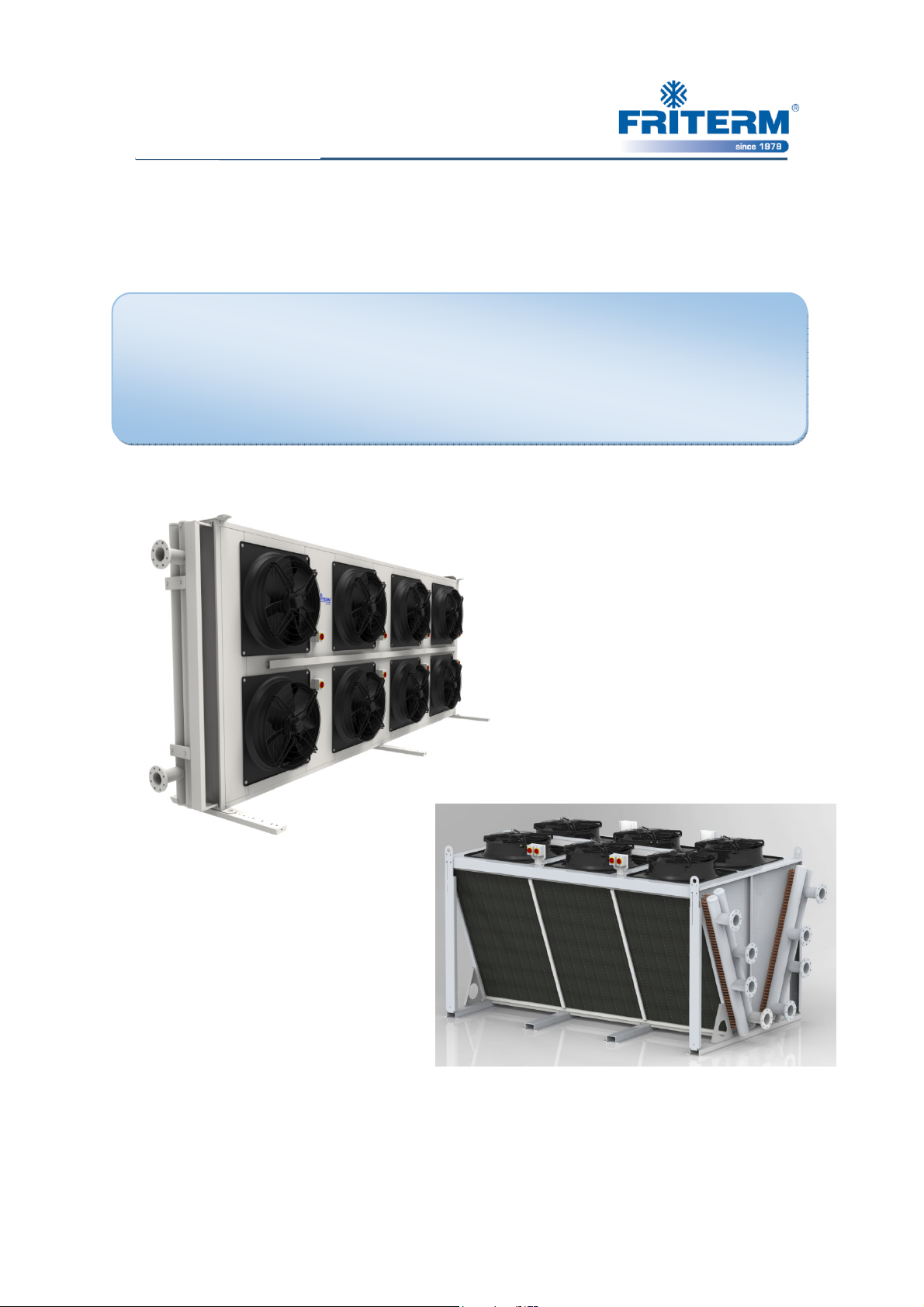

FRITERM FDH, FDW, FDV Installation, Operation And Maintenance Manual

Dry Coolers

INSTALLATION, OPERATION AND

INSTALLATION, OPERATION AND

INSTALLATION, OPERATION AND INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

MAINTENANCE INSTRUCTIONS

MAINTENANCE INSTRUCTIONSMAINTENANCE INSTRUCTIONS

FDH, FDV, FDW

www.friterm.com

ii

CONTENTS

1. ABOUT THIS MANUAL/GENERAL ............................................................................................ 1

1.1 Examining the operating manual ................................................................................................... 1

1.2 Warranty ........................................................................................................................................ 1

2. SAFETY REGULATIONS .............................................................................................................. 5

2.1 Symbols and warning signs ........................................................................................................... 5

2.2 Personal protection ........................................................................................................................ 6

2.2.1 Personal protection signs ........................................................................................................ 6

2.3 Warnings ....................................................................................................................................... 8

2.4 Improper use .................................................................................................................................. 9

2.4.1 Hazardous rotating machinery ................................................................................................ 9

2.4.2 Hazardous voltage .................................................................................................................. 9

2.4.3 Hazardous thermal .................................................................................................................. 9

2.4.4 Hazardous refrigerant ........................................................................................................... 10

2.5 Environmental protection ............................................................................................................ 11

3. LABELLING ................................................................................................................................... 11

3.1 Product code ................................................................................................................................ 11

3.2 Type plate .................................................................................................................................... 11

3.3 Friterm Logo................................................................................................................................ 12

4. TECHNICAL DATA ...................................................................................................................... 12

4.1 Standards ..................................................................................................................................... 12

4.2 Product ........................................................................................................................................ 12

4.3 Fans ............................................................................................................................................. 13

4.3.1 Fan connection diagrams ...................................................................................................... 14

4.4 Control Systems .......................................................................................................................... 16

