Fritsch Pulverisette 5 Operating Instructions Manual

Operating Instructions

Planetary Mill

„pulverisette 5“

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

FRITSCH

Fritsch GmbH

Manufacturers of Laboratory Instruments

Industriestrasse 8

D - 55743 Idar-Oberstein

Phone: *6784/ 70-0

Fax: *6784/ 70-11

E-Mail: info@fritsch.de

Internet: http://www.fritsch.de

Fritsch GmbH, Laborgerätebau has been certificated by the TÜVZertifizierungsgemeinschaft e.V. on June 24, 1994.

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

FRITSCH

An audit certificated the accordance of the Fritsch GmbH to the

DIN EN ISO 9001.

The enclosed declaration of conformity calls the directives which

the „pulverisette 5“ corresponds to. This permitts us to mark the

instrument with the CE-Sign.

Instrument number 05.500.00 und 05.600.00

applies as of serial number 322

Edition 05/2002 Index 003

Table of contents page

1

General Information / Introduction.............................................. 2

1.1 Notes about Operating Instructions........................................................... 2

1.2 Explanations of the signs at the instrument and

in the operating instructions....................................................................... 2

1.3 Short Description of the Machine ..............................................................3

1.3.1 Applications ...........................................................................................................3

1.3.2 Method of Operation.............................................................................................. 4

1.3.3 Drive Motor and Speed Control .............................................................................4

1.4 Technical Data........................................................................................... 4

2 Operating Safety ...........................................................................6

2.1 General Safety Instructions ....................................................................... 6

2.2 Operators................................................................................................... 7

2.3 Protective Devices..................................................................................... 7

2.4 Danger Points............................................................................................ 8

2.5 Electrical Safety......................................................................................... 8

2.5.1 General.................................................................................................................. 8

2.5.2 Protection against Restarting................................................................................. 8

2.5.3 Overload Protection (see 8 Troubleshooting Checklist)......................................... 8

2.5.4 Unbalance Detection (see 8 Troubleshooting Checklist) ....................................... 8

3 Installation.....................................................................................9

3.1 Unpacking.................................................................................................. 9

3.2 Transport ................................................................................................... 9

3.3 Erection...................................................................................................... 9

3.4 Ambience conditions ................................................................................. 9

3.5 Electrical Connection............................................................................... 10

3.6 Adaptation to Mains Supply Voltage, Changing Timer and

Unbalance Detection in setup mode ....................................................... 10

3.7 Switching On for the First Time / Test for Correct Functioning ............... 11

4 Working with the mill..................................................................12

4.1 Choice of Grinding Bowls and Grinding Balls.......................................... 12

4.1.1 Size of the Grinding Balls .................................................................................... 12

4.1.2 Number of Balls per Grinding Bowl...................................................................... 13

4.2 Filling the Grinding Bowl.......................................................................... 13

4.3 Influencing Quantities During Grinding.................................................... 14

4.3.1 Dry Grinding ........................................................................................................14

4.3.2 Wet Grinding (Grinding in Suspension) ...............................................................14

4.4 Clamping the grinding bowls ...................................................................15

4.4.1 Clamping with the "Safe Lock" Holder .................................................................15

4.4.2 Clamping the 80 ml grinding bowl........................................................................ 15

4.4.3 Clamping with Additional Clamping System......................................................... 16

4.5 Mass Balance .......................................................................................... 17

4.6 Grinding Time .......................................................................................... 17

4.7 Control Panel........................................................................................... 18

4.7.1 Setting the Speed................................................................................................ 18

4.7.2 Setting the Running Time ....................................................................................18

4.7.3 Reversing Operation............................................................................................ 18

4.7.4 Repetition of the Grinding / Break Cycles............................................................ 18

4.8 Performing a Grinding Operation ............................................................ 19

4.9 Cooling the Grinding Bowls ..................................................................... 19

4.10 Standby.................................................................................................... 19

4.11 Grinding under protective gas with gas lid .............................................. 20

4.12 GTM System ............................................................................................22

5 Cleaning.......................................................................................22

6 Maintenance ................................................................................23

7 Warranty ......................................................................................24

8 Troubleshooting Checklist ........................................................24

9 Examples of Comminution Tasks .............................................25

10 List of Keywords.........................................................................27

11 Spare part list and circuit diagrams..........................................27

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

FRITSCH

pulverisette 5 page 1

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

1 General Information / Introduction

1.1 Notes about Operating Instructions

• The copyright to these technical documents is the property of

Fritsch GmbH, Manufacturers of Laboratory Instruments.

