Original Instructions

Assembly Instructions

Centrifugal Pump

FP Series

Pump Type:

Pump No.:

Copyright

© Copyright 2012 Fristam Pumpen KG (GmbH & Co.)

All rights reserved. The contents, including graphic images and layout of this operating instructions manual are

subject to copyright protection and to other laws for the protection of intellectual property. The publication and

modification of the contents are not authorised. Moreover, you may not copy, publish and alter the contents therein for commercial purposes, or transmit the information to a third party.

The German version is the original version of the operating instructions manual. Other languages are translations of the original operating

manual.

Table of Contens

1 Introduction............................................... 5

1.1 Foreword................................................................... 5

1.2 Manufacturer........................................................... 5

1.3 Scope of Supply...................................................... 5

1.4 Pump Without Motor (Optional)...................... 5

1.5 Scope of Documentation.................................... 5

1.6 Display Conventions............................................. 5

2 Safety.......................................................... 6

2.1 Basic Safety Instructions...................................... 6

2.2 Intended Use ........................................................... 6

2.3 Improper Use........................................................... 6

2.4 Warning and Instruction Labels........................ 6

2.5 Noise Emissions ...................................................... 6

2.6 Disposal ..................................................................... 7

3 Design and Function ................................. 7

3.1 Principles of Design............................................... 7

3.2 Models ....................................................................... 8

3.3 Pump Key.................................................................. 9

3.4 Versions ..................................................................... 9

4 Transportation........................................... 9

4.1 Transportation ........................................................ 9

5 Storage ....................................................... 10

5.1 Safety Instructions................................................. 10

5.2 Storage Conditions................................................ 10

5.3 Long-Term Storage ............................................... 11

5.4 Recommissioning .................................................. 11

6.6 Connection of Sealing or Quenching

Liquid (Optional) ................................................... 13

6.7 Cleaning.................................................................... 13

7 Operation .................................................. 13

7.1 Safety Instructions ................................................ 13

7.2 Commencement of Operation......................... 13

7.3 Monitoring of Operation .................................... 14

7.4 Stopping of Operation ........................................ 14

7.5 Pump Decommissioning.................................... 14

7.6 Cleaning in Place................................................... 14

8 Faults ......................................................... 14

8.1 Safety Instructions ................................................ 15

9 Maintenance ............................................. 15

9.1 Safety Instructions ................................................ 15

9.2 Replacement Parts................................................ 15

9.3 Inspection of Sealing and Quenching

Liquid (Optional) ................................................... 15

9.4 Lubrication of Motor Bearings.......................... 15

9.5 Lubrication of Shaft Bearing ............................. 15

9.6 Motor Replacement ............................................. 17

9.7 Shaft Seal Replacement ...................................... 18

9.8 Pump Head Removal .......................................... 18

9.9 Checking of the Clearances............................... 18

9.10 Pump Head Attachment..................................... 20

9.11 Models FPE and FP…V: Mounting and

Alignment of the Pump Shaft........................... 27

9.12 Model L: Coupling Replacement ..................... 27

10 Appendix 1 ................................................ 28

6 Installation................................................. 11

6.1 Safety Instructions................................................. 11

6.2 Installation Location ............................................. 11

6.3 Reduction of Noise and Vibration.................... 11

6.4 Pump Fixation......................................................... 11

6.5 Electrical Connection............................................ 12

10.1 Specifications.......................................................... 28

10.2 Maintenance Intervals1....................................... 28

10.3 Troubleshooting Table........................................ 29

10.4 Number Key ............................................................ 31

10.5 EC Declaration of Conformity........................... 33

10.6 EG Declaration of Incorporation...................... 33

3

/ / FP PUMP SERIES / / /

11 Appendix 2 – Assembly Instructions

(Optional) ................................................... 34

11.1 Safety Instructions................................................. 34

11.2 Scope.......................................................................... 34

11.3 Rating Plate.............................................................. 34

11.4 Moving Without Motor........................................ 34

11.5 Installation Location ............................................. 35

11.6 Pump Installation................................................... 35

4

1Introduction

1.1 Foreword

This operator's manual describes all FP centrifugal pump sizes,

models, and versions.

Information on the model, size, and version of your pump can

be found on the rating plate on your pump and in the "Order-

Related Documents" in the attached documents.

1.2 Manufacturer

FRISTAM Pumpen KG (GmbH & Co.)

Kurt-A.-Körber-Chaussee 55

21033 Hamburg

GERMANY

Tel.: +49-40 - 72556 -0

Fax: +49-40 -72556 -166

E-mail: info@fristam.de

1.3 Scope of Supply

– Documentation on Fristam accessories (if applicable)

– Certificates (materials certificates, etc.), if applicable

– Declaration of Conformity or Declaration of Incorporation

1.6 Display Conventions

List items are preceded by dashes:

–Part 1

–Part 2

Handling instructions that must be performed in a specified

order are numbered:

1. Turn device on.

2. Turn device off.

Handling instructions that do not need to be performed in a

specified order are preceded by triangular bullets:

► Action

► Action

1.6.1 Safety Instructions

The package includes the following items:

– Pump with motor = pump unit

optional: without motor

– Covers for pipe fittings

– Optional: assembly kit

– Fristam accessories (if applicable)

– Documentation

► Check the shipment for completeness and damage.

Immediately notify Fristam of any missing items or damage.

1.4 Pump Without Motor (Optional)

The pump can optionally be supplied without a motor. In this

case, continue reading up to and including Chapter 3, "Design

and Function," page 7, and then skip to Chapter 11, "Appendix 2 –

Assembly Instructions (Optional)," page 34.

1.5 Scope of Documentation

The documentation includes the following items:

– This operator's manual

– Appendix 1 with maintenance, lubrication, and tighten-

ing torque tables

– Appendix 2 with assembly instructions

– Attached documents:

– Order-Related Documents

– Supplier Documentation (motor, coupling, etc.)

A safety instruction with the signal word "Danger" indicates

personal hazards causing death or serious injury.

A safety instruction with the signal word "Warning" indicates

personal hazards that may lead to death or serious injury.

A safety instruction with the signal word "Caution" indicates

personal hazards that may lead to mild to moderate injuries.

A safety instruction with the signal word "Note" warns of the

possibility of material damage.

5

/ / FP PUMP SERIES / / /

1

2

3

5

4

6

7

8

9

10

2 Safety

2.1 Basic Safety Instructions

► Please read this operator's manual completely before using

the pump and keep it available at the pump installation

location.

► Heed the applicable national regulations of the owner's

country and the company's work and safety regulations.

► All work described here may only be performed by qualified

experts with caution.

► Danger of contamination: Heed legal and operational safety

regulations when pumping dangerous media.

2.2 Intended Use

The standard FP centrifugal pump versions are designed for use

in the food industry, the pharmaceutical and biotechnology

industry, and CIP process technology.

They can be used to pump liquids with dynamic viscosities of up

to 1200 mPa s and media temperatures of up to 150°C. The

medium can contain a slight amount of air or gas, be

homogeneous, or contain a small amount of additives.

Each pump is designed according to customer requirements.

The seal materials have been selected for the respective

medium. The pump may only be used to pump the medium it

was designed for (see “Order-Related Documents“ in the attached

documents).

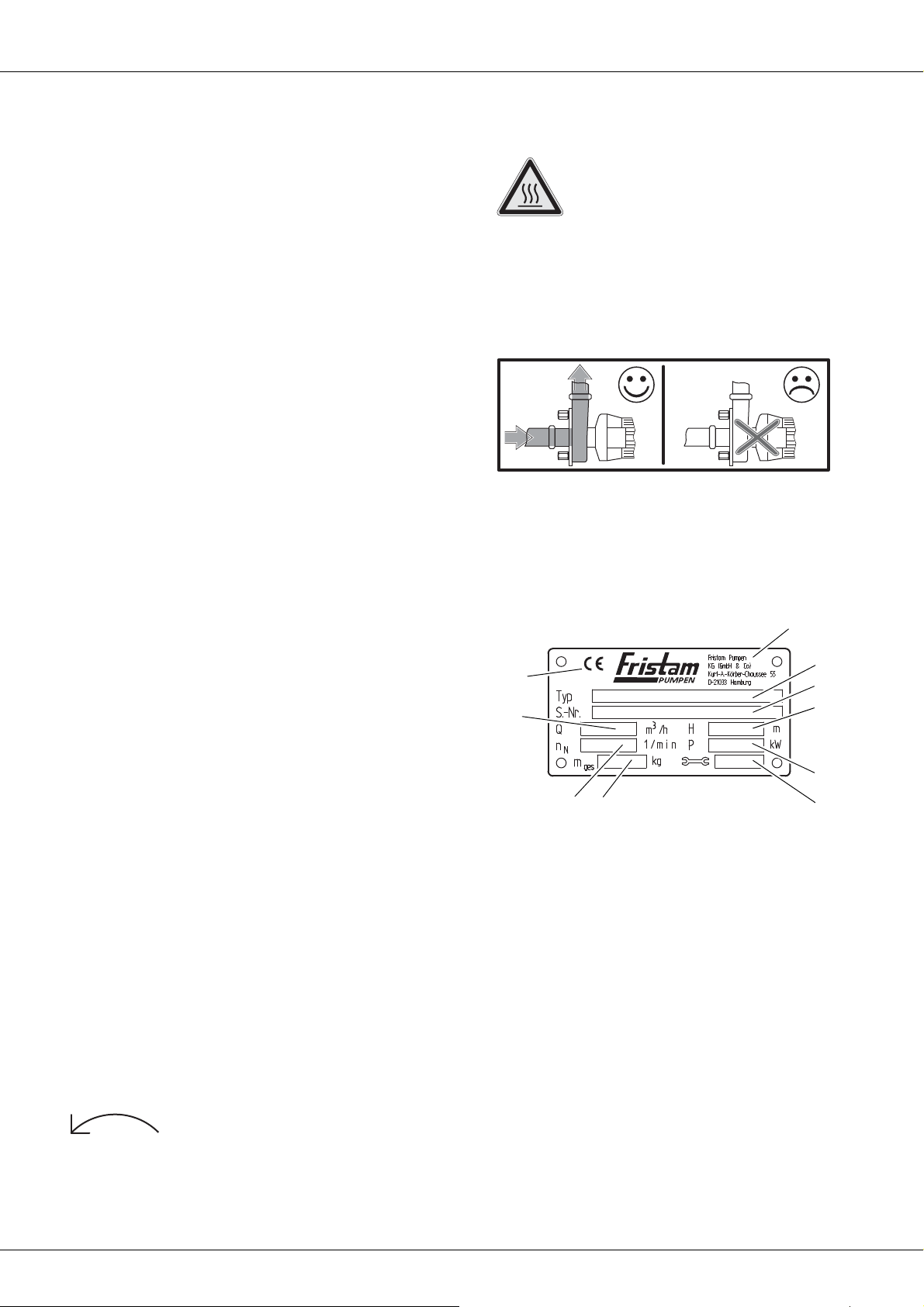

2.4.2 Hot Surface

Fig. 2Safety label: "Hot Surface"

This label indicates that parts can become hot during operation

or, if applicable, that hot media is being pumped. Only touch

the pump if you are wearing suitable gloves.

2.4.3 No Dry Running

Fig. 3Safety label: "No Dry Running"

This label indicates that the pump cannot be run dry. There

must always be medium in the suction line and the pump when

the pump is started. Otherwise, the pump will be damaged.

2.4.4 Rating Plate

2.3 Improper Use

The standard FP centrifugal pump versions may not be used in

explosive atmospheres. Special explosion-proof versions are

available for this.

Pumping of media other than those specified can destroy the

pump.

Standard pump units from Fristam are described in this

operator's manual. If nonstandard items or extras are installed,

the operator assumes the responsibility for operation.

Modifications and changes to the pump are only permissible

with the explicit consent of Fristam.

2.4 Warning and Instruction Labels

► Do not alter or remove the labels on the pump.

► Immediately replace damaged or lost labels with ones that

are true to the originals.

2.4.1 Direction of Rotation

Fig. 1 "Impeller Direction of Rotation" label

This label shows the direction of rotation of the impeller. It is

located at the front on the pump cover.

