Fristam Pump FZP 10, FZ Series, FZ 22, FZ 25, FZ 27 Original Instructions, Assembly Instructions

...

Original Instructions

Assembly Instructions

Side Channel Pump

FZ Series

Pump Type:

Pump No.:

Copyright

© Copyright 2012 Fristam Pumpen KG (GmbH & Co.)

All rights reserved. The contents, including graphic images and layout of this operating instructions

manual are subject to copyright protection and to other laws for the protection of intellectual property.

The publication and modification of the contents are not authorised. Moreover, you may not copy,

publish and alter the contents therein for commercial purposes, or transmit the information to a third

party.

The German version is the original version of the operating instructions manual.

Other languages are translations of the original operating manual.

Table of cont e n t s

1 Introduction............................................................. 5

1.1 Foreword................................................................... 5

1.2 Manufacturer........................................................... 5

1.3 Scope of Supply...................................................... 5

1.4 Pump Without Motor (Optional)...................... 5

1.5 Scope of Documentation.................................... 5

1.6 Display Conventions............................................. 5

2 Safety Instructions................................................. 6

2.1 Basic Safety Instructions...................................... 6

2.2 Intended Use ........................................................... 6

2.3 Improper Use........................................................... 6

2.4 Warning and Instruction Labels........................ 6

2.5 Noise Emissions ...................................................... 7

2.6 Disposal ..................................................................... 7

3 Design and Function ............................................ 7

3.1 Principles of Design............................................... 7

3.2 Models ....................................................................... 8

3.3 Pump Key.................................................................. 9

3.4 Versions ..................................................................... 9

3.5 Pump Sizes ............................................................... 9

4 Transportation ........................................................ 10

4.1 Safety Instructions................................................. 10

4.2 Moving With Industrial Trucks .......................... 10

4.3 Moving With Crane ............................................... 10

5 Storage....................................................................... 11

5.1 Safety Instructions................................................. 11

5.2 Storage Conditions................................................ 11

5.3 Long-Term Storage ............................................... 11

5.4 Recommissioning .................................................. 11

6 Installation................................................................ 11

6.1 Safety Instructions................................................. 11

6.2 Installation Location ............................................. 11

6.3 Reduction of Noise and Vibration.................... 12

6.4 Pump Fixation ........................................................ 12

6.5 Electrical Connection........................................... 13

6.6 Connection of Sealing or Quenching

Liquid (Optional) ................................................... 13

6.7 Cleaning.................................................................... 13

7 Operation................................................................. 14

7.1 Safety Instructions ................................................ 14

7.2 Commencement of Operation......................... 14

7.3 Monitoring of Operation .................................... 14

7.4 Stopping of Operation ........................................ 14

7.5 Pump Decommissioning.................................... 14

7.6 Cleaning in Place................................................... 15

8 Faults ......................................................................... 15

8.1 Safety Instructions ................................................ 15

9 Maintenance........................................................... 15

9.1 Safety Instructions ................................................ 15

9.2 Replacement Parts................................................ 15

9.3 Inspection of Sealing and Quenching

Liquid (Optional) ................................................... 16

9.4 Lubrication of Motor Bearings.......................... 16

9.5 Lubrication of Shaft Bearing ............................. 16

9.6 Motor Replacement ............................................. 17

9.7 Shaft Seal Replacement ...................................... 18

9.8 Pump Head Removal ........................................... 18

9.9 Checking of the Clearances............................... 20

9.10 Pump Head Attachment..................................... 20

9.11 Design FZ 27: Mounting and aligning the

pump shaft .............................................................. 29

9.12 Model L: Coupling Replacement ..................... 30

10 Appendix 1 .............................................................. 31

10.1 Specifications.......................................................... 31

10.2 Maintenance Intervals......................................... 31

10.3 Troubleshooting Table........................................ 32

10.4 Number Key ............................................................ 34

10.5 EC Declaration of Conformity........................... 35

10.6 EG Declaration of Incorporation...................... 35

3

/ / FZ pump series / / /

11 Appendix 2 – Assembly Instructions

(Optional).................................................................. 36

11.1 Safety Instructions................................................. 36

11.2 Scope.......................................................................... 36

11.3 Moving Without Motor........................................ 36

11.4 Installation Location ............................................. 37

11.5 Pump Installation................................................... 37

4

1Introduction

1.1 Foreword

This operator's manual describes all sizes, models, and versions

of the FZ pump series.

Information on the model, size, and version of your pump can

be found on the rating plate on your pump and in the "Order-Re-

lated Documents" in Appendix 2.

– Attached documents

– Order-Related Documents

– Supplier Documentation (motor, coupling, etc.)

– Documentation on Fristam accessories (if applicable)

– Certificates (materials certificates, etc.), if applicable

– Declaration of Conformity

1.6 Display Conventions

1.2 Manufacturer

FRISTAM Pumpen KG (GmbH & Co.)

Kurt-A.-Körber-Chaussee 55

21033 Hamburg

GERMANY

Tel.: +49-40 - 72556 -0

Fax: +49-40 -72556 -166

E-mail: info@fristam.de

1.3 Scope of Supply

The package includes the following items:

– Pump with motor = pump unit

optional: without motor

– Covers for pipe fittings

– Optional: assembly kit

– Fristam accessories (if applicable)

– Documentation

► Check the shipment for completeness and damage. Immedi-

ately notify Fristam of any missing items or damage.

List items are preceded by dashes:

–Part 1

–Part 2

Handling instructions that must be performed in a specified order are numbered:

1. Turn device on.

2. Turn device off.

Handling instructions that do not need to be performed in a

specified order are preceded by triangular bullets:

► Action

► Action

1.6.1 Safety Instructions

A safety instruction with the signal word "Danger" indicates personal hazards causing death or serious injury.

