Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

Op e r a t i n g I ns t r u c t i o ns

P2 Pellet Boiler

with Lambdatronic P 3100 (from version 24.17)

Read and follow the operating instructions and safety information.

Subject to technical change.

Introduction

Page 2

B0190806

I

I

Dear Customer,

Congratulations on choosing a quality product from FRÖLING.

The FRÖLING P2 Pellet Boiler is a state-of-the-art design that conforms

to all currently applicable standards and testing guidelines.

Please read and observe the operating instructions and always keep

them available in close proximity to the boiler. They contain safety

information and all the operation and maintenance specifications needed

to operate the boiler safely, properly, and economically.

The instructions have been prepared to the best of our knowledge.

However if you find any errors please let us know.

Subject to technical change.

Contents

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 3

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

C

1 Product Overview 6

2 Safety 8

2.1 Safety Information 8

2.2 Permitted uses 9

2.2.1 Permitted fuel ................................................................................................... 9

2.2.2 Who can operate the boiler ................................................................................. 9

2.3 Design Information 10

2.3.1 Official approval and obligation to report ............................................................ 10

2.3.2 Requirements for heating water......................................................................... 10

2.3.3 Ventilating the Boiler Room ............................................................................... 10

2.3.4 Heating System Installation/ Standards .............................................................. 11

Return feed lift ............................................................................................... 11

2.3.5 Chimney connection / chimney system ............................................................... 12

Draught limiter ............................................................................................... 12

Boiler data for constructing the flue gas system .................................................. 12

2.4 Safety Devices 13

2.4.1 Devices for preventing the boiler from overheating .............................................. 14

Thermal discharge safety device ....................................................................... 14

Safety Temperature Limiter STL........................................................................ 14

Safety valve ................................................................................................... 14

2.5 Safety information for installation room 14

2.6 Other risks 15

2.7 Emergency procedure 16

2.7.1 System overheating ......................................................................................... 16

2.7.2 Smell of flue gas.............................................................................................. 16

2.7.3 Fire ................................................................................................................ 16

3 Operating the System 17

3.1 Initial startup 17

3.2 Filling/ refilling the store with fuel 17

3.3 Heating up the boiler 18

3.3.1 Switching on the system................................................................................... 18

3.3.2 Switching on the boiler ..................................................................................... 18

3.3.3 Controlling the boiler........................................................................................ 18

3.3.4 Switching off the boiler..................................................................................... 18

3.3.5 Switching off the System .................................................................................. 18

3.4 Emergency (Firewood) Operation 19

3.4.1 Modifying the boiler for emergency operation using firewood................................. 19

3.4.2 Filling the combustion chamber with firewood ..................................................... 20

3.4.3 Setting the controls.......................................................................................... 20

3.5 Modifying the boiler for normal operation 21

Contents

Page 4

B0190806

I

C

4 Lambdatronic P 3100 control system 22

4.1 Heating times table 23

4.2 Display values 24

4.2.1 Modes .............................................................................................................25

4.2.2 Operating statuses............................................................................................26

4.3 Changing parameters and values 27

4.4 Menus 27

4.4.1 Settings menu..................................................................................................28

Setting boiler temperature ................................................................................28

Set storage tank temperatures ..........................................................................28

Set DHW tank temperatures..............................................................................28

Setting heating times .......................................................................................29

Allocating heating times to heating circuits..........................................................29

Setting the runtime of the ash screw ..................................................................30

Setting the pellet filling time .............................................................................30

Setting boiler times ..........................................................................................30

4.4.2 Manual operation menu .....................................................................................30

5 Boiler maintenance 31

5.1 Inspection, cleaning, and maintenance 32

5.1.1 Inspection .......................................................................................................32

Checking the combustion chamber and pellet burner ............................................32

Checking the level of the ash.............................................................................32

Emptying the ash drawer (P2 ash drawer module) ...............................................33

Emptying the ashcan (P2 ash screw module).......................................................33

Cleaning the pellet burner .................................................................................34

Checking the thermal discharge safety device......................................................34

Checking the system pressure ...........................................................................35

5.1.2 Annual Check ...................................................................................................35

Checking the heat-exchanger and flue gas collection chamber ...............................35

Clean the flue gas sensors ................................................................................36

Checking the primary air pipes ..........................................................................36

Checking the gearing........................................................................................36

Cleaning the induced draught ventilator..............................................................36

Clean the smoke flue pipe .................................................................................37

Checking the draught controller flap and explosion flap ........................................37

Checking the combustion chamber door..............................................................37

Clean the bypass line (only for systems with suction unit).....................................37

5.2 Maintenance Agreement / Customer services 38

5.3 Replacement parts 38

6 Troubleshooting 39

6.1 General faults in power supply 39

6.1.1 System procedure following power failure ............................................................39

6.2 Excessive temperature 39

6.3 Faults with a fault message 40

6.3.1 Procedure for fault messages .............................................................................40

6.4 Error message list 41

Contents

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 5

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

C

7 Installers and service technicians 48

7.1 Connection layout of the boards 48

7.2 Connection instructions 50

7.2.1 Mains connection ............................................................................................. 50

7.2.2 Heating circuit pumps for floor or wall heating..................................................... 50

7.2.3 Jumper setting for solar control ......................................................................... 51

7.2.4 Flue gas sensor ............................................................................................... 51

7.2.5 Remote control................................................................................................ 51

7.2.6 RBG 3100 room console ................................................................................... 52

7.2.7 PC Visualisation ............................................................................................... 52

7.2.8 Heating circuit pump 0 / Oil - oil burner contact .................................................. 53

7.3 Connection layout of the pellet module 54

7.3.1 Pellet module with ash discharge ....................................................................... 54

7.3.2 Pellet module with suction system ..................................................................... 55

7.3.3 Overview of connected components ................................................................... 56

7.3.4 Connection instructions for Komfort pellet box..................................................... 57

7.3.5 Boiler Release ................................................................................................. 58

7.4 Initial startup 59

7.4.1 Turn on system ............................................................................................... 59

7.4.2 Changing operating level .................................................................................. 59

7.4.3 Setting system type ......................................................................................... 60

Boiler types and parameters ............................................................................. 60

System .......................................................................................................... 61

7.4.4 Checks before first heating up ........................................................................... 62

Heating system............................................................................................... 62

Drives ........................................................................................................... 63

Sensors ......................................................................................................... 63

Setting sensor “Level Max” ............................................................................... 64

7.4.5 Feeding fuel into the combustion chamber .......................................................... 64

7.4.6 Setting parameters .......................................................................................... 65

7.5 Lambdatronic P 3100 parameter list 66

7.5.1 Menu overview ................................................................................................ 66

7.5.2 Settings menu................................................................................................. 67

7.5.3 Error list menu ................................................................................................ 74

