FRIULAIR AMD 3-168 Users Maintenance And Spare Parts Manual

7425MUM073_EN_2008-05

AMD 3

AMD 3AMD 3

AMD 3-

--

-168

168168

168

REFRIGERATING AIR DRYER

EN

ENEN

EN

USER’S MAINTENANCE AND SPARE PARTS MANUAL

USER’S MAINTENANCE AND SPARE PARTS MANUALUSER’S MAINTENANCE AND SPARE PARTS MANUAL

USER’S MAINTENANCE AND SPARE PARTS MANUAL

----EN

ENEN

EN---- AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

Dear Customer,

thank you for choosing our product. In order to get the best performances out of this product, please read

this manual carefully.

To avoid incorrect operation of the equipment and possible physical risk to the operator, please read and

strictly follow the instructions contained in this manual.

Note, these instructions are in addition to the safety rules that apply in the country where the dryer is

installed. Before packing for shipment each AMD series refrigerated air dryer undergoes a rigorous test to

ensure the absence of any manufacturing faults and to demonstrate that the device can perform all the

functions for which it has been designed.

Once the dryer has been properly installed according to the instructions in this manual, it will be ready for

use without any further adjustment. The operation is fully automatic, and the maintenance is limited to few

controls and some cleaning operations, as detailed in the following chapters.

This manual must be maintained available in any moment for future references and it has to be

intended as inherent part of the relevant dryer.

Due to the continuous technical evolution, we reserve the right to introduce any necessary change without

giving previous notice.

Should you experience any trouble, or for further information, please do not hesitate to contact us.

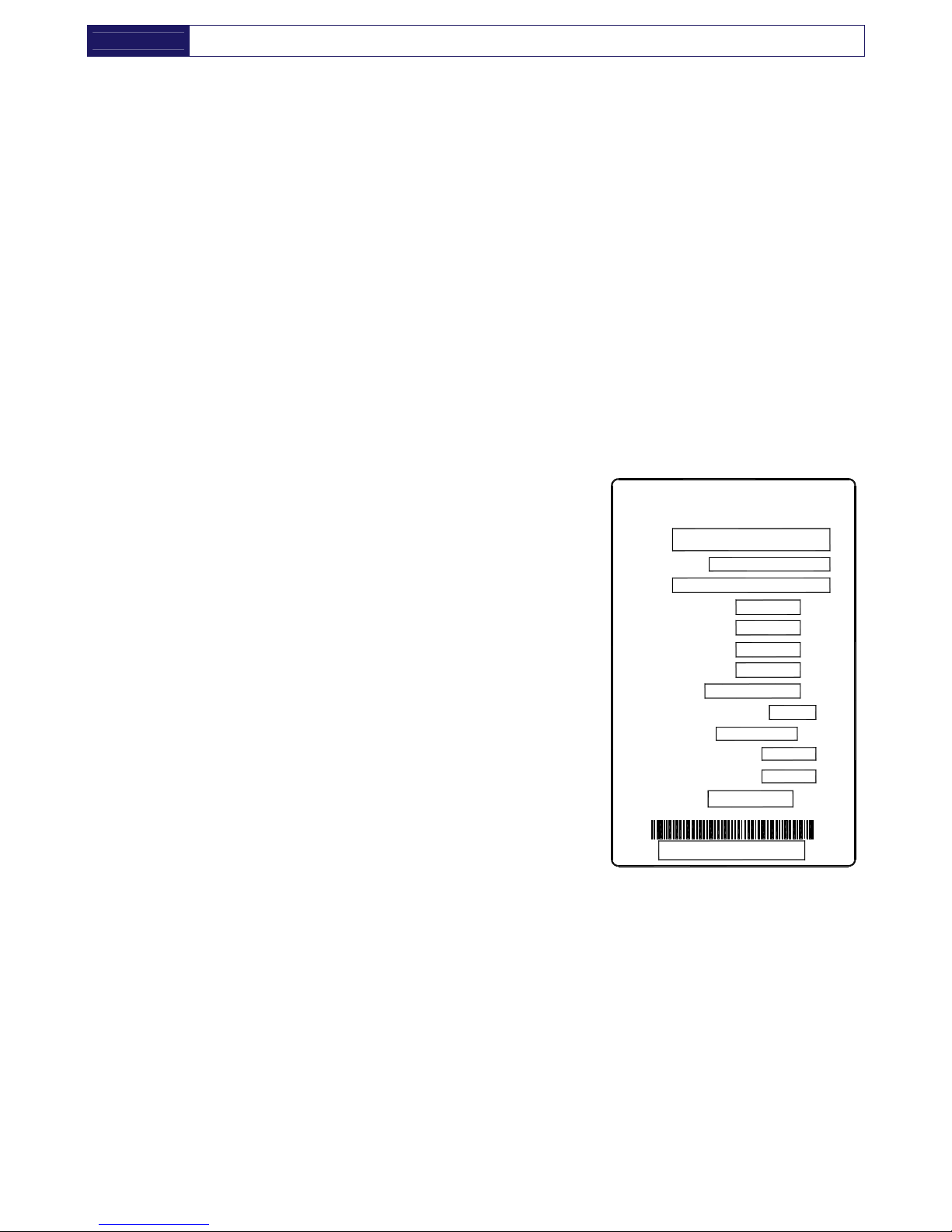

DATA NAMEPLATE

Model

Serial No.

Code

Nominal Flow Rate

Max Air Pressure

Max Inlet Air Temp.

Ambient Temp.

Refrigerant (Type and qty)

Refrig. Design Pres. HP/LP

Electric Supply

Electric Nominal Power

Fuse Max.

Manufactured

The data nameplate is located

on the back of the dryer and

shows all the primary data of the

machine. Upon installation, fill in

the table on the previous page

with all the data shown on the

data nameplate. This data

should always be referred to

when calling the manufacturer

or distributor.

The removal or alteration of the

data nameplate will void the

warranty rights.

T

A

D

0

0

0

6

Refrig. Design Pres.

HP/LP

Max Inlet Air Temp.

Electric Supply

Manufactured

Fuse Max.

Electric Nominal Power

Refrigerant

Ambient Temp.

Nominal Flow Rate

Max Air Pressure

Code

Serial No.

Model

°C

ph/V/Hz

A

W/A

type/kg

barg

°C

Nl/min

barg

WARRANTY CONDITIONS

For 12 months from the installation date, but no longer than 14 months from the delivery date, the warranty

covers eventual faulty parts, which will be repaired or replaced free of charge, except the travel, hotel and

restaurant expenses of our engineer.

The warranty doesn’t cover any responsibility for direct or indirect damages to persons, animals or

equipment caused by improper usage or maintenance, and it’s limited to manufacturing faults only.

The right to warranty repairs is subordinated to the strict compliance with the installation, use and

maintenance instructions contained in this manual.

The warranty will be immediately voided in case of even small changes or alterations to the dryer. To

require repairs during the warranty period, the data reported on the identification plate must be notified.

AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

----EN

ENEN

EN----

1. SAFETY RULES

1.1. Definition of the Conventional Signs Used in This Manual

1.2. Warnings

1.3. Proper use of the dryer

1.4. Instructions for the use of pressure equipment according to ped directive 97/23/ec

2. INSTALLATION

2.1. Transport

2.2. Storange

2.3. Installation site

2.4. Installation layout

2.5. Correction factors

2.6. Connection to the compressed air system

2.7. Electrical connections

2.8. Condensate drain

3. START UP

3.1. Preliminary operation

3.2. First start-up

3.3. Start-up and shut down

4. TECHNICAL SPECIFICATIONS

4.1. Technical specifications AMD 3-25 / 230V / 50-60 Hz

4.2. Technical specifications AMD 32-168 / 230V / 50Hz

4.3. Technical specifications AMD 32E-168E / 230V / 60 Hz

4.4. Technical specifications AMD 3P-25P / 115V / 60 Hz

4.5. Caratteristiche tecniche AMD 32P-75P / 115V / 60 Hz

5. DESCRIZIONE TECNICA

5.1. Control panel

5.2. Operation

5.3. Flow diagram

5.4. Refrigerating compressor

5.5. Condenser

5.6. Filter drier

5.7. Capillary tube

5.8. Alu-dry module

5.9. Hot gas by-pass valve

5.10. Refrigerant pressure switches Pa- Pb- Pv

5.11. Safety thermo-switc T

S

5.12. DMC15 Electronic instrument (Air Dryer Controller)

5.13. Electronic level drain

6. MAINTENANCE, TROUBLESHOOTING, SPARES AND DISMANTLING

6.1. Controls and maintenance

6.2. Troubleshooting

6.3. Spare parts

6.4. Maintenance operation on the refrigerating circuit

6.5. Dismantling of the dryer

7. LIST OF ATTACHMENTS

7.1. Dryers dimensions

7.2. Exploded view

7.3. Electic diagrams

----EN

ENEN

EN---- AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

1. SAFETY RULES

1.1. DEFINITION OF THE CONVENTIONAL SIGNS USED IN THIS MANUAL

Carefully read instruction manual before attempting any service or maintenance procedures on the

dryer.

