Operating Instructions

Wood chip boiler T4 24-150 (Touch)

Translation of the original German operating instructions for the operator

Read and follow the instructions and safety information!

Technical changes, typographical errors and omissions reserved!

B0830113_en | Edition 06/11/2013

Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

Table of Contents

1 General 4

1.1 T4 product overview 5

2 Safety 7

2.1 Hazard levels of warnings 7

2.2 Pictograms used 8

2.3 General safety information 9

2.4 Permitted uses 10

2.4.1 The Clean Air Act 1993 and Smoke Control Areas 10

2.4.2 Permitted fuels 11

Wood chips

11

Wood pellets

11

Changing the fuel

11

2.4.3 Non-permitted fuels 12

2.5 Qualification of operating staff 12

2.6 Protective equipment for operating staff 12

2.7 Design information 12

2.7.1 Installation and approval of the heating system 13

2.7.2 General information for installation room (boiler room) 13

2.7.3 Requirements for central heating water 14

2.7.4 Notes for using pressure maintenance systems 14

2.7.5 Return temperature control 15

2.7.6 Use with storage tank 15

2.7.7 Chimney connection/chimney system 15

2.8 Safety devices 16

2.9 Residual risks 17

2.10 Emergency procedure 18

2.10.1 Overheating of the system 18

2.10.2 Smell of flue gas 18

2.10.3 Fire in the system 19

3 Operating the System 20

3.1 Assembly and initial startup 20

3.2 Filling/refilling the store with fuel 21

3.2.1 Loading of fuel for a partially emptied store with rotary agitator 21

3.2.2 Loading wood chips in an empty store (not under pressure) 21

3.2.3 Blowing in pellets for a store with pellet screw 22

3.2.4 Blowing in fuel for a partially emptied store with rotary agitator 22

3.2.5 Blowing in fuel for an empty store with rotary agitator 22

3.3 Heating up the boiler 23

3.3.1 Switching on the power supply 23

3.3.2 Switching on the boiler 24

3.3.3 Controlling the boiler 24

3.3.4 Switching off the boiler 24

3.3.5 Switching off the power supply 24

4 Boiler Servicing 25

Table of Contents

2 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

4.1 General information on servicing 25

4.2 Inspection and cleaning 27

4.2.1 Inspection 27

Checking the system pressure

27

Checking the safety valve

27

Checking the geared motors

27

4.2.2 Cleaning 28

Emptying the ash container

28

4.2.3 Recurrent check and cleaning 30

Before starting inspection and cleaning work

30

After inspection and cleaning work

30

Cleaning the combustion chamber

31

Cleaning the heat-exchanger and flue gas collection chamber

33

Cleaning the flue gas temperature sensor

35

Cleaning the flue gas pipe

35

Checking the seal on the doors

35

Checking the draught controller flap

36

Cleaning the measurement line of the underpressure controller

36

4.3 Emissions measurement by chimney sweep or regulatory body 38

4.3.1 Measurement at nominal load 38

4.3.2 Measurement at partial load (if necessary) 38

4.4 Maintenance agreement / Customer service 39

4.5 Replacement parts 39

4.6 Disposal information 39

4.6.1 Disposal of the ash 39

4.6.2 Disposal of system components 39

5 Troubleshooting 40

5.1 General fault with power supply 40

5.1.1 Behaviour of system after a power failure 40

5.2 Excessive temperature 40

5.3 Faults with fault message 41

5.3.1 Procedure for fault messages 41

5.3.2 Acknowledging a fault message 41

6 Appendix 42

6.1 Addresses 42

6.1.1 Address of manufacturer 42

6.1.2 Address of the installer 42

Table of Contents

Operating Instructions T4 24-150 (Touch) | B0830113_en 3

1 General

Thank you for choosing a quality product from Froling. The product features a state-ofthe-art design and conforms to all currently applicable standards and testing guide‐

lines.

Please read and observe the documentation provided and always keep it close to the

system for reference. It contains important safety information and all the operation and

maintenance specifications needed to operate the system safely, properly, environ‐

mentally friendly and cost-effectively.

The constant further development of our products means that there may be minor dif‐

ferences from the pictures and content. If you discover any errors, please let us know:

doku@froeling.com

Subject to technical change.

Guarantee conditions

Our sale and delivery conditions generally apply. These conditions have been made

available to customers, and customers have been made aware of them at the time of

order completion.

You can also find the guarantee conditions on the enclosed guarantee certificate.

1

General

4 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

1.1 T4 product overview

1 Froling T4 wood chip boiler

2 Main switch: switches the power supply on and off for the entire system

3 High-limit thermostat STL

4 Mains supply

5 Control panel of the Lambdatronic H 3200 T4 Touch controller

5.1 Status LED (operating status):

- GREEN constant: BOILER SWITCHED ON

- GREEN flashing (interval: 5 sec OFF, 1 sec ON): BOILER SWITCHED OFF

- ORANGE flashing: WARNING

- RED flashing: FAULT

5.2 Large touch screen for displaying and changing operating statuses and parameters

5.3 Brightness sensor to automatically adjust the display brightness

5.4 USB port for connecting a USB stick for software updates

6 Insulating cover

7 Heat exchanger cover

8 Service port

General

1

T4 product overview

Operating Instructions T4 24-150 (Touch) | B0830113_en 5

9 Fuel transport unit with rotary valve as a burn back protection system (BBF) and stok‐

er screw for fuel transport

10 Automatic ignition

11 Combustion chamber with fireclay combustion chamber and automatic tipping grate

12 Ash box for combined automatic ash removal from combustion chamber and heat ex‐

changer

13 Combustion chamber door with screw lock and inspection glass

14 WOS system with turbulators and automatic drive for heat exchanger cleaning

15 Broadband probe

16 Flue gas temperature sensor

1

General

T4 product overview

6 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

2 Safety

2.1 Hazard levels of warnings

This documentation uses warnings with the following hazard levels to indicate direct

hazards and important safety instructions:

DANGER

The dangerous situation is imminent and if measures are not observed it will lead

to serious injury or death. You must follow the instructions!

WARNING

The dangerous situation may occur and if measures are not observed it will lead

to serious injury or death. Work with extreme care.

CAUTION

The dangerous situation may occur and if measures are not observed it will lead

to minor injuries or damage to property.

Safety

2

Hazard levels of warnings

Operating Instructions T4 24-150 (Touch) | B0830113_en 7

2.2 Pictograms used

The following symbols are used in the documentation and/or on the boiler to show

what is required and forbidden and to give warnings.

In accordance with the Machinery Directive, signs fitted directly within the danger area

of the boiler indicate immediate hazards or safety procedures. These stickers must not

be removed or covered.

Refer to the operating instruc‐

tions

Wear safety shoes

Wear protective gloves Turn off the main switch

Keep the doors closed

Unauthorised access prohibited

Warning - hot surface Warning - hazardous electrical

voltage

Warning - hazardous or irritant

materials

Warning - automatic boiler start‐

up

Warning of injury to fingers or

hands, automatic fan

Warning of injury to fingers or

hands, automatic screw

Warning of injury to fingers or

hands, gear/chain drive

Warning of injury to fingers or

hands, cutting edge

2

Safety

Pictograms used

8 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

2.3 General safety information

DANGER

If the device is used incorrectly:

Incorrect use of the system can cause severe injury and damage.

