Froling S3 Turbo 18, S3 Turbo 28, S3 Turbo 45, S3 Turbo 36 Installation Instructions Manual

Installation Instructions

Firewood boiler S3 Turbo

Translation of the original German installation instructions for technicians

Read and follow the instructions and safety information!

Technical changes, typographical errors and omissions reserved!

M1080813_en | Edition 30/09/2013

Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

Table of Contents

1 General 4

2 Safety 5

2.1 Hazard levels of warnings 5

2.2 Qualification of assembly staff 6

2.3 Protective equipment for assembly staff 6

2.4 Design Information 7

2.4.1 Notes on standards 7

General standards for heating systems

7

Standards for structural and safety devices

7

Standards for heating water

7

Standards for permitted fuels

8

2.4.2 Installation and approval of the heating system 8

2.4.3 General information for installation room (boiler room) 8

2.4.4 Requirements for central heating water 9

2.4.5 Notes for using pressure maintenance systems 10

2.4.6 Return lift 10

2.4.7 Combination with storage tank 11

2.4.8 Chimney connection/chimney system 13

Draught limiter

13

Boiler data for planning the flue gas system

13

3 Technology 14

3.1 Dimensions 14

3.2 Components and connections 15

3.3 Technical specifications 16

4 Assembly 19

4.1 Materials supplied 19

4.1.1 Tools required 19

4.2 Positioning 20

4.2.1 Temporary storage 20

4.3 Setting up in the boiler room 21

4.3.1 Remove boiler from pallet 21

4.3.2 Moving the boiler in the boiler room 21

4.3.3 Minimum distances in the boiler room 22

4.4 Before Installation 22

4.4.1 Changing door stops (as needed) 22

Converting the fuel loading door

24

4.4.2 Fitting the door handles 25

4.4.3 Setting and checking the seal on the doors 26

Positioning the doors

27

4.5 Installing the boiler 28

4.5.1 Assembly overview 28

Insulation

28

Air duct system

30

WOS system S3 Turbo 18-28

32

WOS system S3 Turbo 36-45

34

Table of Contents

2 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

4.5.2 Installing the flue gas pipe nozzle 36

4.5.3 Fit the induced draught fan 36

4.5.4 Installing the pneumatic rods for the primary and secondary air 36

4.5.5 Final steps before insulating 38

4.5.6 Installing the insulation 39

4.5.7 Installing the door switch 41

4.5.8 Installing the back panel 41

4.5.9 Aligning the insulation and attaching the controller 42

4.5.10 Installing the cleaning port door and blank cover 44

4.5.11 Installing the insulated door 44

4.5.12 Fitting the sensors 47

4.5.13 Install the broadband probe (only with S-Tronic Lambda) 48

4.5.14 Installing the WOS system 49

4.5.15 Installing the manual controller/servo-motors 51

Mounting the manual controller (with S-Tronic/S-Tronic Plus control)

51

Mounting the servo-motors (with S-Tronic Lambda control)

52

4.6 Power connection and wiring 54

4.6.1 S-Tronic control 54

Power connection

54

Hydraulic system

57

4.6.2 S-Tronic Plus / S-Tronic Lambda control 58

Power connection

58

Hydraulic system

58

4.6.3 Information on circulating pumps 59

4.6.4 Concluding work 59

4.7 Connecting the hydraulic safety devices 61

5 Start-up 62

5.1 Before commissioning / configuring the boiler 62

5.2 Initial startup 63

5.2.1 Permitted fuels 63

Firewood

63

5.2.2 Fuels permitted under certain conditions 63

Wood briquettes

63

5.2.3 Non-permitted fuels 64

5.2.4 Heating up for the first time 64

Boiler with Lambda control

65

Boiler with manual controller

65

6 Decommissioning 68

6.1 Mothballing 68

6.2 Disassembly 68

6.3 Disposal 68

7 Appendix 69

7.1 Pressure equipment regulation 69

7.2 Technical specifications - S3 Turbo with partial load values 70

7.3 Addresses 71

7.3.1 Address of manufacturer 71

7.3.2 Address of the installer 71

Table of Contents

Installation Instructions S3 Turbo | M1080813_en 3

1 General

Thank you for choosing a quality product from Froling. The product features a state-ofthe-art design and conforms to all currently applicable standards and testing guide‐

lines.

Please read and observe the documentation provided and always keep it close to the

system for reference. It contains important safety information and all the operation and

maintenance specifications needed to operate the system safely, properly, environ‐

mentally friendly and cost-effectively.

The constant further development of our products means that there may be minor dif‐

ferences from the pictures and content. If you discover any errors, please let us know:

doku@froeling.com

Subject to technical change.

The EC Declaration of Conformity is only valid in conjunction with a delivery certificate,

which has been filled in correctly and signed as part of the commissioning process.

The original document remains at the installation site. Commissioning installers or

heating engineers are requested to return a copy of the delivery certificate together

with the guarantee card to Froling. On commissioning by FROLING Customer Service

the validity of the delivery certificate will be noted on the customer service record.

Issuing a delivery cer‐

tificate

1

General

4 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

2 Safety

2.1 Hazard levels of warnings

This documentation uses warnings with the following hazard levels to indicate direct

hazards and important safety instructions:

DANGER

The dangerous situation is imminent and if measures are not observed it will lead

to serious injury or death. You must follow the instructions!

WARNING

The dangerous situation may occur and if measures are not observed it will lead

to serious injury or death. Work with extreme care.

CAUTION

The dangerous situation may occur and if measures are not observed it will lead

to minor injuries or damage to property.

Safety

2

Hazard levels of warnings

Installation Instructions S3 Turbo | M1080813_en 5

2.2 Qualification of assembly staff

CAUTION

Assembly and installation by untrained personnel:

Risk of personal injury and damage to property.

During assembly and installation:

❒ Observe the instructions and information in the manuals

❒ Only allow trained staff to carry out assembly and installation

Assembly, installation, initial startup and servicing must always be carried out by quali‐

fied personnel:

- Heating technician / building technician

- Electrical installation technician

- Froling customer services

The assembly staff must have read and understood the instructions in the documenta‐

tion.

2.3 Protective equipment for assembly staff

You must ensure that staff have the protective equipment specified by accident pre‐

vention regulations.

▪ For transportation, setup and assembly:

- suitable workwear

- protective gloves

- sturdy shoes

2

Safety

Qualification of assembly staff

6 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

2.4 Design Information

2.4.1 Notes on standards

The system must be installed and commissioned in accordance with the local fire and

building regulations. The following standards and regulations should always be ob‐

served:

General standards for heating systems

EN 303-5 Boilers for solid fuels, manually and automatically fed combus‐

tion systems, nominal output up to 300 kW

EN 12828 Heating systems in buildings - Design of water-based heating

systems

EN 13384-1 Chimneys - Thermal and fluid dynamic calculation methods

Part 1: Chimneys serving one appliance

ÖNORM M 7510-1 Guidelines for checking central heating systems

Part 1: General requirements and one-off inspections

ÖNORM M 7510-4 Guidelines for checking central heating systems

Part 4: Simple check for heating plants for solid fuels

Standards for structural and safety devices

ÖNORM H 5170 Heating installation - Requirements for construction and safety

engineering, as well as fire prevention and environmental pro‐

tection

Standards for heating water

ÖNORM H 5195-1 Prevention of damage by corrosion and scale formation in

closed warm water heating systems at operating temperatures

up to 100 °C (Austria).

VDI 2035 Sheet 1 Prevention of damage in water heating systems - Scale forma‐

tion in domestic water heating systems and hot water heating

systems (Germany)

SWKI 97-1 Water quality for heating, steam, cooling and air conditioning

systems (Switzerland)

D.P.R. no. 412 Regulations for the planning, installation, running/operation and

maintenance of heating systems in buildings to reduce energy

consumption with reference to Article 4, Comma 4 of the Legis‐

lative Decree of 9 January 1991, No. 10 (Italy)

Safety

2

Design Information

Installation Instructions S3 Turbo | M1080813_en 7

Standards for permitted fuels

EN 14961-3 Solid bio-fuel - Fuel specifications and classes

Part 2: Wood briquettes for non-industrial use

EN 14961-5 Solid bio-fuel - Fuel specifications and classes

Part 5: Firewood for non-industrial use

1. BImSchV First Ordinance of the German Federal Government for imple‐

mentation of the Federal Emission Protection Law, BGBl. I P.

491, in the applicable version.

2.4.2 Installation and approval of the heating system

The boiler should be operated in a closed heating system. The following standards

govern the installation:

ÖNORM / DIN EN 12828 Heating Systems in Buildings

NOTICE! Each heating system must be officially approved.

The appropriate supervisory authority (inspection agency) must always be informed

when installing or modifying a heating system, and authorisation must be obtained

from the building authorities:

Austria: Inform the civic/municipal building authorities.

Germany: Notify an approved chimney sweep and the building authorities.

2.4.3 General information for installation room (boiler room)

Boiler room characteristics

▪ There must not be a potentially explosive atmosphere in the boiler room as the

boiler is not suitable for use in potentially explosive environments.

▪ The boiler room must be frost-free.

▪ The boiler does not provide any light, so the customer must provide sufficient light‐

ing in the boiler room in accordance with national workplace design regulations.

▪ When using the boiler over 2000 metres above sea level you should consult the

manufacturer.

▪ Danger of fire due to flammable materials.

No flammable materials should be stored near the boiler. Flammable objects (e.g.

clothing) must not be put on the boiler to dry.

▪ Damage due to impurities in combustion air.

Do not use any solvents or cleaning agents containing chlorine in the room where

the boiler is installed.

▪ Keep the air suction opening of the boiler free from dust.

Ventilation of the boiler room

Ventilation air for the boiler room should be taken from and expelled directly outside,

and the openings and air ducts should be designed to prevent weather conditions (foli‐

age, snowdrifts, etc.) from obstructing the air flow.

Note on standards

2

Safety

Design Information

8 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

Unless otherwise specified in the applicable building regulations for the boiler room,

the following standards apply to the design and dimensions of the air ducts:

ÖNORM H 5170 - Construction and fire protection requirements

2.4.4 Requirements for central heating water

The following standards and guidelines apply:

Austria:

Germany:

Switzerland:

Italy:

ÖNORM H 5195-1

VDI 2035

SWKI 97-1

D.P.R. no. 412

NOTICE! Note on filling with make-up water: Always bleed the filling hose before con‐

necting, in order to prevent air from entering the system.

Observe the standards and also follow the recommendations below:

❒

Max. cumulative value for alkaline earth: 1.0 mmol/l or 100 mg/l (corresponds to

5.6 dH)

❒ Use softened water as the make-up water

❒ Avoid leaks and use a closed heating system to maintain water quality during op‐

eration

Note on standards

Note on standards

Safety

2

Design Information

Installation Instructions S3 Turbo | M1080813_en 9

2.4.5 Notes for using pressure maintenance systems

Pressure maintenance systems in hot-water heating systems keep the required pres‐

sure within predefined limits and balance out volume variations caused by changes in

the hot-water temperature. Two main systems are used:

Compressor-controlled pressure maintenance

In compressor-controlled pressure maintenance units, a variable air cushion in the ex‐

pansion tank is responsible for volume compensation and pressure maintenance. If

the pressure is too low, the compressor pumps air into the tank. If the pressure is too

high, air is released by means of a solenoid valve. The systems are built solely with

closed-diaphragm expansion tanks to prevent the damaging introduction of oxygen in‐

to the domestic hot water.

Pump-controlled pressure maintenance

A pump-controlled pressure maintenance unit essentially consists of a pressure-main‐

tenance pump, relief valve and an unpressurised receiving tank. The valve releases

hot water into the receiving tank if the pressure is too high. If the pressure drops below

a preset value, the pump draws water from the receiving tank and feeds it back into

the heating system. Pump-controlled pressure maintenance systems with open expan‐

sion tanks (e.g. without a diaphragm) introduce ambient oxygen via the surface of the

water, exposing the connected system components to the risk of corrosion. These

systems offer no oxygen removal for the purposes of corrosion control as required by

VDI 2035 and in the interests of corrosion protection should not be used.

2.4.6 Return lift

If the hot water return is below the minimum return temperature, some of the hot water

outfeed will be mixed in.

CAUTION

Risk of dropping below dew point/condensation formation if operated without re‐

turn temperature control.

Condensation water forms an aggressive condensate when combined with com‐

bustion residue, leading to damage to the boiler.

Take the following precautions:

❒ Regulations stipulate the use of a return temperature control.

➥ The minimum return temperature is 60 °C. We recommend fitting some

sort of control device (e.g. thermometer).

2

Safety

Design Information

10 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

2.4.7 Combination with storage tank

Observe the regional regulations for using a storage tank!

Certain subsidy guidelines prescribe compulsory requirements for the installation of

storage tanks. Up-to-date information about individual subsidy guidelines can be found

at www.froeling.com.

Channelling the heat generated by the Firewood boiler to a storage tank, can bring

major advantages, including:

❒

better utilisation of fuel

❒ more user-friendly operation in terms of reloading intervals

❒ maximum independence from instantaneous heating requirements

❒ minimal dirt in boiler and flue gas system

As the boiler’s minimum continuous heat output is 30% above the nominal heat out‐

put, we as the boiler manufacturer are obliged under EN 303-5:2012, Section 4.4.6 to

advise that the Firewood boiler S3 Turbo must always be connected to a storage tank

with adequate storage capacity.

Certain countries have recommended storage capacities; these are listed below. The

specified values apply when the nominal heat output of the boiler corresponds to the

heating requirements of the building and a maximum of 50% of the nominal heat out‐

put can be dissipated to the building being heated under partial load conditions.

The storage tank capacity can be calculated according to EN 303-5:2012 using the fol‐

lowing formula:

VSp = 15TB x QN (1 - 0.3 x QH/Q

min

)

V

Sp

Q

N

T

B

Q

H

Q

min

Storage tank capacity in [l]

Nominal heat output of boiler in [kW]

Burn-off period of boiler in [h]

1)

Heating load of building in [kW]

Minimum heat output of boiler in [kW]

2)

1.Sample combustion times for various fuels are provided in the technical data

2.

The boiler’s minimum output is the lowest value of the output range in the technical data. If there is no minimum heat output specified, use

the nominal heat output (Q

min

= QN)

NOTICE! EN 303-5:2012 stipulates that the storage tank capacity is at least 300l!

According to the relevant Austrian laws governing energy technology, which are based

on Art. 15a B-VG "Agreement on protective measures for small furnaces" (2012):

No storage tank is required on manually fed biomass boilers that have been positively

tested at both nominal load and partial load (below 50% of nominal load) to ensure

they adhere to the emissions limits specified in that agreement.