Caution warning sign. Risk of danger or possibility of damage to equipment, if related text is not

followed properly.

Electrical hazard. Warning message indicates practices or procedures that could result in personal

injury or fatality if not followed correctly.

Danger hazard. Part or system under pressure.

Danger hazard. High temperature conditions exist during operation of system. Avoid contact until

system or component has dissipated heat.

Danger hazard. Treated air is not suitable for breathing purposes; serious injury or fatality may

result if precautions are not followed.

Danger hazard: In case of fire, use an approved fire extinguisher, water is not an acceptable

means in cases of fire.

Danger hazard. Do not operate equipment with panels removed.

Maintenance or control operation to be performed by qualified personnel only 1.

ARIA

AIR

LUFT

AIR

Compressed air inlet connection point.

ARIA

AIR

LUFT

AIR

Compressed air outlet connection point.

Condensate drain connection point.

Operations which can be worked out by the operator of the machine, if qualified 1.

NOTE : Text to be taken into account, but not involving safety precautions.

In designing this unit a lot of care has been devoted to environmental protection:

• CFC free refrigerants

• CFC free insulation parts

• Energy saving design

• Limited acoustic emission

• Dryer and relevant packaging composed of recyclable materials

This symbol requests that the user heed environmental considerations and abide with suggestions

annotated with this symbol.

1 Experienced and trained personnel acquainted with the relevant rules and laws, capable to perform the needed activities and to identify and

avoid possible dangerous situations while handling, installing, using and servicing the machine.

AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

----EN

ENEN

EN----

1.2. WARNINGS

Compressed air is a highly hazardous energy source.

Never work on the dryer with pressure in the system.

Never point the compressed air or the condensate drain outlet hoses towards anybody.

The user is responsible for the proper installation of the dryer. Failure to follow instructions given in

the “Installation” chapter will void the warranty. Improper installation can create dangerous situations

for personnel and/or damages to the machine could occur.

Only qualified personnel are authorized to service electrically powered devices. Before attempting

maintenance, the following conditions must be satisfied :

• Ensure that main power is off, machine is locked out, tagged for service and power cannot be

restored during service operations.

• Ensure that valves are shut and the air circuit is at atmospheric pressure. De-pressurize the dryer.

These refrigerating air dryers contain R134a or R404A HFC type refrigerant fluid. Refer to the

specific paragraph - maintenance operation on the refrigerating circuit.

Warranty does not apply to any unit damaged by accident, modification, misuse, negligence or

misapplication. Unauthorized alterations will immediately void the warranty.

In case of fire, use an approved fire extinguisher, water is not an acceptable means in cases of

electrical fire.

1.3. PROPER USE OF THE DRYER

This dryer has been designed, manufactured and tested for the purpose of separating the humidity normally

contained in compressed air. Any other use has to be considered improper.

The Manufacturer will not be responsible for any problem arising from improper use; the user will bear

responsibility for any resulting damage.

Moreover, the correct use requires the adherence to the installation instructions, specifically:

• Voltage and frequency of the mains.

• Pressure, temperature and flow-rate of the incoming air.

• Ambient temperature.

This dryer is supplied tested and fully assembled. The only operation left to the user is the connection to the

plant in compliance with the instructions given in the following chapters.

The purpose of the machine is the separation of water and eventual oil particles present in

compressed air. The dried air cannot be used for breathing purposes or for operations leading to

direct contact with foodstuff.

This dryer is not suitable for the treatment of dirty air or of air containing solid particles.

----EN

ENEN

EN---- AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

1.4. INSTRUCTIONS FOR THE USE OF PRESSURE EQUIPMENT ACCORDING TO PED

DIRECTIVE 97/23/EC

To ensure the safe operation of pressure equipments, the user must conform strictly to the above directive

and the following :

1. The equipment must only be operated within the temperature and pressure limits stated on the

manufacturer’s data nameplate.

2. Welding on heat-exchanger is not recommended.

3. The equipment must not be stored in badly ventilated spaces, near a heat source or inflammable

substances;

4. Vibration must be eliminated from the equipment to prevent fatigue failure.

5. Automatic condensate drains should be checked for operation every day to prevent a build up of

condensate in the pressure equipment.

6. The maximum working pressure stated on the manufacturer’s data nameplate must not be exceeded.

Prior to use, the user must fit safety / pressure relief devices.

7. All documentation supplied with the equipment (manual, declaration of conformity etc.) must be kept

for future reference.

8. Do not apply weights or external loads on the vessel or its connecting piping.

TAMPERING, MODIFICATION AND IMPROPER USE OF THE PRESSURE EQUIPMENT ARE

FORBIDDEN. Users of the equipment must comply with all local and national pressure

equipment legislation in the country of installation.

2. INSTALLATION

2.1. TRANSPORT

Check for visible loss or damage, if no visible damage is found place the unit near to the installation point

and unpack the contents.

• Always keep the dryer in the upright vertical position. Damage to compo

nents could result if unit is laid on

its side or if placed upside down.

• Store machine in a clean, dry environment, do not expose to severe weather environments.

• Handle with care. Heavy blows could cause irreparable damage.

2.2. STORANGE

S

C

C

0

0

0

1

Even when packaged, keep the machine

protected from severity of the weather.

Keep the dryer in vertical position, also when

stored. Turning it upside down some parts could

be irreparably damaged.

If not in use, the dryer can be stored in its

packaging in a dust free and protected site at a

maximum temperature of 50 °C, and a specific

humidity not exceeding 90%. Should the

stocking time exceed 12 months, please contact

the manufacturer.

The packaging materials are recyclable. Dispose of material in compliance with the rules

and regulations in force in the destination country.

AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

----EN

ENEN

EN----

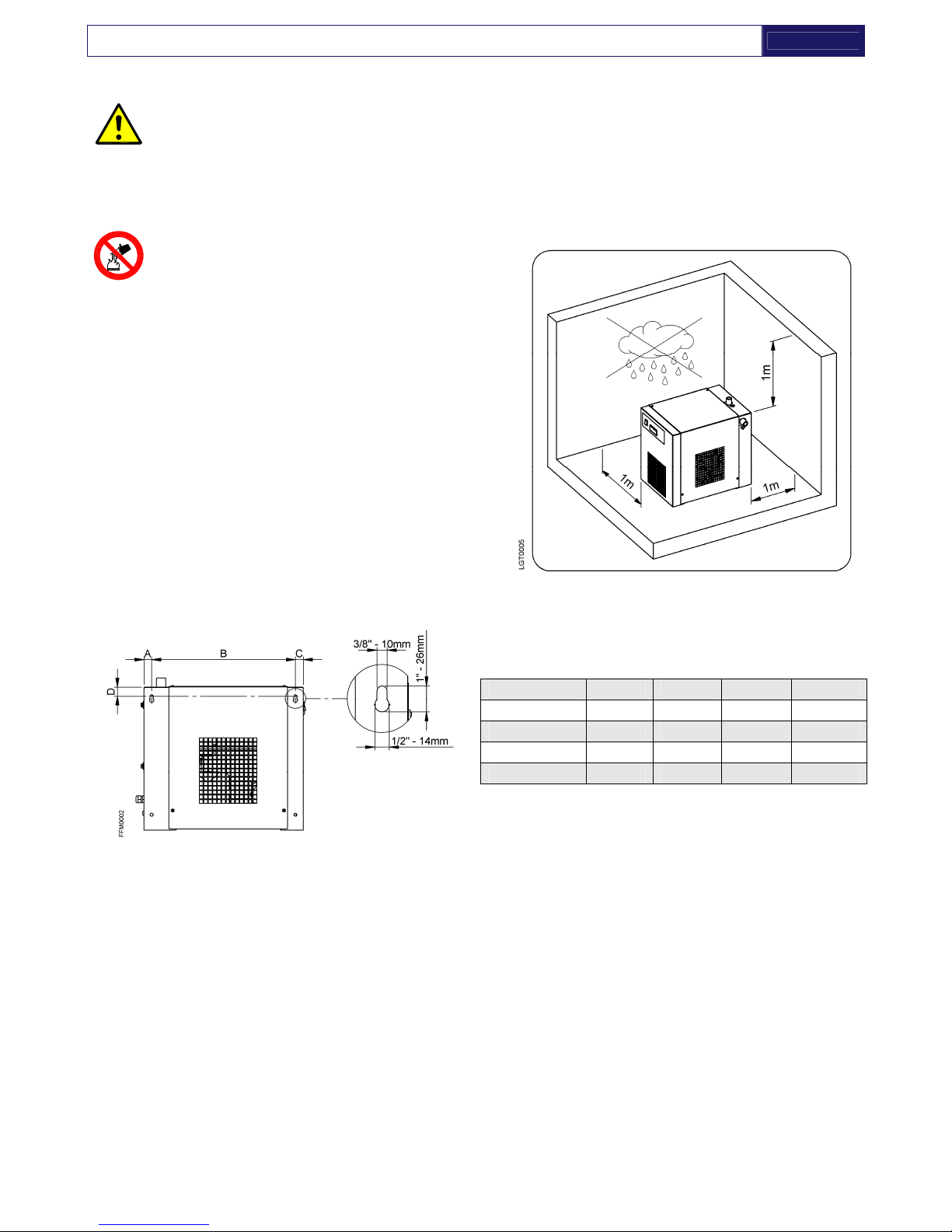

2.3. INSTALLATION SITE

Failure to install dryer in the proper ambient conditions will affect the dryer’s ability to condense

refrigerant gas. This can cause higher loads on the compressor, loss of dryer efficiency and

performance, overheated condenser fan motors, electrical component failure and dryer failure due

to the following: compressor loss, fan motor failure and electrical component failure. Failures of

this type will affect warranty considerations.

Do not install dryer in an environment of corrosive chemicals, explosive gasses, poisonous

gasses; steam heat, areas of high ambient conditions or extreme dust and dirt.

Don’t use water to extinguish fire on the dryer

on in the surrounding area.

Minimal installation requirements :

• Select a clean room dry, free from dust, and protected

from atmospheric disturbances.

• The supporting area must be smooth, horizontal and

able to hold the weight of the dryer.

• Minimum ambient temperature +1 °C.

• Maximum ambient temperature +45°C.

• Leave at least 1 meter of free space on every side of

the drier for ventilation purposes and maintenance

operations.

The dryer doesn't require to be fixed to the supporting

surface. The dryer needs to be fixed to the supporting

s

urface only with particular installation procedures

(dryer on brakets, hanging units, etc.)

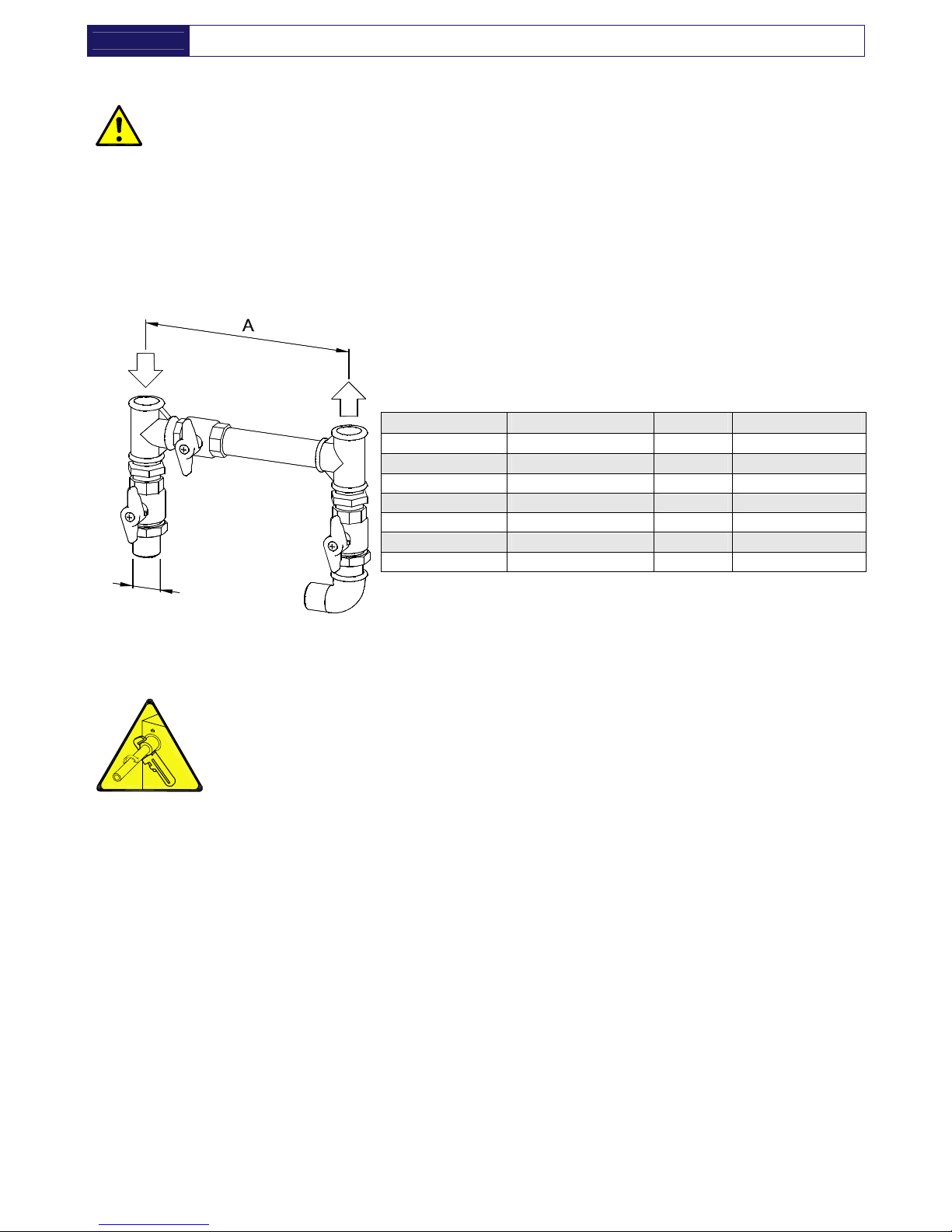

Dryer hanging (AMD 3-32 only):

Dryer A [mm] B [mm] C [mm] D [mm]

