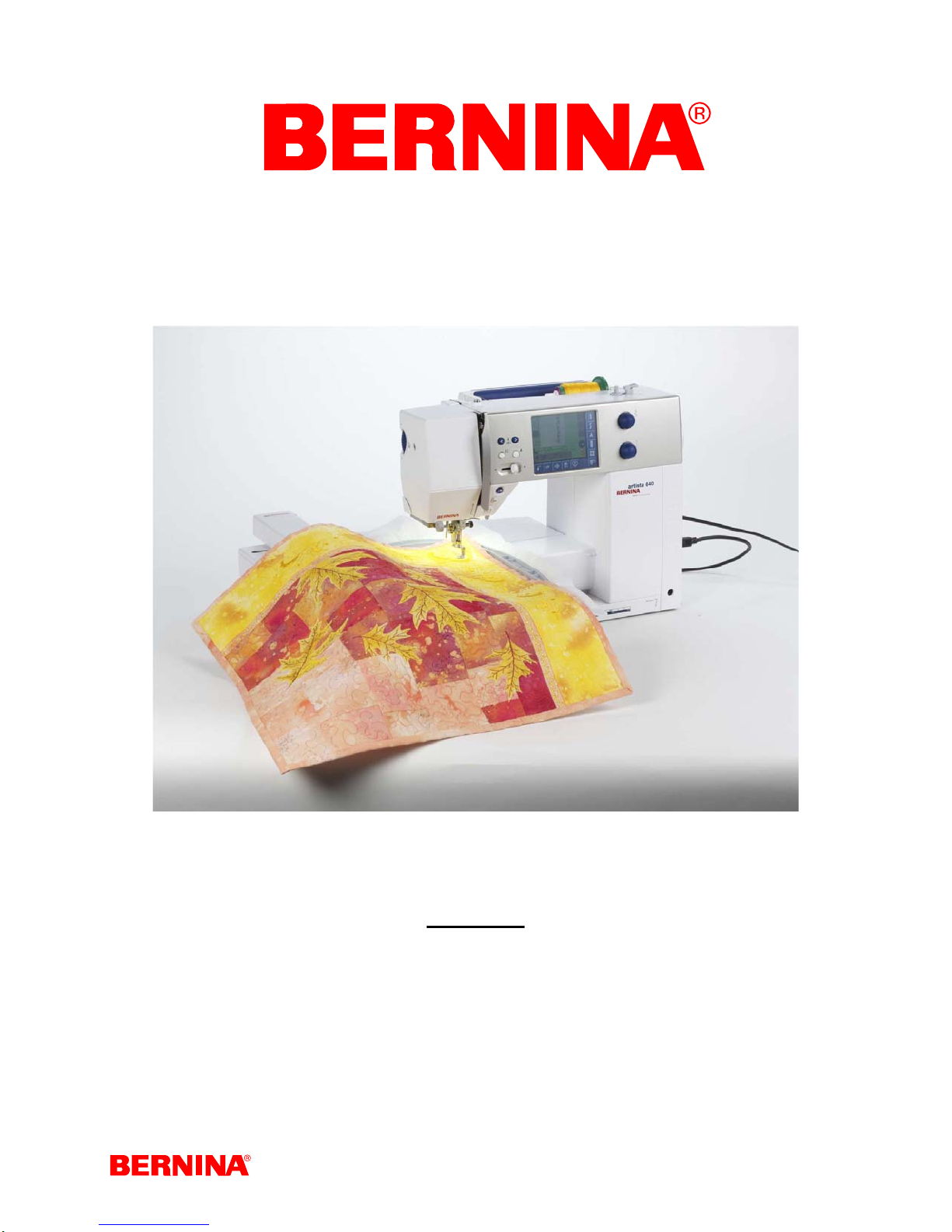

Fritz Gegauf Bernina artista 630, Bernina artista 640 Service Manual

Service Manual

© Fritz Gegauf Ltd.

BERNINA sewing machines

8266 Steckborn

Switzerland

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 1

artista 630-640

Version 4

Chapter 1

General information

1.1 Safety Regulations

Caution!

All electrical and electronic components operate at dangerous voltages. Remov e the mains plug

before making any adjustments to the machine. Wait about 30 seconds after removing the plug

(capacitor discharge).

This service manual is intended to help with minor repairs and adjustments.

The instructions do not claim to be complete or comprehensive. The manual does not provide guidance

for complete assembly or disassembly.

Important:

To enable the work described to be performed correctly, the se wing and embroidery computer

must be in good mechanical and electrical condition (running smoothly, properly oiled and all

leads connected)! When adjustments are carried out in the correct order, the sewing/embroidery

computer will function without a problem.

It is important that only devices approved and distributed by BERNINA® are connected to the

sewing/embroidery computer ports.

When servicing or repairing, always use genuine parts and original accessories, either those

delivered with the machine or purchased afterwards.

These are the following:

• Mains cable

• Foot control unit

• Buttonhole foot

• Presser foot 1

• Bobbin case with bobbin

• Other accessories

• BERNINA stitch length regulator (BSR) foot (if applicable).

The Service Manual and Instructions are protected by copyright laws. These documents are

delivered exclusively to the recipient. It is forbidden to copy, distribute, forward, publish or to

reproduce them in any form without the express prior consent of Fritz Gegauf AG, BERNINA

Steckborn, Switzerland. It is also forbidden to record this Service Manual and Instructions on any

retrieval system, or to translate it, or parts of it, into any human or computer-related language of

any kind, whether electronically, mechanically, magnetically , or otherwise. Furthermore, it is

prohibited to disclose the Service Manual and Instructions to third parties without the express

written approval of Fritz Gegauf AG, BERNINA Sewing machine manufacturers, Steckborn,

Switzerland.

This Manual is subject to revisions without notice. The recipient is responsible for updating the

information provided by Fritz Gegauf AG, BERNINA Sewing machine manufacturers, Steckborn,

Switzerland.

Masthead

Author: Hans Peter Horn

Layout/typesetting: Hans Peter Horn

Print:

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 2

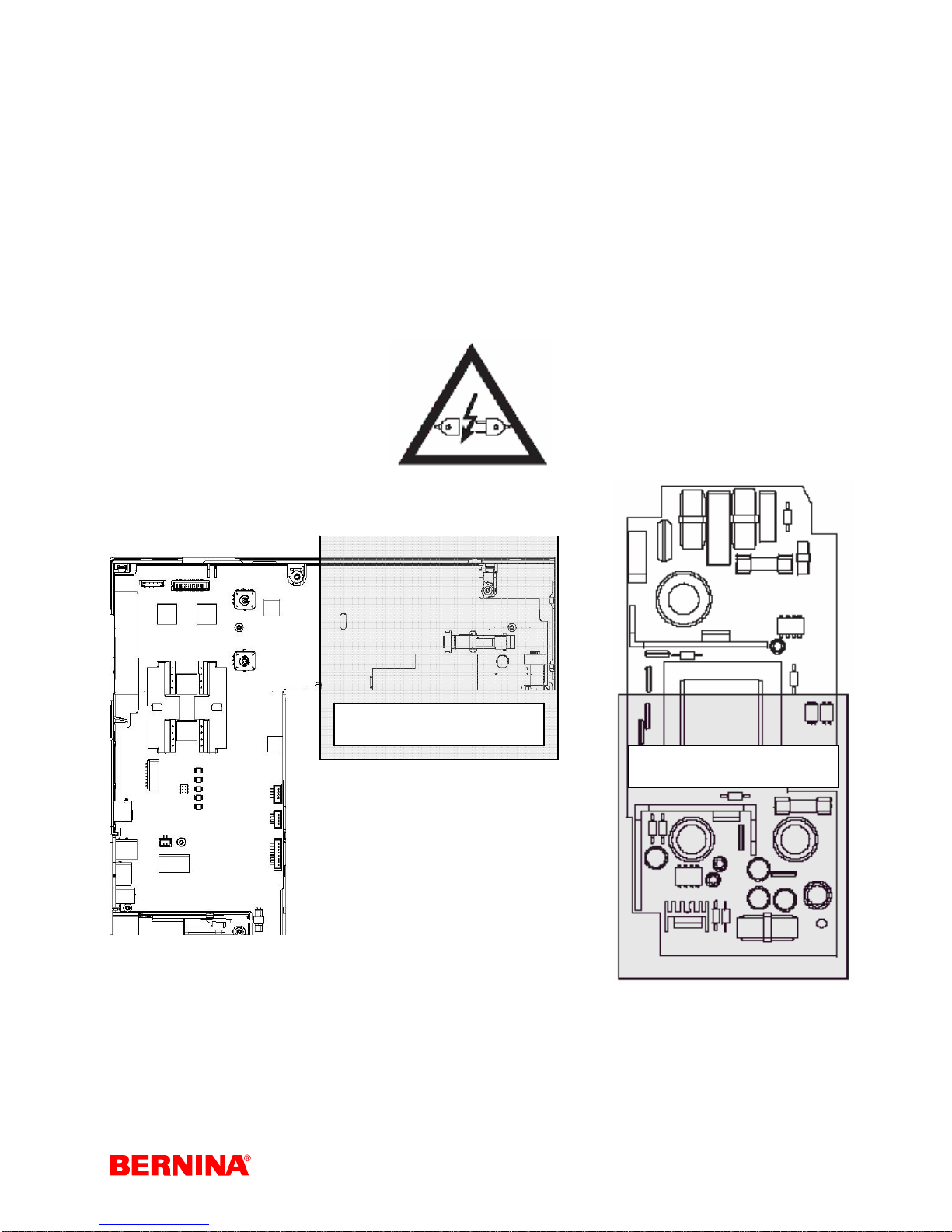

1.2 Warning: Dangerous voltage levels!

Caution!

The L-Print power circuitry, the S-Print CFL voltage supply and the mains cable all carry dangerous

voltages.

For your own safety do not touch the L-Print and S-Print until about 30 seconds after the main voltage has

been switched off. This is the time required for the capacitors to discharge.

Warning!

The sewing/embroidery computer may only be connected to the mains supply when the chassis covers

are mounted. Work on the L-Print, S-Print and mains cable may only be carried out when the mains plug

has been removed from the mains supply.

Caution! High voltage!

Caution! High voltage!

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 3

1.3 Contents

Chapter 1 General information.........................2

1.1 Safety Regulations.....................................2

1.2 Warning: Dangerous voltage levels!..........3

1.3 Contents.....................................................4

1.4 Note on Electrostatic Discharge (ESD)......6

1.5 Tools and gauges.......................................7

Chapter 2 Description of technical details

and electronics ...................................................9

2.1 BERNINA artista 630/640 technical

specifications....................................................9

2.2 Cleaning...................................................10

2.3 Block diagram ..........................................11

2.4 PCBs, plugs and cables...........................12

2.5 General functions of the PCBs.................16

Chapter 3 Functional check and diagnostic

instructions.......................................................18

3.1 Functional check ......................................18

3.2 Diagnostic instructions.............................18

3.3 Sewing-off (a-640 must be sewn-off with

the head cover fitted (light will affect the

threader sensor).............................................19

3.4 External cleaning......................................19

Chapter 4 Replacing Assemblies....................20

4.1 Removing covers .....................................20

4.2 Thread pre-tensioner................................21

4.3 Vertical spool pin......................................22

4.4 Horizontal spool pin and rear thread-guide

eyelet..............................................................22

4.5 Carrying handle........................................23

4.6 Magnifying-glass holder and thread cutter24

4.7 S-Print, keypads, front panel, RET-Print,

touch screen, display and side cover (plugs).25

4.8 P-Print ......................................................27

4.9 L-Print.......................................................28

4.10 CFL.........................................................29

4.11 Presser foot lifter sensor (micro switch).29

4.12 Buttonhole sensor PCB..........................31

4.13 Main motor (complete unit only).............31

4.14 Stitch width stepping motor....................32

4.15 Stepping motor, stitch length and

crankshaft.......................................................33

4.16 Presser foot pressure sensor.................34

4.16 Presser foot pressure sensor.................35

4.17 Winder motor..........................................35

4.18 Base shaft ..............................................36

4.19 artista 630 hook race ring.......................38

4.20 artista 640 stitch plate holder.................39

4.21 Rotary hook (RH), cutting blade and hook

drive belt in artista 640...................................40

4.22 Drive belt (synchronization of main and

base shaft)......................................................41

4.23 artista 630 upper thread tension............41

4.24 artista 640 upper thread tension............42

4.25 Thread take-up lever, thread take-up lever

crank, needle bar and link piece ....................43

Chapter 5 Adjustments...................................44

5.1 Tensioning the drive belt..........................44

5.2 Tensioning the base shaft belt.................44

5.3 artista 640 hook drive belt tension...........45

5.4 Bobbin winder..........................................45

5.5 Position of the head frame plate..............46

5.6 Presser foot fixation.................................46

5.7 Presser foot height...................................47

5.8 Darning foot height ..................................47

5.9 Straight stitch needle position (needle

distribution) ....................................................48

5.10 Stitch width limiter..................................48

5.11 Thread guide plate plate adjustment on

artista 630......................................................49

5.12 Position of driver in hook race of

artista 630......................................................49

5.13 Thread passage on artista 630..............49

5.14 Bobbin case retainer position on

artista 640......................................................50

5.15 artista 630 CB hook, synchronization,

feed and needle drive....................................51

5.16 artista 640 RH hook, synchronization,

feed and needle drive....................................53

5.17 Needle/hook distance............................54

5.17 Needle/hook distance............................55

5.18 artista 630 needle height .......................56

5.19 artista 640 needle height .......................56

5.20 Threader ................................................57

5.21 Feed-dog position in stitch plate............57

5.22 Feed-dog height.....................................58

5.23 Position of synchronizing disc (rough-

adjustment)....................................................59

5.24 Basic balance setting.............................59

5.25 Basic presser foot lifter setting

(Free Hand System (FHS))............................61

5.26 Thread tension release..........................62

5.27 Basting and long stitch device

artista 640......................................................62

5.27 Basting and long stitch device

artista 640......................................................63

5.28 artista 630 CB hook lower thread tension

(basic setting).................................................64

artista 640 RH hook lower thread tension

(basic setting).................................................64

5.29 artista 630 upper thread tension (basic

setting)...........................................................65

5.30 artista 640 upper thread tension (basic

setting)...........................................................65

5.31 Thread regulator spring .........................66

Chapter 6 Service Program............................67

6.1 Starting the test program.........................67

6.2 Virtual keyboard.......................................69

6.3 Menu 1 – Service information..................70

1a Sewing/embroidery computer basic data:

...................................................................70

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 4

1b Sewing/embroidery computer soft- and

firmware data:............................................71

1c Sewing/embroidery computer operating

time data....................................................71

1d Sewing/embroidery computer stitch

counter data:..............................................72

1e BSR (BERNINA Stitch Regulator) data:72

1f Sewing/Embroidery computer servicing

data:...........................................................72

1g Saving of customer data.......................73

1h Customer data: .....................................73

1i Dealer data:............................................73

1j Log file....................................................74

6.4 Menu 2 – screen and beeper..................74

2a Touch screen calibration:......................74

2b LCD (screen):........................................75

2c Blank black LCD (screen): ....................75

2d Blank white LCD (screen):....................75

2e Speaker test:.........................................76

6.5 Menu 3 – Signals and sensors.................76

3a Stitch width and stitch length adjusting

knobs functions..........................................76

3b Functioning of keyboard: ......................76

3c Start/stop unit (SSU) slide control:........77

3d & 3d1 Foot control: ...............................77

3f Presser foot pressure sensor:................78

3g Presser foot lifter micro switch:.............78

3h Winder motor micro switch: ..................78

3i Feed-dog drop light barrier: ...................79

3j artista 640 lower thread indicator:..........79

3k Upper thread indicator: .........................79

3l BERNINA Stitch Regulator (BSR) foot: .80

3m Buttonhole signals A & B.....................80

3n Positioning PCB (P-Print): ....................81

3n Mechanical fine-adjusting of P-Print:....81

3q USB host interface:...............................82

3s EMB interface:.......................................82

3t Foot control interface:............................82

3u BSR foot interface:................................83

6.6 Menu 4 – Motor functions.........................83

4a Stitch length stepping motor:................83

4b Stitch width stepping motor:..................84

4c artista 640 upper thread tension stepping

motor:.........................................................84

4d All stepping motors:..............................84

4f Stitches per minute (SPM) calibration:..85

4g Standard SPM (stitches per minute)

speed:........................................................86

4h Calibrating the SSU (Start/stop unit):...86

4i Standard SSU speed:............................86

4j Automatic start/stop:..............................87

4k Winder motor:.......................................87

4l Basting magnet: artista 640...................87

4m Thread cutter clamping magnet:

artista 640..................................................88

4n Thread cutting process: artista 640......88

6.7 Menu 5 – Adjustments.............................89

5a Sewing-off (customer’s view): ..............89

5b Electronic balance calibration:..............90

5b Mechanical balance fine-adjusting:......90

5b Mechanical balance fine-adjusting:......91

5b Electronic balance fine-adjusting:.........91

5c Buttonhole calibration:..........................92

5e Presser foot pressure sensor calibration

(end stops):................................................92

5f Electronic upper thread tension:

artista 640..................................................93

5g BERNINA Stitch Regulator (BSR) foot

sewing program:........................................93

5h BSR foot update:..................................94

5i Resetting artista 640 upper thread tension

to default....................................................94

5j Resetting to factory settings (Reset All):94

6.8 Menu 6 – Embroidery module (EMB)......95

6a Embroidery module basic data:............95

6b Free-arm adapter sensor:.....................96

6c X-axis sensor:.......................................97

6d Y-axis sensor:.......................................97

6e X- and Y-movement of stepping

motors:.......................................................98

6f Movement of stepping motor X: ............98

6g Movement of stepping motor Y: ...........98

6h Hoop reference position: ......................99

6i Embroidering using the test design:......99

6j Customer’s embroidery view:..............101

Chapter 7 Updating.......................................101

7.1 Updating of sewing/embroidery

computer......................................................101

7.2 BSR update............................................102

5h BSR foot update:................................102

7.3 Update – alternative access ..................103

8. Chapter Lubrication Plan .........................104

8.1 Lubrication Plan artista 630...................104

8.2 Lubrication Plan artista 640 supplementary

to artista 630................................................105

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 5

1.4 Note on Electrostatic Discharge (ESD)

Electrostatic charges are caused by:

• a person's walking (influence) over synthetic tilled or carpeted floor

• friction between and separation of two insulating materials (triboelectricity)

If this static electricity discharges through electronic components, these may be

partially or irreparably damaged. Electrostatically charged persons represent the

greatest danger for components. This can be dissipated by controlled electrostatic

discharge.

Protection of electrical and electronic components against electrostatic

discharges

Be sure to follow these important guidelines:

1. Always work at a stationary, ESD-compliant workstation equipped with the appropriate protective

devices including conductive table and floor mat, earth connection box and earthing wristband when doing

service work.

The cable of the earthing wristband must have a built-in resistance of 1 M ohm to ensure p rotection.

2. Always put on an earthing wristband before starting to work. Always remove any synthetic parts like

plastic bags, covers etc. from your workstation.

3. Only open ESD protective packaging at your ESD-proof workstation while wearing an earthing

wristband. Electronic components must be placed on conductive table mats only. Packing is carried out

under the same conditions.

4. Only use conductive plastic/foil pouches and ESD transport boxes for dispatching electronic

components – even if the components might be faulty.

5. Treat faulty PCBs the same as good ones to prevent addition harm.

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 6

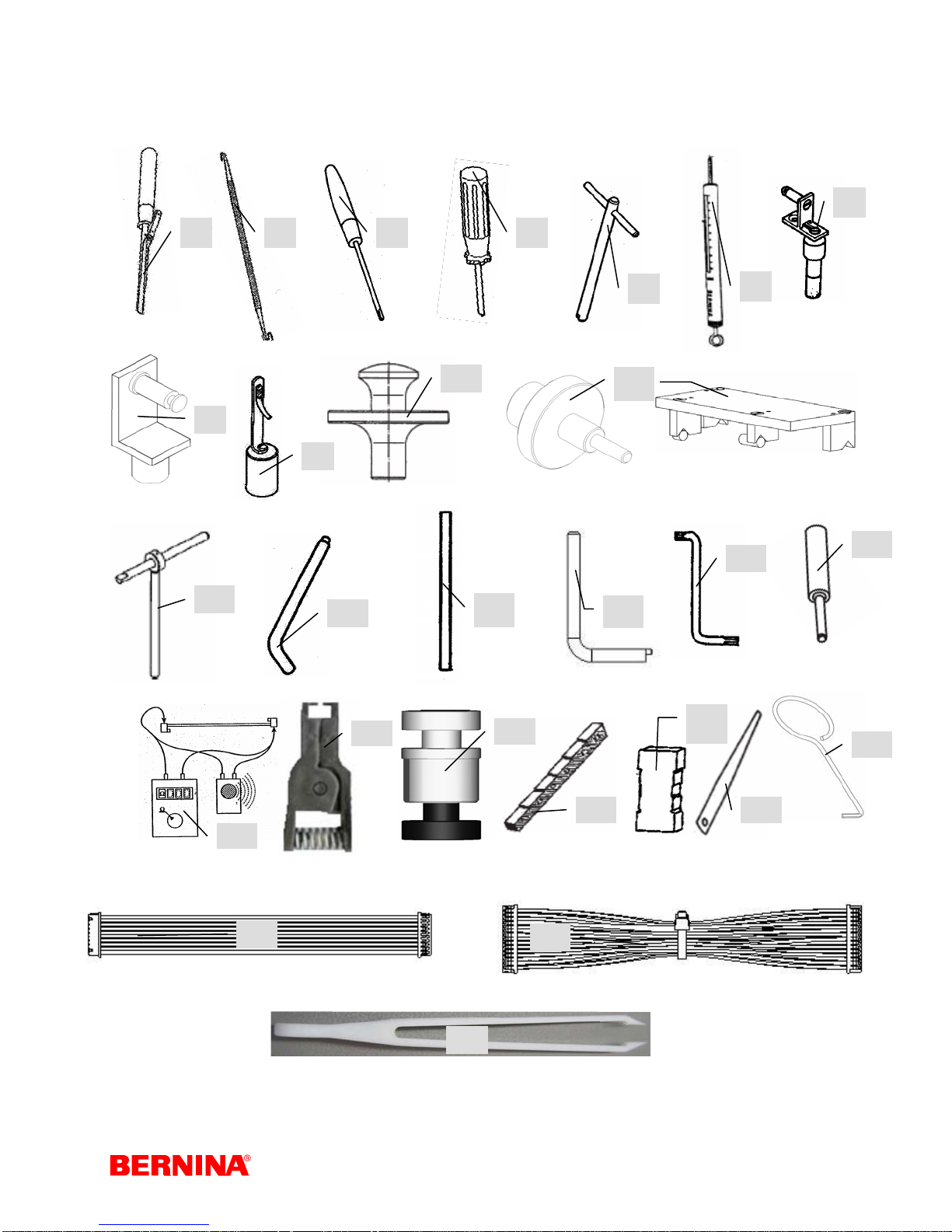

1.5 Tools and gauges

Required tools and gauges (commercially available, not available from BERNINA): Multimeter, ICExtraction tool and TORX screw driver sizes: No. 6, 8, 9, 10, 12, 15, 20, and 25.

1 2 3 4

7

8

12

9

13

19

10

14

20

15

11

5

6

17

16

22

24

18

25

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 7

27

26

21

23

No. Part number Description No. Part number Description

398 083 030 Circlip mounting tool

1

398 112 030 Spring mounting tool

2

398 097 030 Rectifying tool bobbin case

3

spring

001 361.70.00 Eccentric key

4

001 357.70.00 Rectifying tool driver/hook

5

play

006 038.50.00 Spring balance gauge

6

001 358.70.00 Lower thread tension CB

7

006 543.70.01 Lower thread tension RH

8

398 080 040 Upper thread tension

9

006 765.71.00 Hook race gauge CB

10

032 051.70.00 Centering gauge 640

11

Parallel setting gauge (Set)

030 349.70.00 Pinning tool short (Set)

12

030 430.51.00 Pinning tool

12

001 356.50.00 Angular pinning tool

13

007 937.50.00 Pinning tool base shaft

14

031 563.50.00 Eccentric key head frame

15

007 993.50.00 Angular key Torx 8

16

030 883.50.00 Distance gauge for auto

17

threader

Commercially

18

available

Commercially

19

available

031 939.70.00 Bobbin winder gauge

20

398 031 133 Presser foot height

21

398 024 030 Feed-dog height

22

398 022 030 Feeler gauge 0,3 mm

22

398 111 030 Feeler gauge 0,15 mm

23

030 652.50.00 Pinning tool for Stepp motor

24

023 054.50.01 Service cable 50mm 10 pol.

25

031 134.50.01 Service cable 50mm 30 pol.

26

Commercially

27

available

031 950.70.00 BERNINA USB Stick 64MB

Digital Multimeter

IC-Extraction tool (EEPROM)

SL

Composite Tweezers

(disconnecting cables)