General information

Austria

Safety

2

Design Information

Installation Instructions S3 Turbo | M1080813_en 11

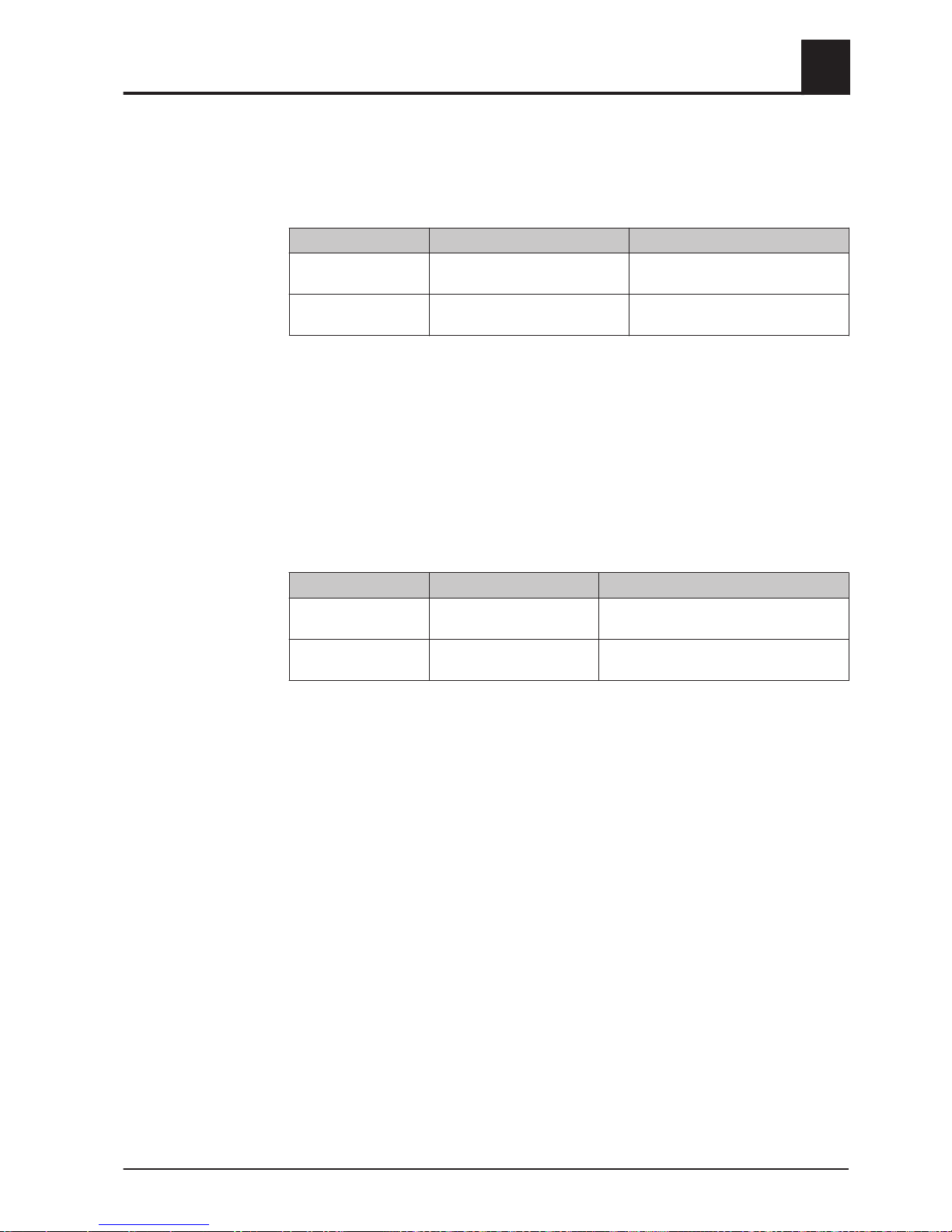

Recommended storage tank capacity:

Unit S3 Turbo

18 - 28

S3 Turbo

36 - 45

Recommended storage tank capacity

1)

[l] 1700 3000

1.Values for calculating the capacity can be found in the technical data or the technical data with partial load inspection (if available)

The first BImSchV (Ordinance on small and medium-sized heating plants of 26 Janu‐

ary 2010, BGBl. I p. 38) stipulates a minimum water heat storage tank capacity of 55

litres per kilowatt of nominal heat output; a water heat storage tank with a capacity of

12 litres per litre of fuel loading chamber is recommended.

Recommended storage tank capacity:

Unit S3 Turbo

18 - 28

S3 Turbo

36 - 45

Recommended storage tank capacity

1)

[l] 1700 3000

1.Values for calculating the capacity can be found in the technical data or the technical data with partial load inspection (if available)

For the correct dimensions of the storage tank and the line insulation

(e.g. in accordance with ÖNORM M 7510 or guideline UZ37) please consult your installer or

Froling.

Germany

2

Safety

Design Information

12 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

2.4.8 Chimney connection/chimney system

EN 303-5 specifies that the entire flue gas system must be designed to prevent, wher‐

ever possible, damage caused by seepage, insufficient feed pressure and condensa‐

tion. Please note in this respect that flue gas temperatures lower than 160K above

room temperature can occur in the permitted operating range of the boiler.

The flue gas temperatures (for clean systems) and additional flue gas values can be

found in the table below.

The connection between the boiler and the chimney system should be as short as

possible. The upward angle of the connection should not exceed 30° - 45°. Insulate

the connection. The entire flue gas system - chimney and connection - should be cal‐

culated in accordance with EN 13384-1.

Local regulations and other statutory regulations also apply.

NOTICE! The chimney must be authorised by a smoke trap sweeper or chimney

sweep.

Draught limiter

The installation of a draught limiter is recommended.

NOTICE! Install the draught limiter directly under the mouth of the flue line, as the

pressure is constantly low at this point.

Boiler data for planning the flue gas system

Description S3 Turbo

18 28 36 45

Flue gas temperature at nominal load °C 150 170 150 170

Flue gas temperature at partial load - 120 110 120

Flue gas mass flow at nominal load kg/s 0.016 0.022 0.026 0.033

Flue gas mass flow at partial load - 0.011 0.013 0.016

Required feed pressure at nominal load mbar 0.08 0.08 0.08 0.08

Required feed pressure at partial load - 0.08 0.08 0.08

Maximum permissible feed pressure as per ÖNORM/DIN EN 303-5

Flue pipe diameter mm 150 150 150 150

Safety

2

Design Information

Installation Instructions S3 Turbo | M1080813_en 13

3 Technology

3.1 Dimensions

Di‐

men‐

sion

Description Unit S3 Turbo

18-28

S3 Turbo

36-45

L Length, boiler mm 1160 1250

L1 Total length incl. induced draught fan 1260 1350

B Width, boiler 570 670

B1 Total width inc. side cleaning door 680 780

H Height, boiler 1470 1570

H1 Total height incl. flue gas nozzle 1530 1630

H2 Height, flue gas pipe connection 1750 1850

H3 Height, flow connection 1280 1380

H4 Height, return connection 140 140

H5 Height, safety battery connection 890 970

H6 Height, drainage connection 120 120

3

Technology

Dimensions

14 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

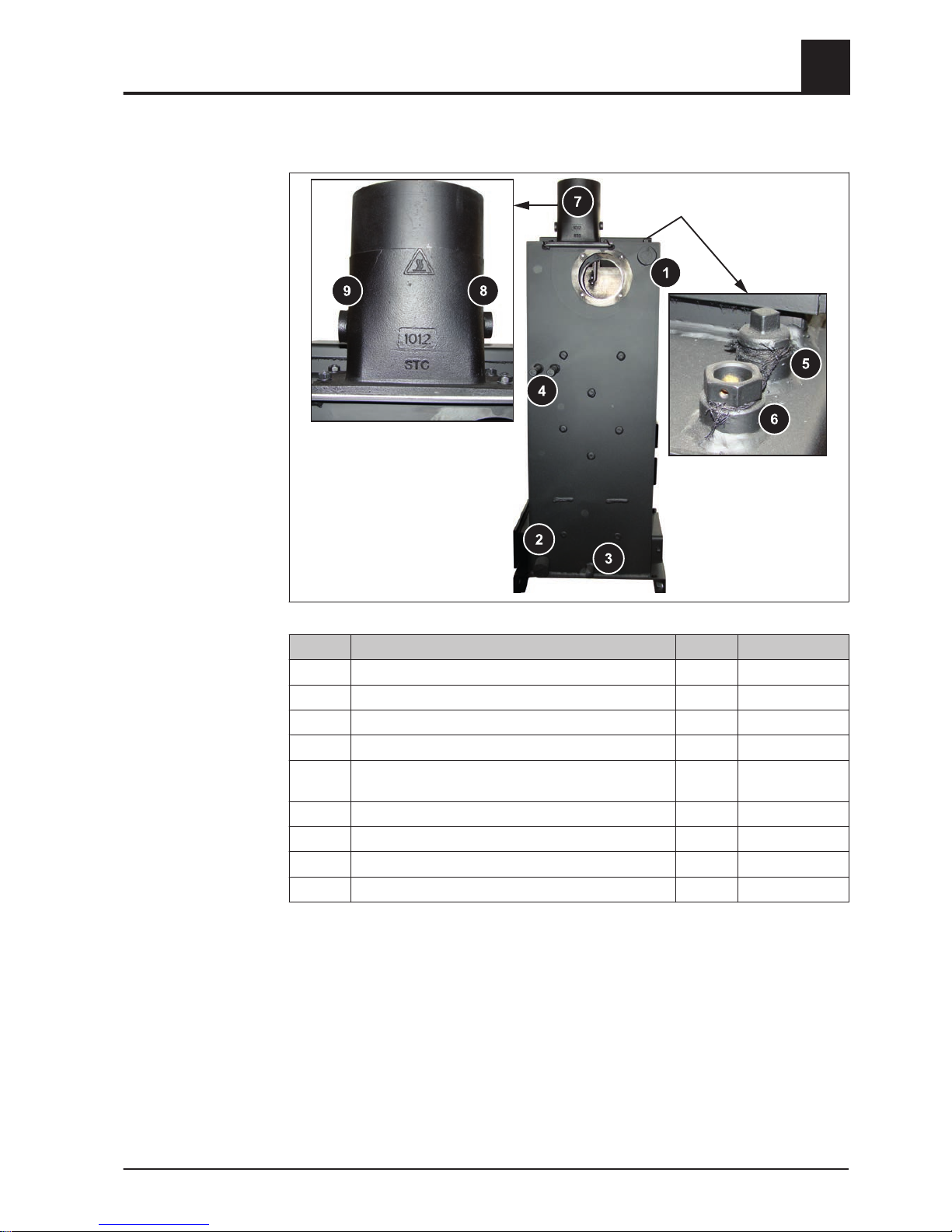

3.2 Components and connections

Item Description Unit S3 Turbo

1 Boiler flow connection inches 6/4

2 Boiler return connection inches 6/4

3 Drainage connection inches 1/2

4 Safety battery connection inches 1/2

5 Immersion sleeve for thermal discharge valve (sup‐

plied by the customer)