7.5.4 Manual operation menu .................................................................................... 75

7.5.5 Manual digi.menu OUT ..................................................................................... 75

7.5.6 Manual anal. menu OUT.................................................................................... 76

7.5.7 Manual digi.menu IN ........................................................................................ 76

8 Appendix 77

8.1 Guarantee conditions 77

8.2 Manufacturer address 77

8.3 Declaration of Conformity 78

9 Your Notes 79

Product Overview

Page 6

B0190806

I

1

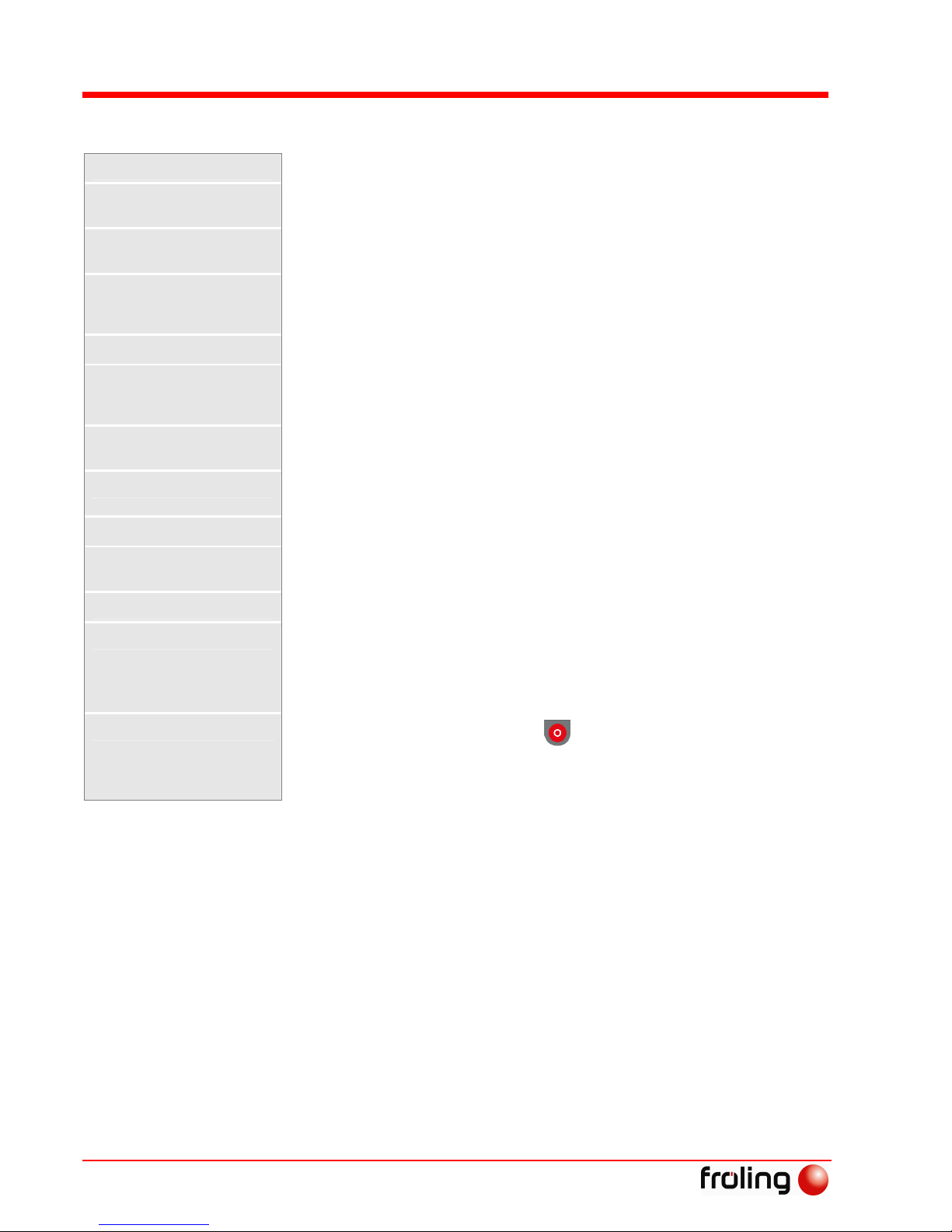

1 Product Overview

4

14

6, 7

15

16

13

18

17

19

20

21 22 23 24

25

26

5

3

2a

1

Key switch for

screw discharge

2b

8

9

10

11

12

Product Overview

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 7

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

1

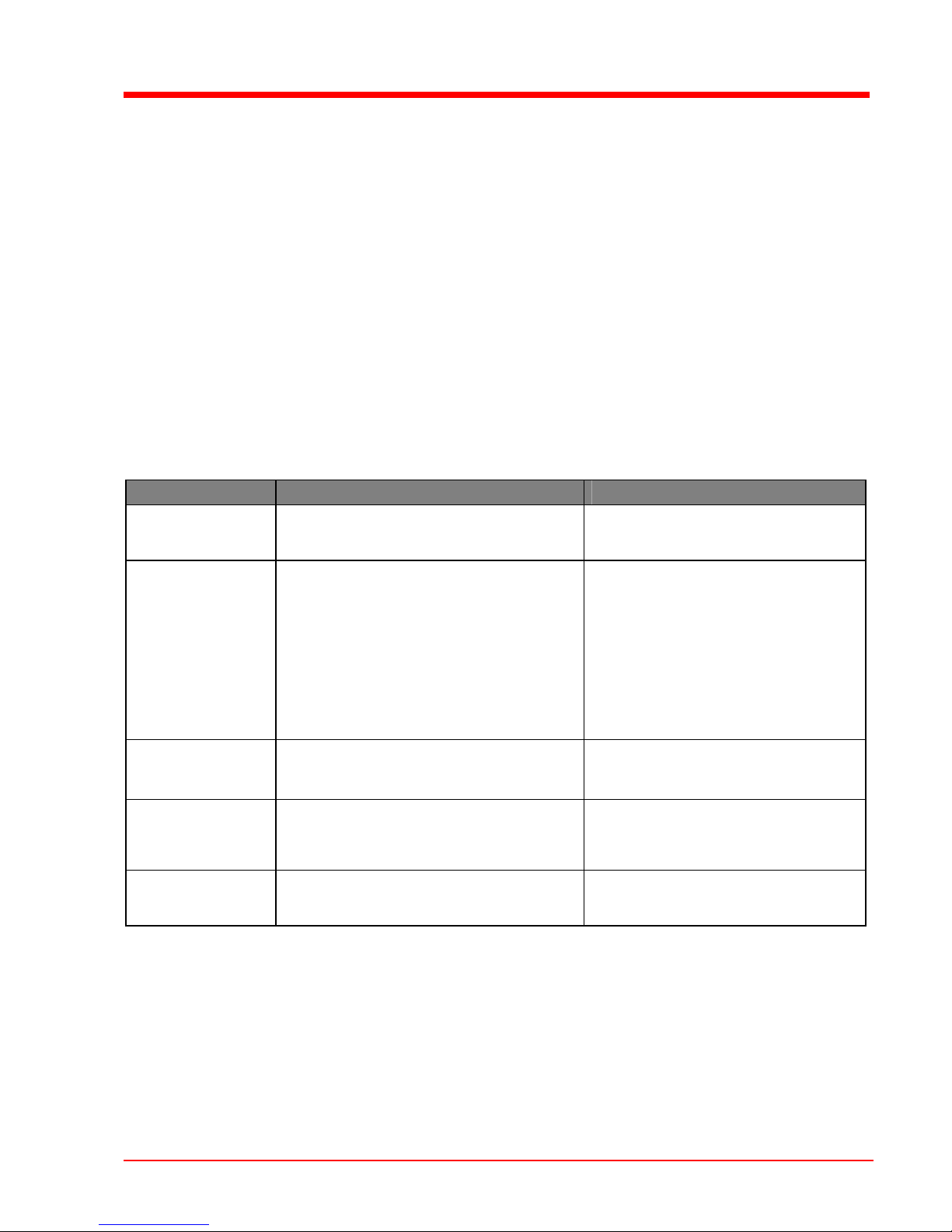

Pos. Component Symbol

1 P2 Pellet Boiler with heat-exchanger

2a Stoker assembly for screw discharge

2b Stoker assembly for suction unit discharge

3 Key switch to lock screw outputs of the pellet module (only for screw discharge)

4 Additional insulating door for reduced heat radiation

5 Combustion chamber door with viewing window

6 Ashcan with wheels and handle (ash screw module)

7 Ash drawer, front and rear (ash drawer module); no illustration

8 Heat-exchange system: Turbulator with automatic heat exchanger cleaning mechanism

9 Pellets lock with two chamber system as protection against blowback

10 Stoker screw for introducing fuel with drive motor

11 Ignition fan with automatic ignition

12 Upper part of gravity shaft to secure fuel for secure fuel delivery (only for direct screw discharge)

o.A. For suction systems: cyclone container with suction motor (attached directly at the pellet lock)

13 Main switch: switches the system on and off

14 HZG 0 / ÖL (Auto/Manual/Off)

15 HEATING 1-4 (Auto/Manual/Off)

16 PUMP 1-3 (Auto/Manual/Off)

17 BLOWER FAN (Auto/Manual/Off)

18 Lambdatronic P 3100 control system with two-row display for showing operating status

19 The corresponding LED illuminates when there is activity from positions 14-17

20 Status LED (Operating Status): - slow, green flashing light: Boiler activated

- fast green flashing light: Boiler deactivated

- red flashing light: Fault

21 Start key: Switch on boiler

22 Stop key: Switch off boiler

23 Back key: Return from a submenu or undo an entry

BACK

24 Up arrow key: Move the arrow up in the menu, increase or activate parameters

25 Down arrow key: Move the arrow down in the menu, decrease or deactivate parameters

26 Enter key: Go to submenus, call up or confirm entries

ENTER

Safety

Safety Information

Page 8

B0190806

I

2

2 Safety

2.1 Safety Information

Non-permitted use!

Incorrect use of the boiler can cause severe injuries and damage!

The instructions and information provided in the instructions

should be observed!

Details on procedure for operation, maintenance and cleaning, as

well as troubleshooting for the boiler are included in the

individual instructions. Any further work should be carried out by

authorised heating engineers or by Fröling customer services.

External influences!

Negative external influences, such as insufficient combustion air or

non-standard fuel can cause serious faults in combustion (e.g.

spontaneous combustion of carbonisation gases or flash fires) which

can in turn cause serious accidents!

Instructions and information for versions and minimum values, as

well as norms and guidelines for heating components in the

instructions must be observed!

Severe injuries and damage can be caused by an inadequate flue gas

system!

Problems with the flue system, such as poor cleaning of the flue pipe

or insufficient chimney draught can cause serious faults in

combustion (such as spontaneous combustion of carbonisation gases

or flash fires)!