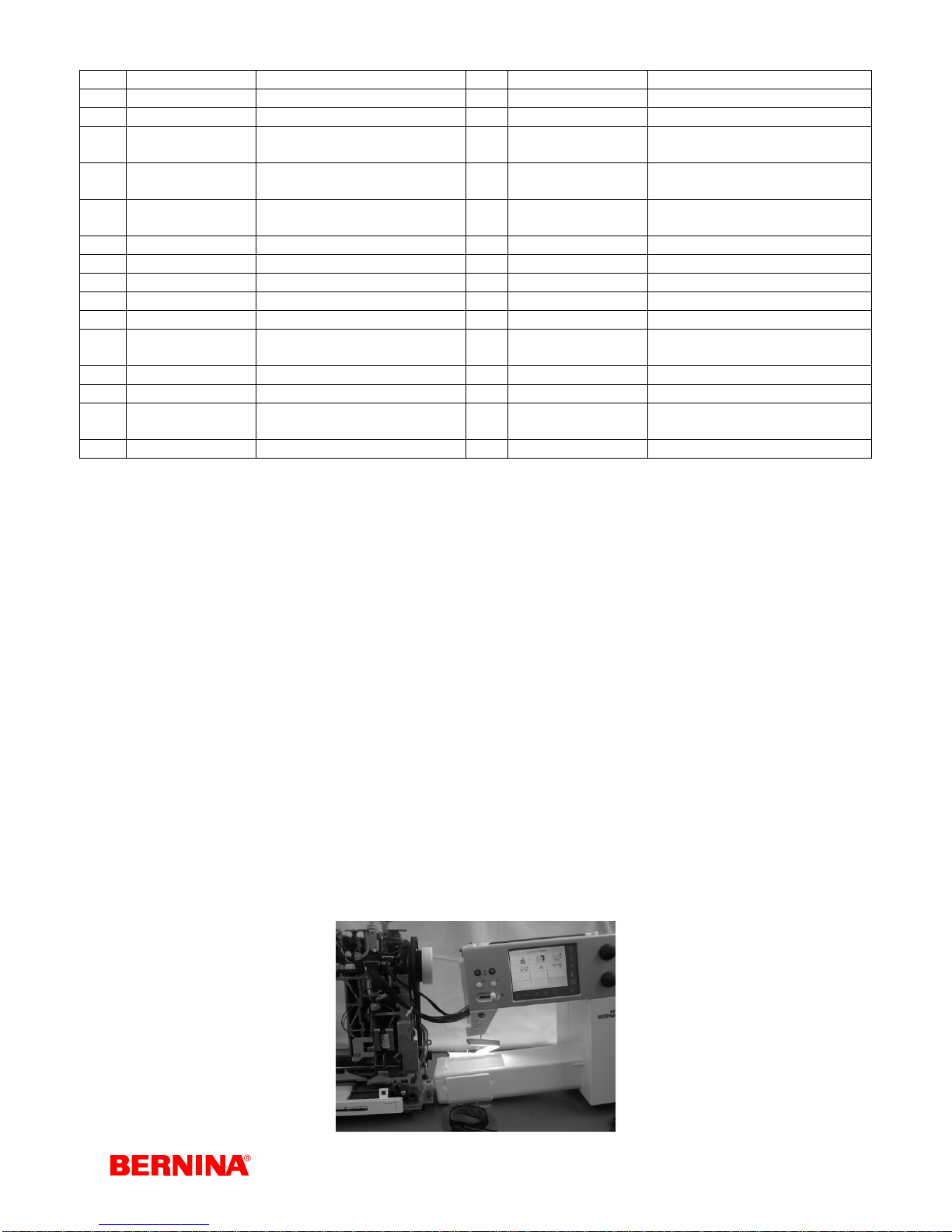

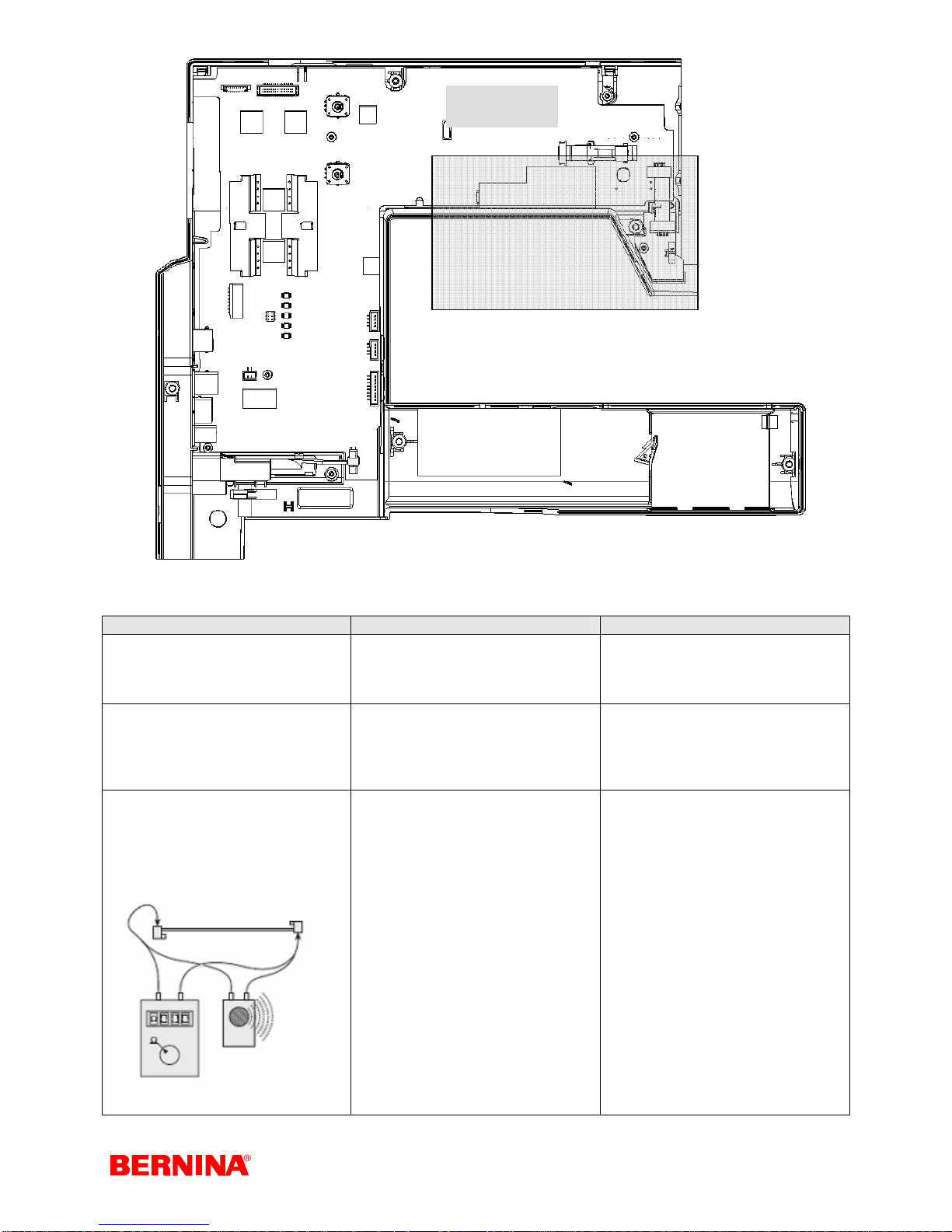

1.6 Where and how to use the service cables # 25 and 26

Where to use:

• In order to have the artista 630 and 640 machines under power whilst the covers have been taken

off, it is necessary to use the service cables 023 054.50.01 (50mm 10 pole) and 031 134.50.01

(50mm 30 pole).

How to use:

1. Observe ESD regulations (page 6).

2. Remove the power cord

3. Remove the covers (pages XXXX). The removed covers must be placed on the ESD mat.

4. Attach the service cables very carefully (straight) to the S-Print and P-Print. The artista 630 only

needs the 30 pole cable. The artista 640 needs also the 10 pole cable.

5. Attach an external CFL sewing light to the S-Print.

Note: Without the CFL sewing attached, the screen will not have any background lighting!

6. Fit the connection cable L-Print / S-Print.

7. Place both the back and front covers together and using the snapper clips, clip together.

8. When necessary the motor cable can also be connected.

9. Connect the power cable and switch the machine on. In order to get into the service program one

has to press the reverse button whilst switching on the machine.

Attention: Make sure that no cable is pinched, trapped or otherwise damaged.

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 8

Chapter 2

Description of technical details and electronics

2.1 BERNINA artista 630/640 technical specifications

Features artista 630 artista 640

Max. stitch length forward in mm...................5..............................................5

Increment in mm............................................0,15.........................................0,15

Max. stitch length reverse in mm...................5..............................................5

Stitch width in mm .........................................5,5...........................................9,0

Increment in mm............................................0,23.........................................0,23

Data interface................................................USB.........................................USB

Hook system..................................................BERNINA CB..........................BERNINA RH

Needle system...............................................130/705 H ..............................130/705 H

Adjusting needle............................................130/705H TCN 80...................130/705H TCN 80

Sideways motion ...........................................no............................................no

Feed-dog drop...............................................yes ..........................................yes

Feed-dog drop via FHS.................................yes ..........................................yes

Needle positions............................................11............................................11

Stitch programs:

Total number of buttonhole types..................7..............................................8

Buttonhole length measuring system............yes ..........................................yes

Quilting stitches.............................................25............................................28

Total number of utility stitches.......................26............................................26

Total number of decorative stitches ..............145..........................................189

Alphabets ......................................................4..............................................5

Eyelets...........................................................2..............................................2

Total number of stitch patterns......................250..........................................300

Functions:

Automatic basic settings................................yes ..........................................yes

Display of recommended optimum settings ..yes ..........................................yes

Display of selected stitch...............................on display................................on display

Clear (clr) button............................................yes ..........................................yes

Balance..........................................................electronically...........................electronically

Sideways mirroring........................................yes ..........................................yes

Permanent reverse sewing............................yes ..........................................yes

Memory (mem)..............................................yes ..........................................yes

Pattern end....................................................yes ..........................................yes

Securing at pattern beginning/ending............yes ..........................................yes

Upper thread indicator...................................yes ..........................................yes

Lower thread indicator...................................no............................................yes

BSR – BERNINA stitch length regulator........yes ..........................................yes

Integrated threader........................................yes ..........................................yes

Hopper mechanism .......................................yes ..........................................yes

Longstitch setting...........................................no............................................yes

Adjustable presser-foot pressure ..................yes ..........................................yes

Free Hand System (FHS) presser foot lifter..yes ..........................................yes

Automatic upper thread tension ....................no............................................yes

Automatic lower thread cutter........................no............................................yes

Operating controls

Screen ...........................................................graphic LCD............................graphic LCD

Colors ............................................................256..........................................256

Size in mm (inch)...........................................80x60 (3.2x2.4).......................80x60 (3.2x2.4)

Number of pixels............................................320x240..................................320x240

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 9

Features artista 630 artista 640

Screen backlighting.......................................yes/white.................................yes/white

Direct stitch/function selection.......................yes/touch screen.....................yes/touch screen

Stitch width bar display..................................yes ..........................................yes

Stitch length bar display ................................yes ..........................................yes

Integrated service program............................yes ..........................................yes

Drive/power unit

Universal power PCB (L-Print), 100-240 Voltyes ..........................................yes

Power max.....................................................100 W......................................100 W

Motor..............................................................DC/65W30V............................DC/65W30V

Sewing speed................................................100-900 S.p.M ........................100-900 S.p.M

Embroidery stitching speed ∅ .......................600 S.p.M................................600 S.p.M

Needle stop ...................................................yes ..........................................yes

Needle stop via foot control...........................yes ..........................................yes

Main power switch.........................................yes ..........................................yes

Mechanical data / housing

Diametral capacity in mm .............................190x110 /215..........................190x110 / 215

(inch)..............................................................(7.5x4.3 / 10.2)........................(7.5x4.3 / 10.2)

Overall length in mm (inch)............................385 (15)...................................385 (15)

Overall width in mm (inch).............................175 (7).....................................175 (7)

Overall height in mm (inch)............................308 (12)...................................308 (12)

Sewing light ..................................................CFL.........................................CFL

Presser foot level in mm................................7,5...........................................7,5

Weight in kg (without accessories) (lbs)........approx. 9.7 (approx. 21) .........approx. 9.7 (approx. 21)

2.2 Cleaning

Remove covers and clean.

Electrostatic charging may occur during cleaning. To prevent this, use antistatic office-equipment cleaning

agents.

We use and recommend BASF’s SURFACE CLEAN surface cleaner

It forms a protective film against static electricity, and is suitable for both plastic and metallic surfaces.

Inside parts

Dust, lint, thread and fabric remnants can accumulate inside the machine behi nd the covers and may lead

to malfunctions.

In the head frame area, this frequently occurs in particular in the thread take-up (joints), the main shaft

(behind the balance piece) and the thread tension device.

In the base area it occurs in:

The main and base shaft belts and their tension units can also be affected by the accumulation of dust,

lint, thread and fabric remnants, as well as by belt residue.

the bobbin case,

the feed-dog,

the hook,

the hook drive,

the hook race,

the base shaft (lift and advance eccentric),

and in the toothed rack.

Attention!

Never use alcohol,

petrol, spirits or any

corrosive fluids, or

abrasive pastes!

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 10

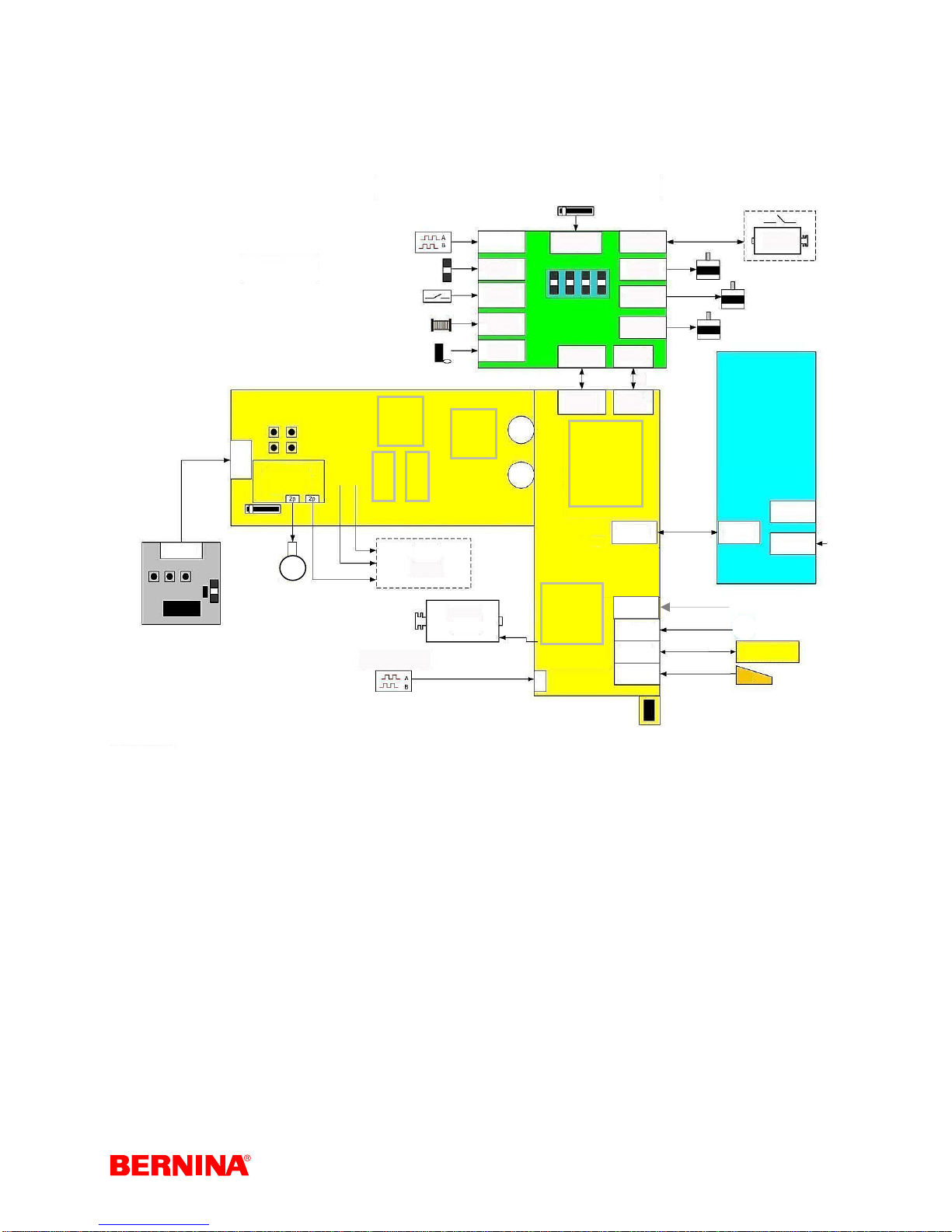

2.3 Block diagram

The electronics of the BERNINA artista 630/640 are primarily accommodated in three main modules

(PCBs) – the L-Print (power PCB), the P-Print (positioning PCB) and the S-Print (control via microprocessor).