inches 1/2

6 Immersion sleeve for boiler sensor and STL inches 1/2

7 Flue gas pipe connection mm 150

8 Flue gas temperature sensor connection inches 1/2

9 Broadband probe connection inches 3/4

Technology

3

Components and connections

Installation Instructions S3 Turbo | M1080813_en 15

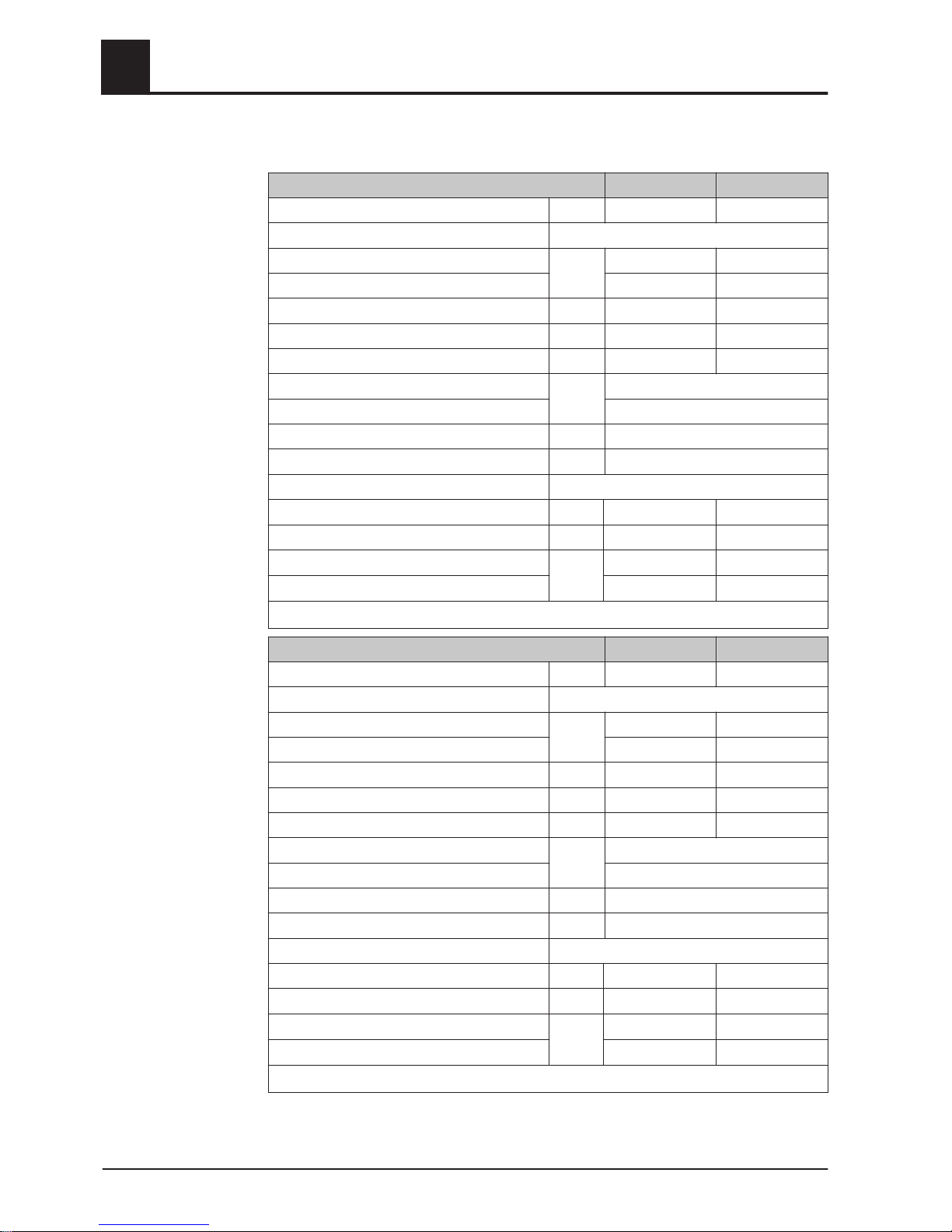

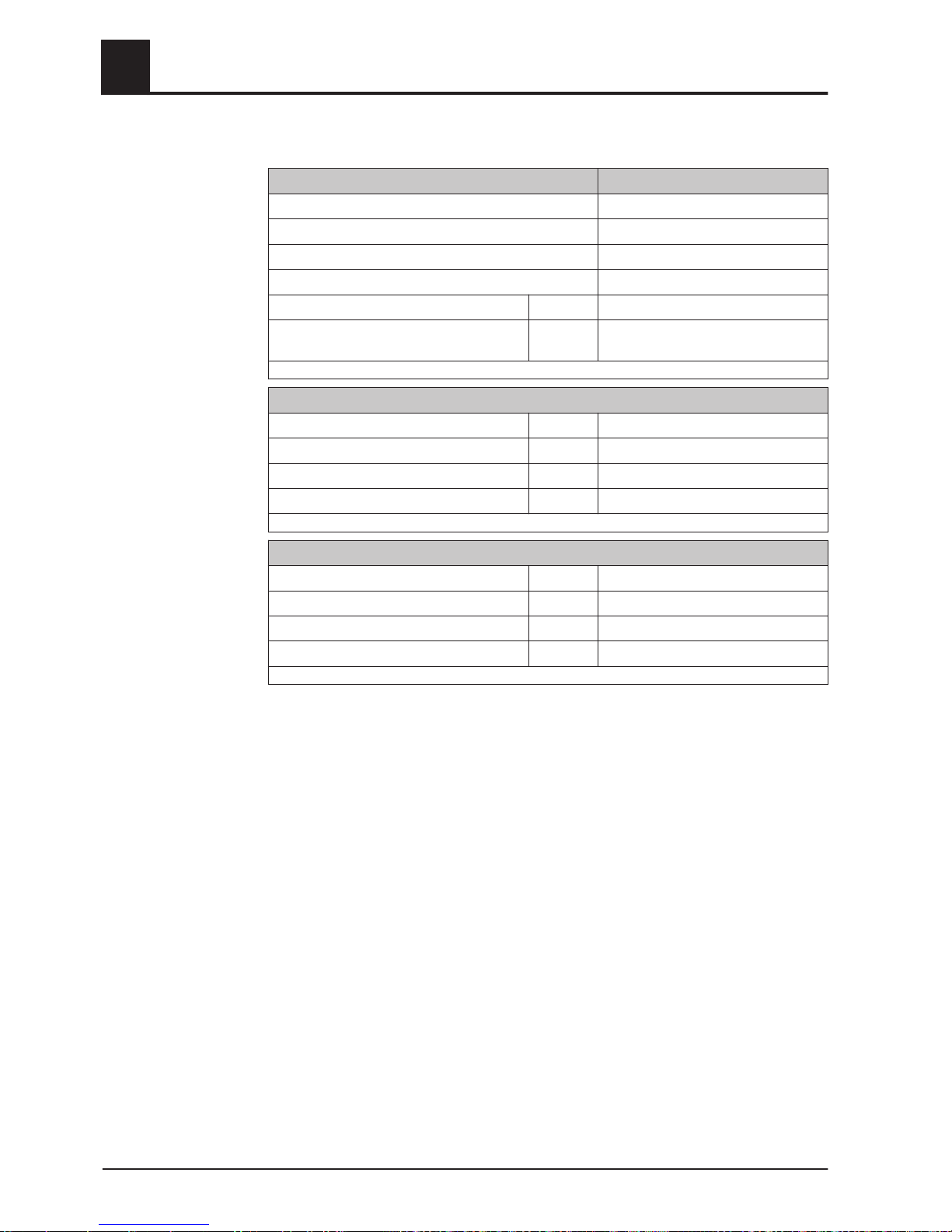

3.3 Technical specifications

Description S3 Turbo 18 S3 Turbo 28

Nominal output kW 22.5 31

Electrical connection 230V / 50Hz / fused C13A

Power consumption at nominal load W 70 50 - 70

Power consumption in slumber mode 3 3

Weight of boiler incl. insulation and control kg 525 535

Total boiler capacity (water) L 120 120

Water pressure drop (ΔT = 10 / 20 K) mbar 4.6 / 1.9 9.5 / 3.2

Minimum boiler return temperature °C 60

Maximum permitted operating temperature 90

Permitted operating pressure bar 3

Airborne sound level dB(A) < 70

Permitted fuel as per EN 14961 Part 5: Firewood class A2 / D15 L50

Fuel loading door dimensions (width / height) mm 330 / 370 330 / 370

Fuel loading chamber capacity L 140 140

Combustion time 1) - Beech

h 4.3 - 6.3 3.9 - 5.6

Combustion time1) - Spruce

3.0 - 4.4 2.8 - 3.9

1.Values specified for combustion time are guideline values at nominal load and will vary depending on water content (15-25%) and fill level

(80-100%).

Description S3 Turbo 36 S3 Turbo 45

Nominal output / range kW 36 / 18 - 36 45 / 22.5 – 45

Electrical connection 230V / 50Hz / fused C13A

Power consumption at nominal load W 45 – 75 65 - 75

Power consumption in slumber mode 3 3

Weight of boiler incl. insulation and control kg 610 620

Total boiler capacity (water) L 190 190

Water pressure drop (ΔT = 10 / 20 K) mbar 7.0 / 2.1 22.0 / 6.3

Minimum boiler return temperature °C 60

Maximum permitted operating temperature 90

Permitted operating pressure bar 3

Airborne sound level dB(A) < 70

Permitted fuel as per EN 14961 Part 5: Firewood class A2 / D15 L50

Fuel loading door dimensions (width / height) mm 330 / 370 330 / 370

Fuel loading chamber capacity L 210 210

Combustion time 1) - Beech

h 4.6 - 6.7 3.9 - 5.6

Combustion time1) - Spruce

3.2 - 4.7 2.7 - 4.0

1.Values specified for combustion time are guideline values at nominal load and will vary depending on water content (15-25%) and fill level

(80-100%).

3

Technology

Technical specifications

16 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

Description S3 Turbo 18 S3 Turbo 28

Testing institute

TÜV Austria

1)

TÜV Austria

1)

Test report no.

11-U-407/SD

2)

11-U-407/SD

2)

Date of issue 22/07/2011 22/07/2011

Boiler class as per EN 303-5:2012 5 5

Boiler efficiency % 91.1 92.3

1.TÜV Austria Services GmbH, Geschäftsbereich Umweltschutz, Am Thalbach 15, A-4600 Thalheim/Wels

2.

As per ÖNORM / DIN EN 303-5, Section 5.1.3 type test: For a boiler from a range with a consistent nominal output from the largest to the

smallest boiler ≤ 2 : 1, to carry out the tests with the smallest and the largest boilers. The boiler manufacturer must ensure that all boilers

fulfil the requirements of the norm, including those in a specific range that have not been tested, which have values that have been deter‐

mined depending on nominal output by interpolation.

Test data - Emissions in [mg/MJ]1) (nominal load)

Carbon monoxide (CO) mg/MJ 90 58

Nitrogen oxide (NOx) mg/MJ 91 83

Organic hydrocarbons (OGC) mg/MJ 6 3

Dust mg/MJ 7 7

1.The pollutant concentration is specified as a mass based on the energy content of the fuel fed to the combustion system in mg/MJ

Test data - Emissions in [mg/m³]1) (nominal load)

Carbon monoxide (CO) mg/m³ 133 86

Nitrogen oxide (NOx) mg/m³ 134 123

Organic hydrocarbons (OGC) mg/m³ 10 5

Dust mg/m³ 11 10

1.Emissions values based on dry flue gas at standard temperature and pressure (0°C, 1013 mbar) with a volume content of oxygen of 13%

Description S3 Turbo 36 S3 Turbo 45

Testing institute

TÜV Austria

1)

TÜV Austria

1)

Test report no. 11-UW/Wels-

EX-128/4

2)

11-UW/Wels-

EX-128/5

Date of issue 21/07/2011 07/11/2011

Boiler class as per EN 303-5:2012 4 5

Boiler efficiency (nominal load / partial

load)

% 93.0 / 92.5 94.1 / 92.7

1.TÜV Austria Services GmbH, Geschäftsbereich Umweltschutz, Am Thalbach 15, A-4600 Thalheim/Wels

2.

The emissions values for the partial load are determined in accordance with the test drawing 10-U-665/SD of 16/12/2010 as indicated in

point 1.6 (a) and point 6 in the test report no. 11-UW/Wels-EX-128/4 of 21/07/2011.

Test data - Emissions in [mg/MJ]1) (nominal load/partial load)

Carbon monoxide (CO) mg/MJ 39 / 380 55 / 190

Nitrogen oxide (NOx) mg/MJ 79 / 76 85 / 86

Organic hydrocarbons (OGC) mg/MJ 1 / 15 2 / 7

Dust mg/MJ 7 / 9 9 / 10

1.The pollutant concentration is specified as a mass based on the energy content of the fuel fed to the combustion system in mg/MJ

Test data - Emissions in [mg/m³]1) (nominal load)

Carbon monoxide (CO) mg/m³ 58 / 559 81 / 280

Nitrogen oxide (NOx) mg/m³ 116 / 111 125 / 127

Organic hydrocarbons (OGC) mg/m³ 2 / 23 3 / 11

Test report data

S3 Turbo 18 - 28

Test report data

S3 Turbo 36 - 45

Technology

3

Technical specifications

Installation Instructions S3 Turbo | M1080813_en 17

Test data - Emissions in [mg/m³]1) (nominal load)

Dust mg/m³ 10 / 14 14 / 15

1.Emissions values based on dry flue gas at standard temperature and pressure (0°C, 1013 mbar) with a volume content of oxygen of 13%

3

Technology

Technical specifications

18 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

4 Assembly

4.1 Materials supplied

The boiler comes on a pallet together with insulation, controller and accessories.

Some of the components come in cardboard packaging.

1 Boiler 5 Flue gas pipe nozzle

2 Insulation 6 Ceramic fibre seal

3 Controller 7 Induced draught fan

4 WOS system (heat exchanger

optimization system)

8 Cardboard box containing small parts

9 Pneumatic rods

10 Ash shovel

11 Cleaning kit

12 Cleaning brush, small

13 Cleaning brush, large

Not pictured: Installation and operating instructions, guarantee certificate, identification

plate

4.1.1 Tools required

The following tools are required for assembly:

❒

Spanner or box wrench set (widths across flats 8 – 32 mm)

❒ Allen key set

❒ Flat head and cross-head screwdrivers

❒ Hammer

❒ Diagonal cutting pliers

❒ Half-round file

❒ Power drill or cordless screwdriver with Torx bit insert

Assembly

4

Materials supplied

Installation Instructions S3 Turbo | M1080813_en 19

4.2 Positioning

NOTICE

Damage to components if handled incorrectly

❒

Follow the transport instructions on the packaging

❒ Transport components with care to avoid damage

❒ Protect the packaging against damp conditions

❒ Pay attention to the pallet's centre of gravity when lifting

❒

Position a fork-lift or similar lifting device at the pallet and bring in the components

If the boiler cannot be brought in on the pallet:

❒ Remove the cardboard and remove the boiler from the pallet

⇨ See "Remove boiler from pallet" [page 21]

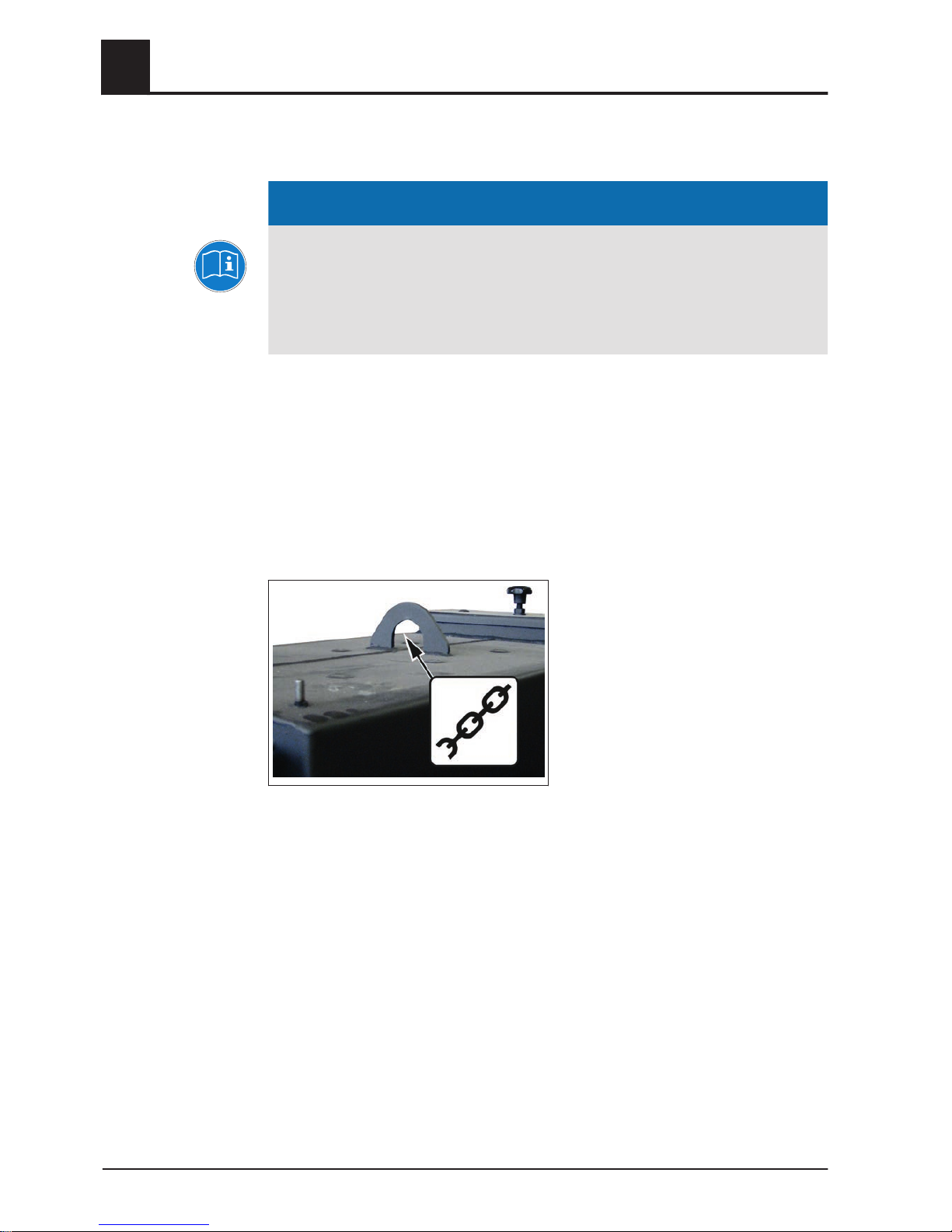

Positioning using a crane

❒ Attach the crane hook to the attachment point correctly and position the boiler

4.2.1 Temporary storage

If the system is to be assembled at a later stage:

❒

Store components at a protected location, which is dry and free from dust

➥ Damp conditions and frost can damage components, particularly electric ones!

