Frisco Eclipse 73 Series Installation Manual

73 Series Door Closer Installation

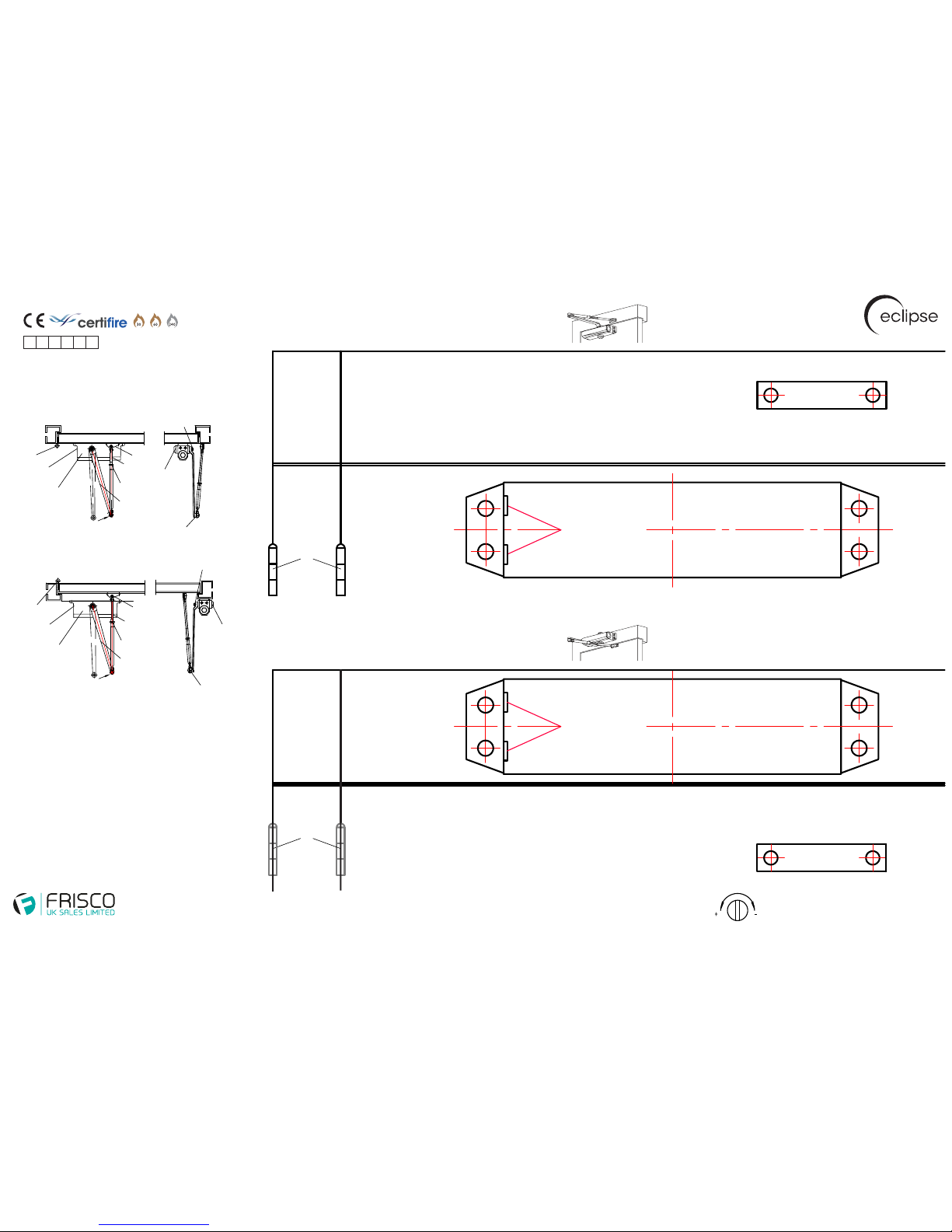

Standard Door Installation (Pull Side) - Fig 1

Frame Fix Installation (Push Side) - Fig 61

To Increase Closing Speed:

Adjust screw valve (1) anti-clockwise by quarter turns until desired speed has been achieved

To Reduce Closing Speed:

Adjust screw valve (1) clockwise by quarter turns until desired speed has been achieved

To Increase Latching Speed:

Adjust screw valve (2) anti-clockwise by quarter turns until desired speed has been achieved

To Reduce Latching Speed:

Adjust screw valve (2) clockwise by quarter turns until desired speed has been achieved

CAUTION

Adjusting valves more than 2 full turns anti-clockwise from factory settings will result in oil leakage damaging the door closer.

