FROMM

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2010

FROMM

Manual battery Robot FR3xx/FR4xx

Stretch Wrapping machine’s

Version 01 Machines

Version 01 List

Website : www.fromm-stretch.com

Manual battreriy robot FR3xx/FR4xx.V01.EN01/a.servisi/ © 06/10

MANUAL-FR3.0014_EN_V01

FROMM

For the last update, check our website at www.fromm-stretch.com and use your login!

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2010

0

TECHNICAL FEATURES OF THE CBHF1-SM SERIES (Robot FR3xx/FR4xx)

The innovative characteristics of the CBHF1-SM range of battery charger are the following:

1. Advanced Mosfet technology with high frequency and insulation transformer.

2. Charging process fully controlled by microprocessor.

3. Visualization on a lit display of the charging current, of the battery voltage, of the charging time, of the

electric charge supplied in Ah’s and of the electric energy absorbed in KWh’s.

4. Possibility to change the charging curve by means of microswitches (DIP-switches), choosing from 16

standard pre-programmed curves for lead-acid, Gel and VRLA batteries. Any other optional curve

available on request.

5. Possibility to change the battery voltage and the charging current by means of the relevant

microswitches.

6. Charging process starting in the “soft start” mode, storing of the data of the cycle just finished and

automatic reset upon connection of a new battery.

7. Protection against polarity inversions, short-circuits, over-voltages or anomalies by means of an output

relay.

8. Battery to battery charger connection without sparks on the output terminals with obvious advantages for

the active safety, thanks to the recognition of the battery voltage downstream the normally opened output

relay.

9. Alphanumeric signals of possible anomalies.

10. Insensitive charge parameters in case of 10% network voltage

11. Efficiency > 85%.

12. Output ripple at maximum charge lower than 100mV.

13. Start of the charge cycle also with 2V batteries.

14. Thermal protection against over heating.

15. An auxiliary relay that permits the partial or total disconnection of an electric traction machine is available

in should the batteries have to be re-charged with the battery charger placed on board the machine. In

this way the relay prevents the machine from starting while the battery charger is operating. This is a

safety device.

OPERATING PRINCIPLE

On switching on a new battery charger of the CBHF1-SM series, programmation data are displayed (these

parameters depend on internal dipswitch configuration).

After the “SPE” logo you can see on display the version of software installed on the machine. At this time

the following programmed parameters are displayed on sequence according to internal dipswitch

configuration (see tables on page n. 4):

battery voltage, charging current, number of charging curve and is displayed the message “GEL” if

programmed charging curve is suitable for gel batteries or “Acd” if programmed charging curve is suitable

for Lead-Acid (Wet) batteries. After these operations the charger is ready to check the battery voltage and to

decide whether to start the charging process. If the battery is not connected to the battery charger, the

message ’bat’ will be displayed. The same message is displayed also in case of negative result of the testing

(for example, reversed polarity or battery having a wrong voltage). If the result of the testing is positive, the

value of the battery voltage is displayed for about 5 seconds, with output relay open. After 5 seconds the

charging of the battery can start. The output relay closes and the current of the first phase rises slowly till it

reaches the nominal value programmed.

If the user disconnects the battery from the battery charger during the charging process, after a few seconds

the battery charger will re-initialize and prepare to start a new charging process.