4

Assembly

Positioning

20 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

4.3 Setting up in the boiler room

4.3.1 Remove boiler from pallet

❒ Remove the cardboard with the controller from the boiler and put in a safe place

❒

Lift the cardboard box with the insulation from the pallet

❒ Remove the transport locks

➥ A total of four screws, left/right, front/rear

❒

Lift boiler from pallet

TIP: Use Froling’s KHV 1400 boiler lifting system to help remove the pallet!

4.3.2 Moving the boiler in the boiler room

❒ Position a fork-lift or similar lifting device with a suitable load-bearing capacity at

the base frame

❒

Lift and transport to the intended position in the installation room

➥ Observe the minimum distances in the boiler room.

Assembly

4

Setting up in the boiler room

Installation Instructions S3 Turbo | M1080813_en 21

4.3.3 Minimum distances in the boiler room

▪ The system should generally be set up so that it is accessible from all sides allow‐

ing quick and easy maintenance.

▪

Regional regulations regarding necessary maintenance areas for inspecting the

chimney should be observed in addition to the specified minimum distances!

▪ Observe the applicable standards and regulations when setting up the system.

▪ Observe additional standards for noise protection

(ÖNORM H 5190 - Noise protection measures)

Dimen‐

sion

Description Unit S3 Turbo

A Distance - front of boiler to wall mm 800

B Distance – side of boiler to wall

800 (200)

1)

C Distance – back to wall 500

D Distance – side of boiler to wall

200 (800)

1)

1.The side of the boiler where the WOS lever is located (B or D) should be at least 800 mm from the wall to allow easy access for connecting

the appliance and for maintenance work (e.g. induced draught).

4.4 Before Installation

4.4.1 Changing door stops (as needed)

The boiler comes with the door stop on the right. To change the side the door stops

are on, proceed as follows.

Changing the stop of the combustion chamber door

The following example shows how to change the door stop on the combustion cham‐

ber door. The procedure is the same for changing the stop on the fuel loading door

and pre-heating chamber door!

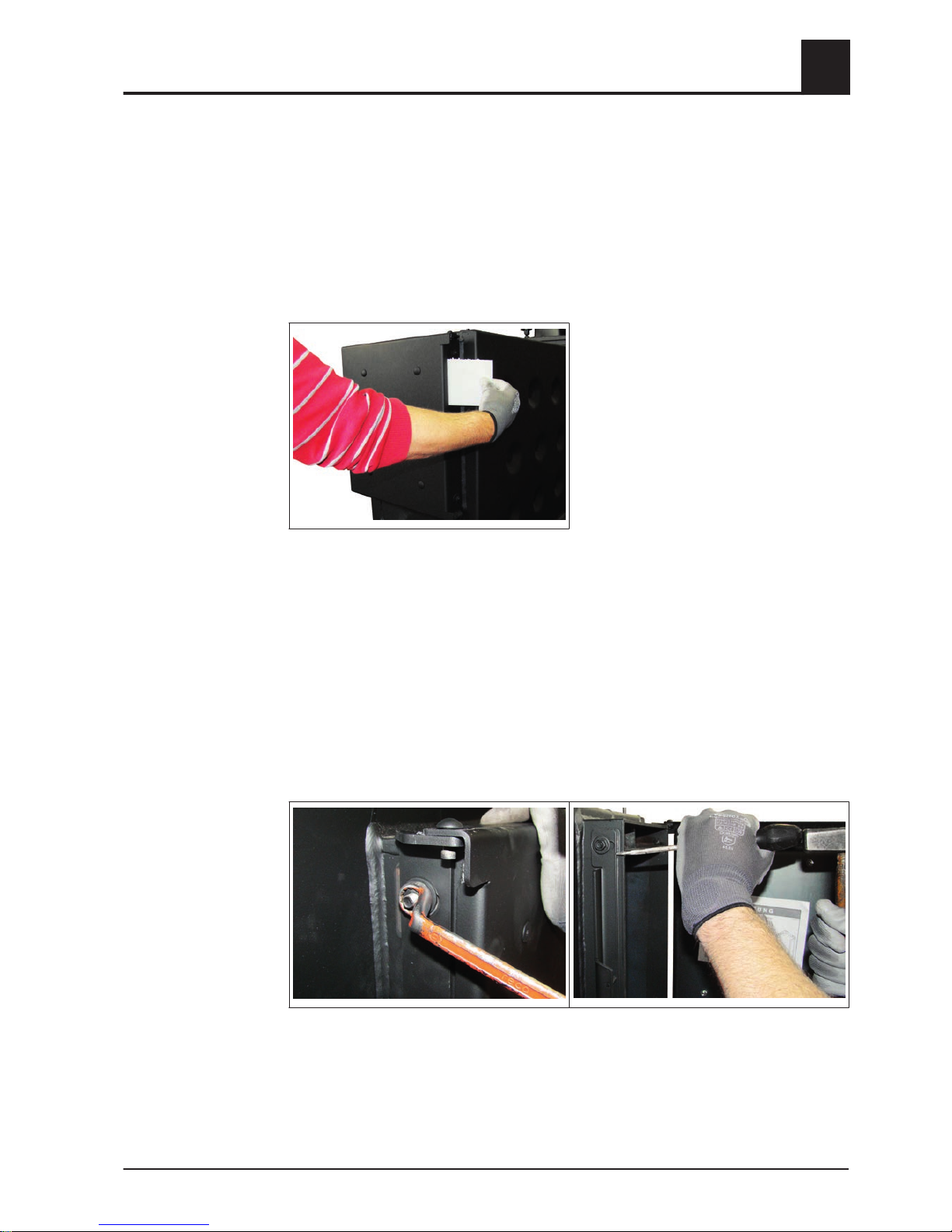

❒ Open the combustion chamber door

4

Assembly

Setting up in the boiler room

22 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

❒ Undo the retainer of the hinge pin at the top and bottom door hinge

➥ You can use two screwdrivers to gently bend the retainer plate out to loosen it

❒

Take out the top and bottom hinge pins and remove the combustion chamber door

❒ Remove the locking plate and hinge

➥ Loosen the nuts (M8) with Allen wrench (13 mm)

❒

Remount the locking plate and hinge with spacer washers and nuts on the other

side

➥ Only partially tighten the nuts

NOTICE! When changing the stop of the fuel loading door, at this point, the fuel load‐

ing door must be converted. ⇨ See "Converting the fuel loading door" [page 24]

❒ Rotate the door and rehang it with the stop on the other side

➥ Secure at the top and bottom with the hinge pins

❒

Refit the retainers to the top and bottom hinge pins

➥ To do so, you can use two screwdrivers

Assembly

4

Before Installation

Installation Instructions S3 Turbo | M1080813_en 23

❒ Use suitable tools (e.g. screwdriver and hammer) to push the hinge far enough to‐

ward the rear so that when the door is closed, there is slight resistance at a gap of

approx. 2-3 cm

➥ Caution: the hinge must be aligned in the same way at the top and bottom!

❒ Tighten the nuts at the top and the bottom on the side of the door with the stop

NOTICE! When the door stops have been changed, you must check the settings and

seal of the door.

⇨ See "Setting and checking the seal on the doors" [page

26]

Converting the fuel loading door

❒ Remove the radiation plate together with the seal

4

Assembly

Before Installation

24 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

❒ Carefully lift out the insulating plate

❒

Turn the insulating plate by 180° and position it so that it lines up with the holes

provided

❒ Re-install the radiation plate

❒

Use contact adhesive to fix the seal in place

4.4.2 Fitting the door handles

The example below shows how to mount the fuel loading door handles. The procedure

is the same for mounting the handles of the combustion chamber door and the preheating chamber door!

❒ Position the door handle in the hole provided

❒

Insert flange bushing into door handle and secure it

Assembly

4

Before Installation

Installation Instructions S3 Turbo | M1080813_en 25

4.4.3 Setting and checking the seal on the doors

The example below shows how to set and check the seals on the fuel loading doors.

The procedure is the same for the combustion chamber door and the pre-heating

chamber door!

On the side with the door stop

❒ Close the door

➥ Slight resistance at a gap of 2 - 3 cm:

Setting okay

➥ No resistance or very slight resistance:

Setting must be corrected - push the hinge toward the back

⇨ See "Positioning the doors" [page

27]

➥ Resistance at a gap of >3 cm:

Setting must be corrected - push the hinge toward the front

⇨ See "Positioning the doors" [page 27]

❒ Open the door

❒

Insert a sheet of paper at both the top and the bottom area of the door stop be‐

tween the door and the boiler

❒ Close the door

❒ Try to pull the sheet of paper out

➥ If the paper cannot be removed:

the door seal is OK!

➥ If the paper can be removed:

the door is not sealed properly - push the hinge toward the back!

⇨ See "Positioning the doors" [page 27]

Checking the setting:

Checking the seal:

4

Assembly

Before Installation

26 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

On the side with the door handle

❒ Close the door

➥ If the door can be opened with the usual force:

Setting okay

➥ If the door cannot be opened with the usual force or must be forced open

:push the locking plate toward the front

⇨ See "Positioning the doors" [page

27]

❒ Open the door

❒

Insert a sheet of paper at both the top and the bottom area at the side of the door

handle between the door and the boiler

❒ Close the door

❒ Try to pull the sheet of paper out

➥ If the paper cannot be removed:

the door seal is OK!

➥ If the paper can be removed:

the door is not sealed properly - push the locking plate toward the back!

⇨ See "Positioning the doors" [page 27]

Positioning the doors

❒ Using an Allen key (13 mm), loosen the nuts on the locking plate and/or hinge at

the top and bottom

❒

Use suitable tools (e.g. screwdriver and hammer) to move the locking plate and/or

hinge to the rear or the front as needed

➥ Caution: The locking plate and/or hinge must be aligned in the same way at the

top and bottom!

❒ Tighten the nuts at the top and bottom

Checking the setting:

Checking the seal:

Assembly

4

Before Installation

Installation Instructions S3 Turbo | M1080813_en 27

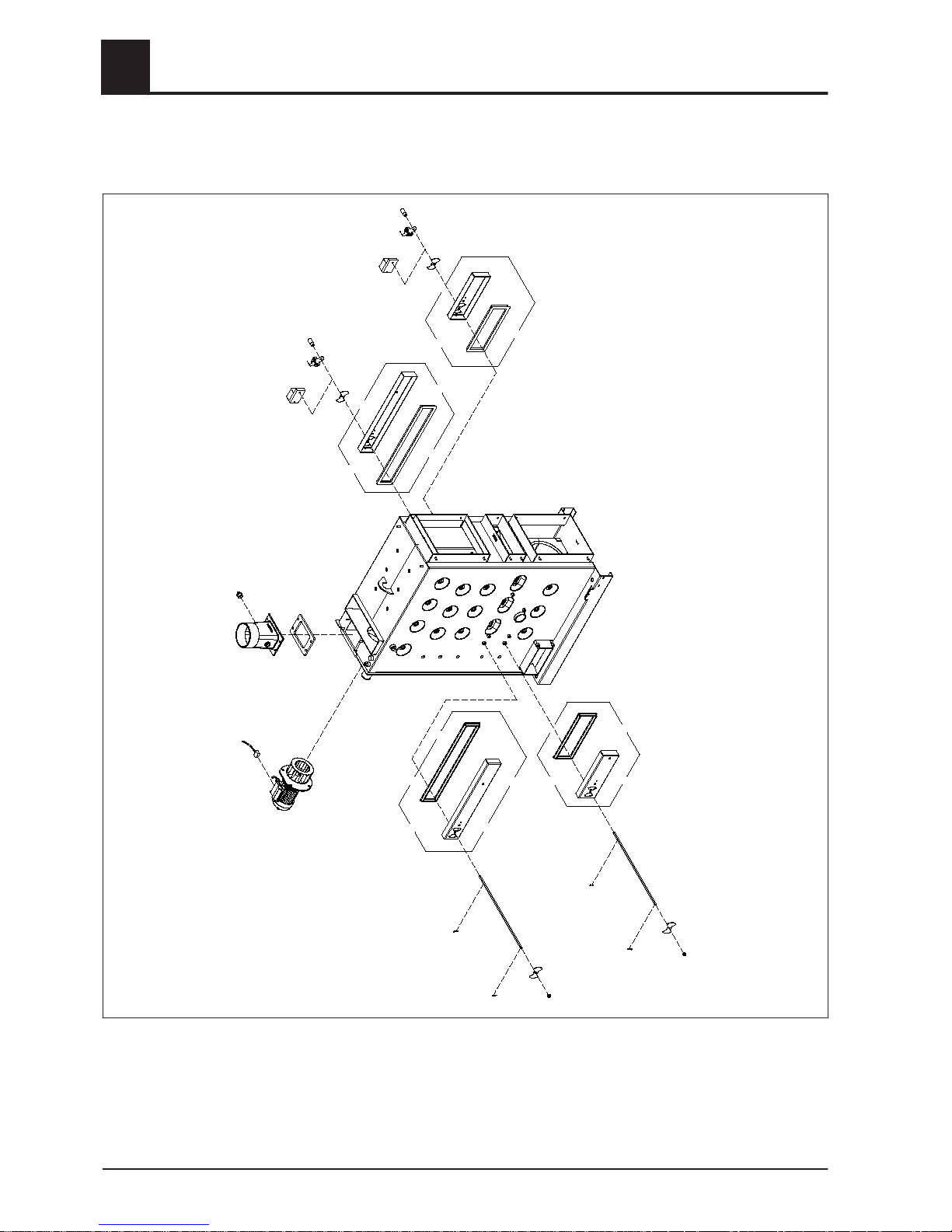

4.5 Installing the boiler

4.5.1 Assembly overview

Insulation

6

7

5

2

3

2

3

6

7

8

9

11

10

12

13

14

16

17

18

19

22

20

23

3

24

28

29

26

27

1

4

4

25

16

32

30

30

31

31

21

A

Detail A

36

37

33

34

22

21

35

15

31

41

41

40

38

39

4

4

S3 Turbo 18/28:

4

Assembly

Installing the boiler

28 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

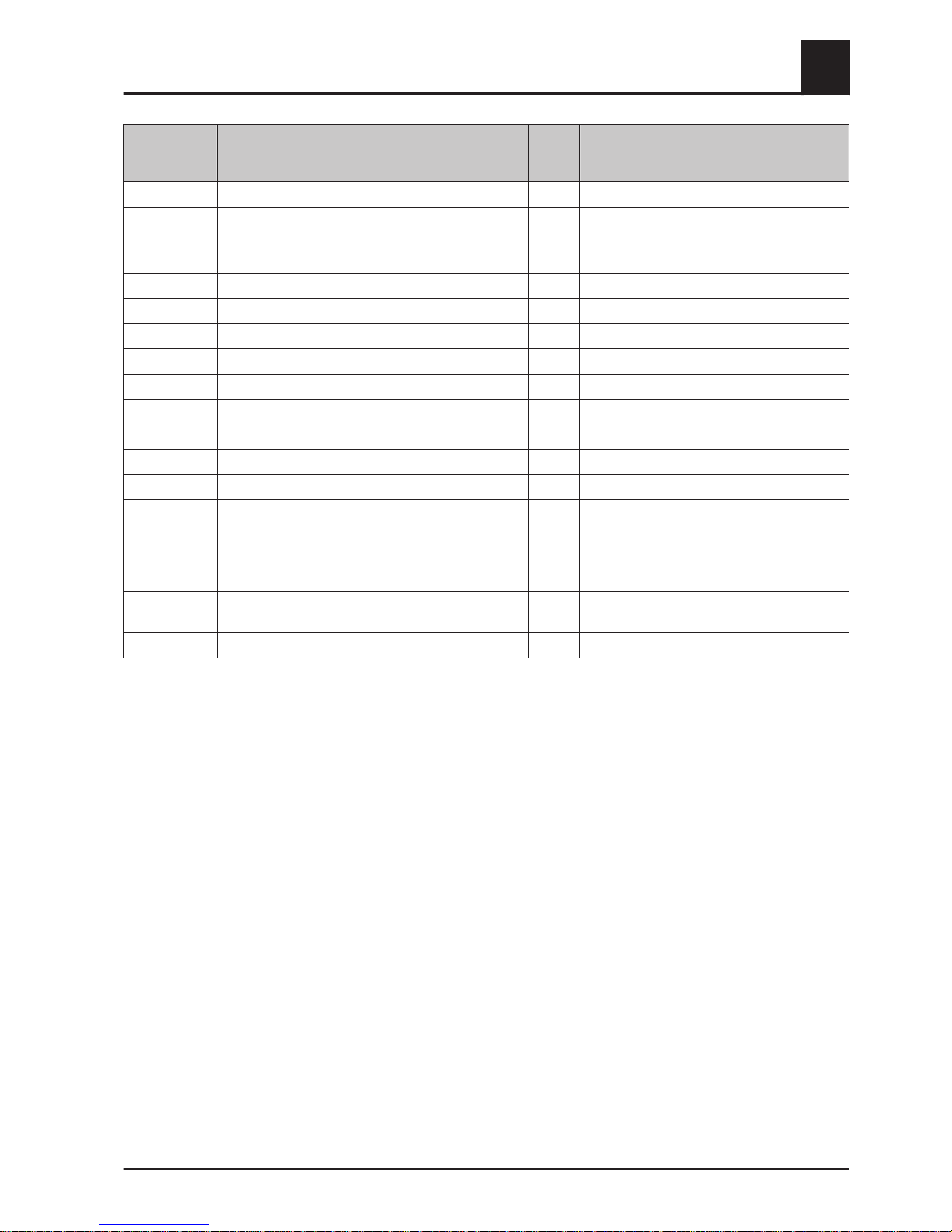

Item Quan‐

tity

[units]

Description Item Quan‐

tity

[units]

Description

1 1 Insulated door, complete 2 2 Magnetic latches

3 3 Grip recess 4 2 Flange bushing (8x6x12x8)

5 1 Sticker, FROELING S3 TURBO 6 1 U-plate – S3 Turbo 36/45

fitting grooved pin (6x30) – S3 Turbo 18/28

7 1 Lower door bracket 8 1 Lower spacer plate

9 1 Complete floor insulation 10 1 Insulation mounting brackets, left

11 1 Insulation cover plate, left 12 1 Cover plate

13 1 Insulating side panel, left, complete 14 1 Thermal insulation, rear

15 1 Back panel, complete 16 2 Cover plate for ID fan

17 1 Heat insulation mat, top/rear 18 1 Heat insulation mat, top

19 1 Heat insulation mat, top/front 20 1 Controller cover

21 2 Contact washer M4 22 2 Hexagonal screw M6 x 100

23 1 Insulating cover, back 24 1 Upper spacer plate

25 1 Hinge pin, insulated door 26 1 Insulation mounting brackets, right

27 1 Insulation cover plate, right 28 1 Insulating side panel, right, complete

33 1 Sticker, "Primary air actuator"

(only with S-Tronic Lambda)

34 1 Sticker, "Secondary air actuator"

(only with S-Tronic Lambda)

35 1 Torque support, servo-motor

(only with S-Tronic Lambda)

36 2 Counter plate for magnetic latches

37 2 Thread forming screw M3x10

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 29

Air duct system

3

4

5

6

7

8

9

11

12

8

6

7

11

12

13

13

8

8

14

14

14

15

15

1

22

21

22

10

9

10

4

Assembly

Installing the boiler

30 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

Item Quan‐

tity

[units]

Description

1 1 Induced draught fan 2800U, complete, with rotation speed transducer

3 1 Ceramic fibre seal 210x144x12

4 1 Flue gas pipe nozzle ø150

5 1 Blanking plug 3/4"

6 2 Air duct, primary air, left and right

7 2 Rubber seal for profile 12x2x15x23, L=1600

8 4 Air flap

9 2 Manual controller for air control system (S-Tronic/S-Tronic Plus)

10 2 Handle, black

11 2 Air duct, secondary air, left and right

12 2 Rubber seal for profile 12x2x15x23, L=1000

13 2 Pneumatic rods

14 4 Split pin ø3.2x20

15 2 Pressure spring ø17.8x1.1x28

21 1 Induced draught cable incl. rotation speed transducer cable - 2m

22 2 Servo-motor LM 24AP5-F/300.1 (S-Tronic Lambda)

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 31

WOS system S3 Turbo 18-28

1

2

3

4

6

7

7

8

9

9

8

10

11

12

13

5

4

Assembly

Installing the boiler

32 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

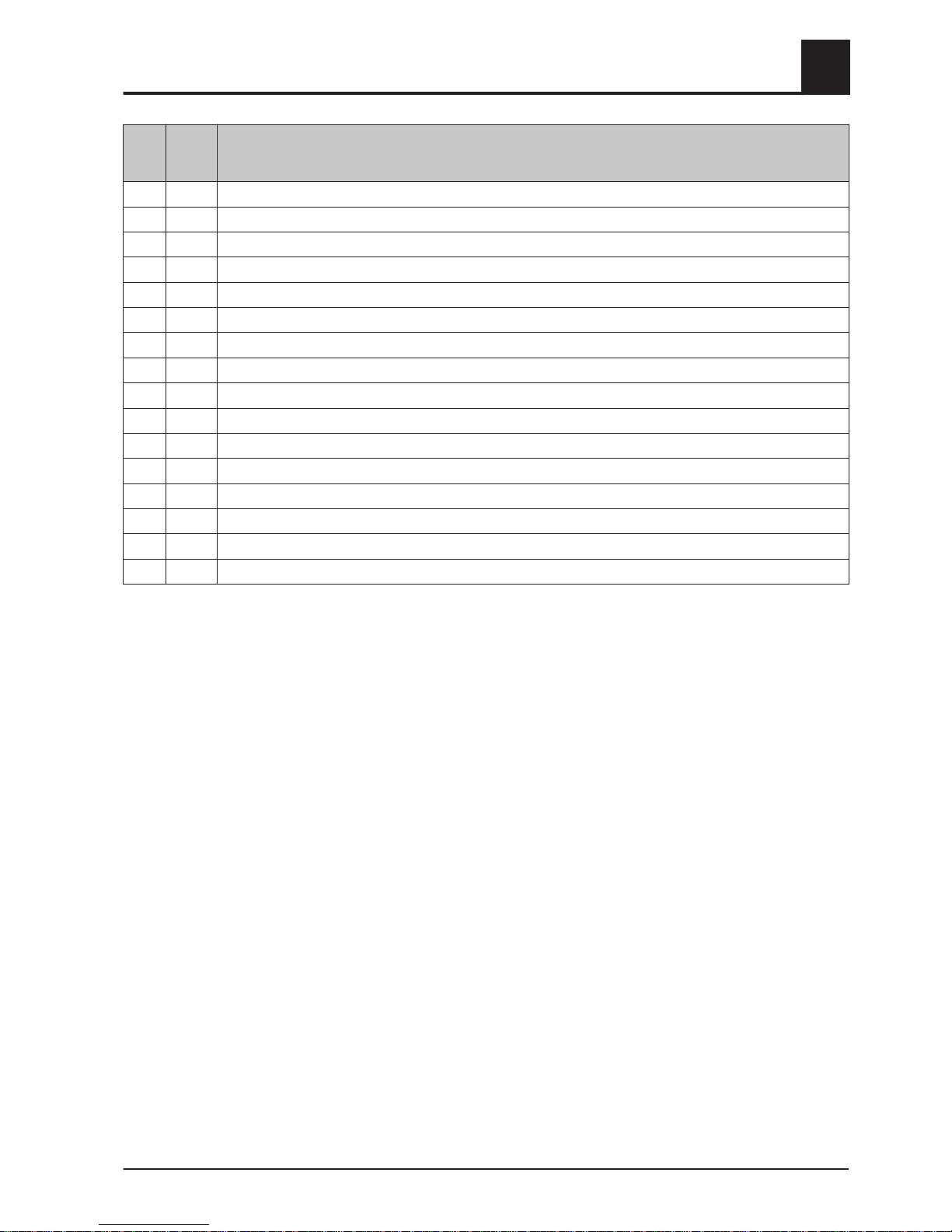

Item Quan‐

tity

[units]

Description

1 1 WOS lever, complete

2 1 Handle

3 1 Brass bushing SW27x20

4 4 WOS turbulator ø50x6x3x837

5 1 WOS bracket, complete 6x3

6 1 Linking plate for turbulator 6x3

7 2 Bolt ø8x16

8 2 Spacer washer M8

9 2 Split pin ø2x16

10 1 Stay tube WOS

11 1 Clamping jaw

12 1 Spacer tube ø21.3x50

13 1 Rosette ø77x15.5

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 33

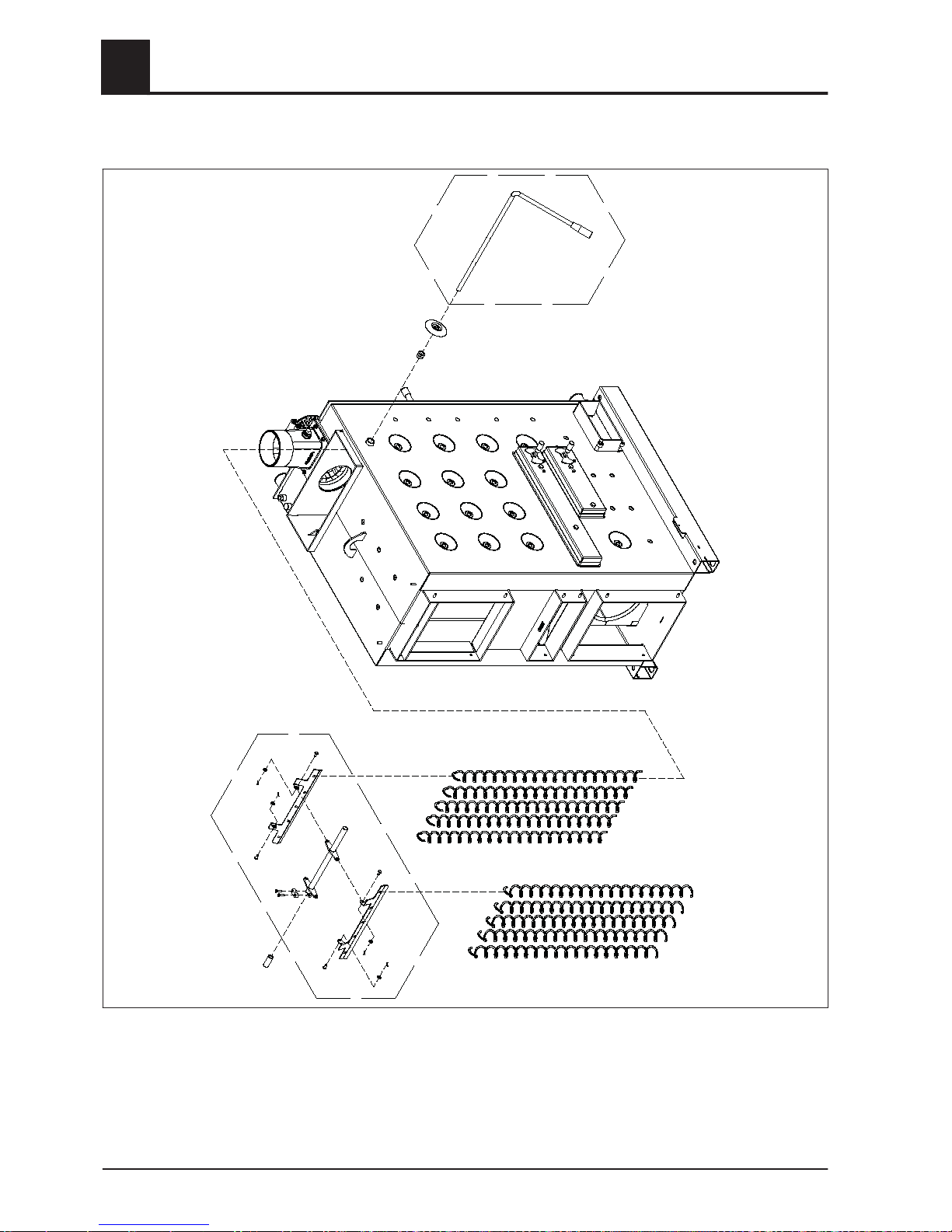

WOS system S3 Turbo 36-45

2

3

1

4

6

7

6

9

9

10

11

10

11

12

9

9

8

4

10

11

10

11

5

13

4

Assembly

Installing the boiler

34 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

Item Quan‐

tity

[units]

Description

1 1 WOS lever, complete

2 1 Handle

3 1 Brass bushing SW27x20

4 10 WOS turbulator ø50x6x3x932

5 1 WOS bracket, complete 6x3

6 2 Linking plate for turbulator 6x3

7 1 Stay tube

8 1 Clamping jaw

9 4 Bolt ø8x16

10 4 Split pin ø2x16

11 4 Spacer washer M8

12 1 Spacer tube ø21.3x91

13 1 Rosette ø77x15.5

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 35

4.5.2 Installing the flue gas pipe nozzle

❒ Place the ceramic fibre seal in position

❒

Position the flue gas pipe nozzle and attach it using the pre-installed spacer wash‐

ers and nuts

➥ Caution: ½" connection must point to the right as seen from behind!

4.5.3 Fit the induced draught fan

❒ Position the induced draught fan on the back of the boiler and mount it with the

four screws

➥ Caution: Do not overstress the flange!