A safety instruction with the signal word "Warning" indicates

personal hazards that may lead to death or serious injury.

1.4 Pump Without Motor (Optional)

The pump can optionally be supplied without a motor. In this

case, continue reading up to and including Chapter 3, "Design

and Function," page 7, and then skip to Chapter 11, "Appendix 2 –

Assembly Instructions (Optional)," page 36.

1.5 Scope of Documentation

The documentation includes the following items:

– This operator's manual

– Maintenance, lubrication, and tightening torque tables

can be found in Appendix 1.

– The assembly instructions for the option "Pump Without

Motor" can be found in Appendix 2.

A safety instruction with the signal word "Caution" indicates personal hazards that may lead to mild to moderate injuries.

A safety instruction with the signal word "Note" warns of the

possibility of material damage.

5

/ / FZ PUMP SERIES / / /

1

2

3

5

4

6

7

8

9

10

2 Safety Instructions

2.1 Basic Safety Instructions

► Please read this operator's manual completely before using

the pump and keep it available at the pump installation location.

► Heed the applicable national regulations of the owner's

country and the company's work and safety regulations.

► All work described here may only be performed by qualified

experts with caution.

► Danger of contamination: Heed legal and operational safety

regulations when pumping dangerous media.

2.2 Intended Use

The standard versions of the FZ pump series are designed for

use in the food industry, the pharmaceutical and biotechnology

industry, and CIP process technology.

FZ pump series pumps are used for the following applications:

– Pumping of products containing gas

– Venting of suction lines

– Emptying of residues in product lines

The FZ pump series can generate discharge pressures of up to

7.0 bar. Depending on the pump size, the system pressure can

reach 15 bar.

Each pump is designed according to customer requirements.

The seal materials have been selected for the respective pumping conditions (medium, pressure, temperature). The pump may

only be used to pump the medium it was designed for

(see Order-Related Documents in the attached documents in

Appendix 2).

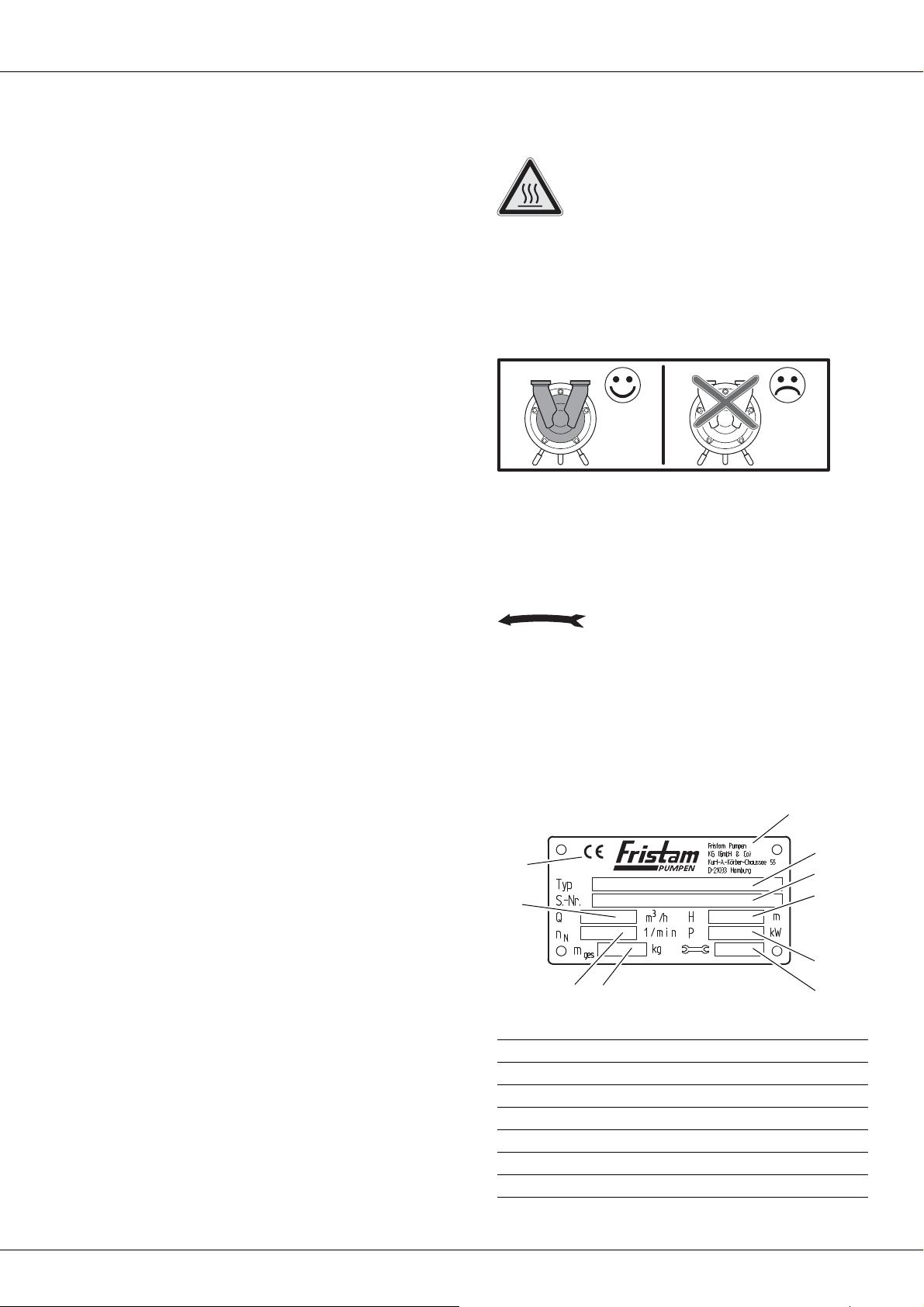

2.4.1 Hot Surface

Fig. 1 Safety label: "Hot Surface"

This label indicates that parts can become hot during operation

or, if applicable, that hot media is being pumped. Only touch

the pump if you are wearing suitable gloves.