AMD 3 20 305 20 30

AMD 6-18 25 465 25 30

AMD 25 40 360 20 30

AMD 32 40 385 20 30

----EN

ENEN

EN---- AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

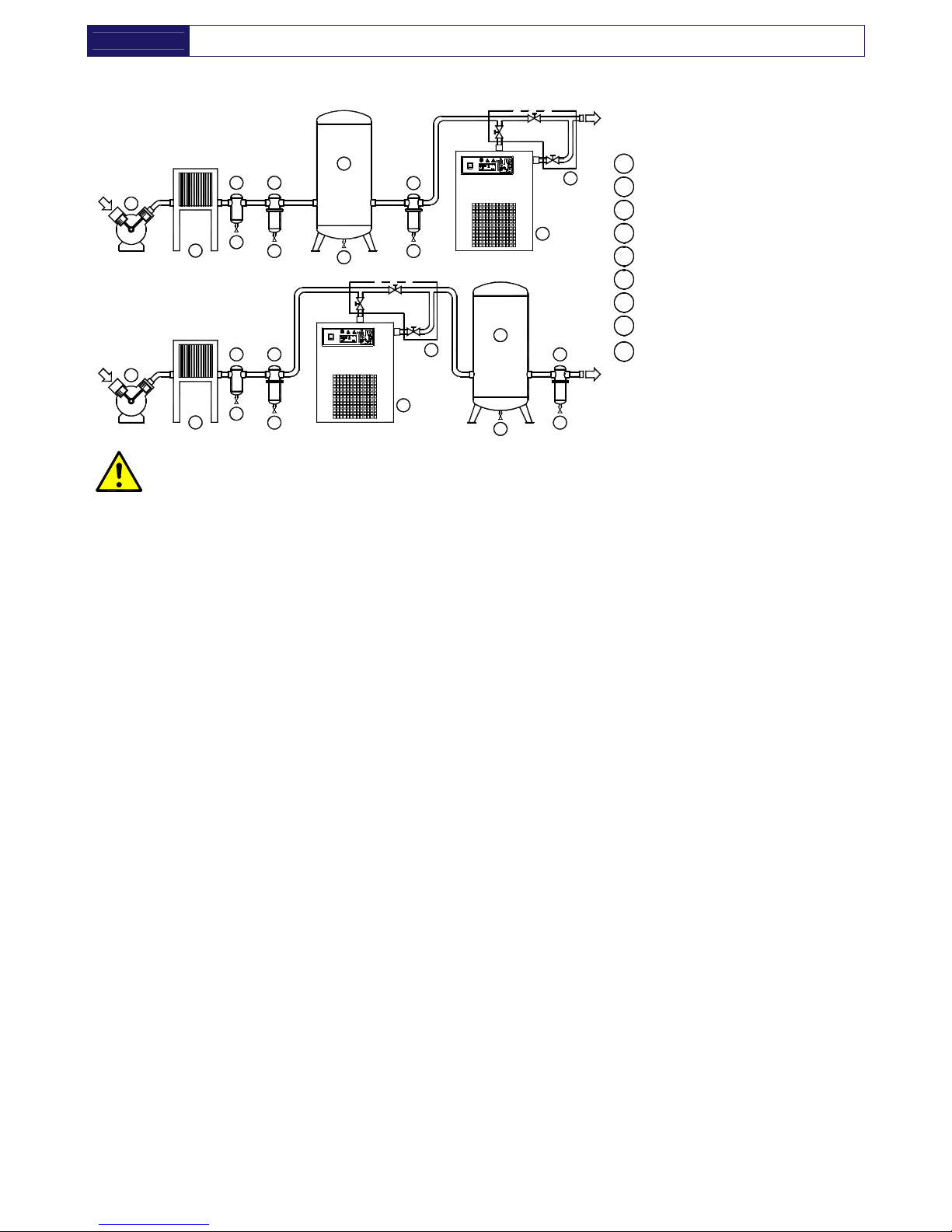

2.4. INSTALLATION LAYOUT

1

Air compressor

2

Final refrigerator

3

Condensate separator

4

Pre-Filter (min. 5 micron)

5

By-pass group

6

Dryer

7

Compressed air tank

8

Final filter

9

Condensate drain

9 9

2

9

- A -

- B -

1

3

9

1

2

9

3

4

IN

5

6

OUT

9

9

4

7

9

8

8

7

6

IN

OUT

5

D

G

T

0

0

0

2

In case of heavily polluted inlet air (ISO 8573.1 class 3.-.3 or worse quality), we recommend

the additional installation of a pre-filter (5 micron minimum) to prevent a clogging of the

heat exchanger.

Type A installation is suggested when the compressor operates at reduced intermittence and the total

consumption equals the compressor flow rate.

Type B installation is suggested when the air consumption can consistently change with peak values highly

exceeding the flow rate of the compressors. The capacity of the tank must be sized in order to compensate

eventual instantaneous demanding conditions (peak air consumption).

AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

----EN

ENEN

EN----

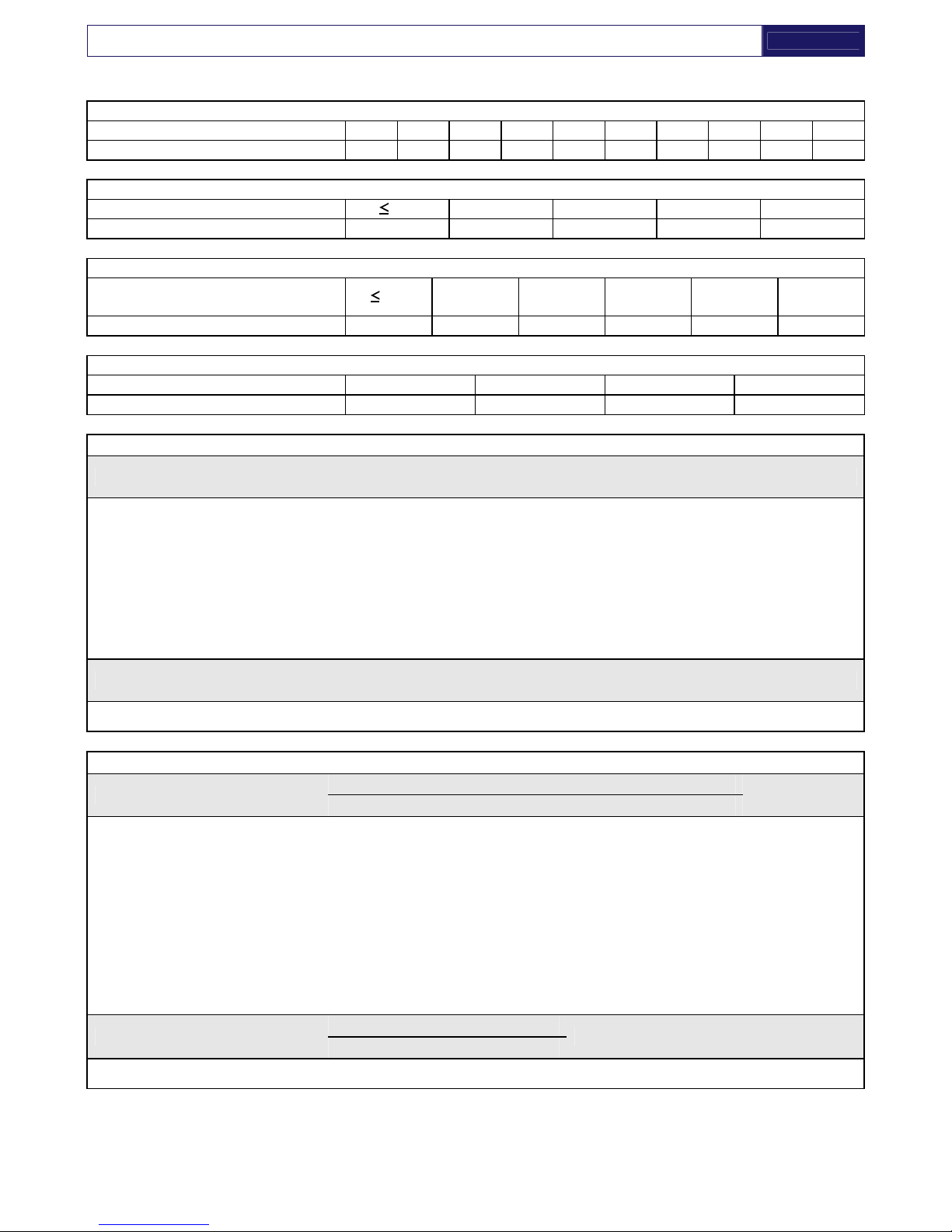

2.5. CORRECTION FACTORS

Correction factor for operating pressure changes :