• These operating instructions are not to be reprinted or copied

without the express approval of Fritsch GmbH.

• Please study these instructions carefully before operation.

• All operators must be familiar with the contents of the operat-

ing instructions.

• Please observe all notes concerning your safety.

• The mill was designed with the user's safety in mind, however

inherent risks cannot be excluded. Follow the advices in these

instructions to avoid risks to users.

• The symbols in the right hand margin highlight the risks described in the text. Symbols are also to be found on the instrument warning users of possible risks.

Warning symbols are surrounded by a triangle.

• These operating instructions do not constitute a complete

technical description. They describe only the details required

for safe operation and maintenance for usage under normal

conditions.

FRITSCH

Attention!

observe operating

instructions

1.2 Explanations of the signs at the instrument and in the operating instructions

Attention!

warning against danger spot

observe operating instructions

Attention! mains voltage

Attention! risk of explosion

Attention! hot surface

Attention! inflammable substances

pulverisette 5 page 2

wear protective gloves!

wear ear protectors!

wear safety goggles!

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

FRITSCH

Do not step below lifted load!

1.3 Short Description of the Machine

1.3.1 Applications

The "pulverisette 5" laboratory planetary mill is universally applicable for quick dry or wet grinding of inorganic and organic samples for analysis, quality control, materials testing and mechanical alloying.

In synthesis, the "pulverisette 5" can be used for mixing and homogenisation of dry samples, of emulsions and of pastes.

