1

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

Instruction Manual

AIRPAD MACHINE

AP100

50.2101

IMPORTANT!

Read these instructions carefully before installing and using this machine for the first time.

This will reduce your risk of injuring yourself or damaging your machine.

2

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

TABLE OF CONTENTS PAGE

1 GENERAL 4

2 DECLARATION OF CONFORMITY 4

3 INTRODUCTION 5

4 GENERAL SAFETY INFORMATION 5

5 SAFETY GUARDS 7

6 MAJOR MACHINE COMPONENTS 7

7 UNAUTHORIZED USE 8

8 RESIDUAL RISKS 8

9 RECOMMENDED PREVENTIVE MEASURES FOR USERS 8

10 DESCRIPTION AND OPERATION 9

11 EXPLANATION OF MACHINE IDENTIFICATION LABEL 9

12 MACHINE TECHNICAL SPECIFICATION 10

13 PACKAGING 10

14 UNPACKING 10

15 MOVING THE UNPACKED MACHINE 11

16 MACHINE INSTALLATION 12

17 VERIFICATIONS TO BE PERFORMED BEFORE STARTING THE MACHINE 12

17.1 Environmental conditions 12

17.2 Lighting conditions 12

18 POWER CONNECTION 13

19 INFORMATION REGARDING THE ELECTRICAL SYSTEM 13

20 CONTROL PANEL 13

21 STARTING THE MACHINE 15

21.1 Power on 15

21.2 Stopping the machine 15

21.3 Shutdown 16

21.4 Film roll loading 16

21.5 Loading the film on the rollers 17

21.6 Inserting the film in the guide 18

21.7 Selecting a program 19

21.8 Adjusting the meters of pillows 20

3

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

TABLE OF CONTENTS PAGE

22 POSSIBLE MACHINE ADJUSTMENTS 21

22.1 Adjusting speed 21

22.2 Adjusting filling 22

22.3 Adjusting heat sealing power 22

22.4 Preset programs 23

23 INSTALLABLE ACCESSORIES 23

24 ALARM WARNING ON THE DISPLAY 24

25 INFORMATION REGARDING NOISE 24

26 MAINTENANCE 24

26.1 Verification type and frequency 25

27 MAINTENANCE OPERATIONS THAT MUST BE PERFORMED EXCLUSIVELY BY QUALIFIED PERSONNEL

25

28 DECOMMISSIONING 25

29 INSTRUCTIONS FOR EMERGENCY SITUATIONS 26

4

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

1 GENERAL

• This machine was designed and built to produce air pillows for packaging using pre-sealed and pre-perforated 20-35

micron PE/PE and PE/PA folded film from FROMM. The use of this machine is reserved for professional operators

who have received appropriate instructions and training.

• This manual is to be used exclusively with the AP100 machine, designed to produce air pillows (Airpad).

• For safety reasons, this entire Instruction Manual must be read before installing or operating the machine, making

repairs or performing maintenance.

• In particular, please carefully read the SAFETY INSTRUCTIONS section, which presents the intended use of the

machine and the hazardous situations that could not be avoided when designing and manufacturing this machine.

• Tampering with the machine or using incompatible products (corrosive or flammable) is prohibited.

• Warranty coverage is valid if the machine is used exclusively for the purpose for which it was designed,

manufactured and protected. Please read the recommendations and information, including general questions,

regarding health and safety requirements, as well as the technical information provided by the Manufacturer to the

User regarding the machine’s use and operation.

• The warranty will not apply if the spare parts used are not original spare parts.

• Inappropriate use of the machine, including use that exceeds operating limits and modification of the machine or

parts thereof releases the manufacturer from any and all liability for personal injury or property damage.

For questions regarding any of the aforementioned, we recommend that our customers contact Customer Service.

2 DECLARATION OF CONFORMITY

Declaration of conformity

pursuant to EC Directives

We certify that the AP100 machine complies with the provisions of Directives 2006/42/EG, 2006/95/EG, 2004/108/EG

The following harmonized standards, national standards and normative documents are applicable:

UNI EN 12100-1/2:2005 + A 1:2009

ISO 13849-1:2008 + AC:2009

CEI EN 60204-1:2006

EN ISO 14121:2007

Technical design file from:

Fromm Italiana s.r.l.

Viale del Lavoro, 21

37013 Caprino Veronese (VR) –

ITALY

20.04.2015

R.Fromm

Administrator

FROMM Holding AG

Hinterbergstrasse 26

CH - 6330 Cham - Switzerland

5

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

3 INTRODUCTION

The AP100 machine was designed and manufactured pursuant to the European Community Directive 2006/42/EEC.

This document contains use and maintenance instructions, which must be carefully followed in order to obtain the best

production results and to maintain the initial dependability of your machine; in particular, it is recommended that you

avoid making any adjustments not indicated in this manual, as this may compromise the safety and reliability of the

machine.

Spare parts must be ordered directly from an authorized supplier.

FROMM is always available to provide you with assistance and reminds you that failure to comply with the information

provided in this document shall immediately void your machine warranty.

To correctly use the machine, it is important to know the basic definitions used to assess risk, and how this machine

was designed for safety:

Hazard

A potential source of personal injury or bodily harm.

Hazard area

Any area inside and/or near a machine in which the presence of a person represents a

risk for the safety and health of the person in question.

Exposed person

Any person who finds him or herself fully or partially inside a hazard area.

Operator

The person(s) in charge of installing, operating, adjusting, cleaning, repairing and

moving a machine, or of performing machine maintenance.

Risk

A combination of the probability and seriousness of personal injury or bodily harm that

may occur in a hazardous situation.

Safety guard

A machine component designed specifically to provide protection using a physical

barrier.

Safety device

A device (other than a guard) that reduces risk, when used alone or concurrently with a

safety guard.

Intended use

Use of the machine that complies with the information provided in the Instruction

Manual.

Predictable improper use

Use of the machine that does not comply with the information provided in the

Instruction Manual, but which may be derived from easily predictable behavior.

Training

The process of transferring information and methods to allow those exposed to learn

the correct and safe way to perform the operations assigned to them.

4 GENERAL SAFETY INFORMATION

Do not start the machine without first having read the Instruction Manual and been trained by qualified

personnel.

The user must always comply with local health and safety norms that apply in the country in which the

machine is installed.

Warning and prohibited action decals on the machine

The following warning and prohibited action decals are located on the machine and/or accessories.

Caution, moving parts, do not remove the safety devices.

6

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

Caution, presence of components that may crush or cut.

Caution, hot surfaces.

Do not perform any operations before disconnecting machine voltage.

SAFETY INSTRUCTIONS

CAUTION!

The following conditions must always be met, unless otherwise indicated elsewhere in this manual.

• This machine was delivered by FROMM AIRPAD AG and may be used to create air pillows for packaging, as

indicated in the machine description and the technical data.

Use of the machine other than for its described purpose may represent a hazard, causing damage to the machine and

putting the safety of the operator or other people in the vicinity of the machine at risk.