Inlet air pressure barg 4 5 6 7 8 10 12 14 15 16

Factor (F1) 0.77 0.86 0.93 1.00 1.05 1.14 1.21 1.27 1.30 1.33

Correction factor for ambient temperature changes (Air-Cooled):

Ambient temperature ºC 25 30 35 40 45

Factor (F2) 1.00 0.98 0.95 0.88 0.80

Correction factor for inlet air temperature changes:

Air temperature

ºC

30 35 40 45 50 55

Factor (F3) 1.15 1.00 0.84 0.71 0.59 0.50

Correction factor for DewPoint changes:

DewPoint ºC 3 5 7 10

Factor (F4) 0.91 1.00 1.10 1.26

How to find the air flow capacity:

Air flow capacity = Nominal duty x Factor (F1) x Factor (F2) x Factor (F3) x Factor (F4)

Example:

An AMD 18 has a nominal duty of 1800 l/min . What is the maximum allowable flow through the dryer under

the following operating conditions:

–

Inlet air pressure = 7 barg

–

Ambient temperature = 35°C

–

Inlet air temperature = 40°C

–

Pressure DewPoint = 3°C

–

Factor (F1) = 1.00

–

Factor (F2) = 0.95

–

Factor (F3) = 0.84

–

Factor (F4) = 0.91

Each item of data has a corresponding numerical factor which multiplied by the design air flow is as follows:

Air flow capacity = 108 x 1.00 x 0.95 x 0.84 x 0.91 = 1307 l/mi n

1307 l/min This is the maximum flow rate that the dryer can accept under these operating conditions.

How to select a suitable dryer for a given duty:

Design air flow

Minimum std. air flow rate =

Factor (F1) x Factor (F2) x Factor (F3) x Factor (F4)

Example:

With the following operating parameters:

–

Design air flow = 1100 l/m in

–

Inlet air pressure = 7 barg

–

Ambient temperature = 35°C

–

Inlet air temperature = 40°C

–

Pressure DewPoint = 3°C

–

Factor (F1) = 1.00

–

Factor (F2) = 0.95

–

Factor (F3) = 0.84

–

Factor (F4) = 0.91

In order to select the correct dryer model the required flow rate is to be divided by the correction factors relating

to above mentioned parameters:

1100

Minimum std. air flow rate =

1.00 x 0.95 x 0.84 x 0.91

= 1515 l/ min

Therefore the model suitable for the conditions above is AMD 18 (1800 l/ min - nominal duty).

----EN

ENEN

EN---- AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

2.6. CONNECTION TO THE COMPRESSED AIR SYSTEM

Operations to be performed by qualified personnel. Never operate with plants under pressure.

The user is responsible to ensure that the dryer will never be operated with pressure exceeding

the nominal values.

Eventual over-pressure could be dangerous both for the operator and the machine.

The temperature and the amount of air entering the dryer must comply with the limits reported on the data

plate. In case of treatment of air at particularly high temperatures, the installation of a final refrigerator could

result necessary. The cross section of the connecting piping, which must be free from dust, rust, chips and

other impurities, must be consistent with the flow-rate of the dryer.

In order to facilitate the maintenance operations, a by-pass group has been installed, as shown in the

following illustration.

Dryer Ø [BSP-F] A [mm] By-Pass Code

AMD 3 G 3/8” BSP-F

40 2240GBP019

AMD 6-18 G 1/2” BSP-F

210 2240GBP021

AMD 25 G 1” BSP-F 205 2240GBP022

AMD 32-52 G 1.1/4” BSP-F

205 2240GBP023

AMD 61-75 G 1.1/2” BSP-F

235 2240GBP024

AMD 105-130 G 2” BSP-F

345 2240GBP025

AMD 168 G 2.1/2” BSP-F

410 2240GBP026

Ø

B

P

Y

0

0

0

1

In realising the dryer, particular measures have been taken in order to limit the vibration which could occur

during the operation. Therefore we recommend to use connecting pipes able to insulate the dryer from

possible vibrations originating from the line (flexible hoses, vibration damping fittings, etc.).

CAUTION:

PIPING THE DRYER, INLET/OUTLET CONNECTIONS MUST BE SUPPORTED AS

SHOW IN THE DIAGRAM.

FAILING WILL RESULT IN DAMAGE

AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

----EN

ENEN

EN----

2.7. ELECTRICAL CONNECTIONS

Qualified personnel should carry out connecting unit to the main power. Be sure to check the local

codes in your area.

Before connecting the unit to the electrical supply, verify the data nameplate for the proper electrical

information. Voltage tolerance is +/- 5%.

AMD 3-75 dryers are supplied with a standard VDE 16A - Shucko power cord and plug assembly (two

poles and a ground). AMD 105-168 dryers are supplied with a junction box.

Be sure to provide the proper fuses or breakers based on the data tag information located on the back of

the unit. The main power receptacle must be protected with a thermal overload/differential relay

(I∆n=0.03A), rated to the power consumption of the dryer (refer to data nameplate for nominal values). The

power supply cord must meet or exceed ratings for the total amp draw of the unit.

Connect to a properly grounded outlet. Improper connection of the equipment-grounding

conductor can result in risk of electric shock.

Do not use adapters on the plug receptacle - if it does not fit the outlet, have a proper outlet

installed by a qualified electrician.

2.8. CONDENSATE DRAIN

The condensate is discharge at the system pressure.

Drain line should be secured

Never point the condensate drain line towards anybody.

The dryer comes with a flexible plastic drain tube.

The condensate drain occurs through a solenoid valve protected with a mechanical strainer.

The condensate coming from the separator is previously filtered, then discharged.

The solenoid valve coil is operated by electronic instrument (dryer controller).

If an electronic drainer is installed, the intervention times are determined by the internal capacitive sensor

(see specific paragraph).

The drainers cannot be connected to pressurized systems.

Don’t dispose the condensate in the environment.

The condensate collected in the dryer contains oil particles released in the air by the compressor.

Dispose the condensate in compliance with the local rules.

We suggest to install a water-oil separator where to convey all the condensate drain coming from

compressors, dryers, tanks, filters, etc.

3. START UP

3.1. PRELIMINARY OPERATION

Verify that the operating parameters match with the nominal values reported on the data plate of the

dryer (voltage, frequency, air pressure, air temperature, ambient temperature, etc.).

Before delivery, each dryer is submitted to accurate tests simulating real operating conditions.

Nevertheless, the unit could be damaged during transportation. We therefore suggest to check the integrity

of the dryer upon arrival and to keep it under control during the first hours of operation.

The start-up must be performed by qualified personnel.

It’s mandatory that the engineer in charge adopt safety operational conditions complying with the

local safety and accident prevention requirements.

The same engineer will be responsible for the proper and safe operation of the dryer.

Never operate the dryer if the panels are not in place.

----EN

ENEN

EN---- AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

3.2. FIRST START-UP

This procedure should be followed on first start-up, after periods of extended shutdown or

following maintenance procedures.

Qualified personnel must perform the start-up.

Sequence of operations (refer to paragraph 5.1 Control Panel) :

• Ensure that all the steps of the “Installation” chapter have been observed.

• Ensure that the connection to the compressed air system is correct and that the piping is suitably fixed

and supported.

• Ensure that the condensate drain pipe is properly fastened and connected to a collection system or

container.

• Ensure that the by-pass system (if installed) is open and the dryer is isolated

• Ensure that the manual valve of the condensate drain circuit is open.

• Remove any packaging and other material which could obstruct the area around the dryer.

• Activate the mains switch.

• Turn on the main switch - pos. 1 on the control panel.

• Ensure that the DMC15 electronic instrument is ON.

• Ensure the consumption matches with the values of the data plate.

• Ensure the fan work properly - wait for its first interventions.

• Allow the dryer temperature to stabilise at the pre-set value.

• Slowly open the air inlet valve.

• Slowly open the air outlet valve.

• Slowly close the central by-pass valve of the system (if installed).

• Check the piping for air leakage.

• Ensure the drain is regularly cycling - wait for its first interventions.