You can only be guaranteed of optimum performance from the boiler if the

flue gas system is running smoothly!

Safety

Permitted Uses

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 9

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

2

2.2 Permitted uses

The boiler should only be operated when it is in full working order.

It should be operated in accordance with the instructions, observing

safety precautions, and you should ensure you are aware of the

potential hazards. Ensure that any faults, which might impact safety are

traced and removed immediately.

The P2 Pellet Boiler is intended exclusively for heating up

heating water. Use only the fuels specified in 2.2.1 below.

The manufacturer or supplier is not liable for any damages

resulting from non-permitted uses.

2.2.1 Permitted fuel

Wood pellets from natural wood with a diameter of 6mm

Applicable standards:

Austria: ÖNORM M 7135 - HP 1 and/or DINplus certification

program

Germany: DIN 51731 - HP 5, DINplus certification program and/or

ÖNORM M 7135 - HP 1

Applies generally:

Before refilling the store, check for pellet dust and clean if necessary.

Non-permitted fuels!

Burning non-permitted fuels lead to a build-up of aggressive

sedimentation and condensation, which can lead to damage to the

boiler and also voids the warranty!

2.2.2 Who can operate the boiler

Only trained operators are permitted to operate the boiler.

No unauthorized access to the boiler room.

Danger: Personal injury and damage to property.

It is the responsibility of the operator to ensure that unauthorized persons,

especially children, are kept away from the boiler.

§

Safety

Design Information

Page 10

B0190806

I

2

2.3 Design Information

It is generally forbidden to carry modifications to the boiler or to change

or deactivate safety equipment.

In addition to the operating instructions and the applicable regulations

for the country in which the boiler will be operated for installation and

operation of the boiler system, all fire, police, and electrical regulations

must be observed.

2.3.1 Official approval and obligation to report

Each heating system must be officially approved.

When installing or modifying a heating system, you must inform the

inspectors from the supervisory authority and get authorisation from the

building authorities.

Austria: Report to the construction authorities of the community or

magistrate

Germany: Report new installations to an approved chimney sweeper and to

the building authorities.

2.3.2 Requirements for heating water

The requirements for heating water are based on the following

standards:

Applicable standards:

Austria: ÖNORM H 5195-1

Germany: VDI 2035

If the system is topped up or refilled:

Prepare (soften) the water to prevent boiler scaling.

2.3.3 Ventilating the Boiler Room

The openings for the supply air and the exhaust air should be arranged

as nearly opposite each other as possible to achieve a good thermal

draught effect.

The supply air must be drawn in directly from outside. The exhaust

air must be discharged directly outside.

Provided they are not contradicted by the relevant building regulations

room where the boiler is to be installed, the following standards apply:

Applicable standards:

- TRVB H 118

- ÖNORM H 5170

§

§

Safety

Design Information

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 11

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

2

Rule of thumb:

Provide a supply air cross-section of 2 cm2 per kW of boiler rated output,

as per ÖNORM H 5170, but a total cross-section of at least 200 cm

2

2.3.4 Heating System Installation/ Standards

The following standards govern the installation of heating systems:

Applicable standards:

ÖNORM / DIN EN 12828 Heating Systems in Buildings

The following prior standards still apply:

Austria: - Closed systems as per ÖNORM B 8131

- open systems as per ÖNORM B 8130

Germany: - closed systems as per DIN 4751 Part 2

- open systems as per DIN 4751 Part 1

A storage tank with the proper dimensions will guarantee the best boiler

operating values during the entire heating period.

Return feed lift

If the heated water return feed is under the minimum return

temperature, a portion of the heated water outfeed will be mixed in.

Below dew point / condensation forms during operation without

return feed lift!

Condensation water and fuel residue combine to form an aggressive

condensate, leading to damage to the boiler!

Regulations demand the use of a return feed lift!

§

Safety

Design Information

Page 12

B0190806

I

2

2.3.5 Chimney connection / chimney system

The standard EN 303-5 specifies that the entire flue gas system must be

designed to prevent, wherever possible, damage caused by seepage,

insufficient feed pressure and condensation.

It should be noted here that flue gas temperatures of less than 160 K

above room temperature can occur within the permitted operating range

of the boiler.

The flue gas temperatures (when cleaned) and the additional flue gas

values can be found in the technical specification sheets.

Page 12, Boiler data for constructing the flue gas system

Install the connection to the chimney via the shortest path, as far as

possible under 30 – 45°. Insulate the connector.

The entire flue gas system (chimney and connection) must be worked

out as per ÖNORM / DIN EN 13384-1 or prior standards ÖNORM M

7515 / DIN 4705-1.

In addition, local and other legal regulations apply!

The chimney must be approved by a smoke trap sweeper or

chimney sweeper.

As per TRVB H 118 (only in Austria) an explosion flap must be

installed in the flue pipe or in the chimney.

Draught limiter

We recommend that you install a draught limiter 1

Install the draught limiter directly under the mouth of the flue line,

as there is always low pressure there.

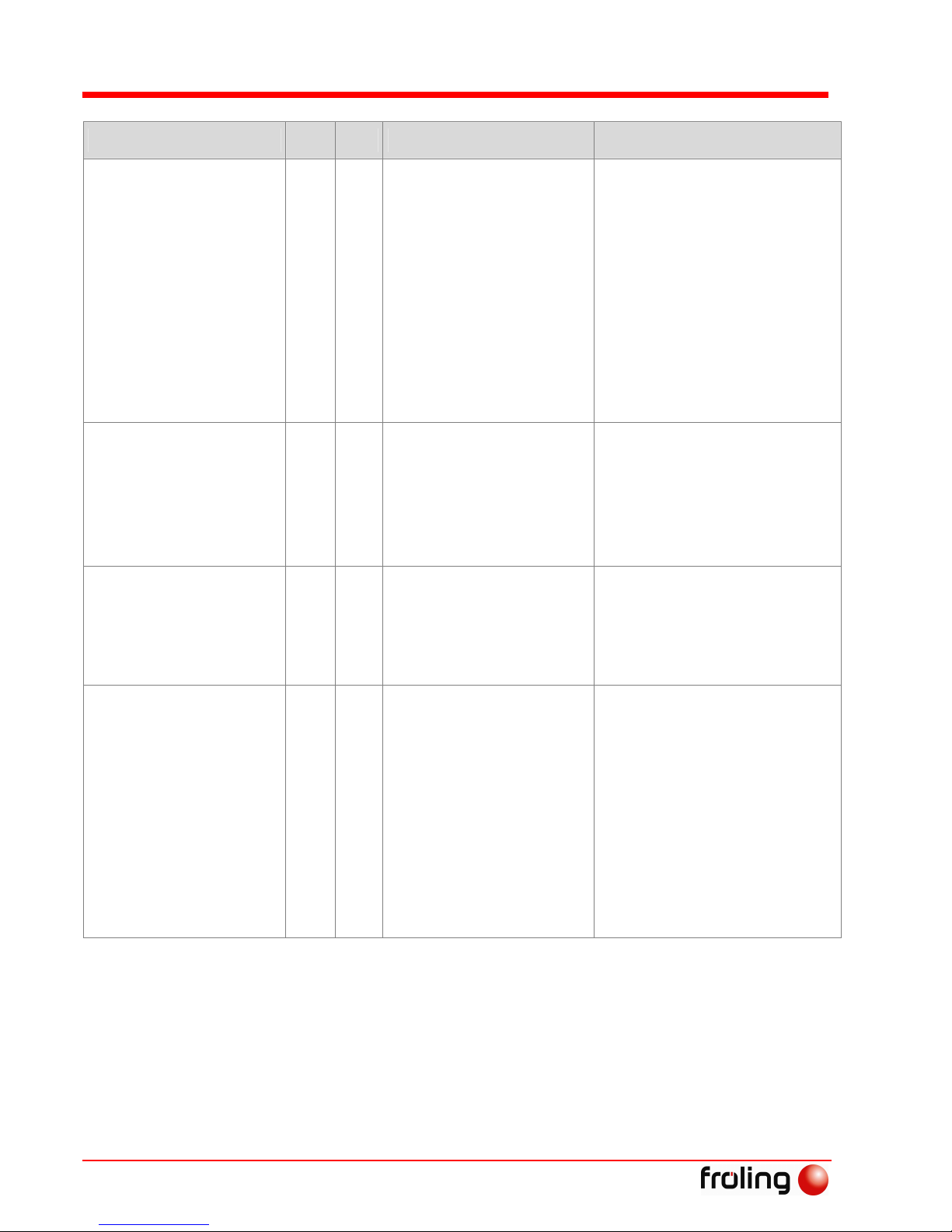

Boiler data for constructing the flue gas system

Component Unit P2-10 P2-15 P2-20 P2-25

Flue gas temperature NL °C 150 150 155 160

Flue gas mass flow NL

PL

kg/h

38

12

38

12

51

16

64

20

Flue gas mass flow NL

PL

kg/s

0.0106

0.0033

0.0106

0.0033

0.0142

0.0044

0.0178

0.0056

Feed pressure required NL

PL

Pa

7

4

7

4

7.5

4.5

8

5

Feed pressure required NL

PL

mbar

0.07

0.04

0.07

0.04

0.075

0.045

0.08

0.05

Flue pipe diameter mm 130 130 130 130

NL = Nominal Load, PL = Partial Load

1

Safety

Safety Devices

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 13

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

2

2.4 Safety Devices

1 STOP key

In case of overheating, shut down the

boiler

The pumps continue to run!