When operating the system:

❒ Observe the instructions and information in the manuals

❒ Observe the details on procedures for operation, maintenance and cleaning,

as well as troubleshooting in the individual manuals.

❒ Any work above and beyond this should be carried out by authorised heating

engineers or by Froling customer services.

WARNING

External influences:

Negative external influences, such as insufficient combustion air or non-standard

fuel, can cause serious faults in combustion (e.g. spontaneous combustion of car‐

bonisation gases or flash fires) which can in turn cause serious accidents!

When operating the boiler, please note the following:

❒ Instructions and information regarding versions and minimum values, as well

as standards and guidelines for heating components in the instructions must

be observed.

WARNING

Severe injuries and damage can be caused by an inadequate flue gas system.

Problems with the flue gas system, such as poor cleaning of the flue pipe or insuf‐

ficient chimney draught, can cause serious faults in combustion (such as sponta‐

neous combustion of carbonisation gases or flash fires).

Take the following precautions:

❒ Optimum boiler performance can only be guaranteed if the flue gas system is

functioning correctly.

Safety

2

General safety information

Operating Instructions T4 24-150 (Touch) | B0830113_en 9

2.4 Permitted uses

The Froling Wood chip boiler T4 is designed solely for heating domestic water. Only

use fuels specified in the "Permitted fuels" section.

⇨ See "Permitted fuels" [page 11]

The unit should only be operated when it is in full working order. It should be operated

in accordance with the instructions, observing safety precautions, and you should en‐

sure you are aware of the potential hazards. The inspection and cleaning intervals in

the operating instructions should be observed. Ensure that any faults which might im‐

pair safety are rectified immediately.

The manufacturer or supplier is not liable for any damage resulting from non-permitted

uses.

2.4.1 The Clean Air Act 1993 and Smoke Control Areas

Under the Clean Air Act local authorities may declare the whole or part of the district of

the authority to be a smoke control area. It is an offence to emit smoke from a chim‐

ney of a building, from a furnance or from any fixed boiler if located in a designated

smoke control area. It is also an offence to acquire an „unauthorised fuel“ for use with‐

in a smoke control area unless it is used in an „exempt“appliance („exempted“ from

the controls which generally apply in the smoke control area). The Secretary of State

for Environment, Food and Rural Affairs has powers under the Act to authorise

smokeless fuels or exempt appliances for use in smoke control areas in England. In

Scotland and Wales this power rests with Ministers in the devolved administrations for

those countries. Separate legislation, the Clean Air (Northern Ireland) Order 1981, ap‐

plies in Northern Ireland. Therefore it is a requirement that fuels burnt or obtained for

use in smoke control areas have been „authorised“ in Regluations and that appliances

used to burn solid fuel in those areas (other than „authorised“ fuels) have been ex‐

empted by an Order made and signed by the Secretary of State or Minister in the de‐

volved administrations.

Further information on the requirements of the Clean Air Act can be found here:

http://

smokecontrol.defra.gov.uk

Your local authority is responsible for implementing the Clean Air Act 1993 including

designation and supervision of smoke control areas and you can contact them for de‐

tails of Clean Air Act requirements.

The Froling T4-24, T4-30, T4-40, T4-50, T4-60, T4-75, T4-90, T4-100, T4-110, T4-130

and T4-150 have been recommended as suitable for use in smoke control areas when

burning fuels as listed under "Permitted fuels".

2

Safety

Permitted uses

10 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

2.4.2 Permitted fuels

Wood chips

Criterion Designation as per Description acc. to

ÖNORM M 7133

ÖNORM M 7133 EN 14961

Water content W20 M20 Air-dried

W30 M30 Suitable for storage

W35 M35 Limited suitability for

storage

Size G30 P16A / P16B Fine wood chip

G50 P45A Medium-sized wood

chips

EU: Fuel acc. to EN 14961 - Part 4: Wood chips class A2 / P16A-P45A

Germany

also: Fuel class 4 (§3 of the 1st BImSchV in the last amended version)

Wood pellets

Wood pellets made from natural wood with a diameter of 6 mm

EU: Fuel acc. to EN 14961 - Part 2: Wood pellets class A1 / D06

and/or: Certification program EN

plus

or DIN

plus

General note:

Before refilling the store, check for pellet dust and clean if necessary.

Changing the fuel

CAUTION

Incorrect fuel parameter settings:

Incorrect parameter settings have a significant adverse effect on the functioning

of the boiler, and as a result this will invalidate the guarantee.

Therefore:

❒ If the fuel is changed (e.g. from wood chips to pellets), the system must be

reset by Froling customer services.

Note on standards

Note on standards

Safety

2

Permitted uses

Operating Instructions T4 24-150 (Touch) | B0830113_en 11

2.4.3 Non-permitted fuels

The use of fuels not defined in the "Permitted fuels" section, and particularly the burn‐

ing of refuse, is not permitted.

CAUTION

In case of use of non-permitted fuels:

Burning non-permitted fuels increases the cleaning requirements and leads to a

build-up of aggressive sedimentation and condensation, which can damage the

boiler and also invalidates the guarantee. Using non-standard fuels can also lead

to serious problems with combustion.

For this reason, when operating the boiler:

❒ Only use permitted fuels

2.5 Qualification of operating staff

CAUTION

If unauthorised persons enter the installation room / boiler room:

Risk of personal injury and damage to property

❒ The operator is responsible for keeping unauthorised persons, in particular

children, away from the system.

Only trained operators are permitted to operate the unit. The operator must also have

read and understood the instructions in the documentation.

2.6 Protective equipment for operating staff

You must ensure that staff have the protective equipment specified by accident pre‐

vention regulations.

▪ For operation, inspection and cleaning:

- suitable work wear

- protective gloves

- sturdy shoes

2.7 Design information

It is forbidden to carry out modifications to the boiler or to change or deactivate safety

equipment.

Always comply with all fire, building, and electrical regulations when installing or oper‐

ating the boiler system, and follow the operating instructions and mandatory regula‐

tions that apply in the country in which the boiler is operated.

2

Safety

Permitted uses

12 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

2.7.1 Installation and approval of the heating system

The boiler should be operated in a closed heating system. The following standards

govern the installation:

ÖNORM / DIN EN 12828 Heating Systems in Buildings

NOTICE! Each heating system must be officially approved.

The appropriate supervisory authority (inspection agency) must always be informed

when installing or modifying a heating system, and authorisation must be obtained

from the building authorities:

Austria: Inform the civic/municipal building authorities.

Germany: Notify an approved chimney sweep and the building authorities.

2.7.2 General information for installation room (boiler room)

Boiler room characteristics

▪ There must not be a potentially explosive atmosphere in the boiler room as the

boiler is not suitable for use in potentially explosive environments.

▪ The boiler room must be frost-free.

▪ The boiler does not provide any light, so the customer must provide sufficient light‐

ing in the boiler room in accordance with national workplace design regulations.

▪ When using the boiler over 2000 metres above sea level you should consult the

manufacturer.

▪ Danger of fire due to flammable materials.