3.3. START-UP AND SHUT DOWN

Start-up (refer to paragraph 5.1 Control Panel) :

• Check the condenser for cleanliness.

• Verify that the system is powered.

• Turn on the main switch - pos. 1 on the control panel.

• Ensure that DMC15 electronic instrument is ON.

• Wait a few minutes; verify that the DewPoint temperature displayed on DMC15 electronic instrument is

correct and that the condensate is regularly drained.

• Switch on the air compressor.

Shut down (refer to paragraph 5.1 Control Panel) :

• Verify that the DewPoint temperature displayed on DMC15 electronic instrument is correct.

• Switch OFF the air compressor.

• After a few minutes, switch off the main switch on the control panel of the dryer (pos. 1).

NOTE : A DewPoint included in the green operating area of the electronic controller is correct

according to the possible working conditions (flow-rate, temperature of the incoming air, ambient

temperature, etc.)

During the operation, the refrigerating compressor will run continuously. The dryer must remain on during

the full usage period of the compressed air, even if the air compressor works intermittently.

The number of starts must be no more than 6 per hour. The dryer must stop running for at

least 5 minutes before being started up again.

The user is responsible for compliance with these rules. Frequent starts may cause

irreparable damage.

AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

----EN

ENEN

EN----

4. TECHNICAL SPECIFICATIONS

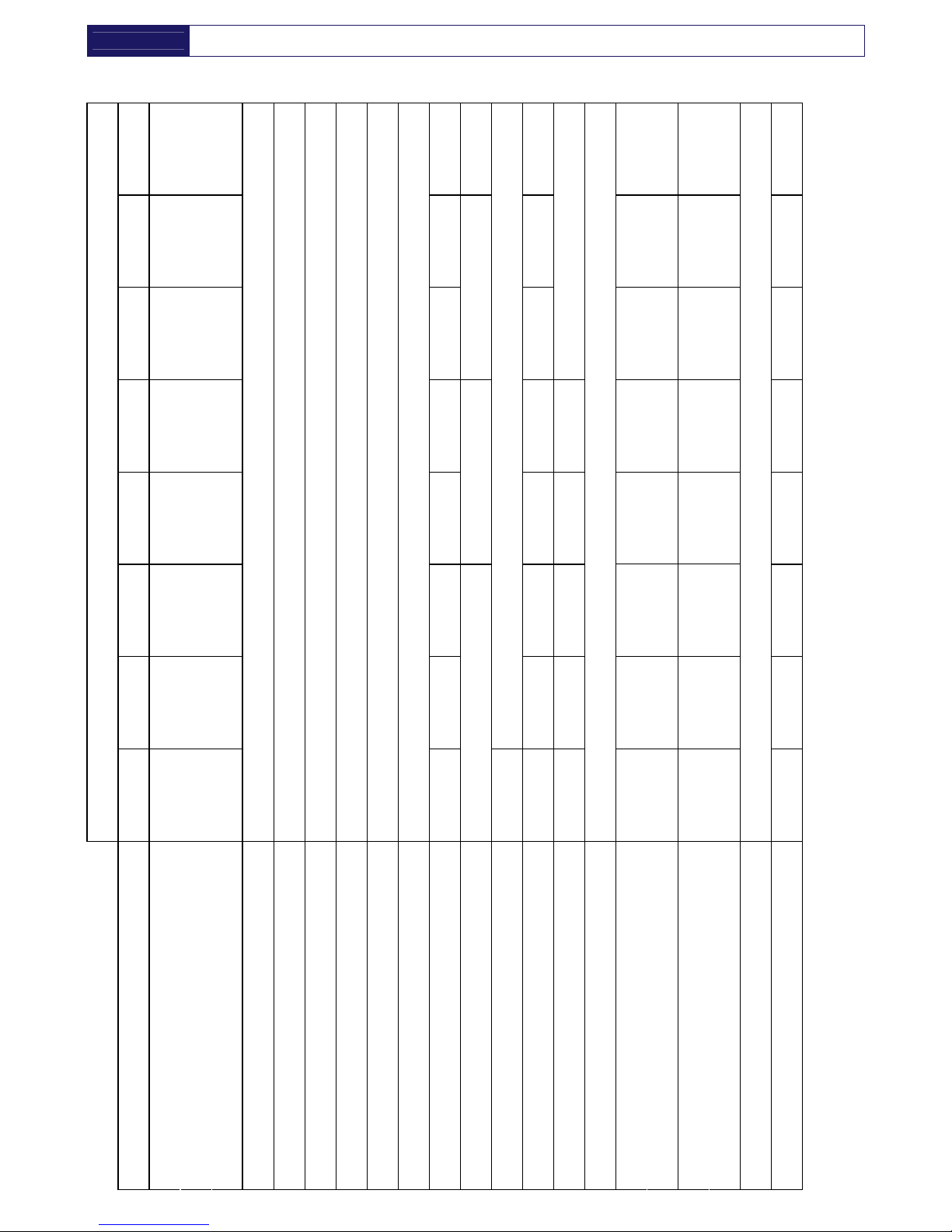

4.1. TECHNICAL SPECIFICATIONS AMD 3-25 / 230V / 50-60 HZ

25

2500

150

88

14

0.24

G 1”

0.33

390 (460)

2.4 (2.5)

610 (670)

3.3 (3.4)

34

18

1800

108

64

0.32

0.30

290 (330)

1.9 (2.0)

390 (460)

2.2 (2.5)

32

12

1200

72

42

0.14

0.25

300

210 (250)

1.4 (1.5)

280 (340)

1.7 (1.8)

28

9

950

57

34

0.09

0.22

190 (210)

1.3 (1.3)

270 (290)

1.5 (1.6)

26

6

600

36

21

0.04

G 1/2”

160 (190)

1.1 (1.2)

200 (250)

1.2 (1.4)

25

Air-Cooled

3

350

21

12

+5

equal to

0.85 g/m

3

di H

2

O

+25 (+45)

+1

+35 (+55)

7

16

0.15

G 3/8”

R134.a

0.20

200

1/230/50-60

150 (180)

1.1 (1.1)

170 (220)

1.2 (1.3)

< 70

21

[l/min]

[m

3

/h]

[scfm]

[°C]

[°C]

[°C]

[°C]

[barg]

[barg]

[bar]

[BSP-F]

[kg]

[m

3

/h]

[Ph/V/Hz]

[W]

[A]

[W]

[A]

[dbA]

[kg]

AMD MODEL

Air flow rate at nominal condition

1

Pressure DewPoint at nominal condition

1

Nominal ambient temperature (max.)

Min. ambient temperature

Nominal inlet air temperature (max.)

Nominal inlet air pressure

Max. inlet air pressure

Air pressure drop - p

Inlet - Outlet connections

Refrigerant type

Refrigerant quantity

2

Cooling air flow

Standard Power Supply

2

Nominal electric absorption 50Hz (60Hz)

Max. electric absorption 50Hz (60Hz)

Max. level noise at 1 m

Weight

1

The nominal condition refers to an ambient temperature of +25°C with inlet air at 7 barg and +35 °C.

2

Check the data shown on the identification plate.