Always end heating with the

STOP key. Never use the main

switch.

2 Key switch (for screw

discharge)

Disengages power from the combustion

unit’s drive components.

CAUTION: The power is still on

in the pellet module!

3 Main switch

For shutting down the entire system

The power to all components is

switched off.

CAUTION: The power is still on

in the pellet module!

4 Safety temperature limiter

(STL)

Page 14, Devices for preventing the

boiler from overheating

5 Fuse Fuse the controls and electrical

components

When changing fuses, fit fuses with

the rated current specified.

2

4

1

3 5

Safety

Safety Devices

Page 14

B0190806

I

2

2.4.1 Devices for preventing the boiler from overheating

Thermal discharge safety device

At around 100 °C a valve opens and sends cold water to the safety

heat-exchanger to decrease the temperature.

Safety Temperature Limiter STL

Stops combustion at a max. boiler temperature of 100 °C. The pumps

continue to run!

As soon as the temperature has gone back down, the STL (1) can

be mechanically unlocked.

Safety valve

Protection against over-heating/ excessive pressure:

When the boiler pressure reaches a maximum of 3 bar, the safety valve

opens and the heating water is released in the form of steam.

2.5 Safety information for installation room

1) Danger of fire due to flammable materials!

No flammable materials should be stored near the boiler.

2) Damage due to impurities in combustion air!

Do not use any hydrogen halides or any cleaning agents containing

chlorine in the room where the boiler is installed.

3) Keep the air suction opening of the boiler free of dust.

4) The room where the boiler is installed must be frost-proof.

1 1

Safety

Other risks

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 15

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

2

2.6 Other risks

Do not touch the hot surface!

Hot parts and the flue pipe can cause serious burns!

Protective gloves should generally be worn when working on

the boiler.

Only operate the boiler using the handles provided for this

purpose.

Insulate the flue pipes or simply avoid touching them during

operation.

Before carrying out work in the boiler:

Turn off the boiler with the key and allow it to cool down

Then switch off the main switch.

Never turn off the boiler directly with the main

switch!

Do not open the combustion chamber door during operation!

This may cause injury, damage and smoke!

It is forbidden to open the doors behind the insulating door

during operation!

Do not use unauthorised fuel!

Non-standard fuels can cause serious faults in combustion (e.g.

spontaneous combustion of carbonisation gases / flash fires) which

can lead to serious accidents!

Only use fuels specified in the chapter on “Permitted Uses” in

these instructions.

Safety

Emergency procedure

Page 16

B0190806

I

2

2.7 Emergency procedure

2.7.1 System overheating

If the system overheats and the safety devices fail to operate, proceed

as follows:

Keep all the doors on the boiler closed.

Turn off the boiler with the key

Under no circumstances use the main switch!

Open all mixer taps, switch on all pumps.

Fröling heating circuit control takes over this function in

automatic operation.

Leave the boiler room and close the door.

Open any available radiator thermostat valves

If the temperature does not drop, inform the installer or Fröling

customer services:

Page 77, 8.2 Manufacturer address

2.7.2 Smell of flue gas

Smell of flue gas!

Flue gases can cause fatal poisoning!

Keep all the doors on the boiler closed.

Turn off the boiler with the key

Under no circumstances use the main switch!

Air the room where the boiler is installed

Close the fire protection door and doors to living areas.

2.7.3 Fire

Fire!

In case of fire, there is risk of burns and explosions!

Turn off the boiler

Use a tested fire extinguisher for fire class AB to fight the fire

AB powder

Operating the System

Initial startup

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 17

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

3

3 Operating the System

3.1 Initial startup

Initial startup should be carried out with an authorised installer or with Fröling

customer services.

The individual steps of the initial setup procedure are explained in the

chapter on “Installers and service technicians”

Page 59, 7.4 Initial startup

If condensation escapes during the initial heatup phase, this does not

indicate a fault.

If this occurs, clean up using a cleaning rag.

3.2 Filling/ refilling the store with fuel

Damage and injuries can occur if the store is filled when the boiler is

on!

Turn off the boiler with the key

Allow the boiler to cool down for at least half an hour.

When the boiler has cooled down:

Close all opening to the store to seal out dust

Fill the store with pellets

Only use permitted pellets

Page 9, 2.2.1 Permitted fuel

Operating the system

Heating up the boiler

Page 18

B0190806

s

3

3.3 Heating up the boiler

3.3.1 Switching on the system

Switch on the main switch on the controls

After the system check by the controls, the system is ready for

operation

3.3.2 Switching on the boiler

All selector switches must be set to “Auto”.

Press the key

The heating system is controlled via the control system according

to the selected mode.

3.3.3 Controlling the boiler

See chapter 4 - Lambdatronic P 3100 control system

3.3.4 Switching off the boiler

Press the key

The boiler follows the shut-down program and switches to

“Burner OFF” status.

The control system then only controls the connected heating

components

3.3.5 Switching off the System

ATTENTION! Only switch off when the boiler has cooled

down.

Switch off the main switch on the controls

The controls are switched off

The system components are powered down.

Caution: The power is still on in the pellet module!

Operating the system

Heating up the boiler

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 19

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

3

3.4 Emergency (Firewood) Operation

The P2 Pellet Boiler allows for emergency manual operation using

firewood.

This requires the “insert set for emergency firewood operation.”

consisting of:

- 1 x insertion grate (1)

- 1 x cover plate (2)

- 4 x combustion chamber

guards (3)

A properly functioning thermal discharge safety device is obligatory!

3.4.1 Modifying the boiler for emergency operation using firewood

Do not carry out modifications when the boiler is hot!

Hot parts and the flue pipe can cause serious burns!

Protective gloves should generally be worn when working on

the boiler.

Only operate the boiler using the handles provided for this

purpose.

Insulate the flue pipes or simply avoid touching them during

operation.

Before carrying out work in the boiler:

Turn off the boiler with the key and allow it to cool down

Then switch off the main switch.

Never turn off the boiler directly with the main

switch!

When the boiler has cooled down:

Remove the combustion set from the

pellet burner

Remove the upper guide plate with

the fuse receptacle

Remove the middle guide plate

1.

1

2

3

Operating the system

Heating up the boiler

Page 20

B0190806

s

3

Exchange the guide plate and replace

as shown

Put the steel cover onto the guide

plate

The combustion gases path over

the guide plates is blocked.

2.

Hang 2 chamber guards each on the

left and right in the combustion

chamber on the bolts provided

3.

Insert the grate

It sits on the angled edges of the

combustion chamber guards.

4.

3.4.2 Filling the combustion chamber with firewood

Place a layer of firewood broken into small pieces on the grate

Place paper, cardboard or similar on top

Fill the rest of the space with firewood

3.4.3 Setting the controls

For emergency firewood operation, the mode must be set to “Firewood

operation” on the controls:

Press the key

ENTER

The arrow on the display

points to “Set”

Press the key

ENTER

Press the key until the arrow

points to mode

For example, winter

operation.

Mode

Winter operation

Set

Error display

Operating the system

Heating up the boiler

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 21

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

3

Press the

ENTER

key

A question mark appears

The value can be changed

Press the key until firewood

operation is shown on the display

Press the

ENTER

key

An arrow appears

Firewood operation has been

set

Press the

BACK

key 3x

The operating status is

displayed

Press the key

Firewood operation is

activated

Light the paper

3.5 Modifying the boiler for normal operation

Naturally, the procedure to modify the boiler for normal operation is

carried out in the opposite order to the modifications for emergency

operation

Before starting up the automatic pellet burner, check and clean the

boiler. The main points to check are the combustion bowl, the induced

draught fan and the heat exchanger equipment!

Page 35, 5.1.2 Annual Check

Firewood operation

Burner OFF

Mode

Firewood operation

Mode

Winter operation ?