No flammable materials should be stored near the boiler. Flammable objects (e.g.

clothing) must not be put on the boiler to dry.

▪ Damage due to impurities in combustion air.

Do not use any solvents or cleaning agents containing chlorine in the room where

the boiler is installed.

▪ Keep the air suction opening of the boiler free from dust.

Ventilation of the boiler room

Ventilation air for the boiler room should be taken from and expelled directly outside,

and the openings and air ducts should be designed to prevent weather conditions (foli‐

age, snowdrifts, etc.) from obstructing the air flow.

Unless otherwise specified in the applicable building regulations for the boiler room,

the following standards apply to the design and dimensions of the air ducts:

ÖNORM H 5170 - Construction and fire protection requirements

TRVB H118 - Technical directives on fire protection/prevention

Note on standards

Note on standards

Safety

2

Design information

Operating Instructions T4 24-150 (Touch) | B0830113_en 13

2.7.3 Requirements for central heating water

The following standards and guidelines apply:

Austria:

Germany:

Switzerland:

Italy:

ÖNORM H 5195-1

VDI 2035

SWKI 97-1

D.P.R. no. 412

NOTICE! Note on filling with make-up water: Always bleed the filling hose before con‐

necting, in order to prevent air from entering the system.

Observe the standards and also follow the recommendations below:

❒

Max. cumulative value for alkaline earth: 1.0 mmol/l or 100 mg/l (corresponds to

5.6 dH)

❒ Use softened water as the make-up water

❒ Avoid leaks and use a closed heating system to maintain water quality during op‐

eration

2.7.4 Notes for using pressure maintenance systems

Pressure maintenance systems in hot-water heating systems keep the required pres‐

sure within predefined limits and balance out volume variations caused by changes in

the hot-water temperature. Two main systems are used:

Compressor-controlled pressure maintenance

In compressor-controlled pressure maintenance units, a variable air cushion in the ex‐

pansion tank is responsible for volume compensation and pressure maintenance. If

the pressure is too low, the compressor pumps air into the tank. If the pressure is too

high, air is released by means of a solenoid valve. The systems are built solely with

closed-diaphragm expansion tanks to prevent the damaging introduction of oxygen in‐

to the domestic hot water.

Pump-controlled pressure maintenance

A pump-controlled pressure maintenance unit essentially consists of a pressure-main‐

tenance pump, relief valve and an unpressurised receiving tank. The valve releases

hot water into the receiving tank if the pressure is too high. If the pressure drops below

a preset value, the pump draws water from the receiving tank and feeds it back into

the heating system. Pump-controlled pressure maintenance systems with open expan‐

sion tanks (e.g. without a diaphragm) introduce ambient oxygen via the surface of the

water, exposing the connected system components to the risk of corrosion. These

systems offer no oxygen removal for the purposes of corrosion control as required by

VDI 2035 and in the interests of corrosion protection should not be used.

Note on standards

2

Safety

Design information

14 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

2.7.5 Return temperature control

If the hot water return is below the minimum return temperature, some of the hot water

outfeed will be mixed in.

CAUTION

Risk of dropping below dew point/condensation formation if operated without re‐

turn temperature control.

Condensation water forms an aggressive condensate when combined with com‐

bustion residue, leading to damage to the boiler.

Take the following precautions:

❒ We recommend using a return temperature control.

➥ The minimum return temperature is 45 °C. We recommend fitting some

sort of control device (e.g. thermometer).

2.7.6 Use with storage tank

NOTICE

In principle it is not necessary to use a storage tank for the system to run smooth‐

ly. However, we recommend that you use the system with a storage tank, as this

ensures a continuous supply of fuel in the ideal output range of the boiler.

For the correct dimensions of the storage tank and the line insulation (in accordance

with ÖNORM M 7510 or guideline UZ37) please consult your installer or Froling.

⇨ See "Addresses" [page 42]

2.7.7 Chimney connection/chimney system

EN 303-5 specifies that the entire flue gas system must be designed to prevent, wher‐

ever possible, damage caused by seepage, insufficient feed pressure and condensa‐

tion. Please note in this respect that flue gas temperatures lower than 160K above

room temperature can occur in the permitted operating range of the boiler.

NOTICE! Please see the technical data contained in the assembly instructions for fur‐

ther information about standards and regulations as well as the flue gas temperatures

when clean and the other flue gas values!

Safety

2

Design information

Operating Instructions T4 24-150 (Touch) | B0830113_en 15

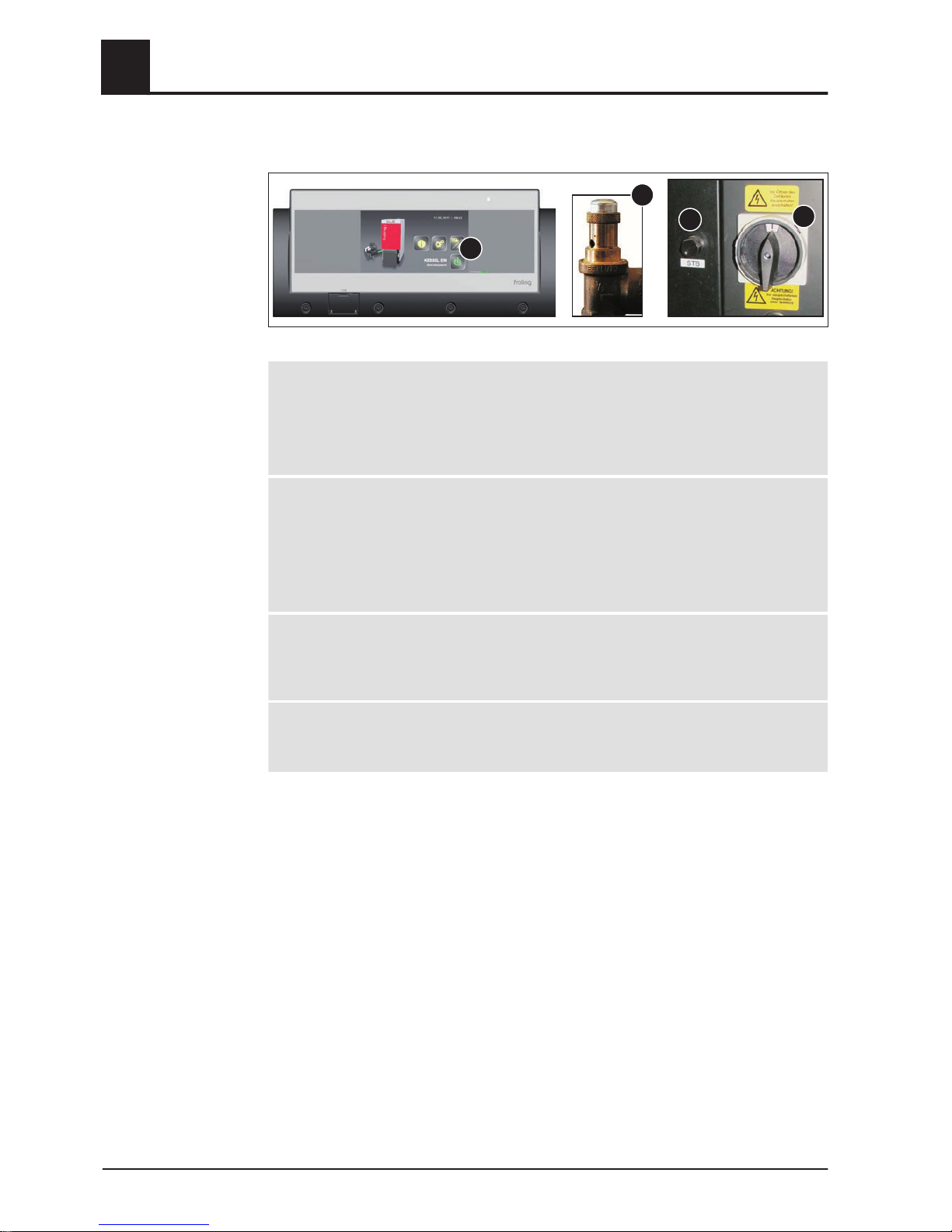

2.8 Safety devices

1

SV

3

2

1 BOILER OFF

(switches off the boiler to prevent overheating)

