FRITSCH PULVERISETTE 16 User Manual

Operating Instructions

Translation of the original

FRITSCH CROSS BEATER MILL

PULVERISETTE 16

Fritsch GmbH

Milling and Sizing

Industriestrasse 8

D - 55743 Idar-Oberstein

Phone: +49 (0)6784/ 70-0

Fax +49 (0)6784/ 70-11

Email: info@fritsch.de

Internet: http://www.fritsch.de

Fritsch GmbH, has been certified by the

TÜV-Zertifizierungsgemeinschaft e.V.

Certificat registration number 71 100 J 596.

It was verified through an audit that Fritsch GmbH satisfies the requirements of

DIN EN ISO 9001:2008.

The enclosed declaration of conformity calls the directives

which the „PULVERISETTE 16“ corresponds to.

This permitts us to mark the instrument with the CE-Sign.

Device number 16.300x.00

Applies as of serial number 101

Edition 12/2000 Index 003

PULVERISETTE 16

Table of contents Page

General/Introduction ............................................................................3

1

1.1 Notes about the operating instructions.........................................................3

1.2 Warnings Used.............................................................................................4

1.3 Explanation of the symbols used on the device and in the operating

instructions....................................................................................................

1.4 Brief description of the device.......................................................................6

1.4.1 Fields of application.............................................................................................6

1.4.2 Method of operation.............................................................................................6

1.5 Technical data...............................................................................................7

1.6 Materials and composition............................................................................7

2 Operating safety...................................................................................9

2.1 General safety instructions ...........................................................................9

2.2 Operators......................................................................................................9

2.3 Protective devices.......................................................................................10

2.4 Danger points..............................................................................................10

5

3 Installation...........................................................................................12

3.1 Unpacking...................................................................................................12

3.2 Transport.....................................................................................................12

3.3 Setup...........................................................................................................12

3.4 Setup on a laboratory table.........................................................................12

3.5 Fastening of the “pulverisette 16” to the universal support.........................13

3.6 Electrical connection...................................................................................14

4 Working with the “pulverisette 16”...................................................15

4.1 Operating elements and operation .............................................................15

4.2 Operating elements and their function........................................................16

4.3 Opening and closing the mill housing.........................................................17

4.4 Inserting the bottom sieve...........................................................................18

4.5 Filter hose and collecting vessel.................................................................18

4.6 Adding material for grinding........................................................................18

4.7 Readjusting the impact gap ........................................................................19

5 Cleaning ..............................................................................................19

6 Maintenance........................................................................................20

7 Required inspections.........................................................................20

8 Warranty..............................................................................................21

9 Disclaimer ...........................................................................................21

Page 2

PULVERISETTE 16

1 General/Introduction

1.1 Notes about the operating instructions

• Study the operating instructions carefully.

• The cross beater mill “pulverisette 16” is referred to below as the cross

beater mill.

• All operators must be familiar with the contents of the operating instructions.

• Please follow the notes for your safety.

• The cross beater mill was designed from a perspective of user safety;

however, some residual dangers could not be eliminated. Follow the advice in these instructions to avoid risks to users.

• The symbols in the right hand margin highlight the risks described in the

text.

• Symbols on the device warn about possible dangers or refer to these operating instructions. The symbol in the right page margin (triangle with an

exclamation point) indicates general dangers and refers to the operating

instructions.

• These operating instructions do not constitute a complete technical description. They describe only the details required for safe operation and

maintenance for usage under normal conditions.

• The copyright to these technical documents is the property of Fritsch

GmbH, Laborgerätebau.

• These operating instructions are not to be reprinted or copied without the

express approval of Fritsch GmbH, Laborgerätebau.

Page 3

PULVERISETTE 16

1.2 Warnings Used

The following symbols are used in this description to indicate important information and possible dangers.

DANGER

WARNING

CAUTION

Indicates a direct danger with high risk that will lead to death

or severe physical injury if not avoided.

Indicates a possible danger with moderate risk that could

lead to death or (severe) physical injury if not avoided.

Indicates a danger with low risk that could result in slight or

moderate physical injuries or material damages if not

avoided.