Hinge knuckle

is visable

Hinge knuckle

is not visable

Door Frame

Door

Door Frame

Door

Step by Step Installation Guide

Use the appropriate template for your installation and place

the template on the door and frame. Pilot drill all fixing holes

as per the template.

1. Position the door closer with the adjustment valves facing

the hinge side of the door. Secure the door closer using

the screws provided into the pre-drilled pilot positioning

holes.

2. Attach the armset to the pivot on the door closer body and

secure using the washer screw.

3. Tension the door closer arm and adjust the arm length

accordingly. Secure the arm set shoe to the door or frame

depending on installation, then tighten the arm set nut.

4. Apply the dust cap to the unused pivot.

5. Adjust the closing and latching speeds as required refer to adjustment instructions.

NB after the first month of operation the closing and latching

speed valves may require minor adjustment.

2 - Latching Speed

Adjustment Valves

Adjustment Valves

1 - Closing Speed

2 - Latching Speed

1 - Closing Speed

2 - Latching Speed

1 - Closing Speed

Door Closer Body

Door Closer Body

Armset Shoe

Armset Shoe

120 degree

door installation

180 degree

door installation

120˚ door

installation

180˚ door

installation

Standard Door Installation

Pull Side - Fig 1

Frame Fix Installation

Push Side - Fig 61

Washer Screw

Dust Cap

Armset Pivot Screw

Hinge Knuckle

Adjustment Valves

Door Closer Body

Preload

Armset

Nut

Threaded

Arm (bolt)

Armset Shoe

Hinge Knuckle

Adjustment Valves

Door Closer Body

Preload

Armset

Nut

Threaded

Arm (bolt)

Armset Shoe

Washer Screw

Armset Pivot Screw

Dust Cap

acceleration deceleration

Unit 14 Pindar Road, Hoddesdon, Hertfordshire, EN11 0DE

Tel: +44 (0)1992 443 010 | Fax: +44 (0)1992 443 020

EN1154:1997 + A1:2002 *Fig 1 application only

EN1634-1:2000 FD60 timber FD240 steel

CE 1121-CPD-AD1069 (2007)