S-Print

Upper Thread

Sensor

RET-

RETPrint

CFL Background

Light Converter

Sewing Light

Proce

ssor

S

Flash

D

R

A

M

LCD / Background-

Lighting

Touch Screen

Lower Thread Sensor

FPGA

Main Motor

30 V / DC

Buttonhole

Sensor

Threader

Sensor

Presser Foot

Sensor

Clamping

Magnet Sensor

BSR

Presser Foot

Pressure

P-Print

S-Print

P-Print

Motor Drivers

S-Print

Main Motor Drive

Stepping

Winder Motor

Motor SB

Motor SL

Motor SP

S-Print

P-Print

L-Print

USB Client

USB Host

EMB

Foot Control

Winder

Motor DC

Stitch width

Stitch length

Upper thread tension

L-Print

Mains Switch

S-Print

Foot Control Unit

Mains Plug

USB Stick

PC

EMB Module

Sensor Feed-Dog Drop

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 11

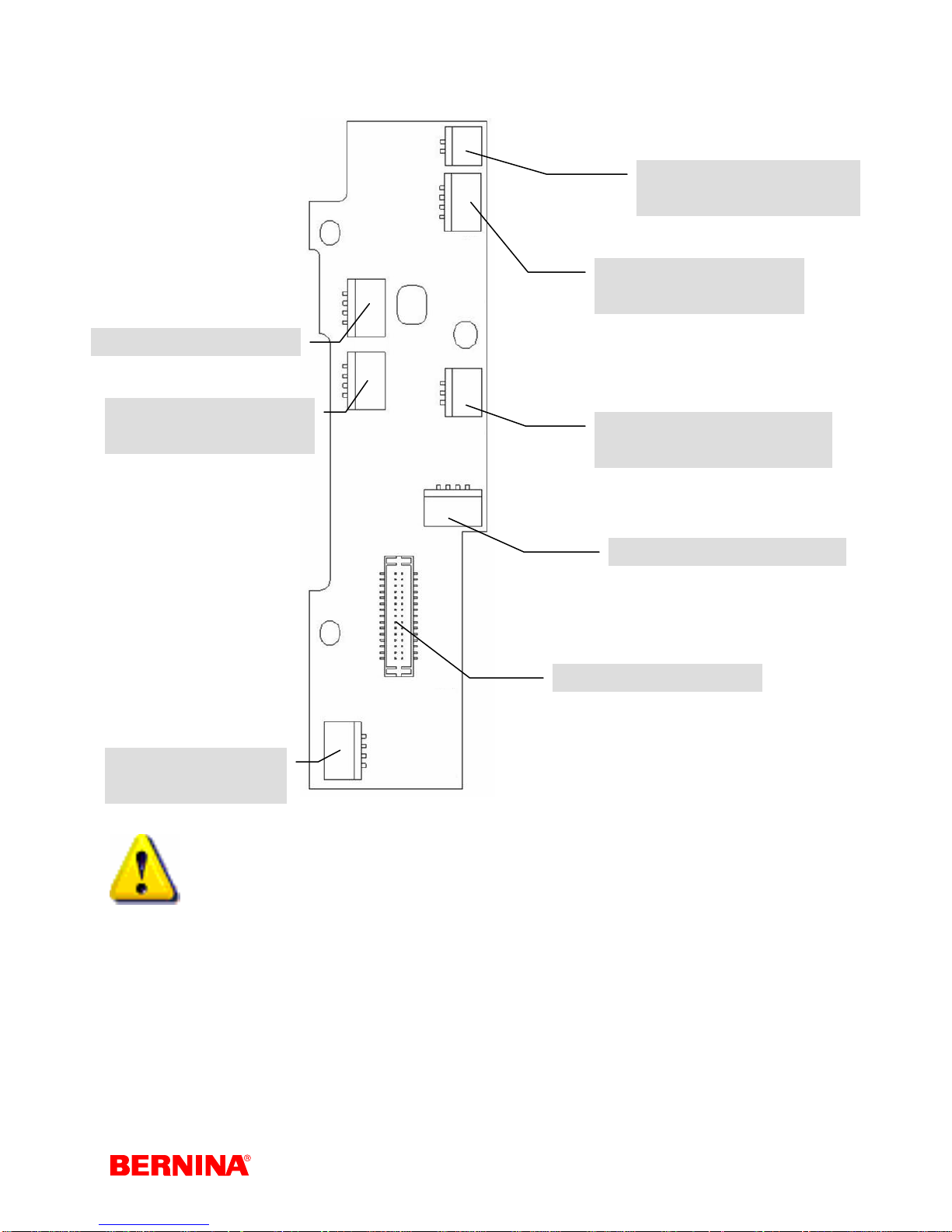

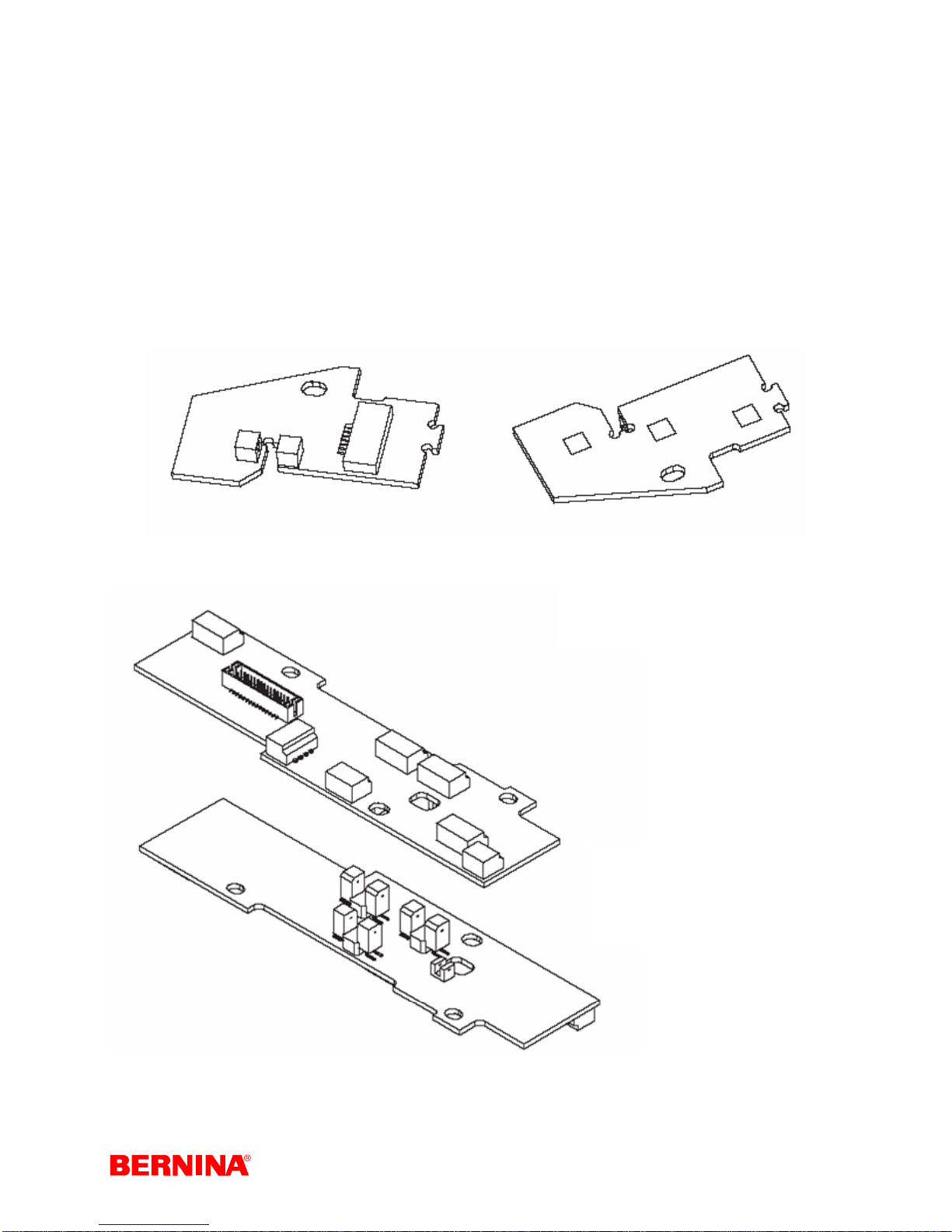

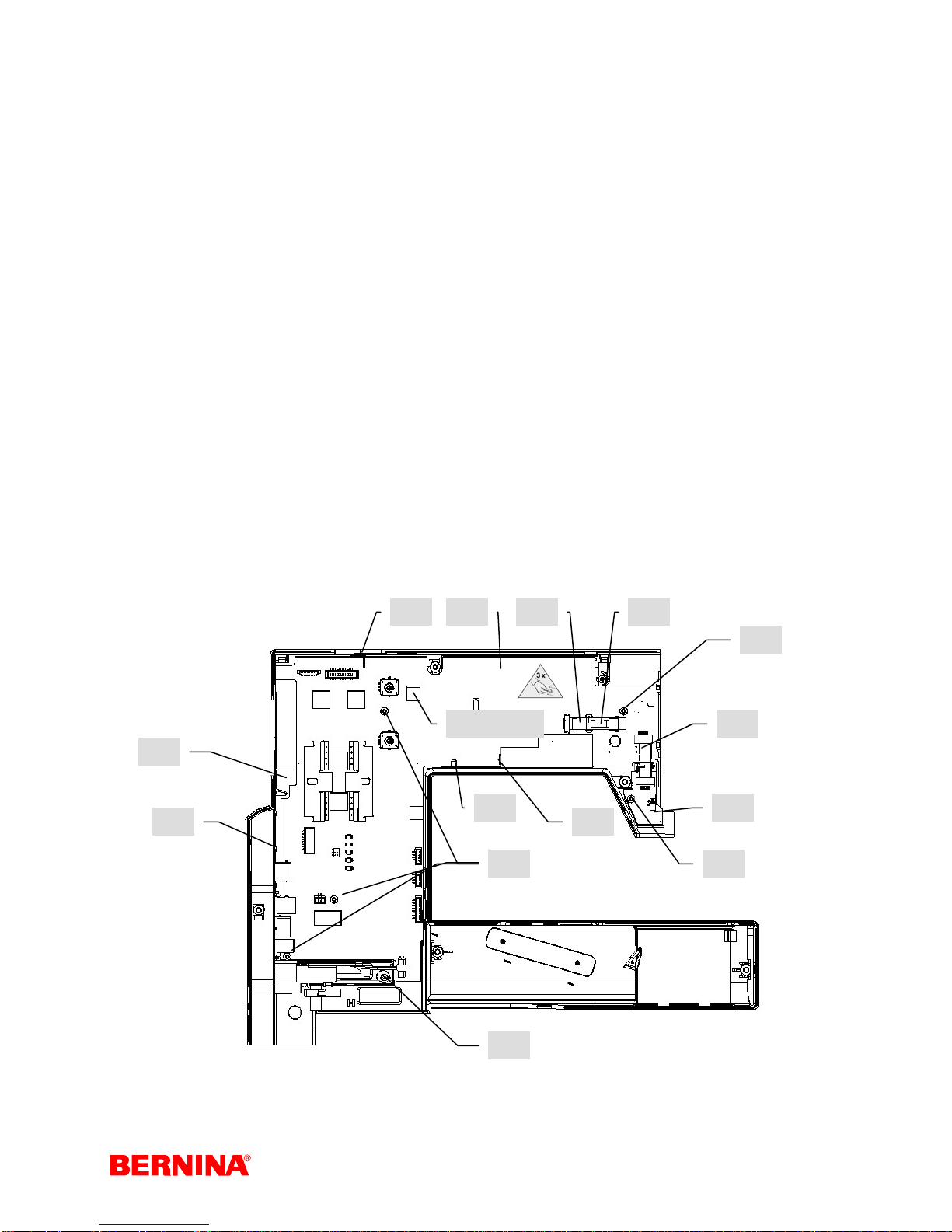

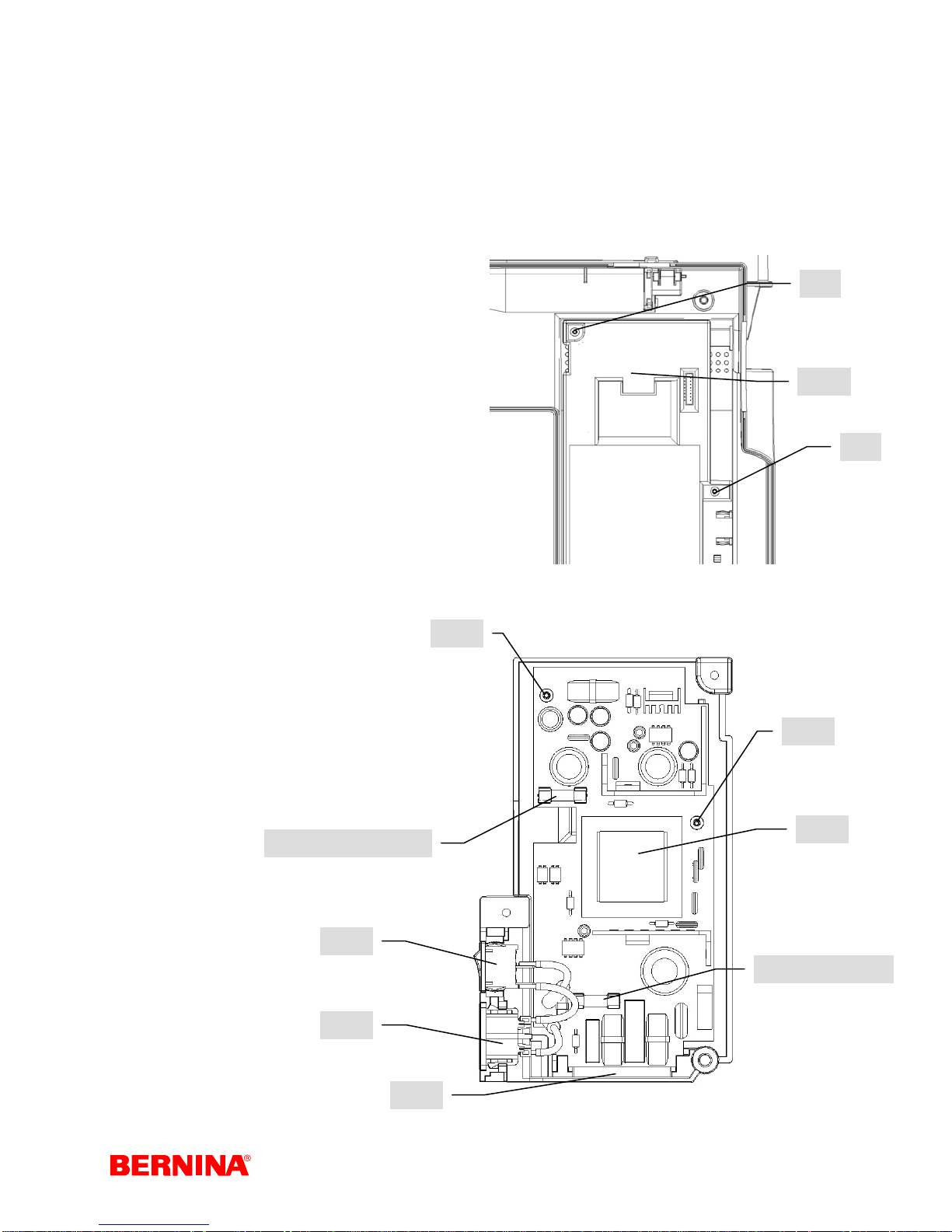

2.4 PCBs, plugs and cables

artista 640 positioning PCB

4 Pole Red = BSR sensor

4 Pole white = Buttonhole

sensor

5 Pole white = Threader

PCB and basting magnet

2 Pole black = Presser-foot

position micro switch

4 Pole white = Stitch width

stepping motor

4 Pole yellow = Upper thread

tension motor

3 Pole red = Presser foot

pressure control

2 Pole white = Clamp magnet

4 Pole yellow = Winder motor

30 Pole white = S-Print

4 Pole blue = Stitch

length stepping motor

10 Pole white = S-Print

Note:

Never connect or disconnect the connecting cables when the machine is powered!

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 12

artista 630 positioning PCB

4 Pole Red = BSR sensor

2 Pole black = Presser-foot

position micro switch

4 Pole white = Stitch width

stepping motor

4 Pole white = Buttonhole

sensor

4 Pole blue = Stitch

length stepping motor

3 Pole red = Presser foot

pressure control

4 Pole yellow = Winder motor

30 Pole white = S-Print

Note:

Never connect or disconnect the connecting cables when the machine is powered!

