned in the

description of the machine in chapter TECHNICAL DATA.

Any other use of the machine as for the described purpose may cause danger due to damage to

the machine and/or the safety of the operator or other persons in the neighbourhood of the

machine.

Read this manual carefully before using the machine, and be aware of the residuals risks which could

not be excluded during the development of this machine.

In any case all the components must be disposed of by scrupulously complying with the

corresponding laws in force in the country in which the machine is used, and only by qualified

persons who are capable of assessing possible risks.

Only personnel trained for the purpose may operate the machine.

Use the emergency stop to halt the machine immediately.

Only trained electricians may perform electrical work on the machine.

Don’t find yourself close to the carriage when the machine is in operation. Be careful especially in

the lowering phase of the carriage. (Use the emergency stop to halt the machine immediately).

Don’t find yourself near the turntable when the machine is in operation.

(Use the emergency stop to halt the machine immediately).

Don’t touch the pallet when the machine is in operation.

(Use the emergency stop to halt the machine immediately).

Don’t place or insert your hand and fingers between mast and carriage.

(Use the emergency stop to halt the machine immediately).

Don’t put your hand or fingers in the mast.

(Use the emergency stop to halt the machine immediately).

Don’t put your hand or fingers near the wheels for the carriage movement.

(Use the emergency stop to halt the machine immediately).

Don’t put your hand or fingers in the electrical box.

(Use the emergency stop to halt the machine immediately).

Don’t cross the space between the mast and turntable.

(Use the emergency stop to halt the machine immediately).

Don’t put your finger in the space between the turntable and the base-unit.

(Use the emergency stop to halt the machine immediately).

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

FROMM

it is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

9

SAFETY INSTRUCTIONS

When installing the machine, as a precaution, always check that the controls and safety systems are

correctly mounted and operating efficiently. If any malfunctions are noted, immediately stop the

production cycle and ask the authorized technical service to intervene.

Examine the data-plates. lf they are in poor condition, replace them with utmost urgency, strictly and

directly contacting the authorized technical service or the Manufacturer

The requirements, as mentioned in chapter MAINTENANCE INSTRUCTIONS should be satisfied

during adjustment and maintenance activities.

People should not step on to means of transport, unless indicated clearly otherwise.

People should not find themselves above the means of transport.

Do not place tools and components on the machine.

Safety devices should not be bridged and put out of operation.

The manufacturer will only make the machine ready for operation, when the electrical main

connection satisfies the standards applicable in the country of delivery.

The supplier will do the training of the operating personnel. If not, the training will have to be done

properly by the company that takes care of the installation.

The machines are designed and implemented conforming to the safety laws in force.

Consequently, no intrinsic fire risks are envisaged when the machine is used normally.

As such, the equipment provided against the possibility of fire outbreaks inside the company are

sufficient for any problems caused by the material used for the process.

In the event a fire breaks out and fire extinguishers are used, it is recommended that extinguishers

filled only with CO2 be used, so as not to damage both the equipment on the machine and the

wiring system.

In the event of flooding, it is compulsory that all the power supplies be disconnected before

entering the room in which the machine is installed.

In the event the wrapping machine was subjected to a flooding, contact the Customer technical

service of MANUFACTURER.

You are strictly recommended not to work in the machine while wearing unsuitable clothing

(unbuttoned, ample garments) or personal objects (bracelets, watches, rings, etc.).

FROMM

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

10

SAFETY DEVICES

We urge on you again that all safety devices are installed for the safety of the operator

etc. and should not be bridged and put out of operation.