Fig. 4 Pump unit rating plate

Manufacturer

1

Type: pump series, pump size, model, version

2

SN: serial number of the pump

3

H: discharge head [m]

4

P: motor output [kW]

5

Year of manufacture

6

mttl: mass (total) [kg]

7

nR: rated speed [1/min]

8

Q: flow rate [m³/h]

9

CE mark

10

2.5 Noise Emissions

► The local noise exposure regulations must be complied with.

For noise emission values for the pumps, please see

Chapter 10.1, "Specifications," page 28.

6

Noise Generated by Running Pump

B

C

A

11

12

13

14

15

16

Hearing damage.

► Wear ear protectors when using pumps with specified sound

pressure levels of greater than 80 dBA.

2.6 Disposal

2.6.1 Disposal of Transportation Package

► Recycle the transportation package.

2.6.2 Models KF and L 1: Disposal of Grease

► Dispose of grease and objects saturated with grease in an

environmentally friendly manner in accordance with applicable regulations.

2.6.3 Models L 2, L 3/L3V, L 4V: Disposal of Lubricating Oil

► Dispose of oil and objects saturated with oil in an

environmentally friendly manner in accordance with

applicable regulations.

3 Design and Function

3.1 Principles of Design

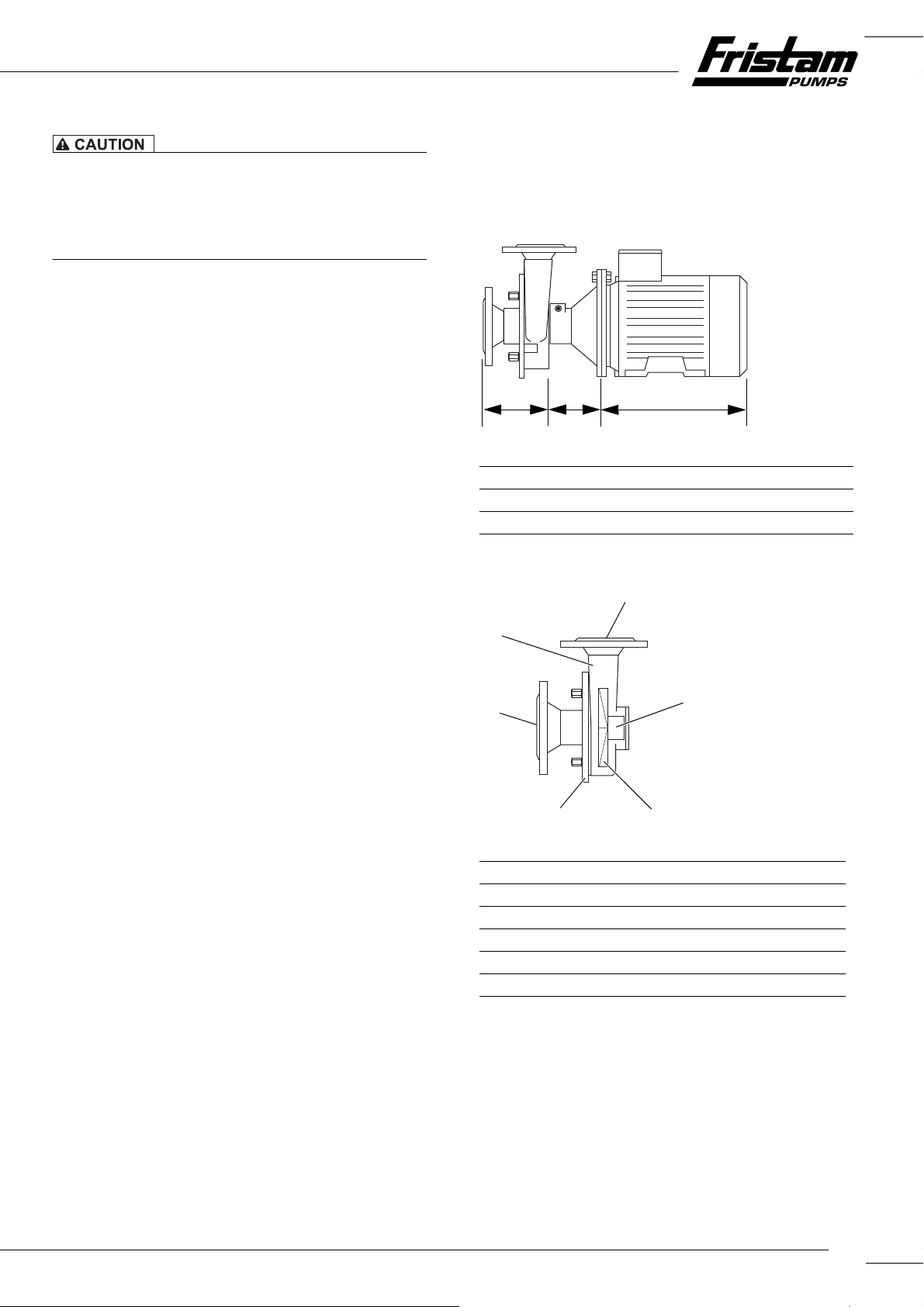

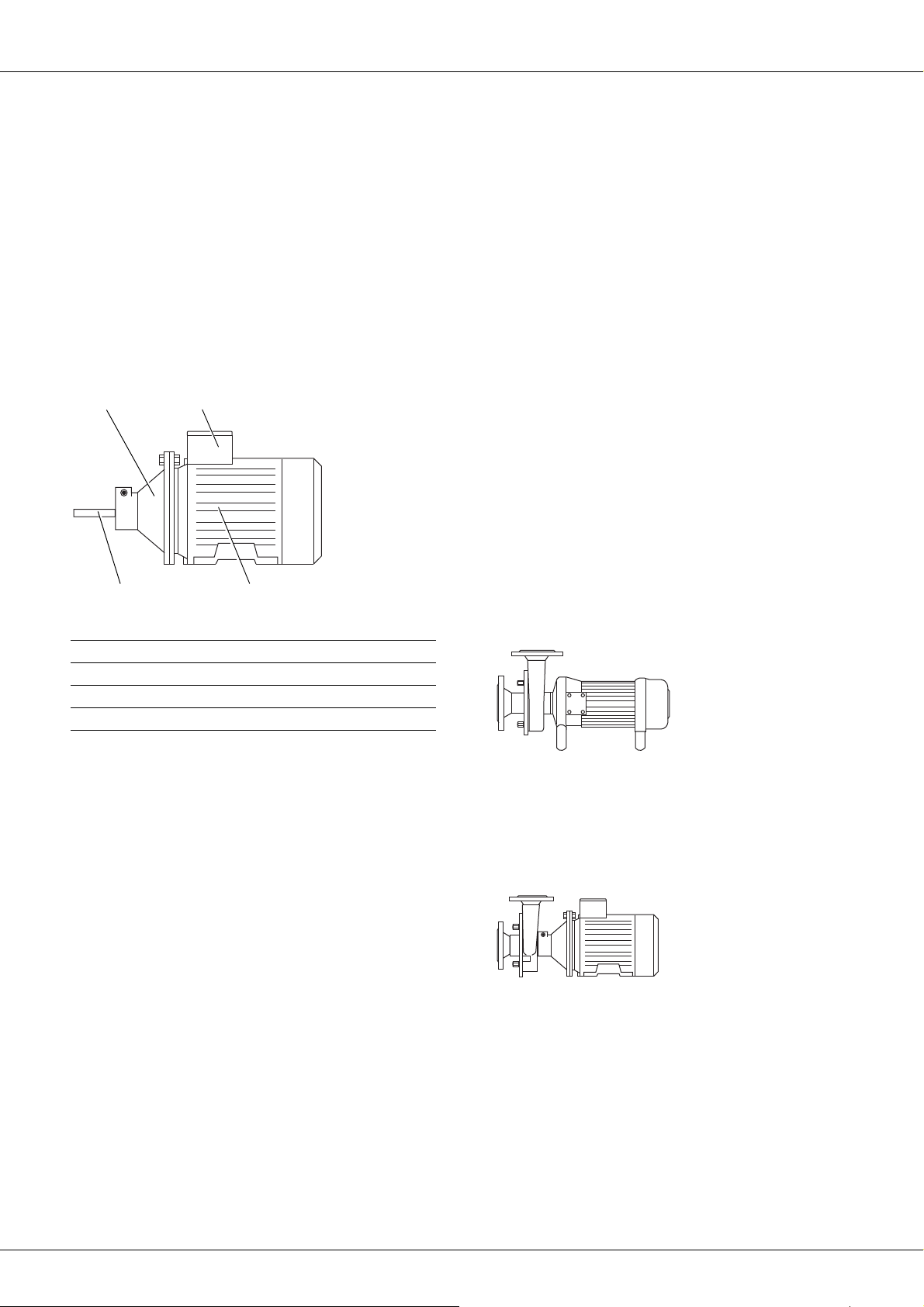

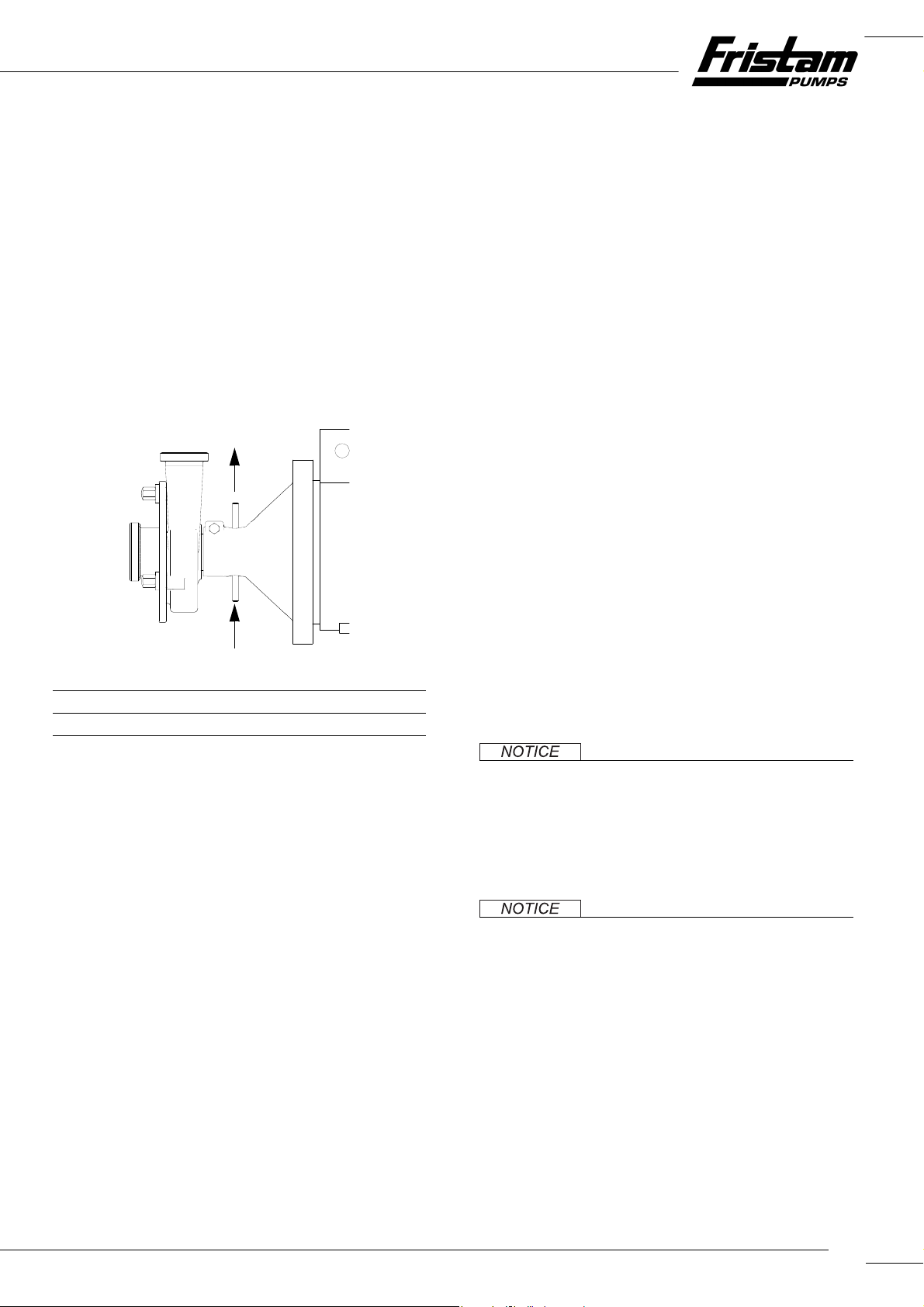

Fig. 5 Principles of design of pumps illustrated using the FPE model

Pump head

A

Lantern

B

Electric motor

C

3.1.1 Pump Head (A)

2.6.4 Disposal of Pump

1. Carefully clean the pump. Dispose of residues in an

environmentally friendly manner in accordance with

applicable regulations.