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 13

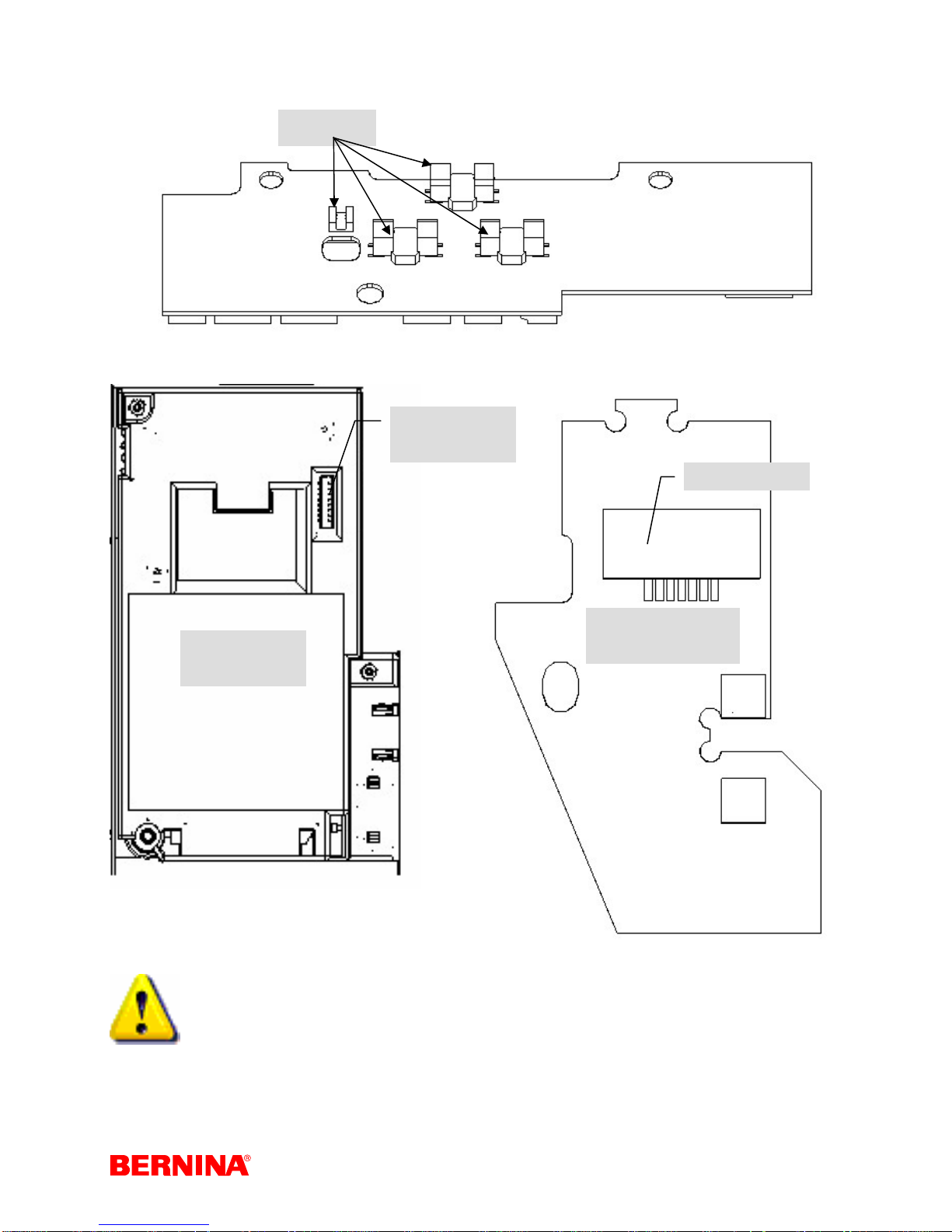

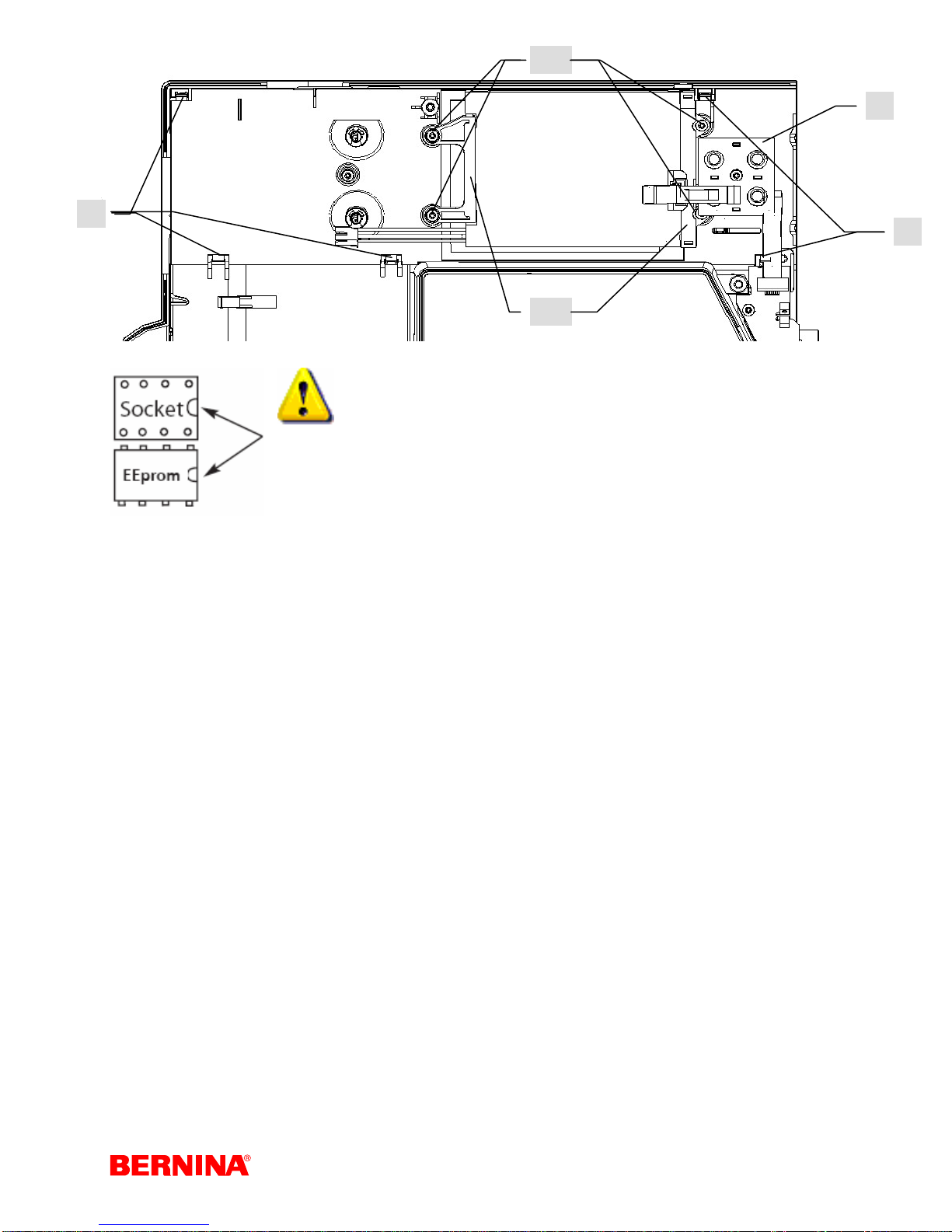

P-Print (artista 630 & 640) reverse side

Sensors

L-Print 8 pole

white

S-Print 7 pole

Ret-Print

L-Print

Upper thread

sensor

Note:

Never connect or disconnect the connecting cables when the machine is powered!

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 14

S-Print

Caution!

High voltage !

Ribbon cable function

What to Test What to adjust Desired status

Electrical resistance of cable

Visual check

Electronic measurement by

ohmmeter or continuity tester

(beeper)

Disconnect mains plug, remove

covers and unplug cables from

both printed circuits

Set measuring instrument to

beeper or Ohm area.

Check each cable wire.

This involves placing the

measuring tips on the top of the

connector against the metal

cutters to check each wire

against the other.

Check cables for damage, short

circuits, and line disconnections

Check plug and socket for

damage, bent or loose contacts

Each wire individually:

If the wire is OK:

• Ohm on the ohmmeter:

beep signal on beeper.

Defective wire:

Ohm on Ohmmeter: no beep

signal on beeper (interruption).

Each wire against the other

wires:

If the wire is OK:

Ohm on Ohmmeter: no beep

signal on beeper

Defective wire:

• Ohm on ohmmeter; beep

signal on beeper (short

circuit, squashed wires)

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 15

2.5 General functions of the PCBs

The microcomputer on the S-Print receives an analogue signal from the foot control which is converted

into a digital signal and reported as a nominal value. The motor r.p.m is adjusted to the required value by

comparison of the predetermined and actual values. When the foot control is released (nominal value

zero) the microcomputer switches on the electrical brake. The motor is stopped very quickly in the

required needle position.

On switching on the sewing/embroidery computer, the stepping motors may be in any given position. The

microcomputer control memory may also have any given value. The stepping motors are moved to their

pinning position by means of a command from the microcomputer to give a defined situation. This position

is then registered and set to zero in the memory. This zero position then allows any stitch program to be

selected and sewn.

The S-Print controls the processes between the individual stepping motors, evaluates the signals of the

sensor and shows the results on the display.

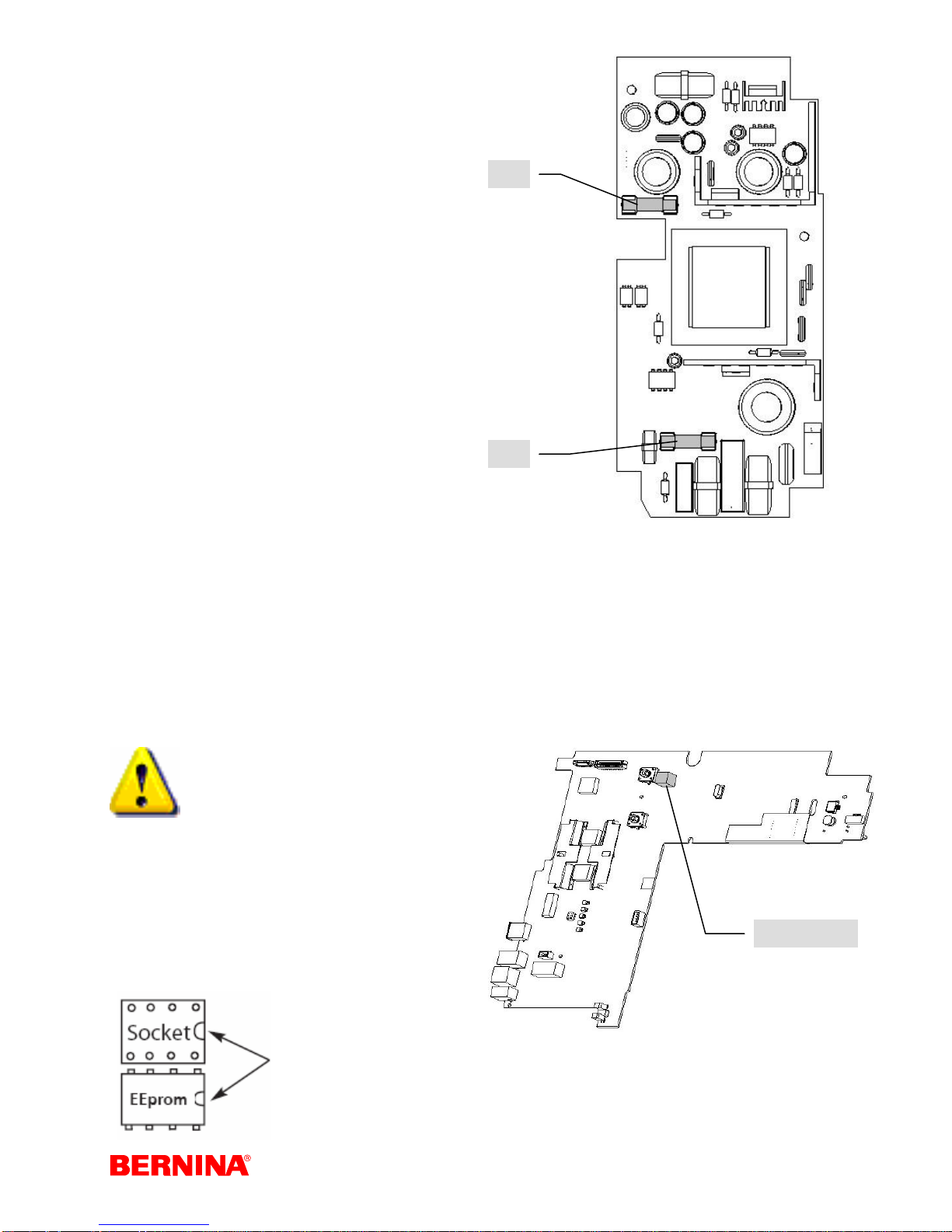

RET-Print (return)

P-Print

The RET-Print

accommodates three

buttons and the upper

thread indicator light

barrier.

The P-Print accommodates

the synchronizing disc light

barriers, and the motor and

sensor connections.

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 16

Universal L-Print (power)

The power PCB (L-Print) is installed in the cover at

the back of the sewing machine.

The circuit components of the L-Print producethe

following direct current voltages:

5 V/DC for the logics on the S-Print

12 V/DC for the sewing light

30 V/DC for the main motor, winder

motor and stepping motors

16 V/DC for the motor control on the

S-Print

In the event of malfunction, the F2 (T-3, 15A

secondary) /F3 (F-4A primary) fuses protect

components against overload. If a fuse blows, this is

always for a reason. The cause must be identified

and removed. An original replacement fuse of the

correct rating must be used. It is essential to test the

functions on replacing the fuse.

The L-Print and S-Print are connected via an 8-pin

ribbon cable.

Fuse F 2 T- 3,15 A Item no. 031 999.50.00

Fuse F 3 F- 4 A Item no. 031 999.50.01

F2

F3

S-Print

The S-Print is manufactured according to S.M.D. (Surface Mounted Device)

technology.

S.M.D. components facilitate very compact circuitry.

S.M.D. printed circuits cannot be repaired with conventional tools!

The sewing computer data is saved on an

EEPROM on the S-Print.

If the S-Print needs to be replaced, that EEPROM

must be moved to the new S-Print.

EEPROM markings must match.

EEPROM

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 17

Chapter 3

Functional check and diagnostic instructions

3.1 Functional check

A correct functional check must be carried out in order to make an error diagnosis.

1) Visual check:

Spool holder

Thread guiding parts

Needle in general, and needle position

Stitch plate

Feed-dog

Bobbin case

Hook, thread guide plate, bobbin case Retainer

Hook driver

2) Functional check:

Functioning of FHS presser foot lifter

Functioning of feed-dog drop

Functioning of presser foot pressure setting

Removal of bobbin case

Functioning of automatic (artista 640) and

manual thread cutter

Connecting machine with original cable and foot

control

LCD screen with backlighting

Functioning of sewing light

Functioning of left and right needle position

Functioning of stitch length and stitch width

Functioning of CLR button

Functioning of winder motor

Test-run the machine and listen for unusual

noises and noise level

Inspect main-, foot-control- and ribbon cables for

loose contacts and electrical resistance.