Lambdatronic P 3100 control system

Menu overview

Page 22

B0190806

s

4

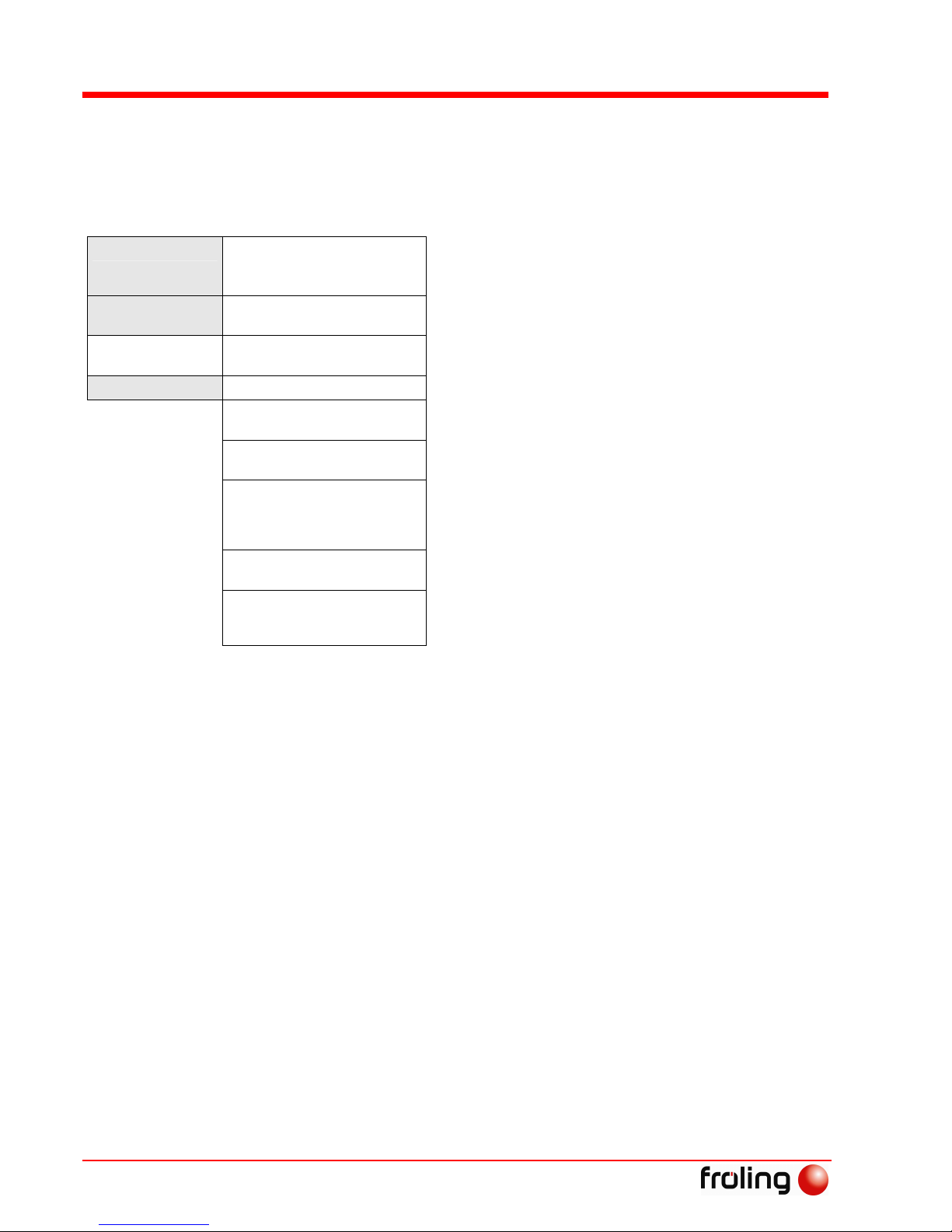

4 Lambdatronic P 3100 control system

Winter Operation

Heating

Boiler temp.

Flue gas temp.

ID Fan

Residual O2

Storage.up.

Storage.mi.

Storage.low

DHW tank temp.

Coll. temp.

Oil boiler

Ext. temp.

Flow temp.

Day

Time

Version

Runtime

User name

customer

Set

Error display

Error list

Manual operation

Man. Digi. OUT

Man. Digi. IN

Man. Anal. OUT

System selection

Ash screw Heat

exchanger filling

Boiler type…

System …

Code:

Service

Installer

Customer

Diagram - heating curve

External temperature

Flow temperature

Example of floor heating

Example of radiators

NOTE:

Number and display of parameters depend

on the system selected!

Areas with a grey background are visible

to the customer!

Boiler temp.

Storage tank

DHW tank

Solar

Heating times

Heating circuit 1

Heating circuit 2

Heating circuit 3

Heating circuit 4

Air parameters

Pellets feed

Outfeeder

Boiler times

(transitional operation)

Mode:

Winter operation

RBG 3100

alloc.: 11

Set day

Set time

Clear error

list

Set boiler temperature

Store temp. Heating circuit release

Store up. min. temp.

Set DHW tank temp.

Recharge when HWT below

Start 1. load

End 1. load

Start 2. load

End 2. load

Setup Sol Register

DHW tank target for solar loading

Heating prog. 1

Heating prog. 2

Heating prog. 14

Weekly prog.

Heating curve

Room temp. set value

Chamber control factor

Flow temp. Reduction

Ex.temp.heatlim. reduced amount

Flow temperature max. value

Mixer type

Frost prot.temp. (inside)

Room temp. set value Drawdown mode

Fan MAX

Slide-in MAX

1. Start time for autom. fillung

2. Start time for autom. fillung

Start 1. heating period

End 1. heating period

Start 2. heating period

End 2. heating period

Winter operation

Summer operation

Transitional operation

Firewood operation

Cleaning

Start 1. heating period

End 1. heating period

Start 2. heating period

End 2. heating period

Mo Tu We Th Fr Sa Su

1 1 1 1 4 9 3

Flow temp. At external -10 °C

Flow temp. At external +10 °C

same as heating

circuit 1

same as heating

prog. 1

1

Lambdatronic P 3100 control system

Display messages

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 23

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

4

4.1 Heating times table

Heating phase 1 Heating phase 2

Heating phase 1 Heating phase

2

Start End Start End Start End Start End

Heating

prog. 1

Heating

prog. 8

Heating

prog. 2

Heating

prog. 9

Heating

prog. 3

Heating

prog. 10

Heating

prog. 4

Heating

prog. 11

Heating

prog. 5

Heating

prog. 12

Heating

prog. 6

Heating

prog. 13

Heating

prog. 7

Heating

prog. 14

You can make a note of your weekly program settings for the individual heating circuits here:

For each day of the week, one of the 14 heating programs can be selected for each heating circuit.

Weekly program Monday Tuesday Wednesday Thursday Friday Saturday Sunday

Heating circuit 1

Heating circuit 2

Heating circuit 3

Heating circuit 4

Notes:

Lambdatronic P 3100 control system

Display messages

Page 24

B0190806

s

4

4.2 Display values

After the main switch has been switched on and the control system has

carried out the system check, the display shows the standard readout

with the mode and operating status.

Winter operation

Burner Off

See 4.2.1 Modes or 4.2.2 Operating statuses

You can use the arrow keys to scroll through the current display values:

Winter operation

Burner Off

Boiler temp. 75°

Flue gas temp. 156°

Flue gas tgt. value 158°

Boiler load 86%

ID Fan 38%

Supply air fan 71%

Slide-in unit 80%

Residual O2 9,0%

O2 regulator 78%

Fill level 73%

Top storage t. 60°

Mid. storage t. 58°

Bot. storage t. 55°

External temp. 8°

Day: Mo 16.10.06

Time: 14:20:36

Version: 24.17

Runtime: 118h

Board temp. 24°

Set boiler

temperature 80°

Choose language

ENGLISH

User

Name CUSTOMER

Mode

Operating status

The parameters, which

are actually displayed,

depend on the boiler

configuration and

operating level.

Lambdatronic P 3100 control system

Display messages

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 25

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

4

4.2.1 Modes

Winter operation The boiler controls the heating and hot water heating according to the timed

program settings. There is no reduction in temperature the boiler stays at

the same temperature and maintains a constant burn.

Summer operation

Systems without storage

The boiler only controls the hot water heating according to the timed program

settings. There is no reduction in performance the boiler switches to “Burner

Off”.

Summer operation

Systems with stores

The boiler regulates domestic hot water (DHW) heating according to the DHW

tank loading times, which have been set. After heating the domestic hot water,

the boiler switches to “Burner Off”.

Transitional operation

Systems without storage

The boiler produces heat during the specified heating phases (“Boiler times”

menu). Heating and hot water are regulated according to the specified times

(heating times, DHW tank loading times). There is no reduction in temperature

the boiler stays at the same temperature and maintains a constant burn.

When the heating phase ends, the boiler switches to “Burner Off”.

Transitional operation

Systems with stores

If the temperature falls below the “Store up min. temp.”, the boiler is turned on

within the specified store loading times. If the store is fully loaded, the boiler

switches to “Burner Off”. When the parameter “End of 1st or 2nd store loading”

is reached, the boiler also switches to “Burner Off”, even if the store is not fully

loaded.