2. Dismantle the pump into its constituent parts.

3. Dispose of the pump parts in an environmentally friendly

manner in accordance with applicable regulations.

2.6.5 Disposal of Electrical and Electronic Scrap

► Dispose of electrical and electronic scrap in accordance with

applicable directives.

Fig. 6Pump head

Discharge line connection

11

Shaft seal

12

Impeller

13

Pump cover

14

Suction line connection

15

Pump casing

16

Shaft Seal (12)

Two seal types are available for use:

– Single shaft seal

– Double shaft seal

With the double shaft seal, there are two additional connections for the sealing liquid on the pump casing. These connections are not shown in the following figures.

7

/ / FP PUMP SERIES / / /

17

18

19

20

Impeller (13)

Open impellers are standardly used in the FP pump series.

Pump Cover (14)

The connection for the suction line is located on the pump

cover.

Pump Casing (16)

The connection for the discharge line is located on the pump

casing. The impeller and the shaft seal are built into the pump

casing.

3.1.2 Lantern (B) and Electric Motor (C)

Electric Motor (19)

The following motor types can be mounted:

– IEC standard motor with drive side fixed bearing (A side),

feather key and shaft pin of the following types:

– IM B3: model with base

– IM B5: model with flange

– IM B3/5: model with flange and base

With the IEC standard motor, a Fristam pump shaft is

clamped to the motor shaft pin.

–Special motor with Fristam pump shaft

With the special motor, the Fristam pump shaft is already integrated and connected permanently to the motor.

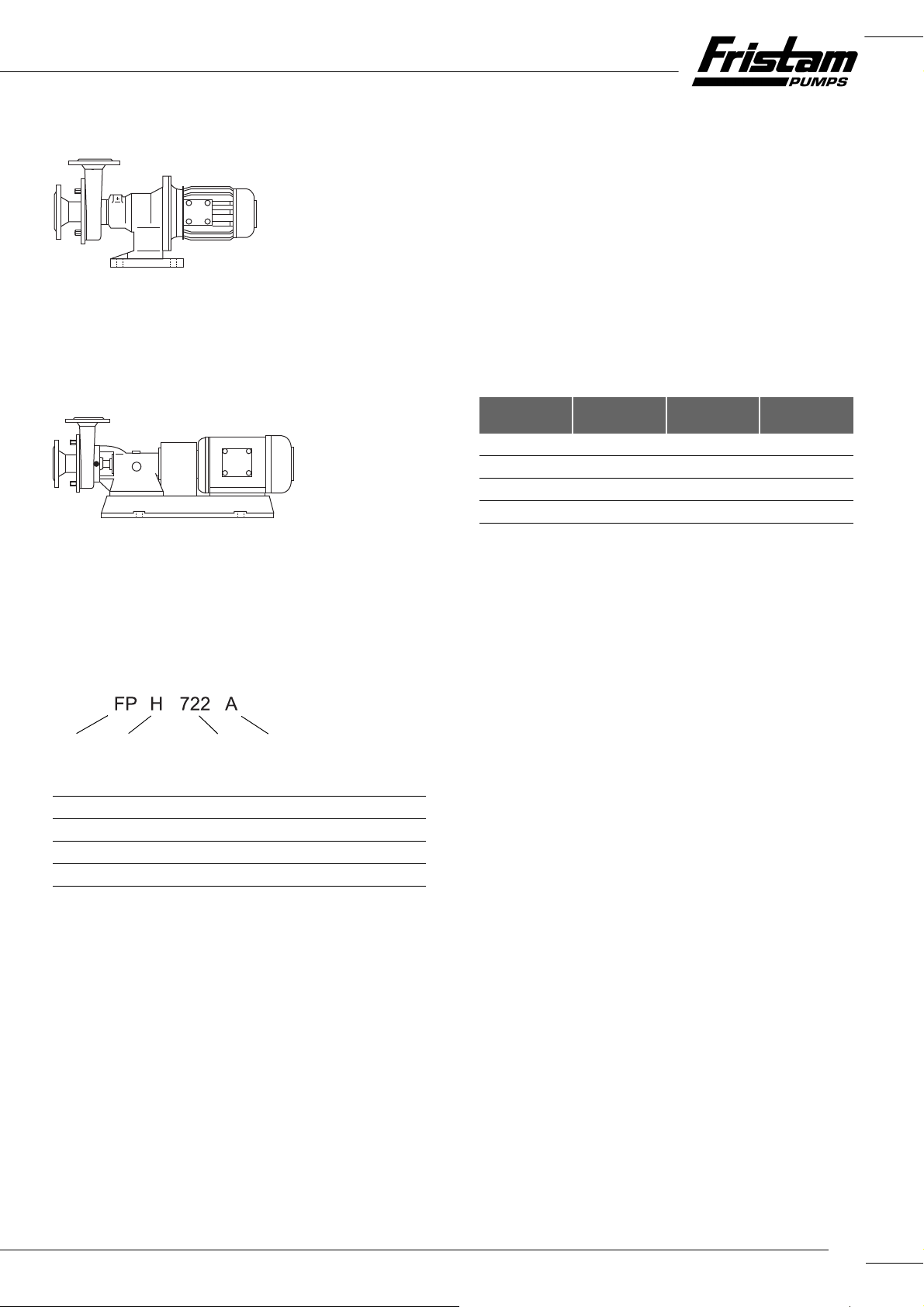

3.2 Models

The model is indicated on the rating plate. See Chapter 2.4.4,

"Rating Plate," page 6.

The following are shown as examples:

– Lantern clamp-mounted

–Without enclosure

See Chapter 3.4, "Versions," page 9.

Fig. 7 Lantern and electric motor

Lantern

17

Electrical connection

18

Electric motor

19

Pump shaft

20

Lantern (17)

The lantern is present in all models except the special motor.

The lantern connects the pump casing to the motor. Two

different versions are possible, depending on pump size:

– The pump casing is screwed to the lantern via a flange con-

nection.

– The pump casing is inserted into the lantern and mounted

with a clamp.

Models with lanterns:

– FPE and FP…V

–KF

An additional bearing for the pump shaft is located inside

the lantern with base.

–L

An additional bearing for the pump shaft is located inside

the lantern with base. The pump shaft is connected to the

motor via a coupling.

3.2.1 Model FP

Fig. 8Model FP

Motor: Special motor

Design: Without lantern

3.2.2 Model FPE or FP…V

Fig. 9 Model FPE or FP...V

Motor: IEC standard motor, model B3/B5

Design: With lantern

8

3.2.3 Model KF

21 23 2422

Fig. 10 Model KF

Motor: IEC standard motor, model B5

Design: Compact bearing support with base

3.2.4 Model L

Fig. 11 Model L

(24) Supplementary Character 2

A, B ,C ,D Versions; see Chapter 3.4, "Versions," page 9:

KF Compact bearing support with base

L1, L2, L3

Bearing block with coupling

V Stainless steel lantern, double shaft seal,

ø75mm at lantern neck

H Pump casing with heating jacket

h Pump cover with heating jacket

3.4 Versions

Version Enclosure Spherical Cap

Legs

A With With Without

B Without Without With

C Without With Without

D With Without With

Table 1 Versions

Motor Foot

Motor: IEC standard motor, model B3

Design: Bearing block with coupling, coupling

protection, base frame

3.3 Pump Key

Fig. 12 Type designation example

Pump type

21

Supplementary character 1

22

Pump size

23

Supplementary character 2

24

(21) Pump Type

FP Special motor with extended motor shaft

FPE Attached pump shaft

FP...V Extended insert shaft as pump shaft

(22) Supplementary Character 1

S Open impeller with large clearance to casing

R Semiopen impeller with large clearance to

cover

H High-pressure pump

X Impeller for high pressures

Z Casing with circulation line

Note: If the (optional) pump without motor is supplied, please

first read Chapter 11, "Appendix 2 – Assembly Instructions

(Optional)" on page 34.

4Transportation

4.1 Transportation

Transportation may only be performed by trained personnel.

The pump can be moved using an industrial truck or a crane.

Always move the pump in the installation condition.

4.1.1 Safety Instructions

► Danger of injury from falling or unsecured parts.

– Only use suitable means of conveyance and hoists. Infor-

mation on pump weight can be found on the pump's rating plate as well as in the “Order-Related Documents“ in

the attached documents.

– Before moving the pump secure it to prevent it from tip-

ping over. Secure the pump to the pallet with tie-down

straps, or screw the pump to the pallet.

– Do not leave the pump in a raised position for longer

than necessary.

► Damage to pump by contamination, impact, or moisture.

– Remove the protective film just prior to installation.

– Remove the pipe fitting covers just prior to connection to

the pipes.

9

/ / FP PUMP SERIES / / /

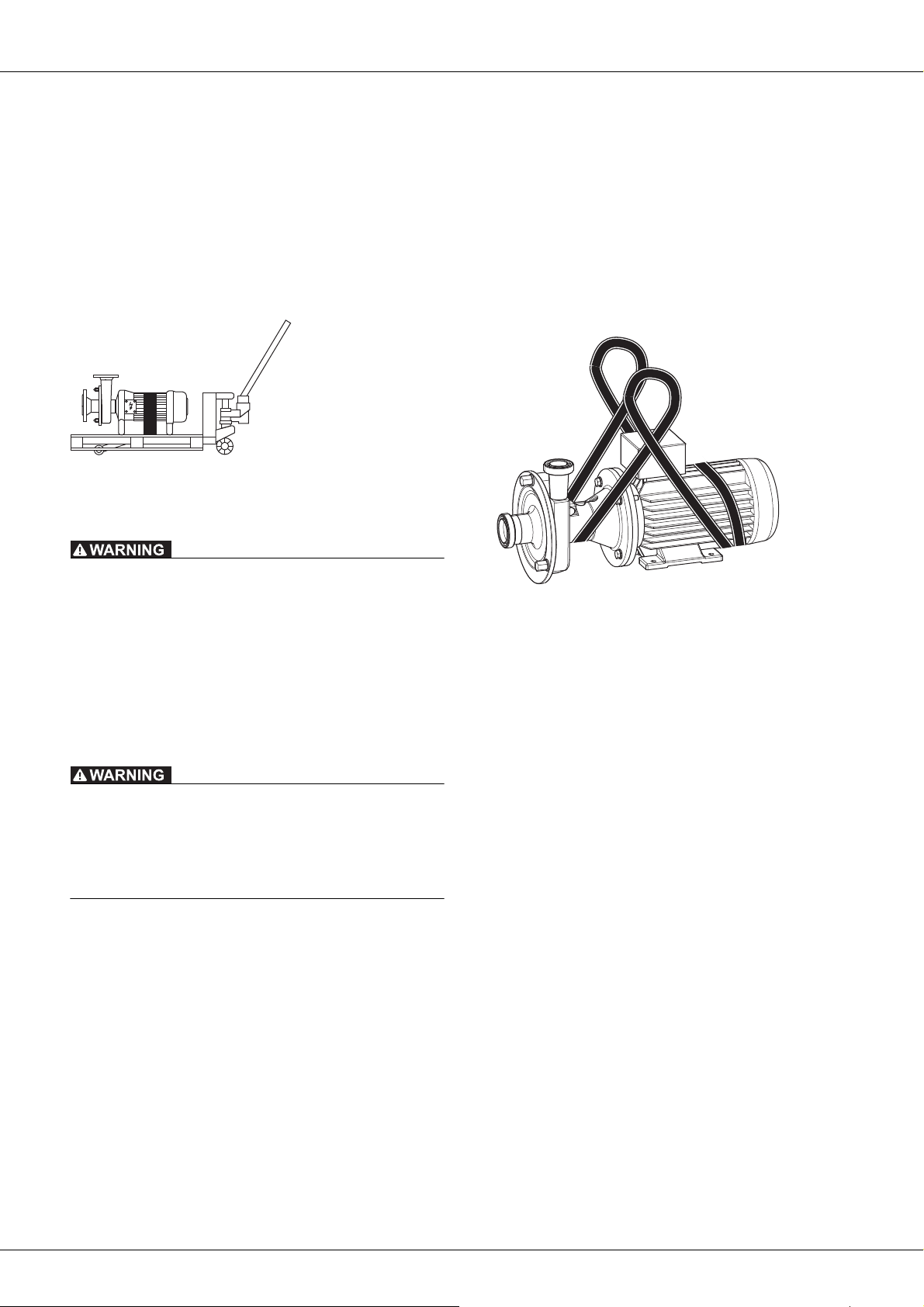

4.1.2 Moving With Industrial Trucks

Preparation

► Ensure that the pump is adequately secured to the pallet.