❒ Tap “Boiler off”

➥ Automatic mode is switched off

➥ Control system follows the boiler shut-down procedure

➥ Pumps continue to run

2 MAIN SWITCH

(switches off the power supply)

Before carrying out work on/in the boiler:

❒ Tap “Boiler off”

➥ Automatic mode is switched off

➥ Control system follows the boiler shut-down procedure

❒ Switch off the main switch and let the boiler cool down

3 SAFETY TEMPERATURE LIMITER (STL)

(protection against overheating)

The STL switches off the combustion system when the boiler reaches 105°C. The

pumps continue to run. Once the temperature falls below approx. 75°C, the STL can

be reset mechanically.

SV SAFETY VALVE

(protection against overheating/excess pressure)

When the boiler pressure reaches a maximum of 3 bar, the safety valve opens and the

heated water is blown off in the form of steam.

2

Safety

Safety devices

16 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

2.9 Residual risks

WARNING

When touching hot surfaces:

Severe burns are possible on hot surfaces and the flue gas pipe!

When work is carried out on the boiler:

❒ Shut down the boiler in a controlled way (operating status "Boiler off") and al‐

low it to cool down

❒ Protective gloves must generally be worn for work on the boiler, and it should

only be operated using the handles provided

❒ Insulate the flue pipes or simply avoid touching them during operation.

WARNING

When inspecting and cleaning the boiler with the main switch on:

Serious injuries possible due to automatic boiler startup!

Before inspection and cleaning work in/on the boiler:

❒ Switch the boiler off by tapping “Boiler off”

The boiler follows the shutdown procedure and switches to "Boiler off“ mode

❒ Allow boiler to cool for at least 1 hour

❒ Switch off the main switch and take precautions to prevent accidental switch‐

ing on.

WARNING

If non-permitted fuel types are used:

Non-standard fuels can cause serious faults in combustion (e.g. spontaneous

combustion of carbonisation gases / flash fires) which can lead to serious acci‐

dents!

Take the following precautions:

❒ Only use fuels specified in the "Permitted fuels" section of these operating in‐

structions.

Safety

2

Residual risks

Operating Instructions T4 24-150 (Touch) | B0830113_en 17

2.10 Emergency procedure

2.10.1 Overheating of the system

If the system overheats and the safety devices fail, proceed as follows:

NOTICE! Do not under any circumstances switch off the main switch or disconnect the

power supply.

❒

Keep all the doors on the boiler closed

❒ Switch boiler off by tapping “Boiler OFF”

❒ Open all mixing valve taps, switch on all pumps.

➥ The Froling heating circuit control performs this function in automatic operation.

❒ If a third-party controller is used, carry out the appropriate measures to activate

the mixer taps and pumps manually.

❒ Leave the boiler room and close the door

❒ Open any available radiator thermostat valves

If the temperature does not drop:

❒ Contact the installer or Froling customer services

⇨ See "Addresses" [page 42]

2.10.2 Smell of flue gas

DANGER

If you smell flue gas in the boiler room:

Inhaling toxic flue gas can be fatal!

If you smell flue gas in the room where the boiler is installed:

❒ Keep all the doors on the boiler closed

❒ Shut down the boiler according to procedure

❒ Ventilate the room where the boiler is installed

❒ Close the fire door and doors to living areas

2

Safety

Emergency procedure

18 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

2.10.3 Fire in the system

DANGER

In case of fire in the system:

Risk of death by fire and poisonous gases

Emergency procedure in case of fire:

❒ Leave the boiler room

❒ Close the doors

❒ Inform the fire department

Safety

2

Emergency procedure

Operating Instructions T4 24-150 (Touch) | B0830113_en 19

3 Operating the System

3.1 Assembly and initial startup

Assembly, installation and initial startup of the boiler must only be carried out by quali‐

fied staff, and these procedures are described in the accompanying assembly instruc‐

tions.

NOTICE! See assembly instructions for the T4

NOTICE

Optimum efficiency and efficient, low-emission operation can only be guaranteed

if the system is set up by trained professionals and the standard factory settings

are observed.

Take the following precautions:

❒

Initial startup should be carried out with an authorised installer or with Froling

customer services

The individual steps for initial start-up are explained in the operating instructions for

the controller

NOTICE! See operating instructions for the Lambdatronic H 3200 T4

The customer is responsible for ensuring the following prior to initial start-up of the

system by Froling customer services:

▪

Electrical installation

▪ Installation of water pipes

▪ Flue gas connection including all insulation work

▪ Work must comply with local fire protection regulations

▪ The necessary "dry run" of the system means that the discharge system must be

empty at the start of initial startup. Fuel must be available, however, so that the

discharge system can be filled once the system is released.

▪ It is essential that the electrician who has carried out the installation work is availa‐

ble when starting up the system for the first time to make any changes to the wir‐

ing which may become necessary.

▪ During initial start-up, operating staff are shown how to use the boiler. It is impera‐

tive for proper handover of the product that those involved are present as this is a

one-off opportunity.

NOTICE

If condensation escapes during the initial heat-up phase, this does not indicate a

fault.

❒

Tip: If this occurs, clean up using a cleaning rag.

3

Operating the System

Assembly and initial startup

20 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

3.2 Filling/refilling the store with fuel

When filling the store you should always ensure that you are using the right fuel:

⇨ See "Permitted fuels" [page 11]

3.2.1 Loading of fuel for a partially emptied store with rotary agitator

If there is still sufficient fuel in the store (the head of the rotary agitator is completely

covered with fuel and the rotary agitator arms are not extended), the store can be fil‐

led:

❒

Load the fuel at the filling opening

3.2.2 Loading wood chips in an empty store (not under pressure)

NOTICE! If the head of the rotary agitator is already free of material and the arms /

spring blades are extended, then the feeder unit must be active during the filling proc‐

ess.

