FRITSCH PULVERISETTE 1 User Manual

JAW CRUSHER

Operating Manual

Translation of the original

FRITSCH JAW CRUSHER

Fritsch GmbH

Milling and Sizing

Industriestrasse 8

D - 55743 Idar-Oberstein

Phone: +49 (0)6784/ 70-0

Fax: +49 (0)6784/ 70-11

E-Mail: info@fritsch.de

Internet: http://www.fritsch.de

Fritsch GmbH, has been certified by the

TÜV-Zertifizierungsgemeinschaft e.V.

Certificat registration number 71 100 J 596.

It was verified through an audit that Fritsch GmbH satisfies the requirements of DIN

EN ISO 9001:2008.

The enclosed conformity statement states the directives

satisfied by the Jaw Crusher "PULVERISETTE 1"

in order to bear the CE mark.

Instrument number 01.50xx.00

Applies as of serial number 2185

Instrument number 01.70xx.00

Applies as of serial number 2180

Edition 12/2003 Index 006

Table of contents page

1 Basic Design.........................................................................................4

2 Safety Instructions and Proper Use....................................................6

2.1 Requirements on the Operator.....................................................................6

2.2 Proper use.....................................................................................................6

2.2.1 Method of Operation............................................................................................6

2.3 Obligations of the Operator...........................................................................7

2.4 Warnings Used .............................................................................................7

2.5 Machine safety instructions...........................................................................8

2.6 Safety equipment..........................................................................................9

2.7 Hazard points................................................................................................9

2.8 Electrical safety.............................................................................................9

2.8.1 General................................................................................................................9

2.8.2 Protection against warm restart...........................................................................9

3 Technical Data....................................................................................10

3.1 Dimensions.................................................................................................10

3.2 Weight.........................................................................................................10

3.3 Working noise.............................................................................................10

3.4 Voltage, Current consumption, Power consumption...................................10

3.5 Electric fuses...............................................................................................10

3.6 Material.......................................................................................................10

3.7 Final fineness..............................................................................................10

4 Installation...........................................................................................11

4.1 Transportation.............................................................................................11

4.2 Unpacking...................................................................................................11

4.3 Setting up....................................................................................................11

4.4 Ambient requirements.................................................................................12

4.5 Assembling the funnel (1)...........................................................................12

4.6 Electrical connection...................................................................................14

4.6.1 Matching the jaw crusher to the mains voltage..................................................14

4.6.2 Drive motor........................................................................................................14

4.6.3 Direction of rotation of drive motor.....................................................................14

4.7 Initial switch-on / performance check..........................................................15

5 Working with the jaw crusher............................................................15

5.1 Selection of crushing plates and lateral support walls................................15

5.2 Mounting the crushing plates (18, 22) and lateral support walls (13).........16

5.2.1 Mounting the crushing plates.............................................................................17

5.2.2 Checking the gap...............................................................................................18

5.2.3 Mounting the support walls................................................................................19

5.3 Crushing of material....................................................................................20

5.3.1 Setting the jaw gap............................................................................................20

5.3.2 Introducing the material to be crushed...............................................................20

5.3.3 Dust exhaust......................................................................................................20

5.3.4 Final size............................................................................................................21

5.3.5 Setting of the link plate ......................................................................................21

Page 2

6 Accessories ........................................................................................22

6.1 Dust extraction............................................................................................22

6.1.1 Converting for dust extraction............................................................................22

6.2 Conversion set for iron-free preliminary grinding........................................24

6.2.1 Model I...............................................................................................................24

6.2.2 Model II..............................................................................................................24

6.2.3 Changing the funnel...........................................................................................24

6.2.3.1 Conversion set................................................................................................24

6.2.3.2 Tools ...............................................................................................................25

6.2.3.3 Assembly.........................................................................................................25