Procedure

1. Pick up the pallet with the forks on the industrial truck.

2. Carefully move the pallet to the designated location and set

down.

Fig. 13 Moving with industrial truck

4.1.3 Moving With Crane

Falling Parts

Death from crushing, pinching of extremities, material damage.

► Do not lift the pump at the eyebolts on the motor and pump

casing to move because these eyebolts are not designed for

the total weight.

► Only use hoists that are designed for the total weight of the

pump.

► Ensure that the area below the pump is clear of people.

3. Guide both loops to the crane hook and rotate by 180° to ensure that the belt will not slip on the hook.

4. For double shaft seal:

Note: Round sling compresses sealing water tubes. Material

damage to double shaft seal.

► Do not lay the round sling on the sealing water tubes.

5. Position the center of gravity to ensure that the pump is lifted horizontally.

6. Lift the pump.

.

Fig. 14 Moving with crane

5Storage

5.1 Safety Instructions

Swinging Parts

Crushing and serious injuries.

► Start and stop the crane with pump smoothly.

► Ensure that the danger zone of the pump is clear of people.

Auxiliary Equipment

Hoists: round slings tested in accordance with DIN EN 1492-1

and 1492-2

Preparation

► Remove load-securing devices.

Procedure

1. Wrap the round sling twice around the back end of the

motor. Do not lay over the fan shroud (see

Fig. 14 Moving

with crane).

2. Lay the other end of the round sling between the lantern

and the pump casing. Do not lay the round sling over any

sharp edges or corners.

► Corrosion: Condensation can build up under a tarp and

destroy the pump.

– Ensure adequate ventilation.

5.2 Storage Conditions

► Store the pump as follows:

– Dry, in low humidity

– Protected against frost and heat, optimally at a tempera-

ture of 20°C to 25°C

– Ventilated

–Dust-free

10

5.3 Long-Term Storage

6.2 Installation Location

For a storage time of longer than six months, heed the

following:

► The shaft seals must be specially treated before long-term

storage:

– For single shaft seal

The impeller nut must be loosened so that the seal can

relax and the elastomers do not stick together.

– For double shaft seal

Remove the complete shaft seal and store separately to

prevent the elastomers from sticking together.

Information on the shaft seal can be found in the “Order-Re-

lated Documents“.

► All movable pump parts must be rotated every three

months.

5.3.1 Storage of Elastomers

Storage Conditions

– Storage temperature between +5°C and +20°C

– Relative air humidity below 70 %

– No direct sunlight

– Deformation-free storage

5.4 Recommissioning

► After long-term storage and before commissioning, check

seals, bearings, and lubrication.

6Installation

For standard pumps, the installation location must meet the

following requirements:

– Nonexplosive atmosphere

– Dust-free environment

– Ambient temperature: –20°C to +40°C

– Moisture and salt contents in ambient air:

The values are given in the motor supplier documentation. It

can be found in the attached documents.

– Foundation sized adequately for the pump weight

– Horizontal and level installation surface, adequate installa-

tion surface strength for pump mass

– Adequate clearance for maintenance work

– Adequate air supply for motor cooling

6.3 Reduction of Noise and Vibration

6.3.1 Primary Measures

► Operate the pump in the optimum working range.

– Do not starve the pump. Avoid throttling too much. Only

operate with a low flow rate if necessary for regulation

purposes.

– Do not operate with very high flow rates. Optionally in-

stall a flow controller in the discharge line.

– Operate the pump without cavitation (see Chapter 6.4.1,

"Installation of Pipes," page 12).

► Decouple the suction and discharge lines from vibrations.

–Support lines.

– Align lines.

– Install vibration isolators.

6.1 Safety Instructions

► Danger of injury from falling parts.

– Wear safety shoes.

– Check load capacity and attachment of hoists.

► Danger of injury from unstable assembly.

– Tighten screws to the specified tightening torque (see

Chapter 10.1.1, "Tightening Torques for Screws and Nuts,"

page 28).

– Use a torque wrench or an impact driver with adjustable

torque.

► Material damage from swinging during adjustment of

spherical cap feet.

– Use spherical cap base plates.

6.3.2 Secondary Measures

► Take structural measures such as the following:

– Acoustic paneling

– Enclosure in housing

6.4 Pump Fixation

Models FP/FPE/FP...V

► Versions A and C:

Set up the pump on the spherical cap bearings and align.

► Versions B and D:

Screw the pump on the motor foot to the foundation.

Model KF

► Versions A and C:

Set up the pump on the spherical cap bearings and align.

11

/ / FP PUMP SERIES / / /

5 - 10 x D

R ≥ 2 x D

D

► Versions B and D:

Screw the pump on the compact bearing support with base

to the foundation.

Model L

► Versions A and C:

Set up the pump on the spherical cap bearings and align.

► Versions B and D:

Screw the pump on the base frame to the foundation.

Carriage (Optional)

1. Set up the pump at the installation location. Lock the locks

on the rollers (if present) or secure the carriage with chocks.

2. Ground the carriage to dissipate electrostatic charge.

3. Position hose line to ensure that it cannot be damaged.

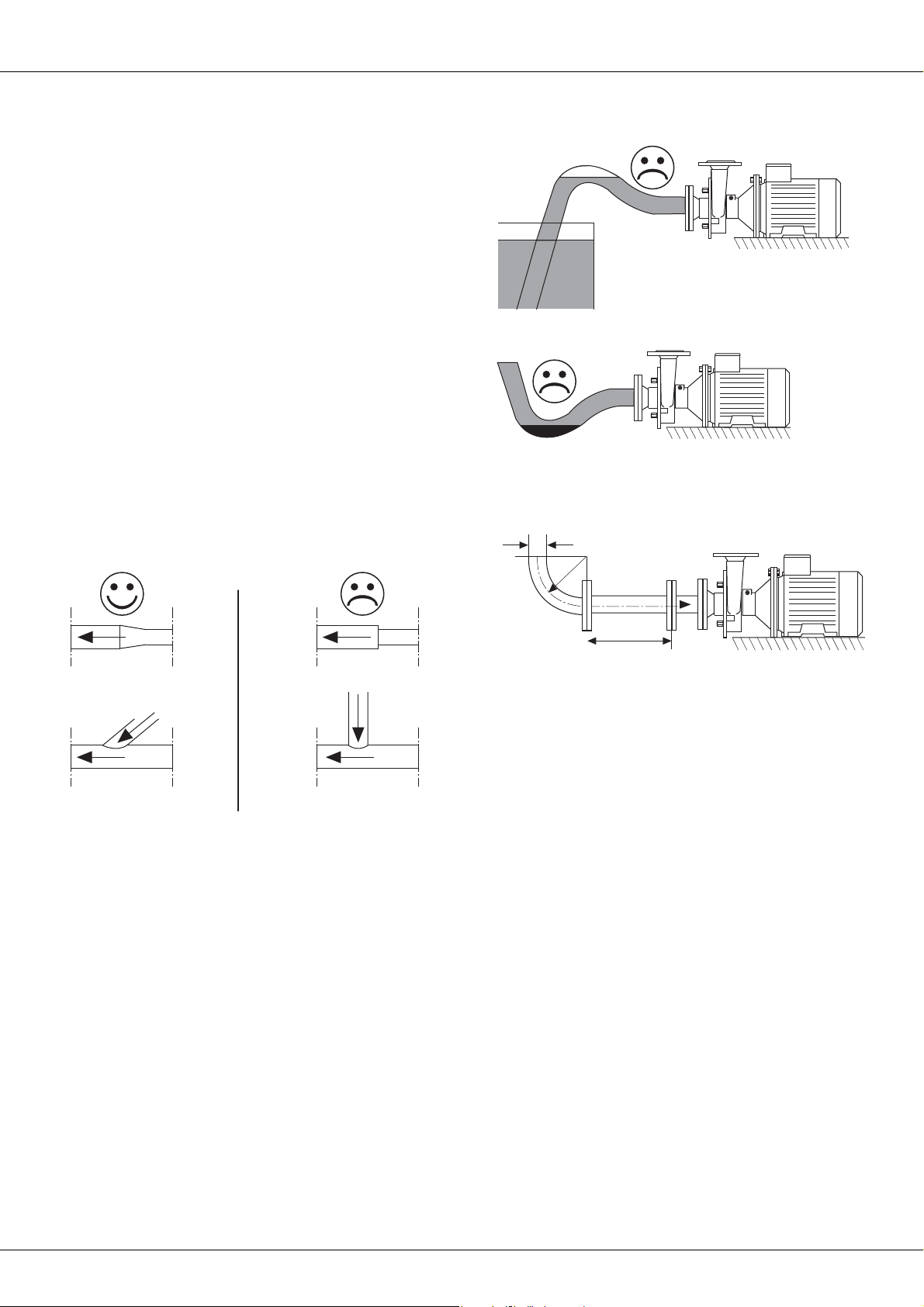

6.4.1 Installation of Pipes

► Lay and connect pipes as follows:

– Keep the pipe resistance as low as possible: Avoid unnec-

essary installation of valves, elbows, and abrupt pipe

transitions.

Fig. 16 Air pocket

Fig. 17 Dip in pipe

– Pipe bends upstream of suction connection: Heed mini-

mum clearance and minimum bend radius:

Fig. 18 Laying of the suction line

– Connect the pipes to the pump so that they are free of

tension and compression to ensure that no stresses are

applied to the pump.

– Secure pipes to ceilings, walls, or floor using pipe clamps.

– Align pipes flush with pump connections using a bracket.

Fig. 15 Pipe transitions

12

– Design pipe cross section so that no unnecessary pres-

sure losses or cavitation occurs in the suction area and so

that the condition

NPSHa > NPSH

r

is fulfilled.

Verify this in the project planning stage.

– Install the suction lines in horizontal position or at a con-

stant dropping angle towards the pump unit. Rule out

the possibility of air pockets and dips in the pipes.

6.5 Electrical Connection

Electrical connection may only be performed by a qualified

electrician.

1. Heed the connection values on the motor's rating plate. The

specified voltage must not be exceeded.

2. Connect the motor according to the circuit diagram in the

terminal box of the motor.

3. Protect cable feedthroughs against penetration by moisture.

4. Turn on the motor for 2 to 3 seconds. Compare the direction

of rotation of the motor fan wheel against the direction indicated by the arrow on the pump head.

5. Reverse the polarity if necessary.

6.6 Connection of Sealing or Quenching Liquid

25

26

(Optional)

7Operation

In versions with double shaft seal, the seal chamber must be

flushed with a sealing or quenching liquid.

► Use a suitable medium, e.g., water, as a sealing or quenching

liquid.

6.6.1 Installing the pipelines

1. Install and seal the supplied flushing tubes.

2. As a standard, the feed line should be fitted at the bottom

of the shaft seal.