2.4.2 No Dry Running

Fig. 2 Safety label: "No Dry Running"

This label indicates that the pump cannot be run dry. There

must always be medium in the suction line and the pump when

the pump is started. Otherwise, the pump will be damaged.

2.4.3 Direction of Rotation

Fig. 3 "Impeller Direction of Rotation" label

This label shows the direction of rotation of the impeller. It is located at the front on the pump cover.

Fristam can provide operation independent of the direction of

rotation for special versions.

2.4.4 Rating Plate

2.3 Improper Use

The standard FZ pump series versions may not be used in explosive atmospheres. Special explosion-proof versions are available

for this.

Pumping of media other than those specified can destroy the

pump.

Standard pump units from Fristam are described in this operator's manual. If nonstandard items or extras are installed, the operator assumes the responsibility for operation.

Modifications and changes to the pump are only permissible

with the explicit consent of Fristam.

2.4 Warning and Instruction Labels

► Do not alter or remove the labels on the pump.

► Immediately replace damaged or lost labels with ones that

are true to the originals.

6

Fig. 4 Pump unit rating plate

Manufacturer

1

Typ: pump series, pump size, model, version

2

S.-Nr.: serial number of the pump

3

H: discharge head [m]

4

motor output [kW]

P:

5

Year of manufacture

6

ttl: mass (total) [kg]

m

7

n

B

C

A

11

12

13

14

15

: rated speed [1/min]

8

R

Q: flow rate [m³/h]

9

CE mark

10

2.5 Noise Emissions

► The local noise exposure regulations must be complied with.

For noise emission values for the pumps, please see

Chapter 10.1, "Specifications," page 31.

Noise Generated by Running Pump

Hearing damage.

► Wear ear protectors when using pumps with specified sound

pressure levels of greater than 80 dBA.