6.3 Crushing and comminuting to the fineness of a disk mill............................29

7 Cleaning ..............................................................................................30

7.1 Cleaning the grinding chamber...................................................................30

7.2 Cleaning the intake.....................................................................................30

8 Maintenance........................................................................................31

8.1 Crushing plate.............................................................................................31

8.2 V-belts.........................................................................................................31

8.3 Greasing the bearings.................................................................................31

9 Warranty..............................................................................................31

10 Disclaimer ...........................................................................................32

Page 3

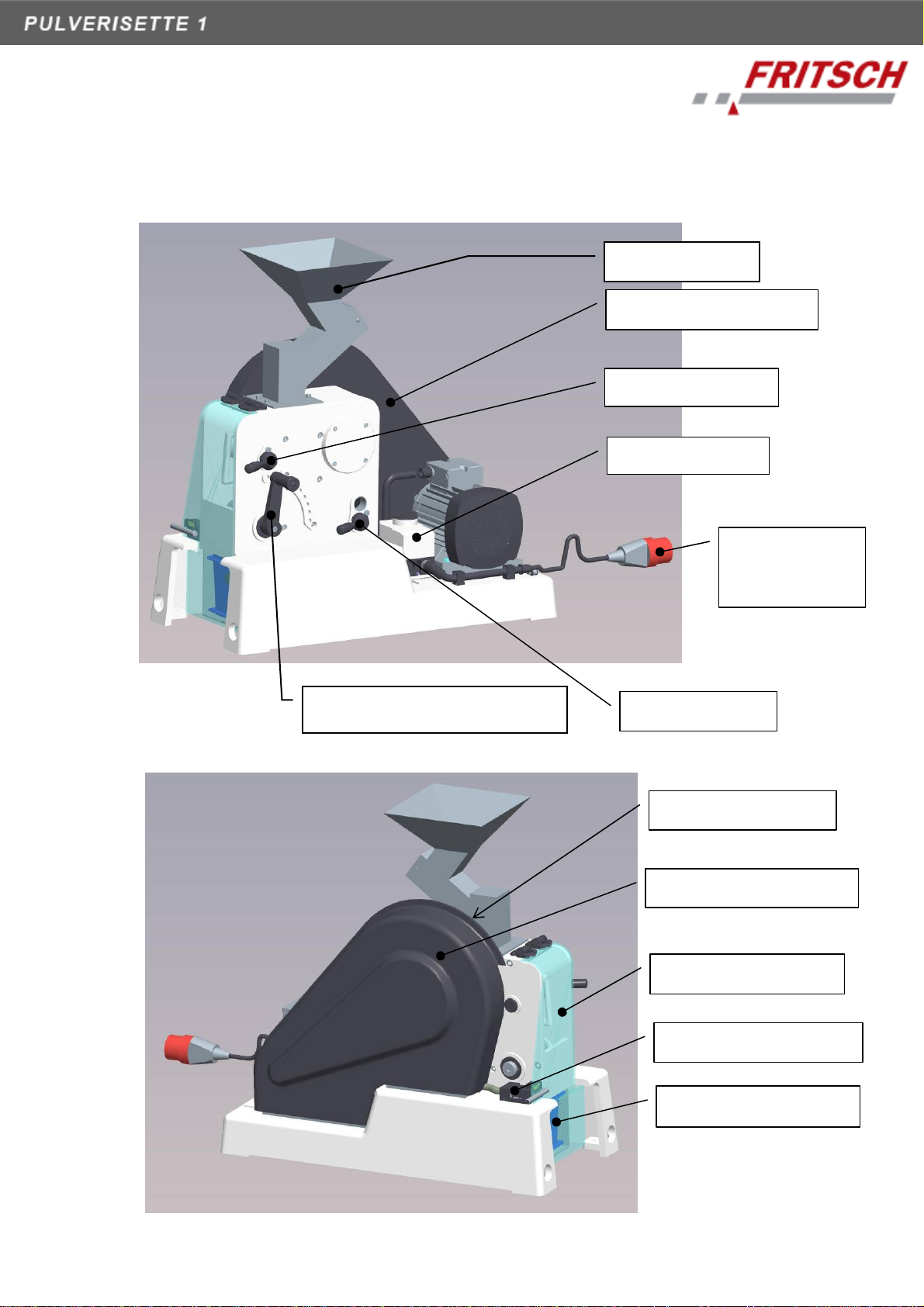

1 Basic Design

The designations and numbering shown below are used throughout this operating

manual.