Page 4

PULVERISETTE 16

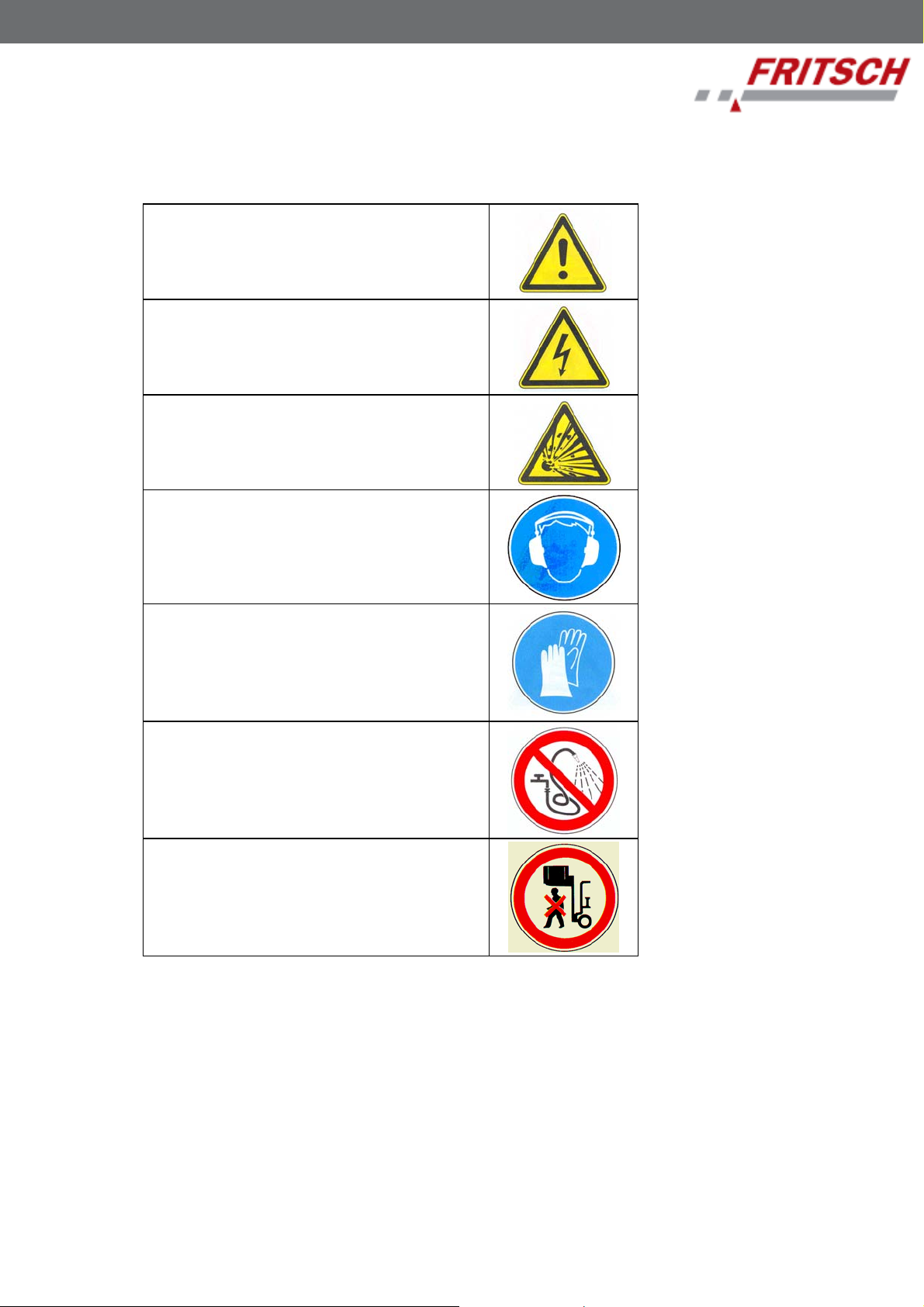

1.3 Explanation of the symbols used on the device and in

the operating instructions

Attention!

Warning against danger spot

Observe operating instructions

Attention! Mains voltage

Attention! Hazard of explosion

Wear ear protection!

Wear protective gloves!

Spraying with water forbidden!

Do not step below lifted load!

Page 5

PULVERISETTE 16

1.4 Brief description of the device

1.4.1 Fields of application

The cross beater mill serves primarily for preliminary and fine comminution of

medium-hard, brittle materials up to Mohs hardness of 6. Thanks to a large

selection of accessories, the cross beater mill is a device with wide-ranging

fields of application primarily in the areas of chemicals and ceramics, in mining and metallurgy as well as in the preparation of soil samples, etc. in the

laboratory and in industry.

The achievable final fineness depends on the hole width of the bottom sieve

and the grinding properties of the material to be ground. Under good conditions, fineness levels < 100 µm can be achieved.

Typical applications for soft materials:

Needles, leaves, grain, resins, cellulose, chemicals, dried fruits, peat, seeds,

dried plants

Typical applications for medium-hard materials:

Animal feed, salts, pellets, coal, porcelain clay, spices, gypsum, drugs, pot-

ash, tablets, slag, minerals, ash, stone and earth (bauxite, limestone, dried

clay, etc.), synthetic resins, pyrite, cement clinker, coke, ores, refractory materials.

1.4.2 Method of operation

The comminution in the cross beater mill takes place through impacting, colliding and shearing effects. After introduction into the filling

funnel, the material enters the grinding chamber, where the comminution process occurs between the cross beater, grinding insert

and bottom sieve.

As soon as the material has reached the corresponding final fineness, it passes through the bottom sieve into the collecting vessel.

A back draft of the air flow generated by the rotating cross beater is

prevented and an acceleration of the material throughput is partially

achieved with the use of a textile filter hose between

mill

and the collecting vessel.

This ensures a gentle grinding process.

the cross beater

Page 6

PULVERISETTE 16

1.5 Technical data

Dimensions:

“pulverisette 16” approx. 560x420x445mm (height x width x depth)

“pulverisette 16” with base frame approx. 1183x560x700mm (height x width x depth)

Weight:

“pulverisette 16” net approx. 36 kg

with base frame net approx. 58 kg

Operating noise

Noise measurement according to DIN 45635-31-01-KL3

The noise values are also influenced by the properties of the ma-

terial being ground.

Example:

Noise level LWA = 95dB(A)

Workplace emissions value L

Input material: Quartz pebbles, grain size < 3 mm

Filling level of the grinding chamber: Input quantity until rated motor power

was reached

= 86dB(A)

pAeq

Drive:

1 and 3 phase alternating current motor with brake

Rotation speed:

2850 rpm

Rated power:

1100 watts

Input grain size:

Max. 20 mm

Collecting vessel volume:

5,000 ml or 30,000 ml

Protection class:

IP 54

1.6 Materials and composition

Collecting vessel 5l and bottom sieves

of stainless steel

Material no.

Short name

Composition Fe 77,325 %

Cr 18,000 %

Ni 02,500 %

Mn 02,000 %

Si 01,000 %

C 00,070 %

P 00,045 %

S 00,030 %

1.4301

X 5 CrNi 18 9

Page 7

Loading...

Loading...