2.6 Disposal

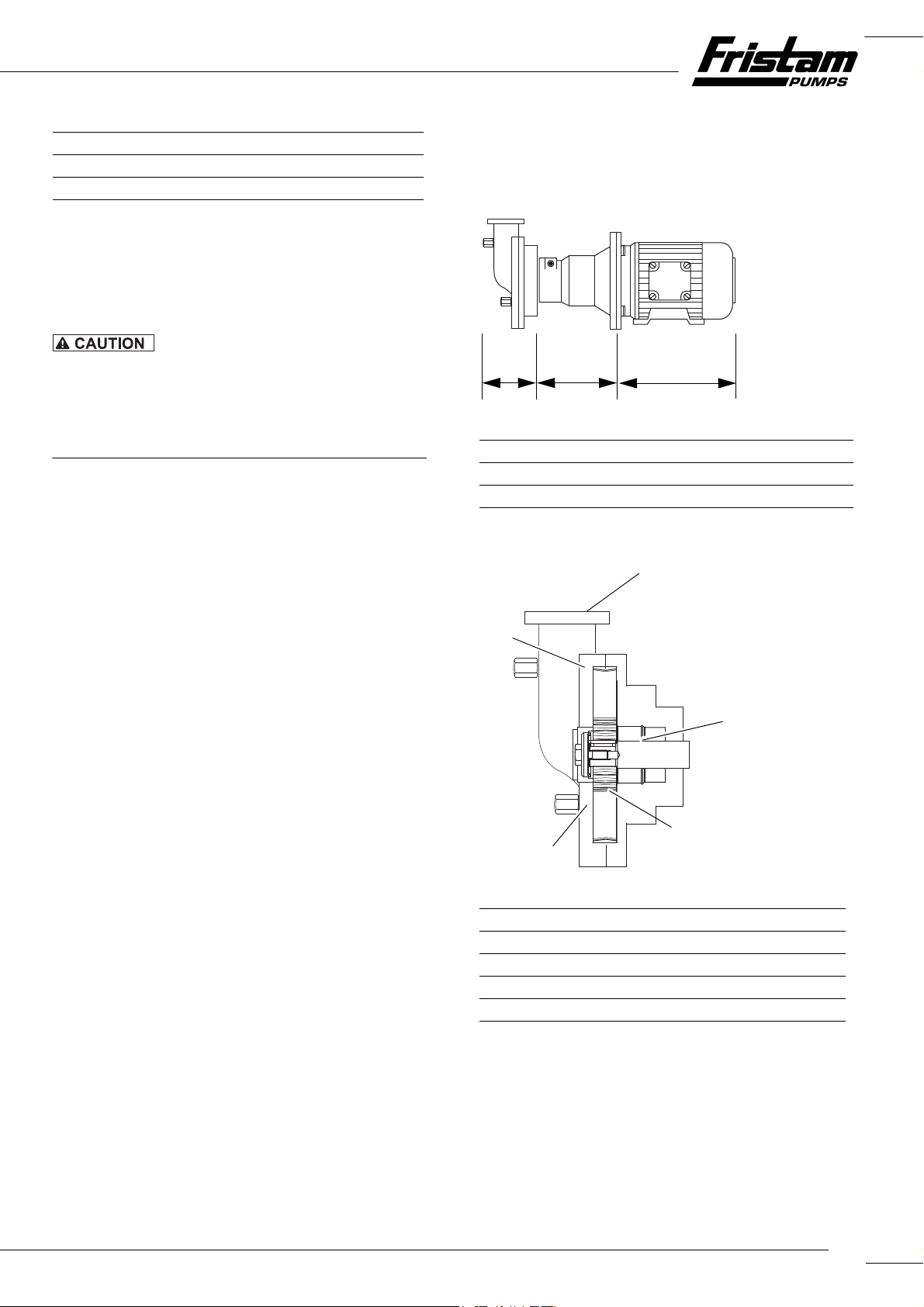

3 Design and Function

3.1 Principles of Design

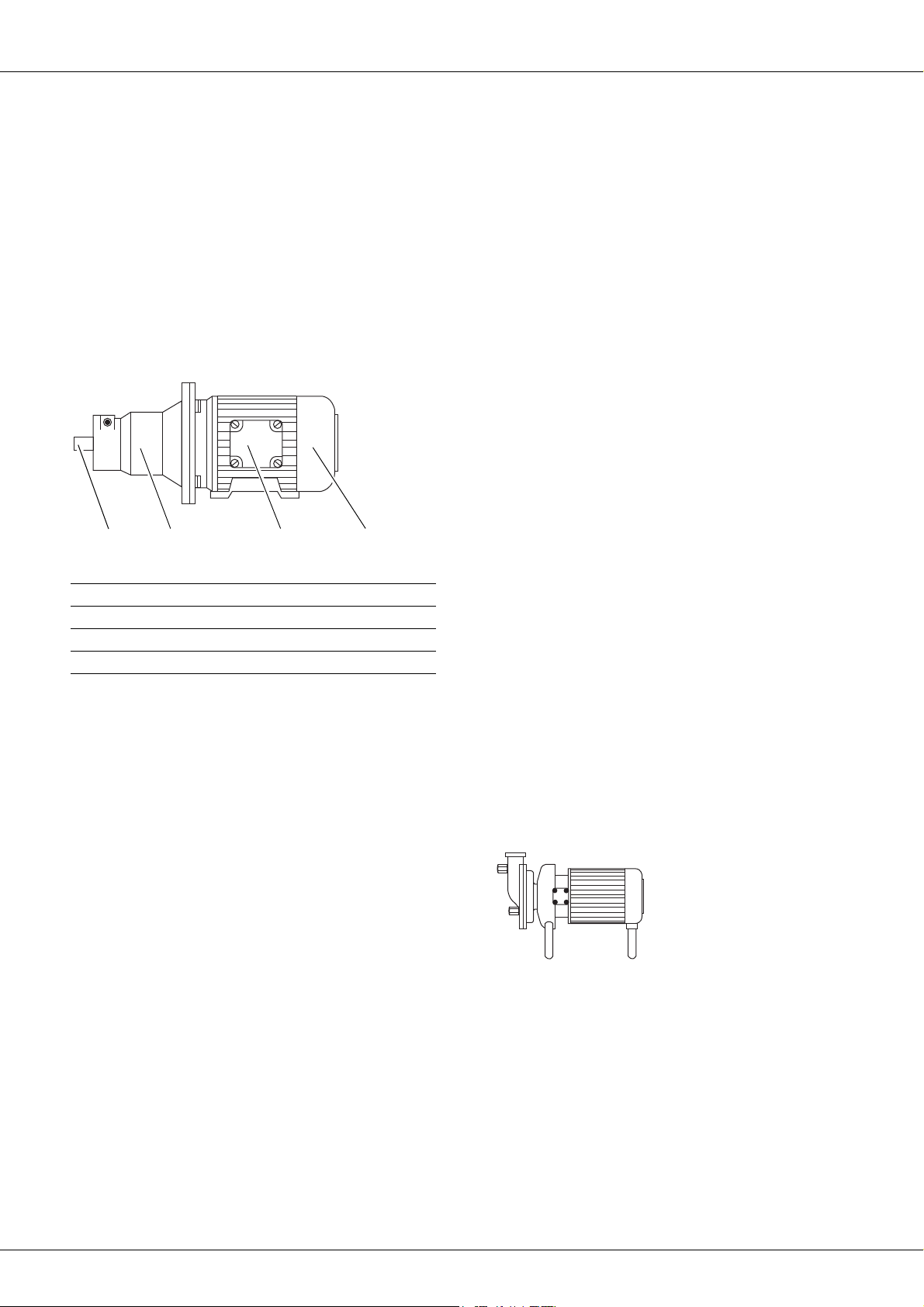

Fig. 5 Principles of design of pumps illustrated using the K model

Pump head

A

Lantern

B

Electric motor

C

2.6.1 Disposal of Transportation Package

► Recycle the transportation package.

2.6.2 Models K, KF, and L 1: Disposal of Grease

► Dispose of grease and objects saturated with grease in an

environmentally friendly manner in accordance with applicable regulations.

2.6.3 Model L 2: Disposal of Lubricating Oil

► Dispose of oil and objects saturated with oil in an environ-

mentally friendly manner in accordance with applicable regulations.

2.6.4 Disposal of Pump

1. Carefully clean the pump. Dispose of residues in an environmentally friendly manner in accordance with applicable regulations.

2. Dismantle the pump into its constituent parts.

3. Dispose of the pump parts in an environmentally friendly

manner in accordance with applicable regulations.

2.6.5 Disposal of Electrical and Electronic Scrap

► Dispose of electrical and electronic scrap in accordance with

applicable directives.