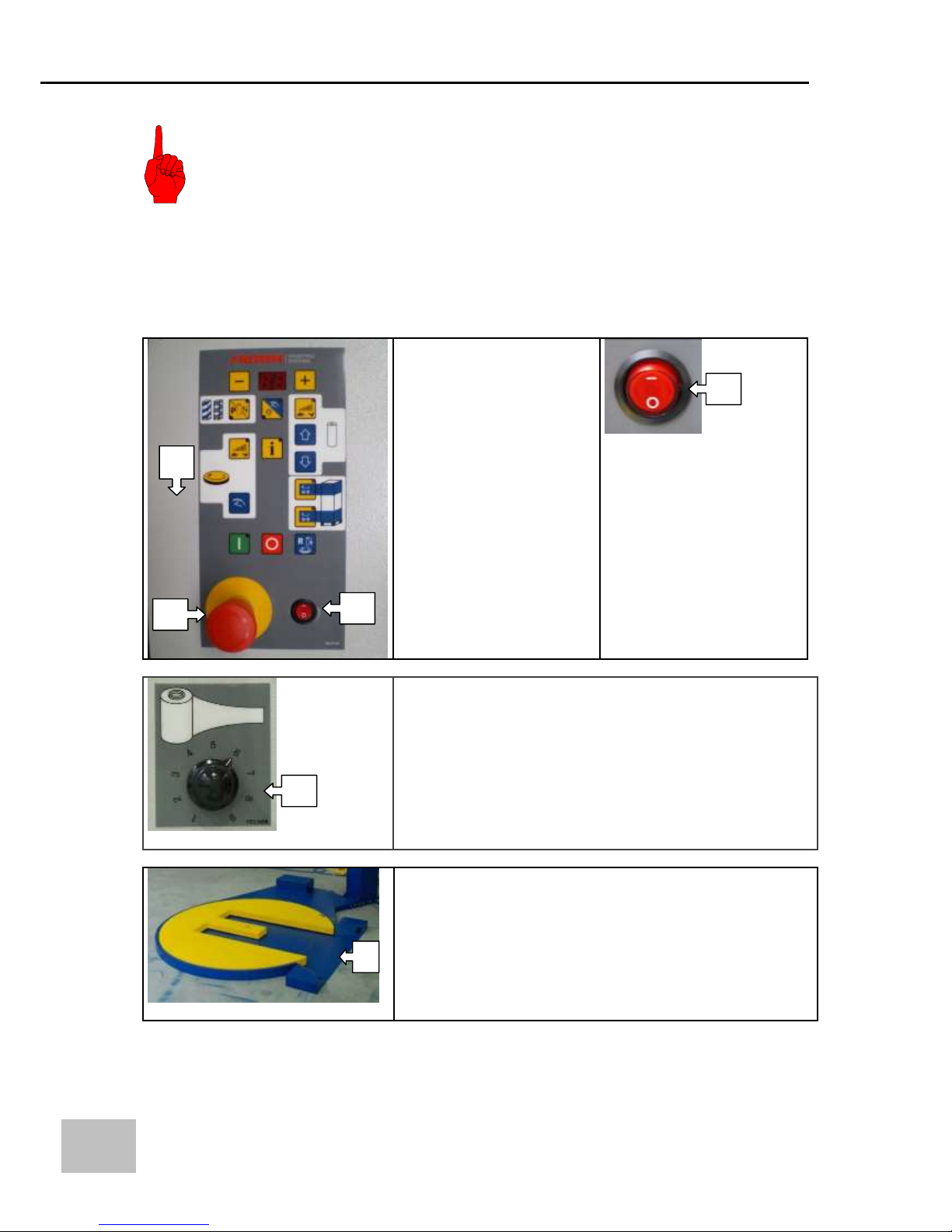

Refer to the drawing below for the applied references.

Survey control panel

A = Acoustic signal

B = Emergency stop

C= Main switch

Light On, when the power

is On

C = Main switch

The main supply (1x230V) is

switched on and off with the

main switch.

The supply voltage for the

control part (24VAC) is thus

equally switched on and off.