----EN

ENEN

EN---- AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

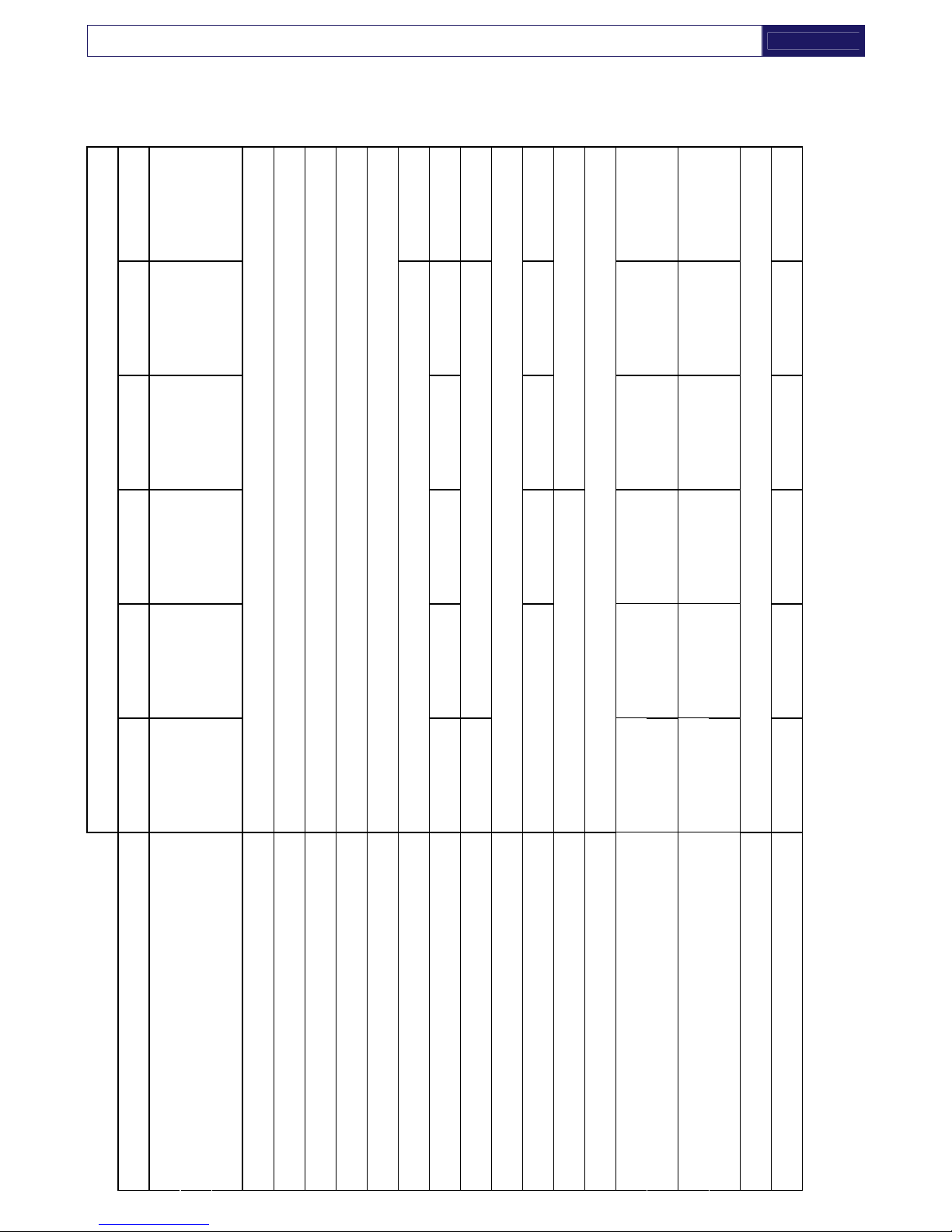

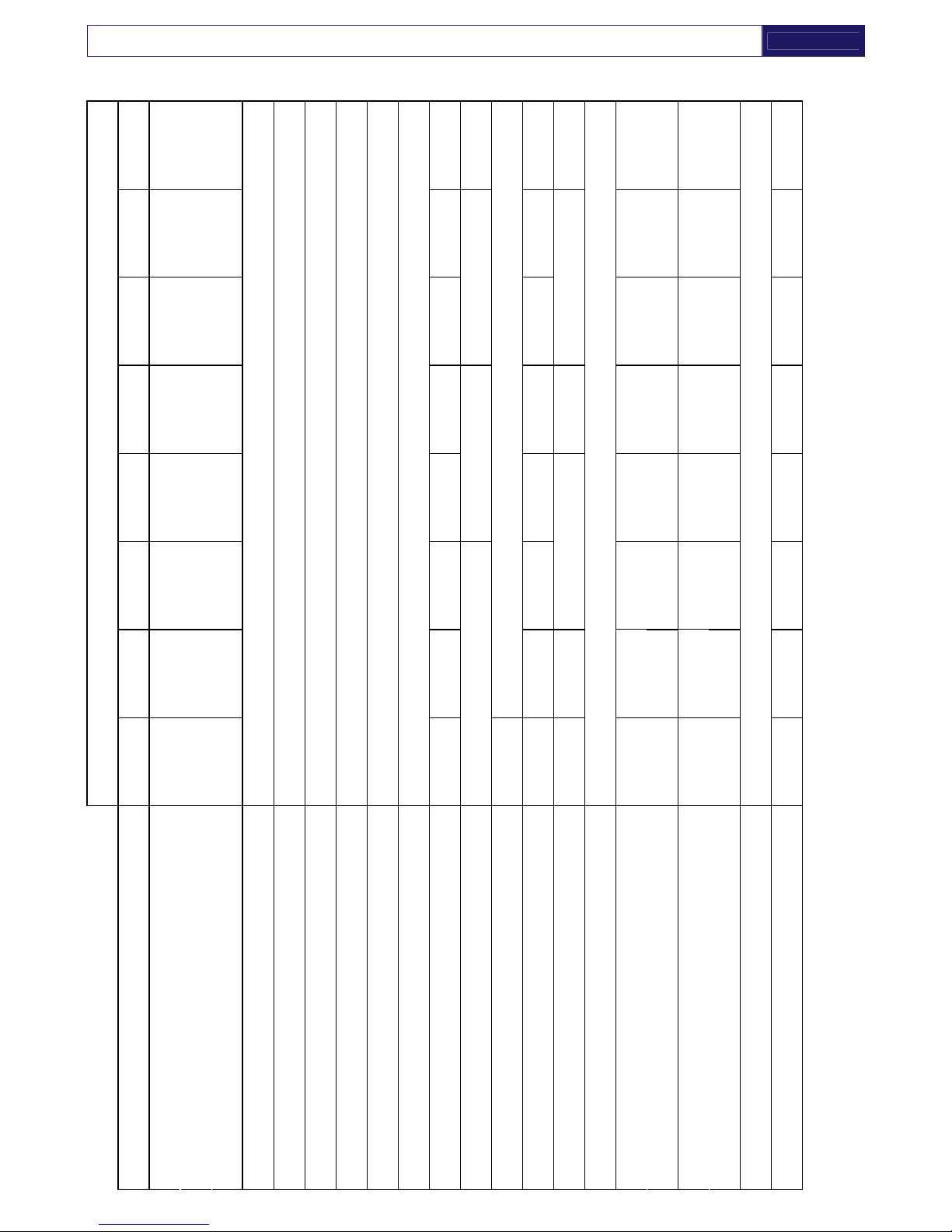

4.2. TECHNICAL SPECIFICATIONS AMD 32-168 / 230V / 50HZ

168

16800

1008

594

0.15

G 2.1/2”

1.90

1590

7.5

2350

11.3

144

130

13000

780

459

0.20

1.30

1550

7.4

2100

9.8

96

105

10500

630

371

0.14

G 2”

1.10

1900

940

4.3

1350

6.3

94

75

7500

450

265

0.25

0.70

450

740

3.6

1050

4.8

56

61

6100

366

216

0.19

G 1.1/2”

0.57

400

950

4.7

1400

6.8

54

52

5200

312

184

0.34

0.42

600

930

4.6

1350

6.6

41

43

4300

258

152

0.24

R404A

0.40

380

750

3.3

1150

5.4

40

Air-Cooled

32

3200

192

113

+5

equal to

0.85 g/m

3

di H

2

O

+25 (+45)

+1

+35 (+55)

7

14

0.16

G 1.1/4”

R134.a

0.44

350

1/230/50

480

2.9

700

3.8

< 70

39

[l/min]

[m

3

/h]

[scfm]

[°C]

[°C]

[°C]

[°C]

[barg]

[barg]

[bar]

[BSP-F]

[kg]

[m

3

/h]

[Ph/V/Hz

]

[W]

[A]

[W]

[A]

[dbA]

[kg]

AMD MODEL

Air flow rate at nominal condition

1

Pressure DewPoint at nominal condition

1

Nominal ambient temperature (max.)

Min. ambient temperature

Nominal inlet air temperature (max.)