3.1.1 Pump Head (A)

Fig. 6 Pump head

Suction/discharge line connection

11

Shaft seal

12

Impeller

13

Pump cover

14

Pump casing

15

Shaft Seal (12)

Two seal types are available for use:

– Single shaft seal

– Double shaft seal

With the double shaft seal, there are two additional connections

for the sealing liquid on the pump casing. These connections are

not shown in the figures in this operator's manual.

7

/ / FZ PUMP SERIES / / /

16 17 18 19

Impeller (13)

Open impellers with radial blades are standardly used in the

FZ pump series.

Pump Cover (14)

The connections for the suction and discharge lines are located

on the pump cover.

Pump Casing (15)

The impeller and the shaft seal are built into the pump casing.

3.1.2 Lantern (B) and Electric Motor (C)

Fig. 7 Lantern and electric motor

Pump shaft

16

Lantern

17

Electrical connection

18

Electric motor

19

Lantern (16)

The lantern is present in all models except the special motor.

The lantern connects the pump casing to the motor. Two different versions are possible, depending on pump size:

– The pump casing is screwed to the lantern via a flange con-

nection.

– The pump casing is inserted into the lantern and mounted

with a clamp.

Models with lanterns:

–FZP

–K

Compact bearing support. An additional bearing for the

pump shaft is located inside the lantern.

–KF

Compact bearing support with base. An additional bearing

for the pump shaft is located inside the lantern with base.

–L

Bearing block. An additional bearing for the pump shaft is

located inside the lantern with base. The pump shaft is connected to the motor via a coupling.

Electric Motor (19)

The following motor types can be mounted:

– IEC standard motor with drive side fixed bearing (A side),

feather key and shaft pin of the following types:

– IM B3: motor model with base

– IM B5: motor model with flange

– IM B3/B5: motor model with flange and base

Various mounting types are possible for the IEC standard

motor:

–A Fristam pump shaft is clamped to the motor shaft pin.

– The motor is fastened to the flange on the compact bear-

ing support (with base).

– The motor is connected to the bearing block via a cou-

pling.

–Special motor with Fristam pump shaft

With the special motor, the Fristam pump shaft is already integrated and connected permanently to the motor.

3.2 Models

The model is indicated on the rating plate. See Chapter 2.4,

"Warning and Instruction Labels," page 6.

The following are shown as examples:

– Lantern clamp-mounted

– Without enclosure

See Chapter 3.4, "Versions," page 9.