3. As a standard, the return line should be fitted at the top of

the shaft seal.

Fig. 19 Installing the pipelines

7.1 Safety Instructions

► Danger of burning: Pumping of hot media can cause the

pump to become very hot. Check the temperature before

touching the pump.

► Noise emissions: The A-weighted sound pressure level of the

pumps can be greater than 80 dBA. Always wear ear

protectors in the vicinity of the running pump.

► Danger of bursting: If the allowable pressure and

temperature ranges are exceeded, the pump may burst or

become leaky. The pressure and temperature ranges for the

pump must be complied with; see “Order-Related

Documents“ in the attached documents.

► Danger of bursting: Cold extinguishing agents used to

extinguish a pump fire can cause the hot pump to burst. Do

not cool the pump down excessively when extinguishing the

fire.

► Pump running in reverse direction despite emergency shut-

off: If the pump is shut off using the emergency shut-off

function, it will run in reverse direction due to the pumping

medium in the discharge line. Install a check valve in the

discharge line.

► Destruction of shaft seal when pump runs in reverse

direction. Reverse running destroys the springs in the shaft

seal. Always operate the pump in the direction of rotation.

Chapter 2.4.1, "Direction of Rotation," page 6.

See

Return line

25

Inlet

26

4. Install the following valves into the pipelines:

– Install the sight glass in the return line.

6.7 Cleaning

Only use cleaning agents that comply with the hygiene

guidelines for the respective pumping medium.

1. Before sealing the pump ensure that there are no foreign

objects inside the pump or pipes.

2. Seal the pump.

3. Connect the pipes.

4. Thoroughly clean the pump and the pipe system before ini-

tial use.

7.2 Commencement of Operation

Damage to Shaft Seals

If the pump runs without a pumping medium, the mechanical

seal will be damaged.

► Ensure that the pumping medium always reaches the upper

edge of the outlet side before and during operation.

Damage to Double Shaft Seals

If the pump runs without a sealing medium, the shaft seal will

be damaged.

Ensure that during operation:

► The sealing liquid flows with the necessary pressure through

the double shaft seal.

The prescribed sealing fluid pressure is specified in the "Order-related documents" in the sectional drawing of the shaft

seal. The "Order-related documents" are included in this op

erating manual.

– Negative pressure in the seal chamber is not allowed.

If no pressure is noted in the "Sectional drawing of the shaft

seal", the following applies:

-

13

/ / FP PUMP SERIES / / /

– A max. pressure of 0.2 bar is allowed for seals to which

sealing fluid is applied without pressure or which are

flushed.

► The temperature of the sealing liquid is maintained at

T < 70 °C.

1. Open the valve in the suction line.

2. Close the valve in the discharge line.

3. Fill the pump and the suction line up to the upper edge of

the pump with pumping medium. Allow any air pockets that

are present to escape.

4. Turn on the motor. The pump now pumps against the closed

valve in the discharge line. This will limit the starting current.

5. Slowly open the valve in the discharge line and adjust to the

working point.

7.3 Monitoring of Operation

During operation heed the following points:

► Damage to shaft seal: Regulation of the pump output via the

suction-side valve can lead to damage of the pump and the

shaft seals. Regulate the pump output only by means of the

discharge-side valve.

► Damage to pumping medium: If during operation the valve

in the discharge line is closed abruptly or for a long period of

time, water hammers can occur in the pump and lead to

damage to the pump and/or the pumping medium. During

operation do not close the valve in the discharge line

abruptly or for a long period of time.

► Damage to pump: Exceeding of the output can lead to

damage of the pump and the shaft seals. Do not exceed the

maximum speed of 3,600 rpm.

► Damage to motor during operation with frequency

converter: If the speed is too low, the motor will overheat.

Please refer to the motor supplier documentation in the

attached documents.

7.4 Stopping of Operation

1. Turn off the motor.

2. Close the valve in the suction line to prevent dry running of

the pump.

3. Close the valve in the discharge line.

7. Dry the pump.

8. Protect the interior of the pump from moisture, e.g., with silica gel.

9. Seal the pipe connections with caps to prevent penetration

of dirt and foreign objects.

10. Please see Chapter 5, "Storage," page 10 for additional steps.

7.6 Cleaning in Place

7.6.1 CIP Process

The FP series pumps are suitable for the CIP (Cleaning In Place)

process. The following guidelines apply to the CIP process:

Example of a Cleaning Cycle

1. Perform preliminary flush with water.

2. Perform caustic flush with lye (NaOH; see Table 2 CIP clean-

ing).

3. Perform intermediate flush with water.

4. Perform acid flush with nitric acid (HNO3; see Table 2 CIP

cleaning).

5. Flush with water.

Medium Process Temperature [°C]

NaOH (approx. 1%–2%) 80–85

HNO3 (approx. 1%) 60–65

Table 2 CIP cleaning

The pump's differential pressure should be 2–3 bar so that

adequate flow rates are reached.

If values deviate from these specifications, please contact

Fristam.

7.6.2 SIP Process

The FP series pumps can only be used with the SIP (Sterilization

In Place) process with the prior approval of Fristam.

Suitability depends on the selected elastomers.

The maximum process temperature is 145°C.

In ATEX operation, temperatures might deviate, see

supplementary ATEX manual, "Temperature limits".

7.5 Pump Decommissioning

1. Turn off the motor.

2. Close the valve in the suction line.

3. Close the valve in the discharge line.

4. De-energize the pump.

5. Empty the pump.

6. Clean the pump.

14

8Faults

For information on faults, possible causes, and remedies, please

Chapter 10.3, "Troubleshooting Table," page 29.

see

8.1 Safety Instructions

► Danger of burning: Pumping of hot media can cause the

pump to become very hot. Check the temperature before

touching the pump.

► Pump running in reverse direction despite emergency shut-

off: If the pump is shut off using the emergency shut-off

function, it can continue to run in reverse direction due to

the pumping medium in the discharge line. Install a check

valve.

9 Maintenance

For information on maintenance intervals, please see

Chapter 10.2, "Maintenance Intervals1," page 28.

9.1 Safety Instructions

► Rotating parts: Danger of injury. Before removing the

coupling guard and guard plate, turn off the pump motor

and prevent it from being able to be turned on accidentally.

► Danger of burning: Pumping of hot media can cause the

pump to become very hot. Check the temperature before

touching the pump.

► Electric shock: Liquids flowing through the system result in

buildup of electrostatic charge. Ground the pipes and the

pump.

► Uncontrolled outflow of liquids: Before maintenance or

adjustment of the pump:

– Close the suction and discharge valves in front of and be-

hind the pump.

– Block off the sealing or quenching liquid line.

► Leaking liquids: Acid burns and contamination. Before

opening the pump completely empty the pump casing.

► Tension cracks: Do not rapidly cool the pump. Material

damage from scratching of polished surfaces. For a polished

surface, use a copper socket wrench socket.

9.2 Replacement Parts

► Use of replacement parts that are not approved by Fristam

Pumpen KG (GMBH & Co.) can lead to serious personal injury

and material damage. If you have any questions regarding

approved replacement parts, please contact Fristam.

► Fristam registers all shipped pumps. For ordering

replacement parts from Fristam, you require the following

information:

Serial number: see

– rating plate or

– number stamped into pump casing.

9.3 Inspection of Sealing and Quenching Liquid (Optional)

For pumps equipped for "locking system" or "quenching

system," the sealing liquid head must be checked daily.

► Check the sealing liquid head and compare with the

specified value.

The specified value can be found in the Order-Related Docu-

ments on the "Sectional Drawing" of the shaft seal. The OrderRelated Documents are attached to this operator's manual.

► The sealing liquid is heated by hot pumping medium and by

operation of the pump.

Ensure that the temperature of the sealing liquid is T < 70 °C

during operation.

9.4 Lubrication of Motor Bearings

► Lubricate the motor bearings in accordance with the motor

manufacturer's specifications (see "Motor Supplier

Documentation").

9.5 Lubrication of Shaft Bearing

9.5.1 Models FP, FPE and FP…V

The models FP, FPE, and FP…V do not have additional shaft

bearings, and hence no shaft bearing lubrication is necessary.

9.5.2 Models L 2, L 3/L3V and L 4V

For the models L 2, L 3/L3V, and L 4V, the oil must be changed at

regular intervals.

1. Turn on the motor and let it run until the normal operating

temperature is reached.

2. Turn off the motor and prevent it from being able to be

turned on accidentally.

3. Place a suitable oil collection container under the oil drain

plug.

4. Caution! Danger of burning from hot oil.

► Wear suitable protective gloves.

► Loosen and remove the oil drain plug.

5. Drain the oil completely and dispose of oil in accordance

with local regulations.

6. Clean and remount the oil drain plug and seal.

7. Fill with new oil. We recommended using the: SAE 15W40 oil

type. Alternatively, use an equivalent brand of lubricant of

similar quality and viscosity. For the required amount, please

Table 3 Oil volumes.

see

Type Oil Volume

L 2 1 liter

L 3/L3V 3 liters

Table 3 Oil volumes

15

/ / FP PUMP SERIES / / /

27

28

29

30

Type Oil Volume

L 4V 13 liters

Tab le 3 Oil volumes

9.5.3 Model L1

► Do not relubricate the deep groove ball bearing, but replace

it completely.

– At constant operating conditions, the raising of power con-

sumption, noise level or vibration indicates that wear has occurred. Replace the deep groove ball bearing consequently.

Model Bearing Grease Amount

L1 10 g

Tab le 4 Bearing grease amount: model L1

Prerequisites

– Pump head has been removed.

– Motor with coupling has been removed.

Procedure

Fig. 22 Model L1, pump shaft, motor-side

3. Remove the bearing cap (30) on the motor side.

4. Force out the shaft in the direction of the pump head.

Note: All parts that are gray in the above two figures remain

on the shaft.

5. Clean the surfaces of all parts and check for damage. Replace

if necessary.

6. Relubricate the angular contact ball bearing. We recommended using: JAX Halo-Guard FG-2 bearing grease or alternatively a white NSF H1 grease. Alternatively, use an equivalent brand of lubricant of similar quality and viscosity. See

Table 4 Bearing grease amount: model L1.

7. Press the pump shaft with the bearing into the bearing

block.

8. Mount the bearing cap on the motor side.

9. Mount the bearing cap on the pump side.

10. Mount the cover (27).

Fig. 20 Removing bearing block cover

1. Take the cover (27) off of the bearing block (28).

Fig. 21 Model L1, pump shaft, pump-side

2. Remove the bearing cap (29) on the pump side.

9.5.4 Model KF

► Do not relubricate the deep groove ball bearing, but replace

it completely.

– At constant operating conditions, the raising of power con-

sumption, noise level or vibration indicates that wear has occurred. Replace the deep groove ball bearing consequently.

► Grease the cylindrical roller bearing with bearing grease.

Model Bearing Grease Amount

KF 1 20 g

KF 2 40 g

KF 3 60 g

Table 5 Bearing grease amounts: model KF

Prerequisites

– Pump head has been removed.

– Motor has been removed.

Procedure

1. Remove the bearing cap (33).

2. Force out the pump shaft (31) with the bearing toward the

motor side.

16

Fig. 23 Model KF, shaft bearing

35

33

32

34

31

3. Remove the bearing nut (34) and the guard plate (35).

4. Remove the outer race of the cylindrical roller bearing.

Note: All parts that are gray in the above figure remain on

the shaft.

5. Clean the surfaces of all parts and check for damage. Replace

if necessary.

6. Relubricate the cylindrical roller bearing (31). We recommended using: JAX Halo-Guard FG-2 bearing grease or alternatively a white NSF H1 grease. Alternatively, use an equivalent brand of lubricant of similar quality and viscosity. See

Table 5 Bearing grease amounts: model KF.

7. Put the outer race back onto the shaft.

8. Place the guard plate and the bearing nut on the shaft, and

tighten the bearing nut.

9. Press the pump shaft with the bearing back into the lantern.

10. Mount the bearing cap (33).

9.6 Motor Replacement

Special Motor

1. Turn off the motor and prevent it from being able to be

turned on accidentally.

2. Remove the pump head (see Chapter 9.8, " Pump Head Re-

moval," page 18).