4.5.4 Installing the pneumatic rods for the primary and secondary air

Manual controllers or servo-motors can be mounted on either the left or the right side

on the boiler

❒

Remove the split pin on both pneumatic rods opposite the spring and pull one of

the air flaps off of each

4

Assembly

Installing the boiler

36 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

❒ Loosen the two screws at the lower and upper air duct on the right side of the boil‐

er

❒

Screw in the screws at the lower and upper air duct on the left side of the boiler far

enough to allow the air flap to make contact with the thread

❒ Loosen the screws at the lower and upper air duct on the right side of the boiler far

enough to allow the air flap to make contact with the thread

The following procedures are used to mount the pneumatic rod if the manual control‐

lers/servo-motors are mounted on the left side of the boiler. If the manual controllers/

servo-motors are mounted on the right side of the boiler, complete the following proce‐

dures with the sides reversed accordingly.

❒ Insert both pneumatic rods at the right-hand side of the boiler

➥ The air flaps with springs lie flat on the right air ducts!

Manual controller/ser‐

vo-motor, left

Manual controller/ser‐

vo-motor, right

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 37

❒ Insert the air flaps on the pneumatic rods on the left side and secure them with

split pins

➥ CAUTION: The air flaps must be situation in the same position as those on the

opposite side!

❒

Turn both pneumatic rods in an anti-clockwise direction as far as the stop

4.5.5 Final steps before insulating

❒ Seal and screw in the immersion sleeve for thermal discharge safety device sen‐

sor

❒ Detach blanking plate for the side cleaning port

❒ Remove the screw cap from the side on which the WOS lever will be mounted lat‐

er and replace it with a brass bushing

➥ Tighten the brass bushing with Allen wrench (27 mm)

❒

Seal the broadband probe connection with a 3/4" blanking plug (2)

➥ On the S3 Turbo with S-Tronic Lambda, the broadband probe will be mounted

here later

Only for S-Tronic

and S-Tronic Plus:

4

Assembly

Installing the boiler

38 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

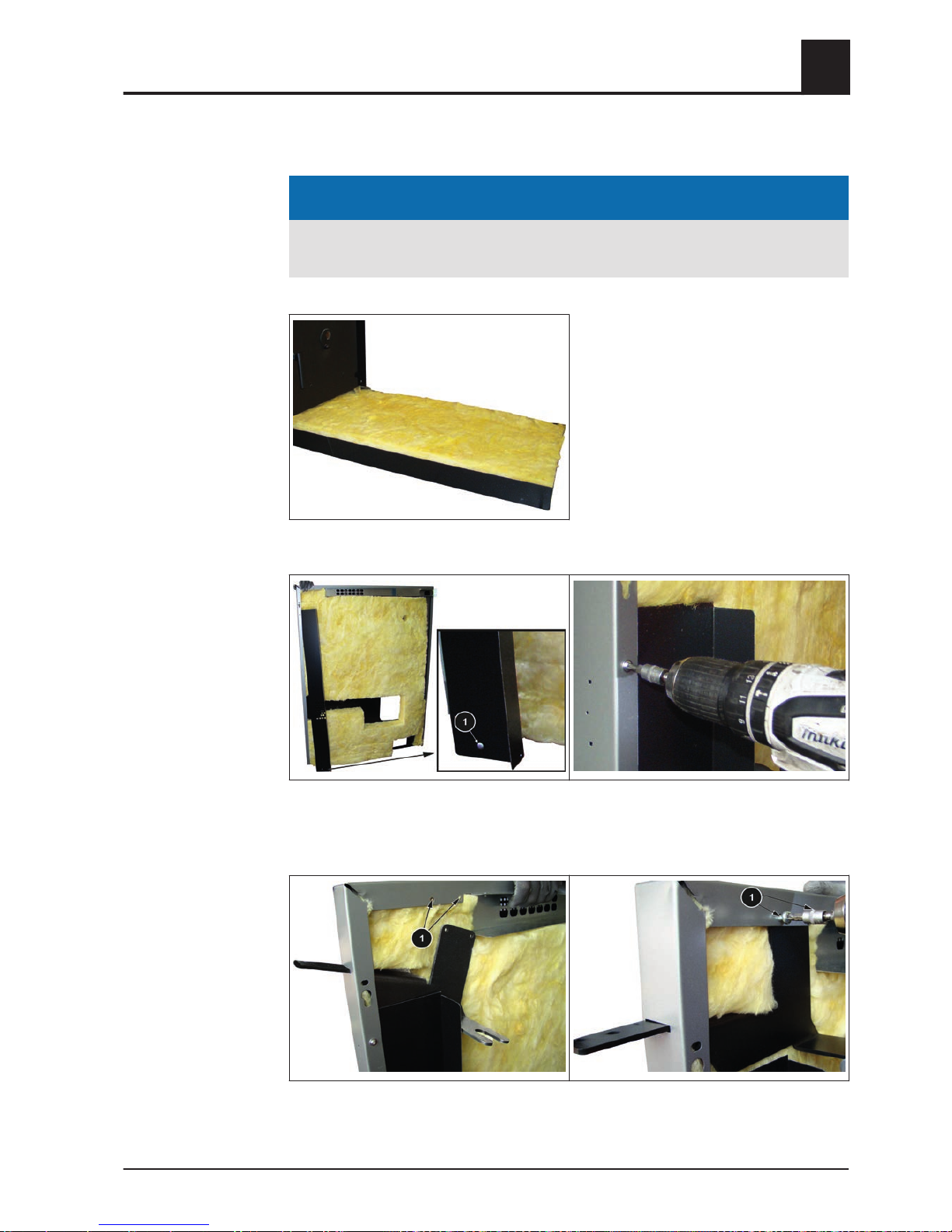

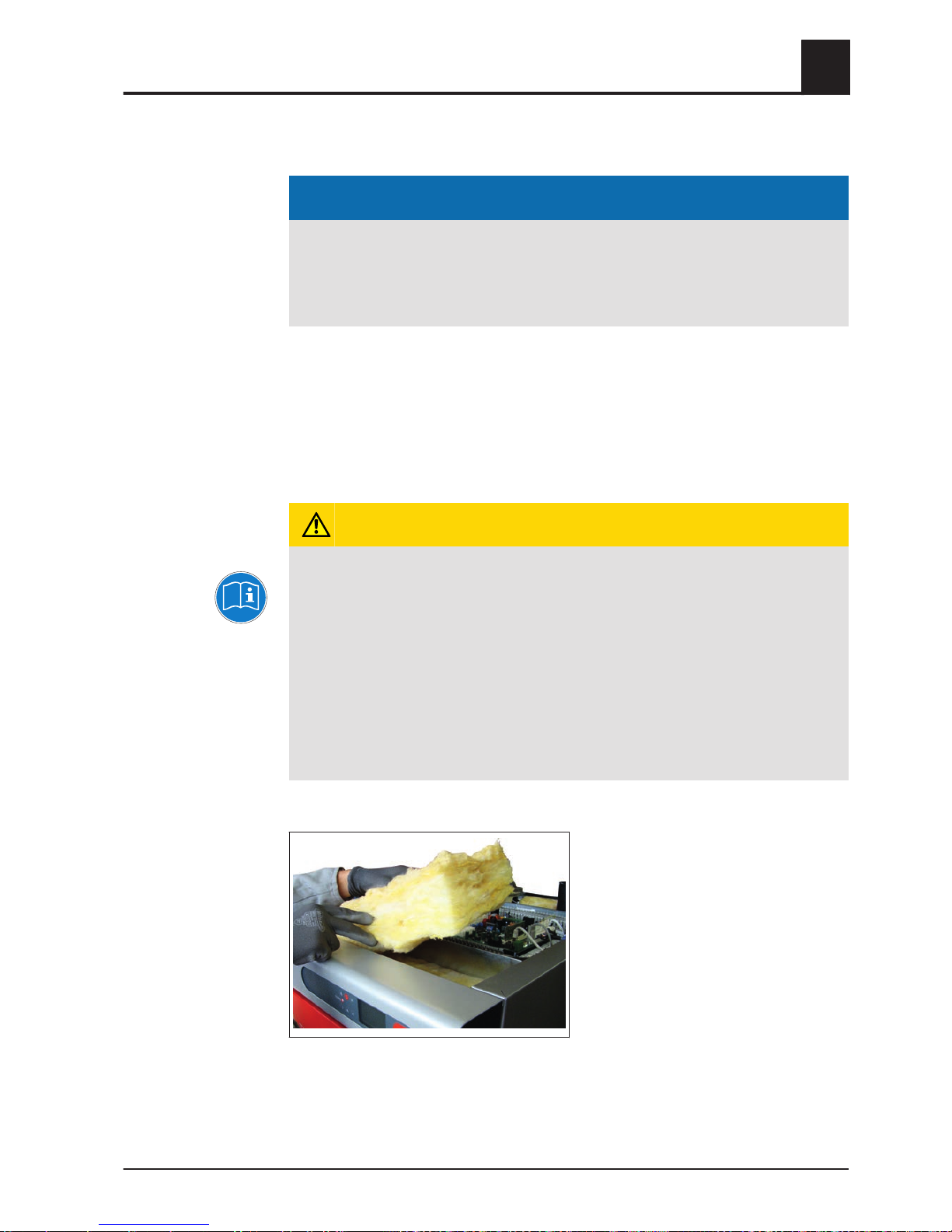

4.5.6 Installing the insulation

NOTICE

Separate parts of the boiler are fitted with a protective film. This MUST be re‐

moved before assemby!

❒ Push in the bottom insulation

❒ Inset the two L-shaped insulation cover plates at the insulating side panels at left

and right and secure them with three thread forming screws each

➥ Insert the cover plates such that the rivet (1) is at the bottom!

❒ Insert the insulation mounting brackets at both insulating side panels and secure

them with the two top thread forming screws (1)

➥ At the front, the bracket will be secured later when the upper spacer plate is

inserted!

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 39

❒ Cut the perforated plates for the cleanout opening on both sides and bend them

inward

➥ Caution: bend the plates > 100° inward!

❒ Place one large spacer washer on each of the threaded bolts to the right and the

left above on the boiler

❒

Insert the insulating side panels at the base of the boiler at the flap and push them

onto the boiler

❒ Position the side panels with the door bracket onto the threaded bolts and secure

them lightly with a large and a small spacer washer and nut (1)

❒

Hang the upper spacer plate on the rivets between the insulating side panels and

attach with a thread forming screw (2)

➥ At the same time, this procedure also secures the bracket to the insulating side

panels at the front

4

Assembly

Installing the boiler

40 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

4.5.7 Installing the door switch

❒ Secure the bracket with pre-mounted door switch to the upper spacer plate with

two thread forming screws M4x8

4.5.8 Installing the back panel

❒ Position the rear thermal insulation on the rear side of the boiler

❒

Insert insulating back panel over induced draught fan

❒ Secure the insulating back panel to the left and right with nine thread forming

screws each

❒

Install the cover plates for ID fan

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 41

4.5.9 Aligning the insulation and attaching the controller

❒ Hang the lower spacer plate on the rivets (1) between the insulating side panels

and attach with one thread forming screw (2) each

❒

Push the insulating side panels toward the rear until the borehole on the flaps cor‐

responds with the borehole on the side panels

❒ Secure the insulating side panels to the right and left at the flap on the boiler base

with thread forming screws

❒

Measure the diagonals and align the insulating side panels so that the two diago‐

nals are the same

➥ Adjust the position of the side panels if necessary

❒ Tighten the nuts on the two brackets of the insulating side panels at the top on the

boiler

❒

Position the control on top

4

Assembly

Installing the boiler

42 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

❒ Insert one countersunk cross-head screw each to the left and right through the

bracket and control from below

❒

Use nuts to secure the countersunk cross-head screws from the top.

❒ Put the top heat insulation mat on

➥ The heat insulation mat must touch the front sheet

❒

Place the controller box on the boiler

❒ Use eight thread forming screws incl. contact washers (1) to install controller box

on the cable duct of the side panels

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 43

❒ Screw in two carrying bolts (hexagonal bolts M6x100) to the left and right at the

bottom rear side of the controller far enough to ensure that the controller and insu‐

lation are supported adequately

4.5.10 Installing the cleaning port door and blank cover

NOTICE! Recommendation for easier maintenance: mount the cleaning port door on

the same side as the WOS lever!

❒ Use three Allen screws to mount the cleaning port door on the desired side

➥ Start with the screws at upper right!

❒

Attach the door handle for the cleaning port door using a round headed screw

❒ Install the blank cover for the side cleaning port on the opposite side

4.5.11 Installing the insulated door

The illustrations show the assembly for the door stop on the right. If the insulated door

is attached on the left, complete the following procedures with the sides reversed ac‐

cordingly.

4

Assembly

Installing the boiler

44 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

❒ Tap in a fitting grooved pin at the lower door bracket

❒

Slide the lower door bracket into the base of the boiler

➥ Insert the fitting grooved pin (1) into the insulation

➥ Lightly tighten the two hexagonal screws M6x12 (2)

❒ Mount the lower door bracket with two hexagonal screws M6x12 on the U-profile

❒

Insert the door bracket with the U-profile and lightly tighten the two hexagonal

screws M6x12

❒ Measure the distance from the insulating side panel to the centre of the borehole

for the insulated door on the upper bracket

❒

Measure the distance from the insulating side panel to the centre of the borehole

on the lower door bracket

➥ The two distances must be equal!