(1) funnel

(2) belt guard inside

(3) guide bolt

(4) main switch

(7) indexing cranked handles

(5) mains plug

with mains

cable

(6) link pin

(8) edge protection

(9) belt guard outside

(10) front cover

(11) safety switch

(12) collecting vessel

Page 4

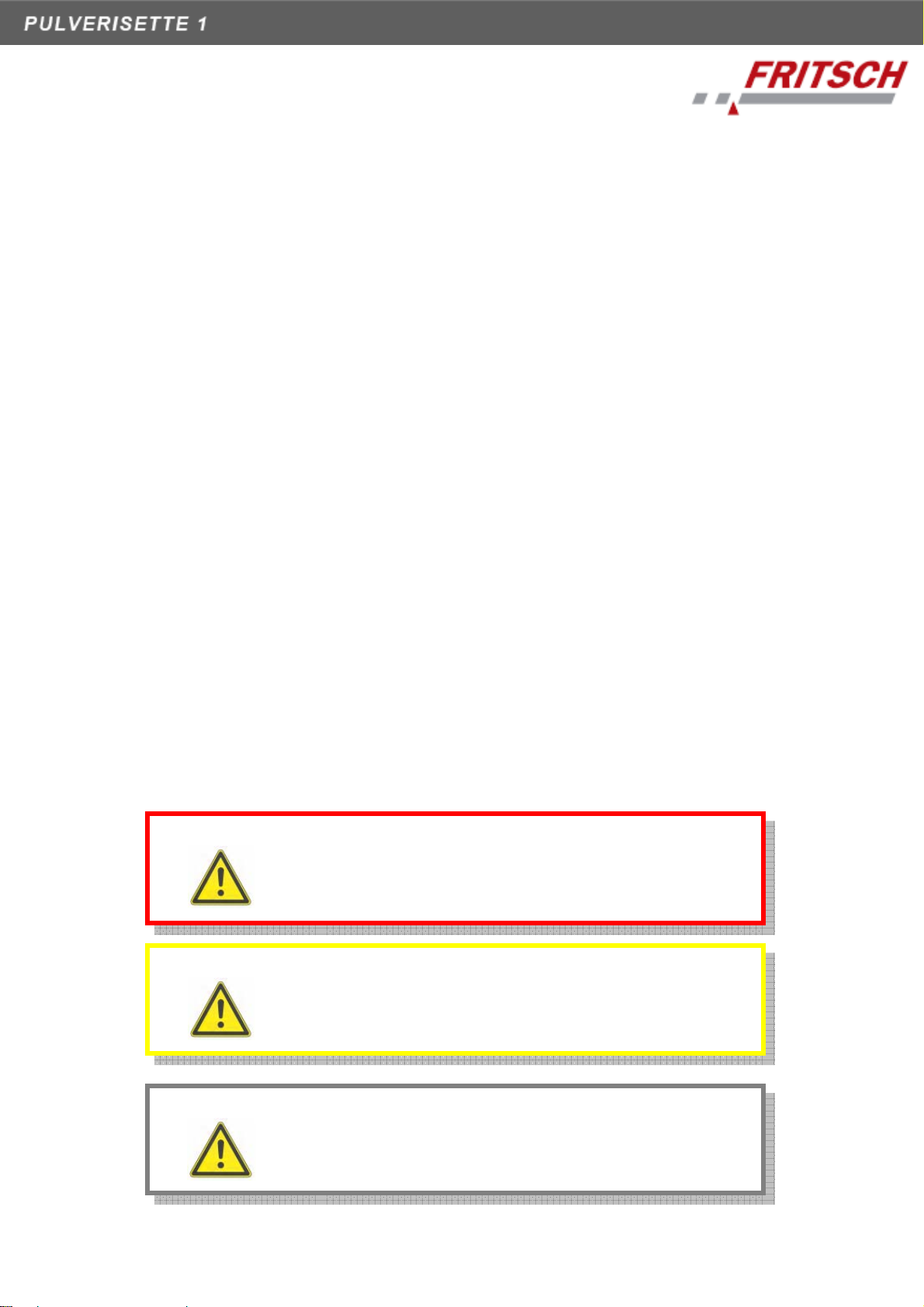

(3) guide bolt

(13) support wall (both sides)

(14) crusher jaw movable cpl.

(15) crusher jaw fixed cpl.

(7) indexing cranked handles

(6) link pin

(16) clamping block

(17) crusher jaw fixed

(18) crushing plate fixed

(19) pressure plate

(20) compensating plate

(21) crusher jaw movable

(22) crushing plate movable

(23) link plate

(24) clamping block

Page 5

2 Safety Instructions and Proper Use

2.1 Requirements on the Operator

This operating manual is intended for persons who are assigned the operation and

supervision of Fritsch Jaw Crusher.

Persons under the influence of health impairments, medications, drugs, alcohol or

excessive fatigue may not operate the instrument.

The instrument may only be operated by authorised persons and may only be

maintained and repaired by trained experts. All commissioning, maintenance and

repair work may only be performed by qualified personnel!

The instructions of this manual must be heeded in order to avoid danger to the

user.

This operating manual is not a complete technical description. Only the details

required for operation and preserving the operability of the instrument are described

here.

Fritsch created and checked this operating manual with great care. However, no

guarantee can be provided with regard to completeness and the absence of errors.

Subject to technical changes.

2.2 Proper use

The „pulverisette 1“ is a laboratory jaw crusher for the pre-crushing of hard-brittle

substances especially for the following fields of application: mining and metallurgy,

geology and mineralogy, chemistry, glass and ceramics, earths and stones.

The initial feed size is of a maximum

• of 65 mm for the type P1/I

• of 100 mm for the type P1/II