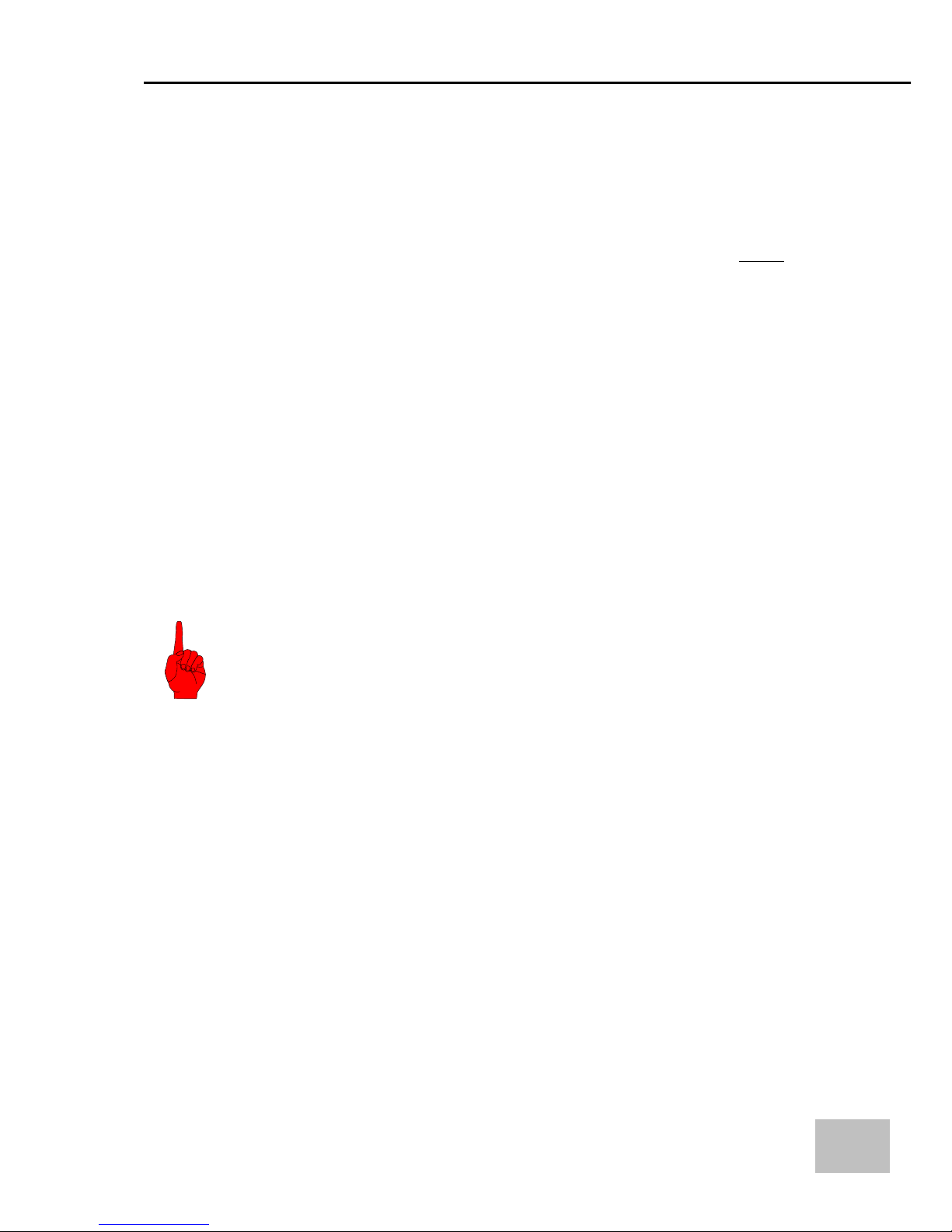

E = potential meter for film tension.

E = Adjustment FILM Tension.

(Only when the machine has been equipped with film

carriage 4)

G = crush-proof guard

This is a entrance safety guard, interlocked by means of

Photocell sensor and reflector.

Any time underlying foreign matter comes between this guard, it

inverts the film carriage's motion and causes the

turntable to stop in emergency.

B A C

C

E

G

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

FROMM

it is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

11

WARNINGS

The mean weighed noise level of the machine is less than 80 dBa. It is possible that, depending on

the applied film, during wrapping of the pallets / products incidentally a noise level with a maximum

of 80 dBa will be measured. Carrying of noise protecting devices is advised.

One has to reckon with the possibility that the film (roll) contains an electrostatic charge.

Utmost caution has to be taken with respect to the complete electrical installation. ONLY trained

persons may carry out activities to it, after having taken the required safety measures as mentioned

in the chapter SAFETY INSTRUCTIONS.

One has to reckon with the European safety requirements and standards if the machine has to be

adapted and thus safety measures or protection covers also have to be adapted.

Touching the electrical equipment will hazard your personal safety.

Persons who carry out changes in or adaptations (function, operation or principles) to the machine

are fully responsible for those changes and/or adaptations.

All relevant safety measures should be taken when carrying out any activity on the machine,

especially during maintenance activities and solving failures.

Take care that the main switch is switched off (position "0") and locked (If possible), or that the power

cable is disconnected in order to prevent other persons in putting in action the machine during your

activities.

All the normally valid safety measures or customs with respect to safety should also be taken during

those activities.

Playing with or around the machine may cause dangerous situations with a machine in operation.

This playing is never allowed!

All other prescriptions and laws with respect to working conditions and safety on the working spot

should be observed with this machine.

An acoustic signal device has been installed in the control cabinet, which will be activated first during

a short period, as a warning every time before the machine is starting.

FROMM

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

12

IDENTIFICATION PLATE

The serial identification plate with the following information is affixed to the back of the column.

Name of manufacturer : FROMM Slovakia a.s.

Type : Machine Type.

Serial number : Manufacturer’s production number

Voltage : Power supply voltage.