• Carefully read this manual before using the machine.

• The machine was not built using components that pose particular disposal issues.

• In any event, these components must be disposed of in strict compliance with corresponding laws that are applicable

in the country in which the machine is used, and only by qualified personnel able to assess any potential risks.

• Only personnel trained for this purpose may operate the machine.

• Use the emergency shutdown to stop the machine immediately.

• Only qualified electricians may perform work on the machine’s electrical system.

• When the machine is installed, always make sure that the safety system controls are correctly installed and operate

efficiently. If there are any malfunctions, immediately interrupt the production cycle and ask authorized Technical

Assistance to intervene.

• Perform adjustment and maintenance operations periodically and in compliance with requested requirements, as

indicated in the MAINTENANCE section.

• Safety devices must not be tampered with and/or deactivated.

• The manufacturer supplies the machine ready-to-use, to meet the electrical standards that apply in the country of

use.

• The manufacturer will provide training for machine operators. Otherwise, training must be provided by the installation

company.

• The machines are designed and built to comply with all applicable safety standards.

7

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

• In the event of fire, only dry chemical powder or CO2 extinguishers must be used, in order to avoid damaging

machine equipment or its wiring.

• In the event of flooding, all power sources must be disconnected before entering the room in which the machine is

installed.

5 SAFETY GUARDS

Safety devices and standard behavior

This machine was designed and created to produce air pillows for packaging under safe conditions and with a

minimum amount of effort from the operator.

This section lists the safety devices used, as well as rules that must be respected in order to minimize residual risk.

Fixed protection

The AP100 features fixed guards to prevent access to hazardous areas (moving components or parts with high

surface temperatures, including heat-seal units).

Machine operators must wear appropriate clothing. Use of this machine is restricted to appropriately-trained

professionals.

IMPORTANT

STARTING OR USING THE MACHINE WITH THE SAFETY GUARDS REMOVED IS

PROHIBITED.

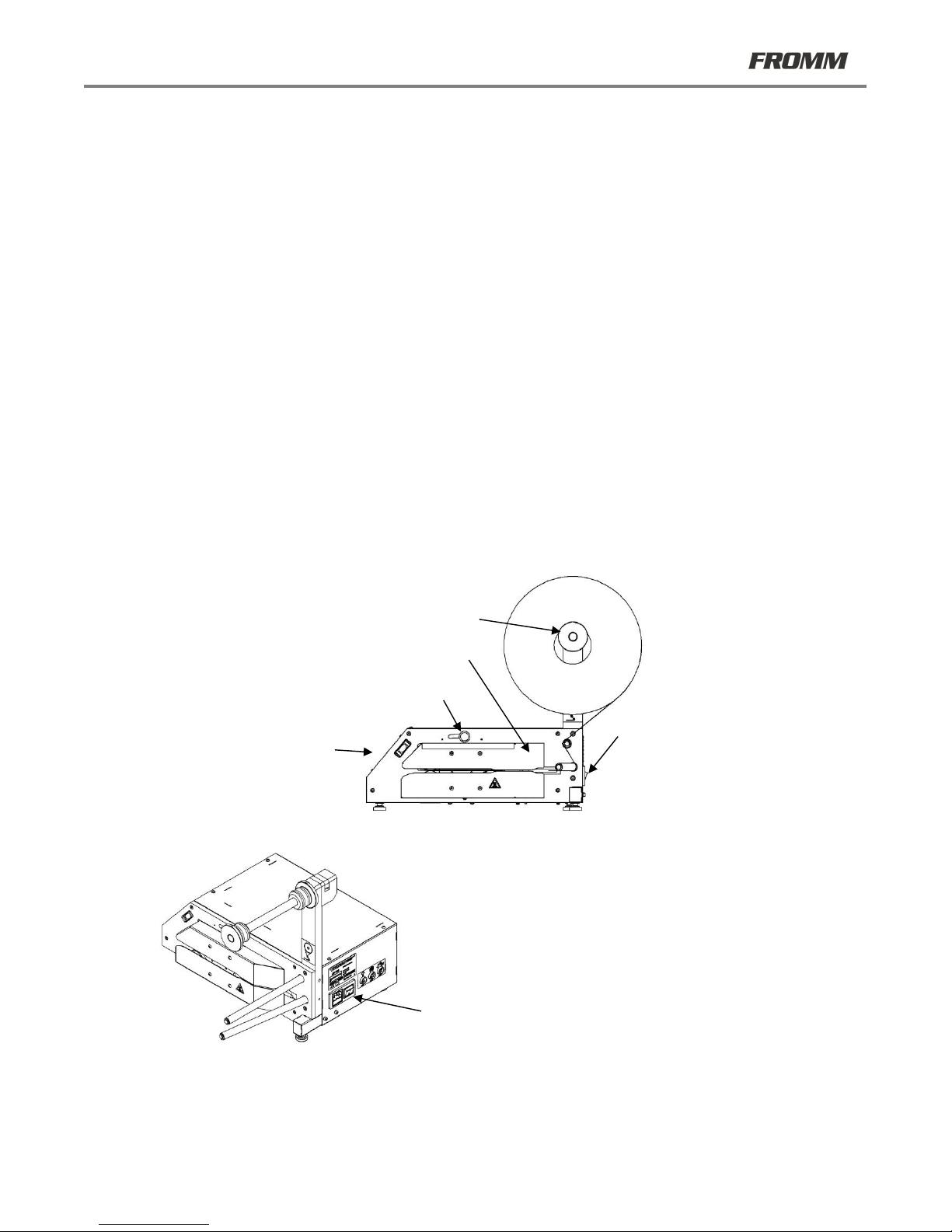

6 MAJOR MACHINE COMPONENTS

Caution! For safety reasons, do not remove the protective housings from the machine.

Start / emgergency switch

Film roll holder

Protective housing

Unit lifting knob

Control panel

Start / emergency switch

8

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

7 UNAUTHORIZED USE

This machine must be used only for the purposes intended by the manufacturer.

In particular, it is prohibited to use even part of the machine:

- without guards and/or with deactivated or missing safety devices;

- if the machine has not been correctly installed;

- to handle materials other than those supplied by FROMM;

- outdoors, where the machine may be exposed to rain or high levels of humidity;

- in dangerous conditions or if the machine malfunctions;

- for improper use of the machine or for use by untrained personnel;

- for use that does not comply with specific standards;

- in the event of power supply issues;

- in the event of irregular maintenance;

- subsequent to unauthorized modifications or operations;

- with full or partial failure to comply with instructions;

- with accessories other than those recommended by the manufacturer;

Use of the machine is not foreseen:

- in environments at temperatures below +5 or above +30°C.

- in environments with humidity above 80%.

A written statement from the manufacturer is required for exceptions to the above.

Modifications not authorized by the Manufacturer, which alter the machine’s functions and modify risks and/or create

new risk, shall be the full responsibility of the party who performed these modifications.