➥ If necessary, correct the position of the lower door bracket

S3 Turbo 18/28:

S3 Turbo 36/45:

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 45

❒ Secure the lower door bracket

❒

At the front end of the lower door bracket, insert a hexagonal screw M6x30 from

below, secure it with a nut and place a spacer washer on top

❒ Insert flange bushings at the top and the bottom on the side of the insulated door

with the stop

❒

Mount the insulated door onto the lower door bracket using the hexagonal screw

❒ Attach the insulated door to the upper door bracket with hinge pin (1)

➥ Insert the hinge pin through the control and the upper door bracket

4

Assembly

Installing the boiler

46 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

❒ Position magnetic latches on the inside of the insulated door at the top and bottom

❒

Mount counter plates for the magnetic latches to the left insulation side panel

❒ Check to see if the gap between the insulation side panel and the insulated door is

the same size along the entire height of the boiler

➥ If necessary, correct the position of the lower door bracket

4.5.12 Fitting the sensors

❒ Screw in the brass bushing for the flue gas temperature sensor

➥ Make sure that the borehole with the thread is situated at the upper area of the

brass bushing

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 47

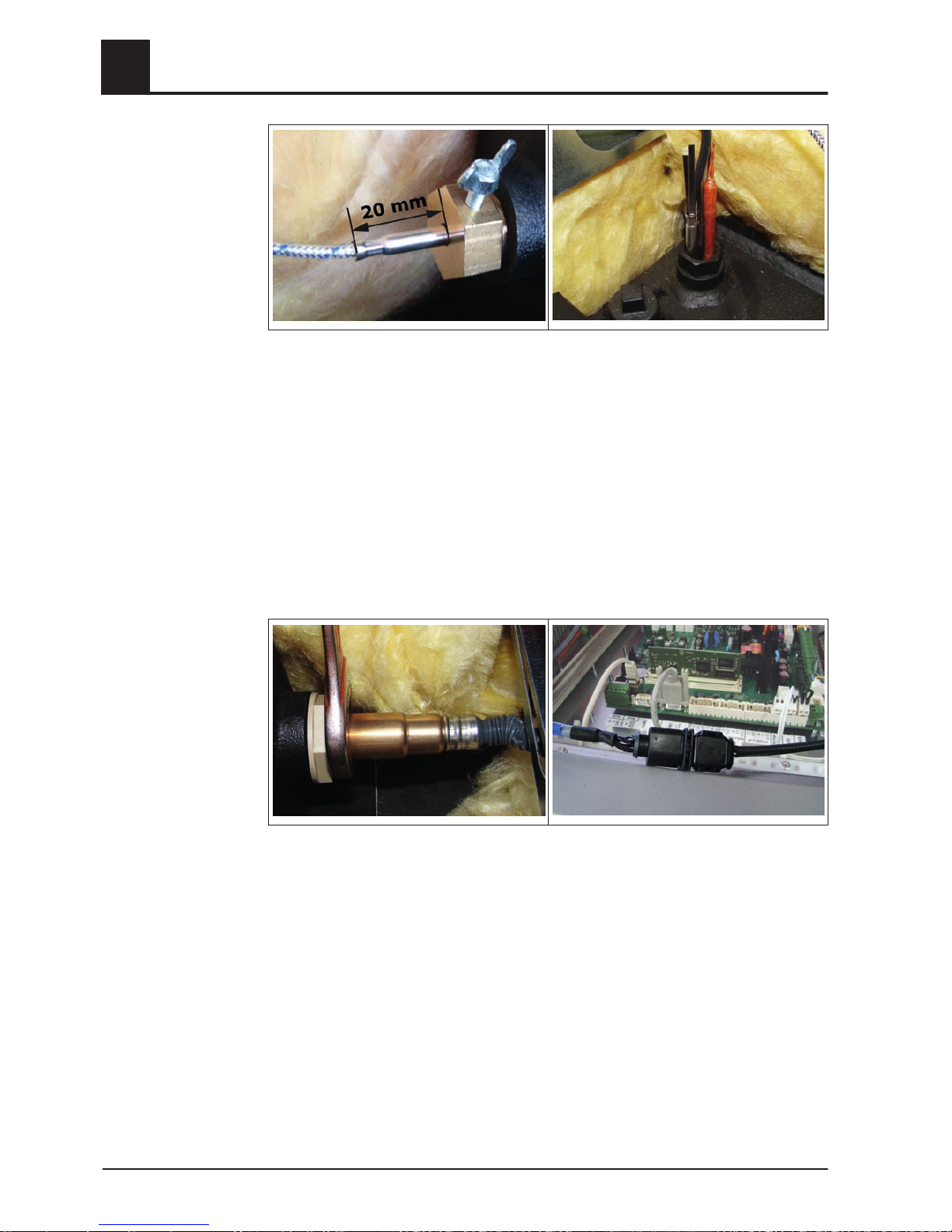

❒ Push the flue gas temperature sensor in so that it protrudes approx. 20 mm from

the housing and secure the position with the wing screw

❒

Push the boiler sensor and STL capillary into the pre-installed immersion sleeve

with the pressure spring during boiler outfeed

❒ Run the cable through the cable duct to the controller box

➥ Tuck any extra cable into the cable duct

4.5.13 Install the broadband probe (only with S-Tronic Lambda)

❒

Unscrew the pre-installed bushing from the broadband probe

❒ Screw the bushing into the flue gas nozzle and gently tighten

❒ Screw the broadband probe into the bushing and gently tighten using an Allen

wrench (22 mm)

❒

Plug in the extension cable for the Lambda probe and un the cable through the ca‐

ble duct to the controller box

➥ Tuck any extra cable into the cable duct

4

Assembly

Installing the boiler

48 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

4.5.14 Installing the WOS system

❒ Remove the pre-punched blanking in the insulation side panel on the same side

as the brass bushing

➥ File rough edges using a half-round file and remove burrs

❒

Slide the plastic cover onto the WOS lever

S3 Turbo 18/28:

S3 Turbo 36/45:

❒ Remove the heat exchanger cover

❒ Hang the WOS turbulators on the linking plate of the stay tube

➥ Make sure that you fit the turbulators in the right direction:

➥ Hold the linking plate with the edge toward the top

➥ Hang the WOS turbulators over the edge

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 49

❒ Position the WOS turbulators at the heat exchanger pipes

❒ Position the WOS turbulators at the heat exchanger pipes

❒ Position the spacer tube at the stay tube

❒

Push the WOS lever through the distance and stay tubes from the outside and se‐

cure it at the stay tube with a clamping jaw

S3 Turbo 18/28:

S3 Turbo 36/45:

4

Assembly

Installing the boiler

50 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

S3 Turbo 18/28: S3 Turbo 36/45:

❒ Place the heat exchanger cover on top

❒

Turn the handle of the heat exchanger cover to the right

❒ Tighten the nut below the handle

4.5.15 Installing the manual controller/servo-motors

❒ Use thread forming screws to secure the cover plate on the manual controller/ser‐

vo-motor side

➥ Check to see if the air flaps are at the left stop

Mounting the manual controller (with S-Tronic/S-Tronic Plus control)

❒ Place the air flap manual controllers on the pneumatic rod so that the manual con‐

troller is at the left stop and secure them with one thread forming screw each

❒

Place the handle onto the pneumatic rod

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 51

❒ Check to see if the air flaps can be opened to the right

➥ The exact position of the manual controller is set on initial start-up

⇨ See "Boiler with manual controller" [page

65]

❒ Use thread forming screws to secure the cover plate on the opposite side

Mounting the servo-motors (with S-Tronic Lambda control)

❒ Check to see if the air flaps are at the left stop

➥ All air flaps are closed

❒ Set the servo-motors:

➥ Set the direction of rotation of the servo-motor (1) to left (L)

➥ Press the unlock key (2) and turn the drive for the shaft to the air duct (3) in an

anti-clockwise direction as far as the stop

❒

Place the servo-motors onto the pneumatic rod

❒ Position the torque support and partially tighten the screws

❒

Align the servo-motors so that they are straight and tighten the screws

4

Assembly

Installing the boiler

52 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

❒ Use thread forming screws to secure the cover plate on the opposite side

❒ Attach the sticker at the end of the servo-motor cable

➥ Primary air: top servo-motor

➥ Secondary air: bottom servo-motor

❒

Push in the pre-punched opening for the cable duct onto the insulation

❒ Run the cable from the two servo-motors through the cable duct upward to the

controller

Assembly

4

Installing the boiler

Installation Instructions S3 Turbo | M1080813_en 53

4.6 Power connection and wiring

DANGER

When working on electrical components:

Risk of electrocution!

When work is carried out on electrical components:

❒ Only have work carried out by a qualified electrician

❒ Observe the applicable standards and regulations

➥ Work must not be carried out on electrical components by unauthorised

persons

4.6.1 S-Tronic control

Power connection

Core module S-Tronic

4

Assembly

Power connection and wiring

54 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

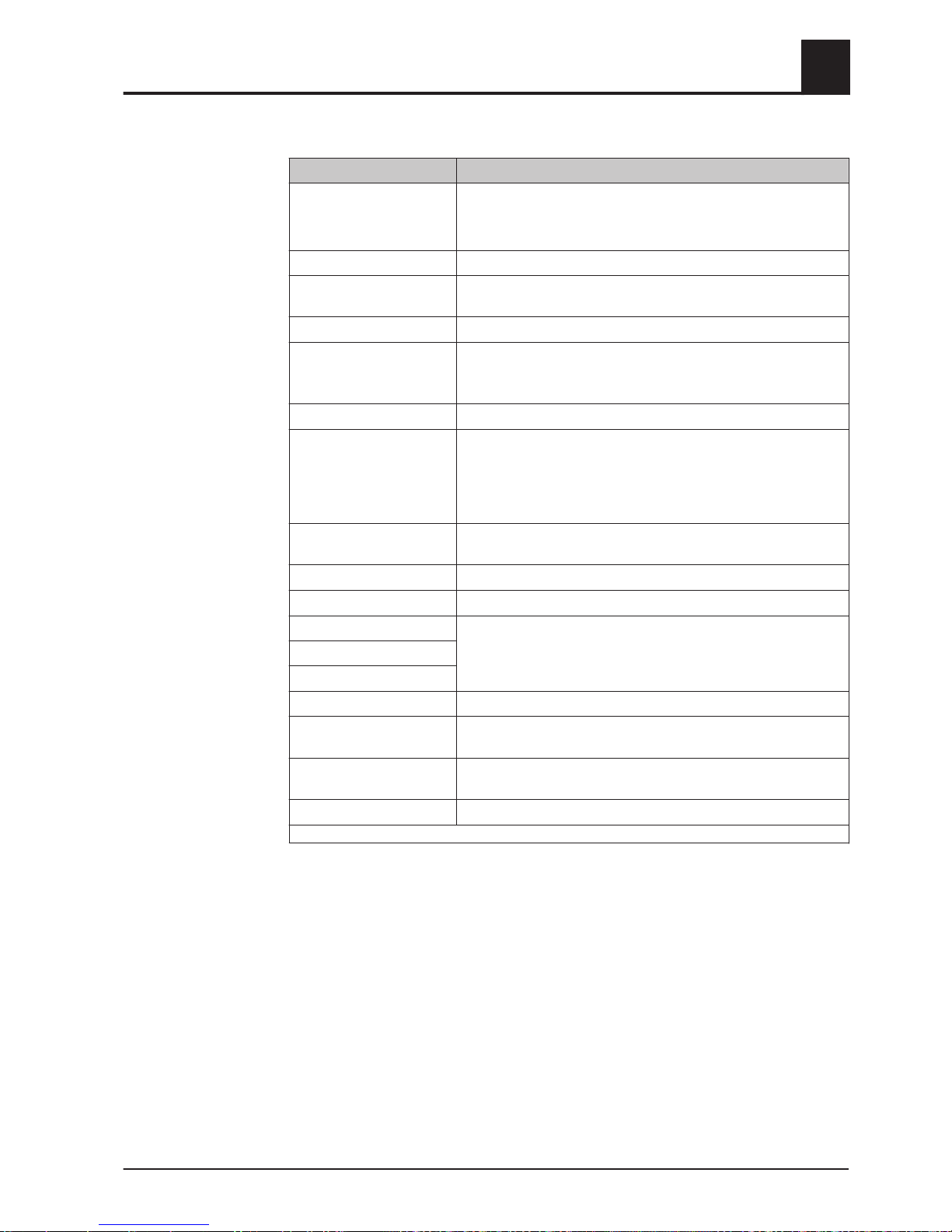

Connection instructions

Port Cable dimensions / Specifications / Information

Bus (1) Port with cable – LIYCY paired 2x2x0.5;

Connecting the bus cable

❒

Warning! CAN L and CAN H must not be connected to +U

BUS

!

Bus (2) Patch cable CAT 5 RJ45 SFTP 1:1 configuration

Bus (3) Patch cable CAT 5 RJ45 SFTP 1:1 configuration, boiler display

port

COM 2 (4) Null modem cable 9-pin SUB-D

COM 1 (5) Null modem cable 9-pin SUB-D

Service interface for installing new boiler software or port for the

visualisation software

STL (6)

Connection cable1) 2 x 0.75mm

2

EMERGENCY STOP (7)

Connection cable1) 2 x 0.75mm

2

❒

Warning! Do not connect the emergency off/emergency stop

switch to the power supply cable of the boiler. The switch

must be a N/C switch and it must be linked to the 24V safety

chain of the STL at this terminal.

Outside temperature sen‐

sor (8)

Connection cable1) 2 x 0.75mm2, shielded from 25m cable length

Door switch TCS (9)

Connection cable1) 2 x 0.75mm

2

Sensor (10 + 11)

Connection cable1) 2 x 0.75mm2, shielded from 25m cable length

Return sensor RTS (12)

Connection cable1) 2 x 0.75mm

2

Boiler sensor BS (13)

PWM / 0-10V pump 1 (14)

Induced draught (15)

Connection cable1) 5 x 1.5mm

2

Pump 1 on

core module (16)

Connection cable1) 3 x 1.5mm2, max. 1.5A / 280W / 230V

Mains (17)

Connection cable 1) 3 x 1.5 mm2; fused with 16A (provided by the

customer)

Heating circuit pump 0 (18)

Connection cable1) 3 x 1.5mm2, max. 3A / 600VA

1.YMM as per ÖVE-K41-5 or H05VV-F as per DIN VDE 0881-5

Wiring

❒ Run the cable of the flue gas temperature sensor, boiler sensor, induced draught,

STL, display and door switch to the controller

➥ Tuck any extra cable into the cable duct

❒

Connect the components according to the power connection diagram

➥ DThe flexible sheathed cable must be used for the wiring; this must be of the

correct size to comply with applicable regional standards and regulations!

Assembly

4

Power connection and wiring

Installation Instructions S3 Turbo | M1080813_en 55

Mains connection

❒ Connect power supply at ST 18 plug (1)

➥ The power supply line (mains connection) must be fitted with a max. C13A fuse

by the customer!