pulverisette 5 page 3

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

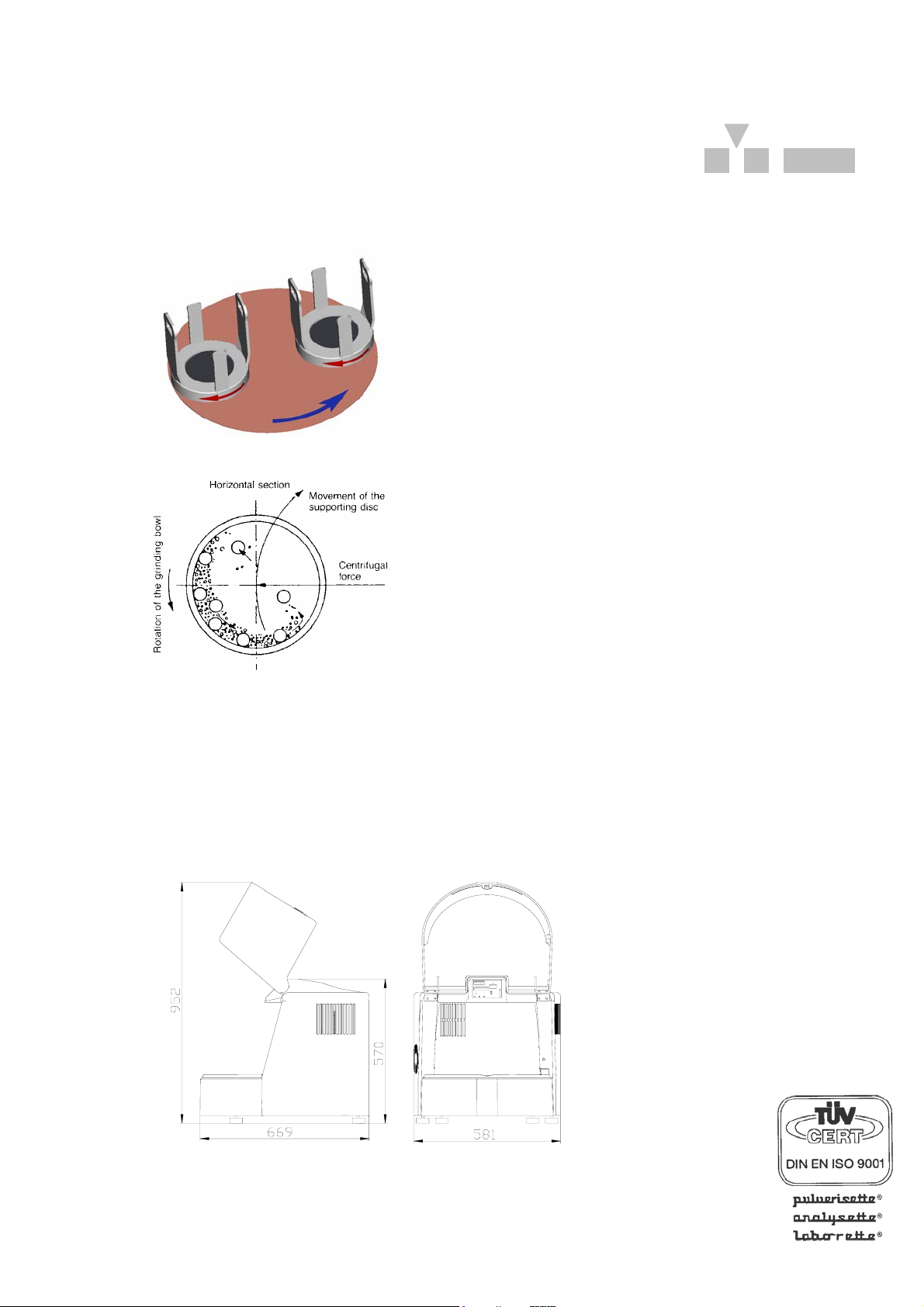

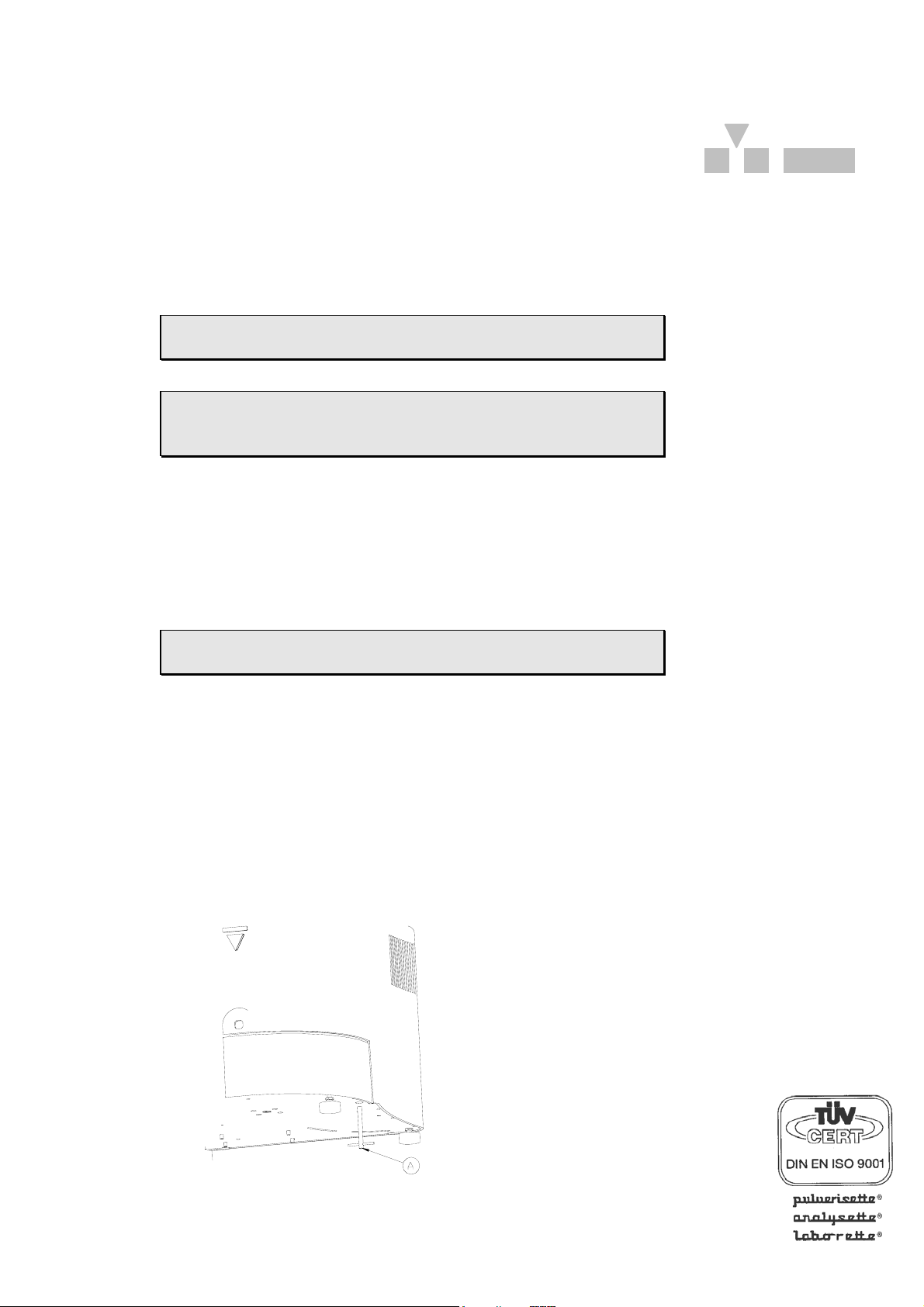

1.3.2 Method of Operation

The material is crushed and torn apart in two or four grinding

bowls by grinding balls. The grinding balls and the material in the

grinding bowl are acted upon by the centrifugal forces due to the

rotation of the grinding bowl about its own axis and due to the rotating supporting disc.

The grinding bowl and the

supporting disc rotate in opposite

directions, so that the centrifugal

forces alternately act in the same

and opposite directions.

This results in, as a frictional

effect, the grinding balls running

along the inner wall of the bowl,

and as an impact effect, the balls

impacting against the opposite

wall of the grinding bowl.

The impact effect is en-

hanced by the grinding

balls impacting against

one another.

Loss-free grinding, even in

the case of grinding of

suspensions, is guaranteed by a hermetic seal

between the grinding bowl

and the cover.

FRITSCH

1.3.3 Drive Motor and Speed Control

The machine is driven by a three-phase a.c. motor, which receives three-phase a.c. 230 V of variable frequency from a frequency converter.

1.4 Technical Data

Dimensions and Weight

Weight: 120 kg

pulverisette 5 page 4

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

Operating Noise

The noise level is about 85dB (A). The value fluctuates greatly

depending on the speed and the material being ground and on

the type of grinding bowl and grinding balls.

Voltage

The machine can be operated in two voltage ranges:

• Single-phase alternating voltage 100-120V ± 10% and

• Single-phase alternating voltage 200-240V ± 10%.

(see also section 3.6 Adaptation to Mains Supply Voltage,

Changing Timer and Unbalance Detection in setup mode)

Transient overvoltages according to overvoltage category II allowed.