Nominal inlet air pressure

Max. inlet air pressure

Air pressure drop - p

Inlet - Outlet connections

Refrigerant type

Refrigerant quantity

2

Cooling air flow

Standard Power Supply

2

Nominal electric absorption

Max. electric absorption

Max. level noise at 1 m

Weight

1

The nominal condition refers to an ambient temperature of +25°C with inlet air at 7 barg and +35 °C.

2

Check the data shown on the identification plate.

AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

----EN

ENEN

EN----

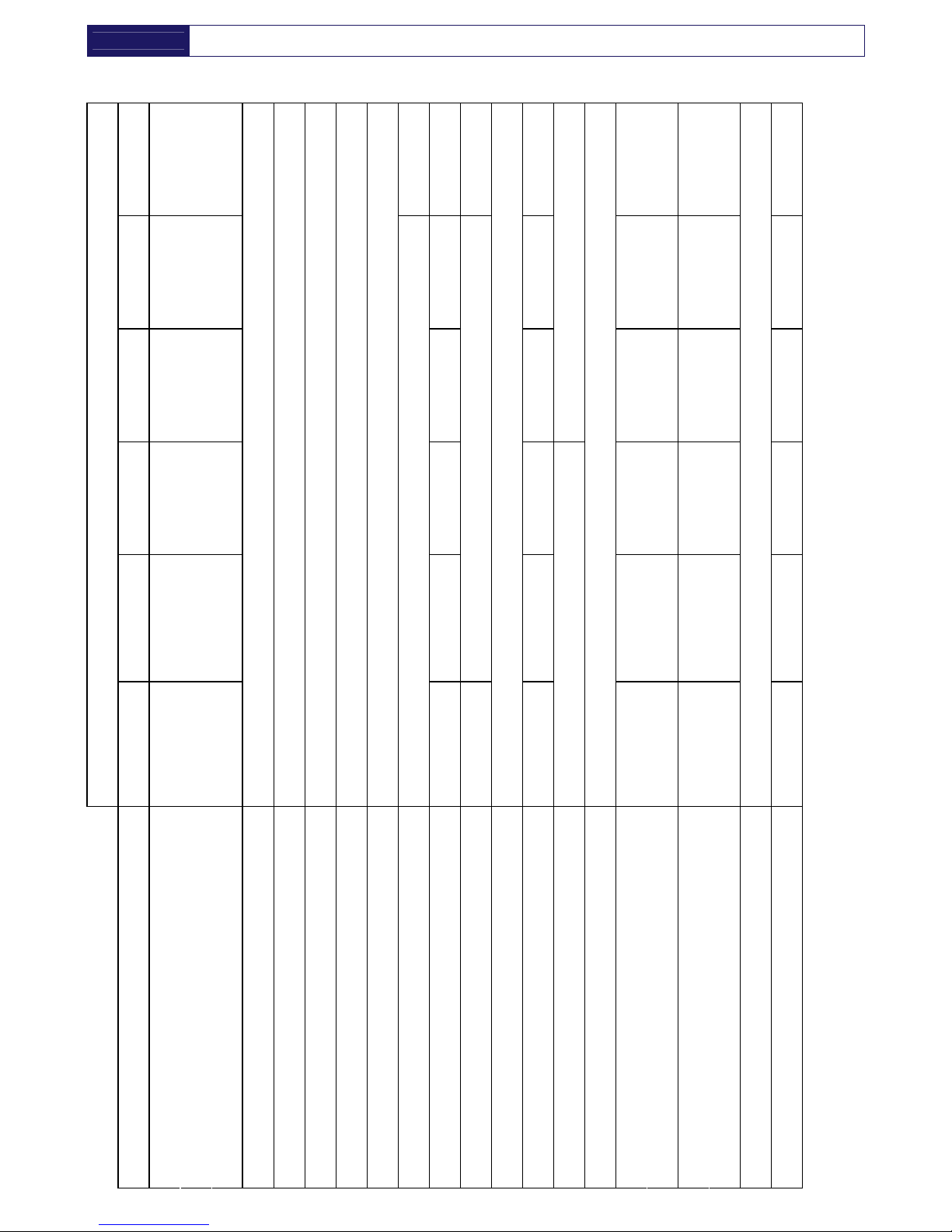

4.3. TECHNICAL SPECIFICATIONS AMD 32E-168E / 230V / 60 HZ

168E

16800

1008

594

0.15

G 2.1/2”

2.10

2600

2250

10.3

2950

14.5

144

130E

13000

780

459

0.20

1.40

2070

9.6

2890

13.2

96

105E

10500

630

371

0.14

G 2”

1.20

2400

1150

5.1

1550

7.2

94

75E

7500

450

265

0.25

0.85

900

910

4.1

1260

5.7

56

61E

6100

366

216

0.19

G 1.1/2”

0.68

1050

4.6

1460

6.6

54

52E

5200

312

184

0.34

0.47

600

1000

4.5

1400

6.2

45

43E

4300

258

152

0.24

R404A

0.45

380

970

4.4

1350

5.9

42

Air-Cooled

32E

3200

192

113

+5

equal to

0.85 g/m

3

di H

2

O

+25 (+45)

+1

+35 (+55)

7

14

0.16

G 1.1/4”

R134.a

0.44

350

1/230/60

630

3.8

720

4.3

< 70

39

[l/min]

[m

3

/h]

[scfm]

[°C]

[°C]

[°C]

[°C]

[barg]

[barg]

[bar]

[BSP-F]

[kg]

[m

3

/h]

[Ph/V/Hz]

[W]

[A]

[W]

[A]

[dbA]

[kg]

AMD MODEL

Air flow rate at nominal condition

1

Pressure DewPoint at nominal condition

1

Nominal ambient temperature (max.)

Min. ambient temperature

Nominal inlet air temperature (max.)

Nominal inlet air pressure

Max. inlet air pressure

Air pressure drop - p

Inlet - Outlet connections

Refrigerant type

Refrigerant quantity

2

Cooling air flow

Standard Power Supply

2

Nominal electric absorption

Max. electric absorption

Max. level noise at 1 m

Weight

1

The nominal condition refers to an ambient temperature of +25°C with inlet air at 7 barg and +35 °C.

2

Check the data shown on the identification plate.

----EN

ENEN

EN---- AMD 3

AMD 3AMD 3

AMD 3----168

168168

168

4.4. TECHNICAL SPECIFICATIONS AMD 3P-25P / 115V / 60 HZ

25P

2500

150

88

14

0.24

G 1”

0.33

490

5.1

650

6.0

34

18P

1800

108

64

0.32

0.30

420

3.5

460

3.9

32

12P

1200

72

42

0.14

0.25

300

280

3.0

320

3.5

28

9P

950

57

34

0.09

0.22

220

2.6

280

3.1

26

6P

600

36

21

0.04

G 1/2”

0.21

190

2.4

240

2.8

25

Air-Cooled

3P

350

21

12

+5

equal to

0.85 g/m

3

di H

2

O

+25 (+45)

+1

+35 (+55)

7

16

0.15

G 3/8”

R134.a

0.20

200

1/115/60

180

2.2

220

2.4

< 70

21

[l/min]

[m

3

/h]

[scfm]

[°C]

[°C]

[°C]

[°C]

[barg]

[barg]

[bar]

[BSP-F]

[kg]

[m

3

/h]

[Ph/V/Hz]

[W]

[A]

[W]

[A]

[dbA]

[kg]

AMD MODEL

Air flow rate at nominal condition

1

Pressure DewPoint at nominal condition

1

Nominal ambient temperature (max.)

Min. ambient temperature

Nominal inlet air temperature (max.)

Nominal inlet air pressure

Max. inlet air pressure

Air pressure drop - p

Inlet - Outlet connections

Refrigerant type

Refrigerant quantity

2

Cooling air flow

Standard Power Supply

2

Nominal electric absorption

Max. electric absorption

Max. level noise at 1 m

Weight

1

The nominal condition refers to an ambient temperature of +25°C with inlet air at 7 barg and +35 °C.

2

Check the data shown on the identification plate.

Loading...

Loading...