4.4.1 Thermostat (Dixell XC650C) Keyboard .............................................................................. 16

4.4.2 Icons ..................................................................................................................................... 17

4.4.3 Parameters ............................................................................................................................ 18

4.4.4 Tables of Alarms .................................................................................................................. 21

4.4.5 Wiring Connection: .............................................................................................................. 22

4.4.6 The Adjustment of Thermostat Control Part According to the Application of Different

Fan Number ................................................................................................................................... 23

4.4.7 Power Wiring ....................................................................................................................... 24

4.4.8 Control Wiring ..................................................................................................................... 25

4.5 Sound pressure level .................................................................................................................... 26

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

iii

4.6 Sound power level ....................................................................................................................... 26

5. TRANSPORT AND STORAGE ................................................................................................... 27

5.1 Check for completeness and transport damage ........................................................................... 27

5.2 Transport ..................................................................................................................................... 27

5.3 Storage ......................................................................................................................................... 30

6. INSTALLATION ............................................................................................................................ 30

6.1 Location ....................................................................................................................................... 31

6.2 Requirements at the set up point ................................................................................................. 31

6.2.1 Outdoor set up of FCH unit .................................................................................................. 31

6.2.2 Set up next to wall ................................................................................................................ 31

6.2.3 Set up in pit-hallow .............................................................................................................. 32

6.2.4 Several FDH units ................................................................................................................ 33

6.2.5 Requirements at the set up point (FDW units) ..................................................................... 33

6.2.6 Several FDW units ............................................................................................................... 34

6.2.7 Requirements at the set up point (FDV units) ...................................................................... 34

6.2.8 Side-by-side setup (FDV units) ............................................................................................ 35

6.3 Mounting ..................................................................................................................................... 35

6.3.1 Ideal mounting scheme ......................................................................................................... 38

6.3.2 Leg mounting ....................................................................................................................... 38

6.4 Electrical Connection .................................................................................................................. 51

7. OPERATION .................................................................................................................................. 52

7.1 Initial commissioning .................................................................................................................. 52

7.2 Regular commissioning ............................................................................................................... 52

7.3 Shutting down.............................................................................................................................. 53

7.4 Step control application (If Applicable) ...................................................................................... 53

8. MAINTENANCE ........................................................................................................................... 54

8.1 Maintenance intervals .................................................................................................................. 54

8.2 Fan motor maintenance ............................................................................................................... 55

8.3 Periodical controls (Once a year) ................................................................................................ 56

9. TROUBLESHOOTING .................................................................................................................. 57

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

1

1. ABOUT THIS MANUAL/GENERAL

This document specifies the instructions for installation, operating and maintenance of the

Dry Coolers (FDH, FDV, FDW models) manufactured by FRITERM A.Ş., Turkey.

The instructions below must be followed strictly for the labor health and safety reasons during

installation and maintenance of products.

Upon receipt, the product should be visually inspected, and in case of any damage or fault, the

supplier must be notified within 7 days.

The manufacturer will not accept any responsibility in these situations;

• Damages caused by persons,

• Damages product due to the disregarding of the recommendations indicated in this

handbook.

1.1 Examining the operating manual

To follow the instructions defined in this document is a prerequisite for safety of the staff and

for the products to be operated in a fault-free and safe manner.

• The operating manual must always be available.

• All persons who are responsible for the transport, assembly, initial commissioning,

operating, maintenance or repair of the component must be acquainted with the operating

manual. The operator should accept in written form that they are acquainted with the

operating manual.

• Whenever you have difficulty in understanding and/or comprehend and description or

definition given/expressed in this manual, please immediately ask for help from an

expert or from then manufacturer. It is of great importance to understand this manual

completely and correctly for the sake of labor health and safety.

1.2 Responsibilities

The manufacturer is strictly responsible for supplying a manual accompanying the product

which comprises the necessary and enough detailed information regarding the

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

1.2.1 Manufacturer’s Responsibilities

2

installation/mounting and operation of the product. Besides, the product is expected to fulfill

the requirements and satisfy with the anticipated functioning.

The construction of the product should comply with the presumed operational conditions. The

product is expected to be robust enough and resistive against all the mechanical, thermal

and

chemical challenges. The material used to produce should be compatible with the fluid and

the mixture of fluids used as heat transfer media.

All the materials and components used in constructing the product should be resistive against

all the stress and pressure that the product will be subjected to.

1.2.2 Contractor’s Responsibilities (Installation, Commissioning)

• Should follow all the instructions and provide all the conditions stated in this manual.

• All the documentation accompanying the product are complementary to this manual. The

safety instructions and all other information stated in this manual should be considered.

• The national regulations regarding the protection of environment and labor safety should

be strictly followed besides the instructions for safe and correct operation.

• In case of any problem encountered during the installation, FRITERM A.Ş. should be

informed and asked for technical assistance if necessary.

• Emergency instructions and the required infrastructure should be prepared and redy for

use in any case.

• The regular maintenance/servicing periods and instructions should be determined and

defined.

• The additive in order to prevent the freezing of the operating fluid should be feed as

requires and as much as required.

• If storage of the product for a long period is needed, a clean, non-hazardous and low

humidity environment is recommended.

• The fans of the products that are stored horizontally are recommended to be run for 4-5

hours a week. In case of difficulty of running the fans, then they should be covered and

protected from rain and excess humidity.

• In case of storing vertically, it is not recommended to store more than 1 month.

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

3

1.2.3 Operator’s or Owner’s Responsibilities (Operation and

Maintenance)

• The director is the responsible person who employs the adequate staff for servicing

• operating and monitoring the system.

• All requirements and instructions in this operating manual must be complied with.

• The documentation of purchased products is a constituent part of this operating manual.