Current Input

The maximum current input is approx.:

• 100-120V.............. 14 A

• 200-240V.............. 6 A

Power consumption

The maximum power consumption is approx. :

• 100-120V.............. 1500W

• 200-240V.............. 1300W

FRITSCH

Electrical Fuses

Automatic circuit breaker at the rear of the machine: 16 A

Switch on again by pressing in the black button at the rear of the

machine.

Material

• Maximum feed size in the case of hard material approx. 10

mm

• Maximum feed quantity 900 ml

divided in 4 x 500 ml grinding bowls + grinding balls

• Achievable mean final fineness (depending on material) down

to d

< 1 µm

50

Final Fineness

• Dry grinding

down to d

< 20 µm (depending on material)

50

• Wet grinding

down to d

< 1 µm (depending on material)

50

pulverisette 5 page 5

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

2 Operating Safety

2.1 General Safety Instructions

• Read the operating instructions carefully before use.

• The instrument can only to be used for the purpose described

in Section 1.3 Short Description of the Machine

• Use only original accessories and original spare parts. Failure

to do so may call into question the performance of the instrument.

• Do not use damaged accessories.

• The operators must be familiar with the contents of the operat-

ing instructions.

To this end, for example, the operating instructions must with

the instrument.

• Do not remove labels.

• Protective devices must not be made unserviceable or re-

moved.

• Unauthorized modification of the instrument or any part

thereof will result in the loss of the conformity to European directives which is asserted by Fritsch and the warranty.

• Wear protective gloves!

Grinding bowls may be very hot after grinding.

• Wear safety glasses

Wet grinding may cause high pressure in the grinding bowlDanger of squirting!

• Wear ear protectors - noise level up to 85dB(A).