❒

Activate “Extra heating” mode in the quick menu

❒ Load a small quantity of wood chips and wait until the arms / spring blades are

touching the head of the rotary agitator (approx. 2 revolutions)

❒ Only then should you load the remaining material

Operating the System

3

Filling/refilling the store with fuel

Operating Instructions T4 24-150 (Touch) | B0830113_en 21

3.2.3 Blowing in pellets for a store with pellet screw

❒ Switch off the boiler by tapping “Boiler off” at the mode icon and allow to cool for at

least two hours

❒

Close all openings to the store to seal out dust

❒ Blow the fuel into the store

3.2.4 Blowing in fuel for a partially emptied store with rotary agitator

If there is still sufficient fuel in the store (the head of the rotary agitator is completely

covered with fuel and the rotary agitator arms are not extended), the store can be filled

as follows:

❒

Switch off the boiler by tapping “Boiler off” at the mode icon and allow to cool for at

least two hours

❒ Close all openings to the store to seal out dust

❒ Blow the fuel into the store

3.2.5 Blowing in fuel for an empty store with rotary agitator

3

Operating the System

Filling/refilling the store with fuel

22 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

NOTICE! If the head of the rotary agitator is already free of material and the arms /

spring blades are extended, then the store must not be filled until the following actions

have been taken:

❒

Switch off the boiler by tapping “Boiler off” at the mode icon and switch off main

switch

❒ Turn off the main switch on the expansion switch cabinet (if installed)

❒ Distribute any fuel remaining in the store (in corners, against walls) over the head

of the rotary agitator with your hands

➥ Follow the instructions on working in the fuel store!

NOTICE! Refer to the notice (supplied with the boiler) at the entrance to the store

After working in the store:

❒ Turn on the main switch on the boiler and on the expansion switch cabinet (if in‐

stalled)

❒ Activate “Extra heating” mode in the quick menu

❒ Wait until the arms / spring blades are touching the head of the rotary agitator (ap‐

prox. 2 revolutions)

❒ Switch off the boiler by tapping “Boiler off” at the mode icon and allow to cool for at

least two hours

❒ Close all openings to the store to seal out dust

❒ Blow the fuel into the store

If the fuel store is completely empty and there is no residual fuel to redistribute:

❒ Contact Froling and seek advice before filling the fuel store

⇨ See "Address of manufacturer" [page 42]

3.3 Heating up the boiler

NOTICE

Do not modify the factory settings!

Changing the system's factory settings can be detrimental to efficiency and emis‐

sions of the system.

3.3.1 Switching on the power supply

❒ Turn on the main switch

➥ There is voltage at all of the boiler's components

➥ When the control has completed the system start, the boiler is ready for opera‐

tion

Operating the System

3

Heating up the boiler

Operating Instructions T4 24-150 (Touch) | B0830113_en 23

3.3.2 Switching on the boiler

❒ Switch the boiler on by tapping “Boiler ON”

➥ Automatic mode is active

➥ The heating system is controlled via the controller according to the selected

mode in automatic mode

❒

For other modes press the relevant function key

➥ Information on function keys in the relevant operating instructions for the

"Lambdatronic H 3200 T4" boiler controller

3.3.3 Controlling the boiler

Please see the relevant operating instructions for the "Lambdatronic H 3200 T4" boiler

controller for the necessary control steps, as well as displaying and modifying parame‐

ters

3.3.4 Switching off the boiler

❒ Switch boiler off by tapping “Boiler OFF”

➥ The boiler follows the shutdown program and switches to "

Boiler off" status

➥ The combustion unit is switched off, the chamber discharge unit and the entire

hydraulic system remain active

3.3.5 Switching off the power supply

WARNING

When turning off the main switch in automatic mode:

Serious combustion faults leading to serious accidents are possible.

Before turning off the main switch:

❒ Switch boiler off by tapping “Boiler OFF”

➥ The boiler follows the shutdown procedure and switches to "Boiler off“ sta‐

tus after the cleaning cycle

❒ Turn off the main switch

➥ Boiler controller is switched off

➥ The components powered via the control cabinet are powered down

➥ CAUTION: The expansion switch cabinet, which has its own power supply, is

still live.

NOTICE! Frost protection function is no longer active!

3

Operating the System

Heating up the boiler

24 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

4 Boiler Servicing

4.1 General information on servicing

DANGER

When working on electrical components:

Risk of electrocution!

When work is carried out on electrical components:

❒ Only have work carried out by a qualified electrician

❒ Observe the applicable standards and regulations

➥ Work must not be carried out on electrical components by unauthorised

people

WARNING

When inspecting and cleaning the boiler with the main switch on:

Serious injuries possible due to automatic boiler startup!

Before inspection and cleaning work in/on the boiler:

❒ Switch the boiler off by tapping “Boiler off”

The boiler follows the shutdown procedure and switches to "Boiler off“ mode

❒ Allow boiler to cool for at least 1 hour

❒ Switch off the main switch and take precautions to prevent accidental switch‐

ing on.

WARNING

During inspection and cleaning work to the hot boiler:

Hot parts and the flue gas pipe can cause serious burns!

Take the following precautions:

❒ It should be standard practice to wear protective gloves when working on the

boiler.

❒ Only operate the boiler using the handles provided

❒ Before starting any maintenance work activate “Service mode” in the quick

menu

➥ The boiler follows the shutdown procedure and switches to "Boiler off" sta‐

tus

❒ Allow boiler to cool for at least 1 hour

❒ After maintenance has been carried out switch the boiler on in the desired

mode.

➥ In service mode the boiler does not start automatically.

Boiler Servicing

4

General information on servicing

Operating Instructions T4 24-150 (Touch) | B0830113_en 25

WARNING

Incorrect inspection and cleaning:

Incorrect or insufficient inspection and cleaning of the boiler can cause serious

faults in combustion (e.g. spontaneous combustion of carbonisation gases / flash

fires) and this can lead to serious accidents and damage!

Take the following precautions:

❒ Clean the boiler following the instructions in the instruction manual. Follow the

boiler operating instructions.

NOTICE

We recommend that you keep a maintenance book in accordance with ÖNORM

M7510 of the Technical Directive for Fire Prevention (TRVB)

4

Boiler Servicing

General information on servicing

26 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

4.2 Inspection and cleaning

❒ Regular cleaning of the boiler extends its life and is a basic requirement for

smooth running.

❒

Recommendation: use an ash vacuum for cleaning.

4.2.1 Inspection

Checking the system pressure

❒ Check the system pressure on the pressure gauge

➥ The value must be 20% above the pre-stressed pressure of the expansion tank

NOTICE! Check that the position of the pressure gauge and rated pressure of

the expansion tank match your installer's specifications!

If the system pressure decreases:

❒ Top up with water

NOTICE! If this happens frequently, the seal of the heating system is faulty! Inform

your installer

If large pressure fluctuations are observed:

❒ Ask an expert to inspect the expansion tank

Checking the safety valve

❒ Check the seal of the safety valve regularly and ensure that the valve is not dirty

NOTICE! Inspection work must be carried out in accordance with the manufactur‐

er’s instructions.

Checking the geared motors

❒ Carry out a visual inspection of the seal on all the geared motors in the system

➥ There should be no significant leakage of lubricant.

NOTICE! The presence of a few drops of lubricant may be normal. If there is

significant loss of lubricant, inform your installer or Froling customer services.

Boiler Servicing

4

Inspection and cleaning

Operating Instructions T4 24-150 (Touch) | B0830113_en 27

4.2.2 Cleaning

Emptying the ash container

The ash container must be emptied at appropriate intervals depending on energy re‐

quirements and fuel quality.