When these modifications are performed without prior manufacturer authorization, they will nullify all forms of warranty

and invalidate the Declaration of Conformity for the Machine Directive 2006/42/EC.

Use of this machine for purposes other than those recommended by the manufacturer in this manual is strictly

prohibited.

Consequently, the Manufacturer shall not be held liable for injury to persons or animals or damage to property caused

by the improper or prohibited use of the machine.

8 RESIDUAL RISKS

a) Noise:

- though the machine is not noisy, the use of noise protection may be requested due to the sound pressure level

(SPL) in the environment in which the machine is installed.

b) When, for operation or maintenance, the machine must be used in manual mode, the following Personal Protective

Equipment must be used:

- Gloves

c) Heat-related (burns): even though the machine features specific safety guards and signs to warn the operator, a

risk for burns exists when coming into contact with the heat-sealing elements during maintenance;

d) Electricity-related (electrocution, burns):

- risk created by the dangerous residual voltage and current inside the machine, even after the main source of

power has been disconnected.

9 RECOMMENDED PREVENTIVE MEASURES FOR USERS

Startup and operation procedures must be correctly followed

Before performing any maintenance operations or removing any guards, ensure that the machine has been

stopped and that the cutoff switches have been used to disconnect the electrical power supply

9

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

Only remove the guards to perform maintenance activities

10 DESCRIPTION AND OPERATION

The AP100 is a machine designed to produce air pillows for product protection and void-filling. The machine uses film

supplied by FROMM or made to its specifications. Heat seals are made using a pulsed heat-sealing process. Each

type of pillow uses the appropriate temperature and filling pressure for the specific product. The use of this machine is

reserved for professional operators who have received appropriate instructions and training.

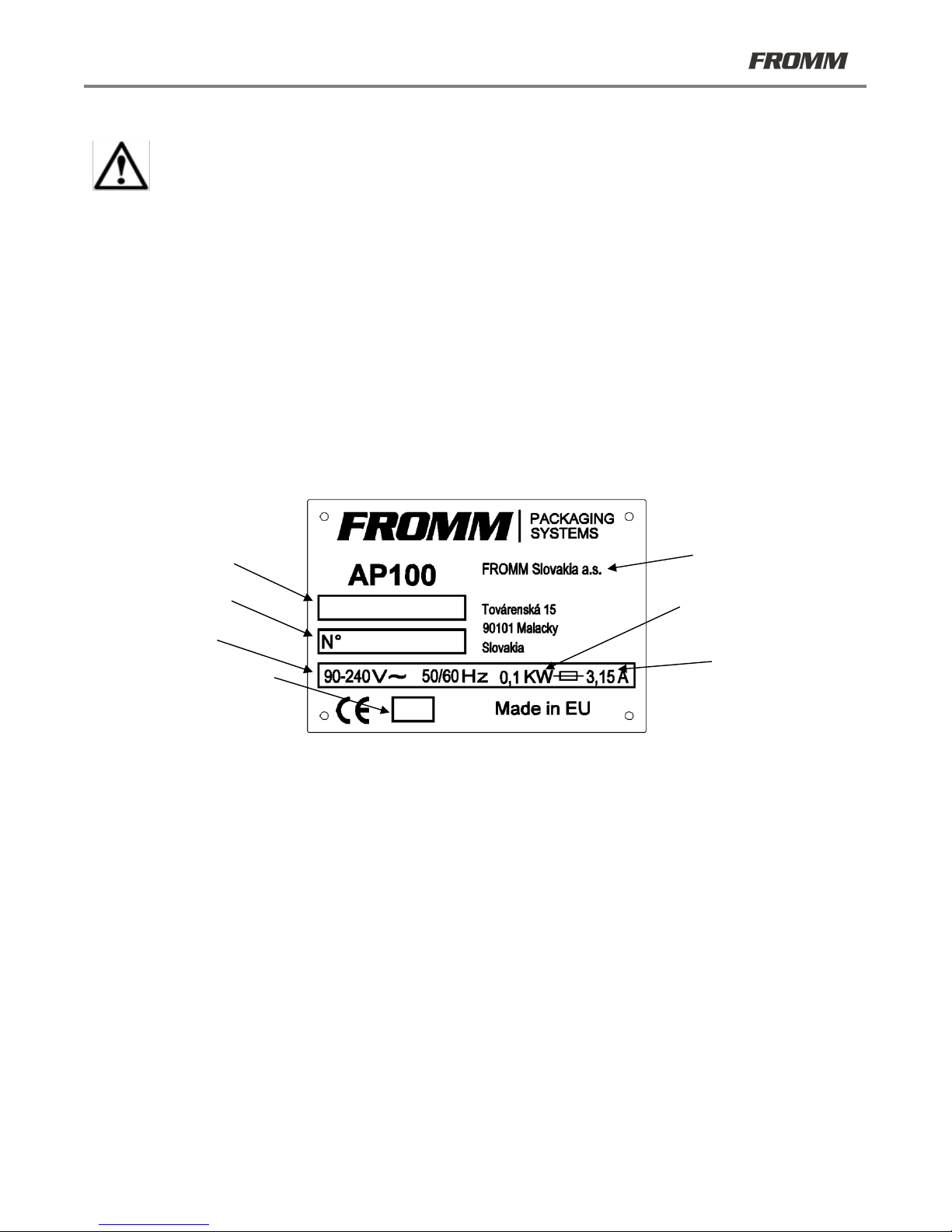

11 EXPLANATION OF MACHINE IDENTIFICATION LABEL

An identification label containing the following information is affixed to the rear of the machine. If the label is damaged,

contact the Manufacturer immediately.

Manufacturer name: FROMM SLOVAKIA a.s.

Machine type: AP100

Serial number: Manufacturer serial number.

Power supply: 90-240V 50/60 Hz.

Power used: 0,1 kW

Breaking fuse: 3.15 Amp

Year of manufacture: Year in which the machine was produced by the manufacturer.