Drive check of stepping motors.

Inspect USB, embroidery module, PC and foot

control interfaces for connection capabilities.

Note machine’s operating hours, firmware

version and balance values in service program.

3) Mechanical checks:

Remove all covers.

Cleaning of mechanical parts

Check bevel gears for wear and tear

Checking of:

Main shaft play

Base shaft play

Thread take-up lever

Needle bar support

Feed-dog

Functioning of bobbin case hinge

Functioning of upper and lower thread tension.

Lubricate the machine.

4) Sewing checks:

Sewing-off using the following:

Functioning of the Quick reverse button

(securing stitches)

Straight stitch

Zigzag stitch

Honeycomb stitch

Automatic buttonhole stitch

Automatic darning

Embroidery module (if there is one) using the

test embroidery design

BSR foot (if available)

3.2 Diagnostic instructions

Powering the stepping motors

¾ In order to allow the stepping motors to operate correctly, it is essential that they are returned to

their "zero" position after each restart of the sewing computer or change of function. In order to

adjust this "zero" position, the stepping motors must be powered (under current). Replacement

motors should be adjusted before they are fitted into the machine. To achieve this, the motor must

be connected to the P-Print at the appropriate plug, which in turn must be connected to the SPrint, and the S-Print to the power supply. Plug in the power cable, then select pinning positions in

the service program (SP 4e). This program powers the stepping motors to their correct current

values. The motors can then be adjusted according to the servicing instructions of the service

manual.

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 18

Saving the data before carrying out any servicing or repair work

¾ Customer and machine data must be recorded on a BERNINA USB data stick before starting

servicing or repair work. This is to avoid loss of data when replacing PCBs or updating the

firmware, and for use when comparing with the factory settings. The machine data is saved on a

replaceable EEPROM (Electrically Erasable Programmable Read-Only Memory) on the S-Print.

This EEPROM can only be exchanged with a special tool and in an ESD environmental workplace

(see page 6).

3.3 Sewing-off (a-640 must be sewn-off with the head cover fitted (light

will affect the threader sensor)

¾ Sewing-off is a way of checking whether the adjustments made have had the desired effect, and

that the machine is functioning correctly.

¾ The following stitches should be checked in sequence using the appropriate criteria.

1)

Straight stitch

Is the thread regulator spring

being moved correctly?

Is the row of stitching straight?

Is the thread feed regular?

2)

Zigzag (default values)

Is the stitch formation

symmetrical?

Is the thread feed regular?

Is the fabric free from puckering?

3)

Satin stitch

Is the stitch formation

symmetrical?

Is the thread feed regular?

Is the fabric free from puckering?

4)

Running stitch

Is the stitch formation

symmetrical?

Is the thread feed regular on both

sides?

Is the fabric free from puckering?

5)

Balance using “9” & “Leaf”

pattern

Is the stitch formation

symmetrical?

The stitched outline in the '9' and

the leaf must correctly meet up.

6)

Any other stitch (e. g.

Honeycomb stitch)

Is the stitch formation

symmetrical?

Is the thread feed regular?

Is the fabric free from puckering?

7)

Buttonhole

Standard buttonhole:

Is the stitch formation

symmetrical?

Are the beads of equal length?

Is the feed correct?

Automatic buttonhole:

Is the stitch formation

symmetrical?

Are the beads of equal length?

Is the feed correct?

Keyhole buttonhole:

Is the stitch formation

symmetrical?

Are the beads of equal length?

Is the feed correct?

Is the stitch formation of the

eyelet part symmetrical?

8)

Sew-off samples for the

customer

At the end of the service, a

sample is prepared for the

customer so that they can see

how the machine sews after the

service or repair.

This sample should contain the

following stitches:

- Straight stitch

- Zigzag stitch

- Running stitch

- Reverse-fed stitch

- Buttonhole

Should the customer have

complained about any specific

stitch, these should also be sewn

on another piece of fabric and

included.

The sample for the customer

must be the technician’s

business card!

9)

BSR foot

Functioning

Even stitching in X/Y directions

10)

Embroidery module

• Test embroidery design or

customer-specific designs if

necessary.

3.4 External cleaning

Caution!

Never use alcohol, petrol, spirits or any other corrosive fluids, or abrasive pastes!

Electrostatic charging may occur during cleaning. To prevent this, use antistatic office-equipment cleaning agents.

We use and recommend “BASF’s SURFACE CLEAN” cleaner It forms a protective film against static charging, and is

suitable for plastic and metallic surfaces.

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 19

Chapter 4

Replacing Assemblies

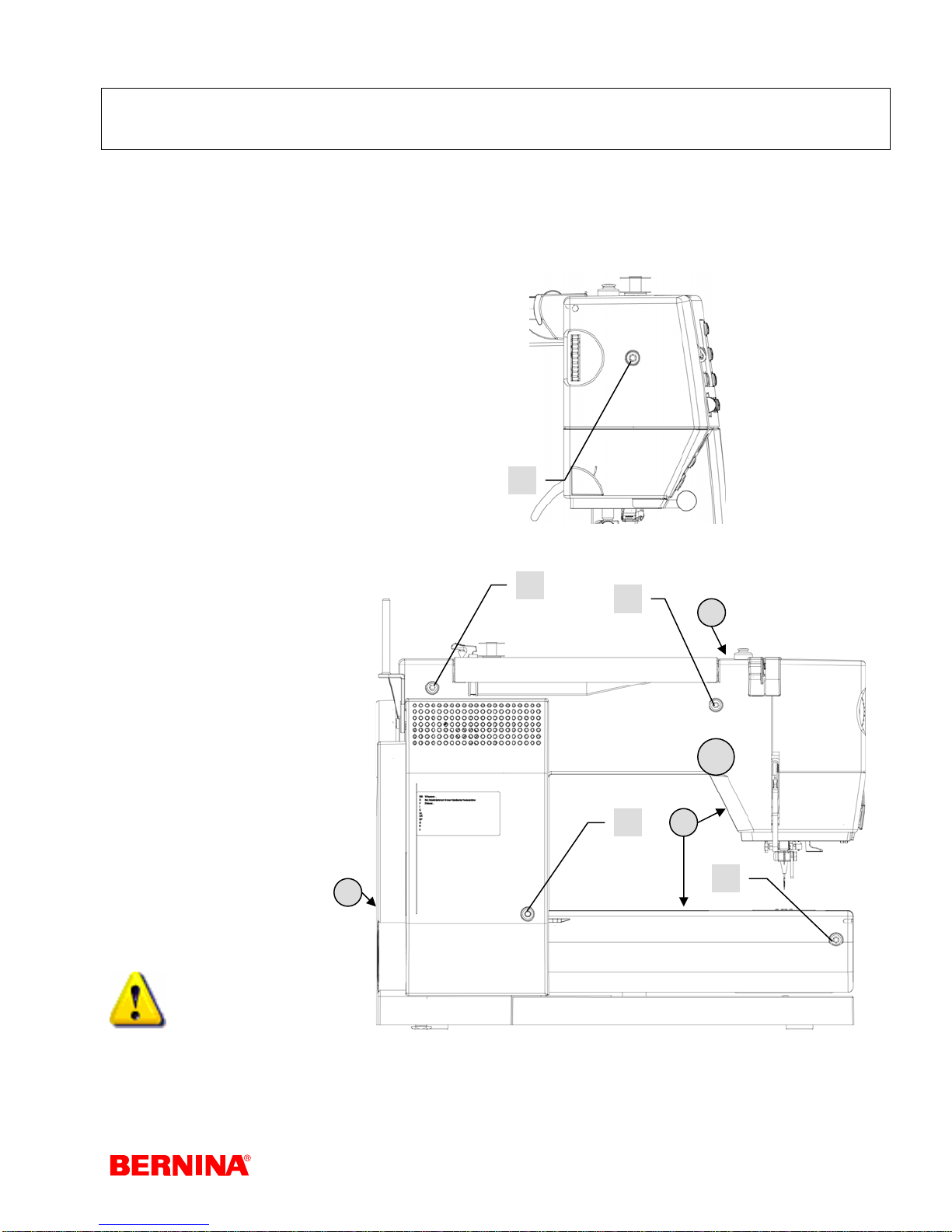

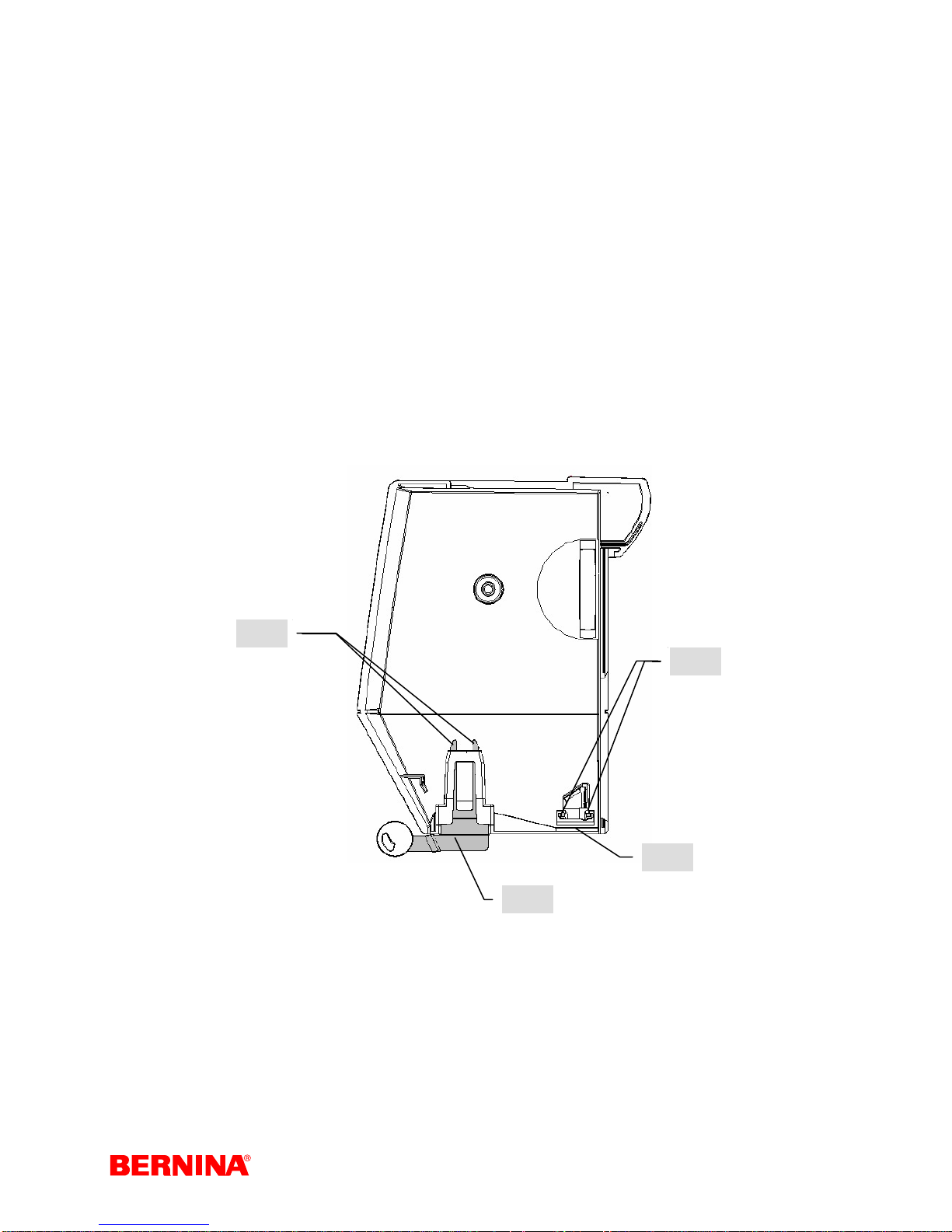

4.1 Removing covers

Before making adjustments, the covers must be removed in the following order:

Head cover:

1. Remove screw (5).

2. Remove head cover.

Attention! The a-640 must have the head cover

refitted when sewing-off.

5

Rear cover:

1. Remove screw (6).

2. Remove screws (7)

(3 screws).

Remove L-Print

cable.

3. Remove rear cover.

4. The covers are linked

with clips

at the points (B).

Slightly press

against the points to

‘de-clip’ them.

Note:

Be sure not to squash the CFL and buttonhole sensor cables in the head area (A) when refitting the covers.

B

7

7

6

B

A

B

B

7

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 20

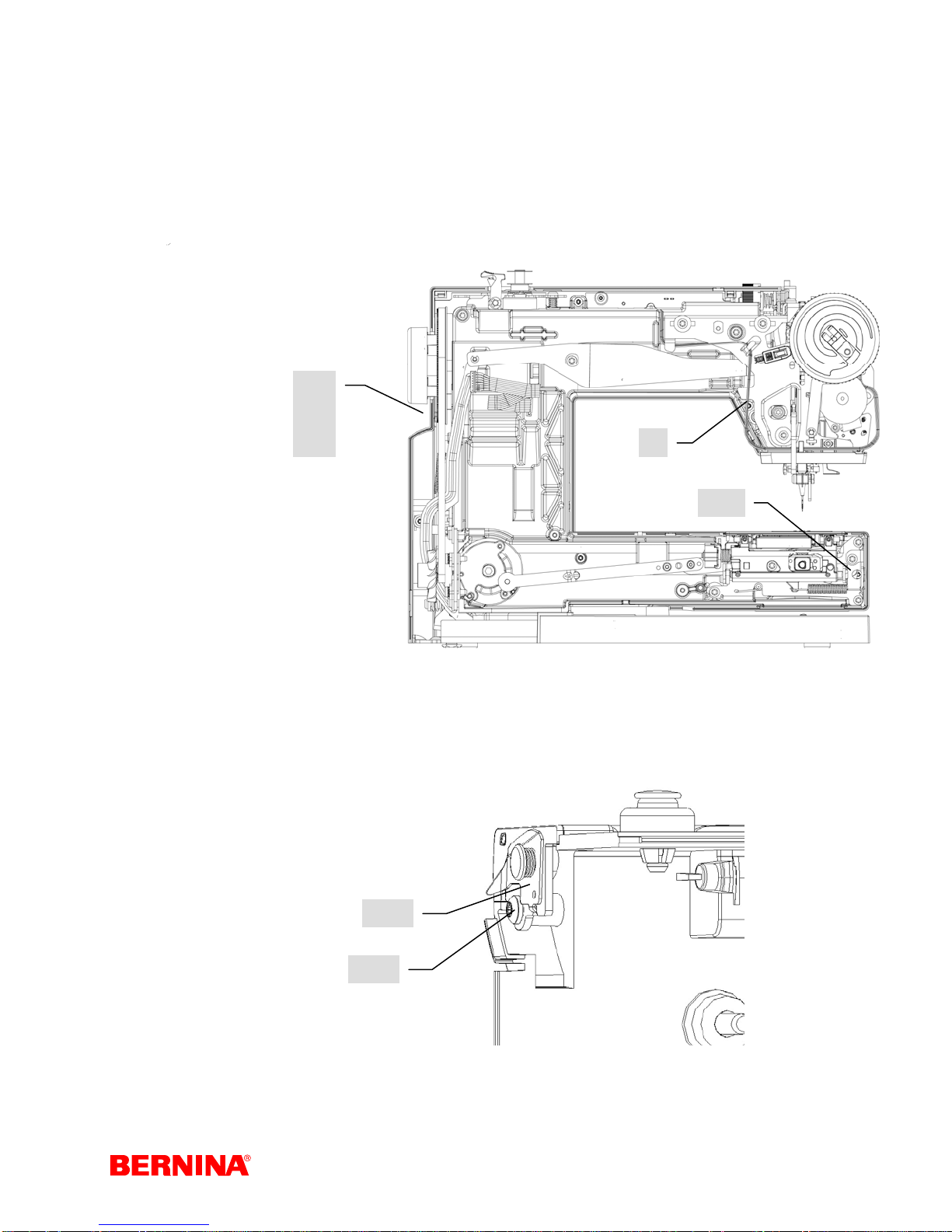

Front cover:

8

1. Remove hook cover.

2. Remove screws (8) (5 screws).

3. Feed-dog drop button must be in sewing position.

4. Turn hand wheel until screw (8a) is accessible (hook drive crank at rear stop).

5. Lift cover over upper thread tension adjusting disc and pull out.

6.