• Don’t run the instrument several hours without cooling phases

- Danger of overheating.

• Behaviour at all times must be such as to strictly preclude any

accidents.

• Furthermore, the MAC values at place of work specified in the

pertinent safety regulations must be adhered to. Where applicable, ventilation must be provided or the instrument must be

operated under an exhaust hood.

• When oxidizable materials such as metals, organic materials,

wood, coal, plastic, etc. are ground or sieved, the risk of spontaneous ignition (dust explosion) exists whenever the fine particles exceed a specific percentage. While such materials are

being ground, it is therefore necessary to take special safety

precautions (e.g. wet grinding) and the work must be supervised by a specialist.

• The instrument is not explosion-proof and is unsuitable to

grind or sieve materials which are explosive, combustible or

promote combustion.

• Do not allow the instrument to run unsupervised. Due to the

vibrations, under certain operating conditions, the machine

may creep along the surface on which it is located or mounted.

FRITSCH

observe operating

instructions!!

wear protective gloves

wear safety goggles!

wear ear protectors!

Attention! risk of explosion

pulverisette 5 page 6

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

2.2 Operators

• No one other than authorized persons should operate the in-

strument and it must be serviced and repaired by trained

specialists.

• No one suffering from medical problems or under the influ-

ence of medications, drugs, alcohol or overtiredness should

be permitted to operate the instrument.

2.3 Protective Devices

Protective devices should be used for the intended purpose

and must not be made unserviceable or removed.

All protective devices should be regularly checked for completeness and to ensure that they are functioning correctly.

See section 6 Maintenance.

The hood must be closed when the machine is started up.

The hood is locked:

• when the machine is disconnected from the mains supply

• during operation

FRITSCH

The hood can be opened only when the drive of the mill has

come to a standstill.

Opening the hood when the machine is disconnected from

the mains supply

• Insert the attached triangular wrench (A) through the bore,

and turn clockwise.

• The closure hatch can now be opened after the spring-loaded

lock at the front of the hood is opened.

• The instrument can now not be switched on. If it is to be swit-

ched on, the safety lock must be activated by turning the

triangular wrench anticlockwise, and the hood must be closed.

pulverisette 5 page 7

2.4 Danger Points

• Danger of crushing when the hood is being closed.

• Danger of crushing at the grinding bowl holder.

2.5 Electrical Safety

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

FRITSCH

2.5.1 General

• The main switch disconnects the machine from the mains

supply at two poles.

• Switch off the main switch if the instrument is to be inopera-

tive for an extended period (e.g. over night).

2.5.2 Protection against Restarting

In the event of a mains failure during operation or after switchingoff with the main switch, the hood will remain locked. When the

mains voltage is restored, the lock of the hood will open. For safety reasons, however, the instrument will not start again.

2.5.3 Overload Protection

(see 8 Troubleshooting Checklist)

In the event of overloading, the speed of the machine will be reduced. This is indicated by the REDUCED SPEED light beeing illuminated.

If the drive motor overheats, the machine will switch off.

If the drive is obstructed, the machine will switch off.

2.5.4 Unbalance Detection

(see 8 Troubleshooting Checklist)

In the event of an excessive unbalance, the machine will switch

off.

Attention!

pulverisette 5 page 8

3 Installation

3.1 Unpacking

• Pull out the nails with which the hood is fastened on the trans-

port pallet. The hood is either a wooden box or a cardboard

box placed over the transport pallet.

• Lift the hood off the transport pallet.

• Check that the items supplied correspond to your order.

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

FRITSCH

3.2 Transport

Transport the mill on the transport pallet with a fork

lift truck or a hand fork lift truck.

To carry the machine, grip it below the edge of the

housing.

Attention: Weight 120kg!

3.3 Erection

• Lift the instrument with the transport pallet.

Do not walk below the transport pallet.

• The instrument is attached to the transport pallet with 7

screws. Undo the screws.

• Lift the instrument off the transport pallet.

Attention: Weight 120kg!

• Place the instrument on a level, stable surface, indoors. It is

not necessary to fasten the instrument on the erection site.

The instrument can also be mounted on a sturdy table.

It is inadvisable to operate the instrument while it is standing on the transport pallet.

Do not step below lifted

loads!

• Ensure that there is good access to the instrument. There

must be enough space to reach the main switch.