Manufacturer

Power used

Fuse

Machine code

Serial number

Volts/Hertz

Year of manufacture

10

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

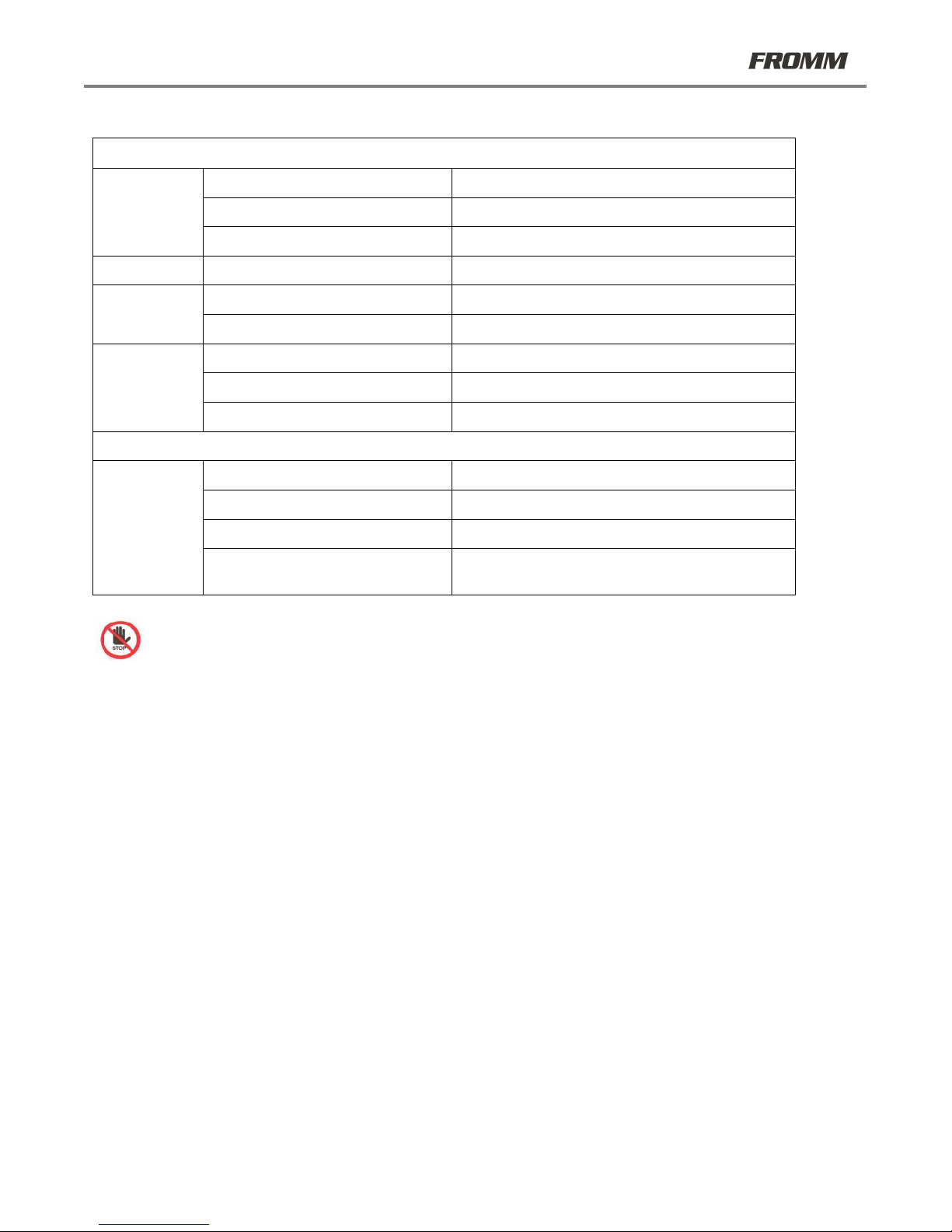

12 MACHINES TECHNICAL SPECIFICATIONS

Machine

Dimensions

Width

470 mm

Length

440 mm

Height (without film roll)

379 mm

Weight

Total weight (without film roll)

approx. 11,4 kg

Conditions

Operating temperature

+ 5 to +30oC

Operating environment

clean, dry

Electricity

Power supply

90-240 V 50/60Hz

Rated power

0.2 kVA

Power used

approx. 0.1 kW

Film

Film width

max. 200 mm

Film type

PE/PE - PE/PA

Film thickness

20 - 35 µm

Film roll dimensions

int.Ø 76 mm

ext.Ø 280 mm max.

CAUTION: do not use film that has not been supplied by FROMM, or that is of a different thickness than

specified without contacting the manufacturer.

13 PACKAGING

The machine is generally shipped in a cardboard box.

The package contents is covered:

- with a barrier bag in low-density polyethylene (LPDE), which is heat-sealed in the event of sea transport;

- with cling film for all other types of transport.

- In both cases, filling materials are added.

In accordance with UNI 9151/3, the packaging contains enough silica gel desiccant to keep moisture levels below

35% during the estimated transport time (unless otherwise agreed).

Note: Boxes can be stacked only 4 high!

14 UNPACKING

UNPACKING AND INSPECTION UPON RECEIPT

Upon receipt, inspect the packaging to ensure that it has not been damaged or tampered with.

THE TRANSPORTER AND MANUFACTURER SHOULD BE NOTIFIED OF ANY DAMAGE TO THE MACHINE

OBSERVED UPON RECEIPT.

Opening the packaging

- Open the cover of the box.

- Remove the filling material.

- Remove the desiccant, if present.

- Ensure that no small machine parts remain in the box.

- Perform a detailed inspection of the general conditions.

11

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

15 MOVING THE UNPACKED MACHINE

Do not stand under hanging loads.

Be especially careful with hanging parts, and the risks associated with these parts.

The machine may be lifted and moved in the following fashion:

- One person may move the machine;

Maintain the machine in a vertical position when moving, taking

care to avoid injuring people and damaging property.

These instructions must be followed under all circumstances.

Do not stand near the operation areas under any circumstances.