Disconnect connectors (9-12).

(9) main motor / S-Print

(10) S-Print voltage supply

(11) P-Print / S-Print

(12) CFL / S-Print

9

10

11

12

8

8a

4.2 Thread pre-tensioner

Disassembly:

1. Remove rear cover.

2. Remove screw (123).

3. Remove thread pre-tensioner (124) and replace.

Assembly:

1. Refit thread pre-tensioner (124).

2. Refit screw (123).

3. Refit cover.

4. Carry out a functional check.

5. Sew-off

124

123

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 21

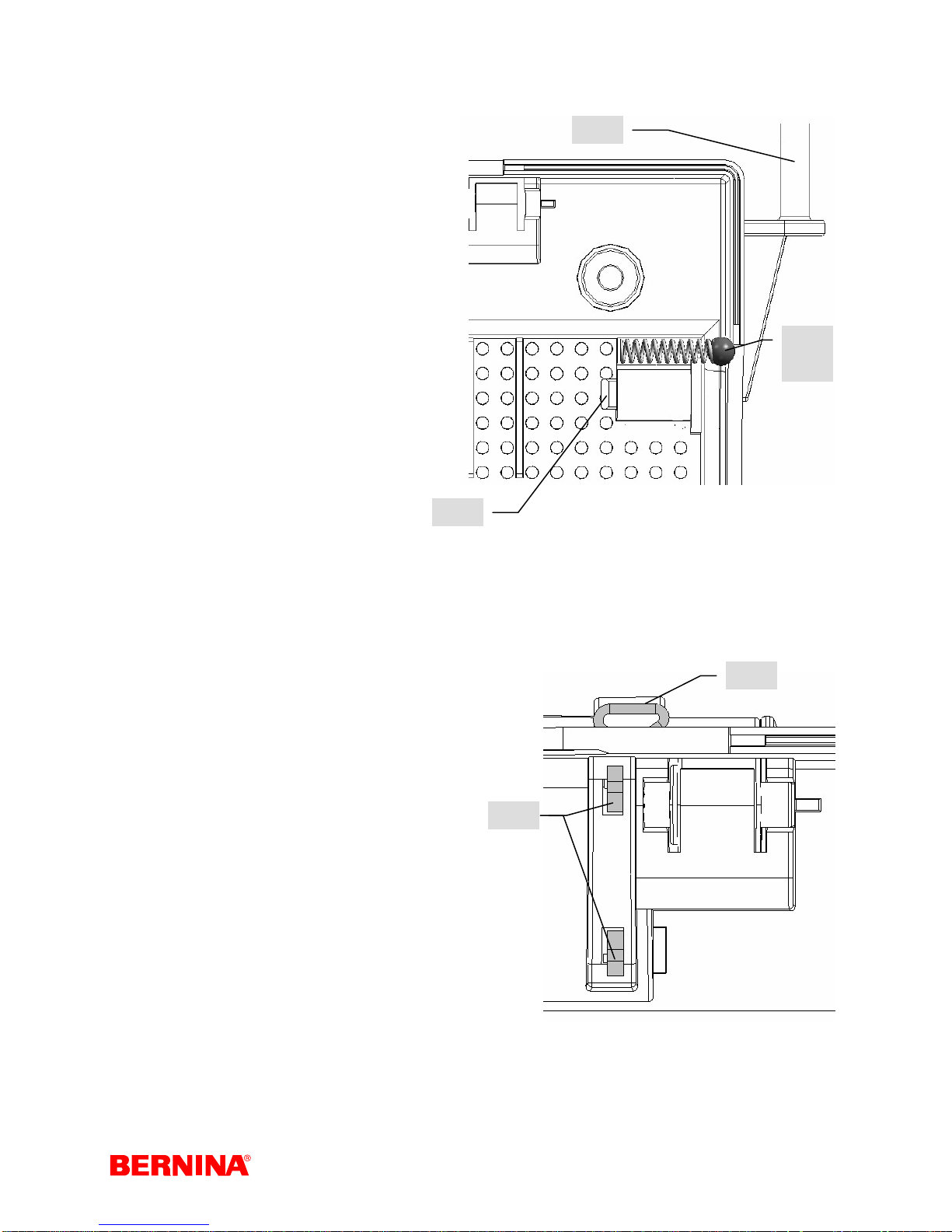

4.3 Vertical spool pin

Disassembly:

1. Remove rear cover.

2. Remove L-Print cover (see p. 27).

3. Push spool pin (125) to the back.

4. Pinch clip (126) and pull spool pin

(125) out to the right. Replace.

Important: Don't lose spring (127) and ball

(128)!

Assembly:

1. Move spool pin (125) to the right in

the guide until clip (126) engages.

Important: Don't forget to refit

2.

spring (127) and ball (128)!

3. Refit L-Print cover.

4. Refit cover. Carry out a functional

check.

5. Sew-off

126

125

127

128

131

4.4 Horizontal spool pin and rear

thread-guide eyelet

Disassembly:

1. Remove rear cover.

2. Pinch clip (129) and

pull spool pin out to the back. Replace.

3. Replace thread-guide eyelet (131).

Assembly:

1. Position thread-guide eyelet (131).

2. Move spool pin forwards in the guide until

clip (129) engages.

3. Refit cover.

4. Carry out a functional check.

5. Sew-off

129

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 22

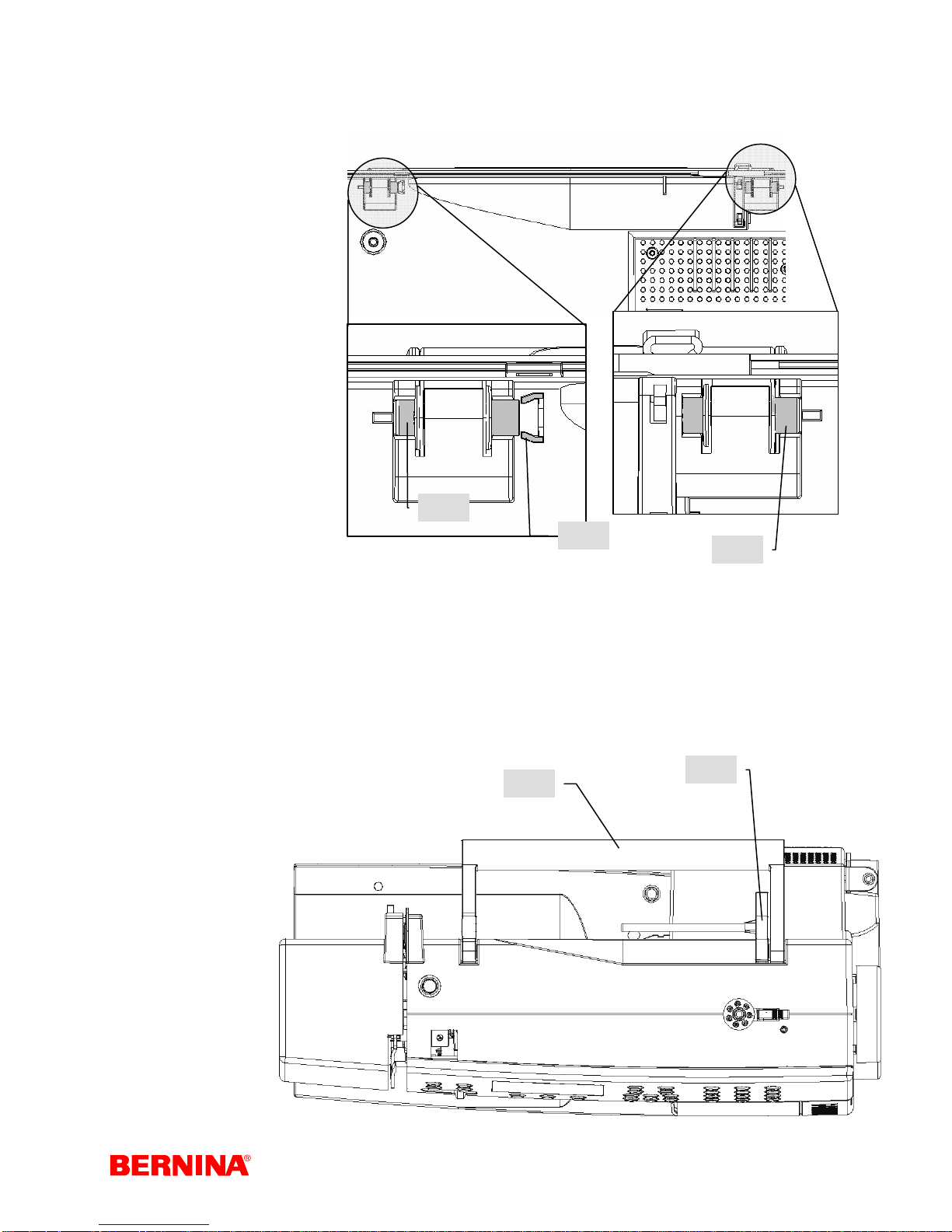

4.5 Carrying handle

Disassembly:

1. Remove rear cover.

2. Remove spool pin (130)

see p. 21.

3. Push pin (132) out to

the left and remove.

4. Carefully prise lock

(133) apart using a

screwdriver. Push pin

(134) out to the right

and remove.

5. Remove handle (135)

and replace.

Assembly:

1. Insert handle (135).

2. Slide pin (134) in from the right until it engages.

3. From the left move pin (132) to the stop.

4. Refit spool pin (130) and thread-guide eyelet (131).

5. Refit cover.

6. Carry out a functional check.

7. Sew-off

134

133

132

130

135

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 23

4.6 Magnifying-glass holder and thread cutter

Disassembly:

1. Remove head cover.

2. Pinch clip (136) and pull magnifying-glass holder (137)

downwards and out. Replace.

3. Pinch clip (138) and pull thread cutter (139) downwards

and out. Replace.

Assembly:

1. Move thread cutter (139) upwards in the guide until clip (138) engages.

2. Move magnifying-glass holder (137) upwards in the guide until clip (136) engages.

3. Refit head cover.

4. Carry out a functional check.

5. Sew-off

136

138

137

139

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 24

4.7 S-Print, keypads, front panel, RET-Print, touch screen, display and

side cover (plugs)

Disassembly:

1. Remove covers.

2. Pull adjusting button off speed regulator.

3. Remove screw (17).

4. Press clip (19) down and remove side cover (20) to the left.

5. The artista 640 requires disconnection of lower thread indicator cable.

6. Carefully slide down the locking clip to disconnect and remove the cables (21) from S-Print (22) and

RET-Print (23).

7. Remove screw (13) from RET-Print.

8. Remove RET-Print (23).

9. Carefully slide down the locking clip to disconnect the ribbon cable (25) from the touch screen.

10. Carefully slide down the locking clip to disconnect the ribbon cable (24) from the LCD.

11. Disconnect LCD backlighting plug (27). Note: Pull only on the plug, and not the LCD lighting cable,

because the CFL tube may break.

12. Remove screws (16) – 4 screws.

13. To remove, lift S-Print (22) from beneath and pull out from under pin (14).

14. Guide plug (27) out through opening (26).

15. Use the special tool (IC extractor) to remove EEPROM from old S-Print. Transfer it directly to new SPrint. NOTE: Take care to place EEPROM in the correct position and avoid bending the contacts.

16. Remove screws (15) – 4 screws – from bridges (18). Remove LCD and touch screen. Replace (p. 24)

17. Remove keypad (4).

18. Remove the five front cover clips (3), remove the front panel and replace.

2214

24 25

16

EEPROM

19

20

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 25

26

27

16 13

17

21

23

3

15

4

3

18

Markings must match!

Assembly:

S-Print, keypad, front panel, RET-Print, touch screen, LCD and side cover (plugs)

1. Slide front panel (4) into guides until front panel clips (3) engage.

2. Insert touch screen into opening – check for dirt before.

3. Insert LCD. Position bridges (18) and fasten with screws (15).

4. Insert keypad (4) – contacts must not be dirty or oily!

5. Insert S-Print (22) and LCD backlighting cable (27) into opening (26). Carefully draw ribbon cables (24

and 25) through the opening.

6. Make sure to insert the shaft faces of the stitch width and stitch length adjusting knobs into the

respective SW/SL potentiometer openings on the S-Print.

7. Tighten screws (16) to fasten S-Print.

8. Reconnect cables (21, 24, 25, 27) and lower thread indicator on artista 640. Make sure that the ribbon

cables sits correctly, and carefully close the locking clip.

9. Refit front cover. Feed-dog switch must be active (in the sewing mode).

10. It is essential to calibrate the maximum speed, the balance and the buttonhole in the service program

before these values can be saved on the S-Print.

11. Carry out a functional check.

12. Sew-off

Important: Is the EEPROM in place?