3. Replace the special motor.

4. Replace the mechanical seal if necessary, and mount the

pump head (see

page 20).

Chapter 9.10, "Pump Head Attachment,"

6. Mount the shaft and align (see Chapter 9.11, "Models FPE and

FP…V: Mounting and Alignment of the Pump Shaft," page 27).

7. Mount the lantern.

8. Only for flange connection: Check the clearance if necessary

Chapter 9.9, "Checking of the Clearances," page 18).

(see

9. Replace the mechanical seal, and mount the pump head (see

Chapter 9.10, "Pump Head Attachment," page 20).

IEC Standard Motor for Model KF

1. Turn off the motor and prevent it from being able to be

turned on accidentally.

2. Take the motor off of the compact bearing support with

base.

3. Dispose of the motor in an environmentally friendly manner.

Chapter 2.6.5, "Disposal of Electrical and Electronic Scrap,"

See

page 7.

4. Insert the key of the old motor into the new motor.

5. Screw the motor to the compact bearing support with base.

IEC Standard Motor for Model L

1. Turn off the motor and prevent it from being able to be

turned on accidentally.

2. Remove the coupling guard.

3. Detach the motor from the base frame or the foundation.

4. Take the coupling parts off of the motor.

5. Dispose of the motor in an environmentally friendly manner.

See Chapter 2.6.5, "Disposal of Electrical and Electronic Scrap,"

page 7.

6. Mount the coupling parts onto the replacement motor (proceed as described in Chapter 9.12, "Model L: Coupling Replace-

ment," page 27 to replace the coupling).

7. Place the replacement motor on the base frame or the foundation.

8. Check the parallel and angular misalignment of the shafts.

Fig. 24 Parallel misalignment

IEC Standard Motor for FPE and FP...V

1. Turn off the motor and prevent it from being able to be

turned on accidentally.

2. Remove the pump head (see Chapter 9.8, " Pump Head Re-

moval," page 18).

3. Take the lantern off of the motor.

4. Remove the shaft.

5. Replace the motor.

Fig. 25 Angular misalignment

9. Minimize deviations from the angular and parallel misalignment. Realign the shafts if necessary.

10. Screw the motor to the base frame or the foundation.

11. Mount the coupling guard.

17

/ / FP PUMP SERIES / / /

36

37

38

39 40 41 42

43

9.7 Shaft Seal Replacement

The shaft seal must be replaced if:

– Pumping medium or sealing or quenching liquid flows out of

the pump on the atmosphere side.

– Sealing liquid leaks into the pumping medium.

Procedure

1. Remove the pump head (see Chapter 9.8, " Pump Head

Removal," page 18).

2. Replace the mechanical seal, and mount the pump head (see

Chapter 9.10, "Pump Head Attachment," page 20). Perform the

following tasks according to the given shaft seal:

► Preassemble the seals on the shaft.

► Preassemble the pump casing.

► Mount the pump casing on the lantern.

► Mount the mechanical seal.

► Mount the impeller.

► Screw on the pump cover.

9.8 Pump Head Removal

9.8.1 Preparation

1. Turn off the motor and prevent it from being able to be

turned on accidentally.

2. Close the valve in the discharge line.

3. Close the valve in the suction line.

4. Completely empty the pump.

9.8.2 Procedure

Fig. 27 Impeller

3. WARNING: Risk of injury when stopping the impeller by

hand. Block the impeller

(42) with a wooden wedge.

Loosen the impeller nut (39), and remove with the O-ring

(40).

4. Take the snap ring (41), the impeller (42), and the key (43)

off of the shaft.

5. Only for pumps with double shaft seals: Remove the flushing

tubes for sealing or quenching liquid.

TIP: For large pump casings, there is an M 12 thread on the

top of the casing. An eyebolt can be screwed into the thread

for suspension of the pump head from a crane.

6. Pull the pump head with the pump-side shaft seal off of the

shaft as follows:

6a. Clamp connection variant

1. Loosen the clamp bolt.

2. Slightly spread the clamp connection with a wedge.

3. Pull the pump casing out of the clamp connection.

6b. Flange connection variant

1. Loosen the fastening screws on the flange and remove.

2. Remove the pump casing.

7. Take the shaft seal out of the pump casing.

Fig. 26 Pump cover

1. Loosen the nuts (36) on the pump cover.

2. Remove the nuts, the washers, the pump cover (37), and the

cover seal (38).

18

9.9 Checking of the Clearances

The position of the impeller is determined by the position on

the shaft. The clearances are set through the position of the

pump casing with respect to that of the impeller.

Note: For clearances, refer to table 6-8.

Prerequisites

– Pump casing is connected firmly to the lantern.

– Pump cover has been removed.

– The impeller has been mounted and the impeller nut tight-

ened.

9.9.1 Measurement of the Impeller–Pump Cover Clear-

H

44

A

45

46

B

47

F

48

ance

1. Measure the height H of the pump cover (44) using vernier

calipers.

Fig. 28 Height

2. Measure the clearance A between the pump casing (45) and

the impeller (46) using vernier calipers.

Fig. 30 Impeller–casing clearance

9.9.3 Measurement of the Impeller–Casing Clearance

1. Measure dimension B between the shaft shoulder and the

pump casing (47) with a leaf feeler gauge.

Fig. 29 Clearance

3. Calculate the clearance (clearance = A–H).

4. Adjust the clearance to the values specified in Table 6 , "Stan-

dard Clearence," page 20, Table 7 , "Clearances in model S,"

page 20 or Table 8 , "Clearances in model R," page 20 respec-

tively.

9.9.2 Measurement of the Impeller Casing Clearance /

Sizes 711/712 - 1231/1232

1. Measure the clearance between the impeller and the casing

using a leaf feeler gauge (Fig. 30, "Impeller–casing clearance,"

page 19).

2. Adjust the clearance to the values specified in Table 6 , "Stan-

dard Clearence," page 20, Table 7 , "Clearances in model S,"

page 20 or Table 8 , "Clearances in model R," page 20 respec-

tively.

Fig. 31 Mea suring the clearance between shaft shoulder and pump casing

2. Measure height F of the stationary bushing (48) with a sliding calliper.

3. Calculate the clearance (= F - B).

Fig. 32 Measuring the stationary bushing

19

/ / FP PUMP SERIES / / /

4. Adjust the clearance to the values specified in Table 6 ,

"Standard Clearence," page 20, Table 7 , "Clearances in model

S," page 20 or Table 8 , "Clearances in model R," page 20 re-

spectively.

Clearance too large

► If the clearance between the housing and the impeller is too

large, rework the stationary bushing.

Grinding stationary bushing to size

1. Remove the stationary bushing from the shaft sealing kit.

The location of the stationary bushing is indicated in the

"Sectional drawing of shaft seal" in the appendix of the "Order

documents".

2. Grind the stationary bushing to the required size.

3. Re-install the stationary bushing.

4. Slide the key and the impeller onto the shaft and tighten

them with the impeller nut.

5. Measure the clearance again.

Pump Size Clearances in mm

Impeller–Pump Cover Impeller–Casing

711/712 0.5 0.5

721/722 0.5 0.7

741/742 0.5 0.5

751/752 1.0 1.0

3401/3402 0.5 0.5

3521/3522 0.5 0.5

3531/3532 0.5 1.5

3541/3542 1.0 1.0

3451/3452 1.0 1.0

3551/3552 1.0 1.0

1151/1152 2.0 2.0

1231/1232 - 1.5

1241/1242 - 1,0

1251/1252 - 1.5

Tab le 6 Standard Clearence

► If the code "S" or "R" (additional letter 1) is printed on the

rating plate, adjust the clearance to the values specified in

Table 7 , "Clearances in model S," page 20 or Table 8 ,

"Clearances in model R," page 20 respectively. (Position of

additional letter 1: See Chapter 3.3, "Pump Key," page 9)

Pump Size Clearance FPS in mm

Impeller / pump cover Impeller / casing

(calculated)

711/712 0,5 (5,5)

721/722 0,5 (5,5)

741/742 0,5 (5,5)

751/752 1.0 (5,0)

Tab l e 7 Clearances in model S

Pump Size Clearance FPS in mm

Impeller / pump cover Impeller / casing

3521/3522 0,5 (10,5)

3531/3532 0,5 (11)

3541/3542 1,0 (11)

3551/3552 1,0 (11)

Table 7 Clearances in model S

Pump Size Clearance FPR in mm

Impeller / pump cover

(calculated)

3521/3522 (10,5) 0,5

3531/3532 (11) 0,5

3541/3542 (11) 1,0

3551/3552 (11) 1,0

Tab l e 8 Clearances in model R

(calculated)

Impeller / casing

9.10 Pump Head Attachment

The pump assembly is dependent on the respective pump size

and model as well as the respective shaft seal (see “Order-

Related Documents“) in the attached documents.

Incorrect Elastomers

Pump leakiness.

► Ensure that the elastomers are appropriate for the condition

of the pumping medium. Please refer to the “Order-Related

Documents“.

Preparation

► Clean all pump parts and check for damage and accuracy of

fit.

► If necessary, rework or replace pump parts.

► Assemble in clean conditions, carefully, and using little force.

The seals could be permanently deformed or break in part.

► Replace all O-rings.

► To reduce friction, wet the O-rings and the sliding faces with

water, alcohol, or silicone grease.

► Clean the sealing surfaces of the mechanical seals with a

degreaser, e.g., OKS 2610 Universal Cleaner. Do not allow the

sealing surfaces to come into contact with oil or grease and

do not touch with your fingers afterwards.

Tip: The joint retaining compound "Euro Lock A64.80," e.g., is suitable for gluing in bearings and bushings.

Tip: The screw retaining compound "Euro Lock A24.10," e.g., is suitable for gluing in set screws.

20

9.10.1 Clearance Setting for Flange Connection

50

49

51

I

II

412.65

475.60

474.63

93-1.60

412.60

412.61

47-2.60

562.60

101

Note: For pumps with flange connections, the clearance is set

using shims. To determine the exact number and thicknesses of

shims needed, first mount the impeller nut, the impeller, and

the key as follows and then remove again.

1. Slide the pump casing (49) and the shims (50) over the shaft

to the flange (51) and screw on.

Fig. 33 Setting the clearance for the flange connection

Application Case

Table 9 Standard shaft seals

Pump Shaft

Seal

D FPE With quench 340/350/740, with clamp

E FP/FP...V Double 340/350/700/1150/1230

F FP/FP...V Double 1240/1250

Pump Sizes

connection: ø 100 mm

1150/1230/750, with flange

connection

Application Case A

2. Slide the seal driver onto the shaft.

3. Slide the key and the impeller onto the shaft.

4. Tighten the impeller nut.

5. Check the clearances (see Chapter 9.9, "Checking of the Clear-

ances," page 18).

6. Remove the impeller nut, the impeller, and the key.

7. Remove the pump casing.

8. If the clearance is incorrect:

► Adjust the clearance using the appropriate shims.

9.10.2 Mounting of Seals

The shaft seal built into the respective pump is given in the

attached documents in the “Order-Related Documents“ in the

form of a “Sectional Drawing“ and a “Replacement Parts List“.

The part numbers in this chapter correspond to DIN 24250.

The assembly of standard shaft seals is described in the

following sections with the application cases A to F. The version

for your order can deviate from this.

If anything is unclear or if you require further information,

please contact Fristam.

Application Case

Tab le 9 Standard shaft seals

Pump Shaft

Seal

A FP/FPE Single 340/350/700/1150/1230

B FP/FPE Single 1240/1250

C FPE With quench 340/350/700, with clamp

Pump Sizes

connection: ø 60 mm

Fig. 34 Application case A

In the above figure, parts are grouped according to assembly

steps:

I Preassembly of the pump casing

II Completion of assembly on the shaft

Fig. 35 Application case A, preassembly of the pump casing

To preassemble the pump casing (I):

21

/ / FP PUMP SERIES / / /

412.62

485.60

412.63

474.60

412.64

472.60

478.60

412.10

412.62

474.50

472.50

54-3.60

477.50

412.51

475.50

412.52

47-1.60

412.60

562.60

914.60

101

1. Glue the cylindrical pin (562.60) into the mechanical seal

chamber (47-2.60) with a retaining compound.