12

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

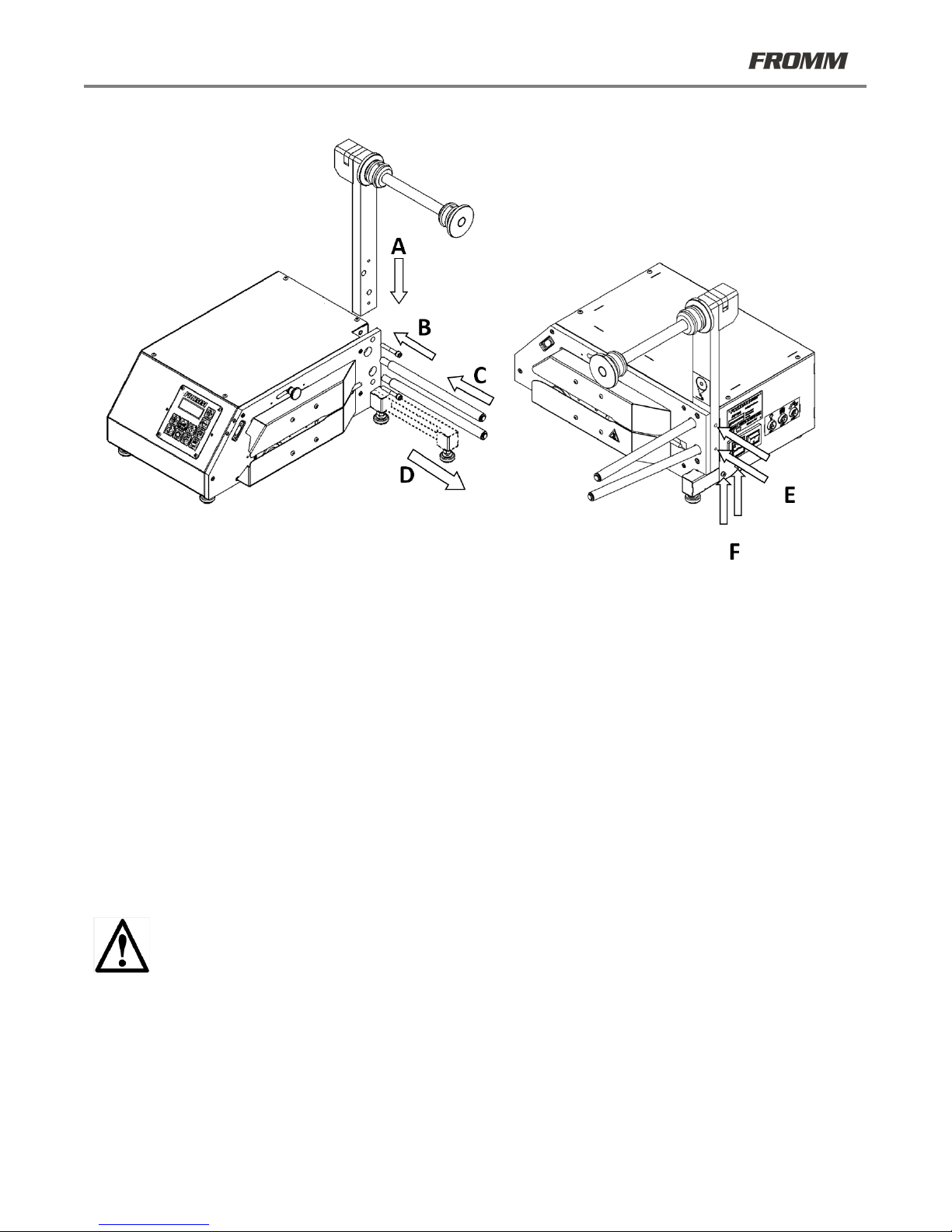

16 MACHINE INSTALLATION

Assemble the machine before positioning it in the area in which it will be operated:

-insert the roll holder arm ( A in the drawing) and secure it with screws ( B in the drawing);

-loosen and remove the screws ( F in the drawing), and remove the footed arm ( D in the drawing) then insert the

screws in their new position and secure the arm in the fully extended position;

-insert the rollers ( C in the drawing), and secure them with hexagon socket head screws ( E in the drawing);

The machine features adjustable feet, and may be wheeled using the trolley provided by FROMM. Otherwise, it must

be positioned on a flat, level and sufficiently resistant surface using the appropriate resistance, ensuring that

the retractable footed support bar is fixed in its external position ( D in the drawing) . The machine must have a

suitable container to collect the air pillows produced, or the abovementioned basket.

17 VERIFICATIONS TO BE PERFORMED BEFORE STARTING THE MACHINE

Before starting the machine, ensure that no parts have been left on any part of the machine.

17.1 Environmental conditions

The machine may operate at temperatures between +5°C and +30°C.

The machine must not be started if exposed to poor weather conditions; in addition, if the machine

is stored, even temporarily, outdoors, it must be suitably protected from the environment.

17.2 Lighting conditions

The work area must be sufficiently lit, with a minimum value of 500 lx.

13

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

18 POWER CONNECTION

CAUTION - RISK OF ELECTROCUTION

The machine is prepared for electrical connection using a male/female power plug, and the cable supplied allows it to

be connected to the electrical mains using a Schuko plug (EC 7/7).

The power socket to which the machine will be connected must have a rated (max 10A) and differential (max 30mA)

circuit breaker installed upstream and coordinated with the User’s ground system.

In addition, upstream of the socket, a power supply cutoff switch must be installed.

The cable supplied is a multi-strand, flexible, PVC-insulated H05VV-F, which must be protected against abrasion and

cutting, and must be positioned such that it does not hinder the passage of people or things.

Caution

Before performing any operations, make sure that the mains voltage and frequency values correspond to

those on the machine's identification label. The Manufacturer shall not be held liable for machine connection

to electrical networks that do not correspond to the machine identification label. All electrical connections

must be performed by specialized personnel, and in full compliance with applicable norms.

19 INFORMATION REGARDING THE ELECTRICAL SYSTEM

The electrical equipment complies with the following standards:

• Low Voltage Directive 2006/95/EC

• Electromagnetic Compatibility Directive 2004/108/EC

• IEC/EN 60204-1 “Safety of machinery – Electrical equipment of machines”

• EC/EN 60439-1 “Low-voltage switchgear and controlgear assemblies (TTA)”

All components meet current market standards of approval.

• Do not have repairs performed by unqualified persons.

• Unauthorized persons must not use or make adjustments to the machine.

• Maintenance activities on the electrical system must be performed solely by qualified and authorized personnel.