All safety information in this operating manual and all other information must be

observed.

• All relevant regulations concerning accident prevention and environmental protection

must be complied as well as the confirmed technical regulations for safe and proper

working.

• Personal ineligibility. All the work should be conducted by authorized and trained

personnel.

• Any defect/damage/malfunction caused by disregarding the instructions given in this

manual is the responsibility of the operator.

• Any defect/damage/malfunction caused by the misuse of the product is the responsibility

of the operator.

• The product should not be put in operation without the completion of the installation and

commissioning.

• The personnel who is responsible for the operation/servicing/maintenance of the product

should be provided with all the necessary documentation including this manual.

1.3 Warranty

• The manufacturer warrants that the equipment delivered to the client shows no defects

caused by failure of design, material, manufacturing and/or workmanship within the

warranty period.

• The client must notify in written form within 10 days from the receipt of the goods, any

perceptible defects including transport damages. For hidden defects, he must notify and

explain in details the defect in written form within 10 days from observation time.

• Unless otherwise agreed, the warranty period shall be 24 months starting from the date of

delivery.

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

4

• The warranty does not cover defects in the product’s operation stemming from a fault in

materials or parts provided by the client, nor shall it cover an installation that has not been

assembled according to the manufacturer’s instructions and according to professional

practice. The products or parts that the costs are not paid to the producer are out of

manufacturer’s warranty.

• The products called “Dry Coolers” mainly used in order to cool the fluid (usually water

but in case of atmospheric conditions below zero degree, antifreezer added solution) to a

desired temperature. The fluid to be cooled down should be transferred to the Dry cooler

via the piping properly installed according to the rules and related instructions. The usage

of the Dry Cooler out of its anticipated functioning is out of the scope of warranty.

• In sub-zero temperatures sufficient antifreeze solution must be added and fluid should be

checked by measuring the freezing temperature on a regular basis. In case of occurring

any damage on the product due to freezing of the fluid, all the fitting actions and materials

used in order to repair the product will be out of manufacturer’s warranty.

• The warranty shall not cover equipment and/or its accessories if they have been modified

by the client without manufacturer’s written consent.

• The warranty clause can only be invoked by the client if the equipment is used normally

and in conformity with its purpose and manufacturer’s instructions.

• The manufacturer’s liability hereunder shall be limited to repair, modify or replace the

parts or equipment that shows defect within the limitation of the items under this article.

• The warranty period of the repaired or modified or replaced parts or equipment shall in no

way extend the warranty period of the original ones.

• The works resulting from the warranty conditions shall be carried out in the

manufacturer’s workshop after the client has sent the defective equipment or parts for

repair or replacement.

• The manufacturer’s responsibility is strictly limited to the obligations as stipulated herein

and it is expressly agreed that he shall not be found to make any other indemnity. In

particular, he shall in no case be liable to compensate loss caused directly or indirectly by

a defect in the equipment delivered.

• The product should be installed and commissioned in accordance with the

national/international regulations and rules.

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

5

In case of operational conditions with temperatures below zero the sufficient amount of antifreezer (

• For the fans having thermal protection, the related wiring should be definitely done and it

is considered as contractor’s and/or owners responsibility. Any defect caused by

misconnection of the thermal protection wiring in accordance to the circuit diagrams

given in this manual would be out of manufacturer’s warranty.

• The power supply which the product is supplies should not deviate 10% from the values

given on the label.

DANGER OF FREEZING

e.g.Ethelene Glycol) should be added unless the water will stay in the system at still times. In order

to be able to avoid the danger of freezing a sufficient amount of antifreezer solution should be

added to reach a freezing temperature of 7-10 C below the operation temperature.

2. SAFETY REGULATIONS

2.1 Symbols and warning signs

The following terms and/or symbols are used in the operating manual for particularly

important information.

Safety messages and symbols are quoted at the relevant positions in the operating manual if

there is danger such as death, personal injury and environmental damage. These safety

warnings must be strictly adhered to.

Indicates a hazardous situation which, if not avoided, may

result in death or serious injury

Indicates a hazardous situation which, if not avoided, may result

in serious injury.

Indicates a hazardous situation which, if not avoided, may result

in moderate or minor injury.

Additional notes, information and tips.