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 26

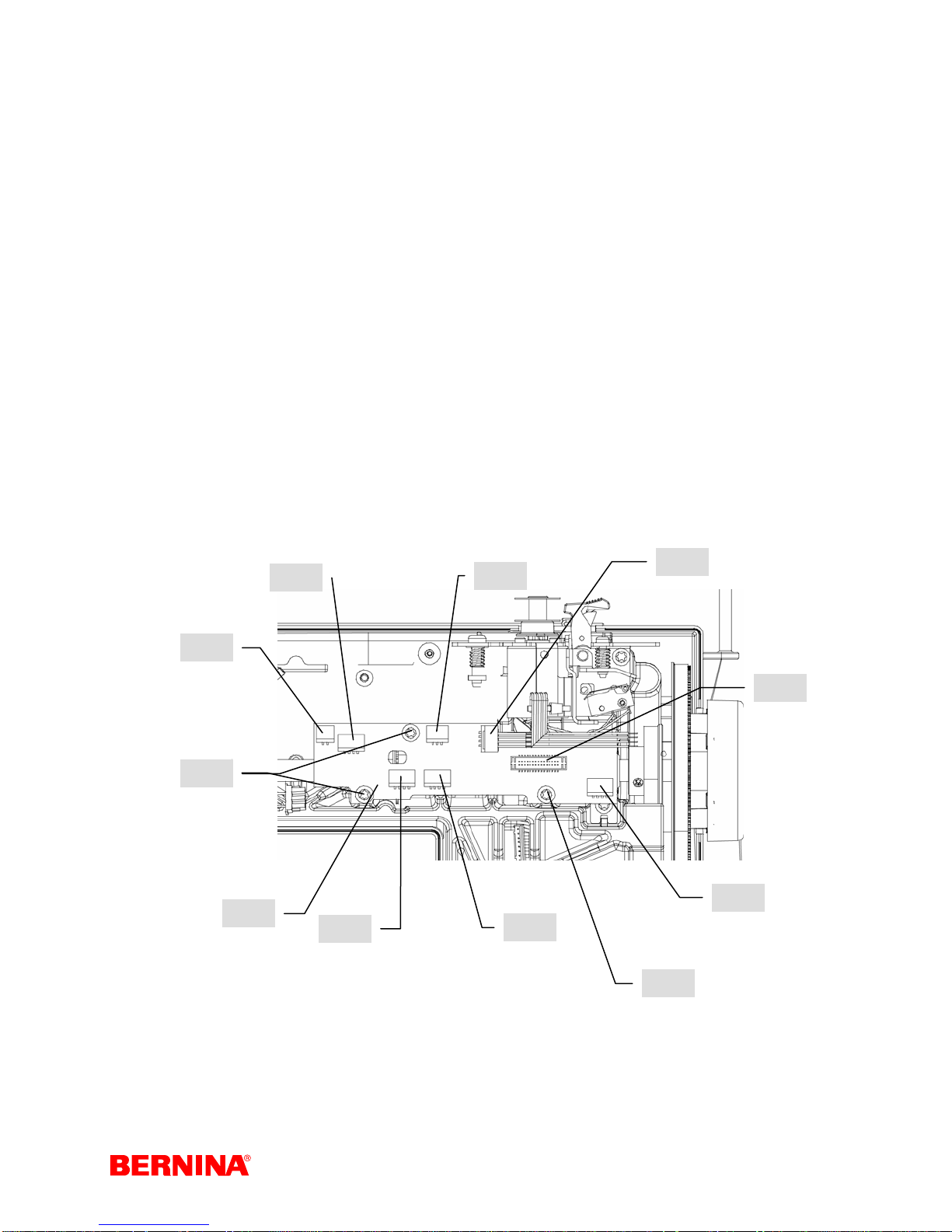

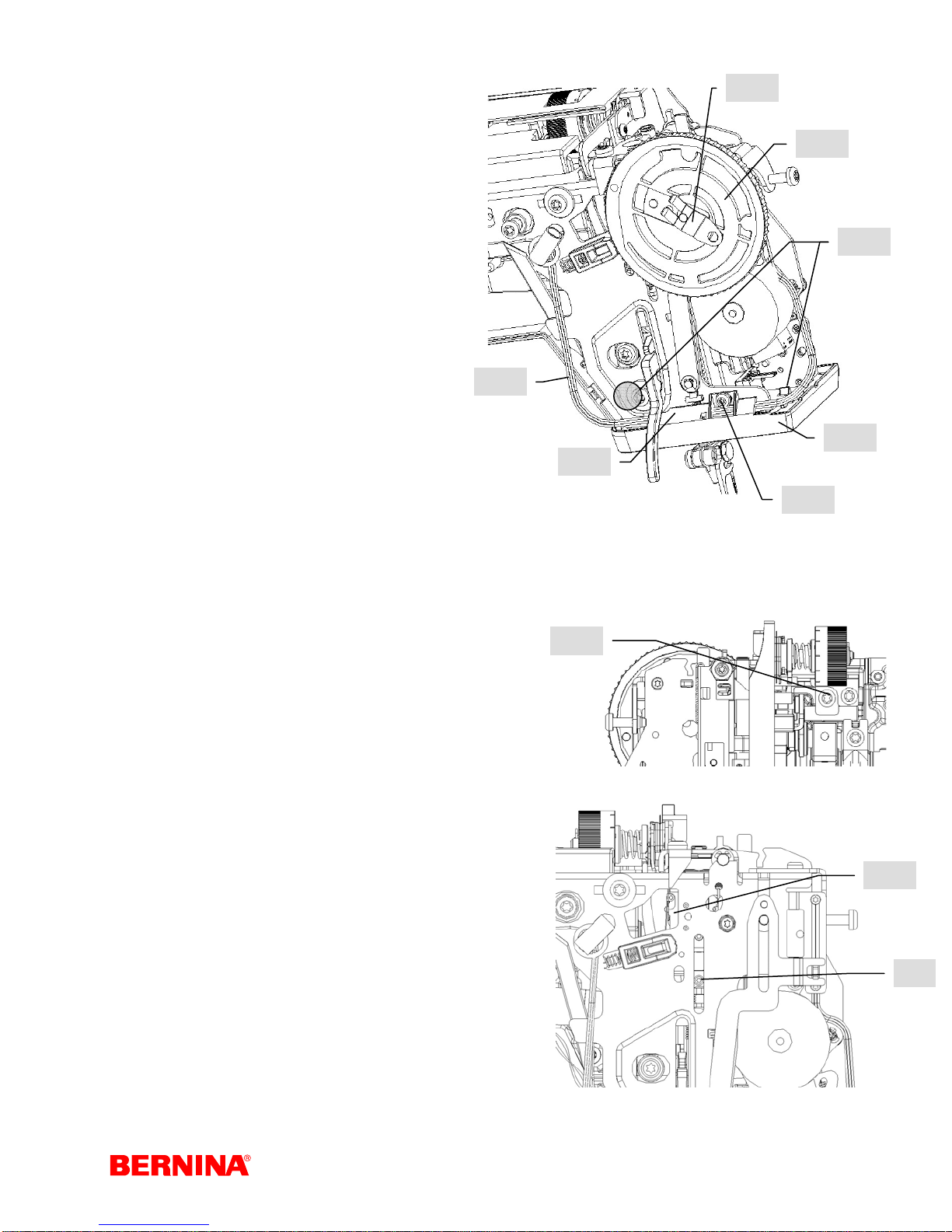

4.8 P-Print

Disassembly:

1. Remove covers.

2. Disconnect plugs (141-148).

3. Remove screws (140).

4. Remove P-Print (149) and replace.

Assembly:

1. Insert P-Print (149).

2. Refit screws (140).

3. Required lateral position of the P-Print (can be seen in the PCB's cut-out) => disc must lie centred in the

light barrier.

4. Reconnect plugs (141-148).

5. Refit covers.

6. Carry out a functional check.

7. Sew-off

Connectors:

141 => presser foot lifter sensor 142 => stitch width stepping motor 143 => presser foot pressure sensor 144 =>

winder motor

145 => S-Print 146 (2 connectors on artista 640’s S-Print) => stitch length stepping motor

147 => buttonhole foot sensor 148 => BSR sensor

142

143

144

141

140

149

148

145

146

147

140

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 27

4.9 L-Print

Disassembly:

1. Remove rear cover.

2. Remove screws (18).

3. Remove L-Print cover (103).

4. Check the primary (157) F2 (3.15A 250V) and secondary (153) F3 (4A - 250V) fuses. Replace if

necessary.

5. Disengage switch (156) and socket (155).

6. Remove screws (151).

7. Lift L-Print (152) from top and pull out of

guide (154).

8. Replace L-Print (152).

Assembly:

1. Refit L-Print (152) and screws (151)

- they are shorter than screws (18).

2. Re-engage switch (156) and socket (155).

3. Refit L-Print cover (103).

4. Refit screws (18) and covers.

5. Calibrate speed.

6. Carry out a functional check.

7. Sew-off

18

103

18

Fuse F 2 T- 3,15 A

Item number

031 999.50.00

Fuse F 3 T- 4 A

Item number

031 999.50.01

151

151

152

157 / 3.15A – 250V

156

153 / 4A –250 V

155

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 28

154

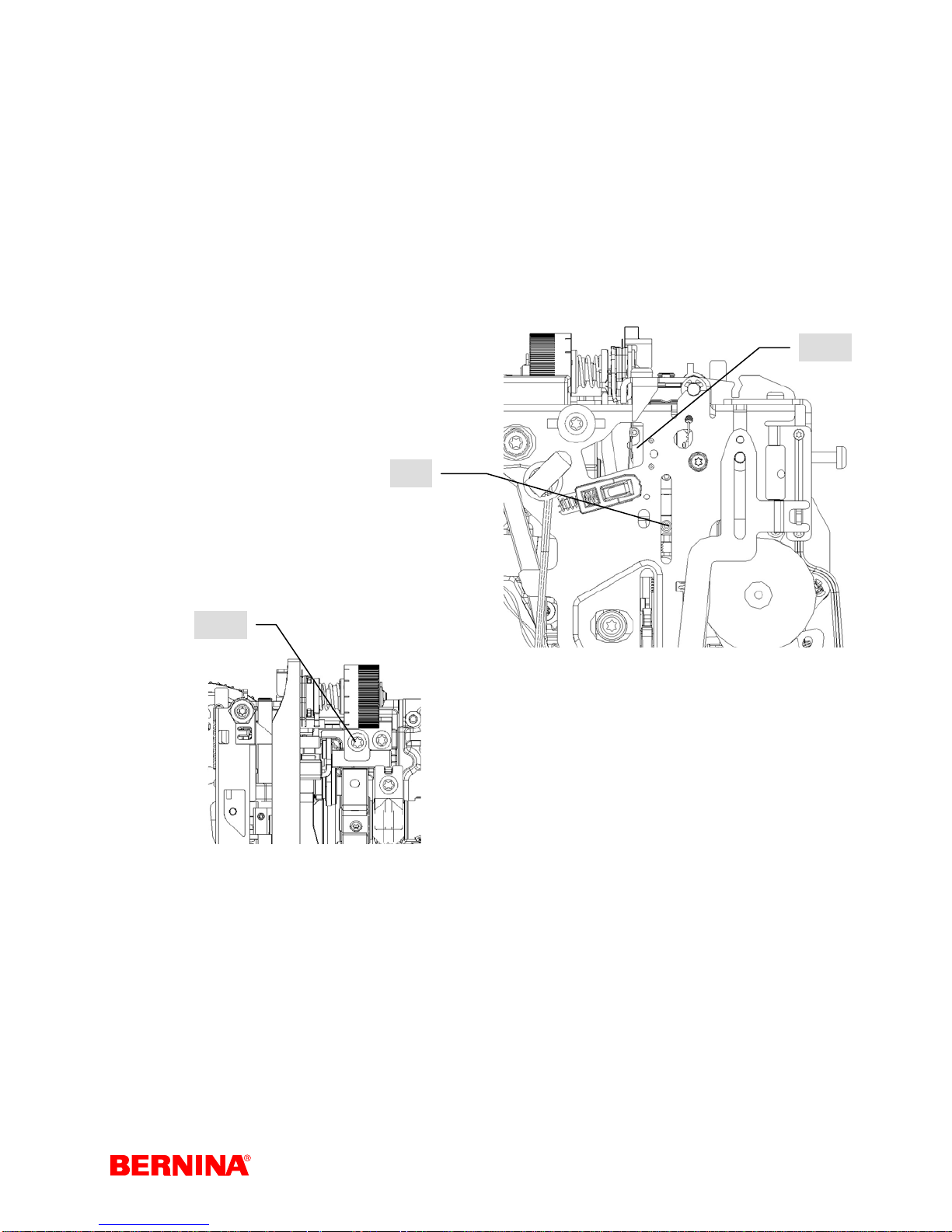

4.10 CFL

Disassembly:

1. Remove covers.

2. Remove screw (159).

3. Disengage CFL (160) from both fastening

clips (168). Replace.

Note:

The presser foot bar must be down!

Do not bend CFL tube!

Assembly:

1. Refit CFL light (160).

2. Place cable (157) into guide (158).

Important: Be sure not to squash the

cables.

3. Refit CFL – the two clips must engage.

4. Refit screws (159) including washers.

5. Refit covers.

6. Carry out a functional check.

7. Sew-off.

Note:

If a fault in the CFL light or the screens

background lighting occurs, then because of

safety regulations the high voltage power is switched off.

If the screen is not lighting, check the CFL first!

157

161

162

168

160

158

159

4.11 Presser foot lifter sensor (micro switch)

Disassembly:

1. Remove covers.

2. Remove adjusting wheel lock (161).

3. Remove carefully the adjusting wheel (162) so

that the spring loaded pressure lever remains in

place.

4. Remove upper thread tension (p. 40/41).

5. Disconnect plug (141) from P-Print (149), see page 26,

and unthread cable from guide.

6. Loosen link shaft screw (163), then remove, including

clamp.

7. Use thread take-up lever to swing link shaft down.

8. Loosen screw (88), then swing hopper mechanism

lever downwards to front.

9. Remove the 2 screws (165) from micro switch and

holder.

10. Slide micro switch including cable out to front.

163

165

88

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 29

Assembly:

1. Refit micro switch (165). Fitting position => the bores of the switch must be placed accurately to the lugs

in the head frame. If the switch is at an angle when the screw is tightened, the switch may be damaged.

2. Draw cables through rear opening and place into cable guides.

3. Connect plug (141) to P-Print (149).

4. Turn hopper mechanism lever into position, then tighten screw (88) slightly.

5. Use thread-take up lever to swing link shaft up. Then refit clamp with screw (163). To clear the thread

take-up’s play, push link shaft slightly to the right.

6. Refit upper thread tension (p. 40/41).

7. Set darning foot height. (p. 46)

8. Refit adjusting wheel (162) and safety stop (161). Make sure the pressure lever fits into the spring, into

the potentiometer and the guide of the adjusting wheel.

9. Refit covers.

10. Carry out a functional check

11. Sewing-off.

163

88

165

Service-Manual_artista_630_640_english_V4.01_032069_50_04.doc 30

Loading...

Loading...