Power : Power consumption

Fuse : 10 Amp

Year of manufacture : year in which the machine was built by the manufacturer

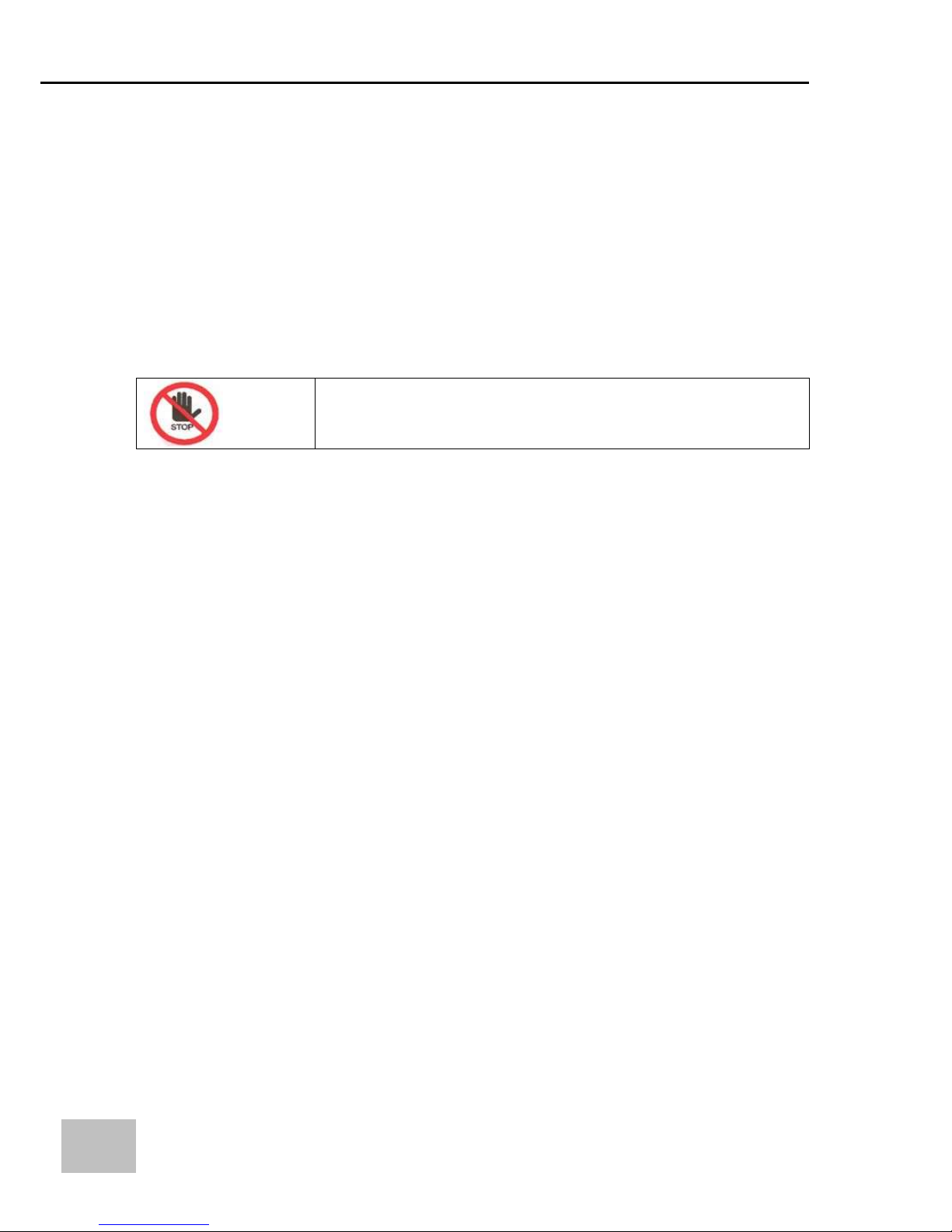

Furthermore, the identification plate shows the CE mark:

CE mark

The machine meets the applicable requirements as provided for in the EC machinery directives:

2006/42/EC (Directive)

2004/108/EC (Electromagnetic compatibility)

2006/95/EC (Low voltage)

It is strictly forbidden to remove the identification plate or to replace it with one that is similar or of a

different type.

If the identification plate should become damaged for any reason, immediately contact the

MANUFACTURER.

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

FROMM

it is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

13

TECHNICAL DATA

Machine - Speed turntable OP2 Adjustable by inverter.

- Capacity max. 25 pallets/hr.

- Operation / working advice Max. 2.300 pallets per year

- Operational hours 8 hrs/day, 5 days/week

- Ceiling height FS1 “CENTO” minimum of 2.400mm / 94,50”

Weight - Total weight FS1 “CENTO” Ø 1.500mm approx. 270kg

Ø 1.650mm approx. 370kg

Conditions - Environmental temperature + 5 to +30oC

- Environment clean, dry and non-aggressive

Electrical - Power supply 1 x 230 V 50/60Hz

- Control voltage 24 VAC

- Motor turntable 0.55kW

- Motor film carriage 0.22kW

- Installed power 1 kW

- Protection class IP44

Pallet goods - Pallet dimensions (Length x width) Ø1500mm 800 x 1.200 x 140

31,5” x 47,24” x 5,51”

- Pallet dimensions (Length x width) Ø1650mm 1.100 x 1.200 x 140mm

43,30” x 47,24” x 5,51”

- Height with load FS150 (pallet included) min. 500mm / max. 2.200mm

min. 19,69” / max. 82,67”

- Dimensions of load outside pallet max. 20mm / 0,79” per side

- Top of load flat

- Maximal weight Ø1.500mm 1.350kg

- Maximal weight Ø1.500mm Horse shoe 1.250kg

- Maximal weight Ø1.650mm 2.000kg

FROMM

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

14

TECHNICAL DATA

Stretch-film - LLDPE Material Max 35 μ / 0,000138”

- Spool core diameter 76 mm / 3”

- Outer diameter of spool Max. 250mm / 9,84”

- Film width Max. 500mm / 19,69”

Colors - Bottom unit, mast : Blue, RAL 5010

- Turntable disk : Yellow, RAL 1021

- Chassis film carriage : Yellow, RAL 1021

- Control cabinet : Grey, RAL 7035

Should the need arise to work with products having a different nature than the above mentioned ones.

It is essential that you contact the technical service of MANUFACTURER in order to receive written

authorization.