If the ash container is full before you check the ash level, the warning “ash box

full, please empty” will appear on the display.

WARNING

When removing the ash container cover during operation:

False air infiltration via the ash screw duct can lead to uncontrolled combustion

and the risk of accidents.

Before checking the ash level / emptying the ash container:

❒ Switch off the boiler by tapping “Boiler off”

➥ The boiler follows the shutdown procedure and switches to "Boiler off" sta‐

tus.

In “Boiler off” operating status:

❒

Open the insulated door

NOTICE! Note the sticker on the cover of the ash container!

❒

Open the side clamps and remove the ash container cover (1)

❒ Check the ash level in both chambers

➥ If either of the two chambers is more than two thirds full, empty the ash con‐

tainer

❒ Open the ash container clamp using the locking lever (2)

❒ Remove the ash container from the boiler (3)

4

Boiler Servicing

Inspection and cleaning

28 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

❒

Place the transport cover over the openings of the ash container

❒ Put on the ash container cover, pull out the transport lever and take the ash con‐

tainer to the emptying point

After emptying the ash container:

❒ Replace the ash container in the boiler and clamp with the locking lever

❒

Replace the cover and secure with the clamps

➥ Make sure that the pin (2) is inserted in the limit switch (1) correctly

Boiler Servicing

4

Inspection and cleaning

Operating Instructions T4 24-150 (Touch) | B0830113_en 29

4.2.3 Recurrent check and cleaning

The boiler must be cleaned and inspected at appropriate intervals depending on the

service hours and fuel quality.

For fuels with a low ash content (standard wood chips), annual cleaning and inspec‐

tion (2000 to 2500 service hours) is usually sufficient. For less efficient fuels and fuels

with a high ash content (indicated by short emptying intervals for the ash container),

the work should be carried out more frequently accordingly.

WARNING

Inspection and cleaning work with the boiler switched on

Serious injuries from automatic startup of the boiler and severe burns from hot

parts and the flue gas pipe are possible.

Therefore:

❒ Only carry out work on the boiler when the main switch is turned off

❒ Always wear protective gloves when working on the boiler

❒ Only operate the boiler using the handles provided

❒ Follow the procedure below when starting and finishing inspection and clean‐

ing work

Before starting inspection and cleaning work

❒ Switch off the boiler by tapping “Boiler off”

➥ Boiler shuts down and switches to "Boiler off” status

❒ Allow boiler to cool for at least 1 hour

❒ On the control, go to the "Manual operation" menu

NOTICE! See operating instructions for boiler controller Lambdatronic H 3200 T4

❒ Use the DOWN arrow to navigate to the “Tip drive” parameter

❒ Set parameter to “ON”

➥ Combustion grate tips

❒ Turn off the main switch

After inspection and cleaning work

❒ Turn on the main switch

➥ Combustion grate previously opened manually now closes automatically and

the boiler switches to “Boiler off” status

❒ Activate “service mode” in the quick menu

➥ The boiler starts the cleaning module and removes any remaining ash in the

combustion chamber

➥ Once self-cleaning is finished the boiler switches to "Boiler off" status.

4

Boiler Servicing

Inspection and cleaning

30 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

Cleaning the combustion chamber

❒

Open the insulated door and loosen the screw connections on the combustion

chamber door

❒ Open the combustion chamber door

❒

Use a small shovel or the like (ash vacuum recommended) to remove any ash

from the combustion chamber

➥ Do not throw the ash onto the grate

❒

Remove the burn-out opening

❒ Remove the dirt on the burn-out opening with a brush

❒ Remove ash build-up on the side walls using the ash scraper

Boiler Servicing

4

Inspection and cleaning

Operating Instructions T4 24-150 (Touch) | B0830113_en 31

❒

Clean the firebrick in the combustion chamber and combustion grate with ash

scraper

❒ Remove any ash build-up and ash on the baffles and under the grate using ash

vacuum

❒ Carry out a visual inspection of the firebrick for damage

❒ Check the combustion grate for cracks and deformation

➥ Small cracks and deformations are not indicative of a fault. Only when entire

parts of the grate are at risk of breaking, should you stop using the boiler. In‐

form Froling customer services if this is the case!

❒

Install the burn-out opening

➥ The opening must be facing the fuel infeed side!