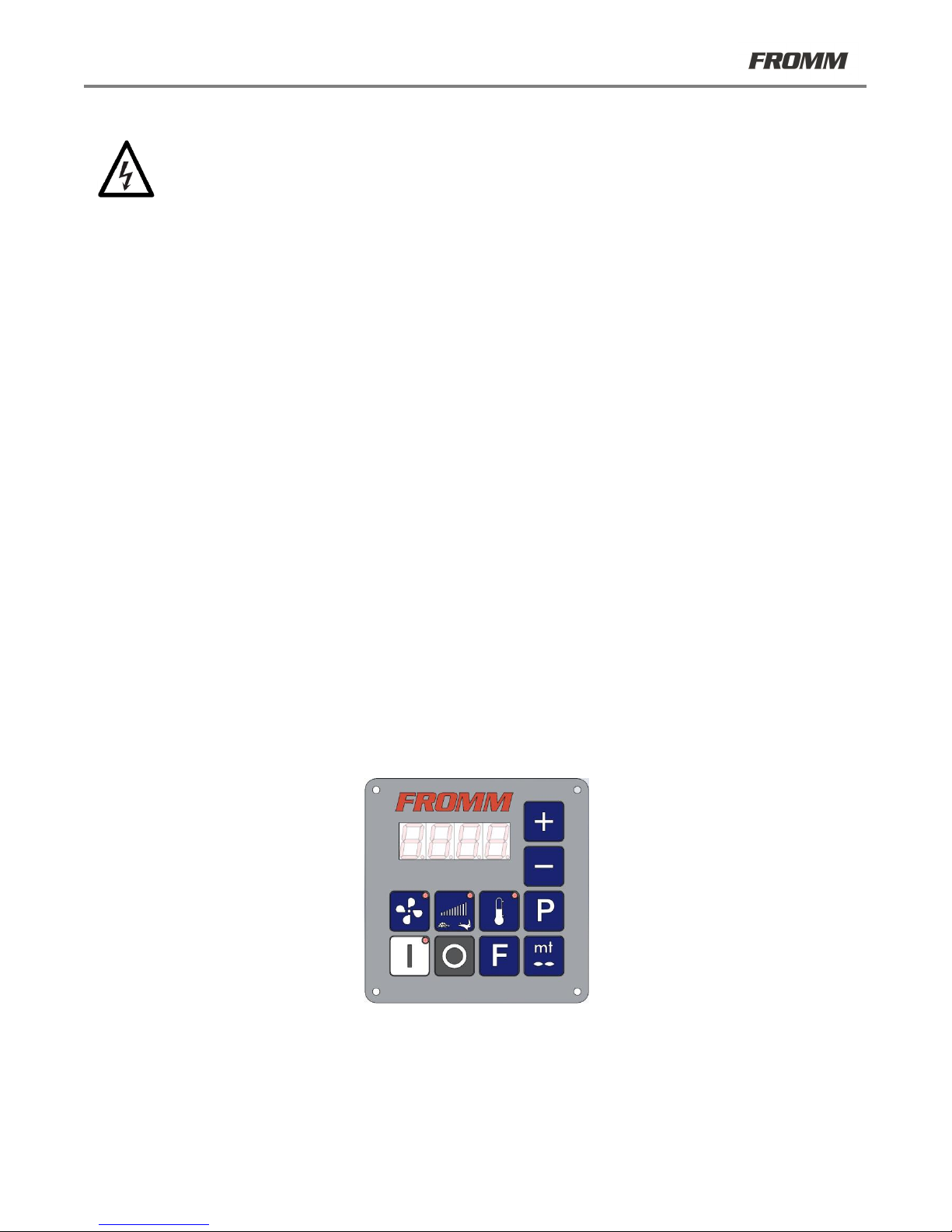

20 CONTROL PANEL

14

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

START - press the button and the red LED will illuminate. The automatic cycle will begin and

the machine will execute the active program.

STOP - press the STOP button to stop the automatic cycle (STOP BUTTON)

PROGRAM SELECTION - press the button. The letter "P" on the display flashes. Select the

desired program using the and keys.

After approximately 4 seconds, the value selected is saved and stops flashing.

CAUTION: The available programs are set according to the film used. Further modifications

may only be made by authorized personnel.

FAN POWER - press the button and the red LED will illuminate. Select the desired value

using the and keys.

After approximately 4 seconds, the selected value is saved and the screen displays the first

page.

CAUTION: the allowed variation interval is limited to prevent the proper machine functioning

from being affected.

SPEED SELECTION - press the button and the red LED will illuminate. Select the desired

value using the and keys.

After approximately 4 seconds, the selected value is saved and the screen displays the first

page.

CAUTION: the allowed variation interval is limited to prevent the proper machine functioning

from being affected.

POWER SELECTION - press the button and the red LED will illuminate. Select the desired

value using the and keys.

After approximately 4 seconds, the selected value is saved and the screen displays the first

page.

CAUTION: the allowed variation interval is limited to prevent the proper machine functioning

from being affected.

METER SELECTION - press the button. A value will appear on the screen. Select the desired

value using the and keys.

After approximately 4 seconds, the selected value is saved and the screen displays the first

page.

Each time the machine is started, the machine will produce a length of pillows equal to the

number of meters selected. This function is disabled when the value 0 is selected.

FUNCTION KEY - press the button. The letter "F" and a value will appear on the screen.

Select the desired value using the and keys.

Each value corresponds to an additional function (if activated).

By pressing F 0 all additional functions are disabled.

15

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

21 STARTING THE MACHINE

21.1 Power on

The machine is turned on using a switch found on the rear of the machine. The electronics start up and the display is

illuminated. Data is loaded in a few minutes and the machine is then ready for use.

Powering on the

machine

When the machine is turned on, it displays the last

program used.

Press the button

The machine will start, using the last program and

parameters selected.

The machine will start in automatic mode according to the operating mode selected. The machine may only be started

in automatic mode.

21.2 STOPPING THE MACHINE

The machine features an on/off switch.

The machine may also be shutdown under any of the following conditions:

- a. Using the stop button .

- b. After an alarm.

- c. When the pillow basket is overfilled (if installed).

- d. When the number of meters selected in the program has been reached.

- e. By the optical sensor on the front of the machine.

In the abovementioned cases, it may be necessary to perform an action to restart the machine or to satisfy a specific

condition:

- a. Press the start button .

- b. Eliminate the error and press start.

- c. The machine starts in automatic mode when the sensor on the machine allows it.

- d. The machine starts when the start button is pressed.

16

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

21.3 Shutdown

Press the STOP button

To end the active cycle.

Shutdown

Use the switch located on the back of the machine to completely shutdown the

machine. This same switch should be used in case of emergency. After the switch is

moved to the 0 position, the machine will stop immediately and power will be cut for

the main parts of the machine.

21.4 Film roll loading

21.4.1

Lift the top feed unit by pulling the knob in the direction

indicated by the arrow.

21.4.2

Insert the roll and ensure that the open channel end of the

film is on the inside.

Open channel

end

17

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

21.4.3

Make sure that the roll is fully inside the containing flanges.

21.4.4

If there is no opening, cut the corner of the film on the open

channel end.

21.5 Loading the film on the rollers

21.5.1

For a right-feed roll, feed the film through the rollers with

the inside on the upper roller and the outside touching the

lower roller.

21.5.2

For a left-feed roll, feed the film around the outside of the

lower roller.

Open channel

end

18

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

21.6 Inserting the film in the guide

21.6.1

Slide the cut corner of the film on the nozzle.

21.6.2

IMPORTANT:

Feed the film through to the end of the housing.

21.6.3

Lower the top feed unit by pulling the knob in the direction

indicated by the arrow.

19

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

21.7 Selecting a program

The machine is supplied with the programs used by the customer.

The programs differ in pillow size and in the film used.

The program may be changed only when the machine is stopped (after the stop button has been pressed).

Proceed as follows to select a program:

Press the button

The active program will flash. The program

may now be changed.

Use the + and - keys

Use the +/- keys to select the desired

program number

After 4 seconds, the newly selected

program is saved.

The machine is ready to be used with the

new program.

20

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

21.8 Adjusting the meters of pillows

Note that selecting 0 as a value will eliminate this function.

This value may also be modified when the machine is in operation.

Press the button

The current value is displayed.

Use the + and - keys

Use the +/- keys to select the number

of meters desired (this number may be

between 0 and 999)

The machine will stop after reaching

the set number of meters.

After approximately 4 seconds, the

selected value is saved and the screen

displays the first page.