WARNING : do not use film thicker than 35 microns without

consulting the Manufacturer

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

FROMM

it is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

15

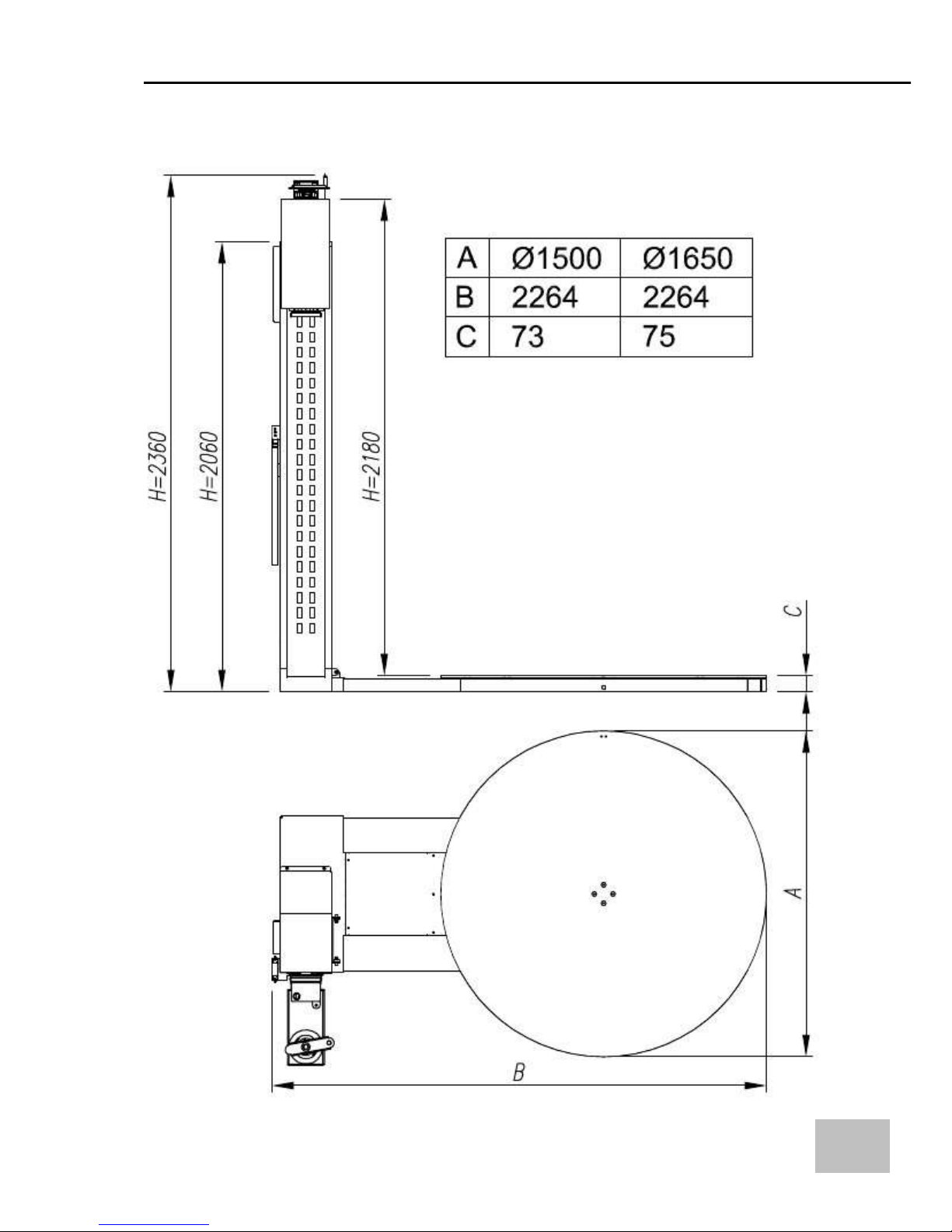

DIMENSIONS

Refer to the LAYOUT on this page for the dimensions.

FROMM

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

16

DIMENSIONS

Refer to the LAYOUT on this page for the dimensions.