The obtainable final size - depending on the gap setting - is from about 15 mm to 2

mm.

The jaw crusher described here is a tool for use in industrial environments.

The instrument may only be used for this purpose.

2.2.1 Method of Operation

The crushing of the materials is being done within a crushing chamber consisting of

two lateral support walls (13), one settable fixed crushing plate (18) and one

movable crushing plate (22). The movable crusher jaw (21) is put into an eccentric

movement by means of a fly-wheel and a sturdy cam.

Due to its special motion sequence, the materials to be crushed are drawn into the

crushing chamber and the blockage of crushed pieces is prevented.

The material drops from the crushing chamber through the adjustable discharge

gap into the collecting vessel (12).

Page 6

2.3 Obligations of the Operator

This manual must be carefully read and understood before using the product. Use

of the product requires specialised knowledge and may only be undertaken by

commercial users.

The operating personnel must be familiar with the contents of the operating manual.

It is therefore very important that this operating manual also actually be provided to

these persons. It must be ensured that this operating manual always remains

alongside the instrument.

The product may only be used within the scope of possible uses described in this

manual and within the framework of the rules and regulations defined in this

manual. In the event that these principles are violated or in event of improper use,

the customer shall bear the full liability for the functionality of the product or for

damages or injuries resulting from failure to heed this obligation.

By using this product, the customer agrees to this and recognises that defects,

faults or errors cannot be completely excluded. In order to avoid the risk of damage

to property or personnel injuries arising from this or any other circumstance or the

risk of other indirect or direct damages, the customer must take sufficient and full

safety precautions while working with the products.