Connecting the door switch and display

❒ Connect the door switch

❒

Insert the door switch and display

Connect the flue gas temperature sensor

green-yellow

red+

blue-

Coremodule

❒ Connect the flue gas temperature sensor

4

Assembly

Power connection and wiring

56 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

Connecting the high-limit thermostat (STL) and boiler sensor

❒ Connect the STL and boiler sensor

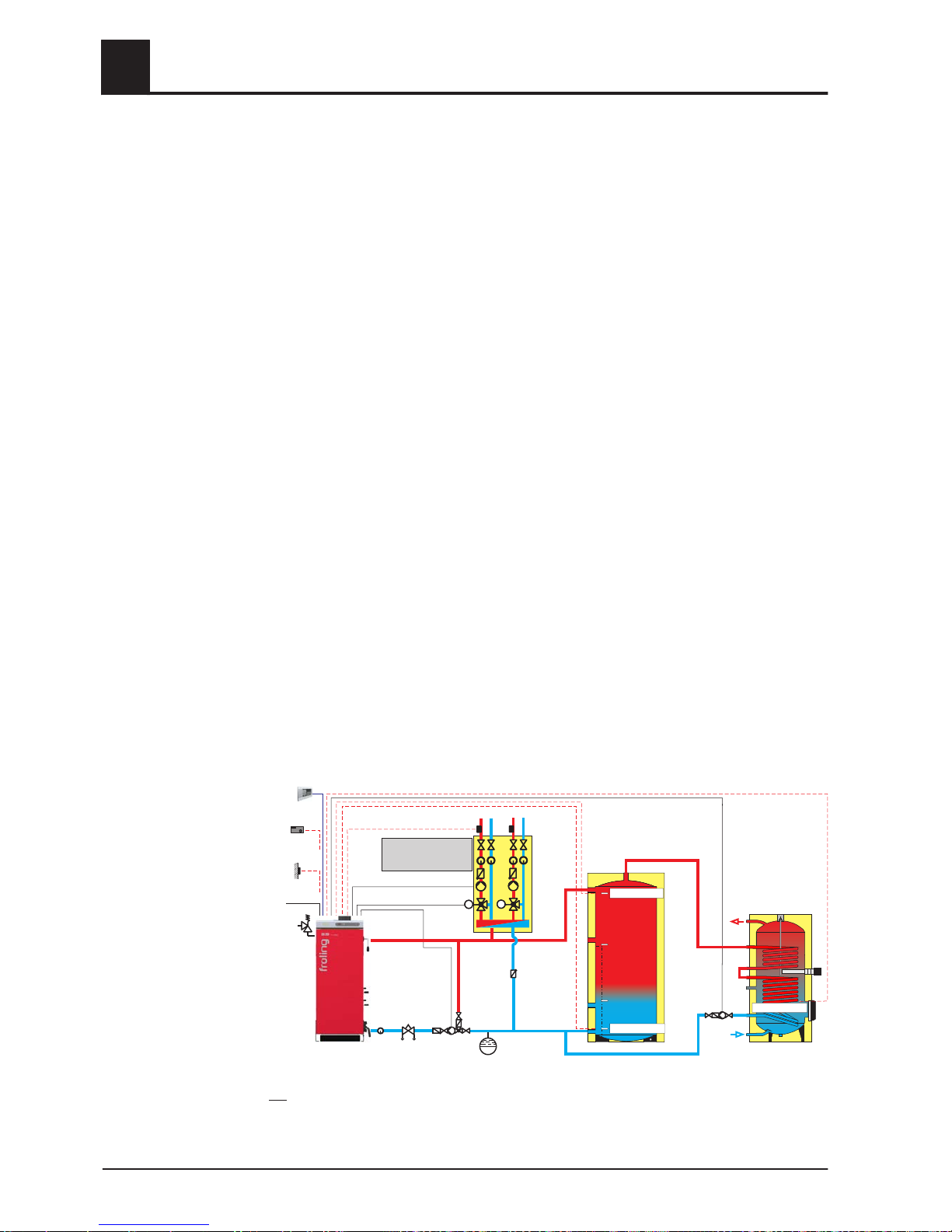

Hydraulic system

Possible, non-binding planning suggestion:

M

Log wood boiler

S3 T

urbo

Temp.sensor 1

Note:

Please install a mixing

valve to limit the outlet

temp. of the Hygienic

layered tank H2:

Connections are

represented schematically.

Sonde 2

Pump 1

Note: Controller S-Tronic

Weather-activated heating circuit control externally!

Balancing

valve

Hygienic layered tank H2

Mains supply

230V

External sensor

Flow temp. sensor 1/2

Heating

circuit 1/2

Mot. mixing

valve 1/2

Domestic

hot water

Cold

water

Temp.sensor 2

Assembly

4

Power connection and wiring

Installation Instructions S3 Turbo | M1080813_en 57

4.6.2 S-Tronic Plus / S-Tronic Lambda control

Power connection

❒ Run the cable of the flue gas temperature sensor, boiler sensor, induced draught,

STL, display and door switch to the controller and connect the wiring in accord‐

ance with the operating instructions of the boiler control

➥ Tuck any extra cable into the cable duct

❒ Run the cable of the broadband probe, servo-motors, flue gas temperature sensor,

boiler sensor, induced draught, STL, display and door switch to the controller and

connect the wiring in accordance with the operating instructions of the boiler con‐

trol

➥ Tuck any extra cable into the cable duct

❒

Connect the components according to the power connection diagram

➥ The flexible sheathed cable must be used for the wiring; this must be of the

correct size to comply with applicable regional standards and regulations!

Once the individual components have been wired:

❒ Wire the mains connection in the controller box

➥ The power supply line (mains connection) must be fitted with a max. C13A fuse

by the customer!

➥ Observe the circuit diagrams in the boiler controller operating instructions.

Hydraulic system

Possible, non-binding planning suggestion:

MM

MM

Room sensor

(Option)

External sensor

Mains supply

230V

Log wood boiler

S3 T

urbo

Pump assembly

FE

Pump 1

Flow temp. sensor 1/2

Heating circuit 1/2

Mot. mixing valve 1/2

Layered tank

Domestic

hot water

HKP 0

Cold

water

Pump assemblyOEDHW tank

Unicell NT

-S

Note: Controller S-Tronic Plus

Temp. sensor 0.1

Temp. sensor 0.2

Return sensor

With heating circuit modules

(Bus connection) up to

heating circuits are available

18

RBG 3200 /

RBG 3200 Touch

(Option)

Balancing

valve

NOTICE! It is not possible to combine the control of a return mixer with the control of a

boiler!

S-Tronic Plus:

S-Tronic Lambda:

4

Assembly

Power connection and wiring

58 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

4.6.3 Information on circulating pumps

NOTICE

According to 2012/622/EU external, wet running circulating pumps must comply

with the following limit values of the Energy Efficiency Index (EEI):

- Effective from 01/01/2013: Wet running circulating pumps with EEI ≤ 0.27

- Effective from 08/01/2015: Wet running circulating pumps with EEI ≤ 0.23

Only high efficiency pumps with a connection option for a control signal (PDM / 0-10V)

should be connected to speed-controlled pump outputs (pump 1 on the core module

and pump outputs on the hydraulic module). In this case, the control line is connected

to the corresponding PDM outputs of the boards. Observe the connection instructions

in the boiler controller documentation!

CAUTION

When using high efficiency pumps without an additional control line at speed-con‐

trolled pump outputs:

Malfunctions of the boiler, the pump and the hydraulic system may occur!

Therefore:

❒ Do not connect EC motor pumps without a control line to the speed-controlled

pump outputs of the boards.

➥ Only use special high efficiency pumps with a connection option for a con‐

trol line (PDM/0-10V)!

➥ Observe the additional instructions and information on board outputs in the

operation instructions for the boiler controller.

4.6.4 Concluding work

❒ Put the front heat insulation mat on

Assembly

4

Power connection and wiring

Installation Instructions S3 Turbo | M1080813_en 59

❒ Attach the covers to the controller cable ducts

❒ Put on the controller cover

❒

Secure the controller cover with 2 screws and contact washers

❒ Put on the back heat insulation mat

❒

Put on the rear insulating cover

4

Assembly

Power connection and wiring

60 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

4.7 Connecting the hydraulic safety devices

1.1

2

3

4

1.2

1.3

1.5

1.4

1 Thermal discharge valve

▪

The thermal discharge safety device must be connected in accordance with

ÖNORM/DIN EN 303-5 and as shown in the diagram above.

▪ The discharge safety device must be connected to a pressurised mains water

supply in such a way that it cannot be shut off

▪ A pressure reducing valve (1.5) is required for a cold water pressure of 6 bar

Minimum cold water pressure = 2 bar

1.1 Sensor of thermal discharge safety device

1.2 Thermal discharge valve (opens at approx. 95 °C)

1.3 Cleaning valve (T-piece)

1.4 Dirt trap

1.5 Pressure reducing valve

2 Safety valve

▪

Safety valve as per prEN 1268-1 with a diameter of DN15

▪ The safety valve must be installed in an accessible place on the heat generator or

in direct proximity in the flow pipe in such a way that it cannot be shut off

3 Return temperature control with pump

4 Diaphragm expansion tank

▪

The diaphragm pressurised expansion tank must conform to EN 13831 and hold

at least the maximum expansion volume of the system’s heated water including a

water seal

▪ Its size must comply with the design information in EN 12828 - Appendix D

▪ Ideally it should be installed in the return line. Follow the manufacturer’s installa‐

tion instructions

Assembly

4

Connecting the hydraulic safety devices

Installation Instructions S3 Turbo | M1080813_en 61

5 Start-up

5.1 Before commissioning / configuring the boiler

The boiler must be adjusted to the heating system during commissioning.

NOTICE

Optimum efficiency and efficient, low-emission operation can only be guaranteed

if the system is set up by trained professionals and the standard factory settings

are observed.

Take the following precautions:

❒

Initial startup should be carried out with an authorised installer or with Froling

customer services

❒

Adjust the boiler controller to the system type

❒ Apply boiler standard values

NOTICE! The keypad assignment and the steps necessary to modify the parameters

are detailed in the operating instructions for the boiler control unit.

❒ Check the system pressure of the heating system

❒ Check that the heating system is completely vented

❒ Check that the safety devices are present and working correctly

❒ Check that there is sufficient ventilation in the boiler room

❒ Check the seal of the boiler

➥ All doors and inspection openings must be tightly sealed!

❒ Check that drives and actuators are working and turning in the right direction

NOTICE! For how to check the analogue and digital outputs, see the operating instruc‐

tions for the boiler controller

❒ Check that the door contact switch is working correctly

NOTICE! For how to check the digital inputs see the operating instructions for the boil‐

er controller.

5

Start-up

Before commissioning / configuring the boiler

62 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

5.2 Initial startup

5.2.1 Permitted fuels

Firewood

Firewood up to max. 55 cm long.

Water content (w) greater than 15% (equivalent to wood moisture u > 17%)

Water content (w) less than 25% (equivalent to wood moisture u < 33%)

EU: Fuel acc. to EN 14961 - Part 5: Firewood class A2 / D15 L50

Germany

also:

Fuel class 4 (§3 of the First Federal Emissions Protection Ordinance

(BimSchV) in the last amended version)

▪ Values in practice:

- Hardwood: 2 years in dry storage

- Soft wood: 1 year in dry storage

▪

Store stacks of split wood sheltered from the rain

▪ Create a dry underlay, where possible with air access (line with round timber, pallets,

etc.)

▪ Use wind-exposed areas where possible for storage (e.g. store at edge of forest instead

of in forest)

▪ Walls of buildings facing the sun are ideal

▪ If possible, stock fuel for the day in a warm place (e.g. in boiler room) (pre-heats the

fuel!)

NOTICE! Use fuels that are consistent in size and water content.

NOTICE! Burning extremely dry fuels (w < 15%) may require repairs by qualified staff.

Please contact Froling customer services or your installer.

5.2.2 Fuels permitted under certain conditions

Wood briquettes

Wood briquettes for non-industrial use with a diameter of 5-10 cm and 5-50 cm long.

EU: Fuel acc. to 14961 - Part 3: Wood briquettes class B / D100 L500

Form 1 - 3

Additional for

Germany:

Fuel class 5a (§3 of the First Federal Emissions Protection Ordinance

(BimSchV) in the last amended version)

Water content

Note on standards

Tips for

storing wood

Note on standards

Start-up

5

Initial startup

Installation Instructions S3 Turbo | M1080813_en 63

▪ When burning wood briquettes use the settings for extremely dry fuel

▪

Wood briquettes must be heated up with firewood as per EN 14961-5

(at least two layers of firewood under the wood briquettes)

▪ The fuel loading chamber must not be filled more than 3/4 full, as the wood briquettes

expand during combustion

▪ Even when using the settings for dry fuel, burning wood briquettes can cause combus‐

tion problems. In such cases, repairs must be carried out by qualified staff. Please con‐

tact Froling customer services or your installer.

5.2.3 Non-permitted fuels

The use of fuels not defined in the "Permitted fuels" section, and particularly the burn‐

ing of refuse, is not permitted.

CAUTION

In case of use of non-permitted fuels:

Burning non-permitted fuels increases the cleaning requirements and leads to a

build-up of aggressive sedimentation and condensation, which can damage the

boiler and also invalidates the guarantee. Using non-standard fuels can also lead

to serious problems with combustion.

For this reason, when operating the boiler:

❒ Only use permitted fuels

5.2.4 Heating up for the first time

CAUTION

If the boiler heats up too quickly on initial start-up:

If the output during the heating-up process is too great, the combustion chamber

may be damaged as a result of drying out too rapidly!

For this reason the following applies the first time you heat up the boiler:

❒ Start the firewood boiler for the first time in accordance with the heating in‐

structions

Heating instructions when starting up a firewood boiler for the first time

❒ Place a piece of wood diagonally across the combustion chamber (see diagram on

left)

➥ Load the boiler with a small amount of firewood (max. 10-20% of the fuel load‐

ing chamber)

➥ Ignite it and allow it to burn slowly with the central pre-heating chamber door

open

NOTICE! Fissures are normal and do not indicate a malfunction

Notes on

use

5

Start-up

Initial startup

64 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at

Once the material in the boiler has burnt down, the boiler can be used in accordance

with the operating instructions ("Operating the system" section).

NOTICE

If condensation escapes during the initial heat-up phase, this does not indicate a

fault.

❒

Tip: If this occurs, clean up using a cleaning rag.

Boiler with Lambda control

❒ Open the insulated door and the fuel loading door

❒ Fill the fuel loading chamber for initial start-up and heat up

NOTICE! See boiler operating instructions

Boiler with manual controller

0%

100%

50%

+

-

❒ Set the manual controller for the air flap as shown in the table below

NOTICE! The information below only applies to split wood and not for round timber,

square timber etc.

Start-up

5

Initial startup

Installation Instructions S3 Turbo | M1080813_en 65

Soft wood Hardwood

Long split wood Short split wood Long split

wood

Short split wood

w > 20% w < 20% w > 20% w < 20% w > 20% w < 20% w > 20% w < 20%

PL

1

75-100%

PL

1

75-100%

PL

1

75-100%

PL

1

50%

PL

1

75-100%

PL

1

75-100%

PL

1

75%

PL

1

50%

SL

2

25-50%

SL

2

50-75%

SL

2

50-75%

SL

2

50-75%

SL

2

50%

SL

2

50-75%

SL

2

75-100%

SL

2

75-100%

1.PL = Primary air

2.

SL = Secondary air

If you use wood briquettes for initial start-up (only permitted under certain conditions!),

you can use roughly the same settings as for short split hardwood.

The table shows the setting values for the manual controller of the air flap, which en‐

sures a smooth start-up. The setting values for the manual controller may need to be

changed during emissions measurements. For this reason, these values should not be

used as standard values for operating the boiler!

The terms used, i.e. “long split wood” (edge length EL > 10 cm) and “short split wood”

(edge length EL < 10 cm), have been defined in these instructions by Froling; there is

no fuel standard or similar guidelines.

❒

Open the insulated door and the fuel loading door

❒ Fill the fuel loading chamber for initial start-up and heat up

NOTICE! See boiler operating instructions

Tip: Line the first 20 cm of the fuel loading chamber with short split wood (edge length

EL < 10 cm). This reduces the time taken for a bed of embers to form.

NOTICE! The smaller the wood is cut, the faster a bed of embers forms

Once the bed of embers has fully formed, the combustion air can be readjusted if nec‐

essary after measuring the O2 content:

5

Start-up

Initial startup

66 Froeling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.at