• Do not block the exit of air from the ventilator louver at the si-

de. There is a danger of overheating if the louver is blocked.

3.4 Ambience conditions

• Use the instrument only inside.

• The air must not contain any electrical conductive dust.

• The ambient temperature must be between 5 and 40°C.

• Height up to 2000m M.S.L.

• Maximum relative humidity of air 80% temperature up to 31°C,

linear decreasing down to 50% relative humidity of air at 40°C

• Contamination level 2 (IEC 664)

pulverisette 5 page 9

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

3.5 Electrical Connection

Before making the connection, compare the voltage and current

values shown on the nameplate with the values of the mains

supply to which the instrument is to be connected.

Single-phase alternating voltage with protective conductor (see

section 1.4 Technical Data).

The connecting cable may be changed only by a trained expert.

3.6 Adaptation to Mains Supply Voltage, Changing

Timer and Unbalance Detection in setup mode

The voltage range of the machine should be switched over

only by specialist staff.

Adaptation to Mains Supply Voltage in setup mode

1. Disconnect the machine from the mains supply.

2. At the rear of the machine, set the changeover switch to the

voltage range.

3. Connect the machine to the mains supply.

4. Press and hold down the STOP button on the control panel at

the front.

5. Switch on the main switch at the rear of the machine and re-

lease the STOP button immediately afterwards.

6. The POWER SUPPLY light is flashing Æ setup mode

The POWER SUPPLY light is not flashing, repeat the procedure

7. With the + / - ROTATIONAL SPEED buttons, select the

mains supply voltage level (90 - 260 V).

8. To store the settings and end the setup mode, press the

STOP button.

FRITSCH

Attention! mains voltage

Further options in setup mode

A unbalance detection: on / off

(right) - button in the TIMER panel

unbalance detection on display: -

unbalance detection off display: 1

B timer function: hours, minutes / minutes, seconds

(right) + button in the TIMER panel

Hours and minutes display: -

Minutes and seconds display: 1

Switching off the unbalance detection at own risk!

see section 2 Operating Safety and 2.5 Electrical Safety

Pressing the REPETITIONS buttons in setup mode alters the

machine type. Do not change anything here: P5 should be

indicated in the display. Otherwise, damage will occur during operation.

pulverisette 5 page 10

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

3.7 Switching On for the First Time /

FRITSCH

Test for Correct Functioning

Switch on the machine only when all the work described in section 3 Installation has been done.

Switching On

1. Connect the machine to the mains supply.

2. Switch on the machine with the main switch at the rear.

3. POWER SUPPLY shines

4. Open the hood.

5. If the grinding bowl holder or any wood are present, take them

out. There should be nothing in the grinding bowl holder.

6. Close the hood.

7. Press START on the control panel.

8. The hood will be locked and the mill will run at the preselected

speed.

Switching Off

• Press STOP on the control panel.

• After a short period (after the mill has come to a standstill), the

hood is unlocked and can be opened.

pulverisette 5 page 11

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN

4 Working with the mill

4.1 Choice of Grinding Bowls and Grinding Balls

In order to prevent excessive abrasion, the hardness of the grinding bowl used and of the grinding balls must be higher than that

of the material used.