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

IN CASE OF DANGER

Switch off the power

Switch off the main

Please ask assistance from an authorized technician

Please do not try to resolv

While working on and standing by the

Protective gloves for fitting and repair work

resistant clothing and protective gloves for cleaning work, especially when

Safety goggles for cleaning work, especially

compressed air for cleaning

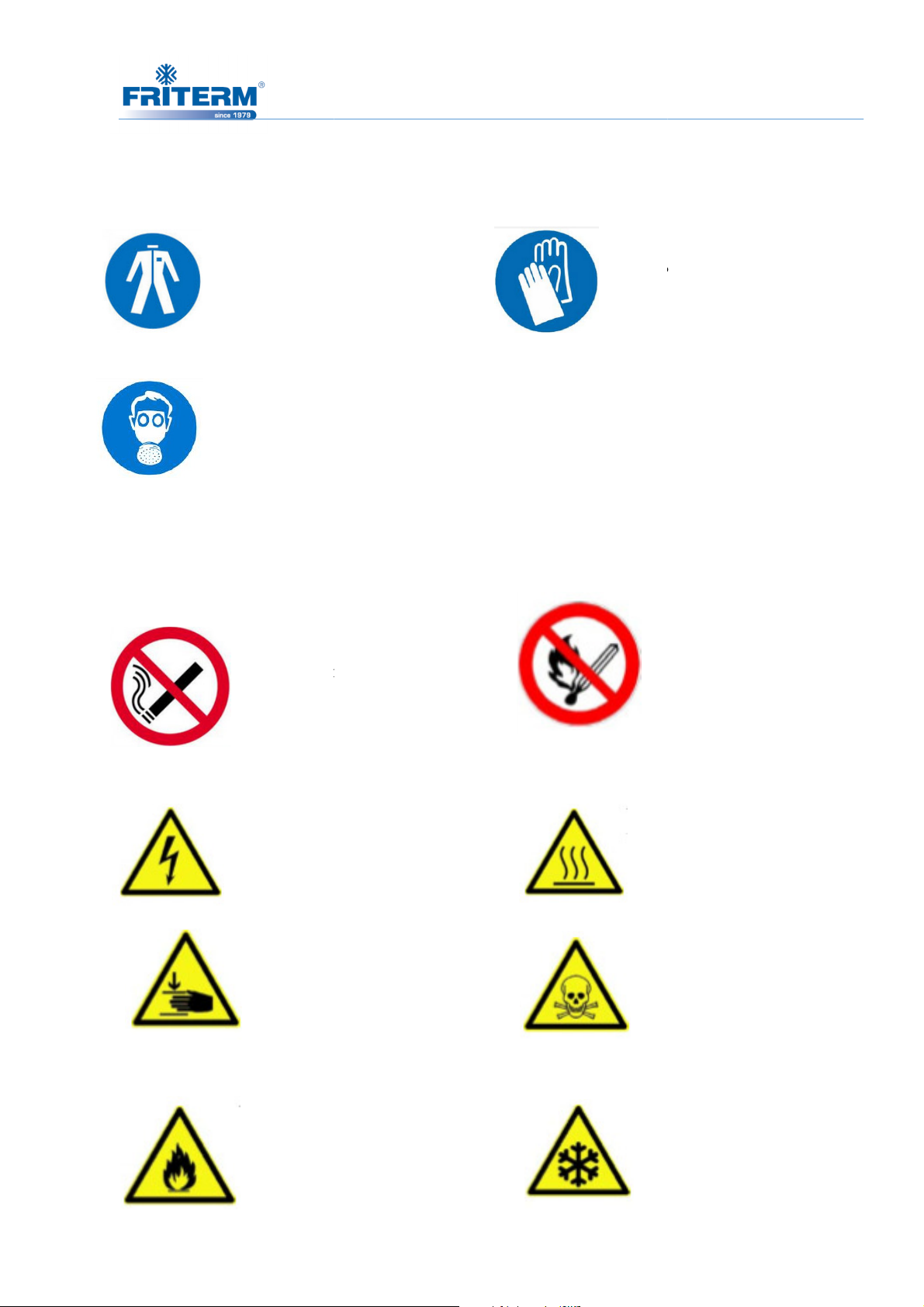

2.2.1 Personal protection signs

Head Protection

Foot Protection

Rev.No:9 Dok. No: KLV.004.ENG

or expert

e any problem by trial and error

, protective clothing must be worn.

handling solvents

Eye Protection

High Visibility Clothing

6

!

•

•

•

•

2.2 Personal protection

• Safety shoes

• Safety helmet

•

• Chemical-

handling solvents

•

.

.

product

while

or using

• Hearing protection

Rev. Tarihi:25.05.2016

Protective Clothing

Respiratory Protection

No Smoking

High Voltage

Hand Injuries

Fire Risk

Rev.No:9 Dok. No: KLV.004.ENG

Hand Protection

Flammable

Hot Surfaces

Poisoning Danger

Frostbite Hazard

7

2.2.2 Warning signs

Rev. Tarihi:25.05.2016

8

2.3 Warnings

• In an unexpected situation use the emergency stop button which is set up on an easily

accessible place.

• Do not exceed maximum operating pressure given on the unit’s type plate.

• Unless the advised safety devices available or fully active the unit must not be

operated.

• Set up the unit with extreme cleanliness.

• The unit must not be operated if it is damaged. FRİTERM A.Ş. must be informed

about all damages.

• The unit must be installed, operated and maintained by authorized/qualified personnel

only.

•

• In case of using any other fluid and additives specified on the label (water, Ethylene

Glycol, propylene Glycol, Brandname thermal fluids) may cause damage, leakage,

danger and environmental pollution.

• No modification is allowed on the product without written permission from the

manufacturer.

• Operational conditions are limited within the specified range by the manufacturer. In

case of need to operate the product out of the range, a confirmation should be asked

from FRITERM A.Ş.