21

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

22 POSSIBLE MACHINE ADJUSTMENTS

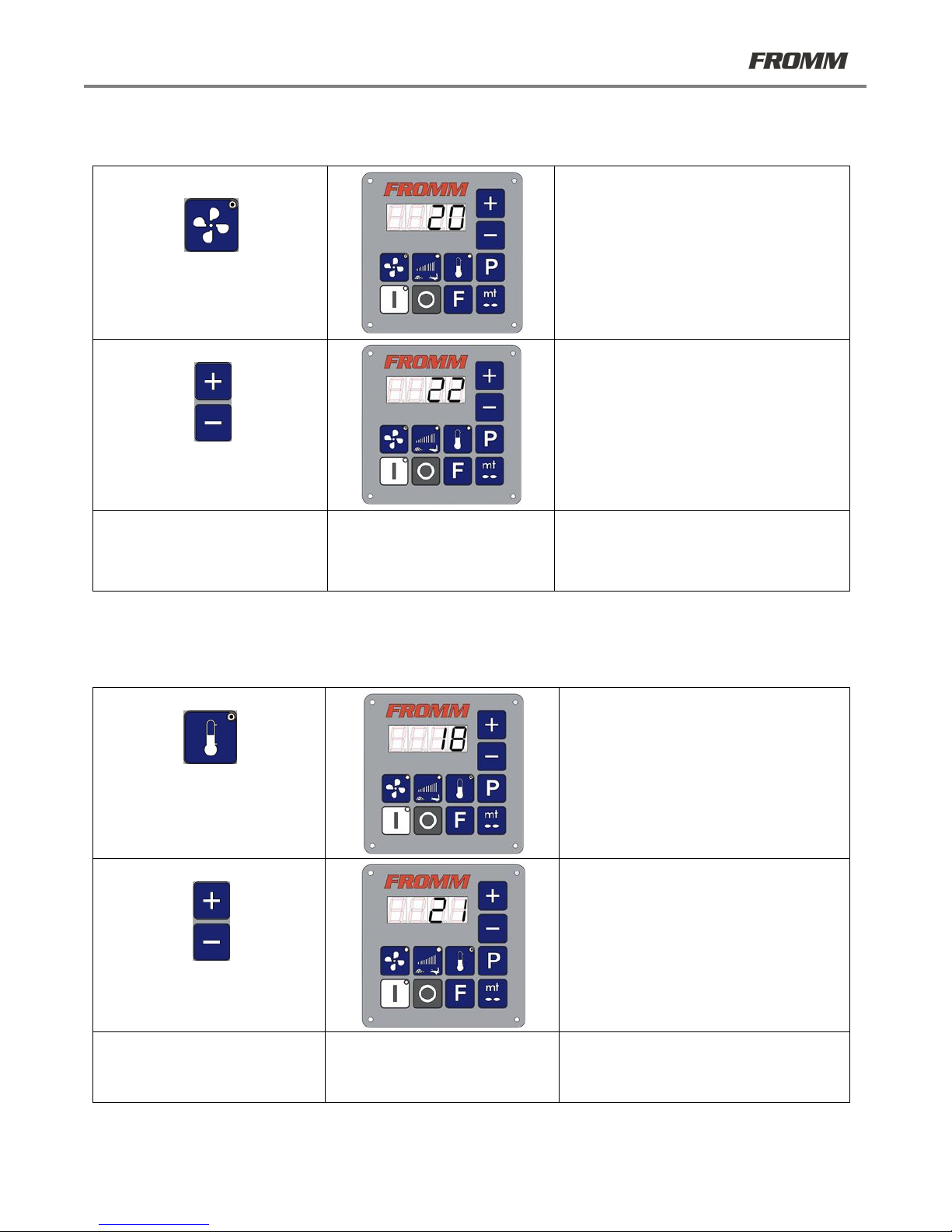

22.1 Adjusting speed

To increase or decrease the feed speed.

This value may also be modified when the machine is in operation.

Press the button

The LED on the button is lit and the

current value is displayed on the

screen.

Use the + and - keys

Select the desired value using the +/keys (this value may be modified by +

or - 5 with respect to the default value,

and always within the limits set by the

Manufacturer).

After approximately 4 seconds, the

selected value is saved and the

screen displays the first page.

22

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

22.2 Adjusting filling

If during the production cycle, the air pillows are too full or not filled sufficiently, the fan speed may be adjusted.

This value may also be modified when the machine is in operation.

Press the button

The LED on the button is lit and the

current value is displayed on the screen.

Use the + and - keys

Select the desired value using the +/- keys

(this value may be modified by + 2 and 10 with respect to the default value, and

always within the limits set by the

Manufacturer).

After approximately 4 seconds, the

selected value is saved and the screen

displays the first page.

22.3 Adjusting heat-sealing power

If during the production cycle, the heat seals are excessively sealed or not sealed enough, the heat-sealing power

may be adjusted.

This value may also be modified when the machine is in operation.

Press the button

The LED on the button is lit and the

current value is displayed on the screen

Use the + and - keys

Select the desired value using the +/keys (this value may be modified by + 3

and - 5 with respect to the default value,

and always within the limits set by the

Manufacturer).

After approximately 4 seconds, the

selected value is saved and the screen

displays the first page.