Note: Glue the cylindrical pins into the mechanical seal

chamber so that they do not touch the shaft when the unit is

fully assembled. Ensure that the cylindrical pins are fully en

gaged in the bores of the stationary seal ring (475.60). If the

stationary seal ring does not feature holes, the cylindrical

pins must engage in the longitudinal recesses in the stationary seal ring (see "Sectional drawing of shaft seal").

2. Place O-rings (412.60) and (412.61) into the mechanical seal

chamber.

3. Guide the preassembled mechanical seal chamber into the

pump casing (101).

4. Place the thrust collar (474.63) on the pump casing and se-

cure with snap ring (93-1.60).

Preassembly of the pump casing is now finished.

5. Equip the stationary seal ring (475.60) with an O-ring

(412.65).

6. Guide the stationary seal ring into the mechanical seal chamber.

Note: Guide in so that the cylindrical pins on the mechanical

seal chamber engage in the slots on the stationary seal ring.

Preassembly of the mechanical seal chamber is now finished.

7. Mount the preassembled pump casing (101) on the shaft as

described in Chapter 9.10.3, "Mounting of the Pump Casing,"

page 25.

Fig. 36 Application case A, completion of assembly on the shaft

To complete assembly on the shaft (II):

8. Equip the rotating seal ring (472.60) with an O-ring

(412.63).

9. Equip the seal driver (485.60) with O-rings (412.62) and

(412.64).

10. Slide the rotating seal ring with the thrust collar (474.60),

the spring (478.60), and the seal driver onto the shaft. Let

the folded end of the spring snap into the rotating seal ring.

11. Finish the assembly of the shaft seal by attaching the impeller; see Chapter 9.10.4, "Mounting of the Impeller," page 26.

Application Case B

-

Fig. 37 Standard shaft seal: application case B

To preassemble the pump casing:

1. Glue the cylindrical pin (562.60) into the mechanical seal

chamber (47-1.60) with a retaining compound.

Note: Glue the cylindrical pins into the mechanical seal

chamber so that they do not touch the shaft when the unit is

fully assembled. Ensure that the cylindrical pins are fully engaged in the bores of the stationary seal ring (475.50). If the

stationary seal ring does not feature holes, the cylindrical

pins must engage in the longitudinal recesses in the stationary seal ring (see "Sectional drawing of shaft seal"). Insert the

O-ring into the mechanical seal chamber.

2. Insert the O-ring (412.60) into the mechanical seal chamber.

3. Use socket screws (914.60) to fasten the mechanical seal

chamber to the pump casing (101).

4. Equip the stationary seal ring (475.50) with an O-ring

(412.52) and guide into the mounted mechanical seal chamber on the pump side.

To complete assembly on the shaft:

5. Slide the rotating seal ring (472.50) with the O-rings

(412.51), (412.62), and (412.10), the thrust collar (474.50),

the spring (477.50), and the seal driver (54-3.60) onto the

shaft. Let the folded end of the spring snap into the rotating

seal ring.

6. Finish the assembly of the shaft seal by attaching the impeller; see Chapter 9.10.4, "Mounting of the Impeller," page 26.

22

Application Case C

III

II

I

101

421.60 412.69 904.60 471.60 524.60

412.62 412.64

543.60

475.60

412.63

543.60 478.60 474.60 472.60 412.65

562.60

Fig. 40 Application case C, completion of assembly on the shaft (III)

Fig. 38 Application case C

In the above figure, parts are grouped according to assembly

steps:

I Preassembly on the shaft

II Preassembly of the pump casing

III Completion of assembly on the shaft

Fig. 39 Application case C, preassembly on the shaft (I) and preassembly of the

pump casing (II)

To preassemble on the shaft (I):

1. Caution! Cutting injuries from sharp-edged shaft protective

sleeves. Wear suitable protective gloves.

► Slide the shaft protective sleeve (524.60) onto the shaft

using an assembly tool (auxiliary pipe). Position on the

shaft: See "Sectional Drawing".

Preassembly of the shaft is now finished.

To preassemble the pump casing (II):

2. Insert an O-ring (412.69) into the groove on the pump casing (101).

3. Insert the rotary shaft seal (421.60) into the seal cover

(471.60).

Note: Heed the installation direction for the rotary shaft seal.

See "Sectional Drawing".

4. Slide the seal cover onto the pump casing on the motor side.

Align the drill holes for the sealing liquid connections verti

cally.

5. Apply a screw retaining compound to the set screws

(904.60) and fasten the seal cover.

Preassembly of the pump casing is now finished.

To complete assembly on the shaft (III):

6. Apply a retaining compound to the cylindrical pin (562.60),

and glue cylindrical pin into the spacer bushing (543.60).

Note: Glue the cylindrical pins into the spacer sleeve so that

they do not touch the shaft when the unit is fully assembled.

Ensure that the cylindrical pins are fully engaged in the

bores of the stationary seal ring

(475.60). If the stationary

seal ring does not feature holes, the cylindrical pins must engage in the longitudinal recesses in the stationary seal ring

(see "Sectional drawing of shaft seal").

7. Use a retaining compound to glue the spacer bushing into

the seal chamber of the pump casing (101).

8. Mount the pump casing. See Chapter 9.10.3, "Mounting of the

Pump Casing," page 25.

9. Equip the stationary seal ring (475.60) with an O-ring

(412.65).

10. Slide the stationary seal ring onto the shaft so that the cylindrical pin on the spacer bushing engages in the slot on the

stationary seal ring.

11. Equip the rotating seal ring (472.60) with an O-ring

(412.63).

12. Equip the rotating seal ring with the thrust collar (474.60)

and the spring (478.60) and slide onto the shaft. Let the

folded end of the spring snap into the slot on the rotating

seal ring.

13. Equip the seal driver (543.60) with O-rings (412.64) and

(412.62) and slide onto the shaft.

14. Finish the assembly of the shaft seal by attaching the impeller; see Chapter 9.10.4, "Mounting of the Impeller," page 26.

-

23

/ / FP PUMP SERIES / / /

III

II

I

474.63

412.61

47-2.60

524.60

421.60

562.60

412.60

93-1.60

101

412.65

475.60

412.62

412.64

474.60

472.60

412.63

478.60485.60

Application Case D

Fig. 41 Application case D

In the above figure, parts are grouped according to assembly

steps:

I Preassembly on the shaft

II Preassembly of the pump casing

III Completion of assembly on the shaft

To preassemble on the shaft (I):

1. Caution! Cutting injuries from sharp-edged shaft protective

sleeves. Wear suitable protective gloves.

► Slide the shaft protective sleeve (524.60) onto the shaft

using an assembly tool (auxiliary pipe). Position on the

shaft: See Sectional Drawing.

Preassembly of the shaft is now finished.

gaged in the bores of the stationary seal ring (475.60). If the

stationary seal ring does not feature holes, the cylindrical

pins must engage in the longitudinal recesses in the station

ary seal ring (see "Sectional drawing of shaft seal").

3. Install O-rings (412.60) and (412.61) from the outside and a

rotary shaft seal (421.60) from the inside of the mechanical

seal chamber.

Note: Heed the installation direction for the rotary shaft seal.

See “Sectional Drawing“.

4. Equip the stationary seal ring (475.60) with an O-ring

(412.65).

5. Guide the stationary seal ring into the mechanical seal chamber and install together in the pump casing (101).

Note: The cylindrical pins on the mechanical seal chamber

must engage in the slots on the stationary seal ring.

6. Place the thrust collar (474.63) on the assembly in the pump

casing and secure with snap ring (93-1.60).

Preassembly of the pump casing is now finished.

7. Mount the preassembled pump casing (101) on the shaft as

described in Chapter 9.10.3, "Mounting of the Pump Casing,"

page 25.

-

Fig. 42 Application case D, preassembly on the shaft (I) and preassembly of the

pump casing (II)

To preassemble the pump casing (II):

2. Glue the cylindrical pin (562.60) into the mechanical seal

chamber (47-2.60) with a retaining compound.

Note: Glue the cylindrical pins into the mechanical seal

chamber so that they do not touch the shaft when the unit is

fully assembled. Ensure that the cylindrical pins are fully en

Fig. 43 Application case D, completion of assembly on the shaft (III)

To complete assembly on the shaft (III):

8. Equip the rotating seal ring (472.60) with an O-ring

(412.63).

9. Equip the seal driver (485.60) with O-rings (412.62) and

(412.64).

10. Slide the rotating seal ring with the thrust collar (474.60),

the spring (478.60), and the seal driver onto the shaft.

Note: Let the folded end of the spring snap into the slot on

the rotating seal ring.

11. Finish the assembly of the shaft seal by attaching the impeller; see Chapter 9.10.4, "Mounting of the Impeller," page 26.

-

24

Application Case E

II

I

475.61

412.67

472.61 474.61

412.66 479.60

550.62

904.61

50-3.60

I

IV

412.53 475.51 472.51 412.54 474.51 479.50

52

53

54

Application Case F

Fig. 44 Application case E

In the above figure, parts are grouped according to assembly

steps:

I Assembly of the shaft seal on the shaft on the motor side

II Assembly of the shaft seal on the shaft on the pump side

Fig. 45 Application case E, assembly of motor-side shaft seal (I)

To assemble the shaft seal on the motor side (I):

1. Only for FP...V: Secure the set collar (50-3.60) to the shaft

using set screws (904.61).

Apply a screw retaining compound to the set screws. Position on the shaft: See “Sectional Drawing“.

2. Slide the washer (550.62) onto the shaft.

3. Equip the rotating seal ring (472.61) with an O-ring

(412.66).

4. Slide the spring (479.60) with the thrust collar (474.61) and

the rotating seal ring (472.61) onto the shaft. Let the folded

end of the spring snap into the slot on the rotating seal ring.

5. Mount the pump casing; see Chapter 9.10.3, "Mounting of the

Pump Casing," page 25.

6. Insert the O-ring (412.67) into the stationary seal

ring (475.61) and insert into the mechanical seal

chamber (47-2.60).

Assembly of the shaft seal on the motor side is now finished.

To assemble the shaft seal on the pump side (II):

7. To assemble the shaft seal on the pump side, proceed as described in Chapter , "Application Case A," page 21.

Fig. 46 Standard shaft seal, application case F

I Pump-side shaft seal

IV Motor-side shaft seal

To assemble the motor-side shaft seal (IV) on the shaft:

Fig. 47 Motor-side shaft seal (IV), application case F

► Slide the spring (479.50) with the thrust collar (474.51), the

O-ring (412.54), the rotating seal ring (472.51), the

stationary seal ring (475.51), and the O-ring (412.53) onto

the shaft. Let the folded end of the spring snap into the

rotating seal ring.

To assemble the pump-side shaft seal (I):

► Assemble the pump-side shaft seal (I) as described in

Chapter , "Application Case B," page 22.

9.10.3 Mounting of the Pump Casing

Pump With Flange Connection

Fig. 48 Mounting of the pump casing with a flange connection

25

/ / FP PUMP SERIES / / /

55

56

57 58 59 60

61

62

63

65

64

► Slide the preassembled pump casing (52) with the shims

(53) over the shaft to the flange (54) and screw on (see

Chapter 10.1, "Specifications," page 28).

Pump With Clamp Connection

Fig. 49 Mounting of the pump casing with a clamp connection

1. Slightly spread the clamp connection with a wedge (55).

2. Only for double shaft seal: Slide the motor-side seal set onto

the pump shaft.

3. Install the entire shaft seal housing with seals into the pump

casing and secure to prevent slippage.

4. Slide the pump casing over the pump shaft into the clamp

connection and slightly tighten the clamp bolt

(56).

5. Slide the pump-side seal set onto the shaft.

6. Insert the key, the slotted plastic ring, and the impeller.

7. Insert the O-ring into the impeller nut, block the impeller to

prevent it from twisting, and tighten the impeller nut.

9.10.4 Mounting of the Impeller

Fig. 50 Mounting of the impeller

1. Force open the plastic snap ring (59) and insert into the shaft

groove.