NOTE: Set a sufficiently large time window (00:00 to 24:00 means that as soon

as the value falls below the parameter “Storage up min” the store is

immediately fully loaded)

NOTE: This is an ideal operating method for systems with storage tanks

Extra heating

Press and hold the key for 5 seconds:

The controls are set to “Override”: the boiler switches on for 4 hours; hot water

heating and heating circuit regulation are active.

Firewood operation This mode is for emergency firewood operation. The pellet feeding system is

deactivated.

Cleaning The boiler turns off the combustion system as directed (“Burner Off” status)

Then the ID fan, combustion air fan, heat-exchanger system and ash screw are

controlled according to the program.

After the cleaning has finished, reset to original mode.

Chimney sweeper

Press and hold the key and the

BACK

key for 5 seconds

The chimney sweeper program for boiler measurement is started.

The system is operated for 30 minutes at nominal load. For this aim the

maximum boiler temperature, the maximum heating circuit flow temperature

and the DHW tank loading are released.

Switched off

Press the key

The boiler turns off following the shutdown routine. The system now only

regulates the connected heating components

For systems with a storage tank, always select transitional operation!

Lambdatronic P 3100 control system

Display messages

Page 26

B0190806

s

4

4.2.2 Operating statuses

Preparation The induced draught fan is switched on.

Heating up The combustion bowl is filled with pellets. The supply air fan, the induced

draught fan and the igniter are turned on.

Pre-heating The pellets are pre-warmed with the fan-assisted ignition and a bed of embers

is formed. No fuel slide-in unit.

Ignition The pellets are ignited with the fan-assisted ignition. The flame is spread across

the whole combustion bowl. The supply air fan, the ID fan, and the slide-in unit

can be set in the “Ignition” menu.

Heating The Lambdatronic controls combustion according to the target boiler values.

Constant burn The boiler has reached the specified temperature and there is no reduction in

temperature. The supply air fan, the ID fan, and the slide-in unit are

deactivated.

STBY. Wait 1 The supply air fan and perhaps the ID fan are running too slowly (“Fan during

shut down”) to burn the remaining pellets. No slide-in.

STBY. Feed 1 Safety slide-in after the first wait time. As with status “STBY. Wait 1”, but

with slide-in, in accordance with the parameter, “Feed off”.

STBY. Wait 2 The supply air blower fan and the induced draught are switched off, no slide-in.

STBY. Feed 2 Safety slide-in after the second wait time. As with status “STBY. Wait 2”, but

with slide-in, in accordance with the parameter, “Feed off”.

Fault ATTENTION - Fault!

Error correction 20 min When the faults “Ignition failed”, “Safety time elapsed too low”, “Safety time

O2 too high” and “Pressure monitor comb chamb” are acknowledged, error

correction starts. When error correction has been carried out (approx. 20 min)

the warning, “Clean/ check burner”, is shown on the display. The warning can

only be acknowledged with the enter key after checking the burner.

Burner Off

This status is reached by pressing the key when store or DHW tank loading

has finished, or after acknowledging an error message, which requires a

shutdown. All parts of the boiler stop. The system now only regulates the

connected heating components.

Lambdatronic P 3100 control system

Menus and parameters

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 27

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

4

4.3 Changing parameters and values

Values are changed as follows:

Save value and go back

ENTER

Unlock parameter for processing Larger

ENTER

Smaller

BACK

Back without saving

4.4 Menus

At the client level the following menus are available

SET ... Boiler temp. ... Page 28, Setting boiler temperature

Storage tank ... Page 28, Set storage tank temperatures

DHW tank ... Page 28, Set DHW tank temperatures

Heating times ... Page 29, Setting heating times

Heating circuit 1 ...

Heating circuit 2 ...

Heating circuit 3 ...

Heating circuit 4 ...

Page 29, Allocating heating times to heating

circuits

Pellets feed ... Page 30, Setting the runtime of the ash screw

Outfeeder ... Page 30, Setting the pellet filling time

Boiler times ... Page 30, Setting boiler times

Boiler temp.

should be 70°?

Boiler temp.

should be 70°

Lambdatronic P 3100 control system

Menus and parameters

Page 28

B0190806

s

4

4.4.1 Settings menu

In the “Settings” operating menu the most important parameters and

values for the system can be changed:

Setting boiler temperature

Boiler temp. ... Boiler temp. should be 80°C The boiler temperature is regulated to this

temperature

Set storage tank temperatures

Storage tank ... Storage temp. heat

circ. launch 30°C

Only for systems with storage tanks

Minimum temperature for releasing the

heating circuit. (Sensor 1)

Store up. min. temp. 60°C Upper store temperature, below which the

boiler is started in transitional operation.

Set DHW tank temperatures

DHW tank ... Set DHW temp 55°C When the specified temperature is reached

in the DHW tank, the DHW tank loading

pump switches off.

Desired DHW tank 2

temperature 60°C

When the specified temperature is reached

in DHW tank 2, DHW tank loading pump 2

switches off.

Reload when the DHW

tank is below 45°C

Reloading of the DHW tank is authorised

when the DHW tank temperature is below

this level.

Reload when the DHW

tank is below 45°C

Reloading of the second DHW boiler is

authorised when the DHW boiler

temperature is below this level.

Start of 1st loading 05:00 Start of authorisation for 1st DHW tank

loading session

End of 1st loading 08:00 End of authorisation for 1st DHW tank

loading session

Start of 2nd loading 15:00 Start of authorisation for 2nd DHW tank

loading session

End of 2nd loading 18:00 End of authorisation for 2nd DHW tank

loading session

Only heat once a day N “Y” prevents heating up several times in

one day

Legionella heating 65° Y The DHW tank is heated to at least 65°C

once a week

Legionella heating day Mo Day of the week for Legionella heating.

Lambdatronic P 3100 control system

Menus and parameters

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 29

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

4

Setting heating times

Heating times ... Heating prog. 1 ... Heating phase 1 start 06:00

Heating phase 1 end 11:00

Heating phase 2 start 15:00

Heating phase 2 end 23:00

Lowered outside the

specified heating times.

Heating prog. 2

:

:

:

Heating prog. 14...

2 heating phases each, like heating prog. 1.

You can program up to 14 heating times each with two

heating phases.

These heating times can be allocated to the individual

days of the week under the parameter “Weekly program”

for the heating circuits 1-4.

Allocating heating times to heating circuits

Heating circuit 1 ... Weekly program

Mo Tu We Th Fr Sa Su

1 1 3 1 1 2 5

Allocating heating times 1- 14 to

the individual days of the week

for heating circuit 1

Heating curve ... Flow temp. at

external -10°C 60°C

Flow temp. at

external +10°C 40°C

These two parameters are the

work points for adjusting the

heating curve to the relevant

system

Room temp.

set value 21°C

Desired room temperature

during heating (only with

remote control).

Room temp. set

value Drawdown

mode 16°C

Desired room temperature

during drawdown mode (only

with remote control).

Ex.temp.

heating limit 18°C

If the external temperature

exceeds this value during the

heating phase, the heating

circuit pump and mixer are

switched off.

Outside temp

Heating limit

Drawdown

mode 7°C

If the external temperature

exceeds this value during

drawdown mode, the heating

circuit pump and mixer are

switched off.

Heating circuit 2 ...

Heating circuit 3 ...

Heating circuit 4 ...

Settings as with heating circuit 1

Flow temperature

External temperature

Example of floor

heating

Example of

radiators

Lambdatronic P 3100 control system

Menus and parameters

Page 30

B0190806

s

4

Setting the runtime of the ash screw

Pellet feed unit ... Ash screw Runtime 5s Runtime of the ash screw

Setting the pellet filling time

Outfeeder ... Start time for 1st filling 15:00 1. Start time for filling.

This is only carried out if the fill level in the

container is under 85%.

Start time for 2nd filling 15:00 2. Start time for filling.

This is also only carried out if the fill level in

the container is under 85%.

Setting boiler times

Boiler times ... Start 1. Storage tank load 05:00

End 1. Storage tank load 10:00

Start 2. Storage tank load 17:00

End 2. Storage tank load 22:00

For systems with storage tank in

transitional operation!

Within this time window the boiler is

activated if the upper storage

temperature falls below the minimum

temperature.

Start 1. heating period 05:00

End 1. heating period 08:00

Start 2. heating period 17:00

End 2. heating period 21:00

For systems without storage tank in

transitional operation!

The boiler is activated within this time

window.

Important! DHW tank loading times

must be within the time window of the

boiler times.