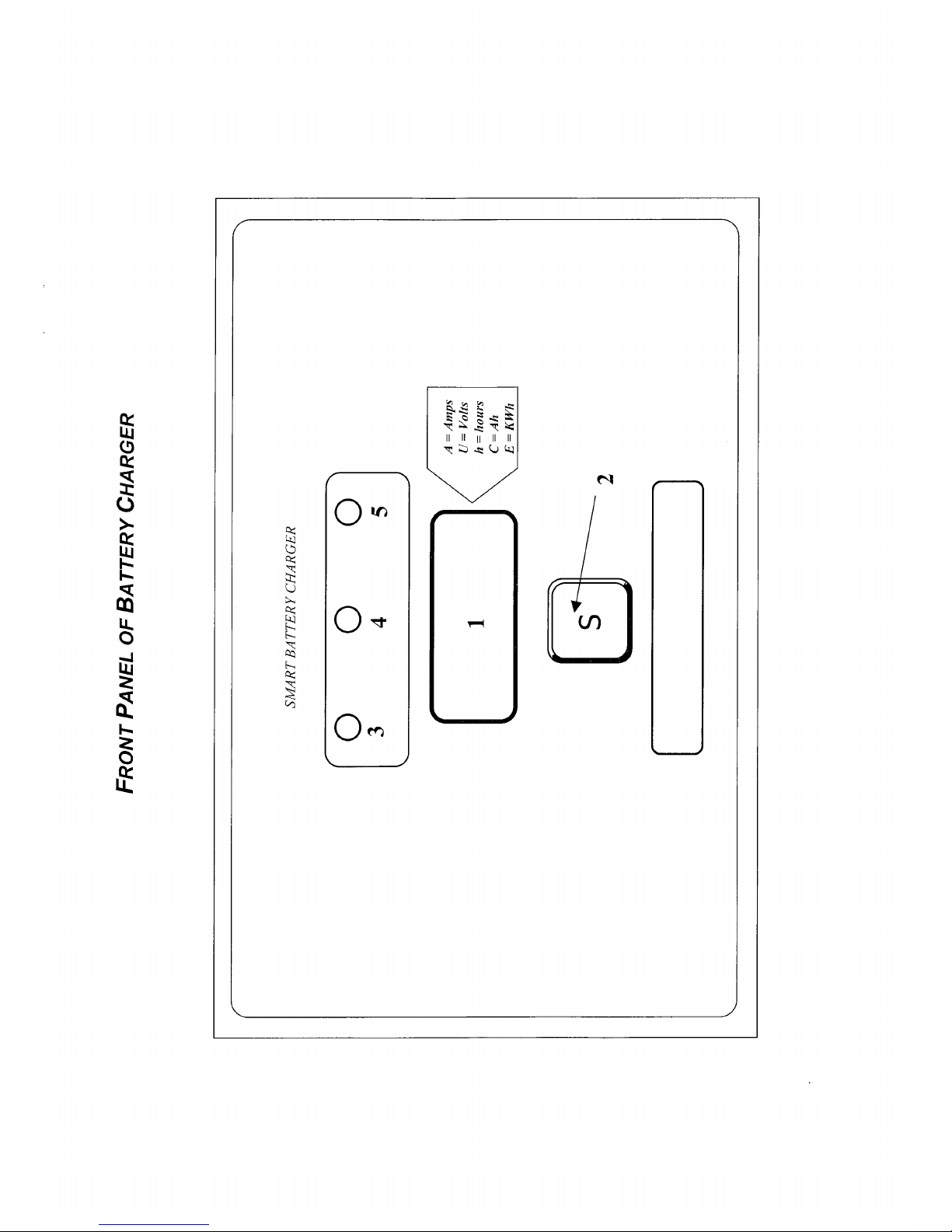

The display always shows the charging current of the battery. The battery voltage, the time since the

beginning of the charge, the charge yielded in Ah’s and the energy consumed in KWh can be seen only by

pressing the button S.

The progress of the charging process is shown by three LED’s: red, yellow and green, as in the whole range

of the battery chargers.

The green LED indicates the stop of the charging or the last phase in case of deep charging process; in the

former case, the relay is opened to disconnect galvanically the battery from the battery charger.

FROMM

MANUAL-FR3.0014_EN_V01

For the last update, check our website at www.fromm-stretch.com and use your login!

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2010

1

Technical remarks

When the maximum voltage admissible for a specific battery is reached (value given by the

manufacturer) the error message „E01‟ is displayed, and the process is terminated.

By using an internal thermostat, the charging can be interrupted in case of excessive battery charger

over-temperature. In this case the error message „E02‟ is displayed.

Possibility of setting each single charging phase. On exceeding this time, the charge will be interrupted

and the error message „E03‟ will be displayed.

The display of the message „SCt‟ indicates safety timer operation.

The message „Srt‟ will be displayed in case of internal short circuit.

On the next page we have written the meaning of dipswitch. Through the set of 8 dipswitches it is possible to

change the charging curve (16 charging curves are available for Wet and Gel batteries and it is possible to

customize the charging profile under the specifications of battery manufacturers), the battery voltage (12V or

24V) and the charging current (4A or 8A or 10A or 12A). The set of 8 dipswitch is easy to find (is located

under the front label of the charger, lifting the corner on the bottom-left) without opening the charger.

MANUAL-FR3.0014_EN_V01

FROMM

For the last update, check our website at www.fromm-stretch.com and use your login!

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2010

2

CBHF1-SM DIP SWITCH CONFIGURATION

In the following tables you can find meaning of all different position of dipswitch

for programming CBHF1-SM battery chargers.

DIP1 DIP2 DIP3 DIP4 for the selection of the CHARGING CURVE

DIP1

DIP2

DIP3

DIP4

CHARGING CURVE

ON

ON

ON

ON

0

OFF

ON

ON

ON

1

(curve for Lead-acid (Wet) traction batteries)

ON

OFF

ON

ON

2

OFF

OFF

ON

ON

3

ON

ON

OFF

ON 4 OFF

ON

OFF

ON

5

ON

OFF

OFF

ON

6

(curve for Sealed Lead-acid and GEL

batteries from

Trojan and other manufacturers)

OFF

OFF

OFF

ON 7 ON

ON

ON

OFF

8

OFF

ON

ON

OFF 9 ON

OFF

ON

OFF

10

OFF

OFF

ON

OFF

11

(curve for GEL batteries from Sonnenschein,

DETA and other manufacturers)