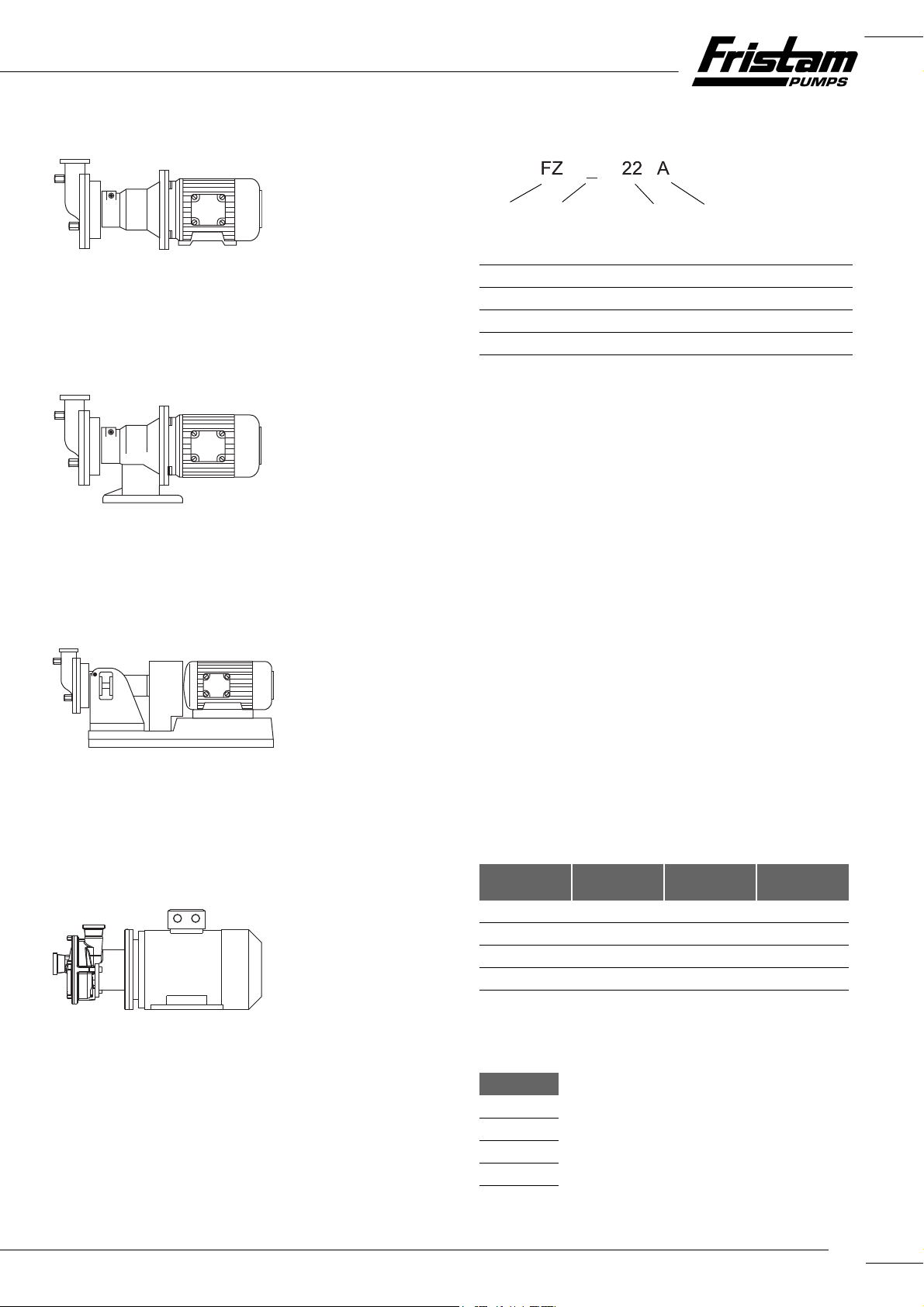

3.2.1 Model FZ or FZP

Fig. 8 Model FZ with special motor

Motor: Special motor

Design: Without lantern

8

3.2.2 Model K

20 22 2321

Fig. 9 Model KF

Motor: IEC standard motor, motor model B3/B5

Design: Compact bearing support

3.3 Pump Key

Fig. 13 Type designation example

Pump type

20

Supplementary character 1

21

Pump size

22

Supplementary character 2

23

3.2.3 Model KF

Fig. 10 Model KF

Motor: IEC standard motor, motor model B5

Design: Compact bearing support with base

3.2.4 Model L

Fig. 11 Model L

Motor: IEC standard motor, motor model B3

Design: Bearing block with coupling, coupling protec-

tion, base frame

(20) Pump Type

FZ Side channel pump

(21) Supplementary Character 1

P Sampling pump (FZ 10)

(22) Pump Size

__ Sizes: see Chapter 3.5, "Pump Sizes," page 9.

(23) Supplementary Character 2

PM Powder mixer

A, B, C, D Versions; see Chapter 3.4, "Versions," page 9:

K Compact bearing support

KF Compact bearing support with base

L1, L2

Bearing block with coupling

H Pump casing with heating jacket

h Pump cover with heating jacket

3.4 Versions

3.2.5 Design FZ 27

Fig. 12 Design FZ 27

Motor: IEC standard motor, model B3/B5

Design: With lantern

Version Enclosure Spherical Cap

Legs

A With With Without

B Without Without With

C Without With Without

D With Without With

Tab le 1 Versions

3.5 Pump Sizes

Pump Sizes

10

15

17

20

Tab le 2 P ump si ze s

Motor Foot

9

/ / FZ PUMP SERIES / / /

Pump Sizes

22

25

27

Tab le 2 P ump si ze s

Note: If the (optional) pump without motor is supplied, please

first read Chapter 11, "Appendix 2 – Assembly Instructions (Option-

al)," page 36.

4Transportation

Transportation may only be performed by trained personnel.

The pump can be moved using an industrial truck or a crane.

Always move the pump in the installation condition.

4.1 Safety Instructions

► Danger of injury from falling or unsecured parts.

– Only use suitable means of conveyance and hoists. Infor-

mation on pump weight can be found on the pump's rating plate as well as in the Order-Related Documents in Ap-

pendix 2.

– Before moving the pump secure it to prevent it from tip-

ping over. Secure the pump to the pallet with tie-down

straps, or screw the pump to the pallet.

– Do not leave the pump in a raised position for longer

than necessary.

► Damage to pump by contamination, impact, or moisture.

– Remove the pipe fitting covers just prior to connection to

the pipes.

4.2 Moving With Industrial Trucks

Preparation

► Ensure that the pump is adequately secured to the pallet.

Procedure

1. Pick up the pallet with the forks on the industrial truck.

2. Carefully move the pallet to the designated location and set

down.

4.3 Moving With Crane

Falling Parts

Death from crushing, pinching of extremities, material damage.

► Do not lift the pump at the eyebolts on the motor and pump

casing to move because these eyebolts are not designed for

the total weight.

► Only use hoists that are designed for the total weight of the

pump.

► Ensure that the area below the pump is clear of people.

Swinging Parts

Crushing and serious injuries.

► Start and stop the crane with pump smoothly.

► Ensure that the danger zone of the pump is clear of people.

Auxiliary Equipment

Hoists: round slings tested in accordance with DIN EN 1492-1

and 1492-2

Preparation

► Remove load-securing devices.

Procedure

1. Wrap the round sling twice around the back end of the motor. Do not lay over the fan shroud (see Fig. 15, "Moving with

crane," page 11).

2. Lay the other end of the round sling between the lantern

and the pump casing. Do not lay the round sling over any

sharp edges or corners.

3. Guide both loops to the crane hook and rotate by 180° to ensure that the belt will not slip on the hook.

4. For double shaft seal:

Note: Round sling compresses sealing water tubes. Material

damage to double shaft seal.

► Do not lay the round sling on the sealing water tubes.