Start EOS 1 08:00 1. Start time for heat exchanger cleaning

The boiler must have been in operation for

at least 2 hours since the last cleaning

Start EOS 2 15:00 2. Start time for heat exchanger cleaning

The boiler must have been in operation for

at least 2 hours since the last cleaning

4.4.2 Manual operation menu

Manual operation is used operate the relevant unit by hand:

ASH SCREW OFF For switching the ash screw on and off manually

EOS OFF For switching the heat exchanger on and off manually

FILLING OFF After activating the parameter, the container is filled with fuel, regardless of fill

level, until the function is turned off or the switch point of the level sensors is

reached. When the level sensor reaches its limit value, the fill level value is set

to 100%.

Important! Parameter only for discharge systems with suction unit

Boiler maintenance

Inspection, cleaning and maintenance

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 31

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

5

5 Boiler maintenance

Working on electrical components.

Serious injuries from electric shocks!

Work on electrical components should only be carried out by authorised

technicians!

Do not carry out maintenance when the boiler is hot!

Hot parts and the flue pipe can cause serious burns!

Protective gloves should generally be worn when working on

the boiler.

Only operate the boiler using the handles provided for this

purpose.

Insulate the flue pipes or simply avoid touching them during

operation.

Before starting any maintenance work:

Turn off the boiler with the key and allow it to cool down

or

set the boiler to “Cleaning” mode

The boiler shuts down as directed and controls the ID fan,

combustion air fan, heat exchanger system and ash screw

according to the program.

Important! After maintenance work, reset the controls to

the original mode

Non-permitted cleaning and maintenance!

Incorrect or insufficient cleaning and maintenance of the boiler can

cause serious faults in combustion (e.g. spontaneous combustion of

carbonisation gases / flash fires) and this can lead to serious

accidents!

Clean the boiler according to the instructions in the instruction

manual!

Boiler maintenance

Inspection, cleaning and maintenance

Page 32

B0190806

s

5

5.1 Inspection, cleaning, and maintenance

Regular cleaning of the boiler extends its life and is a basic

requirement for smooth running.

So clean the boiler regularly!

5.1.1 Inspection

Checking the combustion chamber and pellet burner

Check the boiler regularly for dirt:

Shut down the boiler using the

key and allow it to cool down

Open the insulating door and

combustion chamber door

Cleaning the combustion chamber

and pellet burner

Page 34, Cleaning the pellet burner

Checking the level of the ash

The amount of ash depends on the boiler’s output!

P2 ash drawer module:

Open insulation door

Loosen the star-shaped screw knob

on the front ash drawer by turning it

to the left

Pull out the ash drawer and check the

level

Empty the ash drawer if necessary

Page 33, Emptying the ash

drawer (P2 ash drawer module)

P2 ash screw module:

Open insulation door

Open the clamps on the left and right

Remove the lid and check the ash

level

Empty the ash container if necessary

Page 33, Emptying the ashcan

(P2 ash screw module)

Boiler maintenance

Inspection, cleaning and maintenance

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 33

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

5

Emptying the ash drawer (P2 ash drawer module)

Loosen the star-shaped screw knob on the front ash drawer by

turning it to the left

Pull out the front ash drawer

Insert the ash drawer hook (provided) at the rear cross handle of the

ash drawer

Take the ash drawer to the emptying location

Only dispose of the ash if there are no hot embers left and the

ash has cooled.

Insert the furnace tool at the handle of the rear ash drawer

Pull the ash drawer forward

Insert the ash drawer hook at the rear cross handle like before and

take the ash drawer to the emptying location

Emptying the ashcan (P2 ash screw module)

Open insulation door

Remove the ash container from the bottom end of the ash screw

channel and take it to the emptying location

Only dispose of the ash if there are no hot embers left and the

ash has cooled.

Open the clamps, remove the lid and empty the ash container

Before positioning the ash container at the ash screw channel, the

flap must be opened!

Boiler maintenance

Inspection, cleaning and maintenance

Page 34

B0190806

s

5

Cleaning the pellet burner

Open the insulating door and

combustion chamber door

Remove the combustion mount

Tip the combustion mount

The ash falls past the pellet

burner and into the ashcan

Clean the pellet burner using the ash

scraper

The slit must be free of ash!

Checking the thermal discharge safety device

Check the seal of the discharge valve

The discharge pipe must not drip

Exception: boiler temperature > 95 °C

If water is dripping from the discharge pipe:

Clean the discharge safety device or have

the installer replace it if necessary

Check the safety valve as per the

manufacturer’s specifications

Boiler maintenance

Inspection, cleaning and maintenance

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 35

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

5

Checking the system pressure

Read off the system pressure on the

pressure gauge

The value must be over the prestressed pressure of the

expansion tank by 20%

Expansion tank operating

instructions

If the system pressure drops, refill the

water

If this occurs frequently, the

heating system does not have a

good seal!

Inform your installer!

If large pressure fluctuations are

observed, have the expansion tank

checked

5.1.2 Annual Check

Carry out yearly, or at least after 1500 hours of operation!

Checking the heat-exchanger and flue gas collection chamber

Remove the two screws on the

insulting cover using a Phillips

screwdriver

Remove the insulating cover

Loosen screw at the cleaning port

cover

Remove the cleaning cover

Clean the flue gas collection

chamber and the opening to the

induced draught fan with a brush

Remove any soot which has fallen

in

We recommend that you use an

ash vacuum

Boiler maintenance

Inspection, cleaning and maintenance

Page 36

B0190806

s

5

Clean the flue gas sensors

Remove the insulating cover

Page 35, Checking the heat-

exchanger and flue gas

collection chamber

Release the threaded pin and

remove the sensing element from

the flue gas pipe

Wipe off the flue gas sensor with a

clean cloth

Slide in the flue gas sensing

element and secure it hand-tight

using the threaded pin

Checking the primary air pipes

Open the insulating door and

combustion chamber door

Remove the combustion mount

Check primary air pipes(1) for air

flow

If necessary, clean the pipes

Checking the gearing

At the back of the boiler: Ash screw gearing

There must not be any leaking lubrication!

Cleaning the induced draught ventilator

Detach the induced draught

ventilator on the back side of the

boiler

Check for dirt and damage

Clean the blower wheel with a soft

brush or paint brush

Don’t move the balancing

weights on the blower wheel!

1

Boiler maintenance

Inspection, cleaning and maintenance

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 37

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

5

Clean the smoke flue pipe

Clean the connecting pipe between the boiler and the chimney

regularly with a chimney sweeping brush

Depending on the layout of the flue pipes and the chimney

draught cleaning yearly may not be enough!

Checking the draught controller flap and explosion flap

Check the draught controller flap and explosion flap for ease of

operation

Maximum permissible setting: 25 Pa

Ideal setting: 20 Pa

Checking the combustion chamber door

Close the combustion chamber door

and check its seal

Check fibre-glass seal (1) for

perfect alignment on the door frame

Imprint in the fibre-glass seal

If the seal is coloured black at several points or the imprint is

interrupted:

The seal is no longer efficient.

Tighten the door latches or replace the fibre-glass seal

Clean the bypass line (only for systems with suction unit)

Loosen the hose clips on the T-piece and the rotary valve

Detach the bypass line (1) and double-nippled pipe (2)

Check that the double-nippled pipe and bypass line are clear and if

necessary clean them with compressed air

Remove deposits from the thread (3) of the pellet valve

Depending on the length of the suction hose and the fuel type,

cleaning yearly may not be sufficient!

2

1

3

1

Boiler maintenance

Inspection, cleaning and maintenance

Page 38

B0190806

s

5

5.2 Maintenance Agreement / Customer services

Guarantee a long service-life with a service agreement!

Regular maintenance and servicing by a heating specialist will ensure a

long, trouble-free service life for your heating system.

Regular servicing will ensure that your system stays environmentfriendly and operates efficiently and cost-effectively.

For this reason, FRÖLING offers a service agreement, which optimises

operating safety. Please see the details in the accompanying guarantee

certificate.

Your Fröling customer service office is also glad to provide consultation.

5.3 Replacement parts

With Fröling original replacement parts in your boiler, you are using

parts, which are perfectly coordinated to work together. As the parts fit

together so well, installation times are shortened and lifespan is

maintained.

Installing non-original parts voids the guarantee!

Only replace components or parts with original replacement parts

Troubleshooting

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 39

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

6

6 Troubleshooting

6.1 General faults in power supply

Error Cause of error Error correction

Nothing is shown on the

display

No power to the controls

General power failure

FI circuit breaker or line

protection is switched off

Main switch is turned off

Defective fuse in the controls

Switch on the FI circuit breaker or line

protection

Turn on the main switch

Replace fuse – note current (10AT)

6.1.1 System procedure following power failure

When the power supply has been restored the boiler returns to the

previously specified mode and is controlled according to the specified

program.

EXCEPTION:

If the boiler was at operating status “Heating up”, “Pre-heating” or

“Ignition” troubleshooting is started automatically. When error

correction has been carried out (approx. 20 min) the warning, “Clean/

check burner”, is shown on the display. The warning can only be

acknowledged after checking the burner.