ON

ON

OFF

OFF

12

OFF

ON

OFF

OFF

13

ON

OFF

OFF

OFF

14

OFF

OFF

OFF

OFF

15

DIP5 DIP6 DIP7 for the selection of the CURRENT I1

DIP5

DIP6

DIP7

CORRENTE

ON

ON

ON

4A

OFF

ON

ON

8A

ON

OFF

ON

10A

OFF

OFF

ON

12A

DIP8 for the selection of the battery voltage

DIP8

VB

ON

12

OFF

24

0N

OFF

DIP1

ON

OFF

DIP2

ON

OFF

DIP5

ON

OFF

DIP3

ON

OFF

DIP4

ON

OFF

DIP6

ON

OFF

DIP7

ON

OFF

DIP8

ON

FROMM

MANUAL-FR3.0014_EN_V01

For the last update, check our website at www.fromm-stretch.com and use your login!

It is forbidden to duplicate this manual or parts of it in any way or any form without written permission of the author © 2010

3

PRE-PROGRAMMED CURVES FOR CBHF1-SM

Tab.1

CURVE

CURVE TYPE

DIPSWITCH

DP1-DP2-DP3-DP4

00

IUa SO (IUa + float charge 2,30VPC) = IUUo

Technology for charging DRYFIT TRACTION BLOCK (TRACTION GEL

batteries). In compliance with the DIN 41773 regulations.

ON-ON-ON-ON

01

IUIa Lead-Acid

Technology for charging TRACTION Lead-Acid batteries.

OFF-ON-ON-ON

02

IUUa (2,45VPC)

Technology for charging SEALED LEAD-ACID batteries.

ON-OFF-ON-ON

03

IUUa (2,40VPC)

Technology for charging Sealed Lead-acid and GEL batteries

batteries from Trojan and other manufacturers.

OFF-OFF-ON-ON

04

IUIa Lead-Acid + float charge at 2,30VPC

Technology for charging TRACTION lead-acid batteries.

ON-ON-OFF-ON

05

IUUa (2,45VPC) + float charge at 2,30VPC

Technology for charging SEALED LEAD-ACID batteries.

OFF-ON-OFF-ON

06

IUUa (2,40VPC) + float charge at 2,30VPC

Technology for charging Sealed Lead-acid batteries and GEL

batteries from Trojan and other manufacturers.

ON-OFF-OFF-ON

07

IUIa PzV

Technology for charging large capacity DRYFIT PzV (A800) GEL

batteries. In compliance with the DIN 41773 regulations.

OFF-OFF-OFF-ON

08

IUIa GNB

Technology for charging GNB Sealed Lead-Acid batteries.

ON-ON-ON-OFF

09

IUo (2,35VPC)

Technology for charging Lead-Acid start-up batteries.

OFF-ON-ON-OFF

10

IUIa drysafe (HAGEN)

Technology for charging DRYSAFE HAGEN batteries.

ON-OFF-ON-OFF

11

IUIa per TRACTION BLOCK + float charge 2,30VPC

Technology for charging DRYFIT TRACTION BLOCK batteries from

Sonnenschein, DETA and other manufacturers.

In compliance with the DIN 41773 regulations.

(This curve is an alternative of curve 00)

OFF-OFF-ON-OFF

12

IUa for Lead-Acid batteries (2,40VPC)

Technology for charging Lead-Acid starting batteries with stop.

ON-ON-OFF-OFF

13

Iua for Lead-Acid batteries (2,60VPC)

Technology for charging Lead-Acid starting batteries with stop.

OFF-ON-OFF-OFF

14

---

ON-OFF-OFF-OFF

15

---

OFF-OFF-OFF-OFF

NOTES:

A: charging curves with charge stop.

B: charging curves equivalent to group A but with a float charge of 2,30VPC (maintenance

charge).

A

B

FROMM Stretch Wrapping Division

Manual Battery Robot FR3xx/FR4xx.V01.01

Page: 1/1

FROMM Stretch Wrapping Division IT-37013 Caprino V.se (VR), ITALY

www.fromm-stretch.com E-mail service@fromm-stretch.com

The occurred problem

Charge the battery for 8 hours and after a few pallet the battery charger show orange led.

Possible remedies

Attention: if the tension was interrupted during 8 hours of charging then when re-start the

tension, the battery charger start again from zero.

1. Check all the connection (battery-battery charger);

2. Check the “Dip Switch Configuration”;

3. Discharger completely the battery;

4. Charger again the battery for 8-10 hours (finally shows=green led);

5. After have charger completely the battery, don’t keep away the plug of the tension and

touch the button ”S” on the battery charger (reads and writes the values A, U, h, C, E);

6. Check with the tension meter the voltage of the two batteries, max voltage must be 27

Volt;

The tension between the two batteries must be the same, if isn’t so, the battery that has

less voltage has a part in “short-circuit”.

Should the problem persist, contact the Customer After-Sales Service of Manufacturer.

Loading...

Loading...