Fritsch GmbH is unable to monitor compliance with this manual or the conditions

and methods employed during installation, operation, use and maintenance of the

product. Improper performance of the installation can result in material damage and

subsequently endanger human beings. For this reason, we accept no responsibility

or liability whatsoever for losses, damages or costs resulting from or in any way

associated with faulty installation, improper operation or incorrect use and

maintenance.

The applicable accident prevention regulations must be complied with.

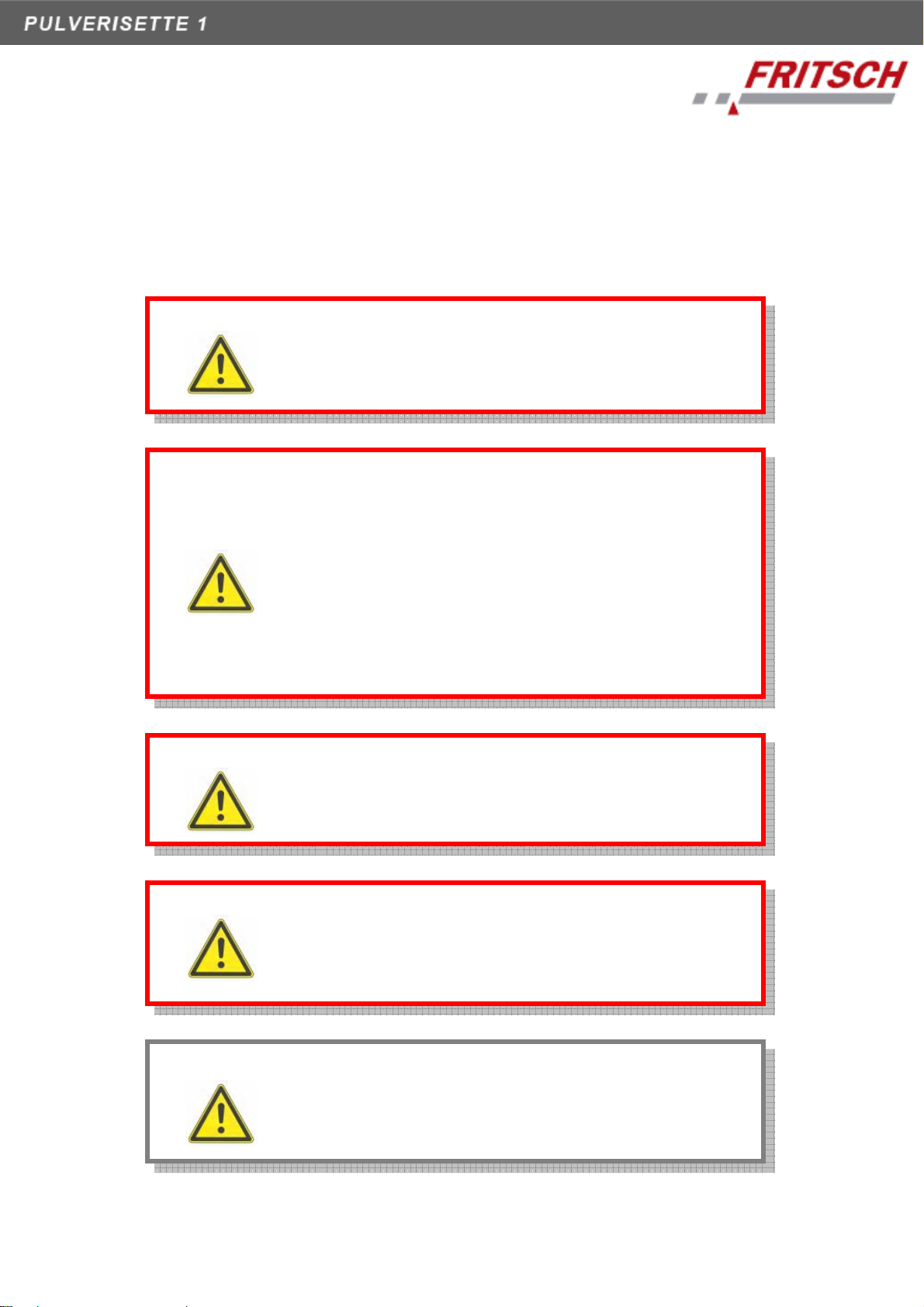

2.4 Warnings Used

The following symbols are used in this description to indicate important information

and possible dangers.