6.2 Excessive temperature

The safety temperature limiter shuts down the boiler when it reaches a

temperature of approx. 100°C. After the boiler has cooled down, the

safety temperature limiter (1) must be manually unlocked:

Unscrew the cap on the safety temperature limiter

Reset the safety temperature limiter by pressing with a screw-driver.

1

Troubleshooting

Page 40

B0190806

s

6

6.3 Faults with a fault message

If a fault has occurred and has not yet been cleared:

Status LED (1) flashes red

A fault message is shown on the display (2)

An internal distinction is made between 3 types of message:

Warning (W) Boiler continues running

Error (E) Boiler follows shutdown procedure

Fault (F) Boiler shuts down immediately, heating circuit controls

and pumps remain active

6.3.1 Procedure for fault messages

Find and eliminate the error.

Acknowledge the error by pressing the

ENTER

key

Restart the boiler with the key

1

2

Troubleshooting

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 41

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

6

6.4 Error message list

Error texts in alphabetical order:

Error text Code Type

Cause of error Error correction

Outdoor sensor temp.

false

036 W • Sensor signal damaged Check sensor and sensor cable

DHW temp. false 006 W • Sensor signal damaged Check sensor and sensor cable

DHW temp.2 false 037 W • Sensor signal damaged Check sensor and sensor cable

Clean /check burner 049 W Signals successful automatic troubleshooting

NOTE: can only be cleared by checking and cleaning the burner

Acknowledge warning

After you have done this, open the insulating door and

combustion chamber door

Clean embers, fuel and slag from the pellet burner (see

chapter on maintenance)

Clean the flue gas guide in the boiler up to the mouth of the

chimney

Empty the ash drawer

Stoker error 030 F Gravity shaft level sensor still

recognises material after 10

minutes of stoker running

time:

• Bridge formation in the

gravity shaft

• Sensor incorrectly set

• Stoker not feeding

Break up the bridge of fuel,

remove foreign bodies if

necessary

Readjust the sensor

Check stoker drive

Remote control 1 error 004 W • Sensor signal damaged Check sensor and sensor cable

Remote control 2 error 005 W • Sensor signal damaged Check sensor and sensor cable

Remote control 3 error 025 W • Sensor signal damaged Check sensor and sensor cable

Remote control 4 error 026 W • Sensor signal damaged Check sensor and sensor cable

Troubleshooting

Page 42

B0190806

s

6

Error text Code Type

Cause of error Error correction

Excess pressure in

combustion chamber

Acknowledge error Pressure monitor comb

chamb

029 F

NOTE: After acknowledging the error, error correction starts

immediately. Keep the doors of the boiler closed!

After error correction starts, check if the induced draught fan is

running

CAUTION! In case of defective induced draught fan inform the

heating engineers or Fröling customer services!

When error correction has been automatically carried out (approx.

20 min) the warning, “Clean/ check burner”, is shown on the

display.

After you have done this, open the insulating door and

combustion chamber door

Clean embers, fuel and slag from the pellet burner

(see chapter on maintenance)

Clean the flue gas guide in the boiler up to the mouth of the

chimney

Empty the ash drawer

Acknowledge warning

Door open -

Empty ash box

040 W Insulating doors are open for

more than 10 minutes during

“HEATING” status!

• The door contact switch

does not close

• Insulating doors not

closed

• Ash box full

Check or adjust switch

Check insulating doors

Empty ash box

Boiler return temp false 007 W • Sensor signal damaged Check sensor and sensor cable

Boiler temp. false 001 W • Sensor signal damaged Check sensor and sensor cable

Solar return temp false 035 W • Sensor signal damaged Check sensor and sensor cable

Comm. to pellet module

false

016 S • Data exchange with pellet

module interrupted

Check cable / plug

Check fuse

Check storage room (for

automatic universal

suction system)

041 S The MAX sensor is not

reached after 10 minutes of

suction per probe:

• No pellets in the suction

probe

• Hose, probe or hose

connections blocked

• Sensor incorrectly set

• Switch motor damaged

Refill pellets in store

ATTENTION! Do not feed any

pellets into the pellet burner

manually - danger of flash fires!

Remove blockage, shake the

hose, if necessary remove

foreign bodies, check pellet

length

Readjust the sensor

Check the plug connection to

the motor

Oil boiler temp. false 011 W • Sensor signal damaged Check sensor and sensor cable

Troubleshooting

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 43

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

6

Error text Code Type

Cause of error Error correction

Store temp. up. false 008 W • Sensor signal damaged Check sensor and sensor cable

Store temp. mid. false 010 W • Sensor signal damaged Check sensor and sensor cable

Outfeed system error

(with screw discharge unit)

027 S Gravity shaft level sensor

does not recognise any

material for 60 minutes:

• No pellets in trough

• Bridge formation over

trough

• Sensor incorrectly set

• Discharge screw drive is

not working

Refill pellets in store

ATTENTION! Do not feed any

pellets into the pellet burner

manually - danger of flash fires!

Break up blocks of fuel, check

length of pellets

Readjust the sensor

Check drive

Check/clean outfeed

system (for screw suction

systems)

For information on errors in

manual universal suction

systems see the next page!

021 S For screw suction

systems:

The MAX sensor is not

reached after 45 minutes of

suction:

• No pellets in trough

• Bridge formation over

trough

• Hose or hose connections

blocked

• Sensor incorrectly set

• Screw drive not working

Jam sensor is covered for

longer than 5 minutes:

• Suction point is blocked

Refill pellets in store

ATTENTION! Do not feed any

pellets into the pellet burner

manually - danger of flash fires!

Break up blocks of fuel, check

length of pellets

Remove blockage, shake hose

Readjust the sensor

Check drive

Clear blockage and remove

foreign bodies if necessary,

check pellet length

Troubleshooting

Page 44

B0190806

s

6

Error text Code Type

Cause of error Error correction

Check/clean outfeed

system (for manual

universal suction systems)

For information on errors in

the screw suction system

see the previous page!

021 S For manual universal

suction systems:

The MAX sensor is not

reached after 15 minutes of

suction at the probe:

• No pellets at the suction

probe

• Hose, probe or hose

connections blocked

•

• Sensor incorrectly set

Refill pellets in store

Remove blockage, shake the

hose, if necessary remove

foreign bodies, check pellet

length.

Install interchange unit on the

other probe

Readjust the sensor

Return temp low too long

015 W • Return feed temperature

too cold

Check return feed lift, check

sensor

Note: Bypass pump with the speed

control; always operate at

maximum power level!

Inform heating engineers or

Fröling customer services

Key switch engaged 028 S For direct screw discharge:

• key switch was turned off

For suction discharge:

• Handle of X9 connection

of the pellet module not

positioned

Turn the key switch on again.

Set handle at connection X9

See 7.3.2 Pellet module with

suction system

Safety temp. limiter

released

000 S Boiler has overheated,

substantial reduction in heat

consumption:

• Heating and pump

switches have gone off.

• Pump suddenly stops

• Slide valves/cut-offs

closed.

Set switch back to “AUTO”

Check pump

Reopen slide valves/cut-offs

Note: After cooling down, the

safety temperature limiter must be

released

See 6.2 Excessive

temperature

Troubleshooting

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestraße 12, A-4710 Grieskirchen, Austria Page 45

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com

B0190806

6

Error text Code Type

Cause of error Error correction

The value for the parameter,

“Min. boiler flue temp dif.” fell

below the specified level for

longer than the safety time.

Acknowledge error

NOTE: After acknowledging the error, error correction starts

immediately. Keep the doors of the boiler closed!

After error correction starts, check if the induced draught fan is

running

CAUTION! In case of defective induced draught fan inform the

heating engineers or Fröling customer services!

When error correction has been automatically carried out (approx.

20 min) the warning, “Clean/ check burner”, is shown on the

display.

After you have done this, open the insulating door and

combustion chamber door

Clean embers, fuel and slag from the pellet burner (see

chapter on maintenance)

Clean the flue gas guide in the boiler up to the mouth of the

chimney

Empty the ash drawer if necessary

Acknowledge warning

“Insufficient safety time

elapsed”.

014 F

• Insufficient pellets fed

into combustion bowl

• Bridge formation over

trough

• Sensor incorrectly set

• Stoker not feeding

Refill pellets in storage tank,

check discharge and stoker

ATTENTION! Do not feed any

pellets into the pellet burner

manually - danger of flash fires!

Break up blocks of fuel, check

length of pellets

Readjust the sensor

Check stoker drive

Troubleshooting

Page 46

B0190806

s

6

Error text Code Type

Cause of error Error correction

Oxygen content is greater

than the “Remaining O2 shut

down” parameter - duration

longer than safety time (in

the HEATING state):

Acknowledge error

NOTE: After acknowledging the error, error correction starts

immediately. Keep the doors of the boiler closed!

After error correction starts, check if the induced draught fan is

running