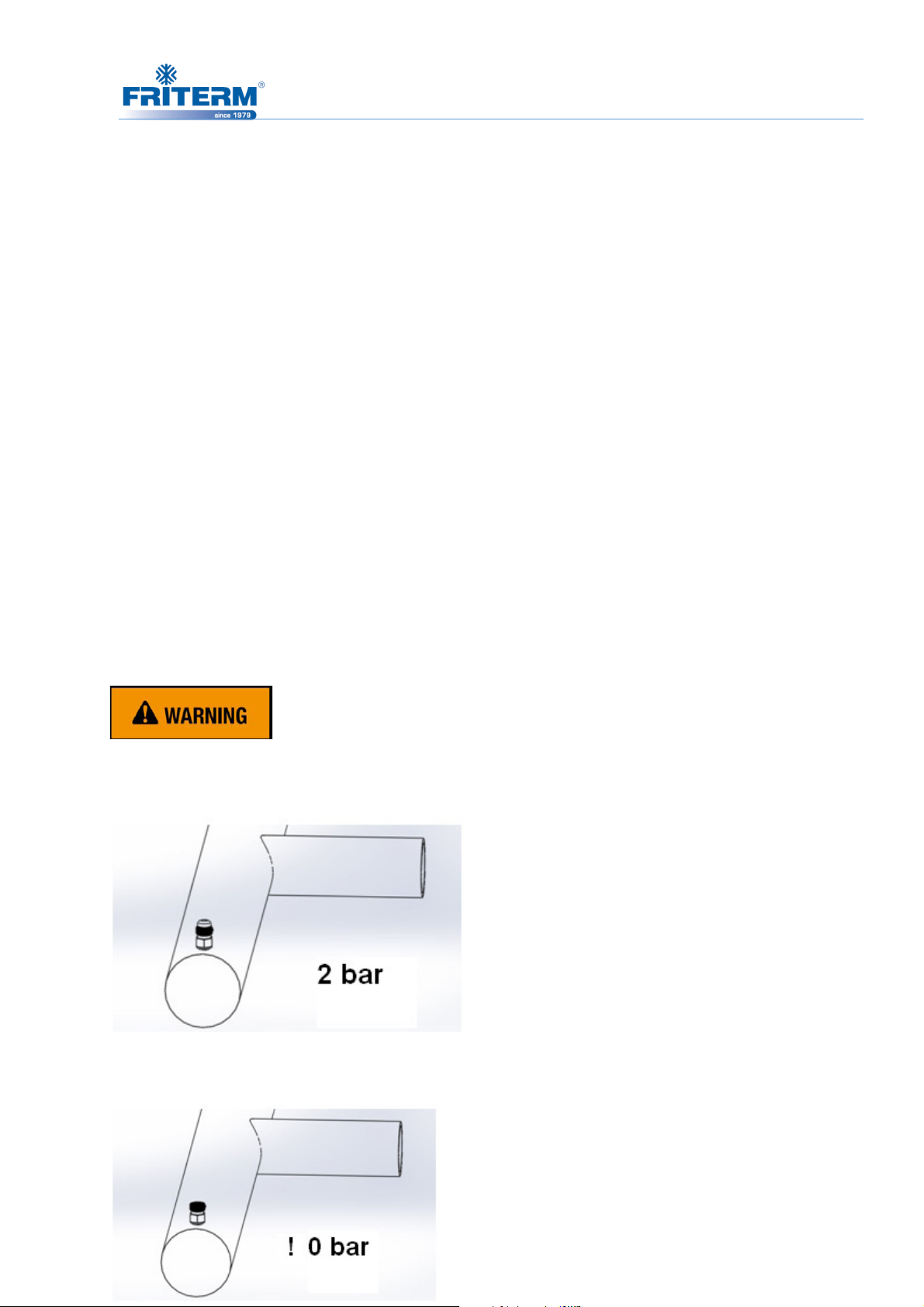

The product is delivered with 2 bar pressure. Upon receipt, it must be checked with

schrader valve.

After checking, unless the product has 2 bar pressure Friterm must be notified

immediately.

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

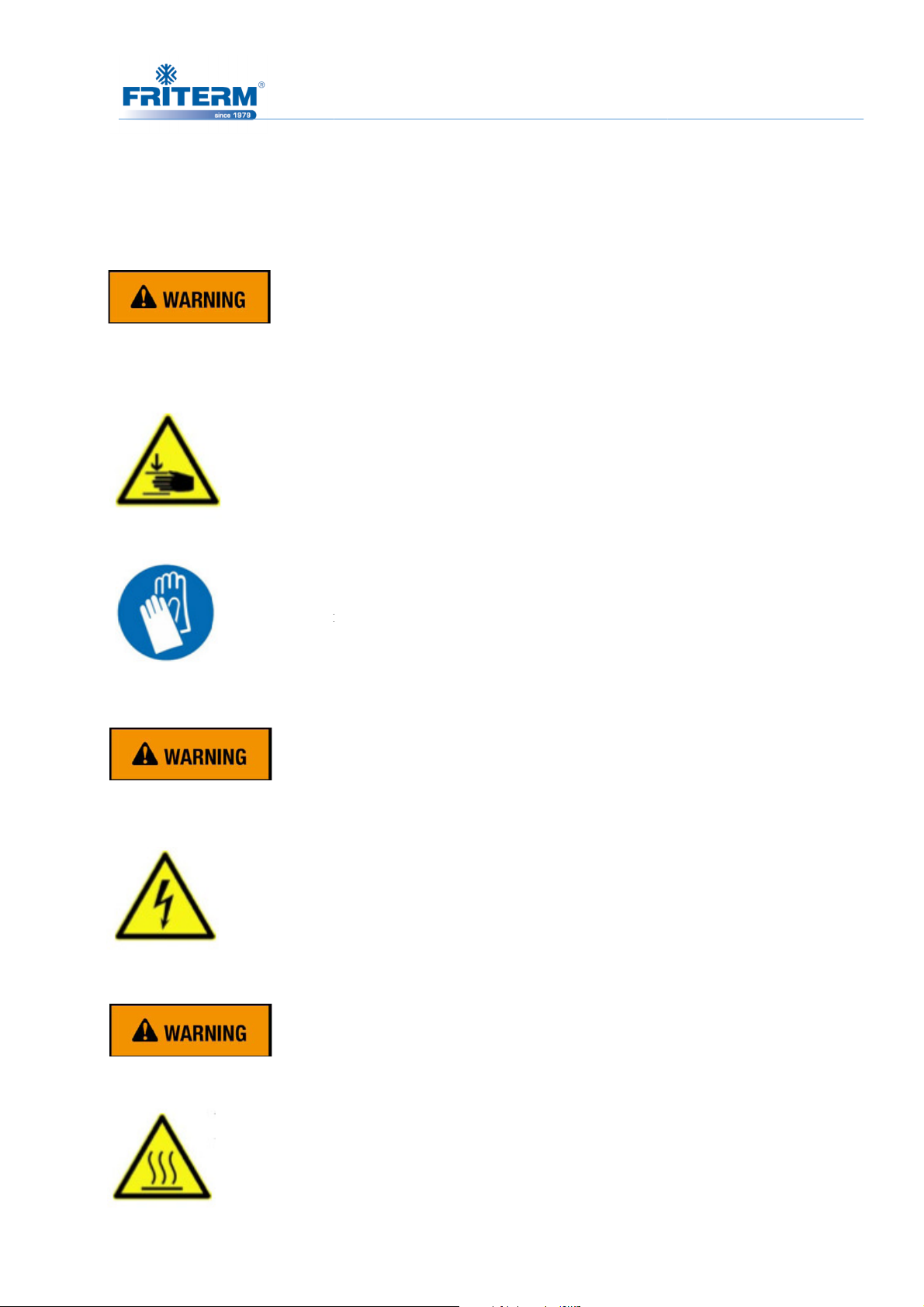

Danger of injuries in improper using;