Certifire CF600

3 8 3 1 1 3

Key

1. Armset Pivot Screw

2. Armset

3. Nut

4. Adjustment Valves

5. Threaded Arm (Bolt)

6. Parallel Bracket

7. Door Closer Body

8. Dust Cap

9. Washer Screw

10. Assembling Screw

1 2 3 4 5 6 7 8 9 10

45˚ Preload

73 Series Door Closer Installation

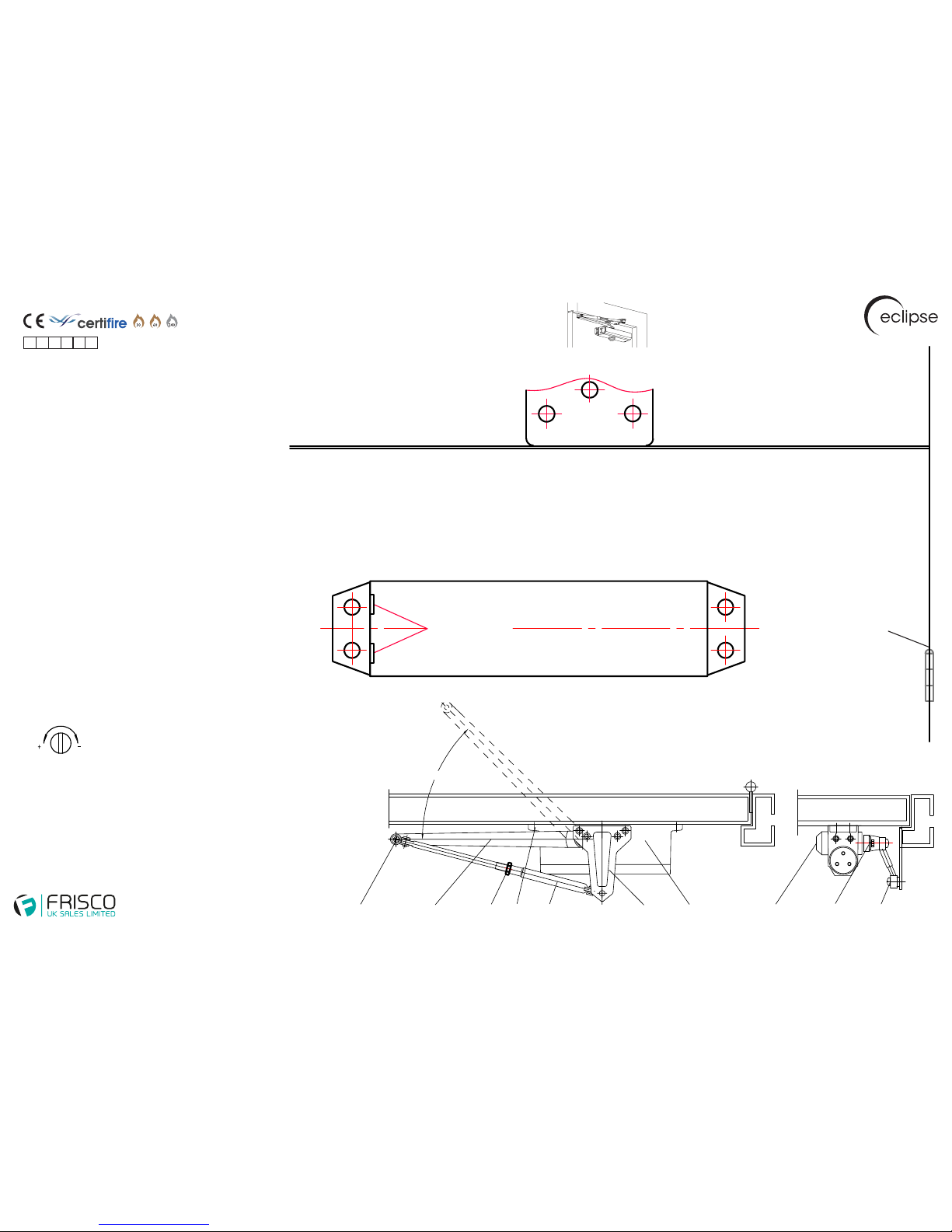

Parallel Arm Installation (Push Side) - Fig 66

Door Closer Body

Adjustment Valves

2 - Latching Speed

1 - Closing Speed

Parallel

Arm Bracket

To Increase Closing Speed:

Adjust screw valve (1) anti-clockwise by quarter turns until desired speed has been achieved

To Reduce Closing Speed:

Adjust screw valve (1) clockwise by quarter turns until desired speed has been achieved

To Increase Latching Speed:

Adjust screw valve (2) anti-clockwise by quarter turns until desired speed has been achieved

To Reduce Latching Speed:

Adjust screw valve (2) clockwise by quarter turns until desired speed has been achieved

CAUTION

Adjusting valves more than 2 full turns anti-clockwise from

factory settings will result in oil leakage damaging the door closer.

acceleration deceleration

Hinge knuckle

is not visable

Door Frame

Door

Unit 14 Pindar Road, Hoddesdon, Hertfordshire, EN11 0DE

Tel: +44 (0)1992 443 010 | Fax: +44 (0)1992 443 020

EN1154:1997 + A1:2002 *Fig 1 application only

EN1634-1:2000 FD60 timber FD240 steel

CE 1121-CPD-AD1069 (2007)

Certifire CF600

3 8 3 1 1 3

Step by Step Installation Guide

Use the appropriate template for your installation and place

the template on the door and frame. Pilot drill all fixing holes

as per the template.

1. Position the door closer with the adjustment valves facing

away from the hinge side of the door. Secure the door closer

and bracket using the screws provided into the pre-drilled

pilot positioning holes.

2. Remove the shoe from the door closer arm.

3. Attach the armset to the pivot on the door closer body parallel

to the door/frame and secure using the washer screw.

4. Tension the door closer arm and adjust the arm length

accordingly. Secure the arm to the figure 66 bracket and tighten

the arm set nut.

5. Add the dust cap to the unused pivot.

6. Adjust the closing and latching speeds as required refer to adjustment instructions.

NB after the first month of operation the closing and latching

speed valves may require minor adjustment.

Loading...

Loading...