5. Position the center of gravity to ensure that the pump is lifted horizontally.

6. Lift the pump.

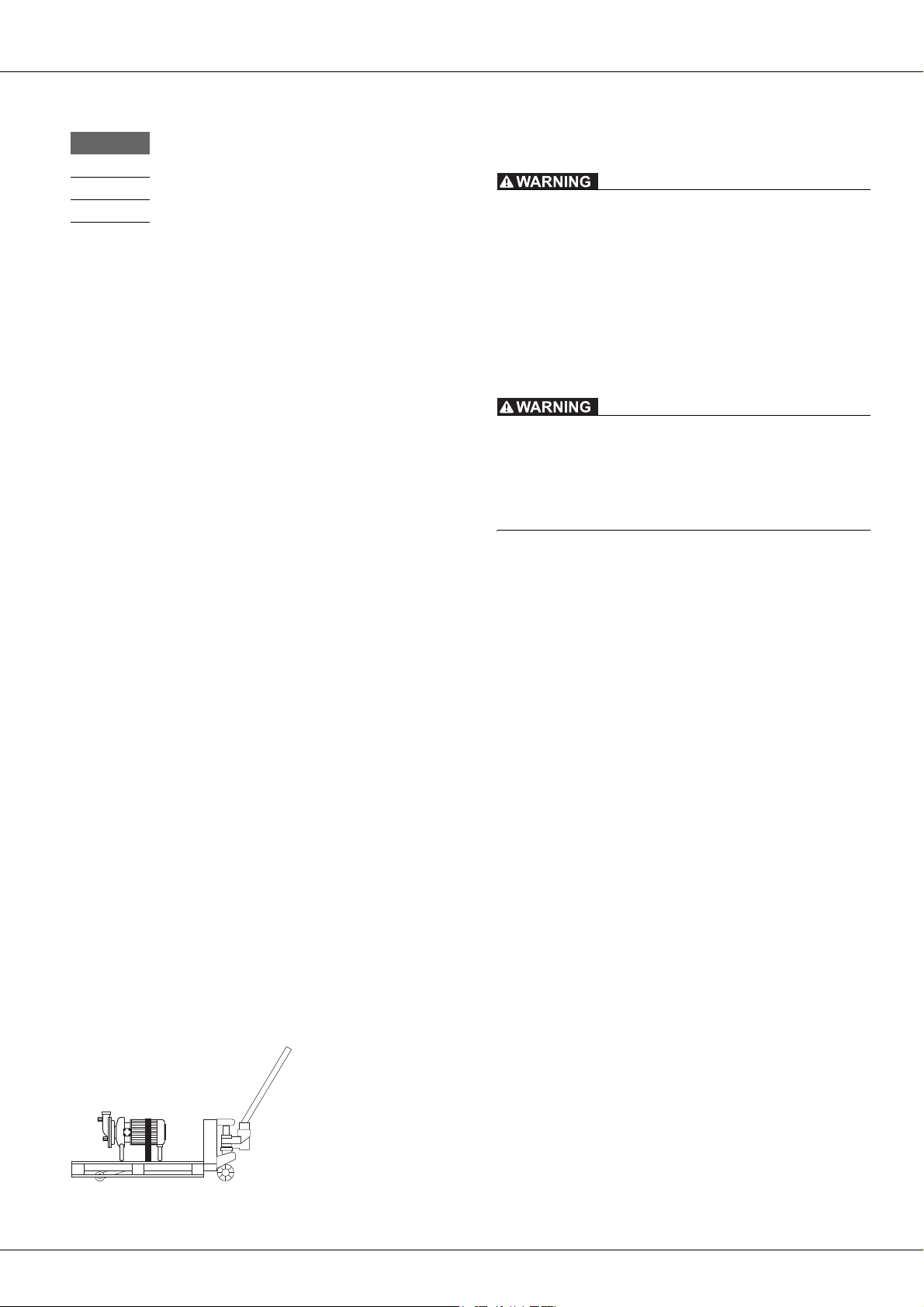

Fig. 14 Moving with industrial truck

10

.

Fig. 15 Moving with crane

5.3.1 Storage of Elastomers

Storage Conditions

– Storage temperature between +5°C and +20°C

– Relative air humidity below 70%

– No direct sunlight

– Deformation-free storage

5.4 Recommissioning

► After long-term storage and before commissioning, check

seals, bearings, and lubrication.

6Installation

5Storage

5.1 Safety Instructions

► Corrosion: Condensation can build up under a tarp and de-

stroy the pump. Ensure adequate ventilation.

5.2 Storage Conditions

► Store the pump as follows:

– Dry, in low humidity

– Protected against frost and heat, optimally at a tempera-

ture of +20°C to +25°C

– Ventilated

– Dust-free

5.3 Long-Term Storage

For a storage time of longer than six months, heed the following:

► The shaft seals must be specially treated before long-term

storage:

– For single shaft seal

The impeller nut must be loosened so that the seal can

relax and the sliding surfaces do not stick together.

– For double shaft seal

Remove the complete shaft seal and store separately to

prevent the sliding surfaces from sticking together.

Information on the shaft seal can be found in the Order-Re-

lated Documents in Appendix 2.

► All movable pump parts must be rotated every three

months.

6.1 Safety Instructions

► Danger of injury from falling parts.

– Wear safety shoes.

– Check load capacity and attachment of hoists.

► Danger of injury from unstable assembly.

– Tighten screws to the specified tightening torque (see

Chapter 10.1.1, "Tightening Torques for Screws and Nuts,"

page 31).

– Use a torque wrench or an impact driver with adjustable

torque.

► Material damage from swinging during adjustment of spher-

ical cap feet.

– Use spherical cap base plates.

6.2 Installation Location

For standard pumps, the installation location must meet the following requirements:

– Nonexplosive atmosphere

– Dust-free environment

– Ambient temperature: –20°C to +40°C

– Moisture and salt contents in ambient air:

The values are given in the motor supplier documentation. It

can be found in the attached documents (Appendix 2).

– Foundation sized adequately for the pump weight

– Horizontal and level installation surface, adequate installa-

tion surface strength for pump mass

– Adequate clearance for maintenance work

– Adequate air supply for motor cooling

11

/ / FZ PUMP SERIES / / /

6.3 Reduction of Noise and Vibration

6.3.1 Primary Measures

► Operate the pump in the optimum working range.

Note: Pump must not be blocked during operation. Pump

may only be throttled to the minimum allowable flow rate;

see "Performance Chart."

► Decouple the suction and discharge lines from vibrations.

– Support lines.

– Align lines.

– Install vibration isolators.