2.4.1 Hazardous rotating machinery

Danger of

authorized technician.

Use hand protection.

oltage can cause serious injuries or death. Do not contact with

voltage direct or indirect. Do not

begin maintenance work.

Some of the components of the unit such as fin and tube have high

Rev.No:9 Dok. No: KLV.004.ENG

Lids should be unscrewed by an

forget to power off the unit before you

2.4 Improper Use

9

2.4.2 Hazardous voltage

Electrical v

cutting hands and fingers.

2.4.3 Hazardous thermal

temperatures.

Rev. Tarihi:25.05.2016

Danger of burns and frostbites.

The danger of frostbite can occur if there

if the unit cannot be drained completely, frostbite hazard occurs after

Fluid: Glycol

Yanıcı özelliğinden dolayı etilen glikol her zaman ate

No smoking.

suitable fire

while working with fire or sparks.

Due to the hazardous effect on human skin and nerve system please avoid

direct contact of skin.

Rev.No:9 Dok. No: KLV.004.ENG

ficient frost protection.

o prevent ignition

For protection use protective clothing.

10

is insuf

Also

draining.

2.4.4 Hazardous

Ensure

fighting equipment is used in order t

Rev. Tarihi:25.05.2016

11

2.5 Environmental protection

While handling the product, it has to be ensured that materials which can endanger the

environment are disposed of properly. Service materials must not be allowed to enter the

sewerage system and the ground water system.

All relevant national regulations concerning environmental protection and the technical issues

for safe and proper working must be complied.

3. LABELLING

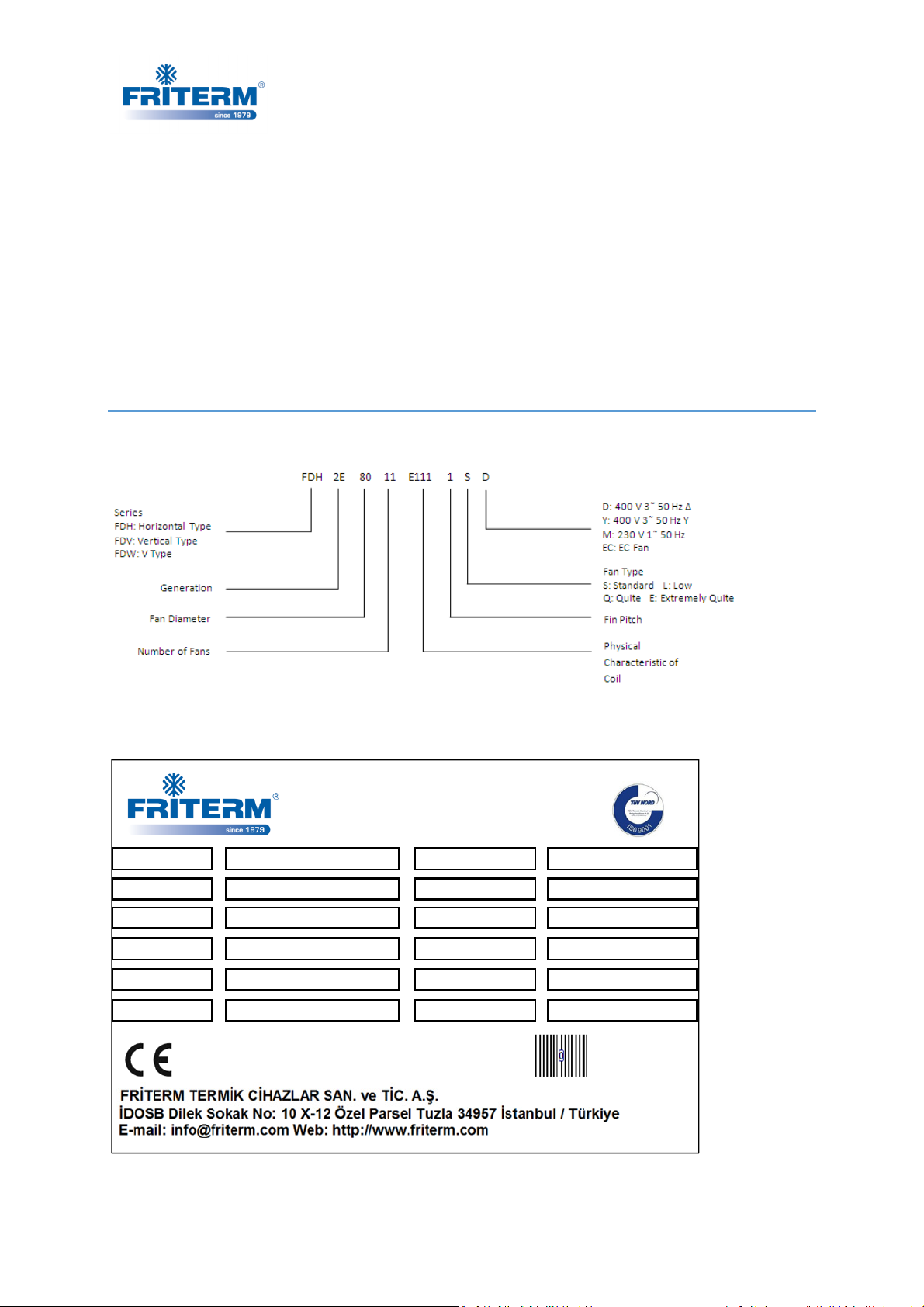

3.1 Product code

3.2 Type plate

Type FDH 2E 8012 E121 3 SD- 6p Fan speed ( Δ/ Y) 890/ 690 rpm

Serial Nr. Total Power

TS min/ max. - 40/ +110 °C Power Supply 400 V AC 3 Ph 50 Hz

Dry Weight

Internal Vol.