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

FROMM

it is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

17

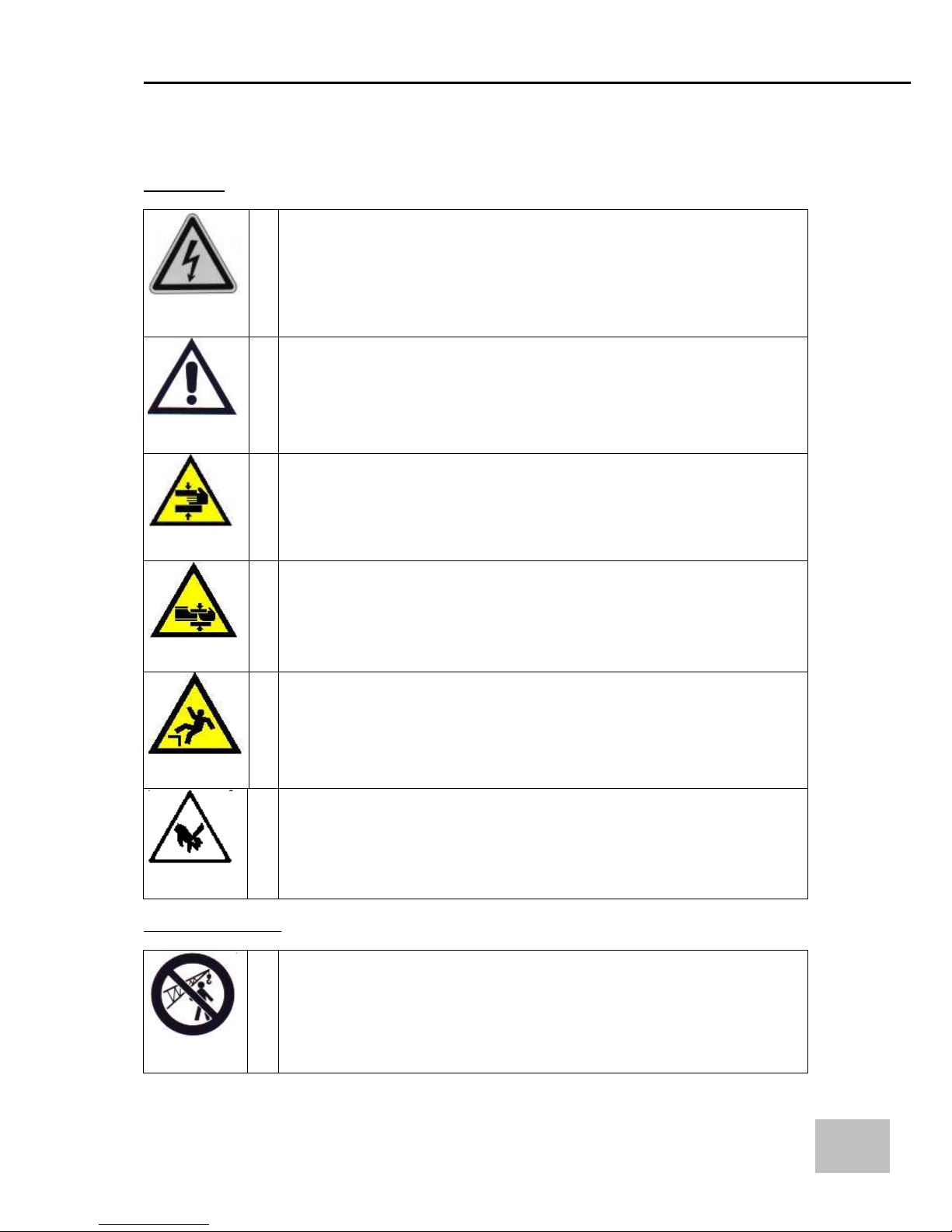

EXPLANATION OF PICTOGRAMS

ATTENTION!! (FOR EVERYTHING IS VALID, IF APPLIED!)

WARNINGS

Fig. 1

Figure 1:

DANGER

High voltage present.

Fig. 2

Figure 2:

Danger Sign

Fig. 3

Figure 3:

Risk of crushing one’s hands

Fig. 4

Figure 4:

Risk of crushing hands and feet

Fig. 5

Figure 5:

Falling hazard

Fig. 6

Figure 6:

Sharp objects

COMMAND PLATES

Fig. 7

Figure 7:

It is prohibited to pass by within the lifting equipment’s ray of action

FROMM

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

18

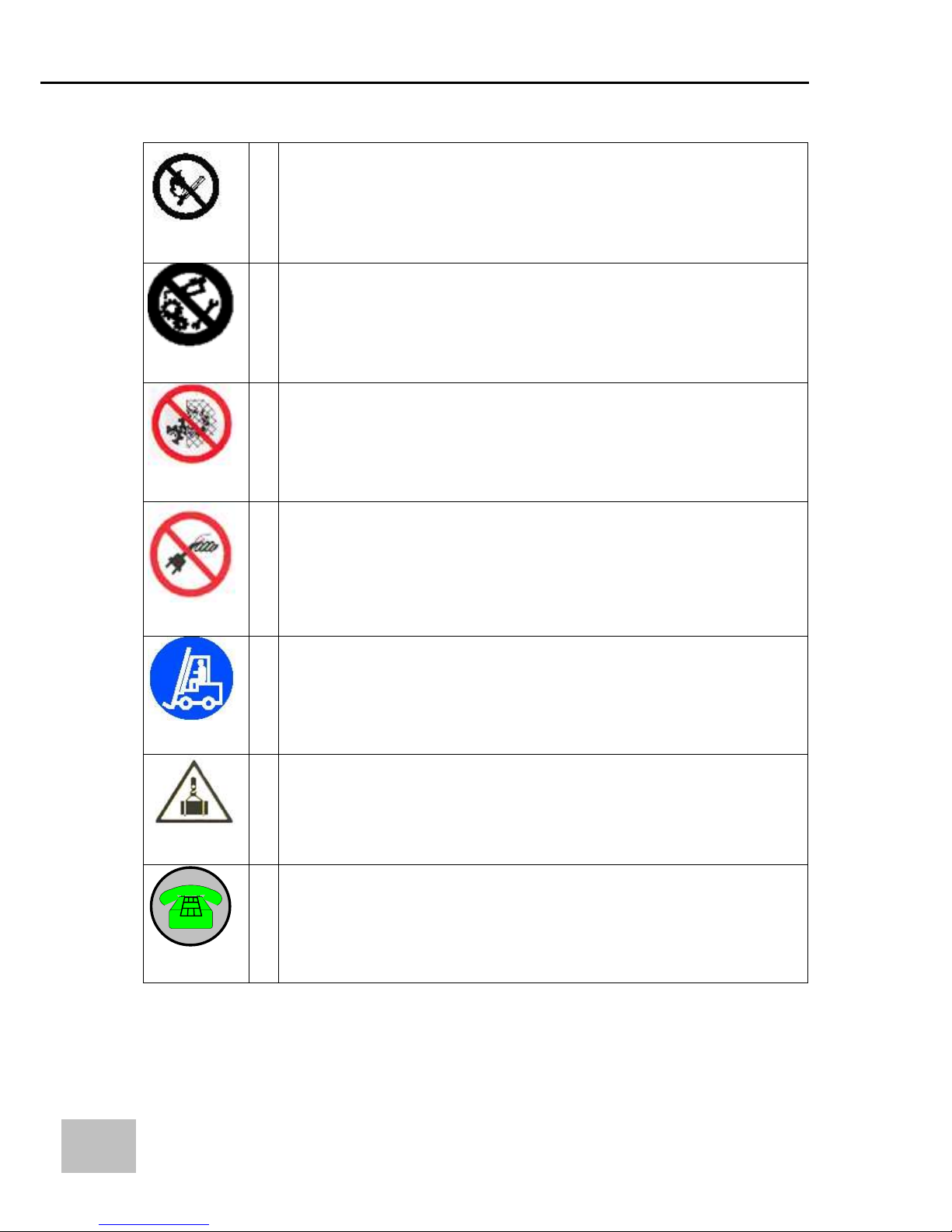

EXPLANATION OF PICTOGRAMS

Fig. 8

Figure 8:

Do not use bare flames and do not smoke

Fig. 9

Figure 9:

Don’t access the area while the machine is working

Fig. 10

Figure 10:

Don’t remove the SAFETY DEVICES

Fig. 11

Figure 11:

Don’t execute any work before taking off the voltage of the machine

Fig. 12

Figure 12:

Truck insertions

Fig. 13

Figure 13:

Lifting points

Fig. 14

Figure 14:

This identifies situations in which

THE SUPPLIER must be contacted

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

FROMM

it is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

19

EXPLANATION OF PICTOGRAMS

Fig. 15

Figure 15:

Very important guidelines that must strictly be complied with. Otherwise

machine operators could be at risk, the consequence of which would be the

voiding of any form of warranty and liability on behalf of FROMM PACKAGING

SYSTEMS.

Fig. 16

Figure 16:

Operations that must never be performed.

CE-MARK

Fig. 17

Figure 17:

Machine fulfils the applied requirements

as mentioned in the CE-machine directives.

FROMM

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

20

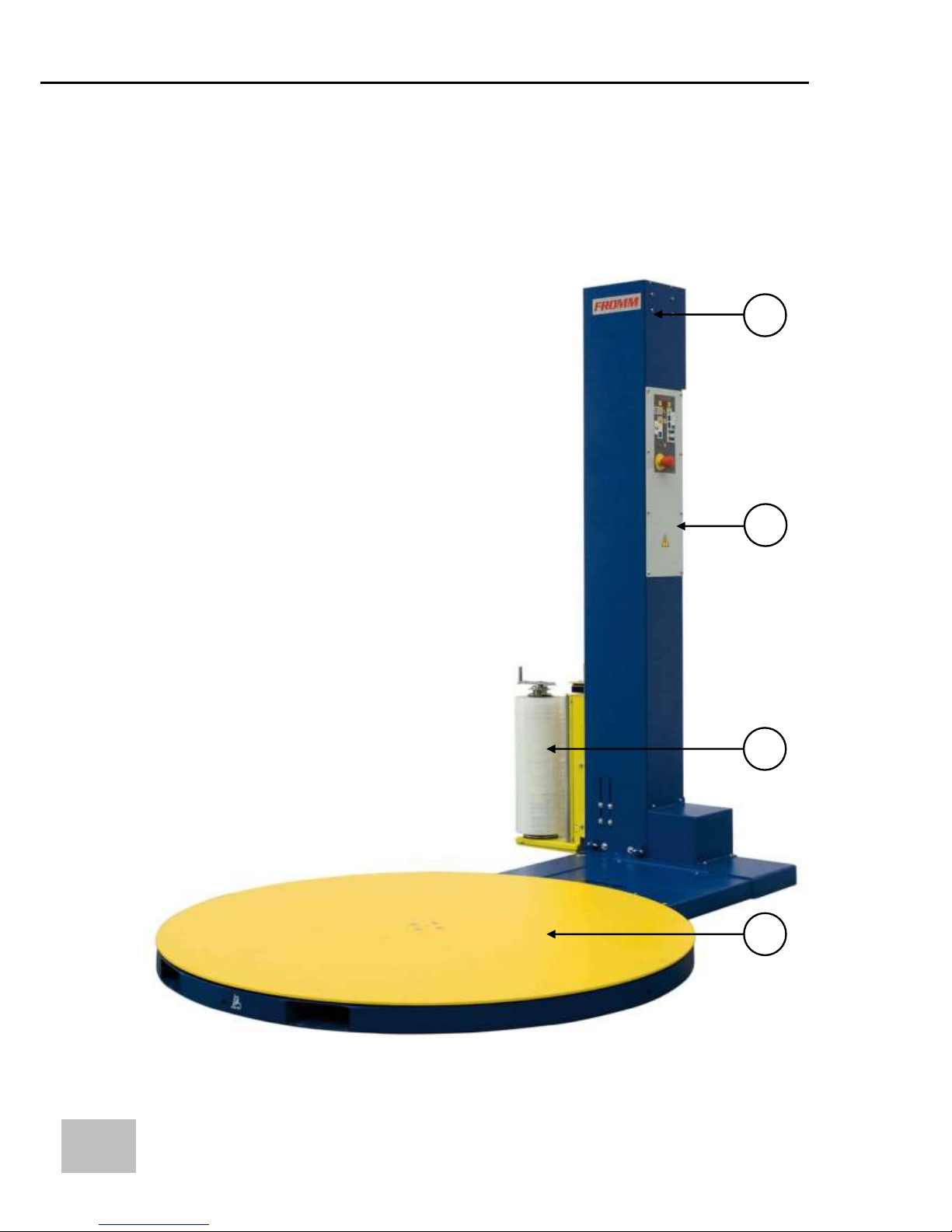

MAIN COMPONENTS

The installation as delivered, consists of the following parts:

1- Mast

2- Control cabinet with control panel

3- Film carriage

4- Turntable

4

2 1 3

SERVICE MANUAL FS15x_V01-V02-V03-EN03_R3.doc

FROMM

it is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2017

website: www.fromm-stretch.com

21

HANDLING & TRANSPORT

ATTENTION!