23

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

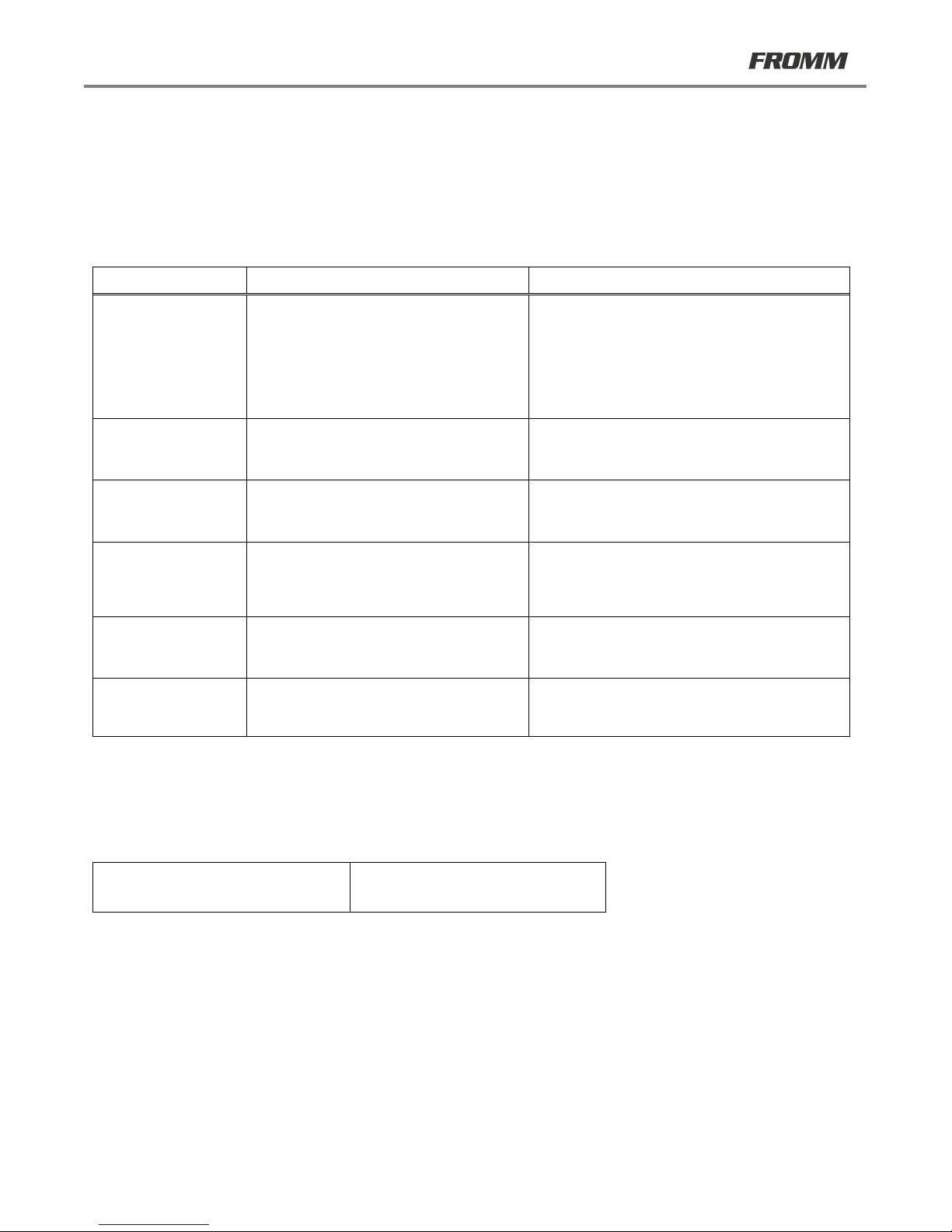

22.4 PRESET PROGRAMS

The machine is supplied with the following factory-set programs.

Program

File code

Pillow length

[mm]

Film

thickness

[µm]

Fan speed

[%]

Feed speed

[%]

Heat-seal

power [%]

1

135

25

15

14

13

2

200

25

17

15

13 3

135

20

15

14

13 4

200

20

17

15

13

23 INSTALLABLE ACCESSORIES

The following optional accessories may be installed on the machine.

Flasher

Remote

sensor

Pedal

control

24

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

24 ALARM WARNING ON THE DISPLAY

The machine features a self-diagnosis system: in the event of an anomaly, sensors transmit signals to the system.

The system uses codes to identify the various anomalies. The table below indicates the code, type of anomaly

causing the alarm and the actions that must be taken.

Code

Cause

Action

E1

Out of film. The film roll is empty.

The film is off the nozzle.

The teflon or silicone belt is broken.

Replace the roll of film and load it onto the

machine.

Repeat the film loading operation (section

21.5).

Replace the teflon or silicone belt.

E2

The front sensor has detected an

accumulation of pillows near the output

rollers.

Remove the accumulated pillows to free the

sensor. The machine will restart in automatic

mode.

E3

Machine operation inhibited by remote

control

E4

Overheating. The machine reached an

excessively high temperature and was

automatically stopped.

After the necessary cooling period had

passed, press the START button. If the error

persists, call Technical Assistance and provide

the error code.

E5

The remote sensor (basket) has

detected an accumulation of pillows in

the basket.

Remove the accumulated pillows to free the

sensor. The machine will restart in automatic

mode.

A1

The machine has filled the maximum

number of meters set in the counter for

scheduled maintenance.

Contact Technical Assistance to have general

maintenance performed on the machine.

25 INFORMATION REGARDING NOISE

For machines identical to this machine, noise has been measured during pillow production using 25 micron film, at 1.6

m from the ground and at 1.5 meters from the machine. The following maximum values were measured:

Continuous sound level pressure

(SLP) equivalent weighted A

Leq db (A) < 70

These values may vary by a maximum of 5% due to environmental and production factors.

26 MAINTENANCE

Maintenance operations that are performed with the safety guards removed must be performed when the machine is

shut off and disconnected from the power supply.

Maintenance personnel qualifications

The operator performing the mechanical and electrical maintenance phases must have completed a theoretical and

practical training course that includes the following:

25

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

- machine theory and function;

- assistance from manufacturer technicians for first startup;

Training duration and the degree of technician preparation must be agreed and verified jointly by the Manufacturer

and the Customer, according to the various situations encountered.

26.1 Verification type and frequency

For supplementary maintenance, we recommend contacting FROMM AIRPAD AG.

When the machine is used correctly and under the proper conditions, it generally does not require being overhauled.

Contact FROMM AIRPAD AG Technical Support should any anomalies appear.

26.1.1 Daily maintenance

- Clean the machine at the end of each shift if the machine operates in a dusty environment

- Do not use flammable liquids to clean the machine.

26.1.2 Quarterly maintenance

Check the condition of the electrical equipment and assess its reliability for the time interval until the next maintenance

inspection.

26.1.3 Yearly or supplementary maintenance

After one year of operation, certain highly-used components in the production cycle may need to be replaced or

overhauled. Depending on the exceptional character of these operations, the customer may decide to:

- Replace these components by ordering original spare parts (customer is responsible in the event of incorrect

installation)

- Request on-site assistance from a technician, for more complex or extensive operations.

- Send the machine to the manufacturer for a complete overhaul.

Note: if the customer decides to personally replace components, it must use a qualified technician able to perform the

necessary operations. The Manufacturer declines all responsibility for supplementary operations performed by the

unauthorized personnel, which might lead to malfunction and/or damage and/or production that does not comply with

standards.

27 MAINTENANCE OPERATIONS THAT MUST BE PERFORMED

EXCLUSIVELY BY QUALIFIED PERSONNEL

All operations performed to correct an anomaly must be performed by FROMM AIRPAD AG Technical Service.

All preventive maintenance or breakdown repair operations not described in this manual must be performed by

employees of FROMM AIRPAD AG or by previously authorized personnel.

CAUTION:

Failure to follow these instructions shall immediately void all contractually-agreed warranty coverage.

28 DECOMMISSIONING

MACHINE DECOMMISSIONING

Before definitively decommissioning the machine, and before disassembly:

- Disconnect the machine from all power sources;

- Disconnect the machine from material loading devices.

26

Copying all or part of this manual in any way or form is strictly prohibited without written permission from its author © 2015

website: www.fromm-pack.com

DISASSEMBLY AND DISMANTLING

Once decommissioning operations have been completed, the various parts of the machine may be disassembled.

DISPOSAL

After the individual components have been removed, sort them according to material.

Metals: frame, connectors etc.

Aluminum;

Plastics: seals, cables etc.

Electrical material.

During disposal, recover components that may be recovered for re-use.

AFTER SORTING, ALL MACHINE COMPONENTS MUST BE DISPOSED OF BY

SPECIALIZED COMPANIES THAT WORK IN ACCORDANCE WITH LAWS THAT ARE

APPLICABLE IN THE COUNTRY OF USE.

29 INSTRUCTIONS FOR EMERGENCY SITUATIONS

TYPE OF FIRE EXTINGUISHING SYSTEMS TO USE

The machine consists almost entirely of metal materials. For this reason, there is not a significant risk of fire. However,

should such an event occur, proceed as follows:

- Disconnect the power supply using the power cutoff switch on the rear of the machine.

- Extinguish the fire using dry chemical powder or CO2 fire extinguishers.

Loading...

Loading...