Medium Water- Glycol/ Fluid G2 Prod. Year

409 kg

41.4 L.

Max. Opr. Pr. 16 Bar

Test Pr. / Medium 20 Bar/ Dry Air

( Δ/ Y) 3.6/ 2.3 kW

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

12

3.3 Friterm Logo

4. TECHNICAL DATA

4.1 Standards

• 97/23/EC PED (Pressure Equipment Directive)

• EN 378 “Refrigeration systems and heat pumps, technical safety and environmental

requirements”

• Capacity standard for dry coolers is defined according to the EN 1048 standard with

the ratio of % 34 ethylene glycol. (

Test methods for establishing the performance)

• The system installer is responsible for that the inherent installation and security

information are harmonized with the valid standards and guidelines (DIN EN 292 /

294).

4.2 Product

The basic principle is to transfer the return water load in the system to air by the aid of a heat

exchanger including fans. Its working principle is that the air sucked by fans cools the fluid

within the tube while it passing through the fins. Thanks to closed fluid circuit, quantity of

water does not diminish hence it is not needed to add extra water to the system.

The unit is delivered for operation with a specific operating point:

• Air inlet temperature and volumetric flow

• Fluid inlet temperature and volumetric flow

Heat exchangers- Air-cooled liquid coolers dry coolers-

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

13

4.3 Fans

• Highly efficient axial Ziehl Abegg, EBM or equivalent fans are used.

• Fans diameters: Ø800/ Ø910 mm

• 400V 3~50Hz,

• Triphase fans can work at two different speeds. Furthermore, providing speed control

is optional for EC fans.

• Variable fan speed regulation can be achieved using triphase fans with frequency

inverter and sine filter.

• Variable voltage speed control system could be used as an alternative fan speed

control system.

• All motors are suitable for speed control applications up to 100 %.

• All motors have feature internal thermal protection.

• Standard wiring of all motors are for one speed.

• Working temperature for exterior mounting is between -40 ºC and +50 ºC - +70 ºC.

• Fans are designed with assuming fans working Fans run in a housing designed to

maximize air flow.

• Recommended starting for motors is 6 starts per hour, maximum starting for motors is

10 starts per hour.

• In case of prolonged stoppage of system, run the fan motors at least 4 hours per week.

• Motor protection IP54; insulation class F.

• Friterm reserves the right to use fans of different manufacturers. Depending on the

type, the fan data may slightly vary.