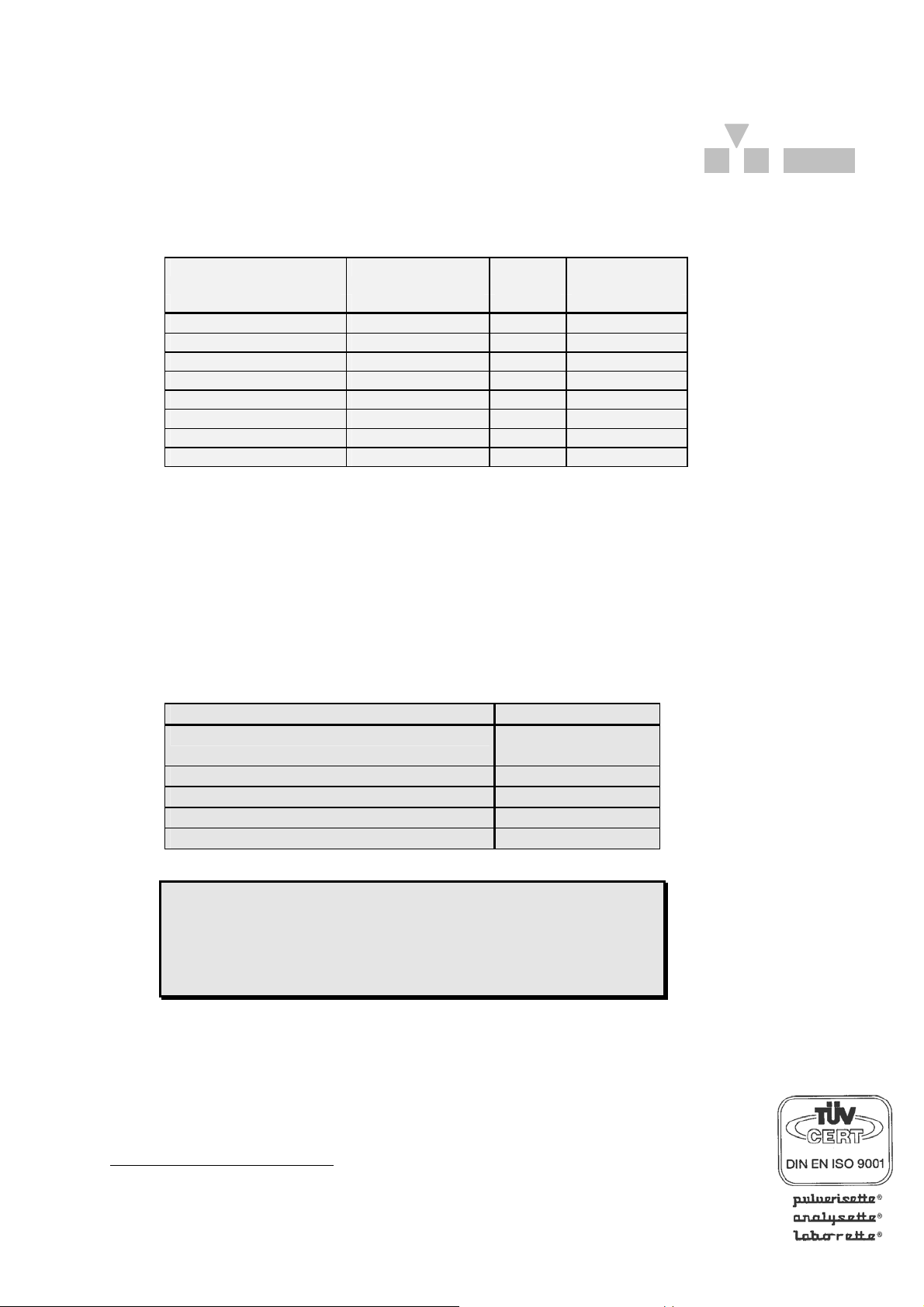

Material density* restistance to

abrasion

(bowl and balls) in g/cm3

Agate (99.9% SiO2) 2.65 Good

Sintered corundum 1 (99.7% Al2O3) 3.7 Fairly good

Sintered corundum 2 (85% Al2O3) 3.5 Fair

Zirconium dioxide (95% ZrO2) 5.7 Very good

Chrome nickel steel 7.9 Fairly good

Hardened chrome steel 7.85 Good

Tungsten carbide (93%WC+6% Co) 14.75 Very good

Silicon nitride (Syalon) (90% Si3N4) 3.2 Extremely good

The grinding bowls and grinding balls of zirconium dioxide are

resistant to acids with the exception of hydrofluoric acid.

Normally, grinding bowls and grinding balls of the same material

should be chosen.

Exeption: Tungsten carbide balls may be combined with steel

bowls.

FRITSCH

The size of the grinding bowls and grinding balls should be determined experimentally.

4.1.1 Size of the Grinding Balls

Type of feed material Ball diameter

Hard samples feed particle size <10 mm 30 mm or

40 mm

Medium piece size (<5 mm) 20 mm

Fine material (0.5 mm) 10 mm / 5 mm

Homogenisation of dry or liquid samples 10 mm / 5 mm

Homogenisation of viscous samples 20 mm

Attentione:

We do not recommend to mix grinding balls with different

diameters.

(If different ball diameters are used there is the danger of

higher abrasion of the balls!)

*

High density means high impact energy

pulverisette 5 page 12

Loading...

Loading...