4

Boiler Servicing

Inspection and cleaning

32 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

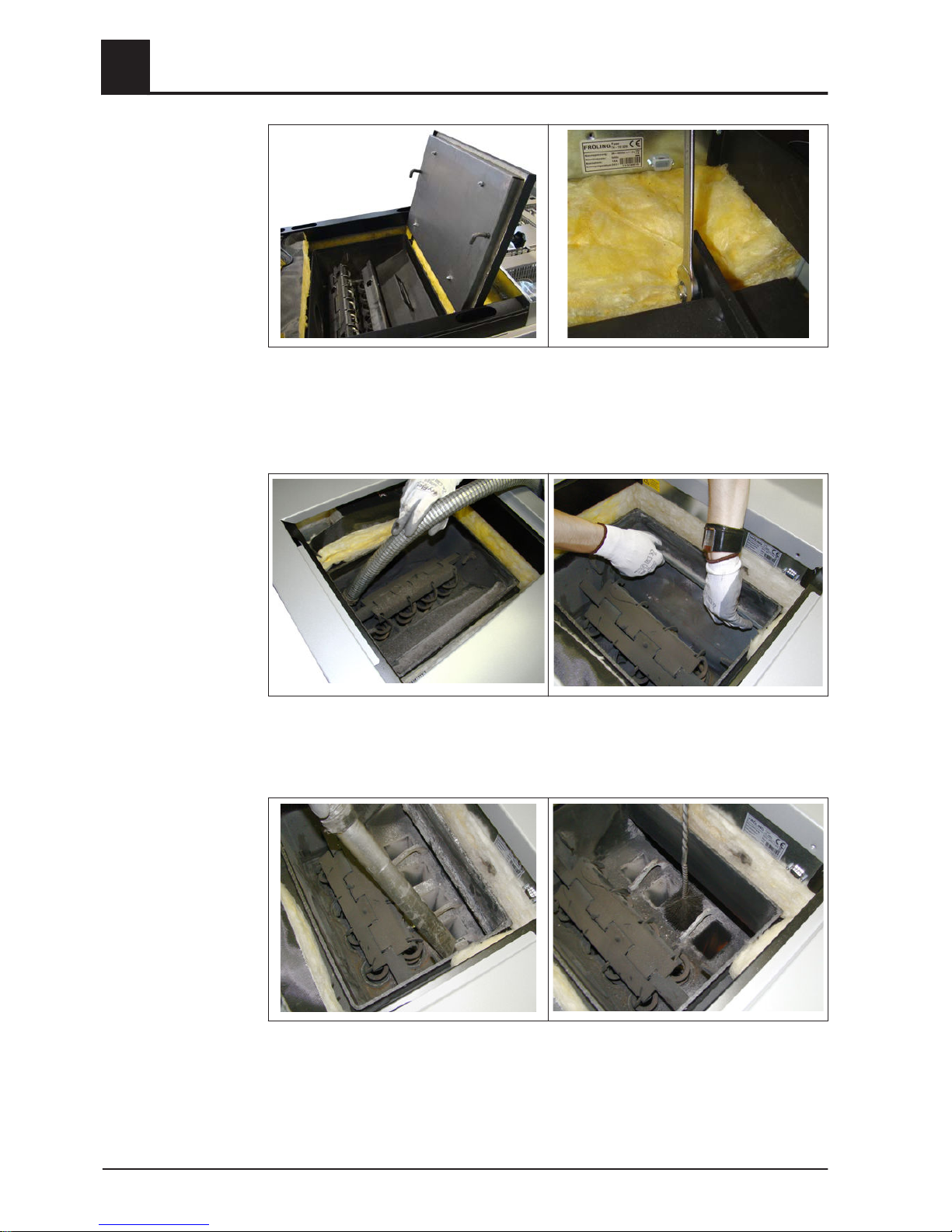

Cleaning the heat-exchanger and flue gas collection chamber

❒

Removing the insulating cover and the insulating mat

❒

Loosen the lock nut on the star-shaped screw knob

❒ Unlock the cover by turning the star-shaped screw knob and remove

Boiler Servicing

4

Inspection and cleaning

Operating Instructions T4 24-150 (Touch) | B0830113_en 33

❒

Unlock the cover by turning the star-shaped screw knob and open

In the case of low down boiler rooms, you can remove the heat exchanger cover:

❒ Undo the screw connections on the hinge of the cover and remove the cover

❒

Clean the flue gas collection chamber with an ash vacuum

❒ Pull out the guide plate(s)

❒ Remove the ash under the guide plate with an ash vacuum

❒ Clean the heat exchanger pipes with the cleaning brush provided

➥ Push the cleaning brush right the way through before taking it out again!

❒ After cleaning, reassemble the dismantled components in the reverse order

For T4 60 – 150

4

Boiler Servicing

Inspection and cleaning

34 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

Cleaning the flue gas temperature sensor

❒

Release the retaining screw and take the flue gas temperature sensor (AF) out of

the flue gas pipe

❒ Wipe the flue gas temperature sensor with a clean cloth

❒ Push in the flue gas temperature sensor until about 20 mm of the sensor remains

protruding from the bushing and secure with fixing screw

Cleaning the flue gas pipe

❒ Switch off the induced draught fan

➥ This prevents damage to the fan from the cleaning brush

❒ Remove the inspection cover on the connecting pipe

❒ Clean the connecting pipe between the boiler and chimney with a chimney sweep‐

ing brush

➥ Depending on the layout of the flue gas pipes and the chimney draught, clean‐

ing once a year may not be enough!

Checking the seal on the doors

D

❒

Close the relevant door and check its seal

❒ Check the seal (D) for perfect alignment on the door frame

➥ Imprint in the seal

❒ If the seal is black or the imprint is broken:

➥ The seal is no longer guaranteed. Tighten the door latches or replace the seal

Boiler Servicing

4

Inspection and cleaning

Operating Instructions T4 24-150 (Touch) | B0830113_en 35

Checking the draught controller flap

❒ Check that the draught controller flap moves freely

Cleaning the measurement line of the underpressure controller

❒ Open the insulated door and remove the ash box

⇨ See "Emptying the ash container" [page 28]

❒

Remove the left and right screws on the front cover plate

❒ Slide the cover plate up and remove

❒

Loosen the twin wire clamp with pliers and remove the measurement line

4

Boiler Servicing

Inspection and cleaning

36 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

❒

Clean the measurement line with gentle compressed air

➥ WARNING! Do not direct compressed air into under-pressure sensor cartridge!

This could damage it!

❒ After cleaning, refit the measurement line (port “-”)

Boiler Servicing

4

Inspection and cleaning

Operating Instructions T4 24-150 (Touch) | B0830113_en 37

4.3 Emissions measurement by chimney sweep or regulatory body

Various legal regulations stipulate that heating systems must be inspected periodical‐

ly. In Germany this is regulated by the First Federal Emissions Protection Ordinance

(BimSchV) in the last amended version, and in Austria by various state laws. The boil‐

er must always be cleaned 2-3 heating days prior to measurement. It is important to

ensure that there is adequate heat consumption on the day of the measurement. (e.g.

storage tank must be able to take heat for the duration of the measurement).

4.3.1 Measurement at nominal load

❒ For the highest possible heat consumption:

▪

Make sure that heating pumps are switched on

▪ Open mixing valves and radiator valves

▪ Set the DHW tank loading time to the current time

▪ Set the boiler temperature setpoint to 85°C

NOTICE! Chimney-sweep mode performs this function

Activate chimney-sweep mode

❒ Activate “Chimney-sweep mode” in the quick menu

➥ The chimney sweeper program is started. The system is operated for 45 mi‐

nutes at nominal load. For this purpose the maximum boiler and heating circuit

flow temperature and DHW tank loading are released.

Permitted measurement parameters:

▪ Flue gas temperature at approx. 140°C

(+/- 20°C depending on the cleanliness of the boiler)

▪ O2 content of the flue gas between 8 and 12%

(corresponds to a CO2 content of between 13 and 19%)

▪ Boiler temperature above 65°C

4.3.2 Measurement at partial load (if necessary)

❒ For heat consumption:

▪

Make sure that heating pumps are switched on

▪ Open mixing valves and radiator valves

▪ Set the DHW tank loading time to the current time

❒ Force partial load:

❒ After measuring at nominal load, lower the boiler temperature setpoint by 5°C

Permitted measurement parameters:

▪ Flue gas temperature at approx. 100°C

(+/- 20°C depending on the cleanliness of the boiler)

▪ O2 content of the flue gas between 10 and 14%

(corresponds to a CO2 content of between 7 and 11%)

▪ Boiler temperature above 65°C

❒ After the measurement all adjusted parameters (e.g. DHW tank loading times,

etc.) must be reset to their original value.

4

Boiler Servicing

Emissions measurement by chimney sweep or regulatory body

38 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

4.4 Maintenance agreement / Customer service

NOTICE! We recommend a yearly inspection by Froling customer services or an au‐

thorised partner (third party maintenance).

Regular maintenance and servicing by a heating specialist will ensure a long, troublefree service life for your heating system. It will ensure that your system stays environ‐

mentally-friendly and operates efficiently and cost-effectively.

In the course of this maintenance the entire system is inspected and optimised, partic‐

ularly regulation and control of the boiler. The emission measurement carried out can

also be used to draw conclusions about the combustion performance of the boiler.

For this reason, FROLING offers a service agreement, which optimises operating

safety. Please see the details in the accompanying guarantee certificate.

Your Froling customer service office will also be happy to advise you.

NOTICE

All national and regional regulations relating to regular testing of the system must

be observed. Please be advised that, in Austria, commercial systems with a rated

heat output of 50 kW or more must be regularly tested at yearly intervals in ac‐

cordance with the Heating Plant Regulations (Feuerungsanlagen-Verordnung).

4.5 Replacement parts

With Froling original replacement parts in your boiler, you are using parts that match

perfectly. As the parts fit together so well, installation times are shortened and a long

service life is maintained.

NOTICE

Installing non-original parts will invalidate the guarantee.