For your safety, please heed the warnings.

DANGER

WARNING

CAUTION

Indicates a direct danger with high risk that will lead to

death or severe physical injury if not avoided.

Indicates a possible danger with moderate risk that

could lead to death or (severe) physical injury if not

avoided.

Indicates a danger with low risk that could result in

slight or moderate physical injuries or material

damages if not avoided.

Page 7

2.5 Machine safety instructions

We recommend that a safety logbook should be kept in which all work (service,

repairs etc.) carried out on the machine should be entered.

Use only original accessories and original spare parts. The safety of the machine is

impaired if this instruction is not followed.

Operating personnel must always operate the machine with safety in mind.

Do not run the laboratory jaw crusher unsupervised.

DANGER

DANGER

DANGER

Danger of explosion!

The machine is not explosion protected and is not

designed to grind explosive materials.

Danger of explosion!

When grinding oxidable materials (e.g. metals or

coal), there is a risk of instantaneous combustion

(dust explosion) if the material exceeds a certain

fineness. The fine material can be absorbed through

a filter in the back of the machine and could ignite on

electric components. It is therefore necessary to take

special safety precautions when grinding such

material and the work must be supervised by a

specialised

Do not deactivate safety devices.

DANGER

CAUTION

Unauthorised changes to the machine void the attestation of conformity to

European directives by FRITSCH as well as the loss of the warranty.

All threshold limit values according to current safety

requirements must be followed; if necessary, a

ventilator must be provided or the machine must be

operated under an extractor outlet.

• Wear protective glasses!

• Wear ear protection! The noise level is above

93dB(A)

• Do not continue to use damaged accessories.

Page 8

2.6 Safety equipment

Safety equipment must be used in accordance with

TIP

Inside the jaw crusher „pulverisette 1“ several elements independently acting

contribute to security:

1. Reaching into the funnel (1) is prevented by the zigzag-shaped material

passageway.

2. A safety switch (11) monitors during the operation the closing of the front cover

(10) and prevents the operation of the machine after the opening of the cover.

⇒ The switch is in accordance with the regulations for the protection of

operators.

the regulations and must not be rendered inoperative

or be removed.

All safety equipment must be checked regularly for

completeness and function.

⇒ The jaw crusher will not start if the front cover is open.

⇒ The jaw crusher will stop if the front cover is opened during operation..

2.7 Hazard points

• Crushing possibility during the closing of the front cover (10)!

2.8 Electrical safety

2.8.1 General

• The main switch (4) disconnects all-phase of the instrument from the mains.

• If the jaw crusher is not in use over a prolonged period of time, for example at

night, unplug the jaw crusher from the mains

• The machine has a motor protection switch (as per nameplate).matched to the

mains voltage

In the event of overload or a faulty motor or cable, a protection switch

automatically interrupts the flow of power. The jaw crusher can be turned back on

with the main switch (4) once the malfunction is eliminated.

• The jaw crusher is switched on and off with the main switch (4)

⇒ Turn the main switch (4) to the start position Æ : The jaw crusher starts.

⇒ By turning of the main switch (4) to the Stop position Æ, the jaw crusher:

comes to a halt after approx. 3 seconds.

⇒ The front cover (10) can now be opened.

2.8.2 Protection against warm restart

In case of Power failure, while the machine is in operation, the jaw crusher: comes

to a halt after approx. 3 seconds. Once power is restored the jaw crusher will not

start back up automatically.

⇒ The jaw crusher is protected against re-start.

⇒ Turning the main switch (4) on start position the jaw crusher will start

again.

Page 9

Loading...

Loading...