6.3.2 Secondary Measures

► Take structural measures such as the following:

– Acoustic paneling

– Enclosure in housing

6.4 Pump Fixation

Models FZ/K/FZP

► Versions A and C:

Set up the pump on the spherical cap bearings and align.

► Versions B and D:

Screw the pump on the motor foot to the foundation.

6.4.1 Installation of Pipes

► Lay and connect pipes as follows:

– Keep the pipe resistance as low as possible: Avoid unnec-

essary installation of valves, elbows, and abrupt pipe

transitions.

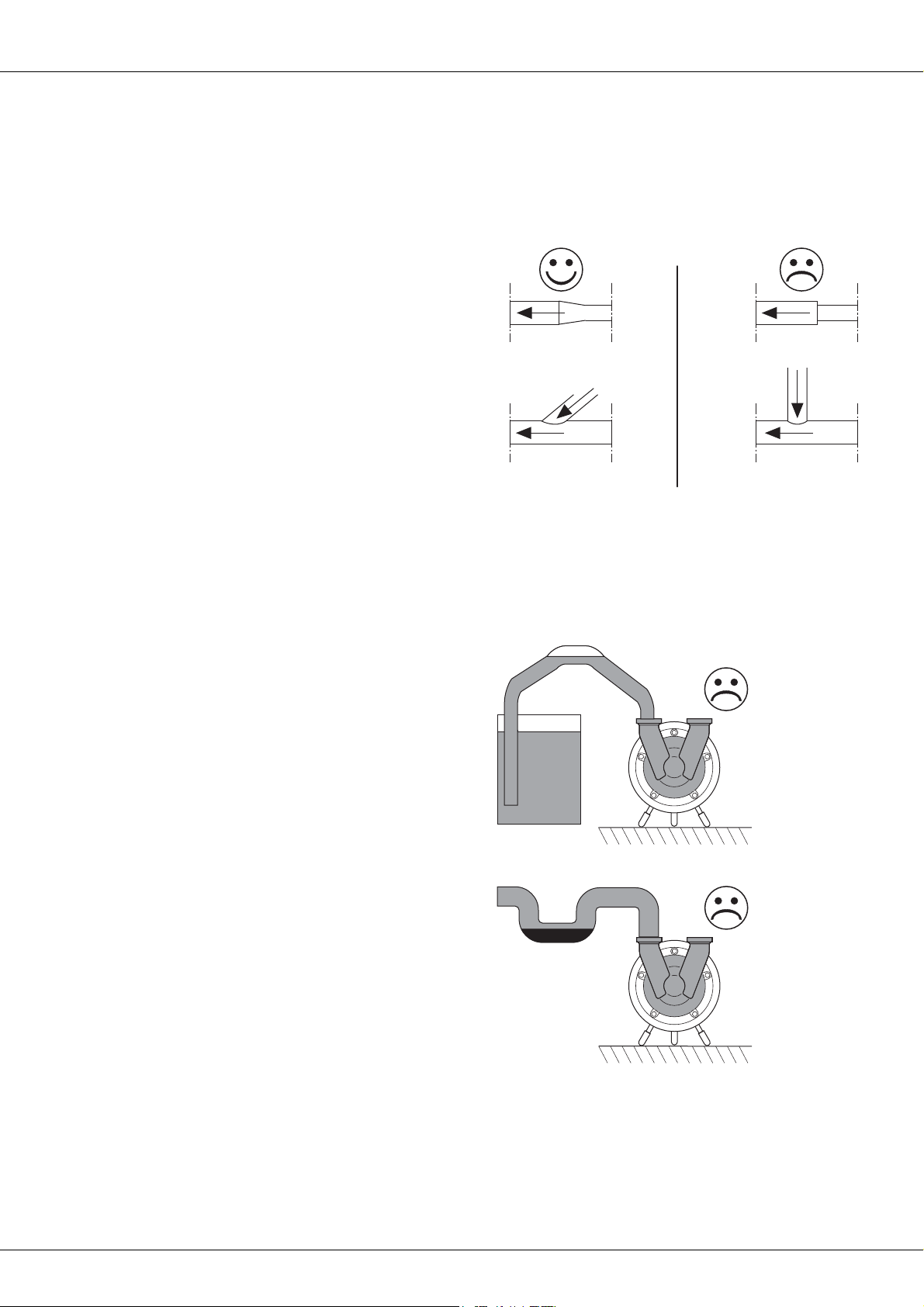

Fig. 16 Pipe transitions

– Design pipe cross section so that no unnecessary pres-

sure losses or cavitation occurs in the suction area. Verify

this in the project planning stage.

– Install the suction lines in horizontal position or at a con-

stant dropping angle towards the pump unit. Rule out

the possibility of air pockets and dips in the pipes.

Model KF

► Versions A and C:

Set up the pump on the spherical cap bearings and align.

► Versions B and D:

Screw the pump on the compact bearing support with base

to the foundation.

Model L

► Versions A and C:

Set up the pump on base frame on the spherical cap bearings and align.

► Versions B and D:

Screw the pump on the base frame to the foundation.

Design FZ 27

► Versions A and C:

Install and align the pump on the spherical cap bearings.

► Versions B and D:

Screw the pump on the pump base to the foundation.

Carriage (Optional)

1. Set up the pump at the installation location. Lock the locks

on the rollers (if present) or secure the carriage with chocks.

2. Ground the carriage to dissipate electrostatic charge.

3. Position hose line to ensure that it cannot be damaged.

Fig. 17 Air pocket in pipe

Fig. 18 Dip in pipe

– Pipe bends upstream of suction connection: Heed mini-

mum clearance and minimum bend radius:

12

Loading...

Loading...