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

14

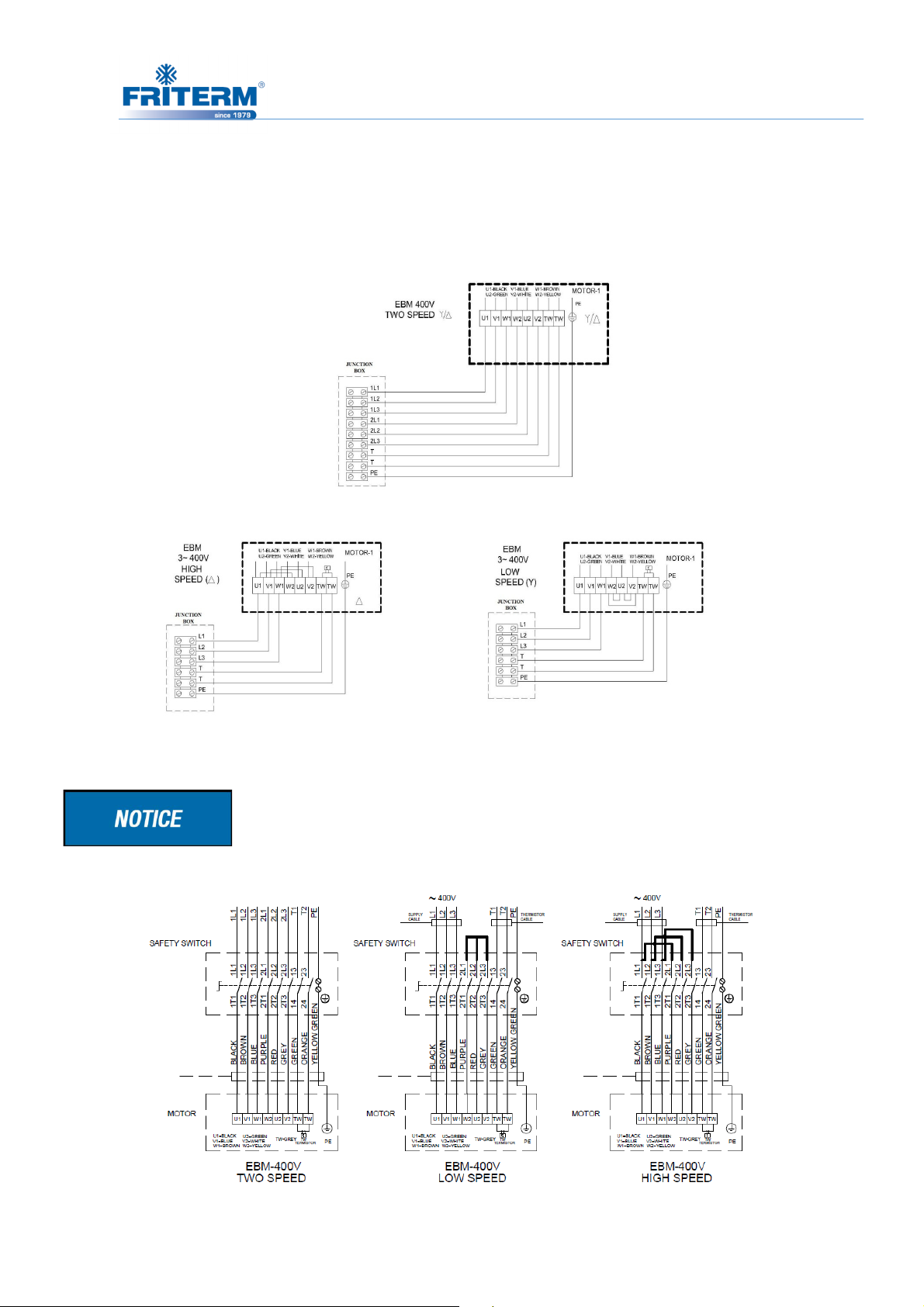

4.3.1 Fan connection diagrams

EBM 400V Fan Connection Diagram

Only specified section in bold lines are scope of supply.

Wiring of Safety Switch and Motor

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

15

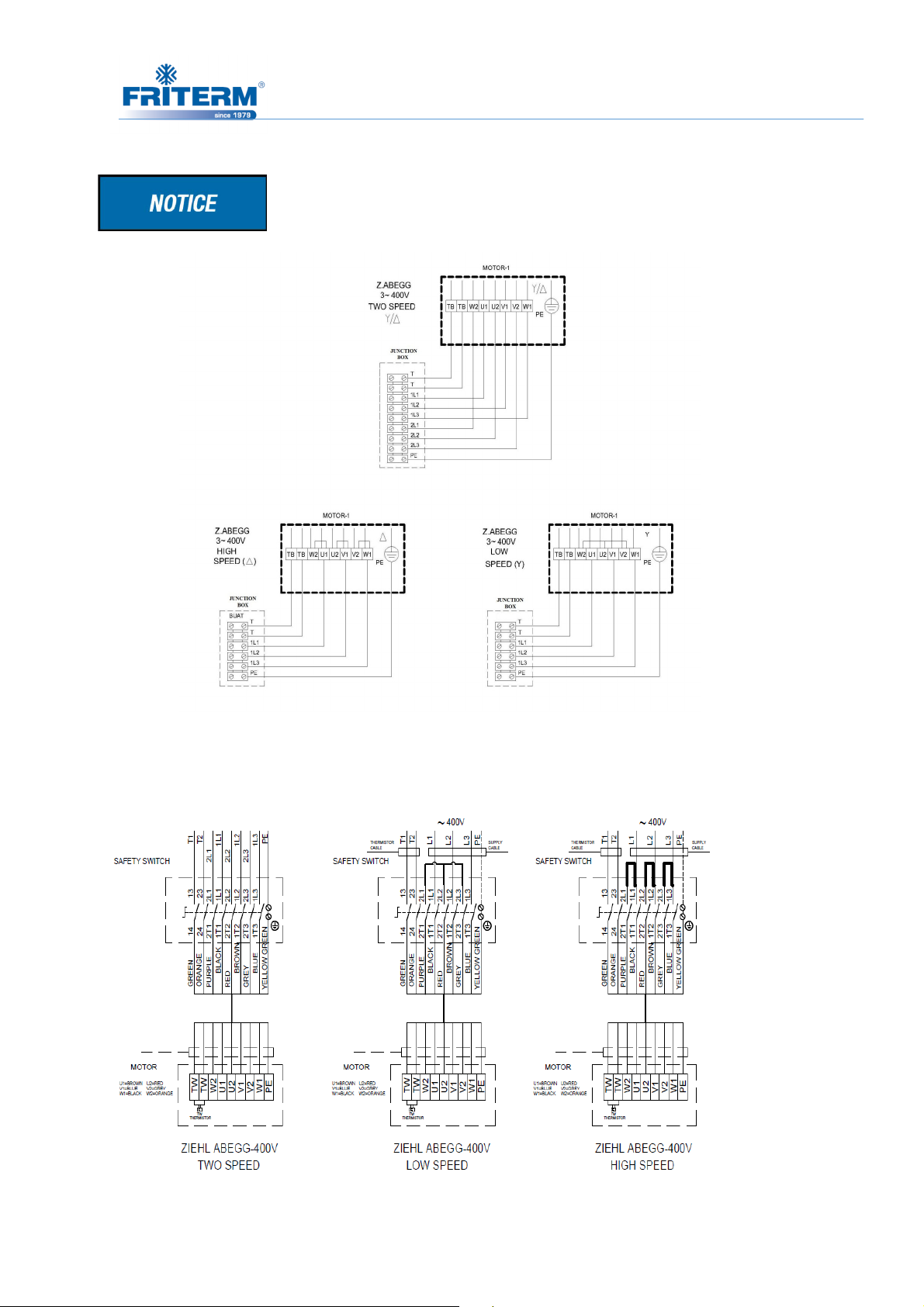

Z.ABEGG 400V Fan Connection Diagrams

Only specified section in bold lines are scope of supply.

Wiring of Safety Switch and Motor

Rev. Tarihi:25.05.2016 Rev.No:9 Dok. No: KLV.004.ENG

Loading...

Loading...