2. Slide the key (61) and the impeller (60) onto the shaft.

3. Caution: Risk of injury when stopping the impeller by hand.

► Block the impeller with a wooden wedge.

4. Screw the impeller nut (57) with the O-ring (58) onto the

shaft and tighten (tightening torque = 100 Nm).

9.10.5 Pump Sealing

Thread Tightening Torque

M16 100 Nm

M24 200 Nm

Tab le 1 0 Tightening torques for impeller nuts

8. Adjust the clearances by sliding the pump head inside the

clamp connection (see

Chapter 9.9, "Checking of the Clearanc-

es," page 18). Align the surface of the outlet side (discharge

line connection) horizontally while doing so.

9. Tighten the clamp bolt (56):

Thread Tightening Torque

Special motor M10 36 Nm

Standard motor M10 45 Nm

Tab le 1 1 Tightening torques for clamp connection

M12 75 Nm

10. Continue with Chapter 9.10.5, "Pump Sealing," page 26.

26

Fig. 51 Pump cover

► Slide the pump cover (64) with the O-ring (65) onto the

pump casing and screw on with washers (63) and nuts (62).

9.11 Models FPE and FP…V: Mounting and

Alignment of the Pump Shaft

10. Straighten the pump shaft if necessary.

Note: After the IEC motor has been replaced the pump shaft

must be mounted and aligned.

Rotating Parts

Bruising and serious injuries.

► Turn off the motor and prevent it from being able to be

turned on accidentally.

1. Take the key out of the motor shaft pin.

2. For electric motors with outputs higher than 30 kW: Insert

the supplied half-key.

3. Degrease the motor shaft pin and the drill hole on the pump

shaft using a cleaner, e.g., OKS 2610 Universal Cleaner.

4. Grind the motor shaft pin and the edges of the key slot with

grinding paper to eliminate unevenness and burrs.

5. Apply a sealing gel, e.g., Stucarit 309, to the motor shaft pin

in the region of the shaft shoulder.

6. Slide the pump shaft with the shrink ring onto the motor

shaft pin up to the shaft shoulder.

7. Tighten the screws crosswise on the shrink ring:

9.12 Model L: Coupling Replacement

Only use couplings approved by Fristam. The coupling must be

appropriate for the characteristic curve of the pump. If you have

any questions, please contact Fristam.

Procedure

1. Turn off the motor and prevent it from being able to be

turned on accidentally.

2. Remove the coupling guard.

3. Remove the coupling tire.

4. Detach the motor from the base frame or the foundation and

remove.

5. Dispose of the old coupling parts in an environmentally

friendly manner.

6. Place new coupling parts (tires, flanges, possibly clamping

rings) on the drive shaft and on the gear shaft.

7. Place the motor on the base frame or the foundation and

slightly tighten the fastening screws.

8. Check the parallel and angular misalignment of the shafts.

Thread Tightening Torque

M5 6 Nm

M6 12 Nm

M8 30 Nm

8. Attach the dial gauge onto the pump shaft to check the runout tolerance.

9. Check the runout of the pump shaft as a function of motor

output.

– Motor < 30 kW: max. runout tolerance = 0.06 mm

– Motor > 30 kW: max. runout tolerance = 0.08 mm

Fig. 52 Parallel misalignment

Fig. 53 Angular misalignment

9. Minimize deviations from the angular and parallel misalignment. Realign the shafts if necessary.

10. Screw the motor to the base frame or the foundation.

11. For information on the spacing between the two coupling

flanges, please see the coupling installation manual. See

"Supplier Documentation“ in the attached documents.

12. Fasten the coupling flanges with the given spacing onto the

shaft.

13. Fasten the coupling tire. Tighten the screws uniformly and

crosswise. Heed the given tightening torques in the coupling

installation manual.

14. Mount the coupling guard.

27

/ / FP PUMP SERIES / / /

10 Appendix 1

10.1 Specifications

10.1.1 Tightening Torques for Screws and Nuts

Material: Steel, Strength Class: 8.8

Thread M6 M8 M10 M12 M16 M20

Tightening

Torque [Nm]

Material: Stainless Steel, Strength Class: 70

Thread M6 M8 M10 M12 M16 M20

Tightening

Torque [Nm]

Material: Stainless Steel, Strength Class: 80

Thread M6 M8 M10 M12 M16 M20

Tightening

Torque [Nm]

11 27 54 93 230 464

7.4 17.5 36 62 150 303

1o 24 49 80 203 393

10.1.2 Noise Emissions

Pump Size Noise Level

dBA

711/712 75

721/722 71

741/742 79

751/752 78

3401/3402 71

3521/3522 74

3531/3532 79

3541/3542 78

3451/3452 81

3551/3552 81

1151/1152 89

1231/1232 79

1241/1242 89

1251/1252 92

Tab le 1 2 Noise emissions

The specified values apply to operation of the pump at the best

efficiency point (see "Pump Characteristic Curve"). The noise level

can differ greatly at other working points.

10.2 Maintenance Intervals

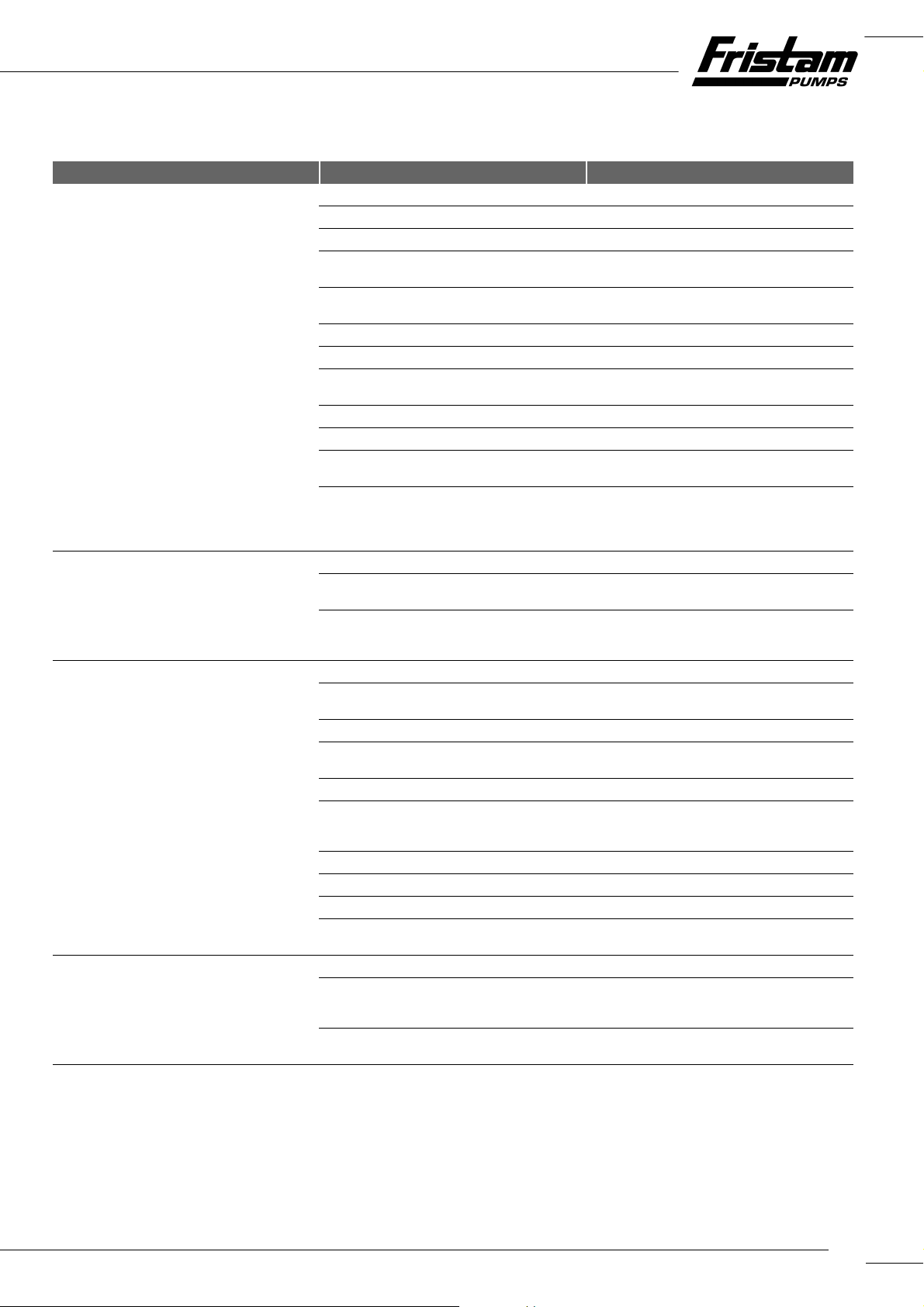

Model Interval Maintenance Task Chapter

All with "Sealing and Quenching Liquid" option

L 2, L 3/L3V, L 4V Once a day Check the oil level.

KF1,KF 2, KF 3 5,000 h Lubricate the shaft bearing. See Chapter 9.5.4, "Model KF," page 16.

L 2, L 3/L3V, L 4V 5,000 h Change the oil. See Chapter 9.5.2, "Models L 2, L 3/L3V and L 4V," page 15.

L1 5,000 h Lubricate the shaft bearing. See Chapter 9.5.3, "Model L1," page 16.

All When necessary Replace the shaft seal. See Chapter 9.7, "Shaft Seal Replacement," page 18.

All When necessary Replace the motor. See Chapter 9.6, "Motor Replacement," page 17.

FPE/FPV When necessary Replace the shaft. See Chapter 9.11, "Models FPE and FP…V: Mounting and Align-

All According to

Tab le 1 3 Maintenance intervals

1

For information on motor maintenance intervals, please see the motor operator's manual.

1

Once a day Check the sealing or quenching liq-

uid.

Lubricate the motor bearings. See Chapter 9.4, "Lubrication of Motor Bearings," page 15.

manufacturer's

specifications

See Chapter 9.3, "Inspection of Sealing and Quenching Liquid

(Optional)," page 15.

ment of the Pump Shaft," page 27.

28

10.3 Troubleshooting Table

Problem Possible Cause Remedy

Pump either does not pump or pumps irregularly.

Flow rate too high. Discharge-side valve opened too wide. Throttle valve.

Flow rate too low; discharge head too low. Selected pump too small. Contact Fristam.

Metal noise. Foreign objects in pump interior. Disassemble, inspect, and repair.

Tab le 1 4 Troubleshooting table

Suction line blocked/clogged. Open/clean suction line.

Suction filter contaminated. Clean suction filter.

Discharge-side shut-off valve closed. Open discharge line.

Pump not completely filled with

liquid.

Pump with geodesic suction head1; liquid level

falls at standstill.

Suction line leaky (drawing in air). Seal suction line.

Foot valve blocked or contaminated. Reestablish proper function of foot valve; clean.

Suction head too high. Lower pump;

Air pocket in suction line. Lay suction line at steady incline.

Excessive air or gas in pumping medium. Install vent valve.

Air ingress at shaft seal. Check shaft seal installation.

Cavitation at impeller inlet;

resistance in suction line too high;

suction head too high.

NPSHa values not adapted to pump.

Discharge line diameter too large. Reduce nominal pipe size;

Impeller diameter too large. Trim impeller outside diameter.

Selected impeller diameter too small. Contact Fristam.

Direction of rotation of motor incorrect. Exchange connections on motor terminal box.

Speed too low

(voltage incorrect).

Nominal pipe sizes too small. Use larger pipe diameters.

Pipe resistances in suction and/or

discharge line too high.

Pipe clogged or full of deposits. Clean pipes.

Foreign objects/deposits in impeller. Remove impeller and clean.

Impeller incorrectly adjusted. Check impeller clearance and readjust.

Density of pumping medium too high.

Viscosity of pumping medium too high.

Impeller catching. Readjust impeller clearance;

Pump/shaft seal running dry. Immediately supply pumping medium;

Install pipe system so that casing is still filled with

liquid when pump is off.

Install foot valve in suction line.

reduce suction head.

Replace elastomers.

Optimize suction line;

increase inlet height;

lower media temperature;

contact Fristam.

insert orifice plate.