❒

Only replace components or parts with original replacement parts

4.6 Disposal information

4.6.1 Disposal of the ash

❒ The ash should be disposed of in accordance with waste management regula‐

tions.

4.6.2 Disposal of system components

❒ Ensure that the system is disposed of in an environmentally friendly way in ac‐

cordance with waste management regulations.

❒

You can separate and clean recyclable materials and send them to a recycling

centre.

❒ The combustion chamber must be disposed of as builders' waste.

Boiler Servicing

4

Maintenance agreement / Customer service

Operating Instructions T4 24-150 (Touch) | B0830113_en 39

5 Troubleshooting

5.1 General fault with power supply

Error characteristics Cause of error Elimination of error

Nothing is shown on the dis‐

play

No power to the controller

General power failure

Main switch is turned off

FI circuit breaker or line pro‐

tection is switched off

Faulty fuse in the controller

Turn on the main switch

Switch on the FI circuit break‐

er or line protection

Replace the fuse – note the

amperage (10AT)

5.1.1 Behaviour of system after a power failure

When the power supply has been restored, the boiler returns to the previous mode

and is controlled according to the specified program.

❒ After a power failure, check whether the STL (high-limit thermostat) has tripped.

❒ Keep the doors of the boiler closed during and after the power failure, at least until

the induced draught fan automatically starts up again.

5.2 Excessive temperature

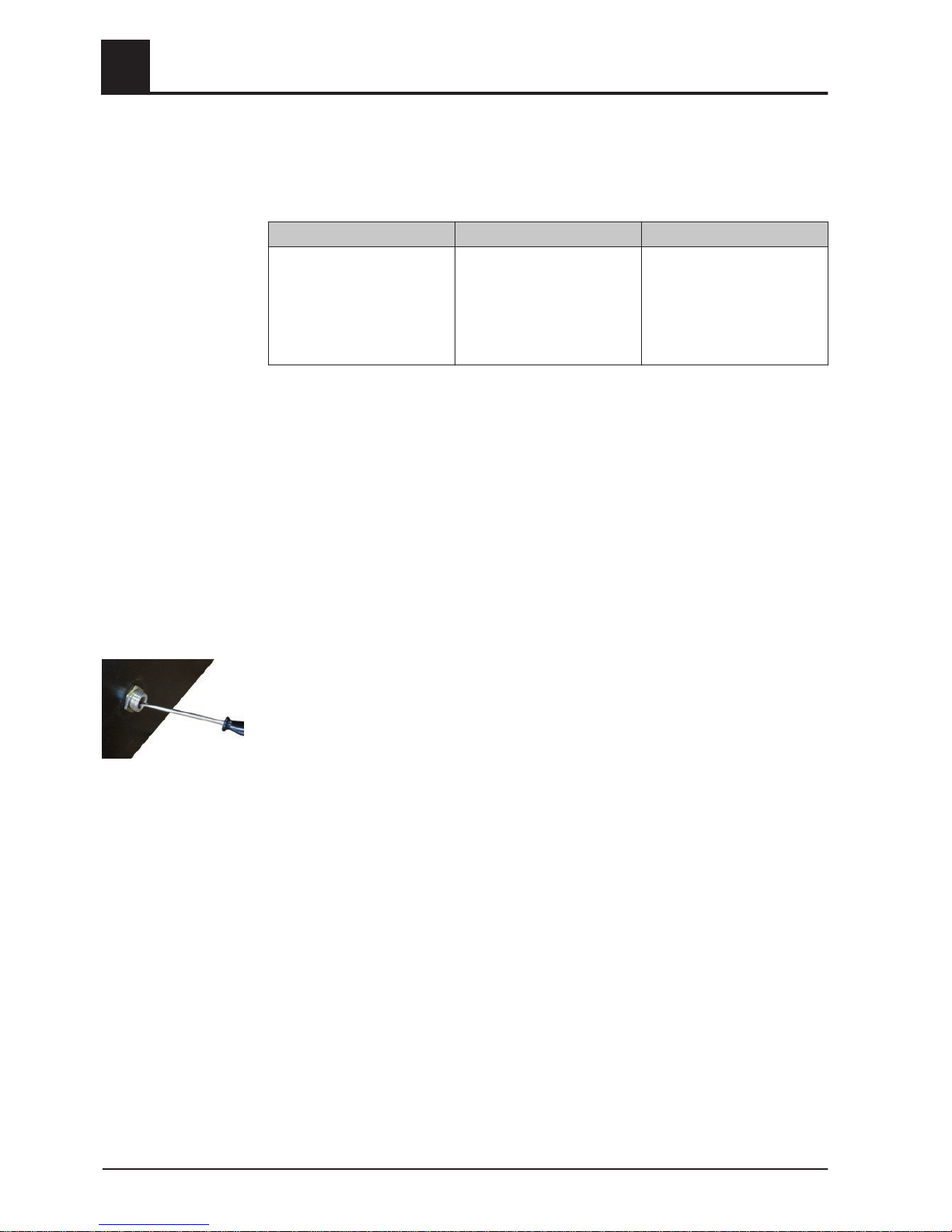

The high-limit thermostat (STL) shuts down the boiler when it reaches a temperature

of max. 105°C. The pumps continue to run.

Once the temperature falls below approx. 75°C, the STL (high-limit thermostat) can be

reset mechanically:

❒

Unscrew the cap on the STL (high-limit thermostat)

❒ Unlock the STL (high-limit thermostat) by pressing with a screwdriver

5

Troubleshooting

General fault with power supply

40 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

5.3 Faults with fault message

If a fault has occurred and has not yet been cleared:

❒

Status LED indicates the nature of the fault

- Orange flashing: Warning

- Red flashing: Error or alarm

❒ A fault message is shown on the display

The term "fault" is a collective term for warnings, errors and alarms. The boiler reacts

differently to the three types of message:

WARNING In case of warnings the boiler initially continues controlled opera‐

tion, giving the option of resolving the error quickly to prevent a

shutdown.

ERROR The boiler follows the shutdown procedure and remains in "Boil‐

er off" status until the problem is resolved.

ALARM An alarm triggers a system emergency stop. The boiler shuts

down immediately, the heating circuit controller and pumps re‐

main active.

5.3.1 Procedure for fault messages

The procedure in the case of a fault message, the causes of faults and procedure for

troubleshooting are described in the operating instructions for the boiler controller:

IMPORTANT! See operating instructions for the

Lambdatronic H 3200 - T4

5.3.2 Acknowledging a fault message

Trace and remove the fault and then:

❒

Tap the “Cancel” symbol

➥ Status LED constant or flashing green light (depending on operating status)

- Green constant: Boiler switched on

- Green flashing: Boiler switched off

Troubleshooting

5

Faults with fault message

Operating Instructions T4 24-150 (Touch) | B0830113_en 41

6 Appendix

6.1 Addresses

6.1.1 Address of manufacturer

FRÖLING

Heizkessel- und Behälterbau GesmbH

Industriestraße 12

A-4710 Grieskirchen

AUSTRIA

TEL 0043 (0)7248 606 0

FAX 0043 (0)7248 606 600

INTERNET www.froeling.com

6.1.2 Address of the installer

Stamp

6

Appendix

Addresses

42 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

Loading...

Loading...