All mentioned activities may only be executed under supervision of qualified personnel from the

manufacturer or his representatives!

Pay attention that proper hoisting and lifting tools are used for handling of the machine.

The machine is supplied in a wooden crate insulated by plastic air bubble film.

It is advisable that two another operators be in attendance on the ground when the machine is moved

by means of the mechanical equipment driven by the operator in charge since the size of the machine

may prevent a clear view during the various phases of the handling operations.

Depending on weight, dimensions, location of machine on the vehicle, available installation space

lifting methods and points suitable for the operations described below must be used, fully observing

the current safety and health laws and the Manufacturer's recommendations.

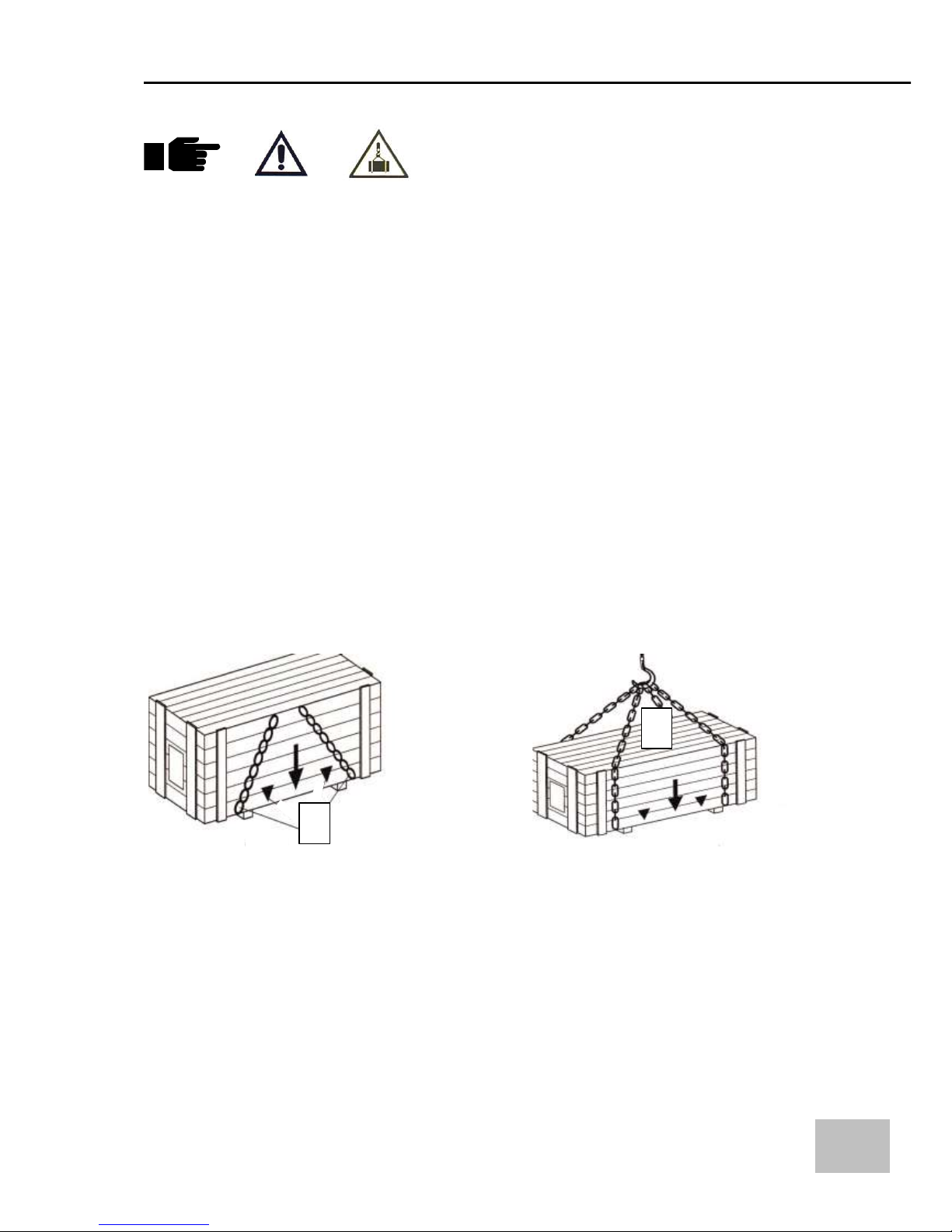

Lifting and handling of packing in a wooden crate by crane

- use a crane and sling of sufficient strength

- bring the vehicle near to the lifting pallet

- pass the sling (and/or ropes - chains) around the case in the positions indicated by the external

markings (1);

First check that the case - sling/hook (2) are well secured, then carefully lift the case and place it in the

designated area, moving it gently.

1

2

Loading...

Loading...